Enhanced Computer Numeric Controller Milling Efficiency via Air-Cutting Minimization Using Logic-Based Benders Decomposition Method

Abstract

1. Introduction

2. Methodology

2.1. Concept of Logic-Based Benders Decomposition

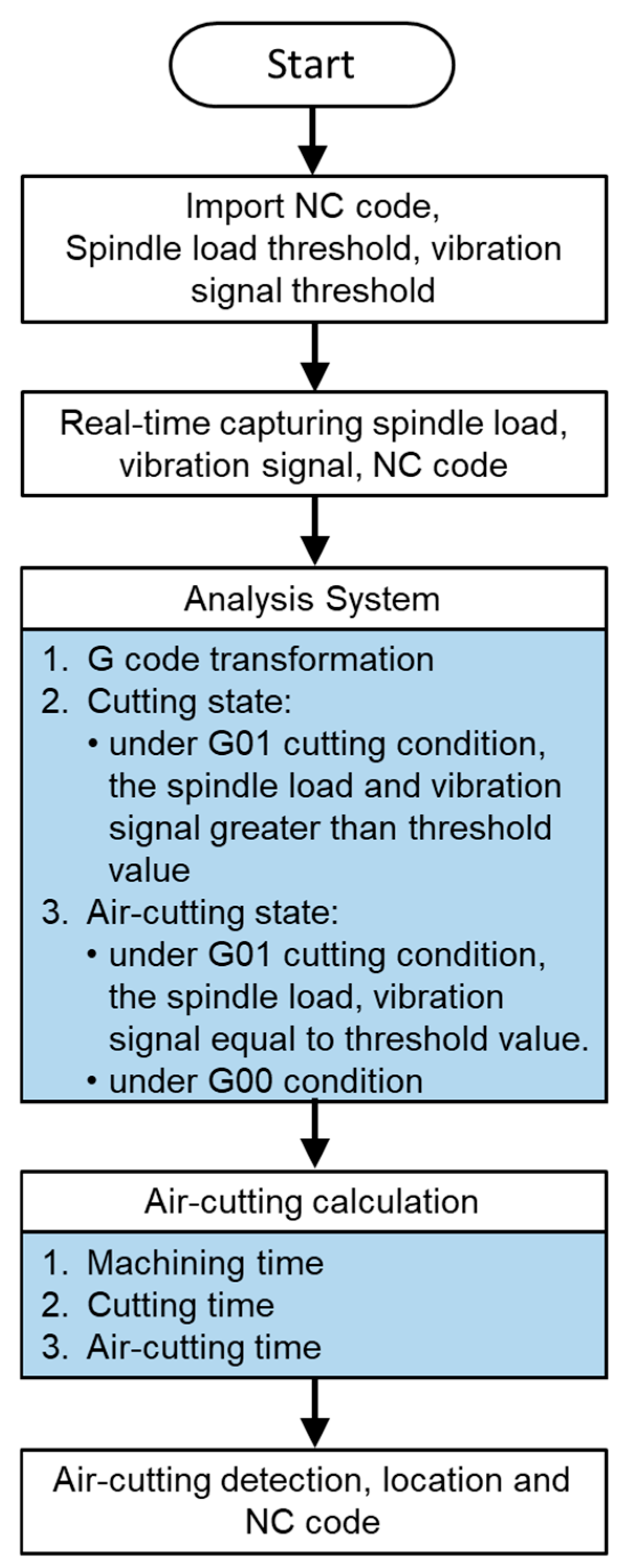

2.2. Air-Cutting Detection with Decomposition

2.3. Air-Cutting Optimization with Decomposition

- Feedrate acceleration under linear motion (G01) for short air-cutting distances.

- Logic-based benders decomposition (LBBD) for longer paths, which segments the motion into rapid (G00) and linear (G01) segments while compensating for machine positioning errors.

- Identify and analyze the air-cutting length (L).

- If L ≤ 10 mm:

- ➢

- Use G01

- ➢

- Increase the feedrate by 50%

- ➢

- New feedrate:

- 3.

- If L > 10 mm:

- ➢

- Apply he decomposition method.

- ➢

- X-axis decomposition:

- ➢

- Y-axis decomposition:

- 4.

- Regenerate the NC code automatically based on optimized movements.

- 5.

- Compare air-cutting and machining time before and after optimization. If the new air-cutting time and machining time are lower than the original, then save this new NC program and finish; otherwise, repeat the analysis to find a better solution.

| Algorithm 1. Pseudocode for air-cutting time optimization |

| Input air-cutting segment with x, y coordinates and original feedrate Measure air-cutting length (L) If L ≤ 10 mm Apply G01 Increase feedrate: Else Apply decomposition: Assign: G00 ⟶ () G01 ⟶ () Generate updated NC code with modified commands Simulate and compare new air-cutting and machining time If new time < original: Save optimized NC program Else: Reiterate decomposition or adjust parameters End |

3. Experiment

3.1. Experiment Design

- Spindle load test:A straight-line cut along the Y-axis (120 mm path, 100 mm actual cut) was repeated 10 times using a feedrate of 1000 mm/min.

- Vibration signal test:Micro-cutting was performed along the X-axis (200 mm path, 100 mm cut) with a feedrate of 600 mm/min and a shallow width of cut (0.1 mm), repeated 3 times.

- Positioning error was experimentally measured across the X and Y axes.

- Feedrates of 3000, 6000, and 12,000 mm/min were tested.

- Interval distances ranging from 10 to 200 mm (in 10 mm steps) were evaluated.

- Each condition was repeated five times to ensure repeatability.

| Feedrate (mm/min) | Interval Distances (mm) | Repetitions Per Step | Axes Measured |

|---|---|---|---|

| 3000 | 10–200 (step: 10 mm) | 5 | X, Y |

| 6000 | 10–200 (step: 10 mm) | 5 | X, Y |

| 12,000 | 10–200 (step: 10 mm) | 5 | X, Y |

3.2. Instruments

4. Human–Machine Interface

5. Results and Discussion

5.1. Air-Cutting Based on Spindle Load

5.2. Air-Cutting Based on Vibration

5.3. Positioning Error

5.4. Verification Experiment

5.4.1. Verification Experiment 1

5.4.2. Verification Experiment 2

5.4.3. Verification Experiment 3

5.4.4. Verification Experiment 4

5.4.5. Verification Using SKD11 Material

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daneshmand, S.; Abdolhoseinni, M.M.; Aghanajafi, C. Investigating the optimal tool path strategies based on machine time in CAD-CAM. Aust. J. Basic Appl. Sci. 2011, 5, 2320–2326. [Google Scholar]

- Corso, L.L.; Zeilman, R.P.; Nicola, G.L.; Missell, F.P.; Gomes, H.M. Using optimization procedures to minimize machining time while maintaining surface quality. Int. J. Adv. Manuf. Technol. 2013, 65, 1659–1667. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, G.; Du, B.; Chu, H.; Wu, F. Mathematical model and algorithm of toolpath optimization on aircraft structural parts. Int. J. Prod. Res. 2014, 52, 1142–1149. [Google Scholar] [CrossRef]

- Zhang, C.; Han, F.; Zhang, W. A cutting sequence optimization method based on tabu search algorithm for complex parts machining. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2019, 233, 745–755. [Google Scholar] [CrossRef]

- Nishida, I.; Shirase, K. Machining time reduction by tool path modification to eliminate air cutting motion for end milling operation. Int. J. Autom. Technol. 2020, 14, 459–466. [Google Scholar] [CrossRef]

- Oysu, C.; Bingul, C. Application of heuristic and hybrid-GASA algorithm to tool-path optimization problem for minimizing airtime during machining. Eng. Appl. Artif. Intell. 2009, 22, 389–396. [Google Scholar] [CrossRef]

- Castelino, K.; D’Souza, R.; Wright, P.K. Toolpath optimization for minimizing airtime during machining. J. Manuf. Syst. 2003, 22, 173–180. [Google Scholar] [CrossRef]

- Palanisamy, P.; Rajendran, I.; Shanmugasundaam, S. Optimization of machining parameters using genetic algorithm and experimental validation for end-milling operations. Int. J. Adv. Manuf. Technol. 2007, 32, 644–655. [Google Scholar] [CrossRef]

- Ghaiebi, H.; Solimnpur, M. An ant algorithm for optimization of hole-making operations. Comput. Ind. Eng. 2007, 52, 308–319. [Google Scholar] [CrossRef]

- Huang, B.; Zhang, S.; Huang, R.; Li, X.; Zhang, Y.; Liang, J. An effective numerical control machining process optimization approach of part with complex pockets for numerical control process reuse. IEEE Access 2019, 7, 45146–45165. [Google Scholar] [CrossRef]

- Liang, Y.C.; Wang, S.; Li, W.D.; Lu, X. Data-driven anomaly diagnosis for machining process. Eng. J. 2019, 5, 646–652. [Google Scholar]

- Emec, S.; Kruger, J.; Seliger, G. Online fault-monitoring in machine tools based on energy consumption analysis and non-invasive data acquisition for improved efficiency. Procedia CIRP 2016, 40, 236–243. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Jin, Y.; Li, L. Optimization of cutting parameters with consideration of electrical energy and embodied energy of materials. Int. J. Adv. Manuf. Technol. 2018, 96, 775–788. [Google Scholar] [CrossRef]

- Song, D.; Otani, N.; Aoki, T.; Kamakoshi, Y.; Ohara, Y.; Tamaki, H. A new approach to cutting state monitoring in end-mill machining. Int. J. Mach. Tool Manuf. 2005, 45, 909–921. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, L.; Huang, L.; Wang, Z. Real-time monitoring method for surface roughness of y-TiAl alloy based on deep learning of time-frequency diagram. Int. J. Adv. Manuf. Technol. 2023, 129, 2989–3007. [Google Scholar] [CrossRef]

- Jones, T.; Cao, Y. Tool wear prediction based on multisensory data fusion and machine learning. Int. J. Adv. Manuf. Technol. 2025, 137, 5213–5225. [Google Scholar] [CrossRef]

- Gohari, H.; Hassan, M.; Shi, B.; Sadek, A.; Attia, H.; Saoubi, R. Cyber-Physical Systems for high-performance machining of difficult to cut materials in I5.0 Era—A review. Sensors 2024, 24, 2324. [Google Scholar] [CrossRef]

- Yu, H.; Yu, D.; Wang, C.; Hu, Y.; Li, Y. Edge intelligence-driven digital twin of CNC system: Architecture and deployment. Robot. Comput. Integr. Manuf. 2023, 79, 102418. [Google Scholar] [CrossRef]

- Massoni, B.R.; Campbell, M.I. A decomposition method for efficient manufacturing of complex parts. Comput. Aided Des. Appl. 2017, 14, 705–719. [Google Scholar] [CrossRef]

- He, K.; Hong, H.; Tang, R.; Wei, J. Analysis of multi-objective optimization of machining allowance distribution and parameters for energy saving strategy. Sustainability 2020, 12, 638. [Google Scholar] [CrossRef]

- Hooker, J.N. Logic-Based Methods for Optimization: Combining Optimization and Constraint Satisfaction, 1st ed.; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Wang, S.M.; Lee, C.Y.; Gunawan, H.; Yeh, C.C. An accuracy-efficiency-power consumption hybrid optimization method for CNC milling process. Appl. Sci. 2019, 9, 1495. [Google Scholar] [CrossRef]

- Fapo Enterprise Co. Ltd. Available online: https://www.fapolu.com.tw/aluminum.html (accessed on 10 June 2025).

- Ju Feng Special Steel. Available online: https://www.jfs-steel.com/zh-TW/product/SKD11.html (accessed on 10 June 2025).

| Condition | Action | Purpose |

|---|---|---|

| L ≤ 10 mm | Apply G01, increase feedrate by 50% | Speed up short non-cutting paths |

| L > 10 mm | Apply decomposition (G00 + G01) | Use rapid + linear motion combination |

| Positioning error | Consider in calculation | Avoid overcut/collision during G00 |

| After regeneration | Simulate and compare the time before saving | Ensure improvement over the original NC |

| Parameter | For Spindle Load | For Vibration |

|---|---|---|

| Spindle rotation (rpm) | 5000 | 4000 |

| Feedrate (mm/min) | 1000 | 600 |

| Width of cut (mm) | 0.3 | 0.1 |

| Depth of cut (mm) | 3 | 3 |

| Feedrate (mm/min) | Machining Time (s) | Cutting Time (s) | Air-Cutting Time (s) |

|---|---|---|---|

| G01-600 | 22.4 | 10.43 | 11.97 |

| G01-600 | 22.37 | 10.4 | 11.97 |

| G01-600 | 22.38 | 10.49 | 11.89 |

| G00-6250 | -- | -- | 7.9 |

| Parameter | Value |

|---|---|

| Spindle rotation (rpm) | 4000 |

| Feedrate (mm/min) | 300 |

| Width of cut (mm) | 3 |

| Depth of cut (mm) | 3 |

| Rapid motion (mm/min) | 3000 |

| Trial | Before Optimization | After Optimization | Saving Total Machining Time (%) | ||||

|---|---|---|---|---|---|---|---|

| Total Machining Time (s) | Cutting Time (s) | No-Cutting Time (s) | Total Machining Time (s) | Cutting Time (s) | No-Cutting Time (s) | ||

| 1 | 95.3 | 51.1 | 44.2 | 71.3 | 52.8 | 18.5 | 24.18 |

| 2 | 95.1 | 52.8 | 42.3 | 70.8 | 53.0 | 17.8 | 25.55 |

| 3 | 94.8 | 52.6 | 42.2 | 71.1 | 52.4 | 18.7 | 25.00 |

| 4 | 94.7 | 52.1 | 42.6 | 71.5 | 52.4 | 19.1 | 24.50 |

| 5 | 94.9 | 52.5 | 42.4 | 71.2 | 52.3 | 18.9 | 24.97 |

| Subject | t-Statistic | p-Value |

|---|---|---|

| Total machining time | 130.12 | 2.09 × 10−8 |

| Cutting time | −1.03 | 0.362 |

| Air-cutting time | 55.44 | 6.34 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gunawan, H.; Sugiono, D.; Tu, R.-Q.; Jong, W.-R.; Mufarrih, A. Enhanced Computer Numeric Controller Milling Efficiency via Air-Cutting Minimization Using Logic-Based Benders Decomposition Method. Electronics 2025, 14, 2613. https://doi.org/10.3390/electronics14132613

Gunawan H, Sugiono D, Tu R-Q, Jong W-R, Mufarrih A. Enhanced Computer Numeric Controller Milling Efficiency via Air-Cutting Minimization Using Logic-Based Benders Decomposition Method. Electronics. 2025; 14(13):2613. https://doi.org/10.3390/electronics14132613

Chicago/Turabian StyleGunawan, Hariyanto, Didik Sugiono, Ren-Qi Tu, Wen-Ren Jong, and AM Mufarrih. 2025. "Enhanced Computer Numeric Controller Milling Efficiency via Air-Cutting Minimization Using Logic-Based Benders Decomposition Method" Electronics 14, no. 13: 2613. https://doi.org/10.3390/electronics14132613

APA StyleGunawan, H., Sugiono, D., Tu, R.-Q., Jong, W.-R., & Mufarrih, A. (2025). Enhanced Computer Numeric Controller Milling Efficiency via Air-Cutting Minimization Using Logic-Based Benders Decomposition Method. Electronics, 14(13), 2613. https://doi.org/10.3390/electronics14132613