Smart Precision Weeding in Agriculture Using 5IR Technologies

Abstract

1. Introduction

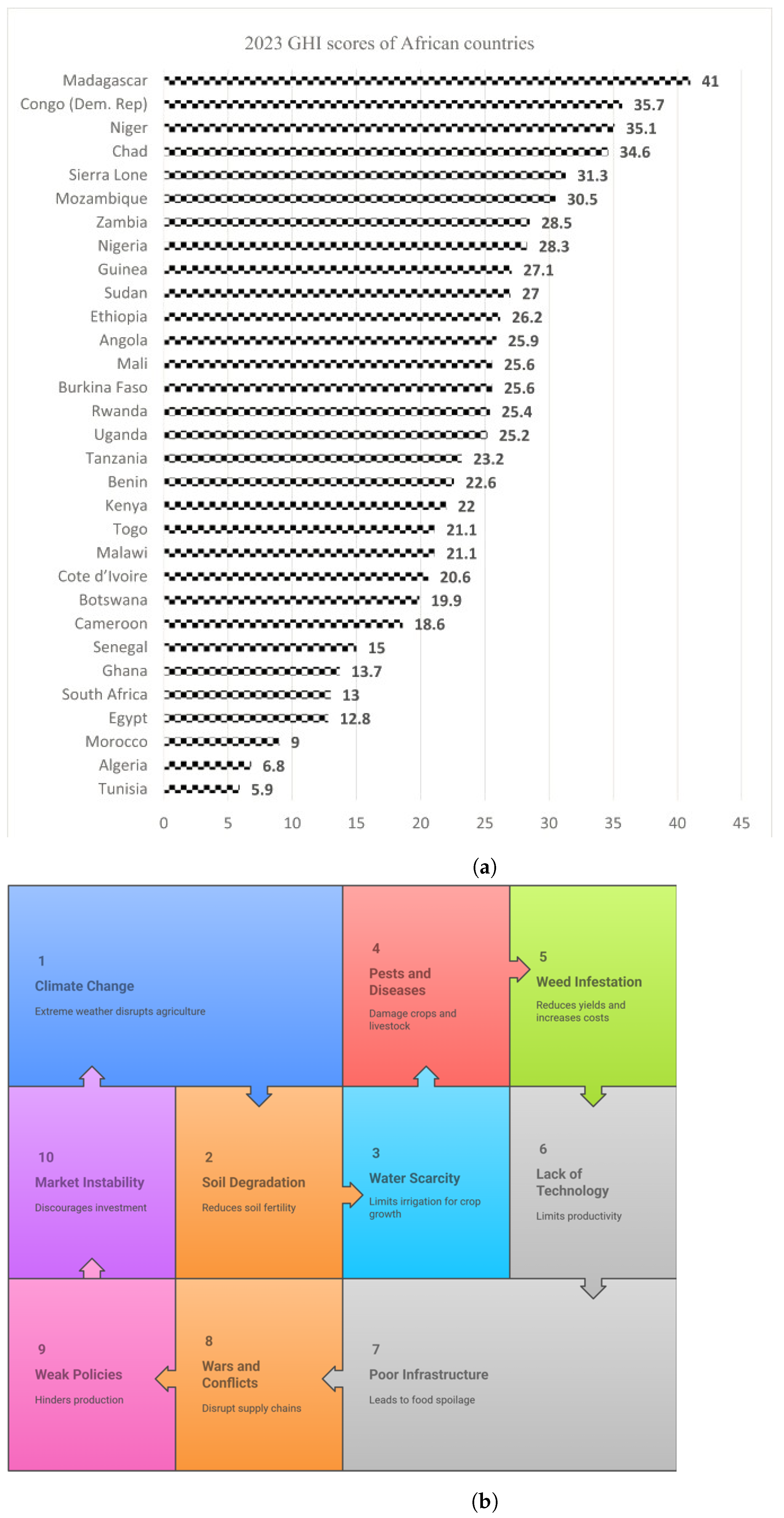

1.1. Background

1.2. Problem Statement

1.3. Purpose of Study

- Provides a cohesive understanding of the functions and synergies of important 5IR technologies, including artificial intelligence (AI), robots, the Internet of Things (IoT), 5G/6G, and edge computing, in the context of smart precision weeding.

- Demonstrates the technological advancements that are driving this change in agricultural operations by methodically charting the evolution from conventional weeding methods to contemporary intelligent systems.

- Identifies important obstacles to adoption in low-resource environments and makes tactical suggestions to promote the global use of smart weeding technologies that are inclusive, scalable, and in line with policies.

1.4. Structural Approach

2. Traditional Weeding and the Transition to Smart Technologies

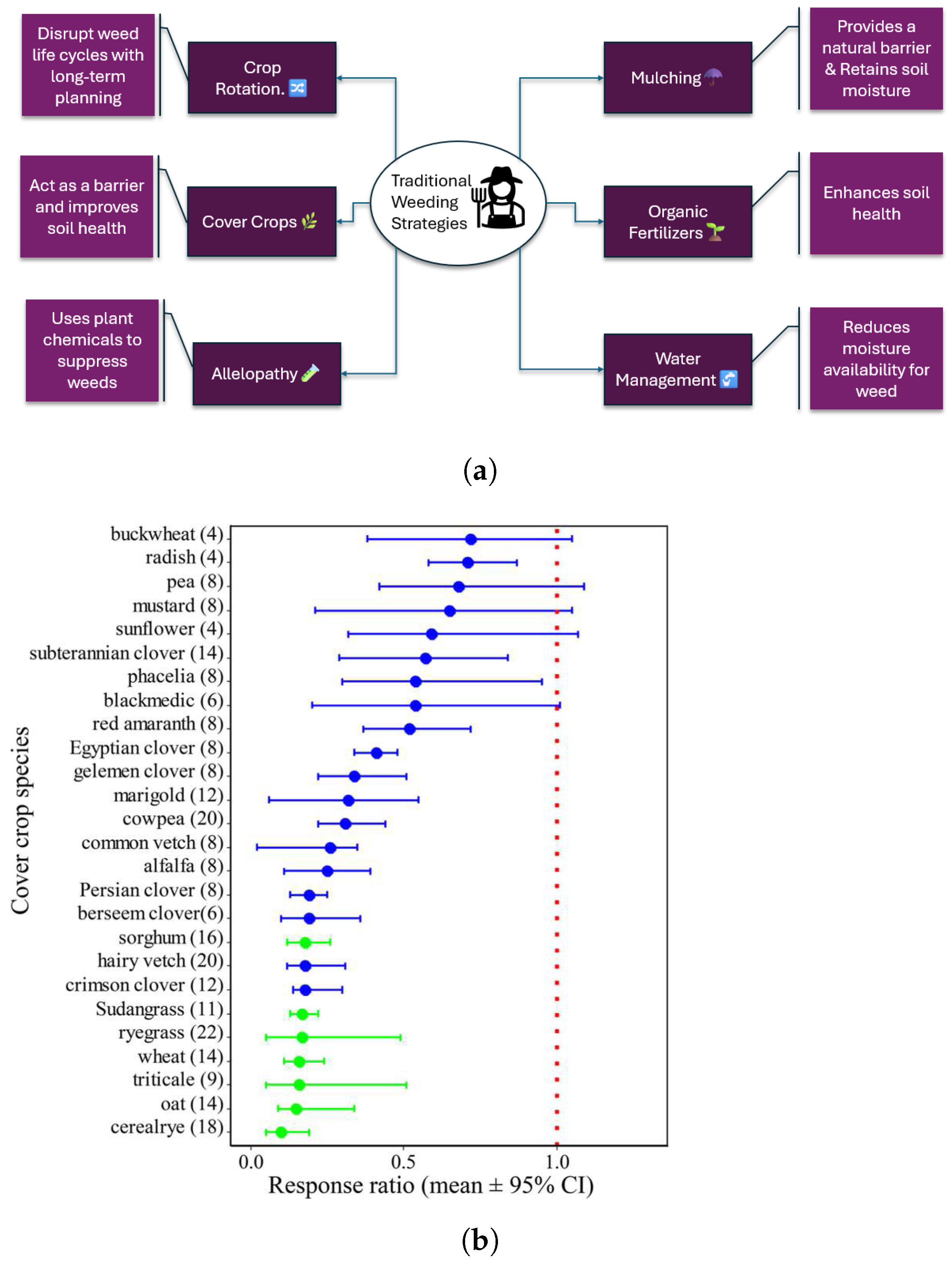

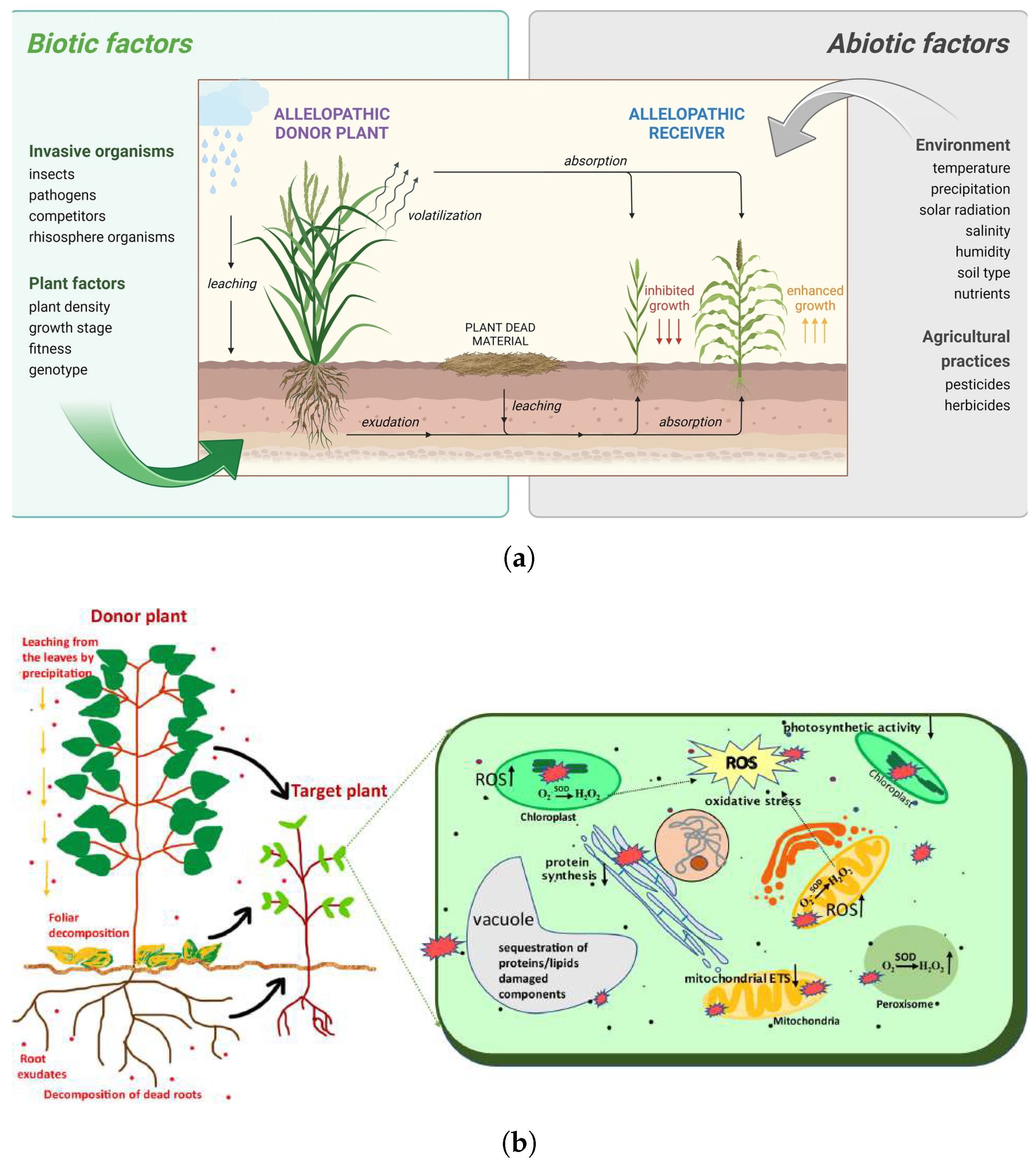

2.1. Overview of Current Weeding Techniques

- Crop–weed interactions to implement crop rotation and diversification effectively.

- Soil conditions and fertility management to optimize organic fertilizers and allelopathic plants.

- Weed biology and growth cycles to time cover crop planting and mulching correctly.

- Water management techniques to suppress weeds without harming crops.

2.2. The Evolution Towards Smart Weeding Technologies

| Category | Methodology | Advantages | Disadvantages |

|---|---|---|---|

| Mechanical | Weeds are physically removed using hand tools, cultivators, or machinery by uprooting, cutting, or tilling [30]. | Effective against annual weeds, which are easily uprooted [31]. Improves soil aeration, enhancing root growth and microbial activity. More environmentally friendly and sustainable than herbicide use [32]. | Less effective on perennial weeds, which may regrow from root fragments. Risk of soil erosion due to repeated tillage, especially in dry conditions. High labor and fuel costs. |

| Manual | Weeds are pulled by hand or with simple tools, ensuring root removal. | Highly selective, removing only weeds while preserving crops. No environmental pollution and no risk of herbicide resistance. | Extremely labor-intensive and time-consuming. Not feasible for large farms due to high labor costs. Weeds can regrow if not removed properly, particularly deep-rooted species. |

| Animal-assisted | Grazing animals, such as goats or sheep, feed on weeds to naturally control their growth. | Provides weed control while producing meat, milk, or eggs. No chemical inputs, making it an environmentally friendly method. Improves soil fertility through natural manure. | Requires proper management to prevent overgrazing and soil degradation. Some weeds may be toxic to livestock, such as ragwort poisoning in cattle [33]. Not effective for all cropping systems, especially row crops. |

| Thermal | Weeds are exposed to direct heat (flaming, steam, or hot water) to disrupt cell structures and cause desiccation [34]. | Chemical free and effective on young weeds. No soil disturbance like herbicides and can fertilize soil by turning weeds into ashes. | Multiple applications usually necessary for perennial weeds. Not effective on deeply rooted weeds. Can cause heat injury to nearby crops. |

| Herbicides | Chemical solutions are applied to selectively or non-selectively kill weeds. | Highly effective and time-saving, allowing farmers to cover large areas quickly [31]. Reduces dependency on manual labor, lowering operational costs. Can be used in combination with no-till farming, reducing soil erosion. | Overuse has led to resistant weeds, such as glyphosate-resistant Palmer amaranth in the U.S [35]. Prolonged exposure to herbicides may affect farmers’ health, and residues in food may pose risks to consumers (e.g., Molinate has been banned in the US since 2009 due to reproductive toxicity). |

| Cover crops | Cover crops suppress weeds through smothering, competition, and allelopathy. | They physically block weed growth by forming a dense cover (smothering), compete for nutrients, water, and light (competition), and release allelochemicals that inhibit weed germination (allelopathy) [19]. | Need knowledge about plant compatibility or it might have negative effects rather than positives [19]. |

3. Core 5IR Technologies Driving Smart Precision Weeding

3.1. 5IR Technologies in Smart Precision Weeding

3.1.1. AI-Driven Decision Intelligence for Weed Management

| Technology | Application | Method or Mechanism | Outcomes | Performance Metrics |

|---|---|---|---|---|

| VRS [53] | Control the amount of pesticide application | Electromechanical flow control | Increases yield while reducing pesticide expenditure | – |

| Microdosing [54] | Weed control in tomato | Hyperspectral imaging (Bayesian classifier) + thermal microdosing with food-grade oil heated to 160 °C | 95.8% of S.nigrum and 93.8% of A.retroflexus eliminated with 2.4% damage to tomato crops | Bayesian classifier: 95.9% accuracy |

| ML [55] | ML-based weed identification using SVM and WCTATP method | Image processing pipeline incorporating Curvelet Transforms and optimized feature selection for accurate weed identification | Spot spraying of herbicides becomes more efficient | SVM: 97.3%, WCTATP: 98.3% accuracy |

| DL [56] | Weed detection and classification | Applies several DL models to detect and classific corn and surrounding weed species | YOLOv7 attained the highest accuracy and speed among all models | mAP of YOLOv7: 89.93%, YOLOv8x: 89.39%, and Faster-RCNN: 81.29% |

| DL [57] | CNN for site-specific weed management | Targeted herbicide application gets easier via weed mapping based on weed’s responsiveness | Weeds prone in bermudagrass turf categorized by sensitivity to ACCase, ALS, and synthetic auxin herbicides. | DenseNet: 99.85%, GoogLeNet: 99.53%, and ResNet: 99.80% accuracy |

| HTP [58] | Soybean phenotyping to optimize crop breeding | Soybean Phenotype Measure-instance Segmentation (SPM-IS) algorithm [feature pyramid network + PCA + instance segmentation] | Reduces time and labor invested in manual phenotyping | mAP: 95.7% |

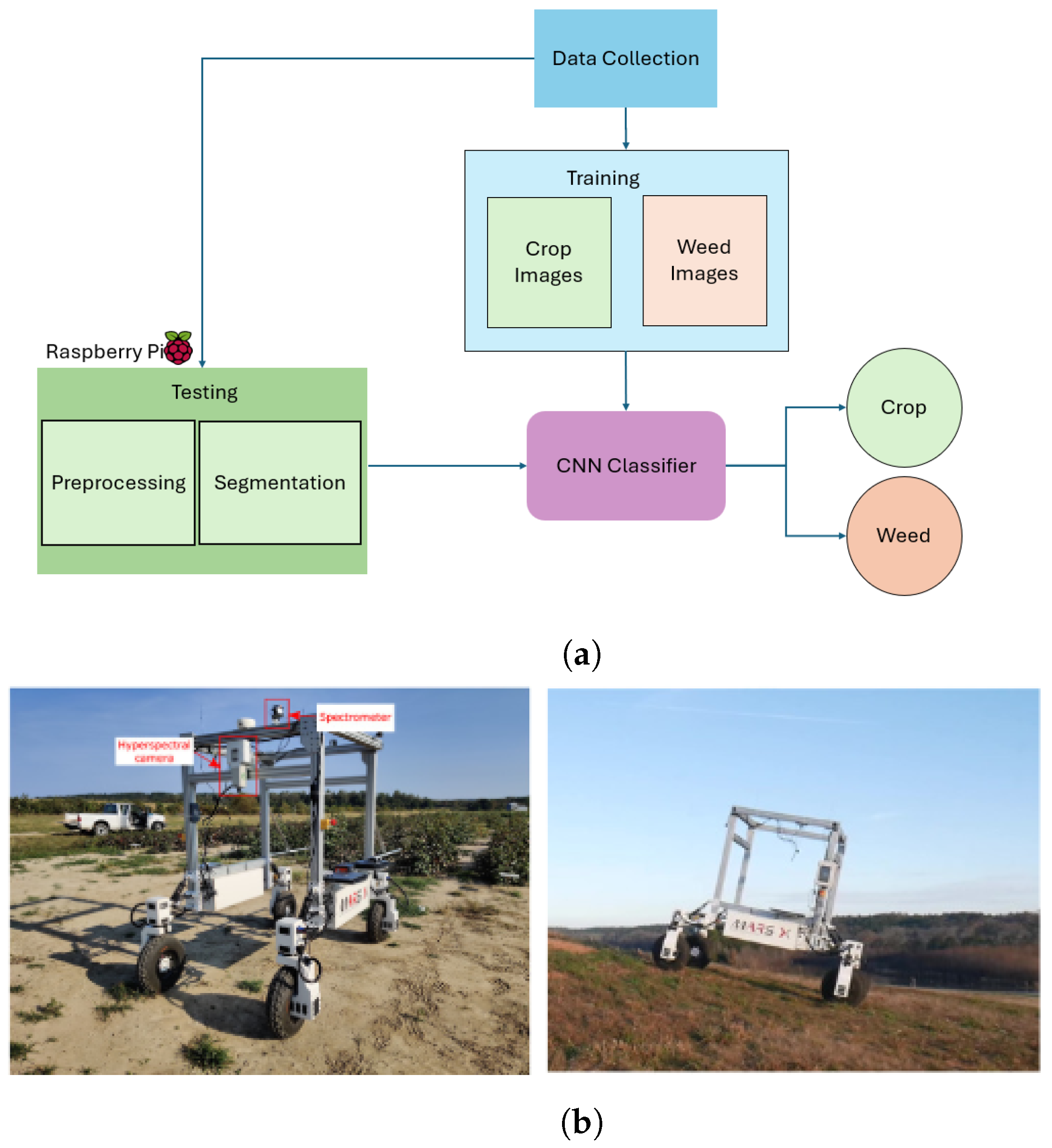

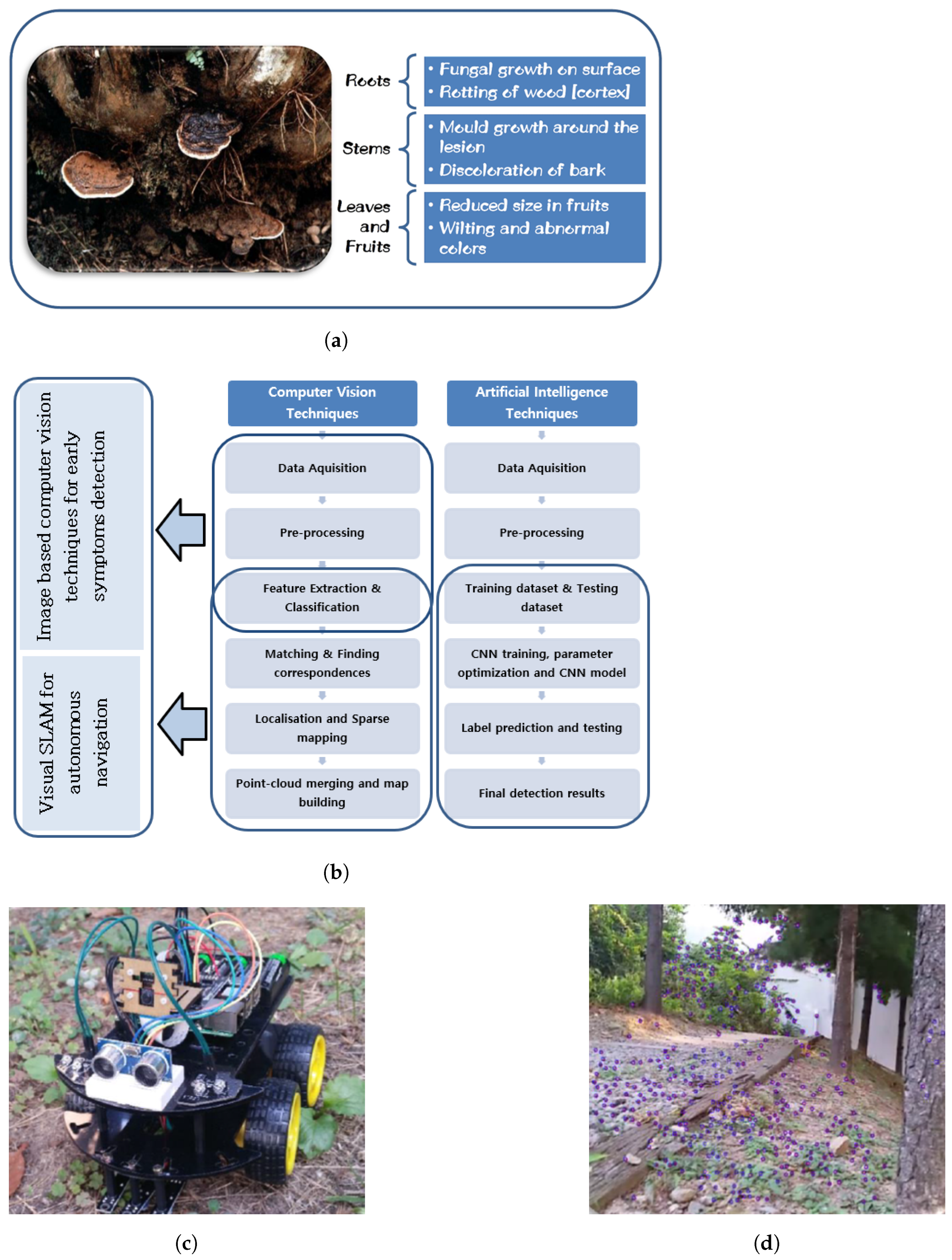

3.1.2. Computer Vision and Sensing for Weed Detection

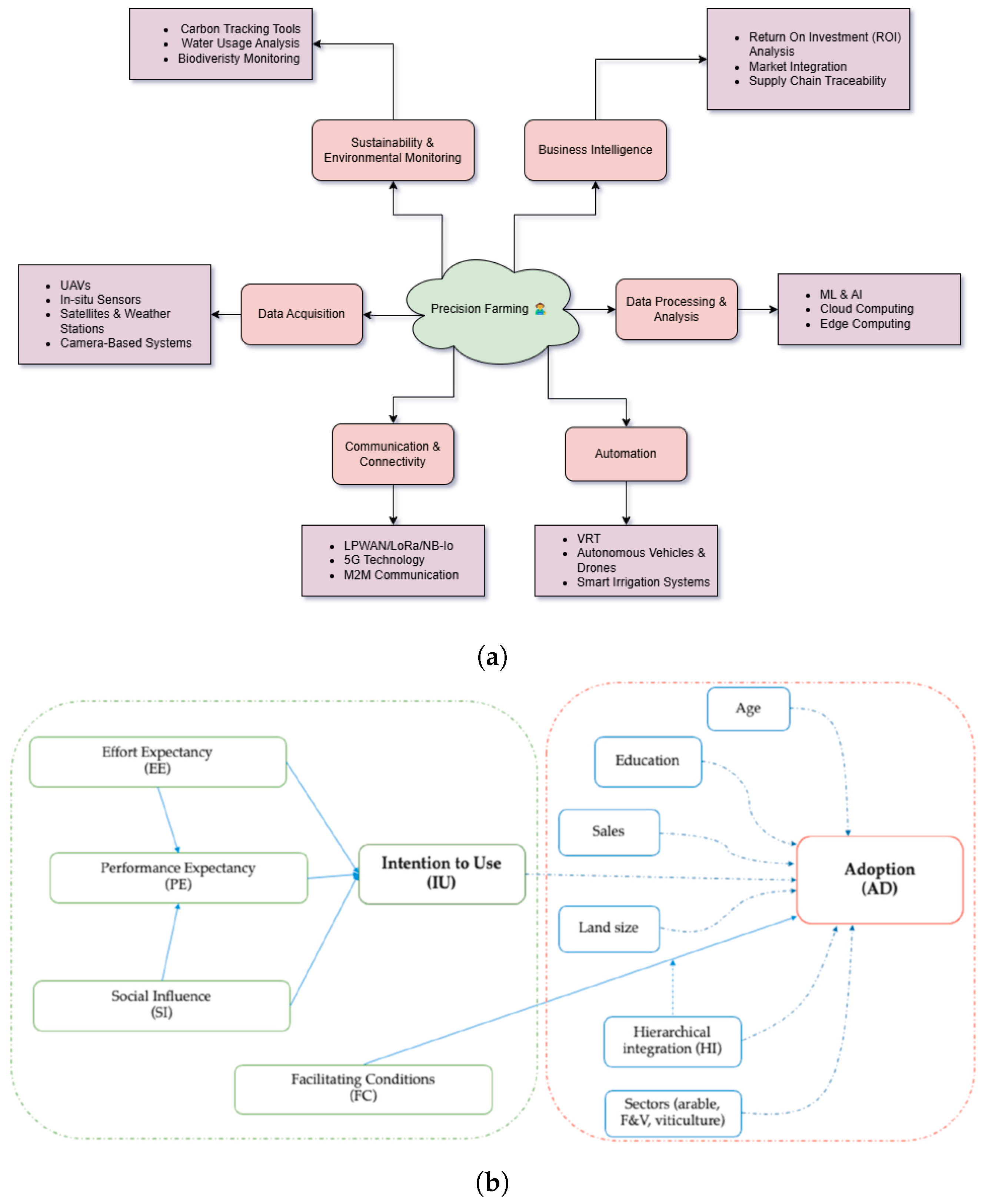

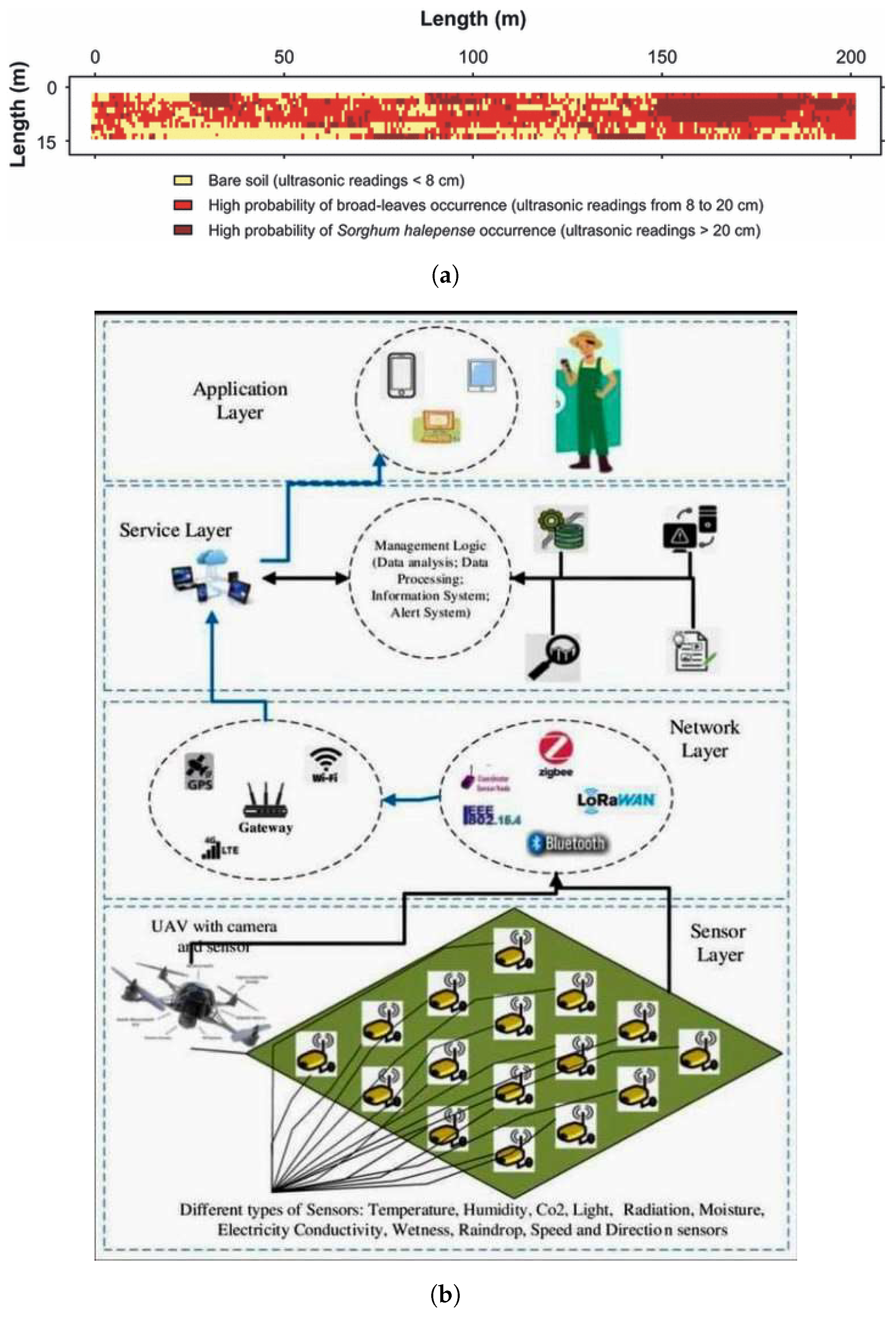

3.1.3. IoT Architecture and Edge Intelligence in AgriTech

3.1.4. Satellite Navigation and GPS-Enabled Precision Targeting

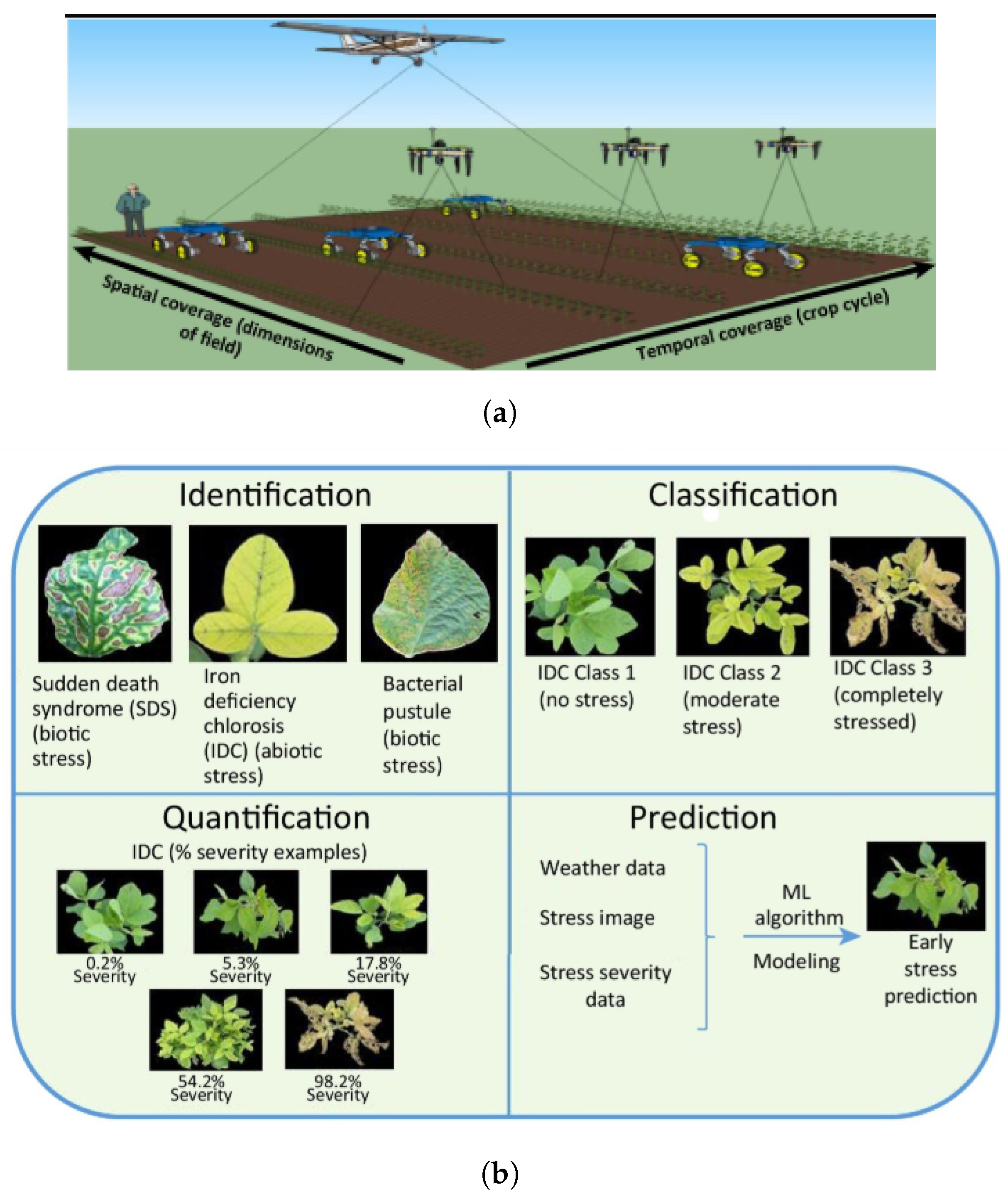

3.1.5. Aerial and Proximal Remote Sensing in Smart Farming

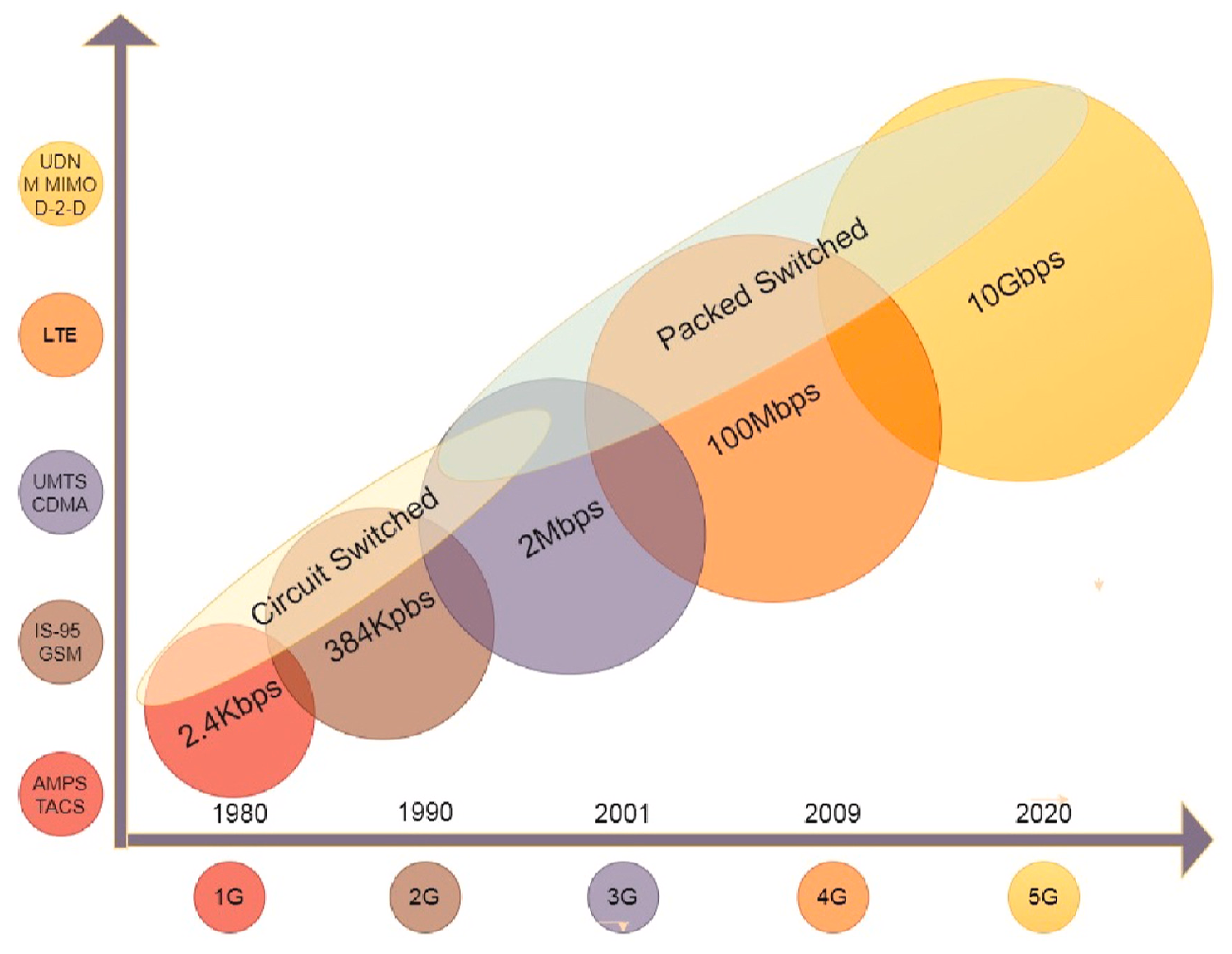

3.1.6. Ultra-Fast Connectivity: Role of 5G and 6G in Smart Weeding

3.1.7. High-Throughput Phenotyping in Precision Weeding

- Identification: ML models analyze RGB, hyperspectral, and thermal imaging data to detect weeds at early growth stages. Techniques like Gaussian mixture models (GMMs) and quadratic discriminant analysis (QDA) [97] can be used to identify species-specific weed infestations.

- Quantification: Once classified, AI models assess weed biomass and density within a given area [91]. Regression-based models and DL approaches provide estimates of weed severity, aiding in decision-making for targeted treatments.

- Prediction: Predictive models use historical and real-time phenotypic data to forecast weed outbreaks, optimizing herbicide application schedules and mechanical weeding strategies.

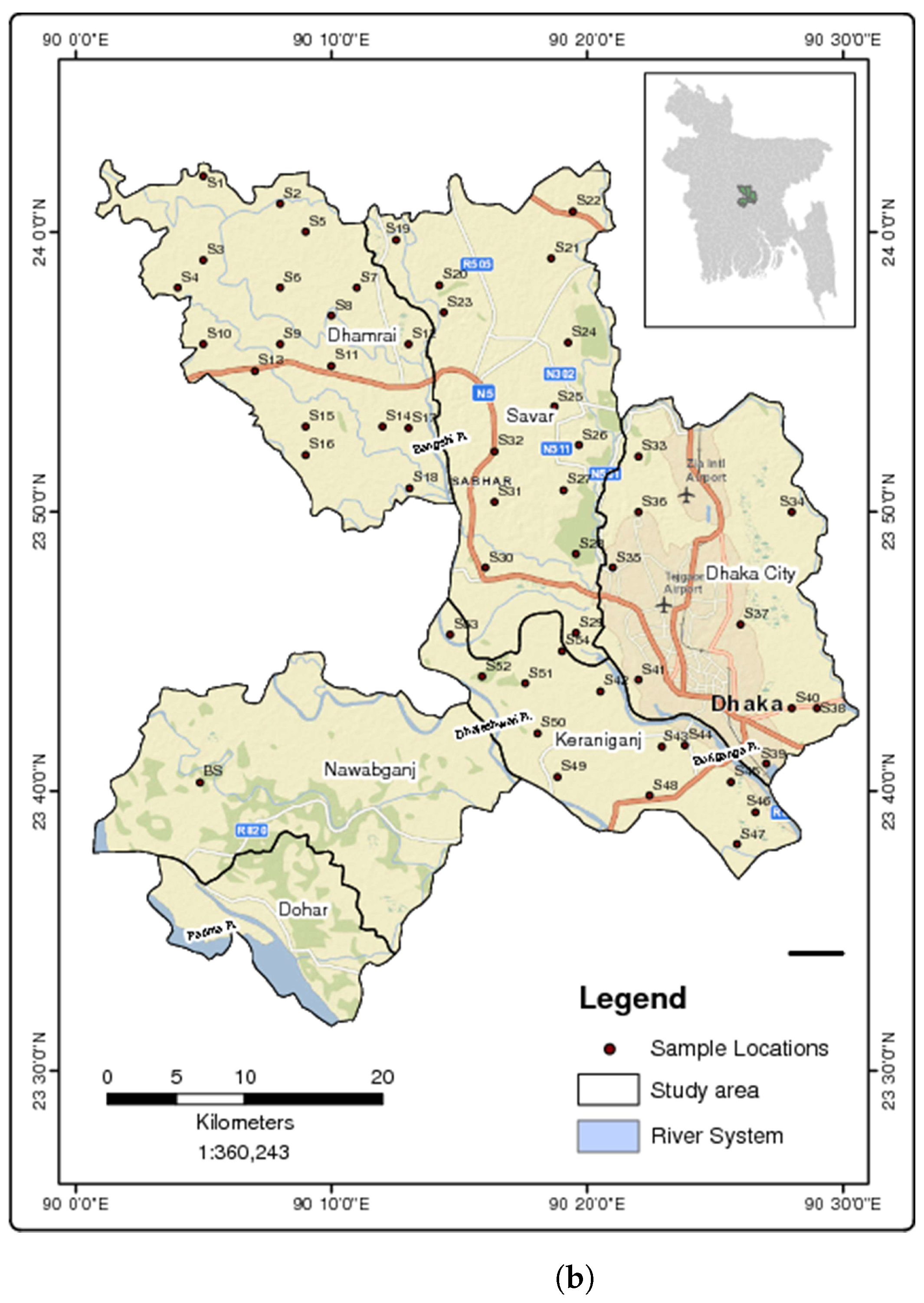

3.1.8. GIS-Based Weed Mapping and Spatial Analysis

3.1.9. Sensor Networks for Real-Time Agro-Environmental Monitoring

| Sensor Name | Functionality | References |

|---|---|---|

| RGB Cameras | Capture high-resolution images | [63,64] |

| Multispectral Sensors | Detect weeds based on differences in light reflectance compared to crops | [107] |

| Hyperspectral Sensors | Provide detailed spectral data | [108] |

| NIR Sensors | Differentiate weeds from crops based on light absorption | [42,51] |

| LiDAR Sensors | Create 3D models of fields and identifies weeds based on height and structure | [109] |

| NDVI Sensors | Measure plant health using vegetation indices | [51,52] |

| Thermal Infrared Sensors | Identify temperature variations | [110] |

| GPS and GIS Sensors | Enable weed mapping and precision herbicide application | [98,100,101,103] |

| Electrochemical and Dielectric Soil Moisture Sensors | Detect soil moisture and nutrient levels | [111] |

| Mechanical Sensors | Detect the force required to penetrate soil | [111] |

3.2. Real-World Applications of AgroTech

- On-Demand Sensing: Data is collected only when requested by the farmer.

- Periodic-Based Sensing: Data is collected and sent at fixed time intervals, which is the most used approach in smart agriculture. However, periodic sensing can contribute to big data problems, causing unnecessary data transmissions that consume energy and increase network congestion [115].

- Event-Driven Sensing: Sensors transmit data only when a significant change in field conditions is detected (e.g., soil moisture drops below a threshold). This can also avoid data overload usually happening in periodic-based sensing.

4. Robotic Innovations and Sustainable Product Solutions

4.1. Commercial Products and Research Solutions

4.2. Integration of Drones and Ground Robots

4.3. Control Algorithms and Navigation Systems

4.4. Sustainability and Green Technologies

| Robot | Sensors/Imaging | Speed/Coverage | Application Type | Power Source | Performance/Accuracy |

|---|---|---|---|---|---|

| Asterix [136] | Nvidia Jetson TK1, 4682 4MP sensor | 0.8 m/s | Chemical | Hybrid (48 V DC, 4-stroke generator) | Drop-On-Demand (DOD) system has been proven to kill off 100% of weed, reducing herbicide usage 10 times |

| AgBotII’s multimodal weed control [137] | RGB camera, Novatel SPAN-IGM-A1 (RTK) | 1.3 m/s | Machanical or chemical | Battery | Classification Accuracy: 92.3% |

| Laserweeder [37] | Nvidia GPUs, RGB cameras, GPS, Lidar | 0.4 m/s | Laser | PTO-driven generator | Kills up to 99% of weeds |

| Robotti | Laser scanner, camera, RTK-GPS | 2.2 m/s | Mechanical | Diesel-hydraulic | Navigational accuracy <±2 cm |

| Model B Sprayer | 4K machine vision camera | NA | Chemical | PTO | Weed identification accuracy 99%; 95% chemical reduction |

| Lee’s precision spraying robot for tomato [138] | Sharp GPB-2 board, AuxLUT card, RGB camera, CIO-DAS 1600 board | 1.2 km/hr | Chemical | NA | Accuracy 73.1% for tomato, 68.8% for weeds |

| Astrand weed removal robot [139] | vision sensors and two cameras: front camera for row recognition and back for offset calculation | 0.2 m/s | Mechanical | battery for indoor testing, combustion engine for application | Accuracy 77% for sugar beet, 87% for weeds |

| Bonirob weed removal bot [140] | four-channel JAI camera | NA | Mechanical | NA | 93.86% weed control rate |

| Kolberg and Wiles’ steam weeding [141,142] | four-channel JAI camera | NA | 0.8 m/s | Thermal | 90% control rate of lambsquarters and redroot pigweed |

5. Intelligent Systems and Ecosystem Integration

5.1. Decision Support Systems (DSS)

5.2. Blockchain for Traceability and Transparency in Sustainable Practices

6. Current Limitations, Market Dynamics, and Economic Considerations

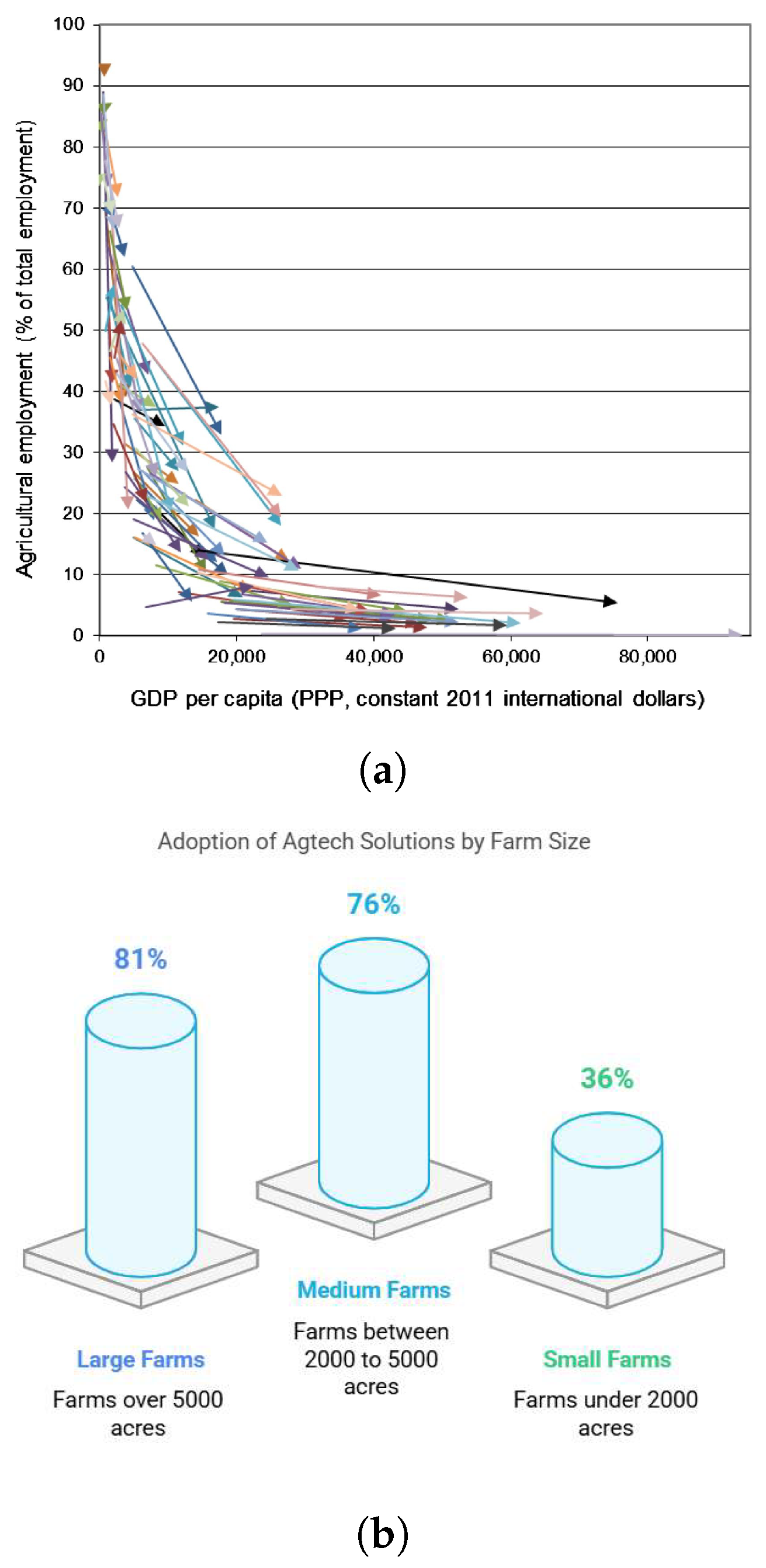

6.1. Market Analysis for Smart Weeding Technologies

- Growth in AgroTech adoption remains limited, with only 4% of farmers planning to adopt precision-agriculture hardware, remote-sensing solutions, or sustainability-related technologies in the next two years. Figure 19 presents detailed data categorized by farm size.

- Among submarkets, precision agriculture products have the highest adoption rate with 39% for software and 15% for hardware, making it one of the most utilized technologies.

- Robotics and automation, which are relevant to precision weeding, have the lowest projected growth rate of 2.5%, probably due to high initial investment.

6.2. Economic Impact at Local and Global Level

7. Recommendations for Enabling Smart Farming at Scale

7.1. Infrastructure Investment

7.2. Policy Considerations

8. Strategic Directions for Future Research

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 5G | 5th Generation |

| ACCase Herbicides | Acetyl-CoA Carboxylase Inhibitor Herbicides |

| AgroTech or AgriTech | Agricultural Technology |

| ALS Herbicides | Acetolactate Synthase Inhibitor Herbicides |

| CS rate | Complete Spraying Rate |

| CVIs | Color Vegetation Indices |

| DSS | Decision Support System |

| GIS | Geographic Information Systems |

| GMMs | Gaussian Mixture Models |

| GNSS | Global Navigation Satellite System |

| HTP | High-throughput Phenotyping |

| IDW | Inverse Distance Weighting |

| IR | Industrial Revolution |

| LiDAR | Light Detection and Ranging |

| NDVI | Normalized Difference Vegetation Index |

| NDWI | Normalized Difference Water Index |

| NIR | Near Infrared |

| NLP | Natural Language Processing |

| PPPs | Public Private Partnerships |

| QDA | Quadratic Discriminant Analysis |

| RF | Random Forest |

| RS | Remote Sensing |

| SDGs | Sustainable Development Goals |

| SLAM | Simultaneous Localization And Mapping |

| VGG-16 | Visual Geometry Group 16-layer network |

| VRT or VRS | Variable Rate Technology |

| WCTATP | Wrapping Curvelet Transformation Based Angular Texture Pattern Extraction |

References

- Galanakis, C.M. The future of food. Foods 2024, 13, 506. [Google Scholar] [CrossRef] [PubMed]

- FAO. FAOSTAT—Food Security Indicators Visualization. 2024. Available online: https://www.fao.org/faostat/en/#data/FS/visualize (accessed on 12 February 2025).

- Fipke, G.M.; Martin, T.N.; Nunes, U.R.; Stecca, J.D.L.; Winck, J.E.M.; Grando, L.F.T.; da Costa Rossato, A. Application of non-selective herbicides in the pre-harvest of wheat damages seed quality. Am. J. Plant Sci. 2018, 9, 107–123. [Google Scholar] [CrossRef]

- Otekunrin, O.A. A Critical Assessment of the Interplay of Conflict, Hunger, Poverty, and Food Insecurity in Africa. Food Humanit. 2025, 4, 100544. [Google Scholar] [CrossRef]

- Vasileiou, M.; Kyrgiakos, L.S.; Kleisiari, C.; Kleftodimos, G.; Vlontzos, G.; Belhouchette, H.; Pardalos, P.M. Transforming weed management in sustainable agriculture with artificial intelligence: A systematic literature review towards weed identification and deep learning. Crop. Prot. 2024, 176, 106522. [Google Scholar] [CrossRef]

- Ekwealor, K.; Echereme, C.; Ofobeze, T.; Okereke, C. Economic importance of weeds: A review. Asian J. Plant. Sci. 2019, 3, 1–11. [Google Scholar] [CrossRef]

- Sharma, G.; Shrestha, S.; Kunwar, S.; Tseng, T.M. Crop diversification for improved weed management: A review. Agriculture 2021, 11, 461. [Google Scholar] [CrossRef]

- Tshewang, S.; Sindel, B.M.; Ghimiray, M.; Chauhan, B.S. Weed management challenges in rice (Oryza sativa L.) for food security in Bhutan: A review. Crop. Prot. 2016, 90, 117–124. [Google Scholar] [CrossRef]

- Belz, R.G. Allelopathy in crop/weed interactions—An update. Pest Manag. Sci. Former. Pestic. Sci. 2007, 63, 308–326. [Google Scholar] [CrossRef]

- Hoang Anh, L.; Van Quan, N.; Tuan Nghia, L.; Dang Xuan, T. Phenolic allelochemicals: Achievements, limitations, and prospective approaches in weed management. Weed Biol. Manag. 2021, 21, 37–67. [Google Scholar] [CrossRef]

- Arora, S.; Husain, T.; Prasad, S.M. Allelochemicals as biocontrol agents: Promising aspects, challenges and opportunities. S. Afr. J. Bot. 2024, 166, 503–511. [Google Scholar] [CrossRef]

- Elstone, L.; How, K.Y.; Brodie, S.; Ghazali, M.Z.; Heath, W.P.; Grieve, B. High speed crop and weed identification in lettuce fields for precision weeding. Sensors 2020, 20, 455. [Google Scholar] [CrossRef] [PubMed]

- Giua, C.; Materia, V.C.; Camanzi, L. Smart farming technologies adoption: Which factors play a role in the digital transition? Technol. Soc. 2022, 68, 101869. [Google Scholar] [CrossRef]

- Kovari, A. Industry 5.0: Generalized definition key applications opportunities and threats. Acta Polytech. Hung. 2024, 21, 267–284. [Google Scholar] [CrossRef]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is industry 5.0 a human-centred approach? A systematic review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Tiwari, S.; Sindel, B.; Smart, N.; Coleman, M.; Fyfe, C.; Lawlor, C.; Vo, B.; Kristiansen, P. Hand weeding tools in vegetable production systems: An agronomic, ergonomic and economic evaluation. Int. J. Agric. Sustain. 2022, 20, 659–674. [Google Scholar] [CrossRef]

- Olson, B.; Lacey, J. Sheep: A method for controlling rangeland weeds. Sheep Res. J. Spec. Issue 1994, 1994, 105–112. [Google Scholar]

- Kaur, S.; Kaur, R.; Chauhan, B.S. Understanding crop-weed-fertilizer-water interactions and their implications for weed management in agricultural systems. Crop. Prot. 2018, 103, 65–72. [Google Scholar] [CrossRef]

- Osipitan, O.A.; Dille, J.A.; Assefa, Y.; Radicetti, E.; Ayeni, A.; Knezevic, S.Z. Impact of cover crop management on level of weed suppression: A meta-analysis. Crop. Sci. 2019, 59, 833–842. [Google Scholar] [CrossRef]

- Aslam, F.; Khaliq, A.; Matloob, A.; Tanveer, A.; Hussain, S.; Zahir, Z.A. Allelopathy in agro-ecosystems: A critical review of wheat allelopathy-concepts and implications. Chemoecology 2017, 27, 1–24. [Google Scholar] [CrossRef]

- Koteish, K.; Harb, H.; Dbouk, M.; Zaki, C.; Abou Jaoude, C. AGRO: A smart sensing and decision-making mechanism for real-time agriculture monitoring. J. King Saud-Univ.-Comput. Inf. Sci. 2022, 34, 7059–7069. [Google Scholar] [CrossRef]

- Idoje, G.; Dagiuklas, T.; Iqbal, M. Survey for smart farming technologies: Challenges and issues. Comput. Electr. Eng. 2021, 92, 107104. [Google Scholar] [CrossRef]

- Morgan-Owen, G.; Johnston, G. Differential GPS positioning. Electron. Commun. Eng. J. 1995, 7, 11–21. [Google Scholar] [CrossRef]

- Bhuiyan, M.A.H.; Karmaker, S.C.; Bodrud-Doza, M.; Rakib, M.A.; Saha, B.B. Enrichment, sources and ecological risk mapping of heavy metals in agricultural soils of dhaka district employing SOM, PMF and GIS methods. Chemosphere 2021, 263, 128339. [Google Scholar] [CrossRef]

- Agency, E.S. Sentinel-2. 2025. Available online: https://dataspace.copernicus.eu/explore-data/data-collections/sentinel-data/sentinel-2 (accessed on 27 February 2025).

- Radočaj, D.; Jurišić, M.; Gašparović, M. The role of remote sensing data and methods in a modern approach to fertilization in precision agriculture. Remote Sens. 2022, 14, 778. [Google Scholar] [CrossRef]

- Dangi, R.; Lalwani, P.; Choudhary, G.; You, I.; Pau, G. Study and investigation on 5G technology: A systematic review. Sensors 2021, 22, 26. [Google Scholar] [CrossRef] [PubMed]

- Bikov, T.; Mihaylov, G.; Iliev, T.; Stoyanov, I. Drone surveillance in the modern agriculture. In Proceedings of the 2022 8th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE), Ruse, Bulgaria, 30 June–2 July 2022; pp. 1–4. [Google Scholar]

- Westwood, J.H.; Charudattan, R.; Duke, S.O.; Fennimore, S.A.; Marrone, P.; Slaughter, D.C.; Swanton, C.; Zollinger, R. Weed management in 2050: Perspectives on the future of weed science. Weed Sci. 2018, 66, 275–285. [Google Scholar] [CrossRef]

- Monteiro, A.; Santos, S. Sustainable approach to weed management: The role of precision weed management. Agronomy 2022, 12, 118. [Google Scholar] [CrossRef]

- Moond, V.; Panotra, N.; Ashoka, P.; Saikanth, D.; Singh, G.; Prabhavathi, N.; Verma, B. Strategies and Technologies in Weed Management: A Comprehensive. Curr. J. Appl. Sci. Technol. 2023, 42, 20–29. [Google Scholar] [CrossRef]

- Liu, C.; Yang, K.; Chen, Y.; Gong, H.; Feng, X.; Tang, Z.; Fu, D.; Qi, L. Benefits of mechanical weeding for weed control, rice growth characteristics and yield in paddy fields. Field Crop. Res. 2023, 293, 108852. [Google Scholar] [CrossRef]

- Stockman, S. Poisoning of cattle with British ragwort. J. Comp. Pathol. Ther. 1917, 30, 131–134. [Google Scholar] [CrossRef]

- Ascard, J.; Hatcher, P.; Melander, B.; Upadhyaya, M.; Blackshaw, R. 10 Thermal weed control. In Non-Chemical Weed Management: Principles, Concepts and Technology; CABI: Wallingford, UK, 2007; pp. 155–175. [Google Scholar]

- Butler-Jones, A.L.; Maloney, E.C.; McClements, M.; Kramer, W.B.; Morran, S.; Gaines, T.A.; Besançon, T.E.; Sosnoskie, L.M. Confirmation of glyphosate-resistant Palmer amaranth (Amaranthus palmeri) populations in New York and responses to alternative chemistries. Weed Sci. 2024, 72, 508–516. [Google Scholar] [CrossRef]

- Ellstrand, N.C.; Heredia, S.M.; Leak-Garcia, J.A.; Heraty, J.M.; Burger, J.C.; Yao, L.; Nohzadeh-Malakshah, S.; Ridley, C.E. Crops gone wild: Evolution of weeds and invasives from domesticated ancestors. Evol. Appl. 2010, 3, 494–504. [Google Scholar] [CrossRef]

- Upadhyay, A.; Zhang, Y.; Koparan, C.; Rai, N.; Howatt, K.; Bajwa, S.; Sun, X. Advances in ground robotic technologies for site-specific weed management in precision agriculture: A review. Comput. Electron. Agric. 2024, 225, 109363. [Google Scholar] [CrossRef]

- Bonomi, F.; Milito, R.; Zhu, J.; Addepalli, S. Fog computing and its role in the internet of things. In Proceedings of the SIGCOMM ’12: ACM SIGCOMM 2012 Conference, Helsinki, Finland, 17 August 2012; pp. 13–16. [Google Scholar]

- Kalyani, Y.; Collier, R. A systematic survey on the role of cloud, fog, and edge computing combination in smart agriculture. Sensors 2021, 21, 5922. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, C.S. The UN sustainable development goals (SDGs) are a great gift to business! Procedia Cirp. 2018, 69, 21–24. [Google Scholar] [CrossRef]

- Liu, J.; Abbas, I.; Noor, R.S. Development of deep learning-based variable rate agrochemical spraying system for targeted weeds control in strawberry crop. Agronomy 2021, 11, 1480. [Google Scholar] [CrossRef]

- Von Bargen, K.; Meyer, G.E.; Mortensen, D.A.; Merritt, S.J.; Woebbecke, D.M. Red/near-infrared reflectance sensor system for detecting plants. In Proceedings of the Optics in Agriculture and Forestry, Boston, MA, USA, 16 November 1992; Volume 1836, pp. 231–238. [Google Scholar]

- Giles, D.; Delwiche, M.; Dodd, R. Sprayer Control by Sensing Orchard Crop Characteristics: Orchard Architecture and Spray Liquid Savings; FAO: Rome, Italy, 1989. [Google Scholar]

- Palacín, J.; Pallejà, T.; Tresanchez, M.; Sanz, R.; Llorens, J.; Ribes-Dasi, M.; Masip, J.; Arnó, J.; Escolà, A.; Rosell, J.R. Real-time tree-foliage surface estimation using a ground laser scanner. IEEE Trans. Instrum. Meas. 2007, 56, 1377–1383. [Google Scholar] [CrossRef]

- Ghimire, A.; Kakani, V.; Kim, H. SSRT: A Sequential Skeleton RGB Transformer to Recognize Fine-grained Human-Object Interactions and Action Recognition. IEEE Access 2023, 11, 51930–51948. [Google Scholar] [CrossRef]

- Lamm, R.D.; Slaughter, D.C.; Giles, D.K. Precision weed control system for cotton. Trans. ASAE 2002, 45, 231. [Google Scholar]

- Prabakaran, N.; Kannadasan, R.; Krishnamoorthy, A.; Kakani, V. A Bidirectional LSTM approach for written script auto evaluation using keywords-based pattern matching. Nat. Lang. Process. J. 2023, 5, 100033. [Google Scholar]

- Holzinger, A.; Schweier, J.; Gollob, C.; Nothdurft, A.; Hasenauer, H.; Kirisits, T.; Häggström, C.; Visser, R.; Cavalli, R.; Spinelli, R.; et al. From industry 5.0 to forestry 5.0: Bridging the gap with human-centered artificial intelligence. Curr. For. Rep. 2024, 10, 442–455. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Han, X. Robotic arms in precision agriculture: A comprehensive review of the technologies, applications, challenges, and future prospects. Comput. Electron. Agric. 2024, 221, 108938. [Google Scholar] [CrossRef]

- Søgaard, H.T.; Lund, I. Application accuracy of a machine vision-controlled robotic micro-dosing system. Biosyst. Eng. 2007, 96, 315–322. [Google Scholar] [CrossRef]

- Lee, M.K.; Golzarian, M.R.; Kim, I. A new color index for vegetation segmentation and classification. Precis. Agric. 2021, 22, 179–204. [Google Scholar] [CrossRef]

- Yousefi, J. Image Binarization Using Otsu Thresholding Algorithm; University of Guelph: Guelph, ON, Canada, 2011. [Google Scholar]

- Taseer, A.; Han, X. Advancements in variable rate spraying for precise spray requirements in precision agriculture using Unmanned aerial spraying Systems: A review. Comput. Electron. Agric. 2024, 219, 108841. [Google Scholar] [CrossRef]

- Zhang, Y.; Staab, E.S.; Slaughter, D.C.; Giles, D.K.; Downey, D. Automated weed control in organic row crops using hyperspectral species identification and thermal micro-dosing. Crop. Prot. 2012, 41, 96–105. [Google Scholar] [CrossRef]

- Kumar, D.A.; Prema, P. A Novel Wrapping Curvelet Transformation Based Angular Texture Pattern (WCTATP) Extraction Method for Weed Identification. ICTACT J. Image Video Process. 2016, 6, 1192–1206. [Google Scholar]

- Hasan, A.M.; Diepeveen, D.; Laga, H.; Jones, M.G.; Sohel, F. Object-level benchmark for deep learning-based detection and classification of weed species. Crop. Prot. 2024, 177, 106561. [Google Scholar] [CrossRef]

- Jin, X.; Zhao, H.; Kong, X.; Han, K.; Lei, J.; Zu, Q.; Chen, Y.; Yu, J. Deep learning-based weed detection for precision herbicide application in turf. Pest Manag. Sci. 2025, 81, 3597–3609. [Google Scholar] [CrossRef]

- Li, S.; Yan, Z.; Guo, Y.; Su, X.; Cao, Y.; Jiang, B.; Yang, F.; Zhang, Z.; Xin, D.; Chen, Q.; et al. SPM-IS: An auto-algorithm to acquire a mature soybean phenotype based on instance segmentation. Crop. J. 2022, 10, 1412–1423. [Google Scholar] [CrossRef]

- Rakhmatulin, I.; Kamilaris, A.; Andreasen, C. Deep neural networks to detect weeds from crops in agricultural environments in real-time: A review. Remote Sens. 2021, 13, 4486. [Google Scholar] [CrossRef]

- Kakani, V.; Kim, H.; Basivi, P.K.; Pasupuleti, V.R. Surface thermo-dynamic characterization of poly (vinylidene chloride-co-acrylonitrile)(P (VDC-co-AN)) using inverse-gas chromatography and investigation of visual traits using computer vision image processing algorithms. Polymers 2020, 12, 1631. [Google Scholar] [CrossRef] [PubMed]

- Basivi, P.K.; Hamieh, T.; Kakani, V.; Pasupuleti, V.R.; Sasikala, G.; Heo, S.M.; Pasupuleti, K.S.; Kim, M.D.; Munagapati, V.S.; Kumar, N.S.; et al. Exploring advanced materials: Harnessing the synergy of inverse gas chromatography and artificial vision intelligence. TrAC Trends Anal. Chem. 2024, 173, 117655. [Google Scholar] [CrossRef]

- Chandrasekaran, K.; Ramesh, S.; Kokkarachedu, V.; Kakani, V. Toxicity reduction of ZnO cauliflower-like structure through trivalent neodymium ion substitution and investigation via computer vision and AI image analysis. Mater. Chem. Phys. 2024, 312, 128640. [Google Scholar] [CrossRef]

- Technology, B.R. Our Products. Available online: https://www.bluerivertechnology.com/our-products/ (accessed on 13 March 2025).

- Deere, J. See & Spray TM Select. Available online: https://www.deere.com/en/sprayers/see-spray-select/ (accessed on 13 March 2025).

- Yeshe, A.; Gourkhede, P.; Vaidya, P. Blue River Technology: Futuristic Approach of Precision Farming; Just Agriculture: Punjab, India, 2022. [Google Scholar]

- NVIDIA. Blue River and John Deere Reduce Herbicide Use with AI-Powered Technology. 2020. Available online: https://blogs.nvidia.com/blog/blue-river-john-deere-reduce-herbicide/ (accessed on 13 March 2025).

- Abdigapporov, S.; Miraliev, S.; Alikhanov, J.; Kakani, V.; Kim, H. Performance Comparison of Backbone Networks for Multi-Tasking in Self-Driving Operations. In Proceedings of the 2022 22nd International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 27 November–1 December 2022; pp. 819–824. [Google Scholar]

- Kakani, V.; Kim, H. Adaptive self-calibration of fisheye and wide-angle cameras. In Proceedings of the TENCON 2019-2019 IEEE Region 10 Conference (TENCON), Kochi, India, 17–20 October 2019; pp. 976–981. [Google Scholar]

- Kakani, V.; Li, X.; Cui, X.; Kim, H.; Kim, B.S.; Kim, H. Implementation of Field-Programmable Gate Array Platform for Object Classification Tasks Using Spike-Based Backpropagated Deep Convolutional Spiking Neural Networks. Micromachines 2023, 14, 1353. [Google Scholar] [CrossRef]

- Miraliev, S.; Abdigapporov, S.; Alikhanov, J.; Kakani, V.; Kim, H. Edge Device Deployment of Multi-Tasking Network for Self-Driving Operations. arXiv 2022, arXiv:2210.04735. [Google Scholar]

- Kansal, I.; Khullar, V.; Verma, J.; Popli, R.; Kumar, R. IoT-Fog-enabled robotics-based robust classification of hazy and normal season agricultural images for weed detection. Paladyn J. Behav. Robot. 2023, 14, 20220105. [Google Scholar] [CrossRef]

- Marín-Tordera, E.; Masip-Bruin, X.; García-Almiñana, J.; Jukan, A.; Ren, G.J.; Zhu, J. Do we all really know what a fog node is? Current trends towards an open definition. Comput. Commun. 2017, 109, 117–130. [Google Scholar] [CrossRef]

- Junior, F.M.R.; Bianchi, R.A.; Prati, R.C.; Kolehmainen, K.; Soininen, J.P.; Kamienski, C.A. Data reduction based on machine learning algorithms for fog computing in IoT smart agriculture. Biosyst. Eng. 2022, 223, 142–158. [Google Scholar] [CrossRef]

- NVIDIA. Jetson Xavier Series. Available online: https://www.nvidia.com/en-us/autonomous-machines/embedded-systems/jetson-xavier-series/ (accessed on 13 March 2025).

- He, K.; Sun, J.; Tang, X. Single image haze removal using dark channel prior. IEEE Trans. Pattern Anal. Mach. Intell. 2010, 33, 2341–2353. [Google Scholar]

- Tan, R.T. Visibility in bad weather from a single image. In Proceedings of the 2008 IEEE Conference on Computer Vision and Pattern Recognition, Anchorage, AK, USA, 23–28 June 2008; pp. 1–8. [Google Scholar]

- Kulkarni, S.; Angadi, S.; Belagavi, V. IoT based weed detection using image processing and CNN. Int. J. Eng. Appl. Sci. Technol 2019, 4, 606–609. [Google Scholar]

- Ren, W.; Liu, S.; Zhang, H.; Pan, J.; Cao, X.; Yang, M.H. Single image dehazing via multi-scale convolutional neural networks. In Proceedings of the Computer Vision—ECCV 2016: 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; pp. 154–169. [Google Scholar]

- Xu, R.; Li, C. A modular agricultural robotic system (MARS) for precision farming: Concept and implementation. J. Field Robot. 2022, 39, 387–409. [Google Scholar] [CrossRef]

- Matosevic, M.; Salcic, Z.; Berber, S. A comparison of accuracy using a GPS and a low-cost DGPS. IEEE Trans. Instrum. Meas. 2006, 55, 1677–1683. [Google Scholar] [CrossRef]

- Deere, J. AutoTrac. Available online: https://www.deere.com/en/technology-products/precision-ag-technology/guidance/auto-trac/ (accessed on 6 March 2025).

- Liu, H.; Du, Z.; Shen, Y.; Du, W.; Zhang, X. Development and evaluation of an intelligent multivariable spraying robot for orchards and nurseries. Comput. Electron. Agric. 2024, 222, 109056. [Google Scholar] [CrossRef]

- Segarra, J.; Buchaillot, M.L.; Araus, J.L.; Kefauver, S.C. Remote sensing for precision agriculture: Sentinel-2 improved features and applications. Agronomy 2020, 10, 641. [Google Scholar] [CrossRef]

- Xie, Q.; Dash, J.; Huete, A.; Jiang, A.; Yin, G.; Ding, Y.; Peng, D.; Hall, C.C.; Brown, L.; Shi, Y.; et al. Retrieval of crop biophysical parameters from Sentinel-2 remote sensing imagery. Int. J. Appl. Earth Obs. Geoinf. 2019, 80, 187–195. [Google Scholar] [CrossRef]

- Skakun, S.; Kalecinski, N.I.; Brown, M.G.; Johnson, D.M.; Vermote, E.F.; Roger, J.C.; Franch, B. Assessing within-field corn and soybean yield variability from WorldView-3, Planet, Sentinel-2, and Landsat 8 satellite imagery. Remote Sens. 2021, 13, 872. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Hoang, T.D.; Pham, M.T.; Vu, T.T.; Nguyen, T.H.; Huynh, Q.T.; Jo, J. Monitoring agriculture areas with satellite images and deep learning. Appl. Soft Comput. 2020, 95, 106565. [Google Scholar] [CrossRef]

- Zhang, C.; Di, L.; Lin, L.; Li, H.; Guo, L.; Yang, Z.; Yu, E.G.; Di, Y.; Yang, A. Towards automation of in-season crop type mapping using spatiotemporal crop information and remote sensing data. Agric. Syst. 2022, 201, 103462. [Google Scholar] [CrossRef]

- Li, N.; Zhang, X.; Zhang, C.; Ge, L.; He, Y.; Wu, X. Review of machine-vision-based plant detection technologies for robotic weeding. In Proceedings of the 2019 IEEE International Conference on Robotics and Biomimetics (ROBIO), Dali, China, 6–8 December 2019; pp. 2370–2377. [Google Scholar]

- Israr, A.; Yang, Q.; Li, W.; Zomaya, A.Y. Renewable energy powered sustainable 5G network infrastructure: Opportunities, challenges and perspectives. J. Netw. Comput. Appl. 2021, 175, 102910. [Google Scholar] [CrossRef]

- Rathinavel, S.; Kavitha, R.; Gitanjali, J.; Saiprasanth, R. Role of 5G technology in enhancing agricultural mechanization. IOP Conf. Ser. Earth Environ. Sci. 2023, 1258, 012010. [Google Scholar] [CrossRef]

- Singh, A.; Ganapathysubramanian, B.; Singh, A.K.; Sarkar, S. Machine learning for high-throughput stress phenotyping in plants. Trends Plant Sci. 2016, 21, 110–124. [Google Scholar] [CrossRef]

- Mohidem, N.A.; Che’Ya, N.N.; Juraimi, A.S.; Fazlil Ilahi, W.F.; Mohd Roslim, M.H.; Sulaiman, N.; Saberioon, M.; Mohd Noor, N. How can unmanned aerial vehicles be used for detecting weeds in agricultural fields? Agriculture 2021, 11, 1004. [Google Scholar] [CrossRef]

- Torres-Sánchez, J.; Pena, J.M.; de Castro, A.I.; López-Granados, F. Multi-temporal mapping of the vegetation fraction in early-season wheat fields using images from UAV. Comput. Electron. Agric. 2014, 103, 104–113. [Google Scholar] [CrossRef]

- Peña, J.M.; Torres-Sánchez, J.; Serrano-Pérez, A.; De Castro, A.I.; López-Granados, F. Quantifying efficacy and limits of unmanned aerial vehicle (UAV) technology for weed seedling detection as affected by sensor resolution. Sensors 2015, 15, 5609–5626. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, Z.; Khot, L.; Meng, X.; Zhang, Q. A real-time weed mapping and precision herbicide spraying system for row crops. Sensors 2018, 18, 4245. [Google Scholar] [CrossRef] [PubMed]

- Yano, I.H.; Mesa, N.F.O.; Santiago, W.E.; Aguiar, R.H.; Teruel, B. Weed identification in sugarcane plantation through images taken from remotely piloted aircraft (RPA) and KNN classifier. J. Food Nutr. Sci 2017, 5, 211. [Google Scholar]

- Casanova, J.J.; O’Shaughnessy, S.A.; Evett, S.R.; Rush, C.M. Development of a wireless computer vision instrument to detect biotic stress in wheat. Sensors 2014, 14, 17753–17769. [Google Scholar] [CrossRef]

- Zhang, F.; Cao, N. Application and research progress of geographic information system (GIS) in agriculture. In Proceedings of the 2019 8th International Conference on Agro-Geoinformatics (Agro-Geoinformatics), Istanbul, Turkey, 16–19 July 2019; pp. 1–5. [Google Scholar]

- Rokhmana, C.A. The potential of UAV-based remote sensing for supporting precision agriculture in Indonesia. Procedia Environ. Sci. 2015, 24, 245–253. [Google Scholar] [CrossRef]

- Budiharto, W.; Chowanda, A.; Gunawan, A.A.S.; Irwansyah, E.; Suroso, J.S. A review and progress of research on autonomous drone in agriculture, delivering items and geographical information systems (GIS). In Proceedings of the 2019 2nd World Symposium on Communication Engineering (WSCE), Nagoya, Japan, 20–23 December 2019; pp. 205–209. [Google Scholar]

- Palaniswami, C.; Gopalasundaram, P.; Bhaskaran, A. Application of GPS and GIS in Sugarcane Agriculture. Sugar Tech 2011, 13, 360–365. [Google Scholar] [CrossRef]

- García-Palacios, P.; Maestre, F.T.; Bardgett, R.D.; de Kroon, H. Plant responses to soil heterogeneity and global environmental change. J. Ecol. 2012, 100, 1303–1314. [Google Scholar] [CrossRef]

- Oshunsanya, S.; Oluwasemire, K.; Taiwo, O. Use of GIS to delineate site-specific management zone for precision agriculture. Commun. Soil Sci. Plant Anal. 2017, 48, 565–575. [Google Scholar] [CrossRef]

- Dasgupta, I.; Saha, J.; Venkatasubbu, P.; Ramasubramanian, P. AI crop predictor and weed detector using wireless technologies: A smart application for farmers. Arab. J. Sci. Eng. 2020, 45, 11115–11127. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, N.; Chen, Z. A cloud computing-enabled spatio-temporal cyber-physical information infrastructure for efficient soil moisture monitoring. ISPRS Int. J. Geo-Inf. 2016, 5, 81. [Google Scholar] [CrossRef]

- Park, D.H.; Kakani, V.; Kim, H.I. Automatic Radial Un-distortion using Conditional Generative Adversarial Network. J. Inst. Control. Robot. Syst. 2019, 25, 1007–1013. [Google Scholar] [CrossRef]

- de Castro, A.I.; Jurado-Expósito, M.; Peña-Barragán, J.M.; López-Granados, F. Airborne multi-spectral imagery for mapping cruciferous weeds in cereal and legume crops. Precis. Agric. 2012, 13, 302–321. [Google Scholar] [CrossRef]

- Sulaiman, N.; Che’Ya, N.N.; Mohd Roslim, M.H.; Juraimi, A.S.; Mohd Noor, N.; Fazlil Ilahi, W.F. The application of hyperspectral remote sensing imagery (HRSI) for weed detection analysis in rice fields: A review. Appl. Sci. 2022, 12, 2570. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; He, X.; Liu, W. Precision variable-rate spraying robot by using single 3D ns in orchards. Agronomy 2022, 12, 2509. [Google Scholar] [CrossRef]

- Eide, A.; Zhang, Y.; Koparan, C.; Stenger, J.; Ostlie, M.; Howatt, K.; Bajwa, S.; Sun, X. Image based thermal sensing for glyphosate resistant weed identification in greenhouse conditions. Comput. Electron. Agric. 2021, 188, 106348. [Google Scholar] [CrossRef]

- Mehedi, I.M.; Hanif, M.S.; Bilal, M.; Vellingiri, M.T.; Palaniswamy, T. Remote sensing and decision support system applications in precision agriculture: Challenges and possibilities. IEEE Access 2024, 12, 44786–44798. [Google Scholar] [CrossRef]

- Andújar, D.; Escolà, A.; Dorado, J.; Fernández-Quintanilla, C. Weed discrimination using ultrasonic sensors. Weed Res. 2011, 51, 543–547. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, L.P.; Gupta, A.; Lohan, S.K. Advancements in smart farming: A comprehensive review of IoT, wireless communication, sensors, and hardware for agricultural automation. Sens. Actuators Phys. 2023, 362, 114605. [Google Scholar] [CrossRef]

- Harb, H.; Idrees, A.K.; Jaber, A.; Makhoul, A.; Zahwe, O.; Taam, M.A. Wireless sensor networks: A big data source in Internet of Things. Int. J. Sensors Wirel. Commun. Control. 2017, 7, 93–109. [Google Scholar] [CrossRef]

- Harb, H.; Makhoul, A.; Tawil, R.; Jaber, A. Energy-efficient data aggregation and transfer in periodic sensor networks. IET Wirel. Sens. Syst. 2014, 4, 149–158. [Google Scholar] [CrossRef]

- Köppen Climate Classification Map. Köppen Climate Classification Interactive Map. 2024. Available online: https://koppen.earth (accessed on 17 June 2025).

- Giselsson, T.M.; Jørgensen, R.N.; Jensen, P.K.; Dyrmann, M.; Midtiby, H.S. A public image database for benchmark of plant seedling classification algorithms. arXiv 2017, arXiv:1711.05458. [Google Scholar]

- Olsen, A.; Konovalov, D.A.; Philippa, B.; Ridd, P.; Wood, J.C.; Johns, J.; Banks, W.; Girgenti, B.; Kenny, O.; Whinney, J.; et al. DeepWeeds: A multiclass weed species image dataset for deep learning. Sci. Rep. 2019, 9, 2058. [Google Scholar] [CrossRef] [PubMed]

- Haug, S.; Ostermann, J. A Crop/Weed Field Image Dataset for the Evaluation of Computer Vision Based Precision Agriculture Tasks. In Proceedings of the Computer Vision—ECCV 2014 Workshops, Zurich, Switzerland, 6–7, 12 September 2024; pp. 105–116. [Google Scholar] [CrossRef]

- Lameski, P.; Zdravevski, E.; Trajkovik, V.; Kulakov, A. Weed detection dataset with RGB images taken under variable light conditions. In Proceedings of the ICT Innovations 2017: Data-Driven Innovation. 9th International Conference, ICT Innovations 2017, Skopje, North Macedonia, 18–23 September 2017; pp. 112–119. [Google Scholar]

- dos Santos Ferreira, A.; Freitas, D.M.; da Silva, G.G.; Pistori, H.; Folhes, M.T. Weed detection in soybean crops using ConvNets. Comput. Electron. Agric. 2017, 143, 314–324. [Google Scholar] [CrossRef]

- Sa, I.; Chen, Z.; Popović, M.; Khanna, R.; Liebisch, F.; Nieto, J.; Siegwart, R. weednet: Dense semantic weed classification using multispectral images and mav for smart farming. IEEE Robot. Autom. Lett. 2017, 3, 588–595. [Google Scholar] [CrossRef]

- Chebrolu, N.; Lottes, P.; Schaefer, A.; Winterhalter, W.; Burgard, W.; Stachniss, C. Agricultural robot dataset for plant classification, localization and mapping on sugar beet fields. Int. J. Robot. Res. 2017, 36, 1045–1052. [Google Scholar] [CrossRef]

- Teimouri, N.; Dyrmann, M.; Nielsen, P.R.; Mathiassen, S.K.; Somerville, G.J.; Jørgensen, R.N. Weed growth stage estimator using deep convolutional neural networks. Sensors 2018, 18, 1580. [Google Scholar] [CrossRef]

- Sa, I.; Popović, M.; Khanna, R.; Chen, Z.; Lottes, P.; Liebisch, F.; Nieto, J.; Stachniss, C.; Walter, A.; Siegwart, R. WeedMap: A large-scale semantic weed mapping framework using aerial multispectral imaging and deep neural network for precision farming. Remote Sens. 2018, 10, 1423. [Google Scholar] [CrossRef]

- Bosilj, P.; Aptoula, E.; Duckett, T.; Cielniak, G. Transfer learning between crop types for semantic segmentation of crops versus weeds in precision agriculture. J. Field Robot. 2020, 37, 7–19. [Google Scholar] [CrossRef]

- Robotics, C. Home. Available online: https://carbonrobotics.com/home (accessed on 23 March 2025).

- EcoRobotix. ARA Field Sprayer. Available online: https://ecorobotix.com/crop-care/ara-field-sprayer/ (accessed on 23 March 2025).

- Torres-Sánchez, J.; López-Granados, F.; De Castro, A.I.; Peña-Barragán, J.M. Configuration and specifications of an unmanned aerial vehicle (UAV) for early site specific weed management. PLoS ONE 2013, 8, e58210. [Google Scholar] [CrossRef]

- Dinelli, C.; Racette, J.; Escarcega, M.; Lotero, S.; Gordon, J.; Montoya, J.; Dunaway, C.; Androulakis, V.; Khaniani, H.; Shao, S.; et al. Configurations and applications of multi-agent hybrid drone/unmanned ground vehicle for underground environments: A review. Drones 2023, 7, 136. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, B.; Zhou, J.; Yan, Y.; Tian, G.; Gu, B. Recent developments and applications of simultaneous localization and mapping in agriculture. J. Field Robot. 2022, 39, 956–983. [Google Scholar] [CrossRef]

- Cheein, F.A.; Steiner, G.; Paina, G.P.; Carelli, R. Optimized EIF-SLAM algorithm for precision agriculture mapping based on stems detection. Comput. Electron. Agric. 2011, 78, 195–207. [Google Scholar] [CrossRef]

- Adewale, C.; Reganold, J.P.; Higgins, S.; Evans, R.D.; Carpenter-Boggs, L. Agricultural carbon footprint is farm specific: Case study of two organic farms. J. Clean. Prod. 2019, 229, 795–805. [Google Scholar] [CrossRef]

- Holka, M.; Kowalska, J.; Jakubowska, M. Reducing carbon footprint of agriculture—Can organic farming help to mitigate climate change? Agriculture 2022, 12, 1383. [Google Scholar] [CrossRef]

- Plonski, P.A.; Tokekar, P.; Isler, V. Energy-efficient path planning for solar-powered mobile robots. J. Field Robot. 2013, 30, 583–601. [Google Scholar] [CrossRef]

- Utstumo, T.; Urdal, F.; Brevik, A.; Dørum, J.; Netland, J.; Overskeid, Ø.; Berge, T.W.; Gravdahl, J.T. Robotic in-row weed control in vegetables. Comput. Electron. Agric. 2018, 154, 36–45. [Google Scholar] [CrossRef]

- Bawden, O.; Kulk, J.; Russell, R.; McCool, C.; English, A.; Dayoub, F.; Lehnert, C.; Perez, T. Robot for weed species plant-specific management. J. Field Robot. 2017, 34, 1179–1199. [Google Scholar] [CrossRef]

- Lee, W.S.; Slaughter, D.; Giles, D. Robotic weed control system for tomatoes. Precis. Agric. 1999, 1, 95–113. [Google Scholar] [CrossRef]

- Åstrand, B.; Baerveldt, A.J. An agricultural mobile robot with vision-based perception for mechanical weed control. Auton. Robot. 2002, 13, 21–35. [Google Scholar] [CrossRef]

- Lottes, P.; Hörferlin, M.; Sander, S.; Stachniss, C. Effective vision-based classification for separating sugar beets and weeds for precision farming. J. Field Robot. 2017, 34, 1160–1178. [Google Scholar] [CrossRef]

- Vijayakumar, V.; Ampatzidis, Y.; Schueller, J.K.; Burks, T. Smart spraying technologies for precision weed management: A review. Smart Agric. Technol. 2023, 6, 100337. [Google Scholar] [CrossRef]

- Kolberg, R.L.; Wiles, L.J. Effect of steam application on cropland weeds. Weed Technol. 2002, 16, 43–49. [Google Scholar] [CrossRef]

- Van Evert, F.K.; Fountas, S.; Jakovetic, D.; Crnojevic, V.; Travlos, I.; Kempenaar, C. Big data for weed control and crop protection. Weed Res. 2017, 57, 218–233. [Google Scholar] [CrossRef]

- Fountas, S.; Carli, G.; Sørensen, C.G.; Tsiropoulos, Z.; Cavalaris, C.; Vatsanidou, A.; Liakos, B.; Canavari, M.; Wiebensohn, J.; Tisserye, B.a. Farm management information systems: Current situation and future perspectives. Comput. Electron. Agric. 2015, 115, 40–50. [Google Scholar] [CrossRef]

- Guisan, A.; Zimmermann, N.E. Predictive habitat distribution models in ecology. Ecol. Model. 2000, 135, 147–186. [Google Scholar] [CrossRef]

- Thuiller, W.; Lafourcade, B.; Engler, R.; Araújo, M.B. BIOMOD—A platform for ensemble forecasting of species distributions. Ecography 2009, 32, 369–373. [Google Scholar] [CrossRef]

- Early, R.; Bradley, B.A.; Dukes, J.S.; Lawler, J.J.; Olden, J.D.; Blumenthal, D.M.; Gonzalez, P.; Grosholz, E.D.; Ibañez, I.; Miller, L.P.; et al. Global threats from invasive alien species in the twenty-first century and national response capacities. Nat. Commun. 2016, 7, 12485. [Google Scholar] [CrossRef]

- Fumanal, B.; Chauvel, B.; Bretagnolle, F. Estimation of the pollen and seed production of common ragweed in Europe. Ann. Agric. Environ. Med. (Aaem) 2007, 14, 233–236. [Google Scholar]

- Song, W.; Zhou, W.; Jin, Z.; Cao, D.; Joel, D.; Takeuchi, Y.; Yoneyama, K. Germination response of Orobanche seeds subjected to conditioning temperature, water potential and growth regulator treatments. Weed Res. 2005, 45, 467–476. [Google Scholar] [CrossRef]

- Prider, J.; Correll, R.; Warren, P. A model for risk-based assessment of Phelipanche mutelii (branched broomrape) eradication in fields. Weed Res. 2012, 52, 526–534. [Google Scholar] [CrossRef]

- IBM. Blockchain. Available online: https://www.ibm.com/think/topics/blockchain (accessed on 22 March 2025).

- Xiong, H.; Dalhaus, T.; Wang, P.; Huang, J. Blockchain technology for agriculture: Applications and rationale. Front. Blockchain 2020, 3, 7. [Google Scholar] [CrossRef]

- Haveson, S.; Lau, A.; Wong, V. Protecting Farmers in Emerging Markets with Blockchain; Cornell Tech: Newyork, NY, USA, 2017. [Google Scholar]

- Sylvester, G. E-Agriculture in Action: Blockchain for Agriculture (Opportunities and Challenges); The Food and Agriculture Organization of United Nation: Rome, Italy, 2019. [Google Scholar]

- Patil, A.S.; Tama, B.A.; Park, Y.; Rhee, K.H. A framework for blockchain based secure smart green house farming. In Proceedings of the Advances in Computer Science and Ubiquitous Computing: CSA-CUTE 17, Taichung, Taiwan, 18–20 December 2017; pp. 1162–1167. [Google Scholar]

- Lin, Y.P.; Petway, J.R.; Anthony, J.; Mukhtar, H.; Liao, S.W.; Chou, C.F.; Ho, Y.F. Blockchain: The evolutionary next step for ICT e-agriculture. Environments 2017, 4, 50. [Google Scholar] [CrossRef]

- Gašparović, M.; Zrinjski, M.; Barković, Đ.; Radočaj, D. An automatic method for weed mapping in oat fields based on UAV imagery. Comput. Electron. Agric. 2020, 173, 105385. [Google Scholar] [CrossRef]

- De Oca, A.M.; Arreola, L.; Flores, A.; Sanchez, J.; Flores, G. Low-cost multispectral imaging system for crop monitoring. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; pp. 443–451. [Google Scholar]

- Chen, D.; Wang, Q.; Lin, Y.; Ma, Z.; Sun, L.; Yu, G. Path tracking control of paddy field weeder integrated with satellite and visual methods. Comput. Electron. Agric. 2025, 234, 110257. [Google Scholar] [CrossRef]

- Mohanraj, B.; Sneka, S.; Udhaya Priya, J.; Shyle Trana, S.; Priya, M.; Sakthivel, P. Next-Gen Agro-Innovation: Blockchain and IoT Convergence for Water Optimization and Weed Detection. In Proceedings of the 2024 9th International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 16–18 December 2024; pp. 759–764. [Google Scholar]

- Swetha, K.; Monisha, D.; Thejaswini, H.; Nikhil, K.; Rahul, N. IoT and Wireless Sensor Network Based Autonomous Farming Robot. In Proceedings of the 2024 International Conference on Knowledge Engineering and Communication Systems (ICKECS), Chikkaballapur, India, 18–19 April 2024; Volume 1, pp. 1–6. [Google Scholar]

- Yuan, J.; Hong, J.; Sattar, J.; Isler, V. ROW-SLAM: Under-canopy cornfield semantic SLAM. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; pp. 2244–2250. [Google Scholar]

- Balafoutis, A.T.; Evert, F.K.V.; Fountas, S. Smart farming technology trends: Economic and environmental effects, labor impact, and adoption readiness. Agronomy 2020, 10, 743. [Google Scholar] [CrossRef]

- Fiocco, D.; Ganesan, V.; de la Serrana Lozano, M.G.; Sharifi, H. Agtech: Breaking Down the Farmer Adoption Dilemma; McKinsey & Company: Chicago, IL, USA, 2023. [Google Scholar]

- Christiaensen, L.; Rutledge, Z.; Taylor, J.E. The future of work in agri-food. Food Policy 2021, 99, 101963. [Google Scholar] [CrossRef]

- U.S. Department of Agriculture. Financial Resources for Farmers and Ranchers: Grants and Loans; U.S. Department of Agriculture: Washington, DC, USA, 2025. [Google Scholar]

- FarmWise. FarmWise—AI-Powered Weeding Solutions for Sustainable Farming. 2025. Available online: https://www.farmwise.io (accessed on 25 March 2025).

- Tracxn. FarmWise—Funding & Investors. 2025. Available online: https://tracxn.com/d/companies/farmwise/__BFycKnYvAKGUm7BGoAnDupZW7Hnmhpsr0VK2VNP8-EA/funding-and-investors (accessed on 25 March 2025).

- Narayanamurthy, G.; Shiva Jayanth, R.S.; Tortorella, G.; Fogliatto, F. Empirical investigation of barriers and benefits of smart farming. Int. J. Qual. Reliab. Manag. 2025; ahead-of-print. [Google Scholar]

- D’Cruze, R.S.; Ahmed, M.U.; Bengtsson, M.; Ur Rehman, A.; Funk, P.; Sohlberg, R. A Case Study on Ontology Development for AI Based Decision Systems in Industry. In Proceedings of the International Congress and Workshop on Industrial AI, Luleå, Sweden, 13–15 June 2023; pp. 693–706. [Google Scholar]

- Sharma, K.; Shivandu, S.K. Integrating artificial intelligence and internet of things (IoT) for enhanced crop monitoring and management in precision agriculture. Sens. Int. 2024, 5, 100292. [Google Scholar] [CrossRef]

- Narvaez, F.Y.; Reina, G.; Torres-Torriti, M.; Kantor, G.; Cheein, F.A. A survey of ranging and imaging techniques for precision agriculture phenotyping. IEEE/ASME Trans. Mechatronics 2017, 22, 2428–2439. [Google Scholar] [CrossRef]

- Jiao, J.; Zang, Y.; Chen, C. Key Technologies of Intelligent Weeding for Vegetables: A Review. Agriculture 2024, 14, 1378. [Google Scholar] [CrossRef]

- Pook, T.; Vandenplas, J.; Boschero, J.C.; Aguilera, E.; Leijnse, K.; Chauhan, A.; Bouzembrak, Y.; Knapen, R.; Aldridge, M. Assessing the potential of quantum computing in agriculture. Comput. Electron. Agric. 2025, 235, 110332. [Google Scholar] [CrossRef]

- Singh, J.; Thakur, H.K.; Sharma, N.; Alsahlanee, A.T.R.; Sahunthala, S.; Shaik, N. Deep Learning and Quantum-Enabled Cloud Platform Approach on Optimized Crop Health Predictions. In Proceedings of the Doctoral Symposium on Computational Intelligence, Lucknow, India, 10 May 2024; pp. 69–80. [Google Scholar]

- Seyam, T.A.; Pathak, A. AgriScan: Next. js powered cross-platform solution for automated plant disease diagnosis and crop health management. J. Electr. Syst. Inf. Technol. 2024, 11, 45. [Google Scholar] [CrossRef]

| Dataset | Description | Properties | Location and Climate Zone | Source |

|---|---|---|---|---|

| Plant seedlings dataset [117] | 960 plants (weed, crops, and others) of 12 species | Annotated RGB, 10 pixels/mm resolution | Denmark, cool temperate, oceanic | https://vision.eng.au.dk/plant-seedlings-dataset/(Access date—11 June 2025) |

| DeepWeeds [118] | 17,509 images of 8 weed species in northern Australia | Annotated, Inception-v3: 95.1%, ResNet-50: 95.7% accuracy | Northern Australia, tropical savanna | https://github.com/AlexOlsen/DeepWeeds (Access date—11 June 2025) |

| Crop/Weed Field Image Dataset [119] | 60 top-down field images of 162 crops and 332 weed plants | Multispectral images, annotated with segmentation mask and weed–crop labels | Bonn, Germany, temperate oceanic | https://github.com/cwfid/dataset?tab=readme-ov-file (Access date—11 June 2025) |

| Weed detection dataset [120] | 39 images of carrot-weed | RGB images taken under variable light conditions | North Macedonia, continental, hot summer | https://github.com/lameski/rgbweeddetection (Access date—11 June 2025) |

| Weed Detection in Soybean Crops [121] | 15,336 images, composed of 3249 soil, 7376 soybean, 3520 grass, and 1191 broadleaf weeds | Annotated, RGB satellite images | Brazil, tropic or subtropical, wet summer | https://data.mendeley.com/datasets/3fmjm7ncc6/2 (Access date—11 June 2025) |

| weedNet Dataset [122] | 465 images are taken from 40 × 40 m field using micro aerial vehicle (MAV) | Multispectral images labelled as weed, crop or backgroud. RGB images are also avaible but not annotated. | Sydney, Australia, warm temperate, dry winter | https://github.com/inkyusa/weedNet?tab=readme-ov-file (Access date—11 June 2025) |

| Sugarbeet 2016 [123] | 5TB data worth of images, containing sugar beet crops and weeds, are taken from a sugar beet farm in Bonn, Germany, over three months | Multispectral, RGB, 3D point cloud data, laser data, odometry measurements, and GPS positions are included. | Germany, temperate oceanic | https://www.ipb.uni-bonn.de/data/sugarbeets2016/index.html (Access date—11 June 2025) |

| Leaf counting dataset [124] | 9372 images of weeds are collected in fields across Denmark using both cell phones and industrial cameras | RGB images of weeds with the number of leaves counted | Denmark, cool temperate | https://vision.eng.au.dk/leaf-counting-dataset/ (Access date—11 June 2025) |

| Remote Sensing 2018 Weed Map Dataset [125] | 18,746 images taken from Eschikon, Switzerland, and Rheinbach, Germany, using drones. | Annotated multispectral or orthomosaic or tiled images, 8.2 cm/pixel and 13 cm/pixel resolutions. | Switzerland and Germany, humid temperate | https://projects.asl.ethz.ch/datasets/doku.php?id=weedmap:remotesensing2018weedmap&s[]=weedmap (Access date—11 June 2025) |

| Crop vs weed discrimination dataset [126] | 40 images of carrot, onion and weeds taken using Teledyne DALSA Genie Nano camera | Annotated multispectral images at 2.5 px/mm resolution | UK, cool temperate, maritime | https://lcas.lincoln.ac.uk/wp/research/data-sets-software/crop-vs-weed-discrimination-dataset/ (Access date—11 June 2025) |

| Core IoT Technology | Methodology | Requirements | Reference |

|---|---|---|---|

| Hyperspectral imagery using UAVs | Classification algorithms are applied on oat field images to perform weed mapping. | Most drones are equipped with digital cameras. Hyperspectral cameras are considerably more expensive and precise camera calibration is necessary to obtain high-quality images. | [157] |

| UAV-based crop monitoring | A low-cost UAV is used to acquire multispectral images. The obtained images are later processed to extract NDVI orthomosaic images. | A drone, a Raspberry Pi microcontroller, and two digital cameras for the hardware. The commercial multispectral cameras can cost up to $5000, while the proposed setup only costs $250. | [158] |

| Improving path tracking precision of autonomous weeders using GNSS | Integrates visual navigation with satellite technology to reduce path deviation. Compared to the visual system alone, the new system reduces the side-to-side drifting by an additional 30.1%. | Navigation hardware devices, including GNSS antennas, receivers, and Ionospheric Pierce Point (IPC) systems, along with industrial-grade cameras for capturing high-resolution images required for visual navigation and processing units to run path-tracking algorithms and process sensor data have to be installed on weeder. | [159] |

| Blockchain integrated with IoT devices for weed detection | IOT devices retrieve data from sites and send them to aggregation and normalization nodes. Multiple blockchain nodes serve as distributed, tamper-resistant data storage sites. | Distributed blockchain nodes to form a decentralized network, a blockchain ledger to store hash data, and off-chain storage for large files connected to hash references on-chain. | [160] |

| Sustainable Farm Assistant Bot | Solor powered robot equipped with advanced sensors and an intelligent control system is used to both monitor the farm and perform labor-intensive tasks such as plowing, sowing, watering, and pesticide spraying. | An Arduino board, DC motor, rain sensor, water pump, IR sensor, soil moisture sensor, soil fertility sensor, and NodeMCU are currently installed on the prototype model. | [161] |

| ROW SLAM, autonomous cornweed-removing robot | Semantic segmentation results are integrated with tracking modules to build a map that contains location, orientation, and semantic information of corn stalks | Structure-from-motion (SfM) for segmentation, SLAM for more accurate tracking results than GPS, and a robot equipped with multiview cameras to obtain front, back, and side views. | [162] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

San, C.T.; Kakani, V. Smart Precision Weeding in Agriculture Using 5IR Technologies. Electronics 2025, 14, 2517. https://doi.org/10.3390/electronics14132517

San CT, Kakani V. Smart Precision Weeding in Agriculture Using 5IR Technologies. Electronics. 2025; 14(13):2517. https://doi.org/10.3390/electronics14132517

Chicago/Turabian StyleSan, Chaw Thiri, and Vijay Kakani. 2025. "Smart Precision Weeding in Agriculture Using 5IR Technologies" Electronics 14, no. 13: 2517. https://doi.org/10.3390/electronics14132517

APA StyleSan, C. T., & Kakani, V. (2025). Smart Precision Weeding in Agriculture Using 5IR Technologies. Electronics, 14(13), 2517. https://doi.org/10.3390/electronics14132517