1. Introduction

Renewable energy systems, industrial equipment, and household appliances use various types of power electronics circuits [

1]. Nonlinear loads such as uninterrupted power supplies (UPSs), computers, LED lighting drivers, variable frequency drives, electric vehicle chargers, etc., distort voltage and current waveforms [

2,

3] and lead to excessive active power losses in the power systems [

4,

5].

Power transformers constitute one of the most prominent and expensive devices in the power system. They are designed and manufactured to operate at nominal frequency and sinusoidal voltages and currents [

6] complying with power quality requirements determined by standards [

7,

8].

Two types of power transformers are commonly used in distributed networks, namely dry-type and liquid-immersed transformers. Experimental analysis aimed at simplifying the choice between oil- and dry-type transformers from the customer’s perspective reveals that for the same nominal voltages and power, oil-type transformers have better insulation properties and less hysteresis losses compared to dry-type transformers [

9]. Moreover, it is revealed that dry-type transformers feature higher load loss compared to oil-type transformers, which results in higher heat dissipation under similar load conditions [

10]. Several studies dealt with transformer design and optimization to improve transformer efficiency [

11,

12]. The latter presents an approach for loss reduction through transformer structural and technological improvements, while in [

13] a minimum material-cost model is presented and discussed in detail.

Many papers have investigated the effect of harmonics on transformer losses supplying nonlinear loads [

1,

14,

15,

16,

17]. Some, refs. [

1,

15,

18,

19], addressed the impact of high load current harmonics on winding temperature. Winding heating increases temperature in the transformer oil [

20], jeopardizes its insulation, and shortens its lifespan [

7,

13,

16,

18,

21]. Therefore, addressing the overheating of power transformers is imperative from both operational and techno-economic points of view.

One approach derates the transformer power rating based on load nonlinearity—as proposed by IEEE std. C57.110-2018 [

18] and various other studies [

1,

6,

12,

14,

21,

22,

23,

24]. In this context, a K-factor metric for weighing load current harmonics [

25] and a practice for evaluating transformers’ capability to supply nonlinear loads [

18] were introduced. The relationship between the K-factor and the standard’s harmonic loss factor is formulated in [

23,

26].

Nowadays, the harmonics profile can be considered in the design process [

15,

26] to improve transformer performances. Nonetheless, there are but a few empirical works addressing harmonic losses in power transformers—while the lion’s share of studies are based on simulated data [

26,

27,

28].

This paper deals with the application of a transformer loss calculation method which may be used as an alternative to IEEE std. C57.110-2018. The method’s fundamentals as well as its application to a standard full-scale 250 kVA oil-type distribution transformer are described in detail.

All published studies addressing transformer loss estimation rely on additional technical data that is mostly unavailable to the user. In contrast to these works, the method demonstrated in this paper employs readily available transformer technical data to simplify the calculation of loss components of an oil-type distribution transformer. The approach—which is discussed in detail in [

29]—can serve as an alternative to the transformer loss calculation method presented in the standard [

18]. While the purpose of the previous study was to present the theoretical concept of the method and its verification in detail using a small non-standard laboratory 4.5 kVA dry-type power transformer, the present study is performed on a standard full-scale 250 kVA oil-type distribution transformer. The importance of the proposed research is twofold:

The remainder of the paper is organized as follows:

Section 2 relates the loss component calculation in detail, as it appears in the standard and published research works, and

Section 3 describes the proposed algorithm for transformer loss calculation and its mathematical formulation. The experimental setup used to validate the theoretical section is described in detail in

Section 4. In

Section 5, a comparison between measured and calculated TTL is carried out. Finally, the conclusion and a discussion of future work are provided in

Section 6.

2. Power Loss Decomposition in Transformer Supplying Nonlinear Loads

According to [

18], the total transformer loss (TTL)

can be divided into two components, namely, no-load loss (NLL)

and total load loss (TLL)

, as follows:

where the NLL is associated with hysteresis, core eddy current, and dielectric losses [

12,

23,

28,

30], and dominated by eddy current loss for frequencies exceeding 50 Hz [

14]. It is also found that hysteresis loss is directly proportional to voltage harmonics and inversely proportional to harmonic frequency [

28]. NLL is independent of load changes, depends only on the transformer input voltage [

31], and increases linearly with transformer aging [

32].

In [

28], a simulation was performed to determine the NLL through core material data. Since, for the most part, power system voltage supplies meet power quality standards [

7,

8]—i.e., the total harmonic distortion (THD) index is expected to be kept well below 5%—it can be assumed that the effect of higher voltage harmonics on the NLL is negligible [

14,

29,

31]. Therefore, it is supposed that the voltage varies within very small limits and the value of NLL is almost constant. As a result, it can be obtained directly from the open-circuit test at nominal input voltage as described in [

29].

The TLL solely depends on load size and is the sum of winding ohmic loss

, winding eddy current

, and other stray loss

, i.e.,

where the winding ohmic loss or DC loss is calculated by

in which

is the

-th current harmonic and

is the total DC resistance of the transformer windings [

18].

The second component of (

2), the winding eddy current loss (WECL) or winding stray loss, is related to skin and proximity effects [

15,

16,

18,

31]. It can be calculated as follows:

where

is the nominal WECL at fundamental frequency and nominal load current

[

18].

The influence of the skin effect on the winding resistance values is considered in [

31], where winding resistance loss in the presence of current harmonics is calculated based on a resistance harmonic loss factor. A similar approach has been described in [

15,

21], where the impact of current harmonics on the rise in the eddy current loss, the resistance, and the temperature was investigated. An analytical formulation describing the temperature effect on winding resistance was obtained in [

15]. In [

16], the temperature impact based on the highest loss ratio was discussed and the hotspot in a specific winding conductor was determined for the highest current-carrying winding.

A study which does not separate DC loss and WECL as recommended by the standard is presented in [

33]. The proposed method is based on measurements carried solely on the low-voltage transformer side. A coefficient, taken from the standard [

18] which depends on the number of phases, is used to calculate the transformer winding loss. In addition, the influence of the power factor on transformer loss in the presence of current harmonics is investigated.

The last component in (

2), the other stray loss (OSL), is associated with leakage magnetic flux in the core clamps, magnetic shields, steel tank walls, and flitch plates [

12,

16,

18,

22]. OSL can be assessed in accordance with the standard [

18] as follows:

where

is the nominal OSL at the fundamental frequency.

The standard also considers the sum of the winding WECL and OSL as a total stray loss (TSL)

and states that in oil-type transformers, WECL equals OSL, i.e.,

—which differs from the dry-type transformer case where

. Other works [

24,

34] attribute OSL to the iron loss or NLL, although iron loss is represented by the parallel branch, while OSL is in the series branch of the equivalent circuit.

A few works have provided quantitative error data. Ref. [

27] employed a finite element method (FEM) to simulation transformer losses for various metal structures with an error margin below 5%. Another FEM approach for assessing loss components was presented in [

27] which demonstrated an error margin of 7.5%. Finally, a measurement-based method for assessing winding eddy current loss which takes into account skin and proximity effects within the windings was presented in [

34] and demonstrated an error margin of ±5%.

The method applied in this paper is based on the calculation of the resistances associated with all TLL components. This scheme considers the configuration of the transformer winding connections, a fact which distinguishes it from the approaches given in [

14,

20,

23,

31,

35,

36]. Another advantage of the approach is its applicability to an asymmetrically loaded transformer.

3. Transformer Loss Calculation

This section describes in detail the algorithm for transformer loss calculation alongside its mathematical formulation. For simplicity’s sake, all formulas are given in per-phase context. The same holds for

Section 4 which details the setup used for experimental validation.

Section 5 and

Appendix A, on the other hand, provide data and power calculations for all three-phases of the transformer.

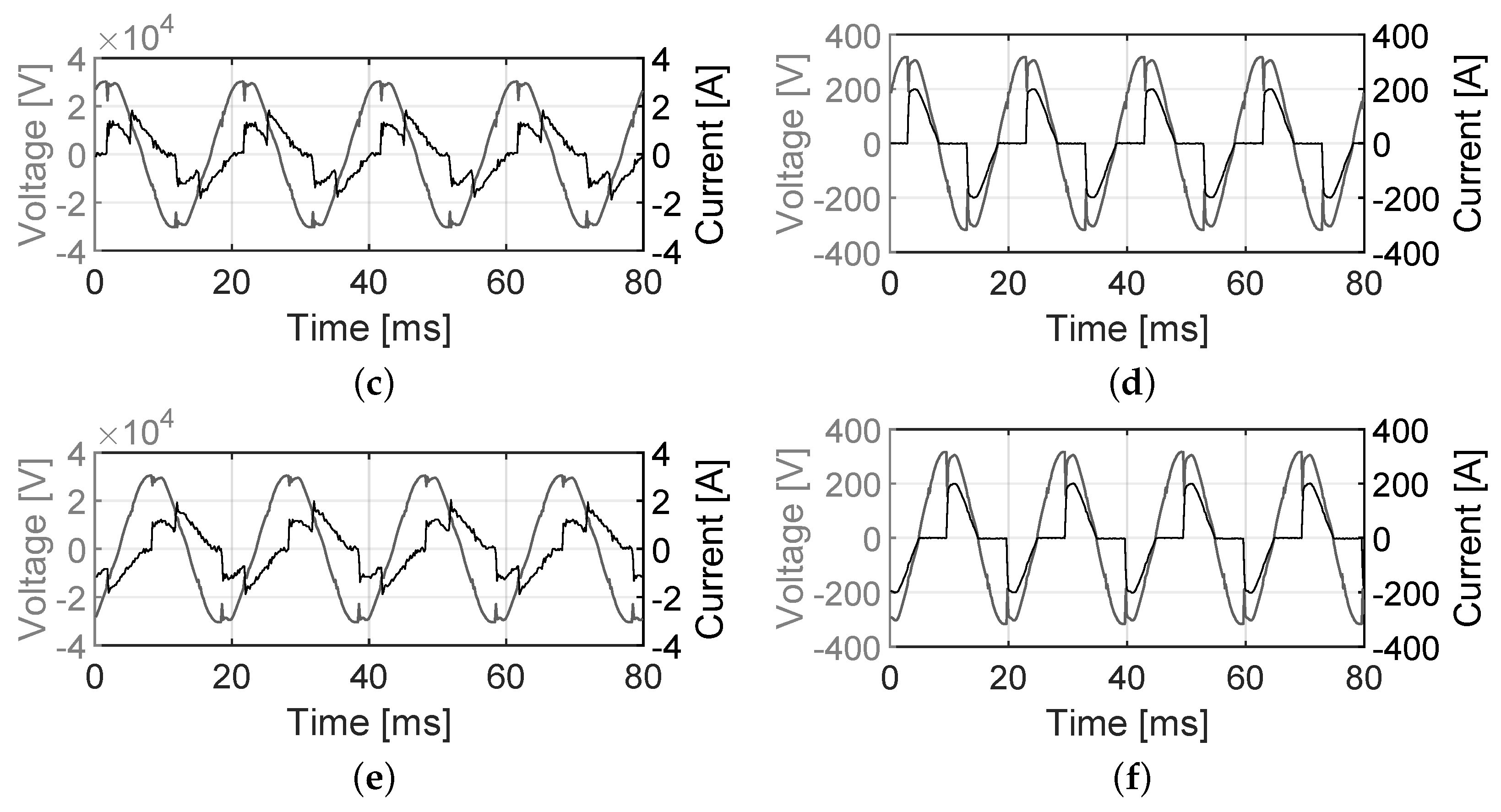

Figure 1 shows an approximated equivalent circuit corresponding to the power loss decomposition described in the standard [

18] and formulated in (

1). As mentioned above, the NLL can be found on the manufacturer datasheet or experimentally obtained from the open-circuit test. The TTL depends only on the load size and—according to the standard—is the sum of the three power loss components expressed in (

2). When load current

I reaches the nominal transformer current

, TLL is the short-circuit power

, i.e.,

Therefore, the total loss resistance

is the short circuit resistance

which can be derived from the short-circuit power

as follows

From (

2), (

7), and (

8) it is inferred that the TLL resistance in each phase is the sum of all resistances associated with the power load loss components, i.e.,

where

is the winding DC resistance,

is the winding EC resistance, and

is the OSL resistance of the transformer. In contrast to what was stated in [

33], the above resistance is dependent on the frequency. As will be discussed later in this paper, in the presence of higher current harmonics,

inevitably increases due to the frequency dependence of

and

.

From (

2) and (

9), an equivalent expression is obtained:

Generally, the primary (p) and secondary (s) windings of a three-phase step-down distribution transformer are connected in a D/y configuration. As the primary windings of the transformer are delta-connected, current triplen harmonics do not appear at the transformer power supply network, i.e., the transformer primary side. However, they flow through and heat the primary windings—and hence their impact on TLL and its components must be considered. Each of the TLL components in (

2) and (

10) are calculated while considering the transformer winding connection.

3.1. DC Loss

The transformer DC loss per phase in (

3) can be represented as the sum of primary and secondary winding DC loss:

where

and

are the

-th current harmonics of, respectively, primary and secondary transformer sides. However, as the triplen harmonics cannot be measured at the primary side of a D/y connected transformer, (

11) is modified as follows:

where both the primary and secondary DC resistances

and

can be directly measured or obtained from the manufacturer datasheet, and

k is the transformer ratio between the primary and secondary phase voltages,

and

, namely,

Finally, the total DC resistance is derived by

3.2. WECL

Similarly to the DC resistance,

can be split into primary and secondary resistances,

and

:

Since the ratio between primary and secondary DC resistances equals the ratio between primary and secondary EC resistances, i.e.,

and

can be derived by solving Equations (

15) and (

16). Hence, in an analogous manner to the DC loss, eddy current loss can be represented as the sum of primary and secondary WECL and (

4) becomes

To account for the triplen harmonics effect, (

17) is modified as follows:

As mentioned above, the winding EC resistance depends on the frequency. This is represented by the factor in the above equation.

3.3. OSL

The OSL is independent of the transformer windings and can be associated with either side of the transformer. For a D/y connected distribution transformer, it is beneficial to correspond the OSL to the secondary where the triplen harmonics can be directly measured and modify (

5) to become

Hence, the OSL resistance referring to the secondary transformer side can be evaluated using (

9) as follows:

As inferred from (

19),

is dependent on the harmonic frequency through a

factor.

The nominal values of the WECL and OSL, as well as their associated resistances, are usually unspecified in the transformer technical documentation. Overcoming this can be achieved by employing the following relation:

From (

9) and (

21), TSL resistance can be derived as follows:

Since in oil-type transformers

[

18], the following relation holds:

4. Experimental Setup

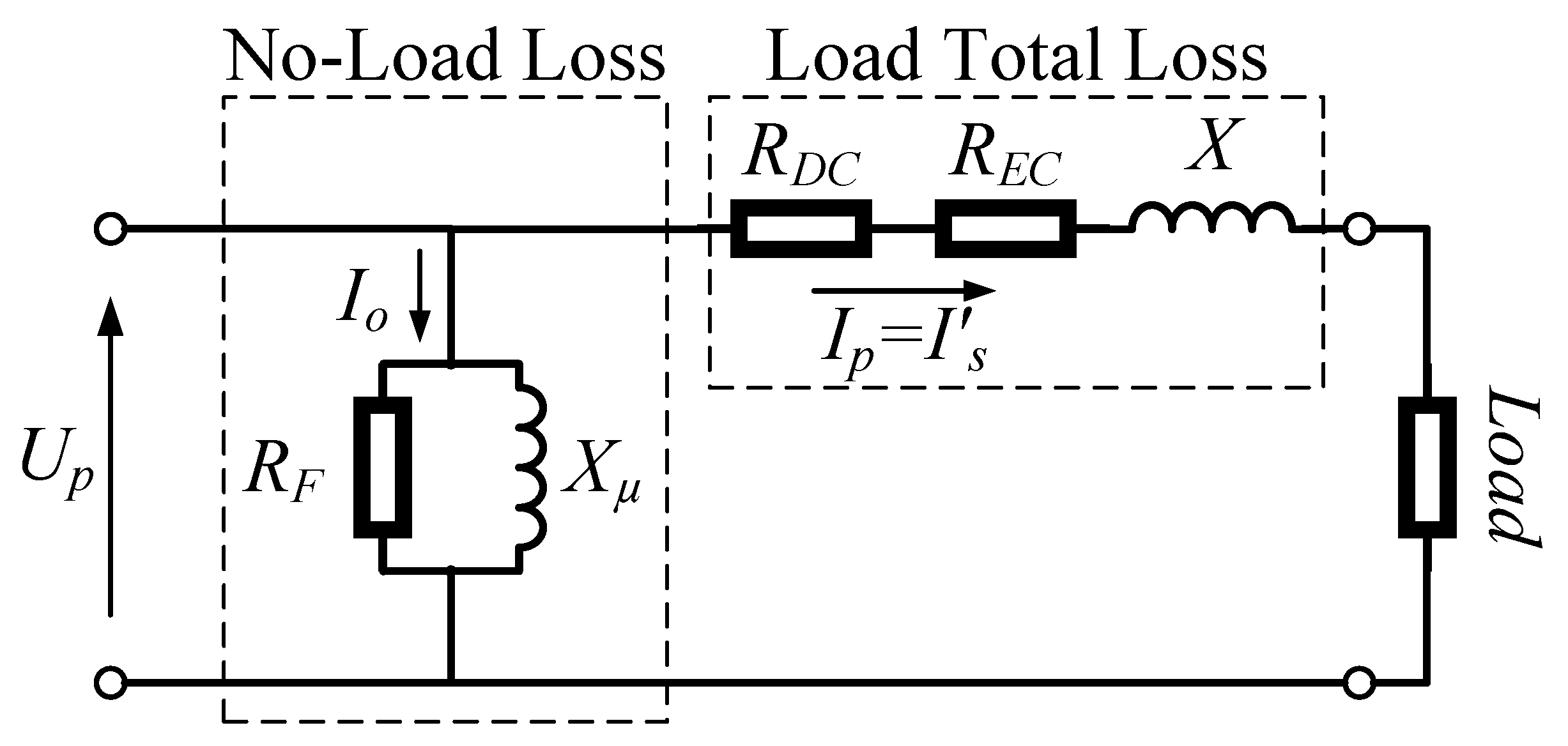

The method presented in this paper was experimentally validated through an experimental setup consisting of a full-scale 250 kVA D/y connected step-down 22/0.4 kV distribution oil-type transformer as shown in

Figure 2. The transformer technical data is given in

Table 1 alongside its no-load and short-circuit test results while the experimental setup schematic is shown in

Figure 3. For measurement purposes and mitigating the influence of adjacent electrical systems, the transformer under test (TUT) was connected to the electrical network through a 0.4 kV/22 kV Y/d auxiliary transformer (AUX).

Measurement of primary voltages, currents, and active power was performed using a SATEC 720 power analyzer Class 0.2S per IEC62053 [

37] connected through a measurement tank—comprising a three-phase voltage transformer 22/0.11 kV and three single-phase current transformers 50/5 A. The accuracy of the measuring voltage transformer is 0.2%, and the accuracy of the measuring current transformers is 0.25%. An additional SATEC 720 was connected at the low-voltage side to measure secondary voltages, currents, and active power. The voltages were measured directly while obtaining the secondary currents in each phase, and the power analyzer was connected via three current transformers, 400/5 A of class 0.2.

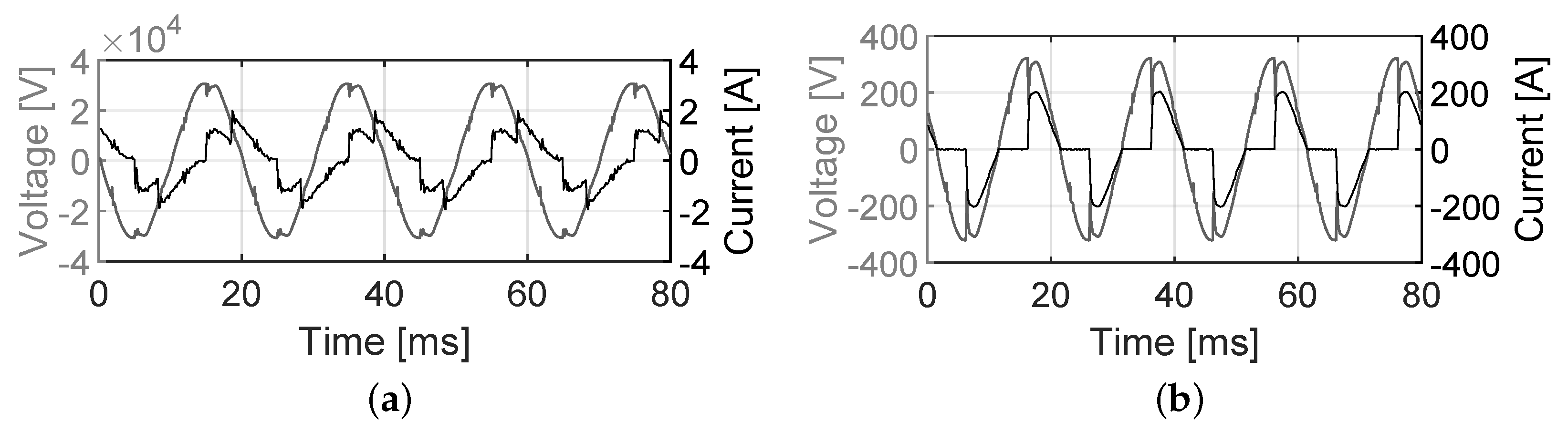

As depicted in

Figure 3, the secondary side of the TUT was connected to a pair of resistive load+TPC and a thyristor power controller (TPC) [

38] which utilized a three-phase nonlinear load. Due to the limitations of laboratory circuit-breakers, the TUT was not fully loaded.

The fundamental active power

and power components corresponding with the

-th harmonic

flow in opposite directions [

39]. The active powers

and

are measured, respectively, at the primary and secondary transformer sides. Hence, the TTL was obtained as follows:

where

and

where

and

are, respectively, the fundamental and

-th active power components measured at the primary side. Similarly,

and

are, respectively, the fundamental and

-th active power components measured at the secondary side.

By substituting (

25) and (

26) into (

24), the following is obtained:

where

and

are, respectively, the transformer loss components due to the fundamental and

-th current harmonics.

6. Conclusions

This paper presented an application of a transformer loss calculation method under nonlinear loads to a full-scale 250 kVA D/y connected step-down 22/0.4 kV distribution oil-immersed transformer which is widely used in distribution networks. Application of the method to oil-type transformers is salient as it extends the method’s validity from a non-standard bare dry-type laboratory transformer to a widely used standard distribution liquid-immersed transformer. This is particularly important in light of the loss characteristic variability between these two types of transformers—as appears in both research papers and the standard.

In contrast to other methods published in the literature, the proposed method relies solely on readily available data and can serve as an alternative to the approach detailed in IEEE std. C57.110-2018. The proposed method also considers the heating effect due to triplen harmonics in a delta-connected transformer winding—a phenomenon which is not addressed by the standard. Finally, the proposed method evaluates per-phase power loss and hence can be applied for imbalanced loading scenarios.

A series of experiments for one linear and three nonlinear loading scenarios were performed and showed a close match to the theoretical model with a maximum error margin smaller than 3%. This outcome is substantially lower than the 5–7.5% error levels reported in the literature as detailed in the

Section 1.

Future work shall explore the application of the proposed method for developing a techno-economic model for optimal transformer asset management in power grids.