Abstract

Exploring crevasses in extreme environments such as Antarctica is highly dangerous yet essential for ensuring safe movement. Recently, robotic systems have been investigated as a means to conduct exploration in such regions. Unlike conventional settings, these environments require integrated capabilities, including mobility in harsh terrain and the ability to operate reliably at extremely low temperatures. In this paper, we propose KAREX (Korea Antarctic Robot EXplorer), a robotic exploration system designed to investigate crevasses and support research activities in extreme environments. The robot is engineered for cold resistance with thermal insulation that enables low-power temperature maintenance, and it supports multiple swappable batteries for extended-range operation. The proposed system was tested at Jang Bogo Station in Antarctica to verify its performance and applicability in real-world extreme conditions.

1. Introduction

In recent years, scientific research in extreme regions such as Antarctica and the Arctic has extended further inland from coastal areas. These activities cover diverse fields, including climate change studies related to environmental pollution and the exploration of new natural resources. However, exploration in these regions involves considerable risks due to extreme cold temperatures, especially further inland. As a result, there has been increasing interest in utilizing unmanned robotic systems for exploration tasks in such environments.

Despite the harsh climate, Antarctica is considered a suitable testbed for robotic exploration systems due to its unique and extreme environmental conditions, which resemble those found in extraterrestrial settings. Various research efforts have focused on developing robots capable of performing tasks that are difficult or hazardous for humans, particularly for environmental monitoring and scientific exploration in Antarctica [1,2,3,4,5,6,7,8,9,10]. Notable examples include the NOMAD robot developed by Carnegie Mellon University, which can autonomously traverse up to 10 km using stereo vision, a laser range finder, and pose sensors for meteorite detection [3,4,5,6]. China’s CHINARE (CHIna National Antarctic Research Expedition) program has also developed an ATV-based exploration rover equipped with LiDAR and dual antennas [7]. However, both systems employ internal combustion engines, which may not be ideal in environmentally sensitive areas like Antarctica. CRREL’s Yeti robot [8], powered by batteries and equipped with Ground-Penetrating Radar (GPR) for detecting crevasses, presents a more eco-friendly alternative. Nonetheless, many of these robots still require manual control, have limited payload capacity, and exhibit restricted operational range, limiting their suitability for extended autonomous missions. In Korea, the Korea Polar Research Institute developed the GENTU (Ground ENvironment Tracking Unmanned robot), a battery-operated robot equipped with GPR for detecting crevasses near Jang Bogo Station [9]. The recent version features reduced power consumption and a sail-assisted energy-saving mechanism. However, it still lacks robust low-speed control, which is essential for autonomous docking and recharging [10,11]. Robots designed for Antarctic exploration must navigate rugged terrain and function reliably across a wide temperature range (from −30 °C to 20 °C) [1,12,13,14,15]. For mission’s further inland, where temperatures can drop below −50 °C, it is essential to ensure enhanced mobility and cold-resistance capabilities.

This paper presents the development and field evaluation of a robotic system designed to operate in sub −50 °C environments and traverse snow-covered mountainous terrain in Antarctica. The system is validated through a series of performance and operational tests conducted at Jang Bogo Station, demonstrating capabilities in remote-controlled, autonomous, and long-distance operation.

The remainder of this paper is organized as follows: Section 2 describes the design methodology of the KAREX (Korea Antarctic Robot EXplorer) system. Section 3 presents performance evaluations in low-temperature and mountainous terrain conditions. Section 4 discusses the field operation results. Section 5 concludes this study and outlines future research directions.

2. Design of Robotic System for Exploration

2.1. Design of Multimodal Sensor Module

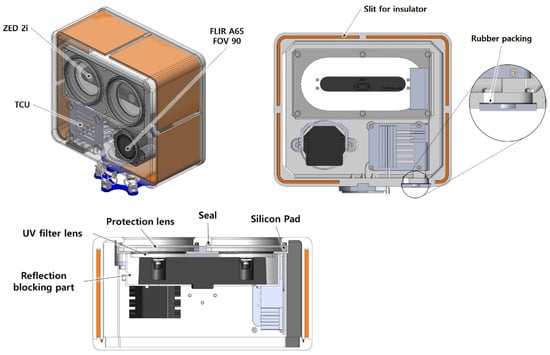

In order to explore, perceive, and make judgments in various environments in extreme regions, a multimodal sensor has been developed [16]. Designed with considerations for characteristics useful in extreme environments, such as temperature conditions, waterproofing, and corrosion resistance, the sensor module ensures robust performance. Additionally, to minimize noise and vibrations affecting sensor data during mobile platform operation, a camera base utilizing wire dampers has been implemented.

The multimodal sensor module includes the Zed 2i stereo camera from StereoLabs and the A65 FOV 90 thermal imaging temperature sensor from FLIR. The mounting method employed for these sensors allows for the future integration of even more diverse sensors. The operational temperatures for the two sensors applied are detailed in Table 1. These vision sensors are used to provide users with images for monitoring during the day and night, as well as to recognize and avoid dynamic obstacles (e.g., people or animals).

Table 1.

Operation temperature.

To ensure operational temperatures below −50 °C in extreme regions, a specialized housing method for the multimodal sensor module, as depicted in Figure 1, was necessary. The housing was fabricated using the Stereo Lithography Apparatus (SLA) 3D printing method, employing ABS-like material known for its impact resistance, mechanical strength, and durability. The multimodal sensor has an opening for the camera lens and a cover part for sensor maintenance. This part requires sealing to ensure waterproof and dustproof performance, which requires the surface quality of the attachment surface and high processing precision. The SLA printing method is optimized to meet these requirements because it provides high precision and excellent surface quality compared to other printing methods. In addition, the slit structure for the insulation may produce printing supporters during production, but this printing method makes it easy to remove the supporters and cleanly remove them from the surface, resulting in high surface quality. Therefore, the assembly process can be performed smoothly in the process of inserting the insulation, and the empty space between the slit structure and the insulation can be minimized, which can more efficiently improve the insulation performance of the multimodal sensor housing. Moreover, the material was chosen for its ability to freely shape complex internal structures required for systems like the multimodal sensor module, accommodating various sensor shapes. To secure the operational performance of the multimodal sensor, seals were applied at the sensor and housing junctions. During housing fabrication, a slit structure was created to accommodate for insulation material, enhancing the durability and maintenance capabilities of the housing. This insulation was mainly manufactured to maintain the temperature at −10 °C, which is the temperature during the exploration period, with minimal TCU power.

Figure 1.

Design of the multimodal sensor module.

To acquire driving data in addition to the multimodal sensor, a 3D LiDAR has been integrated, as shown in Figure 2. Specifically, Robosense’s Bpearl LiDAR units have been mounted on the front and rear of the mobile platform, with two units positioned at each location [17]. This configuration minimizes blind spots around the platform’s bounding volume to gather environmental information effectively, considering that front and rear distinctions are unnecessary during operation. This deployment strategy ensures comprehensive coverage for obtaining environmental data during driving scenarios.

Figure 2.

Design of 3D LiDAR arrangement.

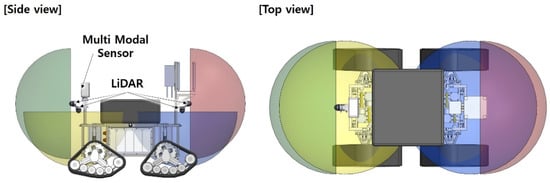

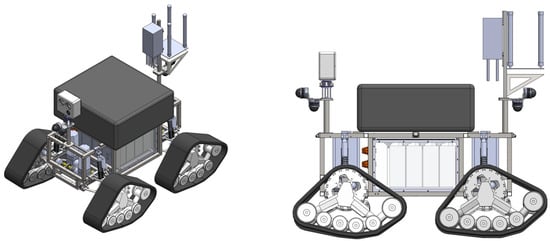

2.2. Design of Robotic System

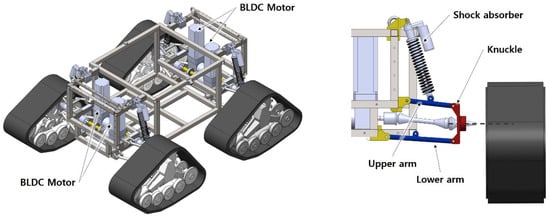

The overall configuration of the mobile platform for extreme environments is depicted in Figure 3. This system utilizes four 3 kW BLDC motors to drive each crawler, adopting a Skid turn driving method for exploring rugged terrain. Each crawler is supported by a Double wishbone suspension, enhancing design flexibility and allowing for the easy adjustment of alignment and robot posture. The entire frame is constructed from SUS304 material to ensure durability and corrosion resistance in polar environments. The mobile platform integrates internal battery and power management systems designed to withstand temperature extremes, corrosion, and provide waterproof performance. Detailed specifications of the system are outlined in Table 2.

Figure 3.

Design of mobile robot for Antarctica.

Table 2.

Robotic system specifications.

To optimize the battery placement, the BLDC motors are not only arranged vertically but also cross-shaped to reduce the width of the robot for entering the shelter for transportation and charging. Furthermore, the crawlers of the platform are designed to maintain a certain horizontal distance from the ground while moving within the range of the suspension system for shock absorption (see Figure 4).

Figure 4.

Design of motor location and suspension system.

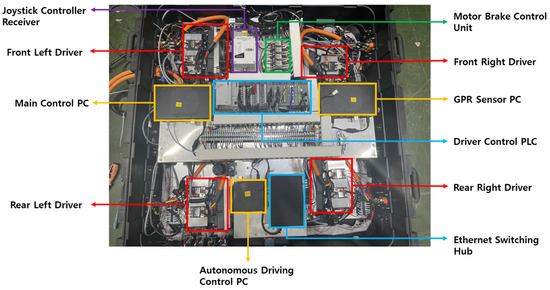

The control box, including the motor driver, is shown in Figure 5. The internal configuration includes a joystick controller receiver for short-range control, a motor brake control unit, and drivers and control PLCs for four motors. Moreover, a total of three PCs were employed, including a PC for the control and data management of the GPR sensor, a PC for the autonomous driving algorithm, and a PC for the main control, and an internal communication network was established via Ethernet.

Figure 5.

Inside of control box.

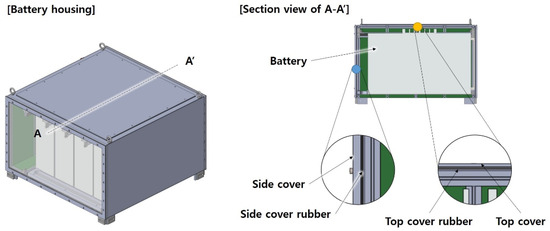

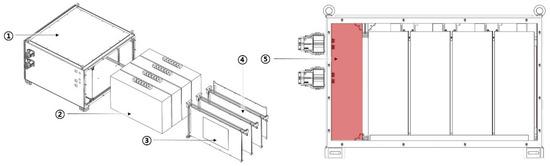

As shown in Figure 6, the battery compartment secured using rubber contains battery packs designed to be easily replaced with a slide structure that integrates insulation and waterproof functions. Each battery pack contains four lithium-ion batteries, a heating pad, a fixed partition, and a TCU (temperature control unit) system, as shown in Figure 7. This system is set to maintain the temperature at 18 °C even at −50 °C. Figure 8 shows the battery packs designed and installed according to the specifications.

Figure 6.

Design of battery pack.

Figure 7.

Design of inside of the battery pack: (1) battery pack housing, (2) lithium-ion battery pack, (3) heating pad, (4) battery retaining bulkhead, and (5) TCU system.

Figure 8.

Battery pack mounted on the robot.

3. Performance Tests of Robotic System

3.1. Freezing Chamber Test

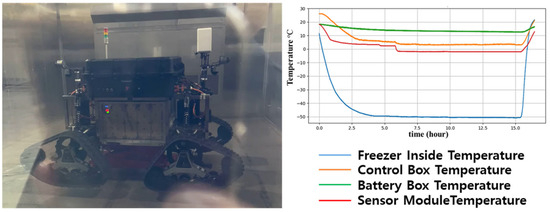

First, to test the insulation of the robot, an experiment was conducted in a freezing chamber at −50 °C for about 13 h to see if the robot could withstand extreme temperatures, as shown in Figure 9. The robot has three compartments: the control box, the battery box, and the sensor module, which enable it to operate at extreme temperatures. The diagram shows that each compartment maintains its designated temperature. Each compartment is equipped with a TCU system, with the battery box set to maintain 18 °C for battery efficiency, while the other compartments are set to maintain 3 °C.

Figure 9.

The results of freezing chamber test.

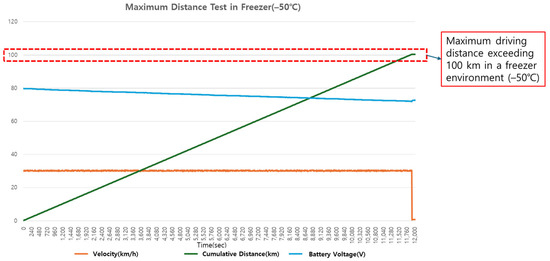

Next, to check the driving performance, we tested the maximum distance that could be driven in the same environment. This experiment was conducted to drive more than 100 km while maintaining a speed of 30 km/h in the freezer, and a cumulative distance of 100 km was achieved, as shown in Figure 10. Therefore, the robot shows that it can drive long distances in a low-temperature environment.

Figure 10.

The results of maximum distance test.

3.2. Antarctic Environmental Robot Performance Test

The developed robot system was disassembled and shipped on the Research Vessel Araon to the Jang Bogo Station in Antarctica for testing in the extreme Antarctic environment. It was transported from Incheon, South Korea, to Jang Bogo Station in Antarctica, where it was reassembled. Using an industrial controller, the basic operations of the robot were tested, and its performance for mobility in the Antarctic terrain was evaluated based on the following criteria. These criteria were determined through discussions with polar researchers and robot experts. The experimental period was from 1 November 2024 to 26 December 2024, and environmental data such as temperature and wind speed can be checked in the monitoring system (for example, on 1 November 2025, the lowest temperature at Browning Pass was −11.5 °C, and on December 26, the lowest temperature was −8.6 °C) [18].

- Overcoming obstacles with height differences of 50 cm or more;

- Crossing crevasses of 30 cm or wider;

- Stopping distance of 65 cm or less;

- Position accuracy error of 15 cm or less based on multimodal sensor data.

First, for the robot to navigate the Antarctic terrain, it needs the ability to overcome certain height differences. Therefore, an experiment was conducted to see if the robot could overcome obstacles higher than 50 cm. The robot was placed in front of a snow mound taller than 50 cm, and its ability to climb over it was tested. As shown in Figure 11, the robot was able to overcome the obstacles by moving forward or backward. This performance was followed by long-distance driving tests, including climbing snow-covered mountains.

Figure 11.

The test of overcoming obstacles with height differences of 50 cm.

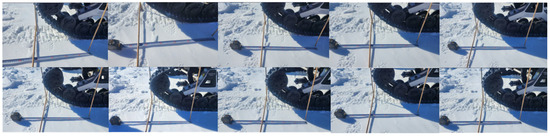

Next, an experiment was conducted to test the robot’s ability to cross crevasses wider than 30 cm. As shown in Figure 12, the robot successfully crossed the crevasse both forwards and backwards. For the results, experiments were conducted to overcome artificially created crevasses by moving forward or backward. This performance was able to overcome small crevasses encountered while driving on the ice track.

Figure 12.

The test of crossing crevasses of 30 cm.

The stopping distance of the robot was measured by determining the distance the robot platform travels after receiving an emergency stop signal while moving at a normal speed. The stopping distance was measured to be 65 cm or less. As shown in Figure 13, measurements were taken 10 times, and each time the stopping distance fell within the allowable range. This capability enables sudden stops when encountering dynamic obstacles such as people or animals.

Figure 13.

The test of stopping distance of 65 cm.

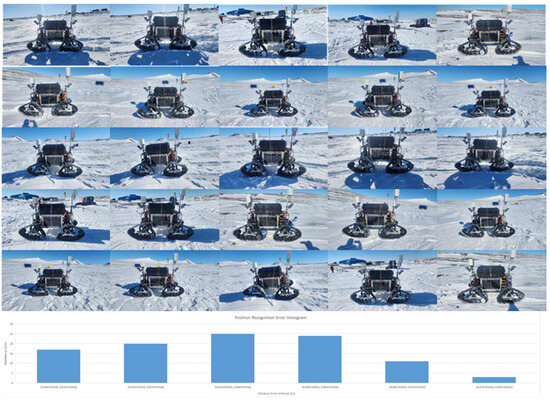

Additionally, Figure 14 shows the results of repeatedly measuring the position accuracy based on multimodal sensor data. The average error was found to be 8 cm, with a maximum error of 13 cm. This result is an important confirmation factor for reaching the destination in autonomous driving as it measures the position error repeatedly more than 100 times based on 10 random points. Meanwhile, the robot uses various sensors to avoid obstacles and crevasses that cannot be crossed [19].

Figure 14.

The test of position accuracy error.

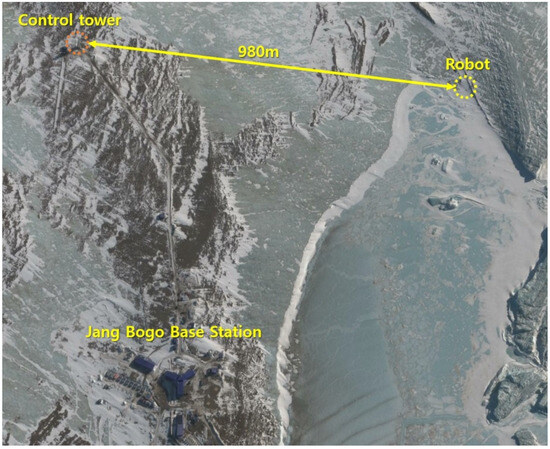

4. Antarctic Environmental Operational Test

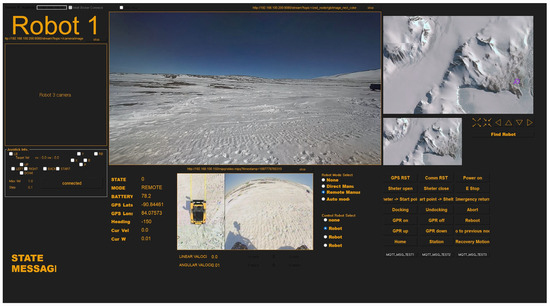

Next, after integrating the long-distance communication network, the communication delay was verified and basic tests were performed. The communication module provided as part of the collaborative project enables communication at a distance of up to 50 km. This module is installed on the robot to transmit real-time multimodal sensor data and robot internal data and receive control data from the control tower, enabling both autonomous and remote control. If communication from the provided communication module is interrupted, the robot performs an automatic recovery mode after three retries if the connection is not established. Moreover, the status data of the robot can be monitored at all times, and the remote control of the controller has priority over the automatic mode. As shown in Figure 15, a remote control test was performed using the communication module and the control software. These tests performed by actual users of the Korea Polar Research Institute confirmed the usability of the system. The user can control the robot by checking the front and surrounding view through the control screen and can check the current location, speed, GPS coordinates, battery voltage, and driving mode on the map. The screen has a menu for performing defined tasks, such as docking for station charging. As a result of the test, remote driving was performed without delay at a distance of about 1 km.

Figure 15.

The test of long–range remote control.

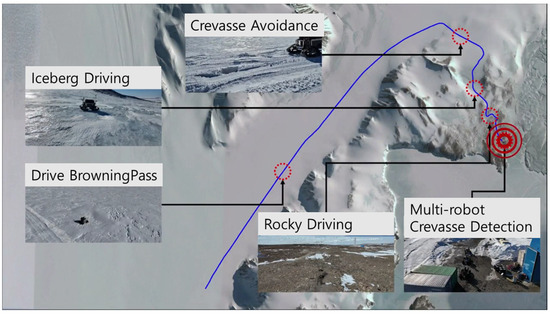

Meanwhile, a long-distance operation test for exploration was conducted. As shown in Figure 16, it traveled an approximately 54 km round trip from Jang Bogo Station to the observatory point of Browning Pass. The route included a small crevice and a steep mountain climbing iceberg path and a rocky field section. Furthermore, it traveled a total of 267.74 km based on accumulated GPS data through long-term operation (over 30 days). It avoided crevasses that actually occurred during the drive and completed all the drives. In addition, the mission verified the stability of the robot by waiting at the starting point for 48 h before returning and maintaining the temperature with minimal power. A total of three robots were operated based on multi-robot task scheduling [20] and simultaneously performed crevasse detection missions in a specific area, as shown in Figure 17, proving its usefulness for Antarctic exploration.

Figure 16.

The test of long–distance operation.

Figure 17.

Three-robot operation for crevasse detection.

5. Conclusions and Future Works

In this study, we designed and developed a robotic platform specifically for crevasse exploration in extreme polar environments, such as Antarctica. The robot was engineered to operate reliably under severe conditions, featuring a waterproof and thermally insulated structure capable of retaining internal temperature. To ensure robust performance in sub-zero temperatures, key components—including a rigid frame, high-torque motors and drivers, reinforced crawlers, a suspension system, temperature-regulated compartments, a modular battery system, and multimodal sensors—were integrated into the design. The robot demonstrated stable operation at temperatures as low as −50 °C and achieved traversal speeds of up to 30 km/h. Field tests conducted near the Jang Bogo Station in Antarctica confirmed its ability to cross 50 cm wide gaps, overcome crevasses up to 30 cm deep, and maintain stopping distance and positional accuracy during autonomous navigation. The system also showed reliable long-distance operation, with successful remote and autonomous driving over distances of approximately 1 km. Over a one-month deployment, the robot traveled more than 270 km, sustained standby operation for up to 48 h, and successfully conducted cooperative crevasse exploration as part of a multi-robot system. These results validate the robot’s suitability for autonomous exploration tasks in extreme Antarctic conditions.

Future work will focus on expanding the robot’s mission scope, including applications such as automated station resupply and coordinated formation driving with multiple robots. Long-term and long-distance testing will be carried out to further validate the system’s performance and reliability under real-world Antarctic operational scenarios.

Author Contributions

Conceptualization, T.U. and Y.C.; methodology, J.K. (Jiwook Kwon); software, J.K. (Jiwook Kwon); validation, K.N., J.K. (Jongchan Kwon) and Y.C.; investigation, J.K. (Jiwook Kwon); resources, H.L.; data curation, J.K. (Jongchan Kwon); writing—original draft preparation, T.U.; writing—review and editing, J.K. (Jiwook Kwon); visualization, H.L.; supervision, Y.C.; project administration, T.U.; funding acquisition, Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Korea Institute of Marine Science & Technology Promotion (KIMST) funded by the Ministry of Trade, Industry and Energy in 2023 (Project Number 20210630).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Apostolopoulos, D.S.; Pedersen, L.; Shamah, B.N.; Shillcutt, K.; Wagner, M.D.; Whittaker, W.L. Robotic Antarctic meteorite search: Outcomes. In Proceedings of the 2001 ICRA, IEEE International Conference on Robotics and Automation (Cat. No. 01CH37164), Seoul, Republic of Korea, 21–26 May 2001; Volume 4, pp. 4174–4179. [Google Scholar]

- Chin, M.A. Antarctica: A Test Bed for Space Exploration. 2003. Available online: http://hdl.handle.net/10092/14005 (accessed on 11 May 2025).

- Pedersen, L.; Apostolopoulos, D.; Whittaker, W. Bayes Networks on Ice: Robotic Search for Antarctic Meteorites. In Proceedings of the Advances in Neural Information Processing Systems, Denver, CO, USA, 27 November–2 December 2000; pp. 1–7. [Google Scholar]

- Pedersen, L.; Wagner, M.; Apostolopoulos, D.; Whittaker, W.R. Autonomous robotic meteorite identification in Antarctica. In Proceedings of the 2001 IEEE International Conference on Robotics and Automation, Seoul, Republic of Korea, 21–26 May 2001; pp. 4158–4165. [Google Scholar]

- Wagner, M.D.; Apostolopoulos, D.; Shillcutt, K.; Shamah, B.; Simmons, R.; Whittaker, W.R. The science autonomy system of the Nomad robot. In Proceedings of the 2001 IEEE International Conference on Robotics and Automation, Seoul, Republic of Korea, 21–26 May 2001; pp. 1742–1749. [Google Scholar]

- Urmson, C.; Shamah, B.; Teza, J.; Wagner, M.D.; Apostolopoulos, D.; Whittaker, W.L. A sensor arm for robotic Antarctic meteorite search. In Proceedings of the 3rd International Conference on Field and Service Robotics, Helsinki, Finland, 11–13 July 2001. [Google Scholar]

- He, Y.; Chen, C.; Bu, C.; Han, J. A polar rover for large-scale scientific surveys: Design, implementation and field test results. Int. J. Adv. Robot. Syst. 2015, 12, 145. [Google Scholar] [CrossRef]

- Lever, J.H.; Delaney, A.J.; Ray, L.E.; Trautmann, E.; Barna, L.A.; Burzynski, A.M. Autonomous GPR surveys using the polar rover Yeti. J. Field Robot. 2012, 30, 194–215. [Google Scholar] [CrossRef]

- Chung, C.; Kim, H.-K.; Yoon, D.-J.; Lee, J. Development of an unmanned ground robot platform for polar regions: GENTU. Korea Robot. Soc. Rev. 2023, 20, 19–27. [Google Scholar]

- Guo, L.; Liu, G.; Luo, Y.; Jiang, P.; Zhao, J. A wind-electric hybrid polar roaming robot: Design, modeling, and experiments. J. Field Robot. 2024, 41, 131–143. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, G.; Guo, L.; Zhu, Y.; Zhao, J. Scalable Wing Sailing and Snowboarding Enhance Efficient and Energy-Saving Mobility of Polar Robot. IEEE/ASME Trans. Mechatron. 2024, 29, 3833–3844. [Google Scholar] [CrossRef]

- Apostolopoulos, D.S.; Wagner, M.D.; Shamah, B.N.; Pedersen, L.; Shillcutt, K.; Whittaker, W.L. Technology and field demonstration of robotic search for Antarctic meteorites. Int. J. Robot. Res. 2000, 19, 1015–1032. [Google Scholar] [CrossRef]

- Turner, J.; Marshall, G.J.; Clem, K.; Colwell, S.; Phillips, T.; Lu, H. Antarctic temperature variability and change from station data. Int. J. Climatol. 2020, 40, 2986–3007. [Google Scholar] [CrossRef]

- Pomerleau, F. Robotics in snow and ice. arXiv 2022, arXiv:2208.05095. [Google Scholar]

- Sevinchan, E.; Dincer, I.; Lang, H. A review on thermal management methods for robots. Appl. Therm. Eng. 2018, 140, 799–813. [Google Scholar] [CrossRef]

- Uhm, T.; Noh, K.; Hwang, H.; Kim, J.-C.; Lee, H.-J.; Choi, Y.-H. Multi-modal sensor module for Antarctica exploration robots. In Proceedings of the 2023 IEEE International Conference on Consumer Electronics, Las Vegas, NV, USA, 6–8 January 2023. [Google Scholar]

- Bpearl, RoboSense/Suteng Innovation Technology Co., Ltd. Available online: https://www.robosense.ai/en/rslidar/Bpearl (accessed on 12 May 2025).

- KEMOS. Available online: http://live.kopri.re.kr/kemos/ (accessed on 12 May 2025).

- Kwon, J.; Lee, H.; Lee, J.; Lee, N.; Kim, J.; Uhm, T.; Choi, Y. UWB-Based Human-Following System with Obstacle and Crevasse Avoidance for Polar-Exploration Robots. Appl. Sci. 2024, 14, 6918. [Google Scholar] [CrossRef]

- Kim, S.; Lee, H. Multi-robot task scheduling with ant colony optimization in antarctic environments. Sensors 2023, 23, 751. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).