Wake-Up Effects on Improving Gradual Switching and Variation in Al2O3-Based RRAM

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

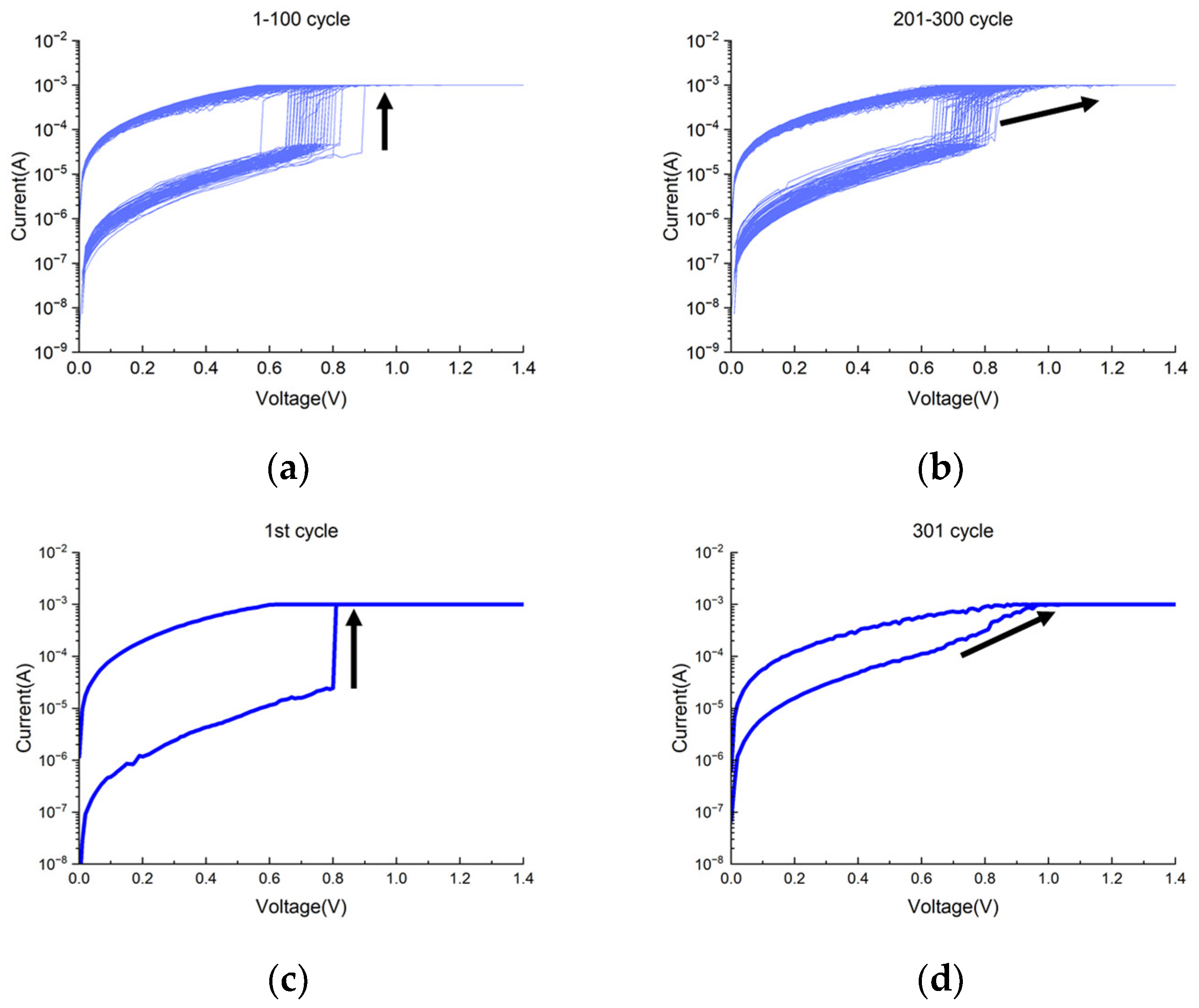

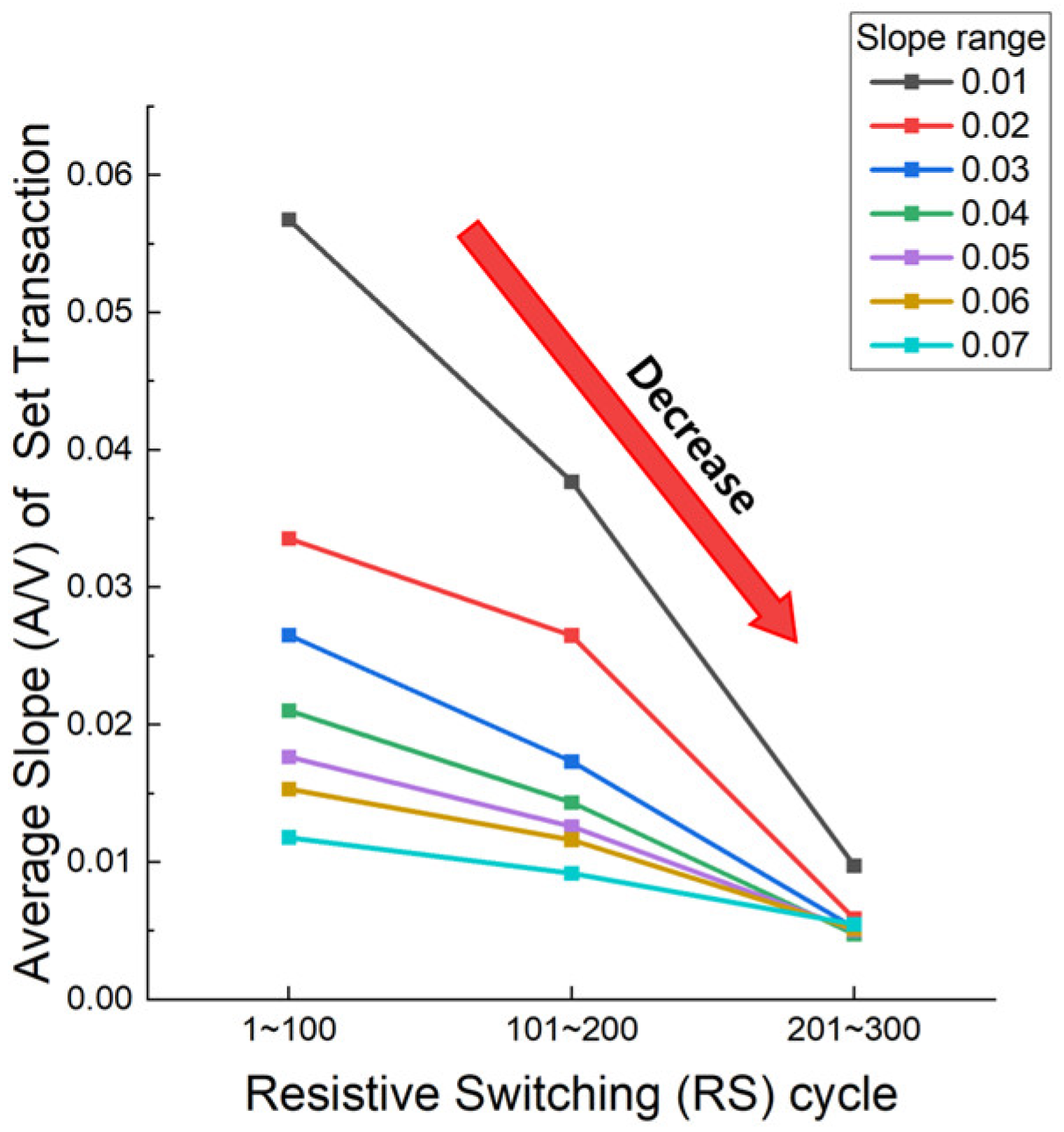

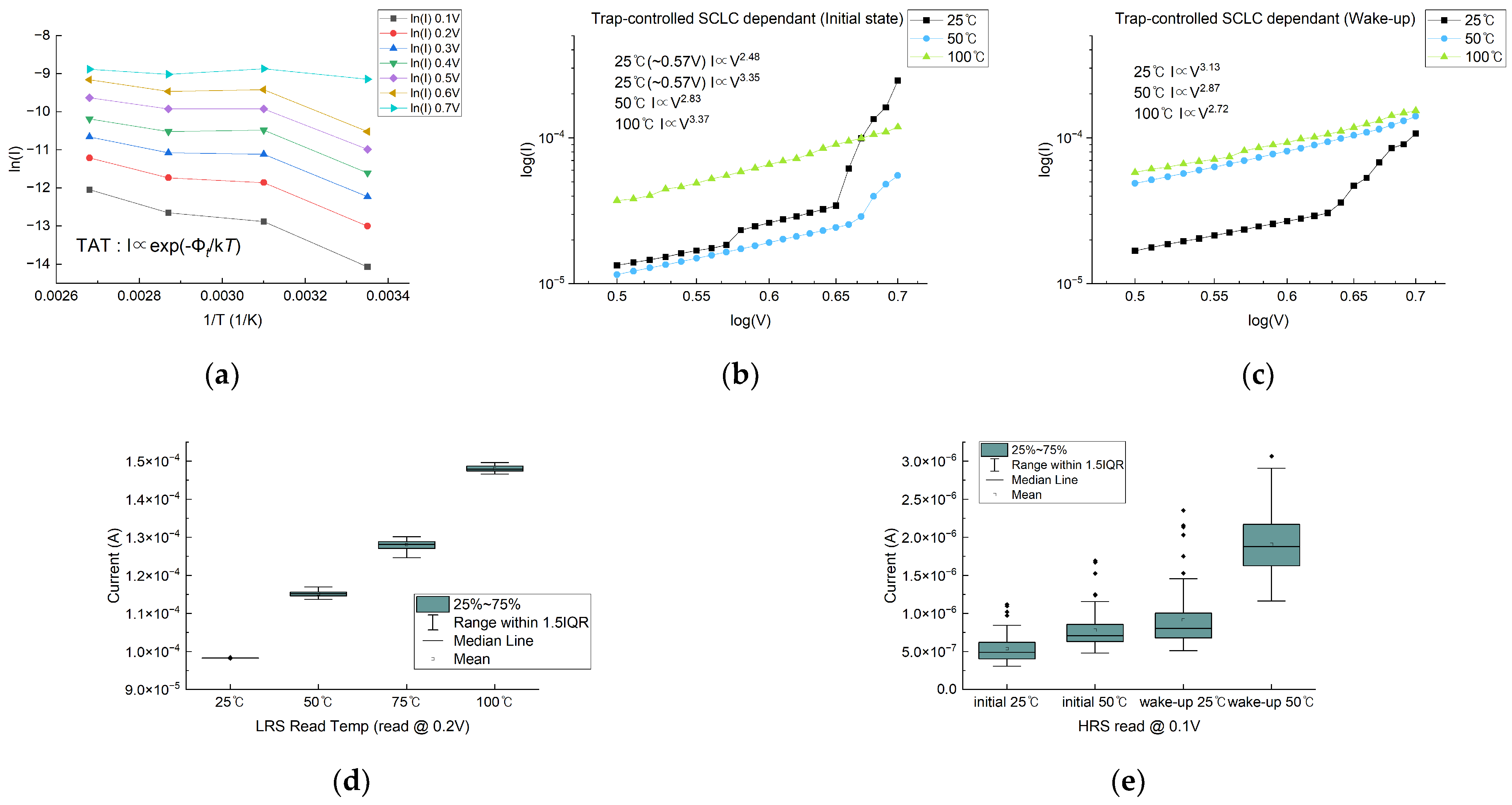

3.1. Gradual Switching Characteristics

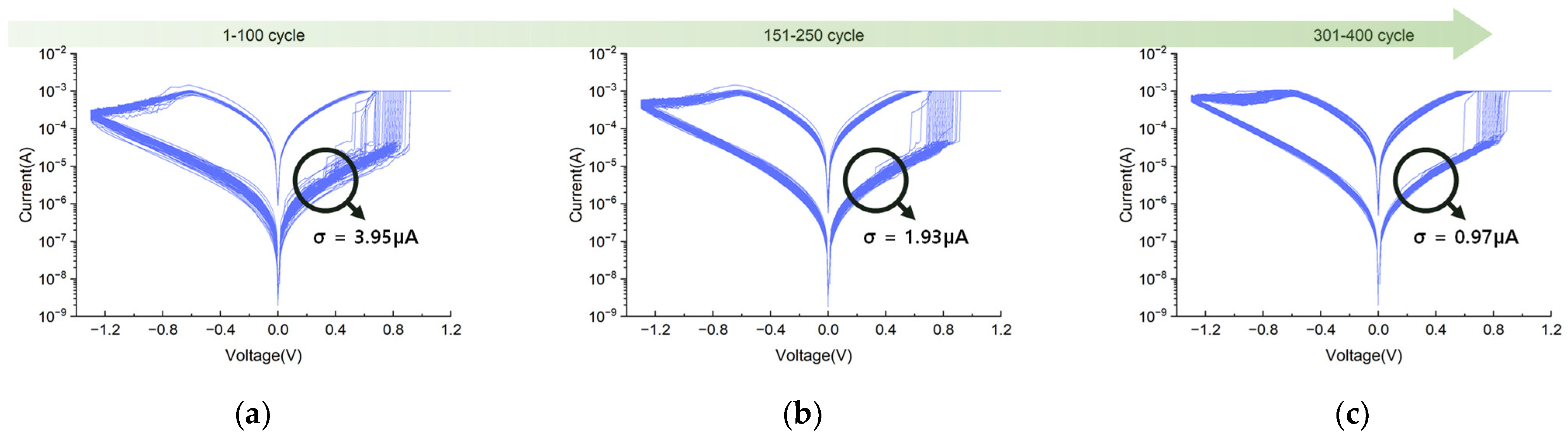

3.2. Variation Reduction Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Waser, R.; Dittmann, R.; Staikov, G.; Szot, K. Redox-Based Resistive Switching Memories—Nanoionic Mechanisms, Prospects, and Challenges. Adv. Mater. 2009, 21, 2632–2663. [Google Scholar] [CrossRef]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale memristor device as synapse in neuromorphic systems. Nano Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, W.; Zhang, X.; Luo, Q.; Lv, H.; Liu, Q.; Long, S.; Liu, M. Design of CMOS Compatible, High-Speed, Highly-Stable Complementary Switching with Multilevel Operation in 3D Vertically Stacked Novel HfO2/Al2O3/TiOx (HAT) RRAM. Adv. Electron. Mater. 2018, 4, 1700561. [Google Scholar] [CrossRef]

- Prezioso, M.; Mahmoodi, M.R.; Bayat, F.M.; Nili, H.; Kim, H.; Vincent, A.; Strukov, D.B. Spike-timing-dependent plasticity learning of coincidence detection with passively integrated memristive circuits. Nat. Commun. 2018, 9, 5311. [Google Scholar] [CrossRef]

- Hong, X.; Loy, D.J.; Dananjaya, P.A.; Tan, F.; Ng, C.; Lew, W. Oxide-based RRAM materials for neuromorphic computing. J. Mater. Sci. 2018, 53, 8720–8746. [Google Scholar] [CrossRef]

- Ji, H.; Kim, S.; Kim, S. Self-Rectifying Short-Term Memory Phenomena Through Integration of TiOx Oxygen Reservoir and Al2O3 Barrier Layers for Neuromorphic System. Adv. Mater. Technol. 2025, 10, 2400895. [Google Scholar] [CrossRef]

- Park, J.; Kim, T.-H.; Kwon, O.; Ismail, M.; Mahata, C.; Kim, Y.; Kim, S.; Kim, S. Implementation of convolutional neural network and 8-bit reservoir computing in CMOS compatible VRRAM. Nano Energy 2022, 104, 107886. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, S.; Hong, K.; Park, J.; Hwang, Y.; Park, B.-G.; Kim, H. Multilevel switching memristor by compliance current adjustment for off-chip training of neuromorphic system. Chaos Solitons Fractals 2021, 153, 111587. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, S.; Park, J.; Youn, S.; Kim, H. Memristor Crossbar Array with Enhanced Device Yield for In-Memory Vector–Matrix Multiplication. ACS Appl. Electron. Mater. 2024, 6, 4099–4107. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, S.; Hong, K.; Kim, H.; Park, B.-G. Enhanced current-voltage nonlinearity by controlling oxygen concentration of TiOx buffer layer for RRAM passive crossbar array. J. Semicond. Technol. Sci. 2022, 22, 417–425. [Google Scholar] [CrossRef]

- Yoon, J.H.; Song, Y.-W.; Ham, W.; Park, J.-M.; Kwon, J.-Y. A review on device requirements of resistive random access memory (RRAM)-based neuromorphic computing. APL Mater. 2023, 11, 090701. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Lee, H.Y.; Yu, S.; Chen, Y.S.; Wu, Y.; Chen, P.S.; Lee, B.; Chen, F.T.; Tsai, M.J. Metal–oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Zahoor, F.; Zulkifli, T.Z.A.; Khanday, F.A. Resistive Random Access Memory (RRAM): An Overview of Materials, Switching Mechanism, Performance, Multilevel Cell (mlc) Storage, Modeling, and Applications. Nanoscale Res. Lett. 2020, 15, 90. [Google Scholar] [CrossRef]

- Grossi, A.; Nowak, E.; Zambelli, C.; Pellissier, C.; Bernasconi, S.; Cibrario, G.; El Hajjam, K.; Crochemore, R.; Nodin, J.; Olivo, P.; et al. Fundamental variability limits of filament-based RRAM. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; pp. 4.7.1–4.7.4. [Google Scholar]

- Chen, P.-Y.; Yu, S. Compact Modeling of RRAM Devices and Its Applications in 1T1R and 1S1R Array Design. IEEE Trans. Electron Devices 2015, 62, 4022–4028. [Google Scholar] [CrossRef]

- Shrestha, P.R.; Nminibapiel, D.M.; Campbell, J.P.; Ryan, J.T.; Veksler, D.; Baumgart, H.; Cheung, K.P. Analysis and Control of RRAM Overshoot Current. IEEE Trans. Electron Devices 2017, 65, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Kumari, K.; Kar, S.; Thakur, A.D.; Ray, S. Role of an oxide interface in a resistive switch. Curr. Appl. Phys. 2022, 35, 16–23. [Google Scholar] [CrossRef]

- Tseng, Y.-T.; Chen, I.-C.; Chang, T.-C.; Huang, J.C.; Shih, C.-C.; Zheng, H.-X.; Chen, W.-C.; Wang, M.-H.; Huang, W.-C.; Chen, M.-C.; et al. Enhanced electrical behavior from the galvanic effect in Ag-Cu alloy electrode conductive bridging resistive switching memory. Appl. Phys. Lett. 2018, 113, 053501. [Google Scholar] [CrossRef]

- Kim, S.; Park, K.; Hong, K.; Kim, T.; Park, J.; Youn, S.; Kim, H.; Choi, W.Y. Overshoot-Suppressed Memristor Crossbar Array with High Yield by AlOx Oxidation for Neuromorphic System. Adv. Mater. Technol. 2024, 9, 2400063. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, J.; Xie, D.; Wang, Z.; Xu, H.; Lin, Y.; Hu, J.; Liu, Y. Natural Acidic Polysaccharide-Based Memristors for Transient Electronics: Highly Controllable Quantized Conductance for Integrated Memory and Nonvolatile Logic Applications. Adv. Mater. 2021, 33, 2104023. [Google Scholar] [CrossRef]

- Lv, Z.; Zhu, S.; Wang, Y.; Ren, Y.; Luo, M.; Wang, H.; Zhang, G.; Zhai, Y.; Zhao, S.; Zhou, Y.; et al. Development of Bio-Voltage Operated Humidity-Sensory Neurons Comprising Self-Assembled Peptide Memristors. Adv. Mater. 2024, 36, e2405145. [Google Scholar] [CrossRef]

- Ielmini, D.; Pedretti, G. Resistive Switching Random-Access Memory (RRAM): Applications and Requirements for Memory and Computing. Chem. Rev. 2025. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wu, T.F.; Mitra, S.; Wong, H.-S.P. Resistive RAM-Centric Computing: Design and Modeling Methodology. IEEE Trans. Circuits Syst. I Regul. Pap. 2017, 64, 2263–2273. [Google Scholar] [CrossRef]

- Kim, T.-H.; Nili, H.; Kim, M.-H.; Min, K.K.; Park, B.-G.; Kim, H. Reset-voltage-dependent precise tuning operation of TiOx/Al2Ox memristive crossbar array. Appl. Phys. Lett. 2020, 117, 152103. [Google Scholar] [CrossRef]

- Panja, R.; Roy, S.; Jana, D.; Maikap, S. Impact of device size and thickness of Al2O3 film on the Cu pillar and resistive switching characteristics for 3D cross-point memory application. Nanoscale Res. Lett. 2014, 9, 692. [Google Scholar] [CrossRef]

- Goux, L.; Raghavan, N.; Fantini, A.; Nigon, R.; Strangio, S.; Degraeve, R.; Kar, G.; Chen, Y.Y.; De Stefano, F.; Afanas’Ev, V.V.; et al. On the bipolar resistive-switching characteristics of Al2O3- and HfO2-based memory cells operated in the soft-breakdown regime. J. Appl. Phys. 2014, 116, 134502. [Google Scholar] [CrossRef]

- Sokolov, A.S.; Son, S.K.; Lim, D.; Han, H.H.; Jeon, Y.; Lee, J.H.; Choi, C. Comparative study of Al2O3, HfO2, and HfAlOx for improved self-compliance bipolar resistive switching. J. Am. Ceram. Soc. 2017, 100, 5638–5648. [Google Scholar] [CrossRef]

- Goux, L.; Opsomer, K.; Degraeve, R.; Müller, R.; Detavernier, C.; Wouters, D.J.; Jurczak, M.; Altimime, L.; Kittl, J.A. Influence of the Cu-Te composition and microstructure on the resistive switching of Cu-Te/Al2O3/Si cells. Appl. Phys. Lett. 2011, 99, 053502. [Google Scholar] [CrossRef]

- Sleiman, A.; Sayers, P.W.; Mabrook, M.F. Mechanism of resistive switching in Cu/AlOx/W nonvolatile memory structures. J. Appl. Phys. 2013, 113, 164506. [Google Scholar] [CrossRef]

- Banerjee, W.; Xu, X.; Lv, H.; Liu, Q.; Long, S.; Liu, M. Variability Improvement of TiOx/Al2O3 Bilayer Nonvolatile Resistive Switching Devices by Interfacial Band Engineering with an Ultrathin Al2O3 Dielectric Material. ACS Omega 2017, 2, 6888–6895. [Google Scholar] [CrossRef]

- Kim, S.; Kim, T.-H.; Kim, H.; Park, B.-G. Current suppressed self-compliance characteristics of oxygen rich TiOy inserted Al2O3/TiOx based RRAM. Appl. Phys. Lett. 2020, 117, 202106. [Google Scholar] [CrossRef]

- Trapatseli, M.; Khiat, A.; Cortese, S.; Serb, A.; Carta, D.; Prodromakis, T. Engineering the switching dynamics of TiOx-based RRAM with Al doping. J. Appl. Phys. 2016, 120, 025108. [Google Scholar] [CrossRef]

- Mahapatra, R.; Maji, S.; Horsfall, A.; Wright, N. Temperature impact on switching characteristics of resistive memory devices with HfOx/TiOx/HfOx stack dielectric. Microelectron. Eng. 2015, 138, 118–121. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, S.; Hong, K.; Park, J.; Youn, S.; Lee, J.-H.; Park, B.-G.; Kim, H. Effect of Program Error in Memristive Neural Network With Weight Quantization. IEEE Trans. Electron Devices 2022, 69, 3151–3157. [Google Scholar] [CrossRef]

- Belmonte, A.; Celano, U.; Chen, Z.; Radhaskrishnan, J.; Redolfi, A.; Clima, S.; Richard, O.; Bender, H.; Kar, G.S.; Vandervorst, W.; et al. Voltage-controlled reverse filament growth boosts resistive switching memory. Nano Res. 2018, 11, 4017–4025. [Google Scholar] [CrossRef]

- Jung, K.; Magyari-Kope, B.; Nishi, Y. Hydrogen-Induced Oxygen Vacancy Bistability and Its Impact on RRAM Device Operation. IEEE Electron Device Lett. 2017, 38, 728–731. [Google Scholar] [CrossRef]

- Patel, K.; Cottom, J.; Bosman, M.; Kenyon, A.J.; Shluger, A.L. An oxygen vacancy mediated Ag reduction and nucleation mechanism in SiO2 RRAM devices. Microelectron. Reliab. 2019, 98, 144–152. [Google Scholar] [CrossRef]

- Duncan, D.; Magyari-Kope, B.; Nishi, Y. Filament-Induced Anisotropic Oxygen Vacancy Diffusion and Charge Trapping Effects in Hafnium Oxide RRAM. IEEE Electron Device Lett. 2016, 37, 400–403. [Google Scholar] [CrossRef]

- Chand, U.; Huang, K.-C.; Huang, C.-Y.; Tseng, T.-Y. Mechanism of Nonlinear Switching in HfO2-Based Crossbar RRAM With Inserting Large Bandgap Tunneling Barrier Layer. IEEE Trans. Electron Devices 2015, 62, 3665–3670. [Google Scholar] [CrossRef]

- Kumar, D.; Chand, U.; Siang, L.W.; Tseng, T.-Y. High-Performance TiN/Al2O3/ZnO/Al2O3/TiN Flexible RRAM Device With High Bending Condition. IEEE Trans. Electron Devices 2020, 67, 493–498. [Google Scholar] [CrossRef]

- Panda, D.; Chu, C.-A.; Pradhan, A.; Chandrasekharan, S.; Pattanayak, B.; Sze, S.M.; Tseng, T.-Y. Synaptic behaviour of TiOx/HfO2 RRAM enhanced by inserting ultrathin Al2O3 layer for neuromorphic computing. Semicond. Sci. Technol. 2021, 36, 045002. [Google Scholar] [CrossRef]

- Kashniyal, U.; Pandey, K.P. Stress induced degradation and reliability of Al2O3 thin film on silicon. Vacuum 2018, 152, 109–113. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, B.; Shim, W.; Kim, T.-H. Wake-Up Effects on Improving Gradual Switching and Variation in Al2O3-Based RRAM. Electronics 2025, 14, 1921. https://doi.org/10.3390/electronics14101921

Oh B, Shim W, Kim T-H. Wake-Up Effects on Improving Gradual Switching and Variation in Al2O3-Based RRAM. Electronics. 2025; 14(10):1921. https://doi.org/10.3390/electronics14101921

Chicago/Turabian StyleOh, Byeongchan, Wonbo Shim, and Tae-Hyeon Kim. 2025. "Wake-Up Effects on Improving Gradual Switching and Variation in Al2O3-Based RRAM" Electronics 14, no. 10: 1921. https://doi.org/10.3390/electronics14101921

APA StyleOh, B., Shim, W., & Kim, T.-H. (2025). Wake-Up Effects on Improving Gradual Switching and Variation in Al2O3-Based RRAM. Electronics, 14(10), 1921. https://doi.org/10.3390/electronics14101921