Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models

Abstract

1. Introduction

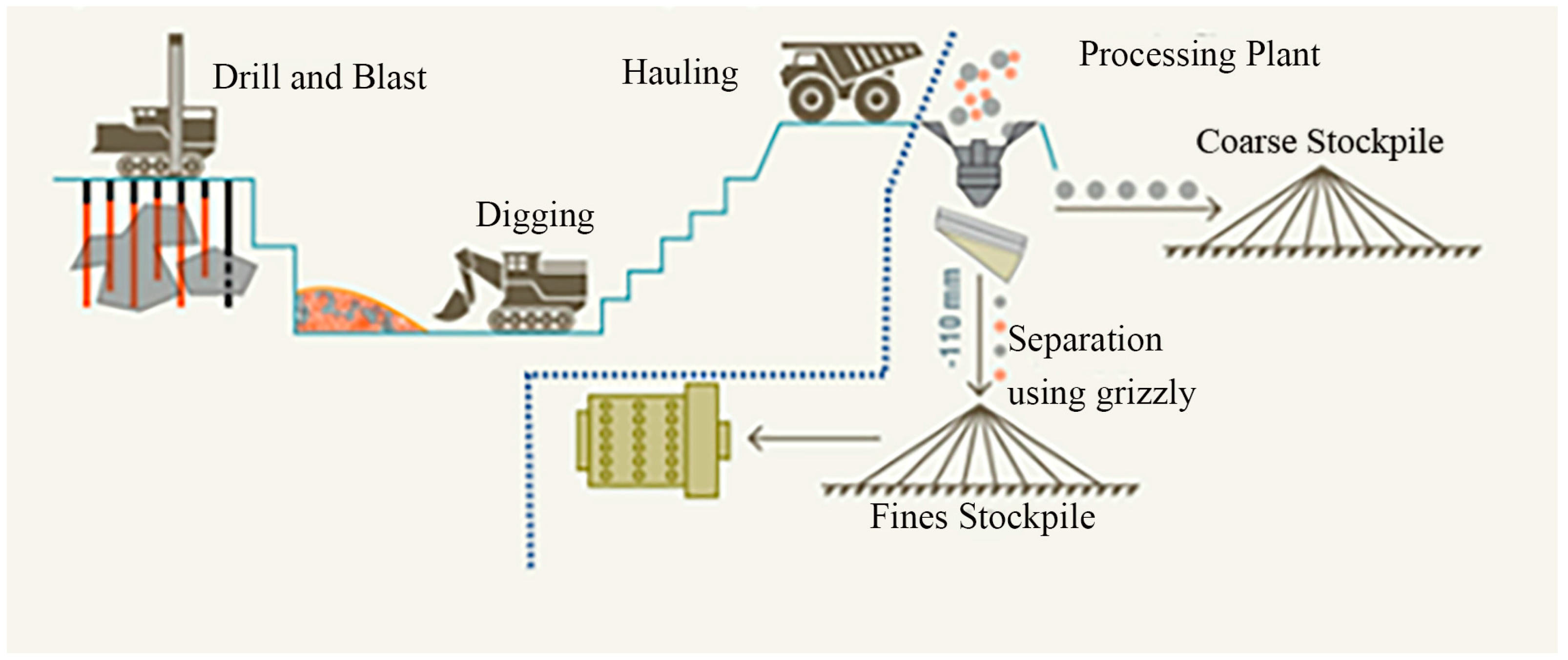

- Importance of drilling accuracy in blasting: Drilling accuracy is the main variable influencing blasting results.

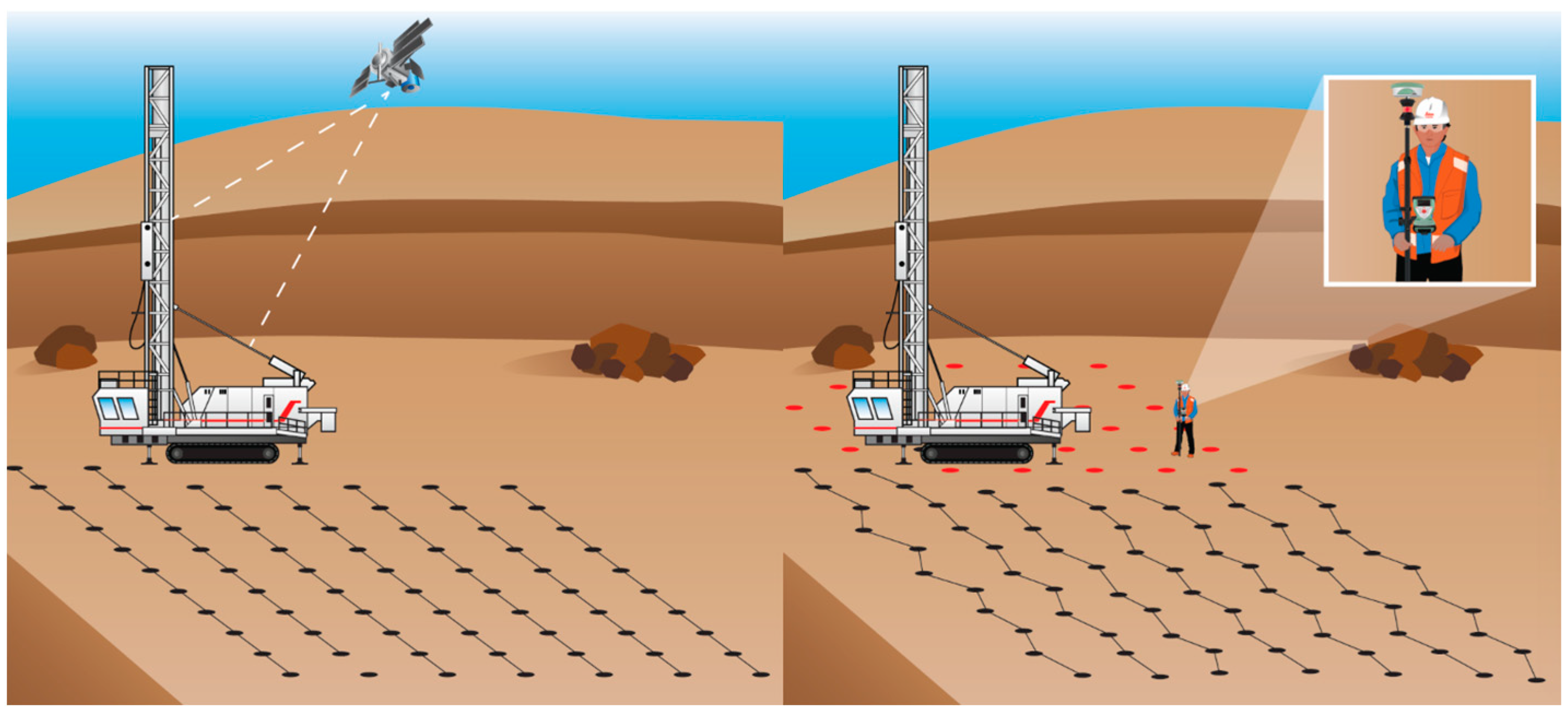

- GPS signal loss: The inconvenience with the GPS mounted on the drilling machines is the loss of signal in some regions of the mine (blind spots), like close to the high walls. The quality of the signal received from the satellites relies on several elements, such as geometry/triangulation regarding the satellites, signal obstruction, atmospheric conditions, and features/technology of the receptor [6].

- Explosive energy distribution: To obtain good rock fragmentation and avoid issues (e.g., flyrocks, misfires, and oversize), it is essential to simulate the explosive energy distribution knowing the blasthole’s final location [7].

- Potential of the research: This research has great potential to be applied to other related object detection problems in the mining industry.

- New methodology to control drilling accuracy: Introducing a complementary or supplementary system to determine the final location of blastholes in cases where the GPS of the drills is inaccurate, has a poor signal, is uncalibrated, or the machine lacks GPS technology (e.g., pre-split drill rigs or older machines without the technology).

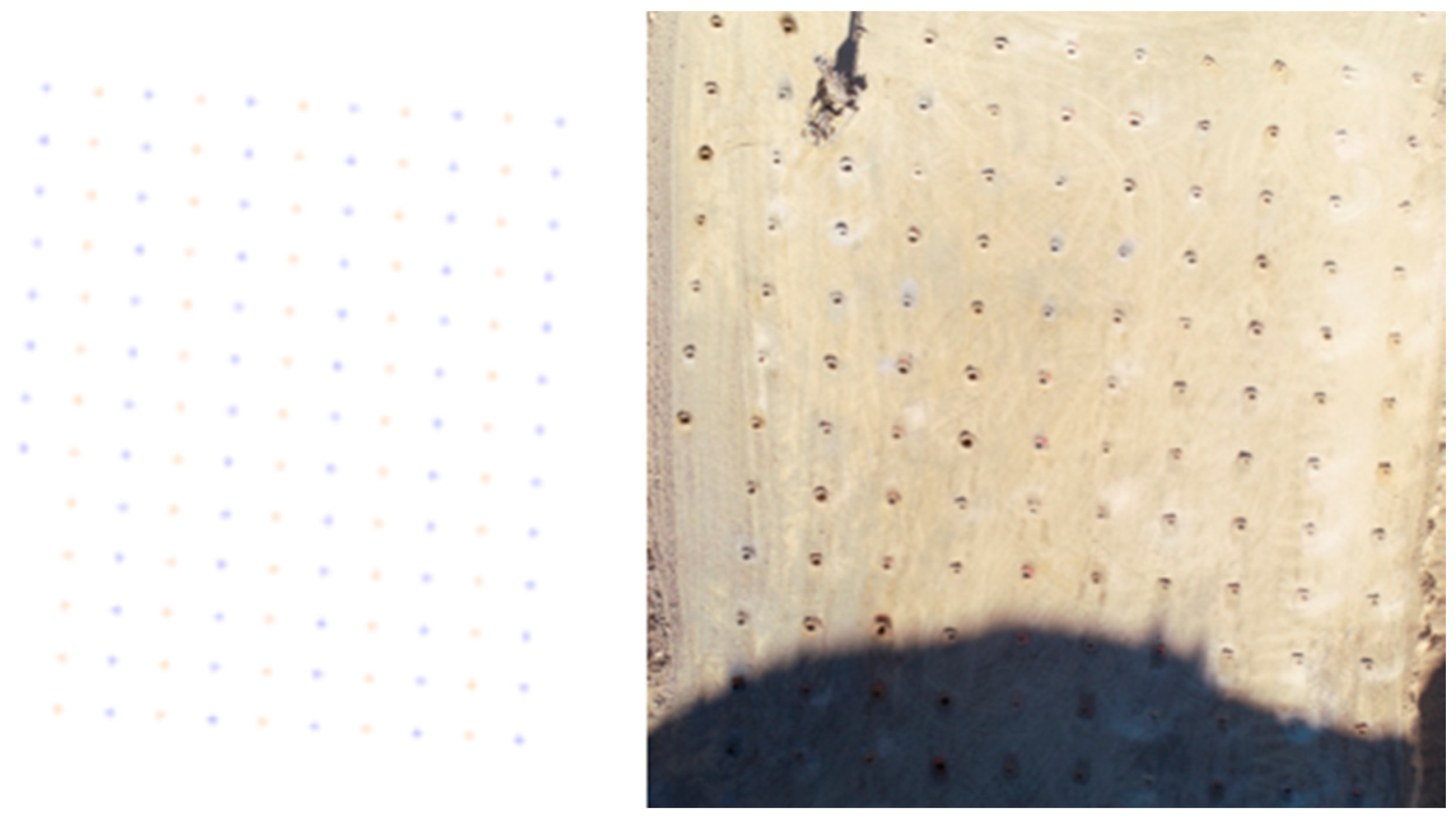

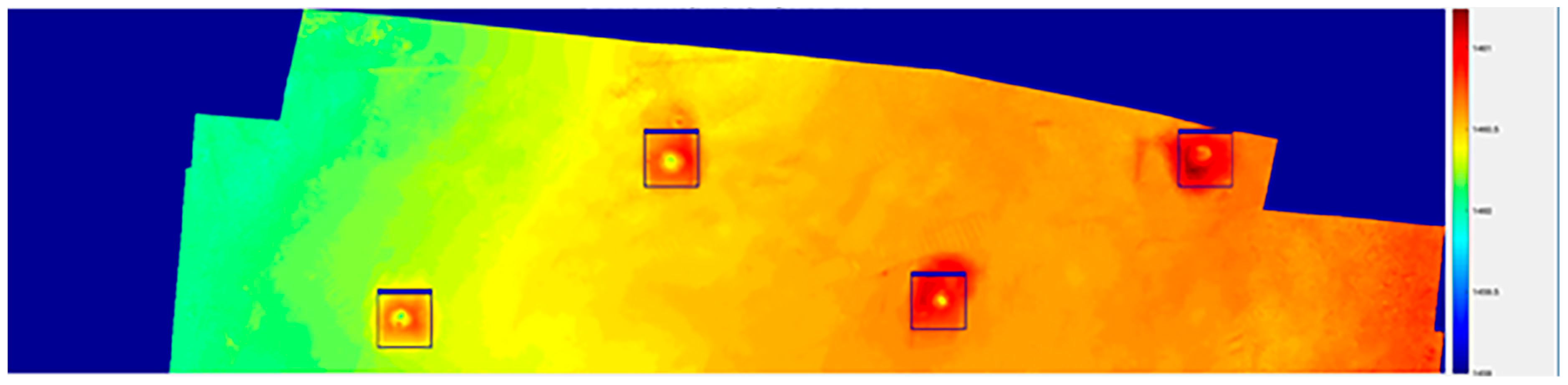

- New approach for object detection using Digital Elevation Models (DEM): Unlike most object detection techniques that use RGB or grayscale images, the proposed methodology, especially the multiple dataset stage, employs elevation data to detect the object of interest (blastholes).

- Providing a new tool to improve blasting results by developing more realistic process simulations.

- Establishing the first blasthole image database could lead to a more extensive blasthole image database from multiple mine sites.

2. Related Work

3. Materials and Methods

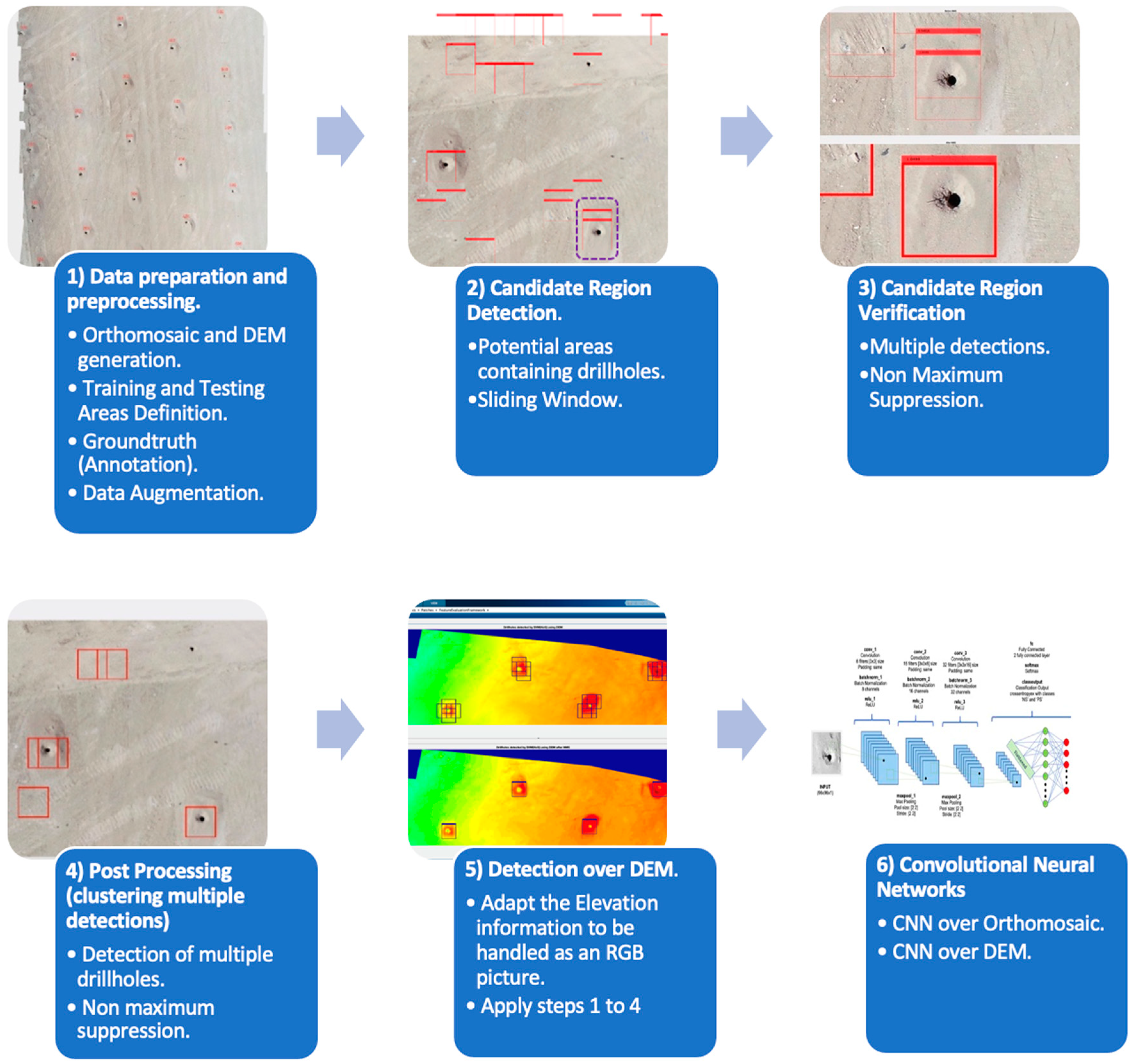

3.1. Framework

- ✓

- Single Dataset

- ○

- Support Vector Machine—Orthomosaic

- ○

- Support Vector Machine—DEM

- ○

- CNN—Orthomosaic

- ✓

- Multiple Datasets

- ○

- CNN—DEM

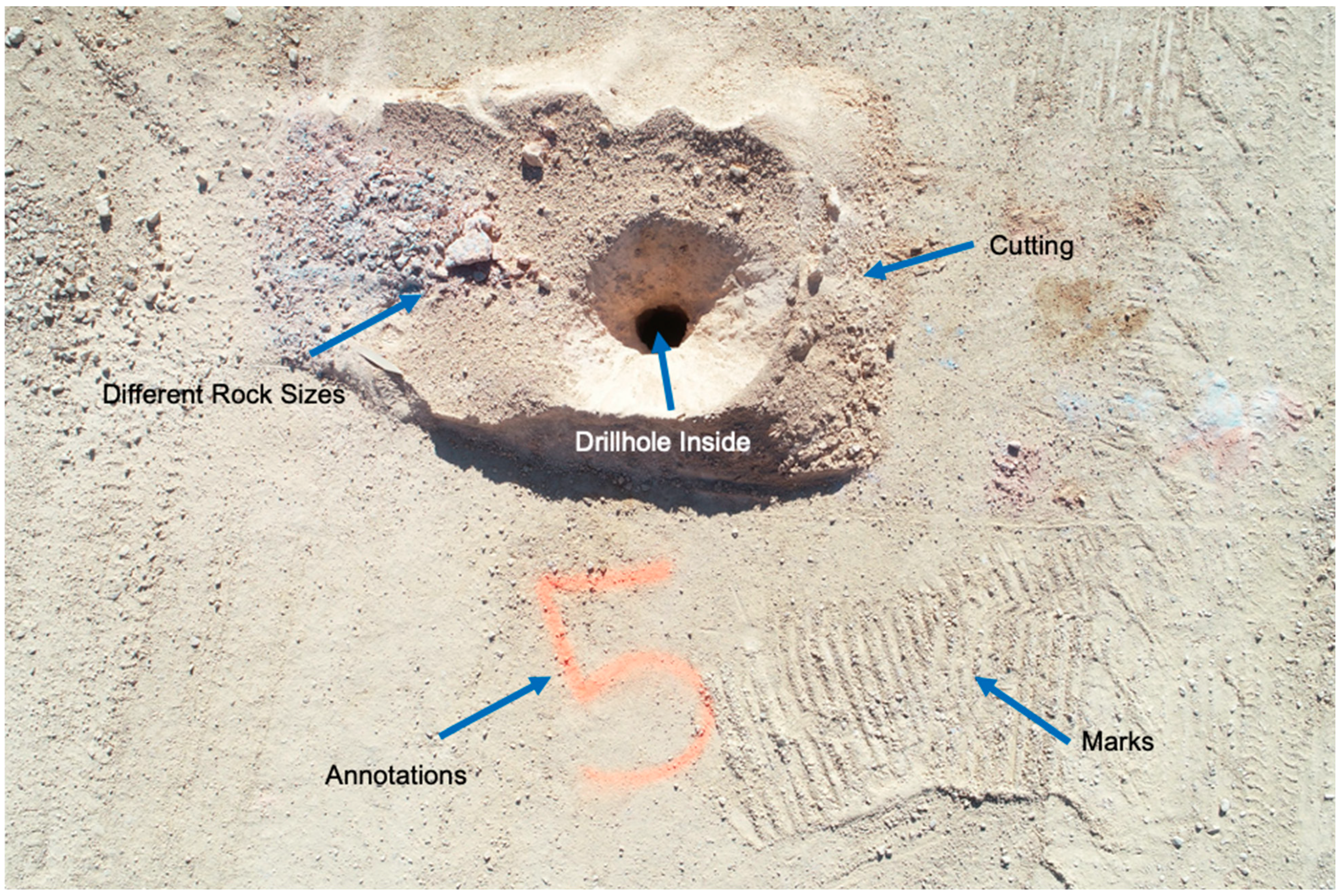

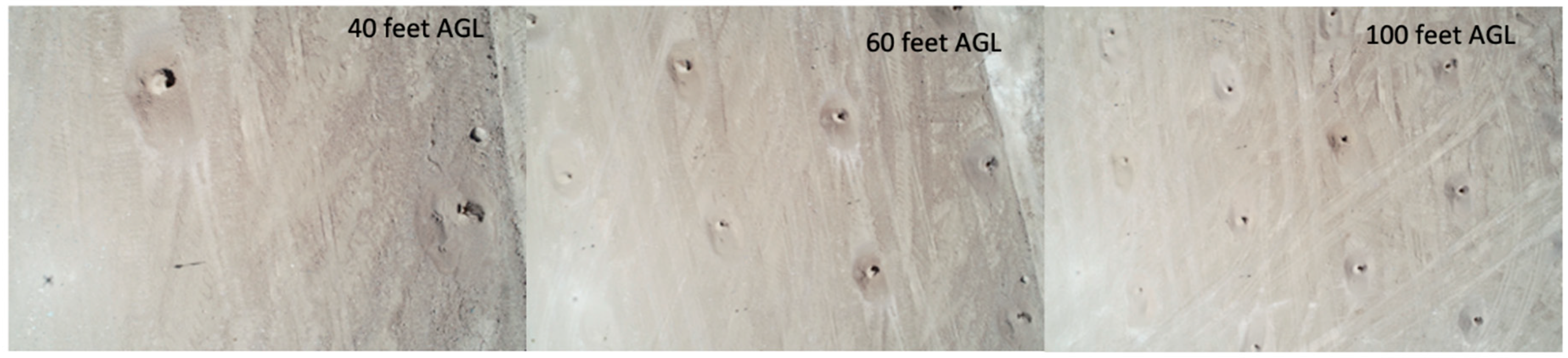

3.2. Data Acquisition

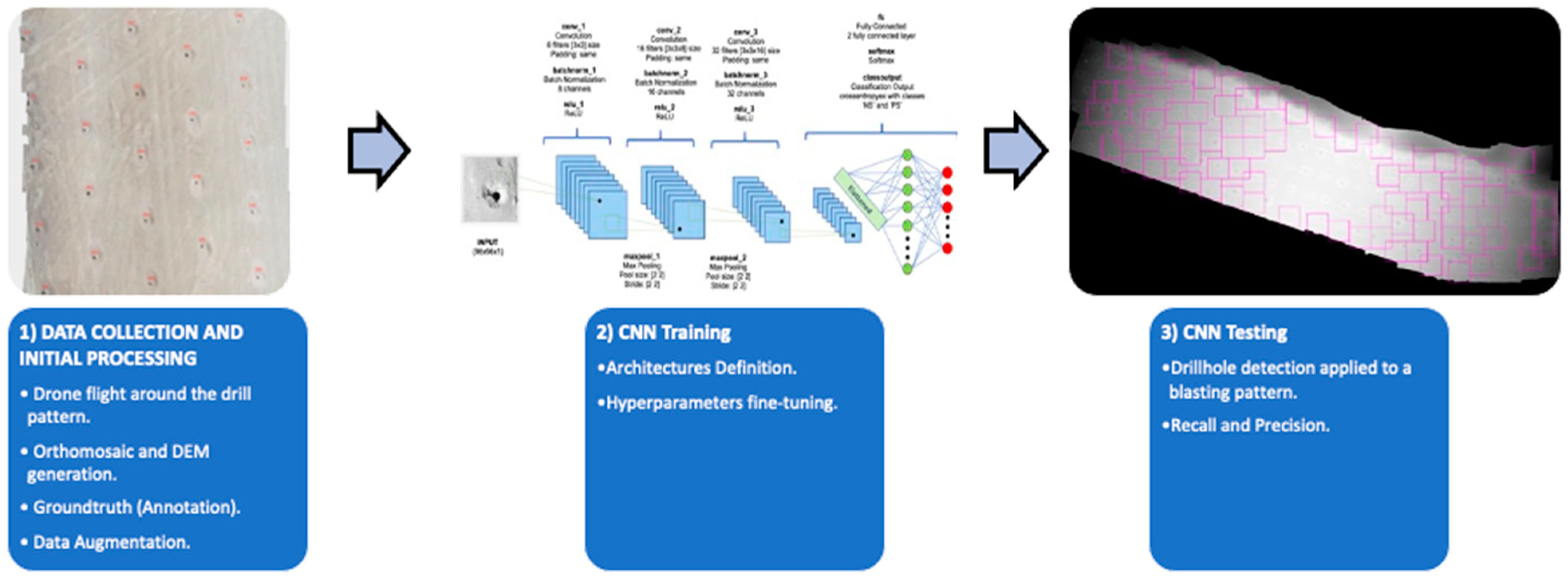

3.3. Data Processing

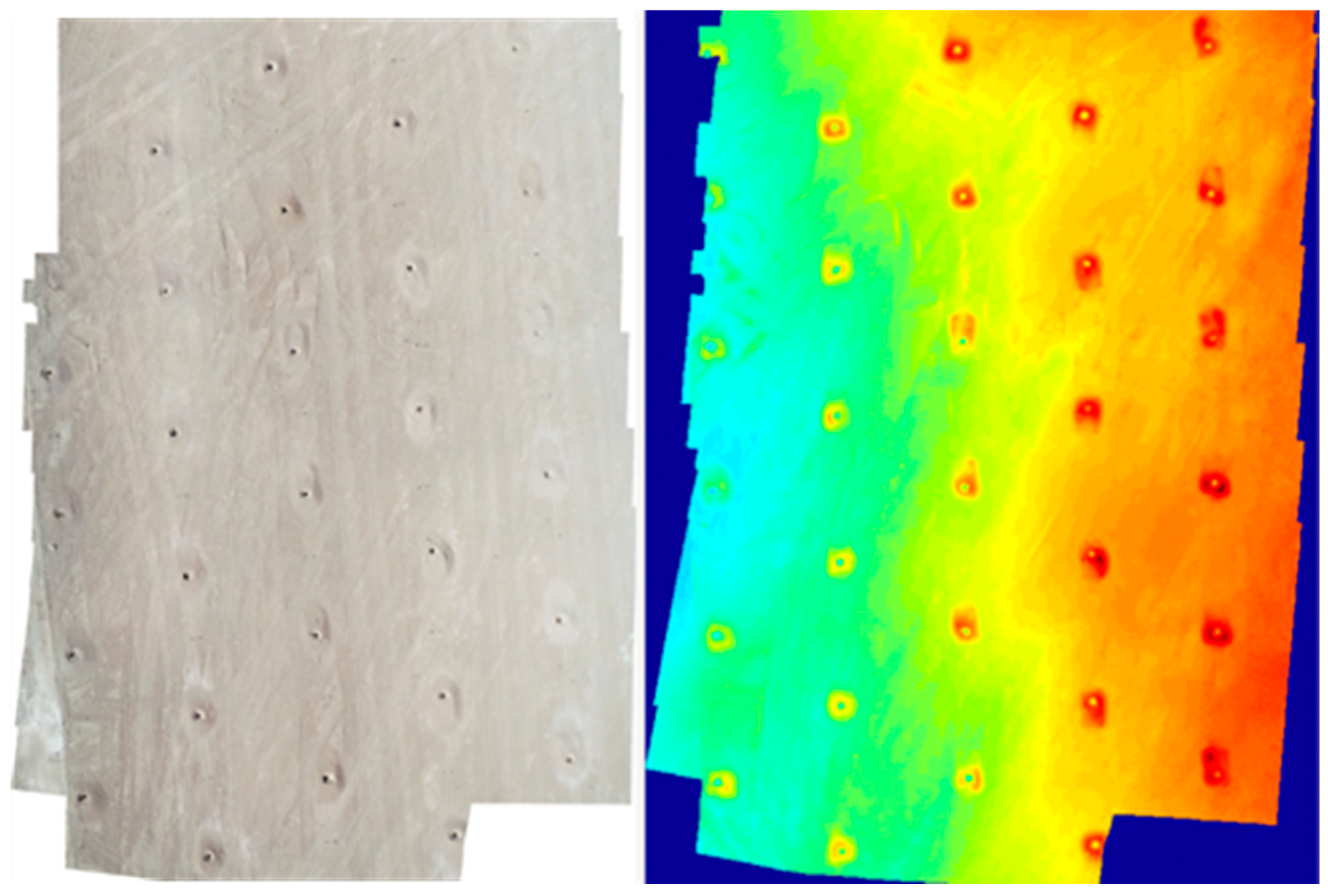

3.3.1. Photogrammetry

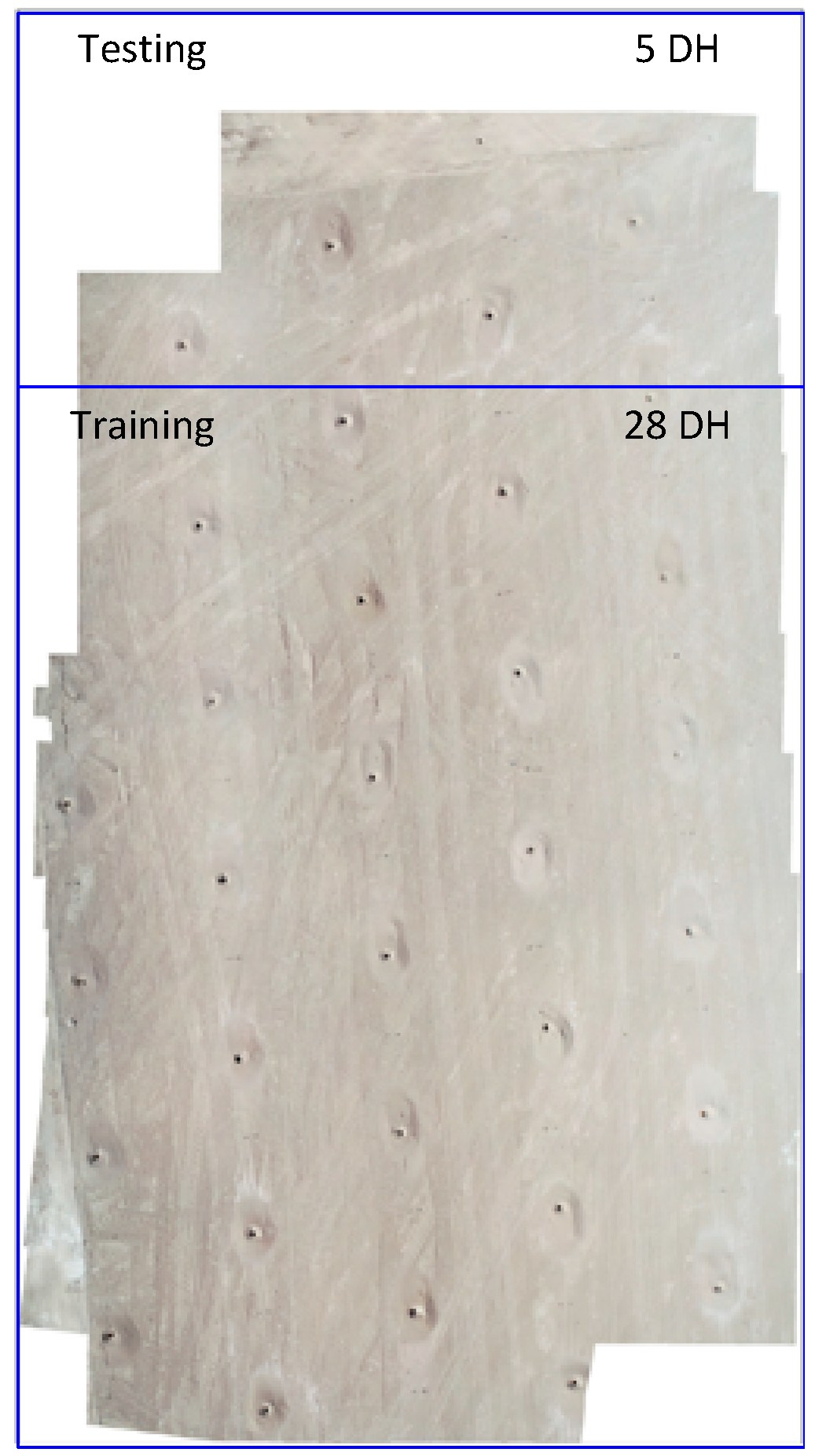

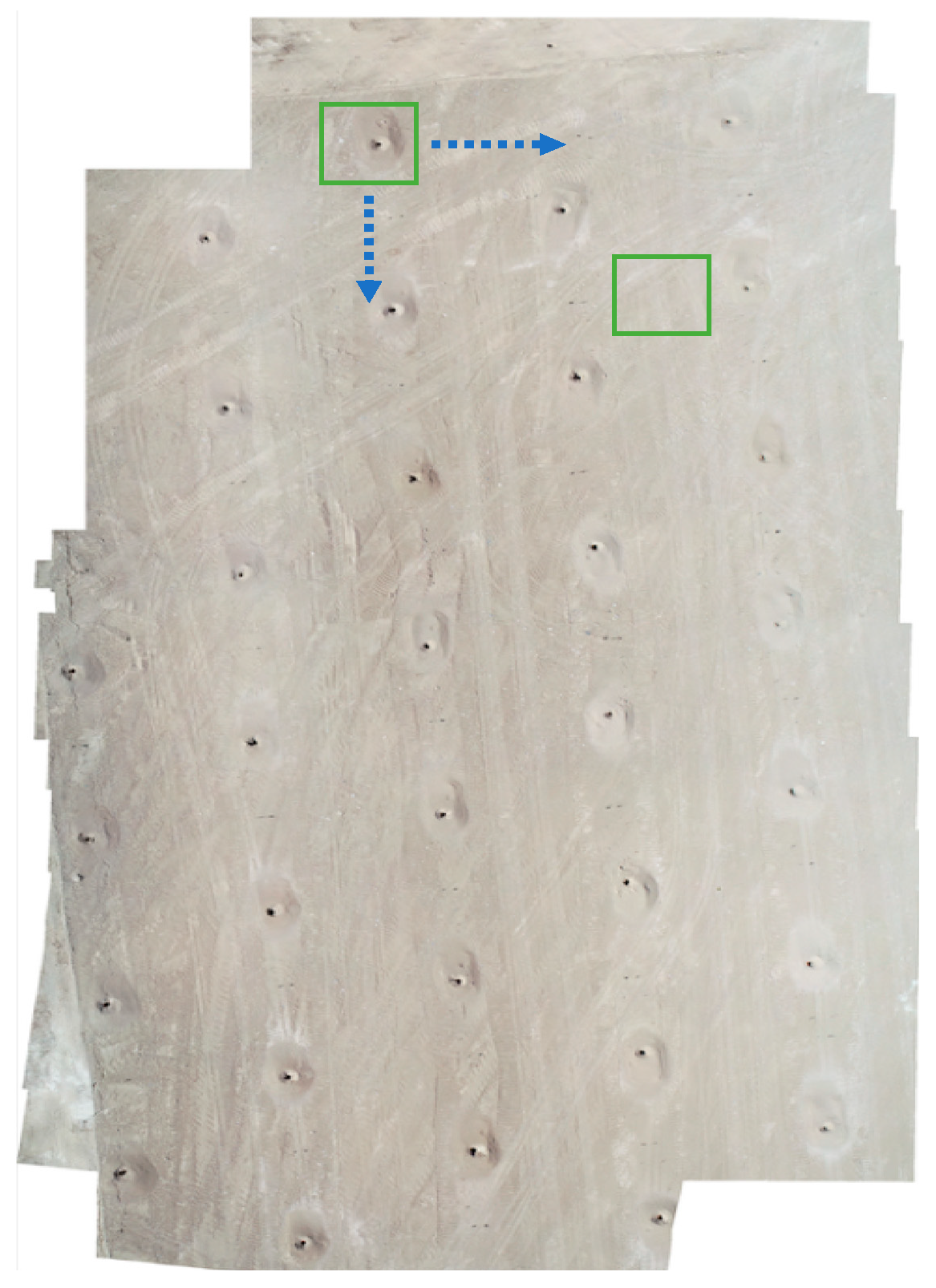

3.3.2. The Definition of Training and Testing Areas

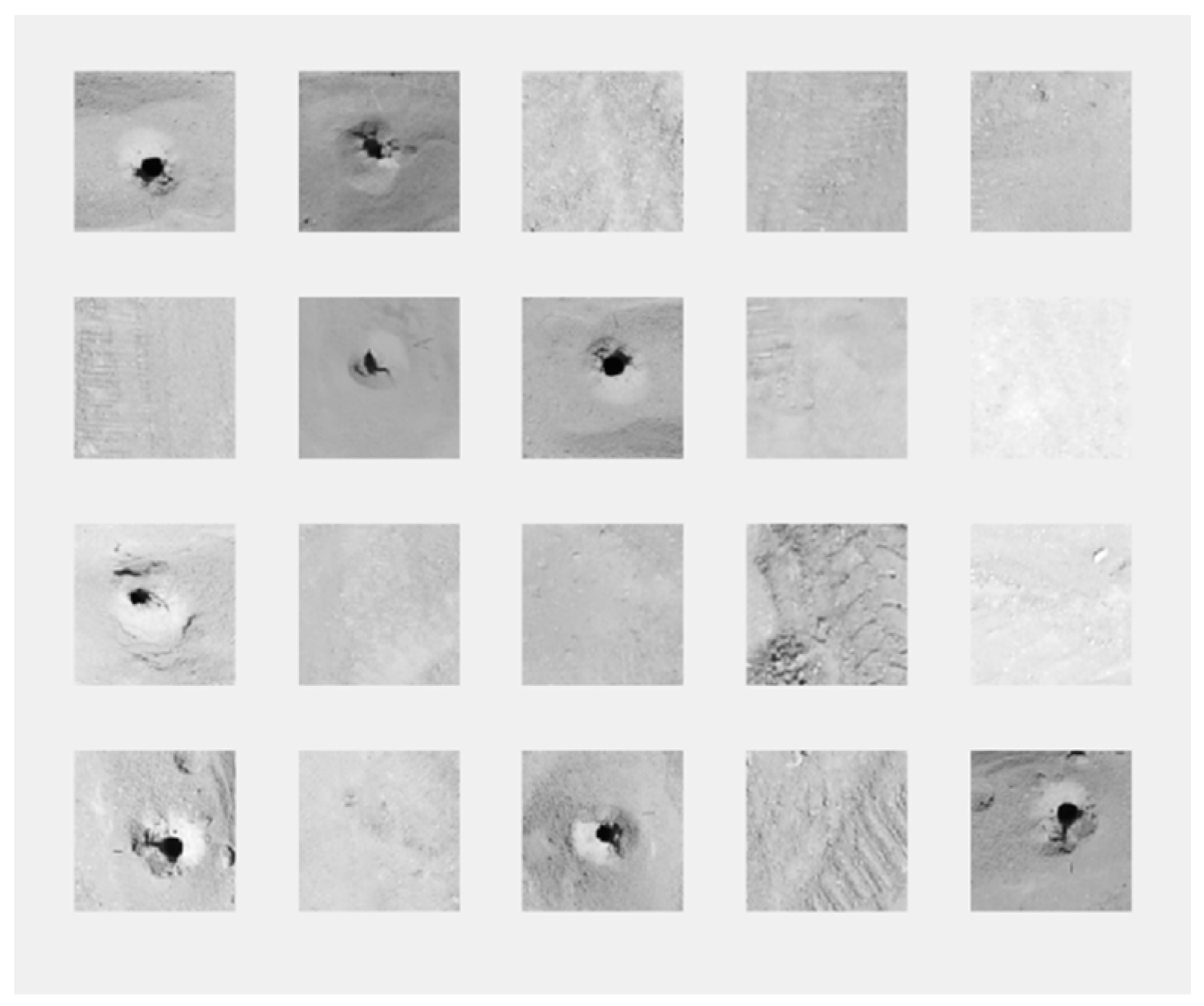

3.3.3. Positive and Negative Samples Generation

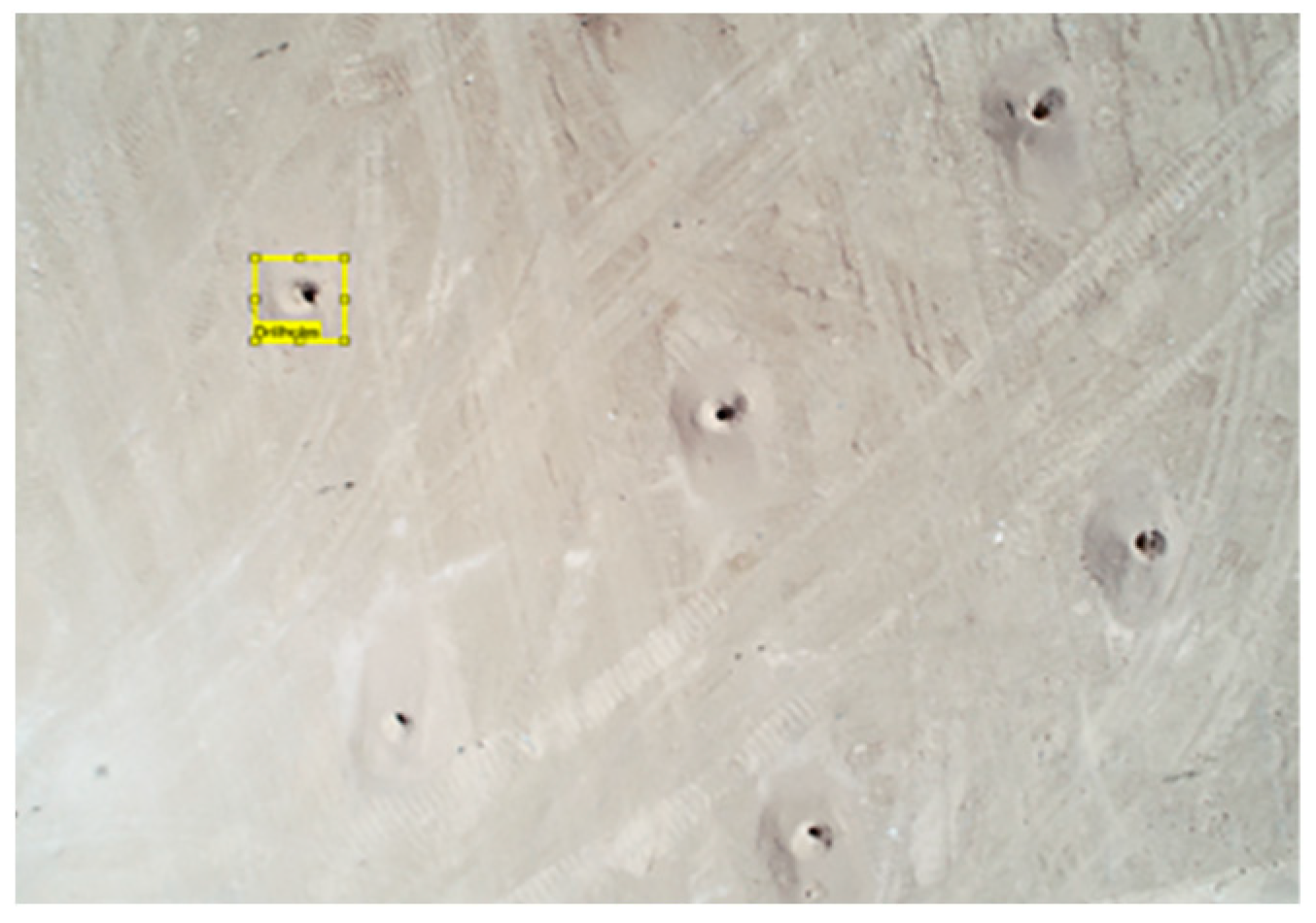

3.3.4. Sliding Window

3.3.5. Data Augmentation

3.3.6. Training SVM

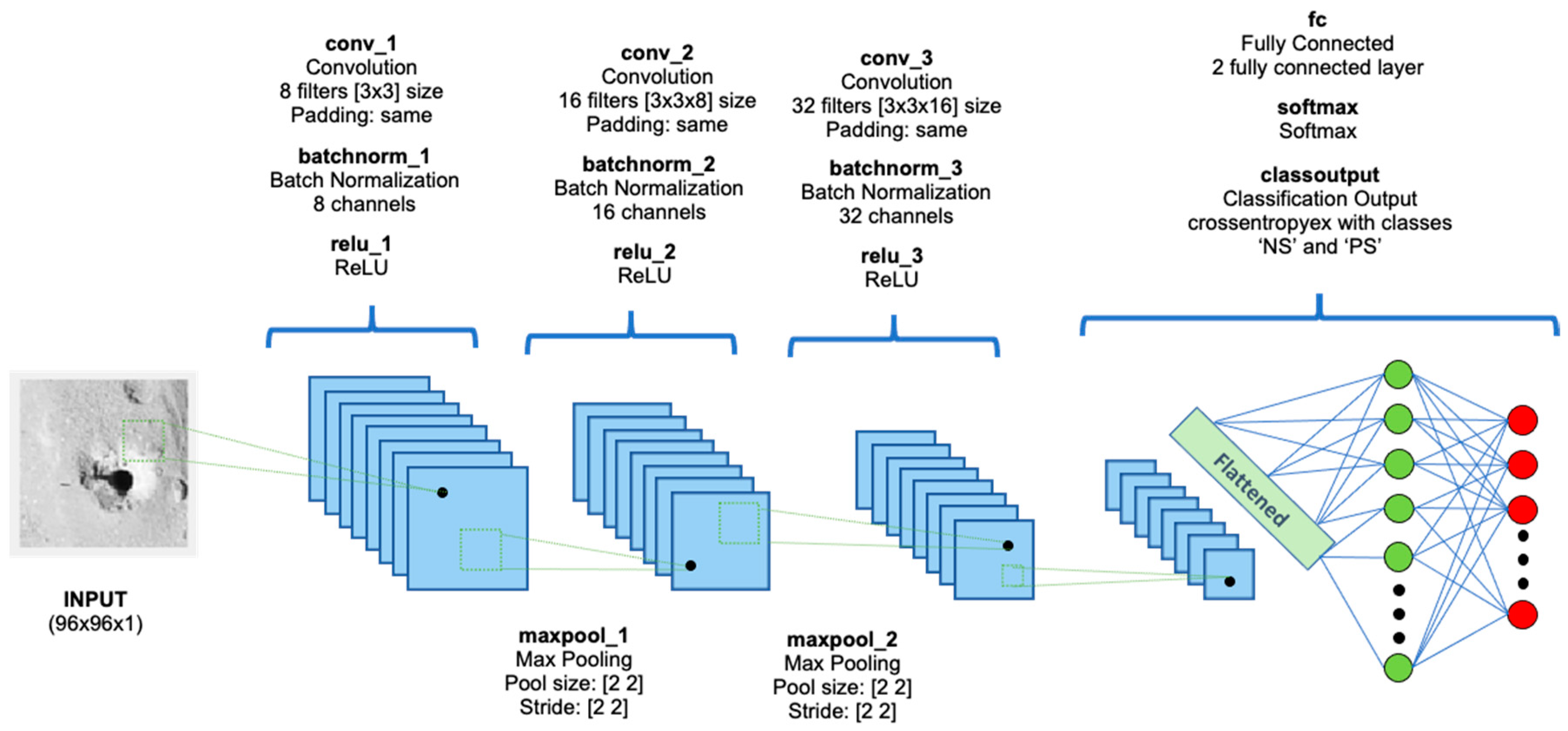

3.3.7. Training Convolutional Neural Networks (CNN)

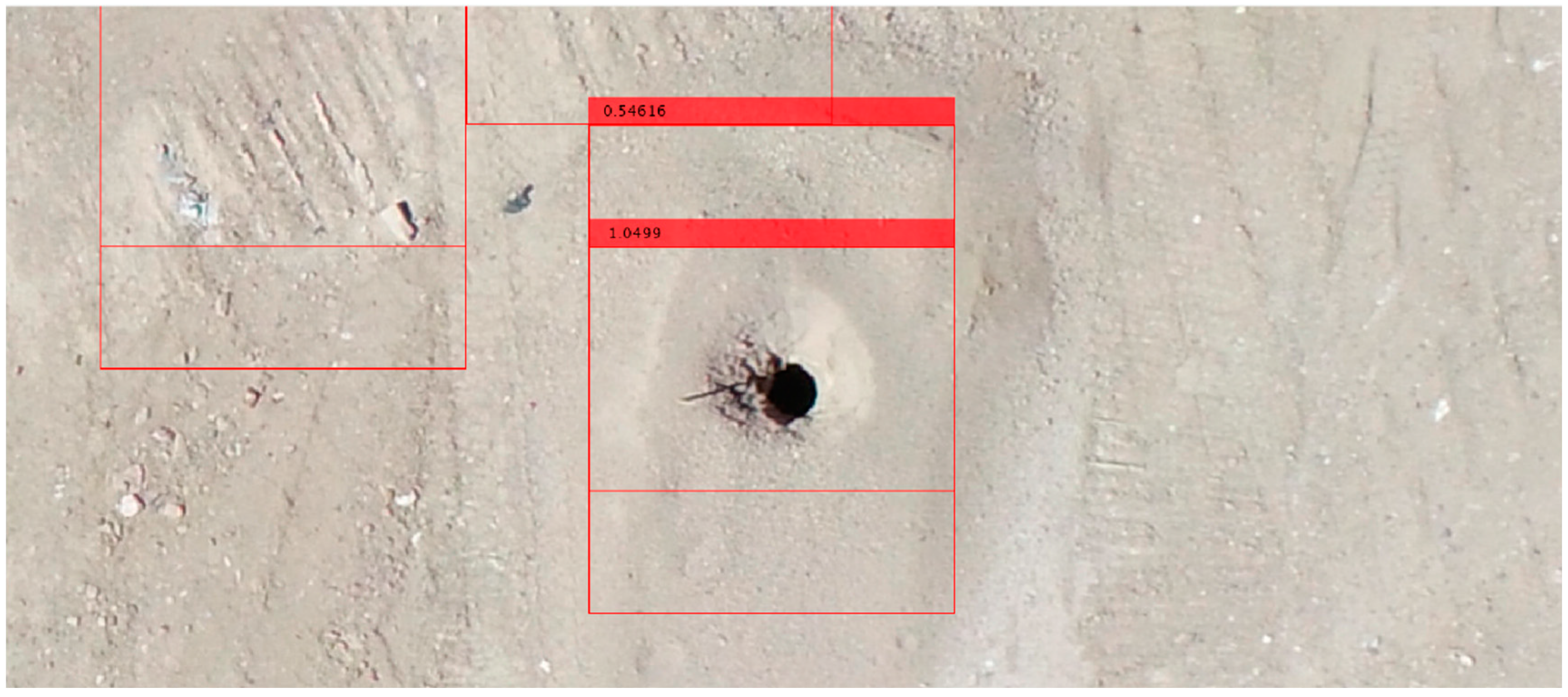

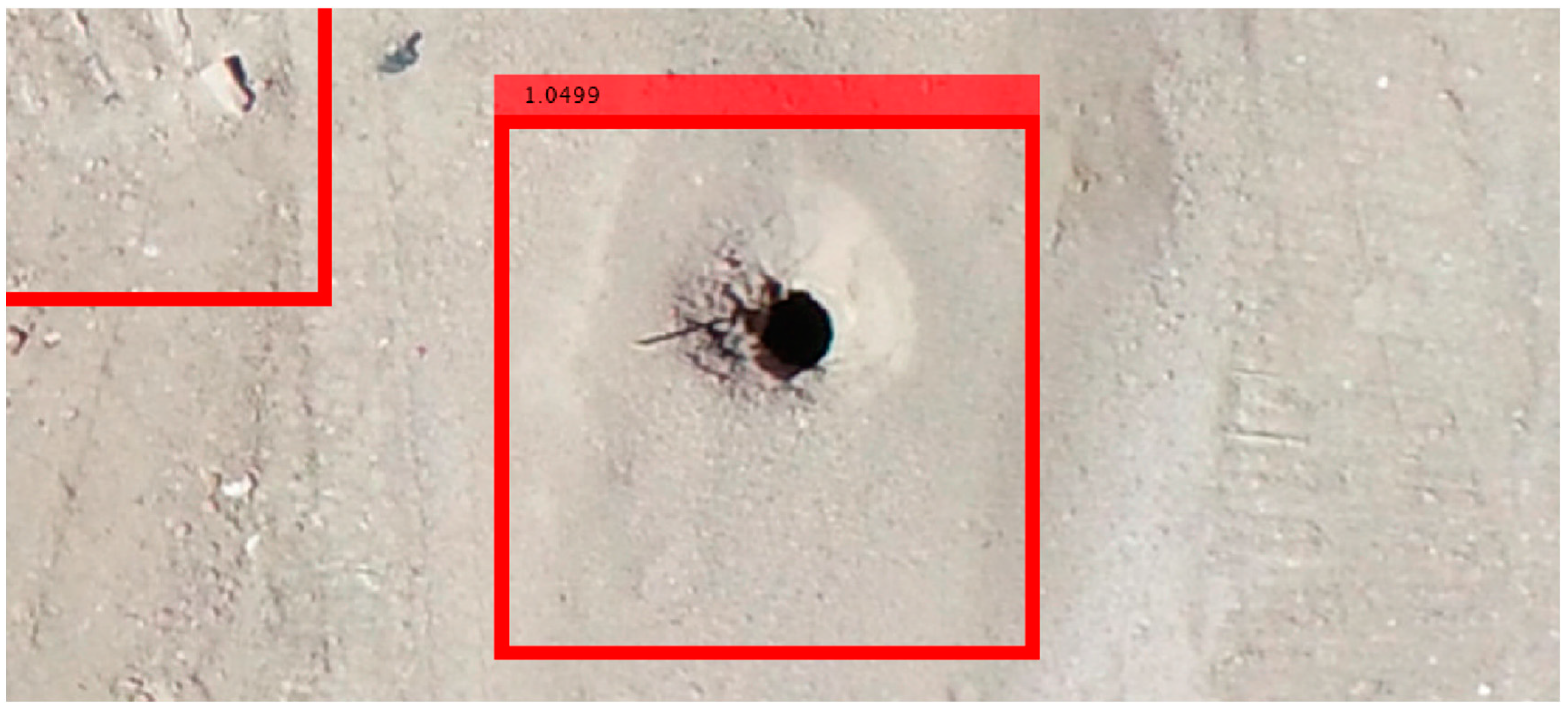

3.3.8. Testing SVM/CNN

4. Results and Discussion

4.1. Single Dataset

4.1.1. SVM—Orthomosaic

4.1.2. SVM—DEM

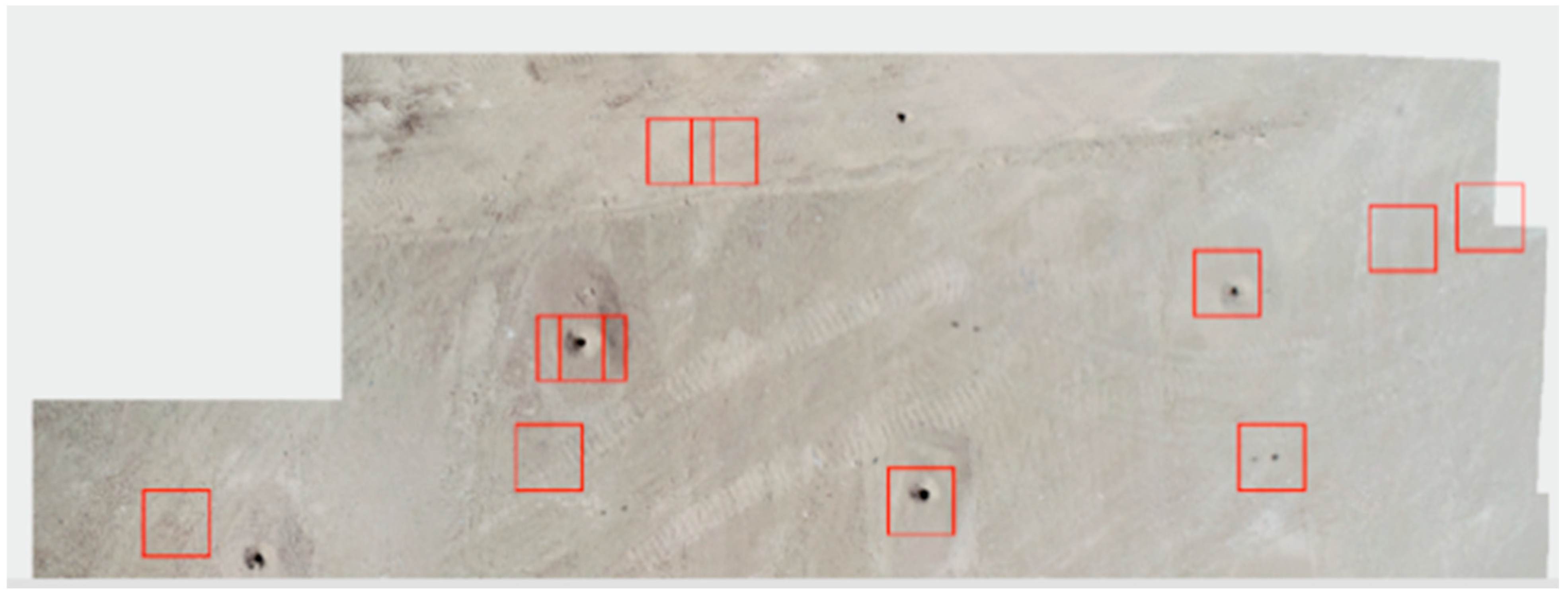

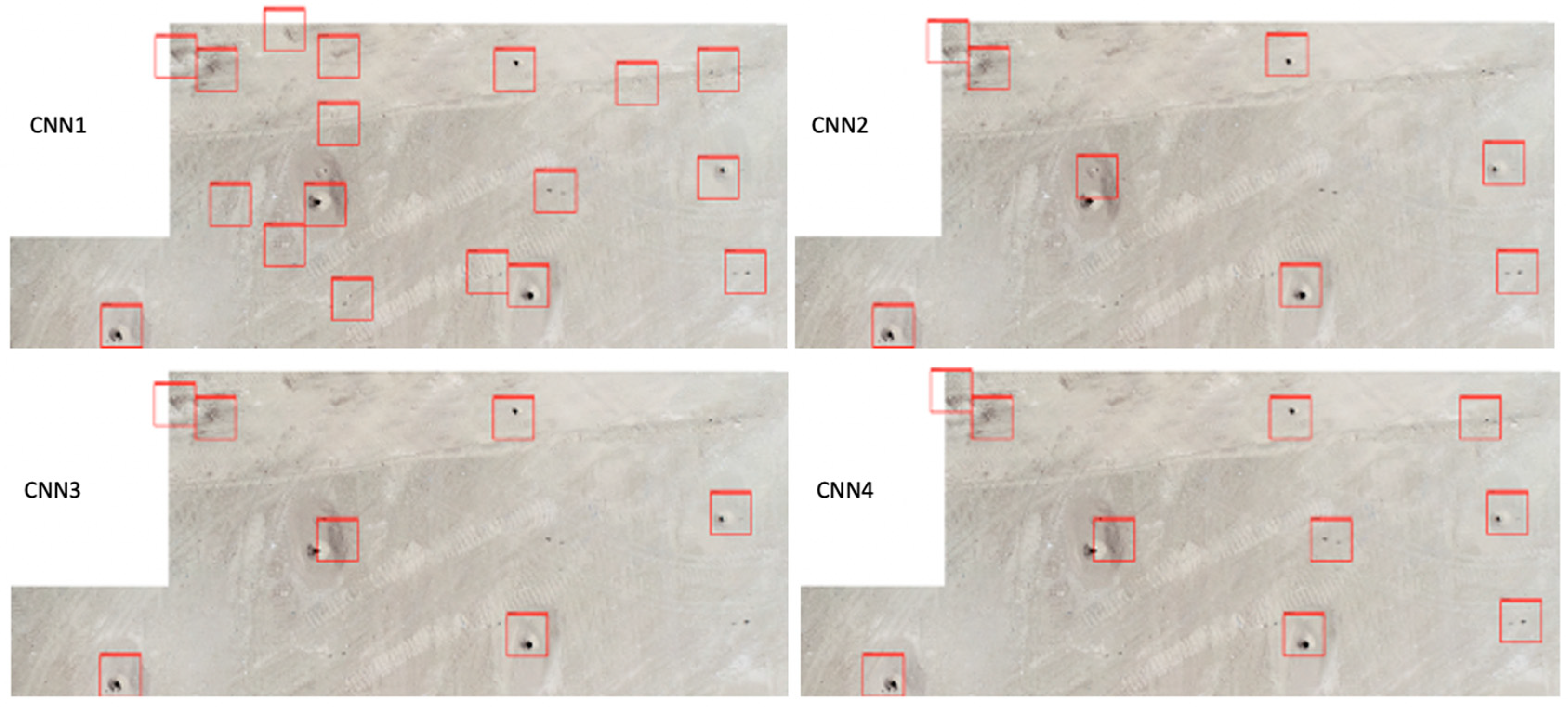

4.1.3. CNN—Orthomosaic

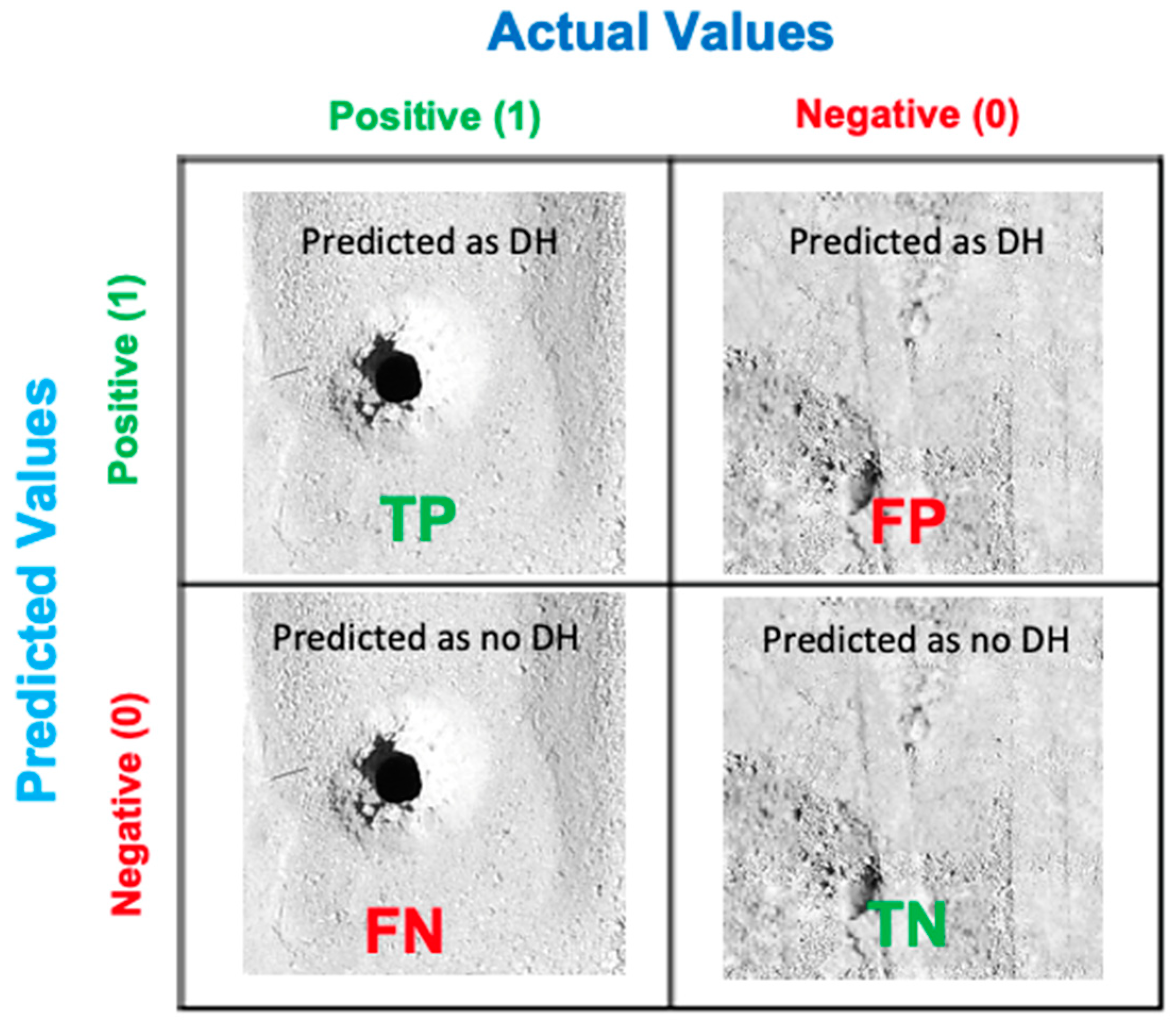

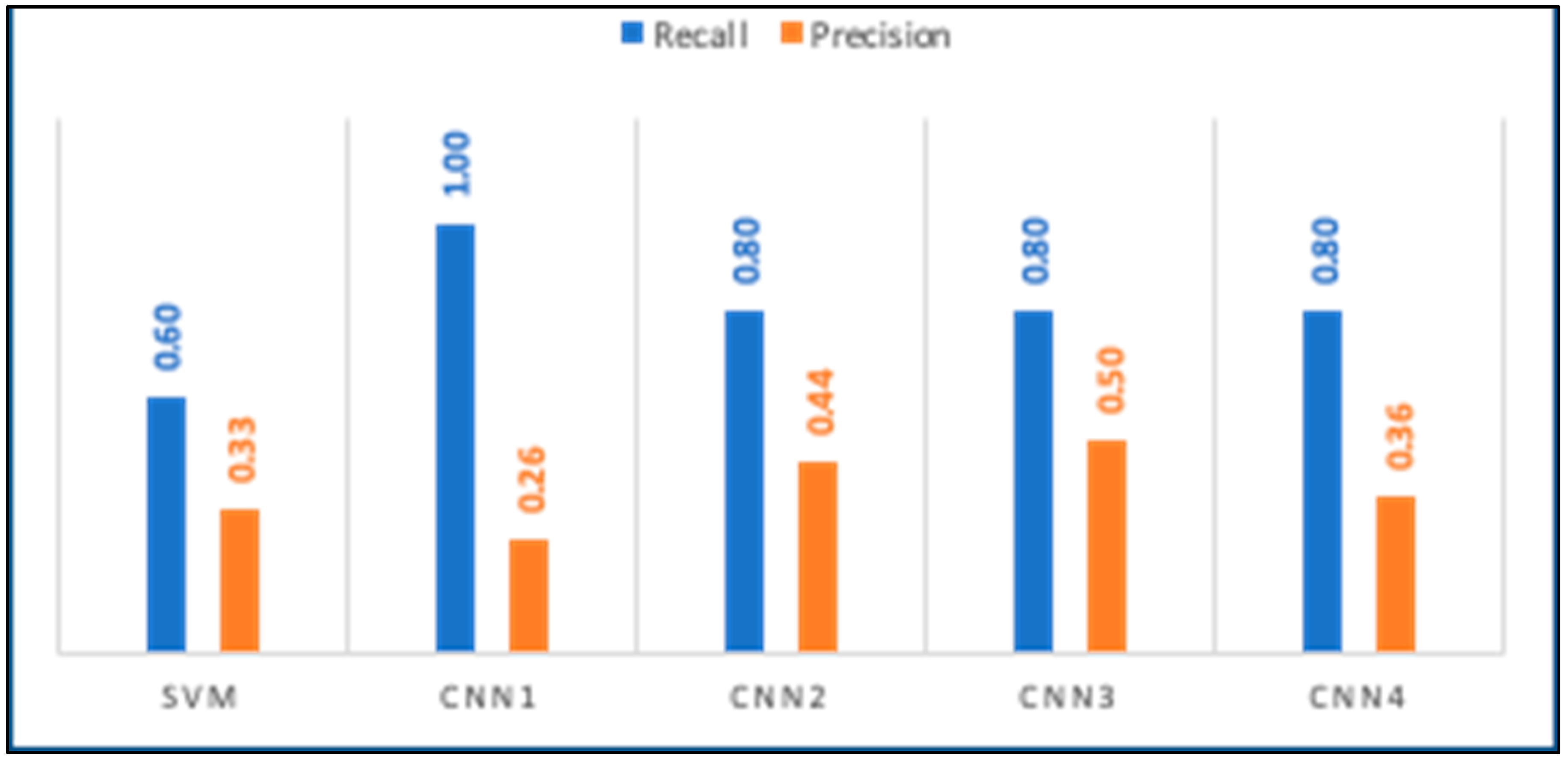

4.1.4. Recall and Precision

- -

- True Positive (TP): Predicted as blasthole when it is a blasthole.

- -

- True Negative (TN): Predicted as no-blasthole when it is not a blasthole.

- -

- False Positive (FP): Predicted as blasthole, but it is not a blasthole.

- -

- False Negative (FN): Predicted as no-blasthole, but it is a blasthole.

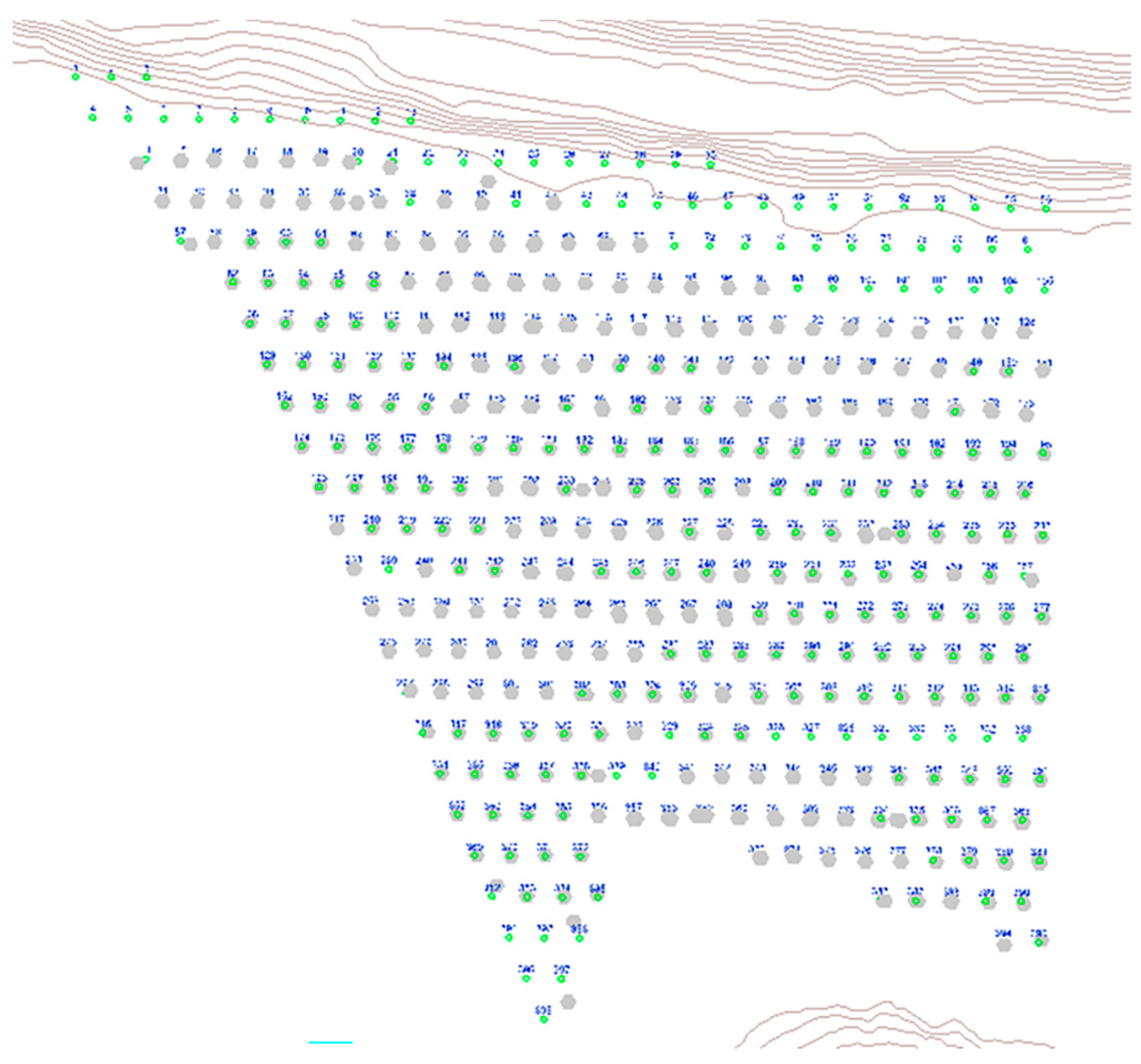

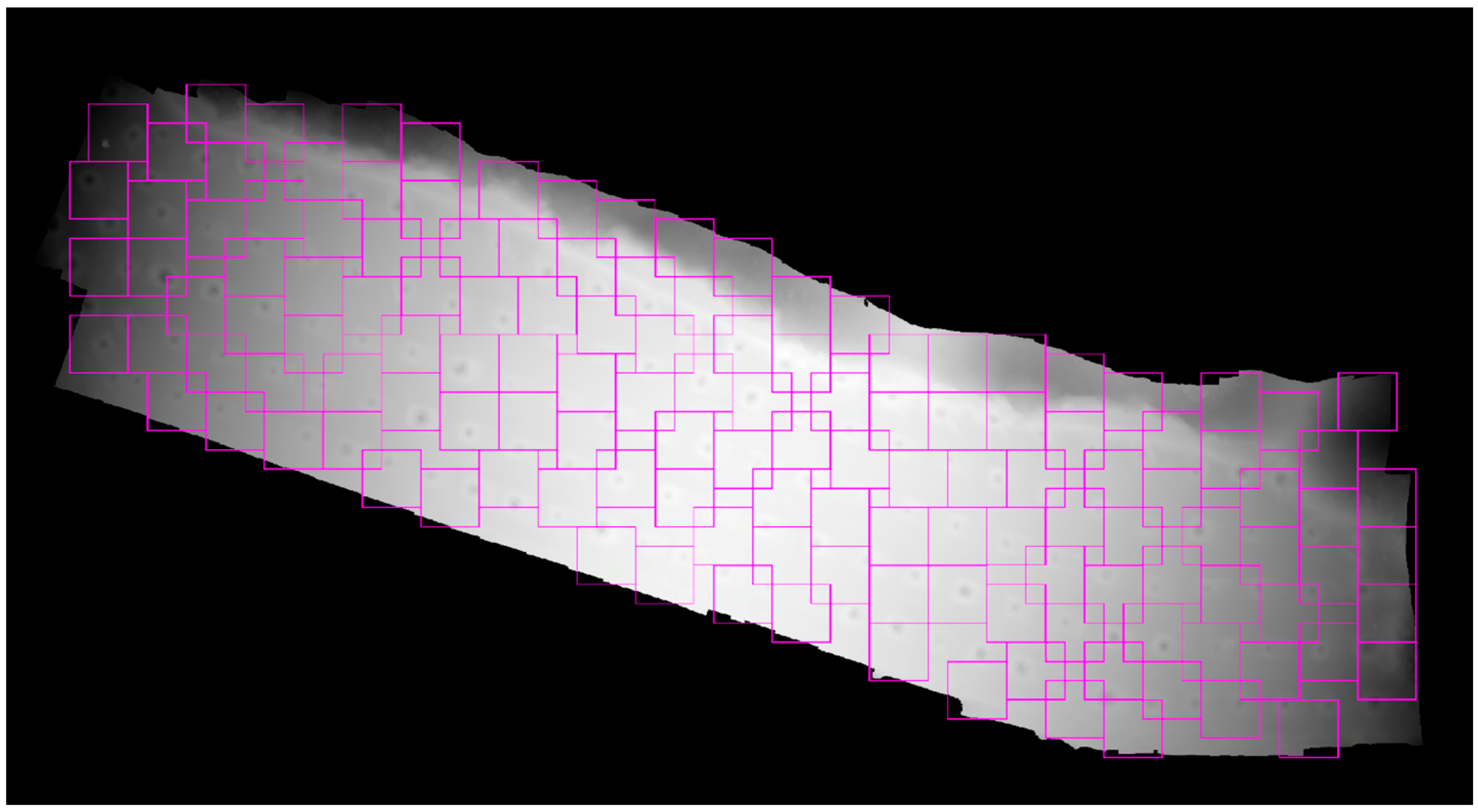

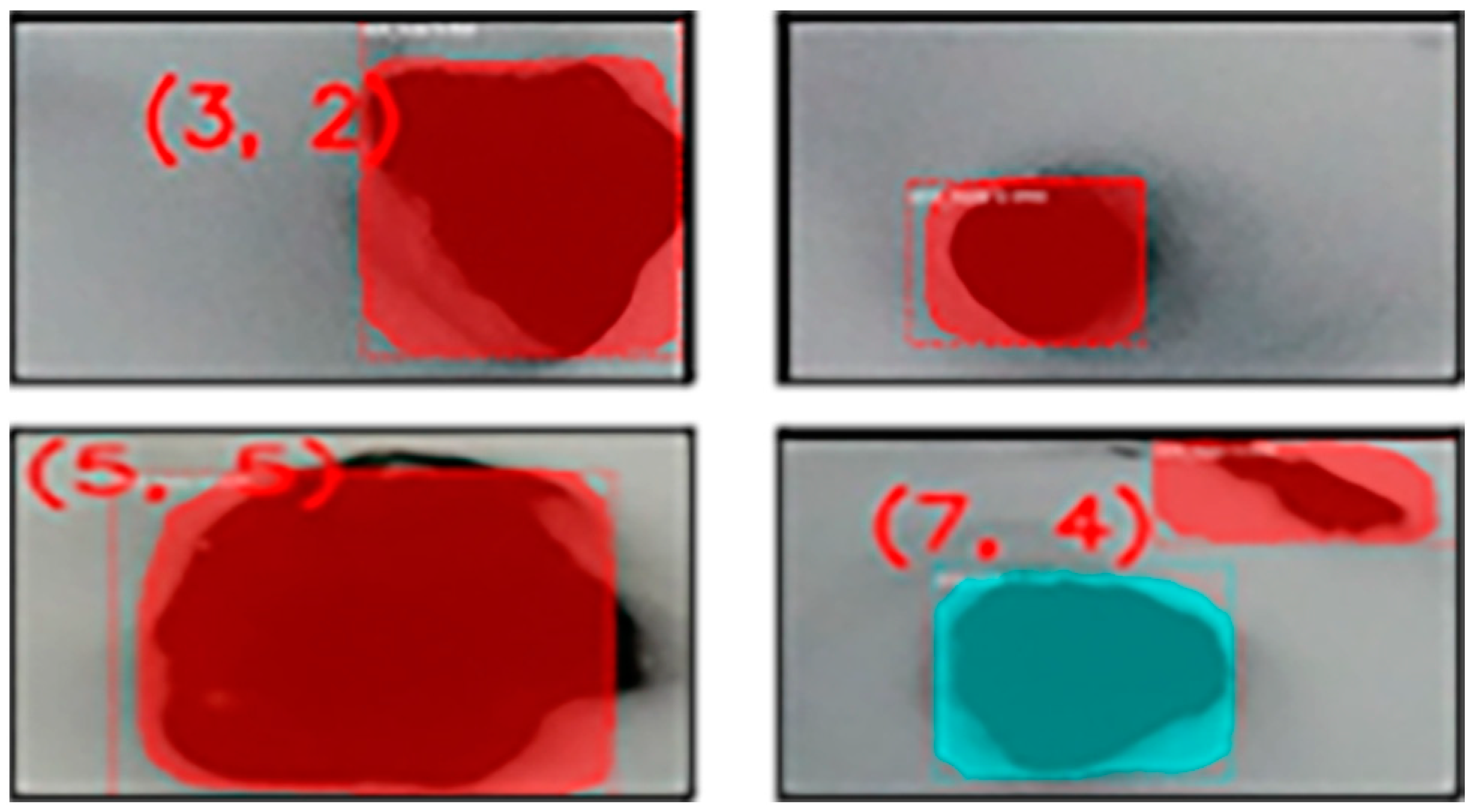

4.2. Multiple Datasets

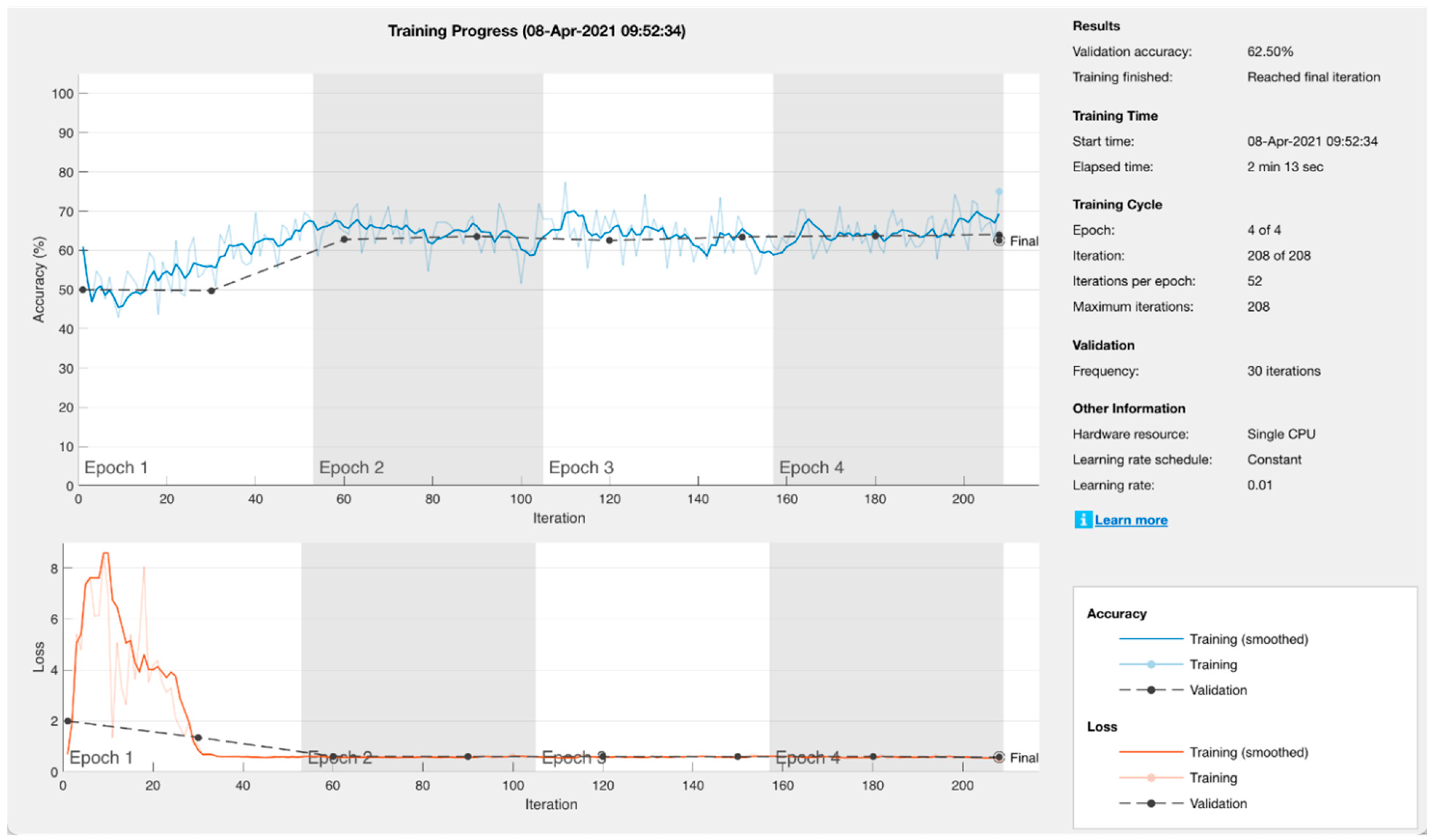

CNN—DEM

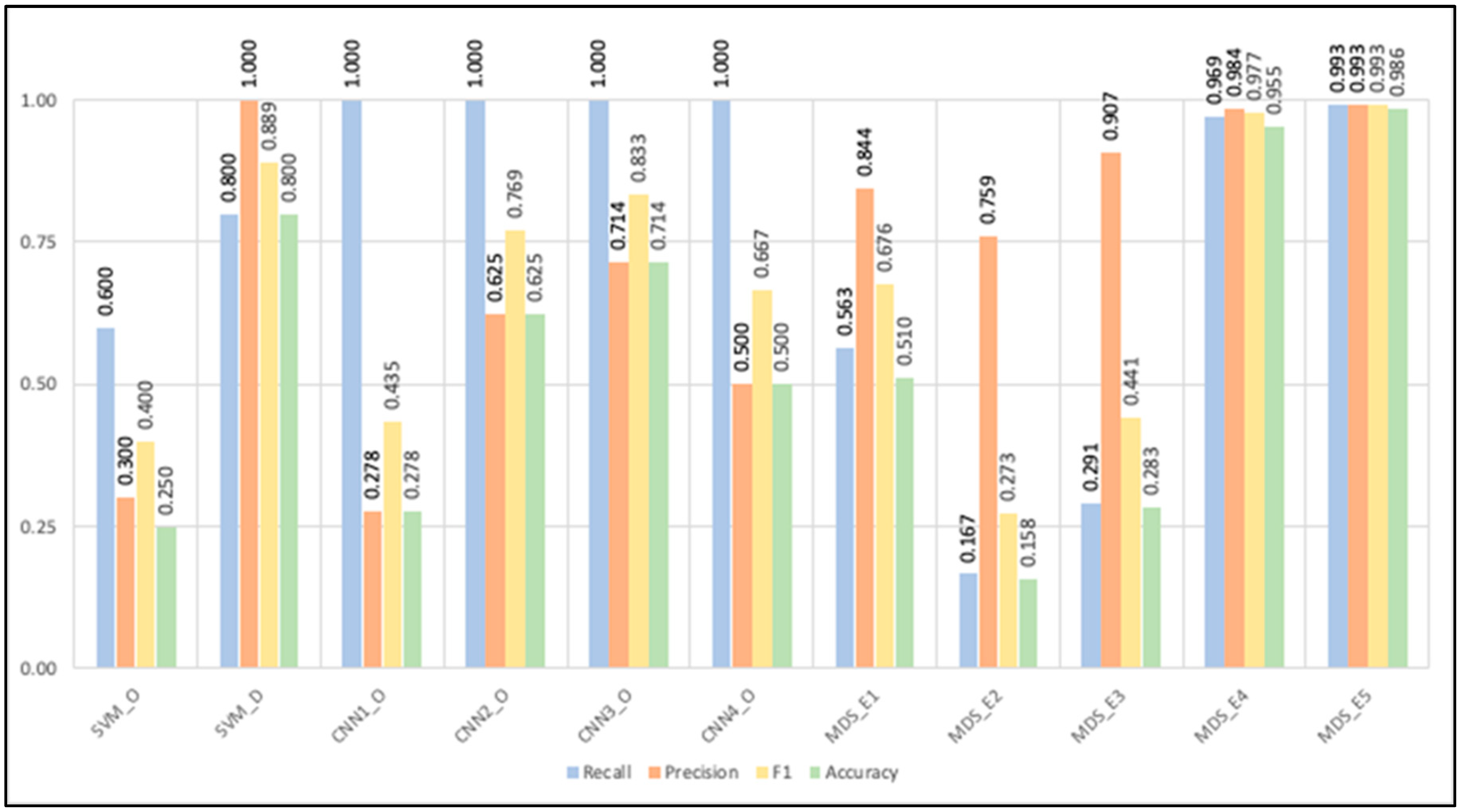

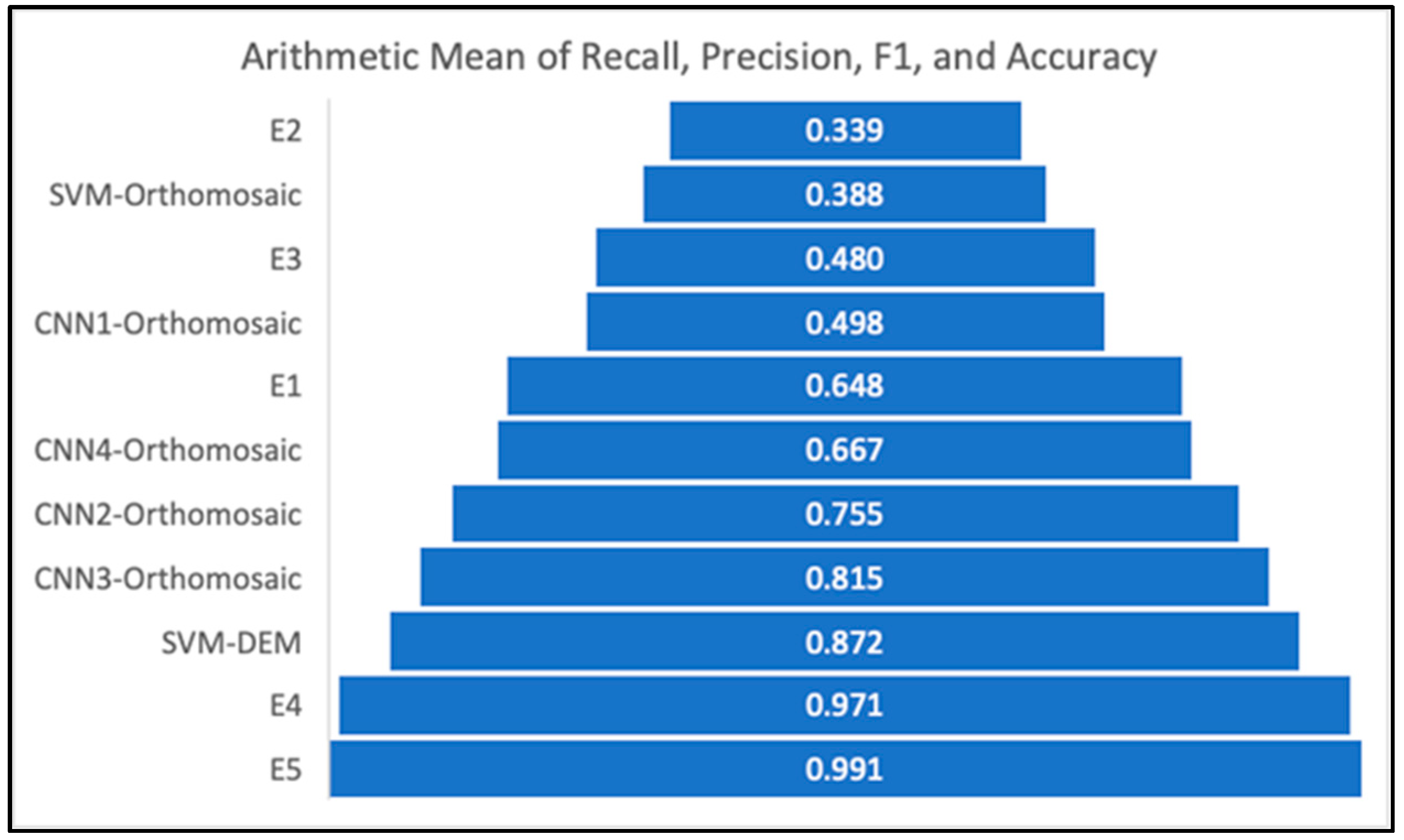

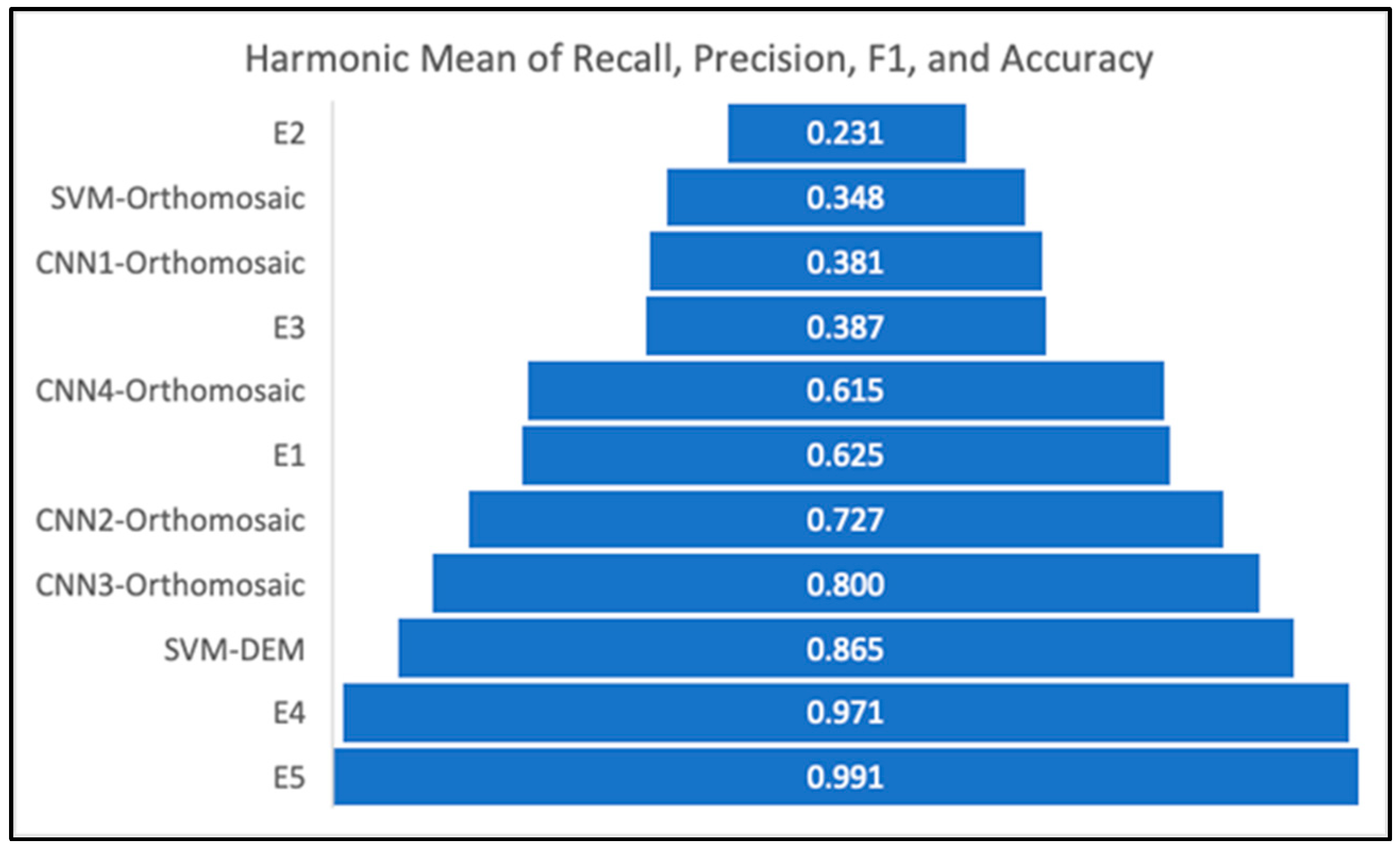

4.3. Performance Analysis of All Experiments

4.4. Detection of Snow-Covered Drill Holes Using CNN

5. Conclusions

- Blasthole detection using drones and machine learning aims to be a complementary or supplementary way to identify the ultimate location of blastholes and improve the distribution of explosive energy in the blasting process.

- The proposed solution in this study can be used in open-pit mines for drilling accuracy control, enabling drill and blast engineers to simulate and adjust blasting parameters, optimizing blasting results, and improving the safety of the process.

- The research offers a new way to control the drilling accuracy in open-pit mines (not just surveys and GPS mounted over the drill rigs).

- The experiment results demonstrated that it could be possible to automatically detect blastholes on aerial images (captured through a drone) under different seasonal conditions, using Support Vector Machine and Convolutional Neural Networks in open-pit mines.

- The proposed solution provides a way to control drilling accuracy deviations in blast patterns. These inaccuracies occur for several reasons: signal loss in certain mine areas (known as blind spots), operational factors such as drilling near pit edges, or overbreaking resulting from previously blasted patterns.

- Another potential application of this research is to define the extension of the polygon blasted for ore control purposes.

- With a single dataset, detection results using SVM over DEM yielded better results than SVM with Orthomosaic representations, but the best results for the single dataset were obtained using Convolutional Neural Networks and Orthomosaic.

- In the case of multiple datasets, the most favorable results were obtained in experiment E5, wherein all 139 blastholes were detected. This process was accomplished using normalized elevation values and specific hyperparameters: 81% of the data for training, 19% for testing, a learning rate of 0.1, and 4 epochs.

- Hyperparameter tuning was the most time-consuming activity during the training of the CNN-DEM architectures because of the high amount of information in the datasets.

- In this machine learning application, prioritizing the detection of blastholes, the percentage of detected holes proves to be a more representative metric compared to the conventional recall and precision metrics. The final goal of the study is to identify as many blastholes as possible.

- In this study, the percentage of detected holes was the best performance metric. This issue differs from typical deep learning applications in computer vision, where recall and precision are commonly used as performance metrics.

- Future work will involve collecting data from various mine sites encompassing different rock formations, drilling diameters, and weather conditions to develop models capable of detecting blastholes across diverse environments.

- Additionally, exploring the utility of the images captured for blasthole detection for other applications, such as delineating blasting overbreak and estimating the volume and tonnage of blast patterns, presents an avenue for further research and application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

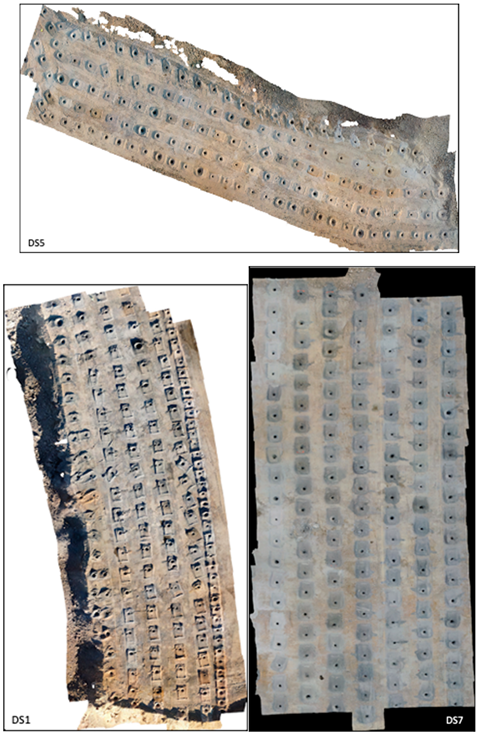

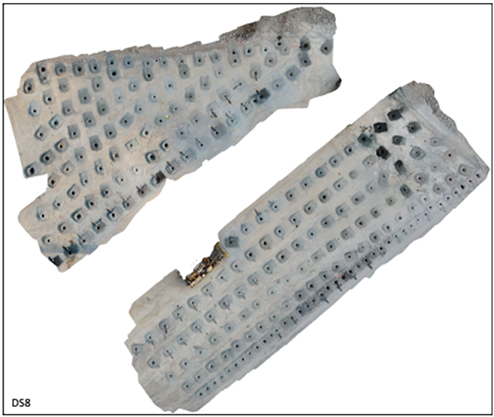

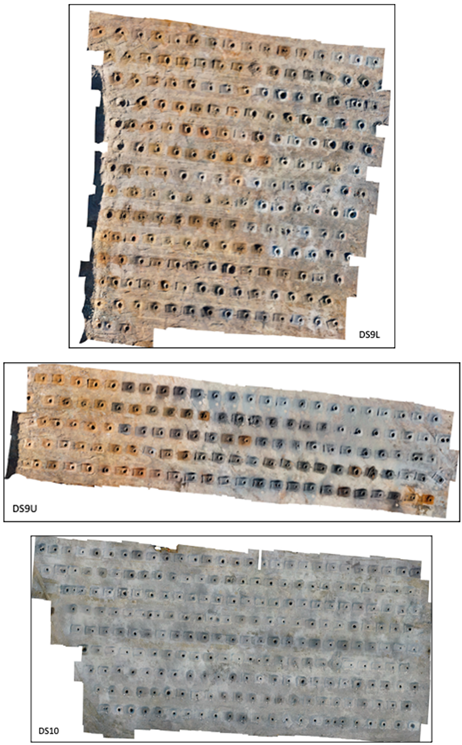

Appendix A. Datasets

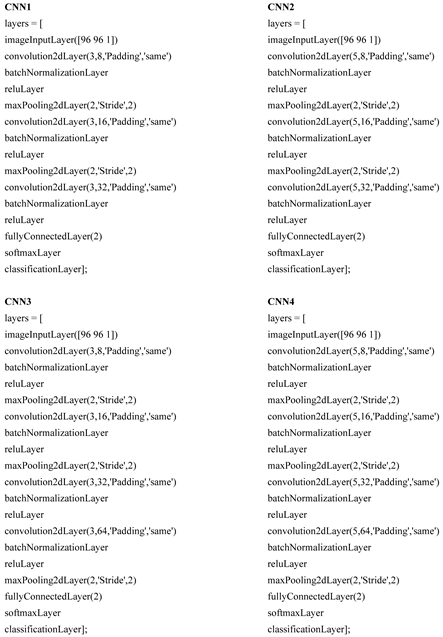

Appendix B. CNN Networks

References

- Bamford, T.; Medinac, F.; Esmaeili, K. Continuous monitoring and improvement of the blasting process in open pit mines using unmanned aerial vehicle techniques. Remote Sens. 2020, 12, 2801. [Google Scholar] [CrossRef]

- Girard, J.M.; McHugh, E. Detecting Problems with Mine Slope Stability. In Proceedings of the Thirty-First Annual Institute on Mining Health, Safety and Research, Roanoke, VA, USA, 27–30 August 2000. [Google Scholar]

- Kamran-Pishhesari, A.; Moniri-Morad, A.; Sattarvand, J. Applications of 3D Reconstruction in Virtual Reality-Based Teleoperation: A Review in the Mining Industry. Technologies 2024, 12, 40. [Google Scholar] [CrossRef]

- Marsh, E.; Dahl, J.; Kamran Pishhesari, A.; Sattarvand, J.; Harris, F.C., Jr. A Virtual Reality Mining Training Simulator for Proximity Detection. In Proceedings of the International Conference on Information Technology-New Generations, Las Vegas, NV, USA, 24 April 2023; pp. 387–393. [Google Scholar]

- A Step Change in Mining Productivity|AusIMM Bulletin. 2015. Available online: https://search.informit.org/doi/abs/10.3316/ielapa.156763317610968 (accessed on 10 July 2021).

- GPS.gov: GPS Accuracy. (n.d.). Available online: https://www.gps.gov/systems/gps/performance/accuracy/ (accessed on 11 July 2022).

- de Ingeniería, F.; Patricio Valencia López Profesor Guía, J.; Humberto Contreras Moreno, E. Evaluación de Alternativas de Perforación y Tronadura Para el Mejoramiento de la Fragmentación; Mina Los Filos: Estado de Guerrero, México, 2015. [Google Scholar]

- The Hole Story: The Benefits of Drill and Blast|Engineer Live. (n.d.). Available online: https://www.engineerlive.com/content/hole-story-benefits-drill-and-blast (accessed on 10 July 2022).

- Pan, S.; Tian, Z.; Qin, Y.; Yue, Z.; Yu, T. Intelligent Blasthole Detection of Roadway Working Face Based on Improved YOLOv7 Network. Appl. Sci. 2023, 13, 6587. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, H.; Liu, Y.; Xu, Q.; Liu, G. A Semi-Supervised Semantic Segmentation Method for Blast-Hole Detection. Symmetry 2022, 14, 653. [Google Scholar] [CrossRef]

- Arthur, C.K.; Temeng, V.A.; Ziggah, Y.Y. Soft computing-based technique as a predictive tool to estimate blast-induced ground vibration. J. Sustain. Min. 2019, 18, 287–296. [Google Scholar] [CrossRef]

- Azimi, Y.; Khoshrou, S.H.; Osanloo, M. Prediction of blast induced ground vibration (BIGV) of quarry mining using hybrid genetic algorithm optimized artificial neural network. Measurement 2019, 147, 106874. [Google Scholar] [CrossRef]

- Dong, L.; Li, X.; Xu, M.; Li, Q. Comparisons of Random Forest and Support Vector Machine for Predicting Blasting Vibration Characteristic Parameters. Procedia Eng. 2011, 26, 1772–1781. [Google Scholar] [CrossRef]

- Hajihassani, M.; Jahed Armaghani, D.; Sohaei, H.; Tonnizam Mohamad, E.; Marto, A. Prediction of airblast-overpressure induced by blasting using a hybrid artificial neural network and particle swarm optimization. Appl. Acoust. 2014, 80, 57–67. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Monjezi, M.; Shahnazar, A.; Jahed Armaghani, D.; Farazmand, A. Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 2015, 75, 289–297. [Google Scholar] [CrossRef]

- Khandelwal, M.; Kankar, P.K.; Harsha, S.P. Evaluation and prediction of blast induced ground vibration using support vector machine. Min. Sci. Technol. China 2010, 20, 64–70. [Google Scholar] [CrossRef]

- Khandelwal, M.; Singh, T.N. Prediction of blast-induced ground vibration using artificial neural network. Int. J. Rock Mech. Min. Sci. 2009, 46, 1214–1222. [Google Scholar] [CrossRef]

- Kulatilake, P.H.; Qiong, W.; Hudaverdi, T.; Kuzu, C. Mean particle size prediction in rock blast fragmentation using neural networks. Eng. Geol. 2010, 114, 298–311. [Google Scholar] [CrossRef]

- Lary, D.J.; Alavi, A.H.; Gandomi, A.H.; Walker, A.L. Machine learning in geosciences and remote sensing. Geosci. Front. 2016, 7, 3–10. [Google Scholar] [CrossRef]

- Liu, K.; Liu, B. Optimization of smooth blasting parameters for mountain tunnel construction with specified control indices based on a GA and ISVR coupling algorithm. Tunn. Undergr. Space Technol. 2017, 70, 363–374. [Google Scholar] [CrossRef]

- Monjezi, M.; Bahrami, A.; Yazdian Varjani, A. Simultaneous prediction of fragmentation and flyrock in blasting operation using artificial neural networks. Int. J. Rock Mech. Min. Sci. 2010, 47, 476–480. [Google Scholar] [CrossRef]

- Mottahedi, A.; Sereshki, F.; Ataei, M. Overbreak prediction in underground excavations using hybrid ANFIS-PSO model. Tunn. Undergr. Space Technol. 2018, 80, 1–9. [Google Scholar] [CrossRef]

- Pu, Y.; Apel, D.B.; Liu, V.; Mitri, H. Machine learning methods for rockburst prediction-state-of-the-art review. Int. J. Min. Sci. Technol. 2019, 29, 565–570. [Google Scholar] [CrossRef]

- Shang, X.; Li, X.; Morales-Esteban, A.; Chen, G. Improving microseismic event and quarry blast classification using Artificial Neural Networks based on Principal Component Analysis. Soil Dyn. Earthq. Eng. 2017, 99, 142–149. [Google Scholar] [CrossRef]

- Song, G.; Cheng, J.; Grattan, K.T.V. Recognition of Microseismic and Blasting Signals in Mines Based on Convolutional Neural Network and Stockwell Transform. IEEE Access 2020, 8, 45523–45530. [Google Scholar] [CrossRef]

- Temeng, V.A.; Ziggah, Y.Y.; Arthur, C.K. A novel artificial intelligent model for predicting air overpressure using brain inspired emotional neural network. Int. J. Min. Sci. Technol. 2020, 30, 683–689. [Google Scholar] [CrossRef]

- Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Pham, B.T. Prediction of ground vibration induced by blasting operations through the use of the Bayesian Network and random forest models. Soil Dyn. Earthq. Eng. 2020, 139, 106390. [Google Scholar] [CrossRef]

- Amnieh, H.B.; Mozdianfard, M.R.; Siamaki, A. Predicting of blasting vibrations in Sarcheshmeh copper mine by neural network. Saf. Sci. 2010, 48, 319–325. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.N.; Raina, A.K. Prediction of blast-induced flyrock in Indian limestone mines using neural networks. J. Rock Mech. Geotech. Eng. 2014, 6, 447–454. [Google Scholar] [CrossRef]

- Adoko, A.C.; Gokceoglu, C.; Wu, L.; Zuo, Q.J. Knowledge-based and data-driven fuzzy modeling for rockburst prediction. Int. J. Rock Mech. Min. Sci. 2013, 61, 86–95. [Google Scholar] [CrossRef]

- Eades, R.Q.; Perry, K. Understanding the connection between blasting and highwall stability. Int. J. Min. Sci. Technol. 2019, 29, 99–103. [Google Scholar] [CrossRef]

- Shi, X.; Jian, Z.; Wu, B.; Huang, D.; Wei, W.E. Support vector machines approach to mean particle size of rock fragmentation due to bench blasting prediction. Trans. Nonferrous Met. Soc. China 2012, 22, 432–441. [Google Scholar] [CrossRef]

- Oluwoye, I.; Dlugogorski, B.Z.; Gore, J.; Oskierski, H.C.; Altarawneh, M. Atmospheric emission of NOx from mining explosives: A critical review. Atmos. Environ. 2017, 167, 81–96. [Google Scholar] [CrossRef]

- Jha, A.; Tukkaraja, P. (n.d.) Detection of Geological Features Using Aerial Image Analysis and Machine Learning. Available online: https://www.researchgate.net/publication/358566169 (accessed on 11 July 2022).

- Dumakor-Dupey, N.K.; Arya, S.; Jha, A. Advances in Blast-Induced Impact Prediction—A Review of Machine Learning Applications. Minerals 2021, 11, 601. [Google Scholar] [CrossRef]

- Cazzato, D.; Cimarelli, C.; Sanchez-Lopez, J.L.; Voos, H.; Leo, M. A survey of computer vision methods for 2d object detection from unmanned aerial vehicles. J. Imaging 2020, 6, 78. [Google Scholar] [CrossRef]

- Somua-Gyimah, G.; Frimpong, S.; Nyaaba, W.; Gbadam, E. A computer vision system for terrain recognition and object detection tasks in mining and construction environments. In Proceedings of the SME Annual Conference, Denver, CO, USA, 24–27 February 2019. [Google Scholar]

- Maitre, J.; Bouchard, K.; Bédard, L.P. Mineral grains recognition using computer vision and machine learning. Comput. Geosci. 2019, 130, 84–93. [Google Scholar] [CrossRef]

- Marblestone, A.H.; Wayne, G.; Kording, K.P. Toward an Integration of Deep Learning and Neuroscience. Front. Comput. Neurosci. 2016, 10, 94. [Google Scholar] [CrossRef] [PubMed]

- Rosebrock, A. Sliding Windows for Object Detection with Python and Opencv; PylmageSearch, Navigation. 2015. Available online: https://pyimagesearch.com/2015/03/23/sliding-windows-for-object-detection-with-python-and-opencv/ (accessed on 26 March 2024).

- Géron, A. Hands-on Machine Learning with Scikit-Learn, Keras, and TensorFlow. In Hands-On Machine Learning with R; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2017; Volume 510. [Google Scholar]

| Before NMS | ||||||

| Detections | TP | FP | FN | Recall | Precision | |

| SVM | 11 | 3 | 8 | 2 | 0.6000 | 0.2727 |

| CNN1 | 23 | 5 | 18 | 0 | 1.0000 | 0.2174 |

| CNN2 | 20 | 5 | 15 | 0 | 1.0000 | 0.2500 |

| CNN3 | 14 | 5 | 9 | 0 | 1.0000 | 0.3571 |

| CNN4 | 22 | 5 | 17 | 0 | 1.0000 | 0.2273 |

| After NMS | ||||||

| Detections | TP | FP | FN | Recall | Precision | |

| SVM | 9 | 3 | 6 | 2 | 0.6000 | 0.3333 |

| CNN1 | 19 | 5 | 14 | 0 | 1.0000 | 0.2632 |

| CNN2 | 9 | 4 | 5 | 1 | 0.8000 | 0.4444 |

| CNN3 | 8 | 4 | 4 | 1 | 0.8000 | 0.5000 |

| CNN4 | 11 | 4 | 7 | 1 | 0.8000 | 0.3636 |

| Datasets | Number of Holes | Number of Patches |

|---|---|---|

| DS1 | 178 | 1245 |

| DS2 | 353 | 2471 |

| DS5 | 139 | 973 |

| DS7 | 142 | 994 |

| DS8 | 225 | 1575 |

| DS9L | 191 | 1337 |

| DS9U | 125 | 875 |

| DS10 | 220 | 1537 |

| Total | 1573 | 11,007 |

| Layers | Experiment | Training (%) | Testing (%) | Training Datasets | Learning Rate | Epochs | Detections after NMS | % Holes Detected |

|---|---|---|---|---|---|---|---|---|

| 15 | E1 | 80 | 20 | DS1,DS2,DS7,DS10,DS11 | 0.01 | 4 | 85 | 61% |

| E2 | 80 | 20 | DS1,DS2,DS7,DS10,DS11 | 0.001 | 4 | 27 | 19% | |

| E3 | 80 | 20 | DS1,DS2,DS7,DS10,DS11 | 0.001 | 10 | 31 | 22% | |

| E4 | 80 | 20 | DS1,DS2,DS7,DS10,DS11 | 0.1 | 4 | 132 | 95% | |

| E5 | 81 | 19 | DS1,DS2,DS7,DS10,DS11 | 0.1 | 4 | 139 | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valencia, J.; Emami, E.; Battulwar, R.; Jha, A.; Gomez, J.A.; Moniri-Morad, A.; Sattarvand, J. Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models. Electronics 2024, 13, 1291. https://doi.org/10.3390/electronics13071291

Valencia J, Emami E, Battulwar R, Jha A, Gomez JA, Moniri-Morad A, Sattarvand J. Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models. Electronics. 2024; 13(7):1291. https://doi.org/10.3390/electronics13071291

Chicago/Turabian StyleValencia, Jorge, Ebrahim Emami, Rushikesh Battulwar, Ankit Jha, Jose A. Gomez, Amin Moniri-Morad, and Javad Sattarvand. 2024. "Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models" Electronics 13, no. 7: 1291. https://doi.org/10.3390/electronics13071291

APA StyleValencia, J., Emami, E., Battulwar, R., Jha, A., Gomez, J. A., Moniri-Morad, A., & Sattarvand, J. (2024). Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models. Electronics, 13(7), 1291. https://doi.org/10.3390/electronics13071291