1. Introduction

With the surge in popularity of electric vehicles (EVs), the charging infrastructure has become a focal point of discussion. Currently, the predominant approach to public charging frequently requires individuals to manually retrieve the charger from the charging station and then plug it into the EV. However, the unwieldy nature of chargers with hefty power cables presents a considerable inconvenience for their users. Unlike the well-established practices in traditional gas stations, where employees undergo extensive training, the potential for misoperation during the EV charging process causes safety concerns. Users, lacking stringent training on charger utilization, may encounter safety hazards. To alleviate user burdens and mitigate potential risks, the concept of employing robotic systems for automated EV charging has emerged as an innovative alternative [

1,

2,

3].

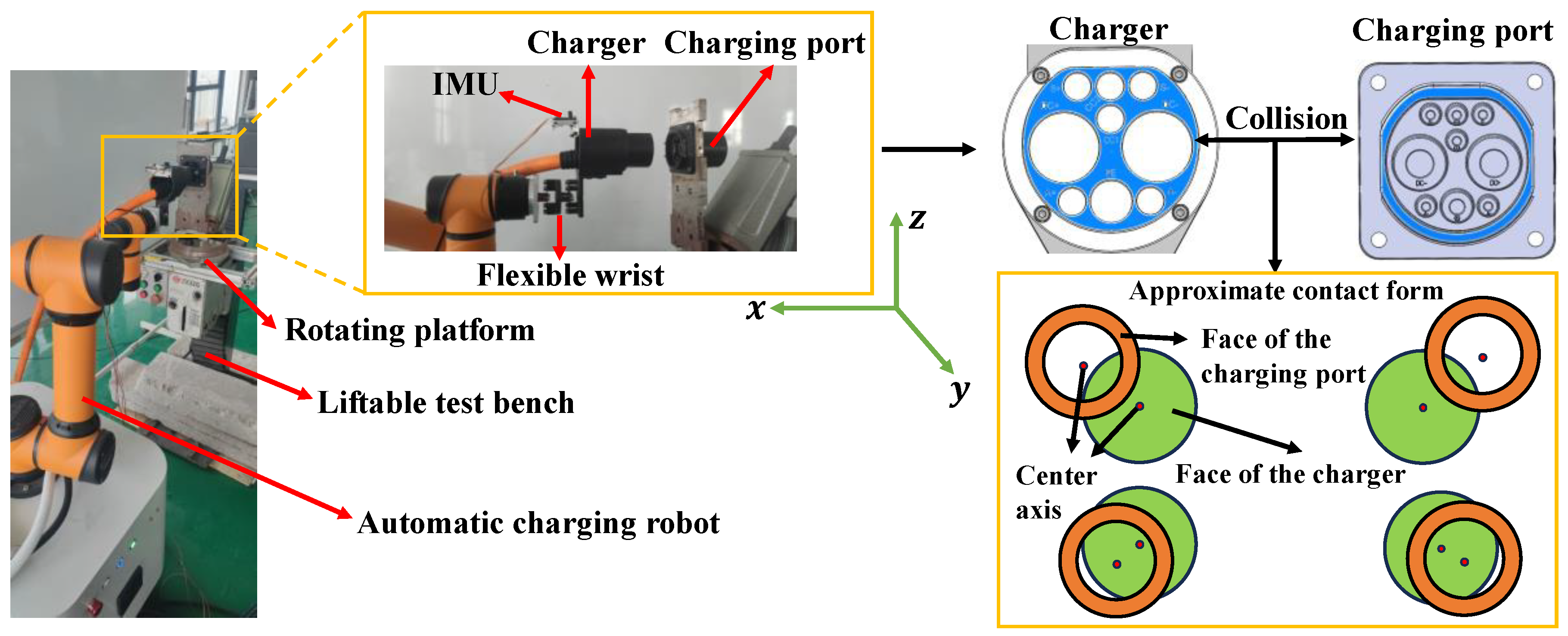

Currently, the positioning of automatic charging systems relies predominantly on machine vision technology at the charging port [

4,

5,

6,

7]. In structured environments, machine vision systems exhibit commendable stability and high precision, meeting the requirements of robot-based electric vehicle (EV) automatic charging solutions for precise plug insertion. However, in unstructured environments, vision systems face various challenges, including variations in light conditions, hazy weather, and fluctuations in temperature and humidity. These changes in external conditions can impact the accuracy of the vision system, leading to difficulties in charging plug insertion. Once external conditions change, rectifying these influences is often challenging in the short term. To address the limitations in visual accuracy, compensation for plug insertion can be achieved using impedance control schemes when plug-in errors are minimal [

8]. However, when deviations are substantial, the charging gun may fail to make contact with the charging port, resulting in collisions with other parts of the vehicle. In such cases, collision classification becomes essential to safeguard the system. In instances of moderate deviations, the aforementioned methods may prove unsuitable, and it becomes necessary to employ a localization approach that involves determining the relative collision position between the charging gun and the charging port, to compensate for deviations in the plug-in process.

In our previous research, we leveraged the vibration signals generated at the end of a robotic arm during collisions, employing a data-driven approach to achieve a preliminary estimation of the collision area [

9]. However, we observed that this estimation was too broad and lacked effectiveness in addressing the compensation challenges associated with actual collision deviations. To overcome this issue, this paper builds upon our previous work by introducing the concept of template matching from the field of computer vision. We propose a method that utilizes vibration information corresponding to collision point positions to construct a collision point matrix template. By integrating this template with a data-driven approach, we establish a more refined collision localization strategy. This approach aims to achieve a finer localization of the collision position between the robotic arm end effector and the charging port, addressing the limitations of relying solely on rough estimates of the collision area.

The rest of the paper is organized as follows:

Section 2 reviews related works on collision localization.

Section 3 describes the methodology for collision localization.

Section 4 provides and discusses the experimental results, and

Section 5 provides the conclusions.

2. Related Work

Automated charging for electric vehicles represents an emerging field, and there is currently limited research on collision localization issues within this domain. In contrast, research on collision handling primarily focuses on collaborative robots. This section reviews the literature on the collision localization of collaborative robots. In [

10], the collision event processing workflow is divided into five components: collision detection, collision localization, collision identification, collision classification, and collision reaction. Among these, collision localization primarily serves to localize the contact point or contact link during a collision. Classical collision localization methods are predominantly based on physical models, and primarily involve constructing system observers to detect abnormal behaviors deviating from the normal operational state. The signals generated during abnormal behaviors are analyzed to estimate the contact position. Currently, the most effective observer for collision localization is the momentum observer, which was initially introduced in the study of De Luca et al. [

11]. Through the implementation of a system momentum observer, Ref. [

10] deduces the specific link that experienced a collision in a two-link system. The fundamental concept behind this design is to treat collisions as fault behaviors in the robot’s actuating system [

12]. By considering collisions as simulated fault events, the decoupling properties of the robot’s generalized momentum can be leveraged to devise effective observers [

13]. Ref. [

14] combines a force–torque sensor mounted at the robot base with a virtual sensor based on a momentum observer, to estimate the magnitude and location of external wrenches along the structure of a robot arm. Ref. [

15] introduces a nonlinear model-based momentum observer for the collision position and force estimation of humanoid robots. This method relies solely on joint position, velocity, and joint torque information, eliminating the need for additional sensors for collision analysis. A sensor redundancy approach was proposed by [

16], extending the classical momentum-based disturbance observer to handle redundancy in force–torque measurements. This extension allows simultaneous collision localization for multiple contact points on different arm segments. The above model-based approaches are capable of effectively estimating the occurrence of collisions on a specific link, and in some instances, they can simultaneously estimate collisions on multiple links. However, such model-based methods have certain limitations in practical applications, primarily stemming from challenges in identifying the physical model parameters and accurately estimating unknown disturbances. These challenges decrease the ability of these methods to achieve high-precision collision localization on a small region of a single link.

Model-based approaches have garnered significant attention due to their minimal reliance on external sensors. Even with the utilization of the robot’s onboard sensors alone, these methods can achieve satisfactory results in collision localization. It is worth noting that the introduction of additional external sensors can indeed further enhance the performance of collision localization strategies. Furthermore, for those seeking the greatest dependence on external sensors, an exceptionally effective solution is the adoption of tactile sensors. These sensors leverage diverse transduction methods, smart materials, engineered structures, intricate electronics, and advanced data processing [

17]. Drawing inspiration from the human somatosensory system, Ref. [

18] mounts tactile sensors on the phalanges of underactuated fingers to collect local information about objects during in-hand manipulation. With the gathered information, the study utilizes machine learning methods to estimate the pose (orientation) of objects when being manipulated by a hand. Ref. [

19] develops a large-scale tactile sensing system for a robotic link, named TacLINK, which features an elongated structure comprising a rigid transparent core enveloped by continuous artificial soft skin. The advantage of this artificial skin lies in its ability to provide tactile force feedback and to alter its form and stiffness through inflation at a low pressure. Ref. [

20] introduces SonicSkin, a system that localizes on-robot human touch and estimates touch pressure using a single pair of piezoelectric transducers (one transmitter and one receiver) attached to the robot. In the contact test, SonicSkin achieves a localization error of less than 2 cm for 96.4% of touches. Ref. [

21] introduces a tactile sensor that comprises overlapping air chambers, each constructed from soft material and sealed with an embedded barometer. These interconnected air chambers emulate the adaptive receptors found in human skin. Barometers within these chambers acquire a global receptive field of the contact surface through pressure propagation in the hyperelastic seal, enabling the skin to achieve a spatial resolution of 0.1 mm under optimal conditions on a 38 × 26 mm

2 surface. Although employing tactile sensors often enhances the precision of collision or contact localization, these complex sensors are typically difficult to install in practical applications. Moreover, their lifespan is constrained by material properties and external load conditions, rendering them unsuitable for high-load and frequently contacted applications.

In addition to methods that use external tactile sensors for collision localization, there is another category of methods that are compatible with both external sensors and onboard sensors. Moreover, these methods typically employ sensors that are commonly available on the market, eliminating the need for complicated designs and manufacturing processes associated with tactile sensors. These methods place a greater emphasis on the analysis of collision data, hence being referred to as data-driven collision localization methods. Ref. [

22] utilizes random forests (RFs) and multilayer perceptrons (MLPs) as machine learning models, combined with a generalized momentum-based approach, to achieve the detection and localization of external contacts. This study, by making assumptions about the form of collision forces, the direction of collision forces, and the collision contact scenarios, constructs a collision dataset that aligns with the real-world collision detection and localization requirements. Ref. [

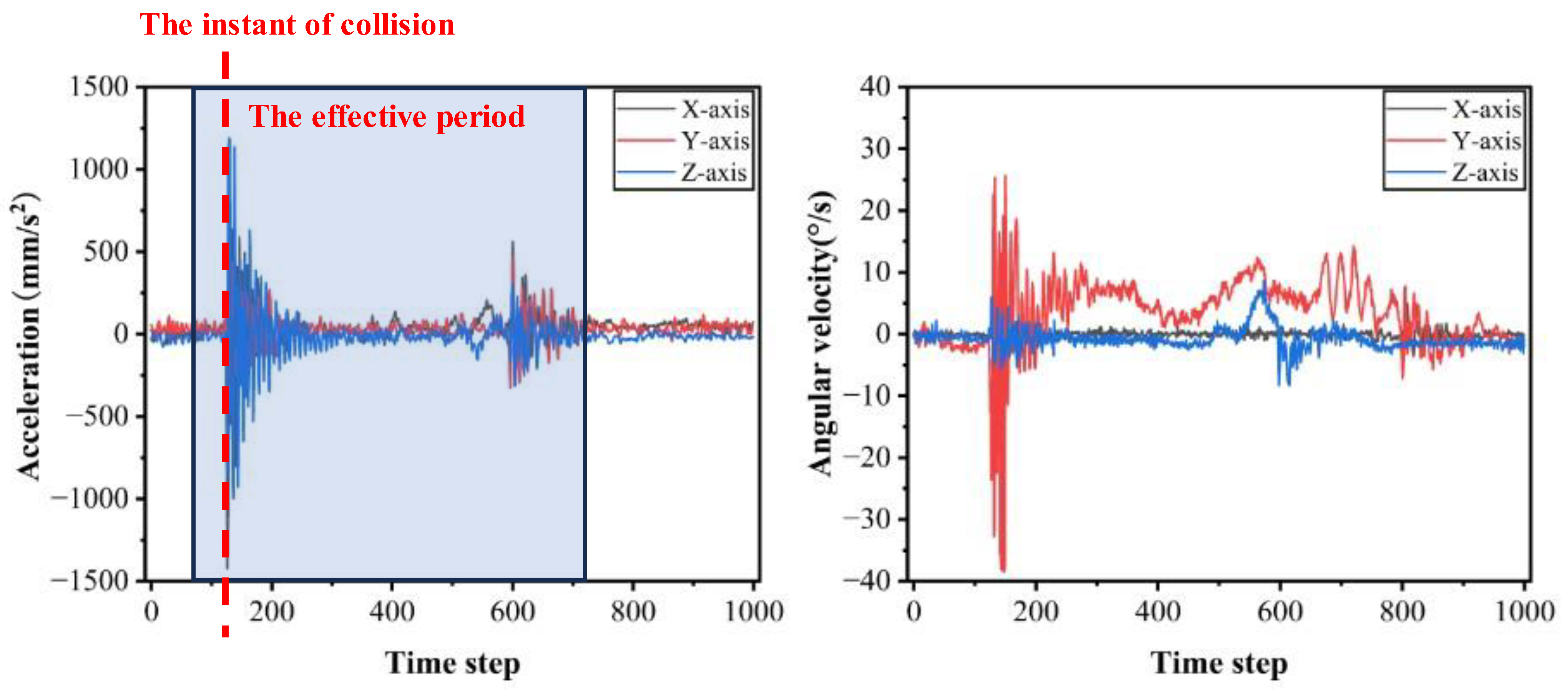

23] constructs a robot collision localization strategy based on collision vibration signals. The collision vibration data were collected by affixing four accelerometers to the external surface of the upper arm of a robot. Subsequently, a multiclass support vector machine (SVM) was trained to estimate the location of detected contact events based on the recorded vibration measurements. The experimental analysis results reveal that the root mean square error distance between the predicted and actual classification locations for this method is 82 mm. Similarly, Ref. [

24] gathers collision vibration information by installing a one-dimensional accelerometer at the base joint and a three-dimensional accelerometer on the end effector. The estimation of which arm segment the collision occurred on is achieved through training an artificial neural network (ANN) classifier. These data-driven methods can be employed to not only estimate which arm segment a collision occurred on but also to determine the specific location of the collision within a local region on one link. However, in practical applications, the effectiveness of such methods depends on the design of appropriate data acquisition rules tailored to specific needs and requirements.

In the process of automatic charging for electric vehicles, situations arise where moderate plug-in offset compensation is needed due to visual failures. Relying solely on model-based collision localization methods often struggles to meet the accuracy demands for plug-in compensation in the cases of moderate offsets. Meanwhile, methods based on tactile skin create challenges in maintaining a high service life in scenarios characterized by high contact loads, frequent friction, and impact. In our previous work, we developed a data-driven approach combined with well-defined regional rules [

9]. By analyzing collision vibration data at the end effector of the manipulator, we achieved estimates of the circumferential and radial regions of collision between the end effector and the charging port during the automatic charging plug-in process for electric vehicles. However, in practical applications, such relatively coarse estimates may not entirely meet the demands for the plug-in compensation caused by visual deviations. In this paper, we enhance the precision of robotic end effector collision localization by introducing more reasonable data collection rules tailored to the charging port. We also propose a data-driven model that aligns with the data collection rules to achieve higher collision localization accuracy. The primary contributions of this paper are as follows:

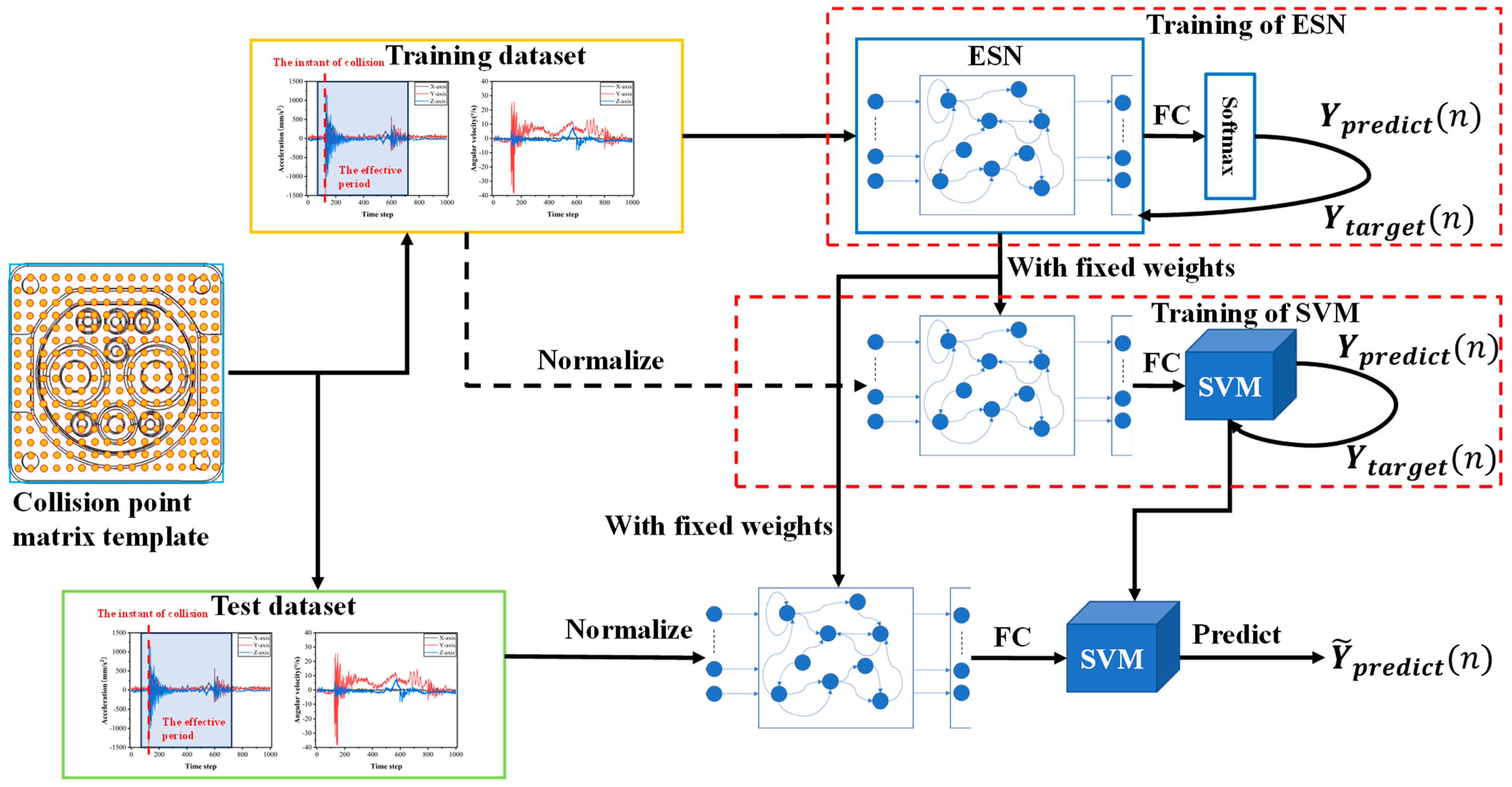

A collision point matrix template is introduced for the first time in the context of automatic charging scenarios for electric vehicles. By utilizing the collision point matrix template, the problem of estimating collision positions between the end effector of the robot and the charging port at different locations is effectively transformed into a problem of estimating collision positions at various points on the collision point matrix template. This transformation enables the high-precision collision localization of the end effector of the robot with respect to the charging port.

A collision localization model matching the collision point matrix template is proposed. The presented collision localization model integrates echo state network (ESN) and support vector machine (SVM) methods. The proposed method fully leverages the outstanding capability of the ESN in extracting features from time-series signals, while imparting desirable sparsity to the extracted features. By combining this with the SVM, which exhibits a strong affinity for sparse features, the model maintains an excellent classification performance. For the first time, this paper introduces the fusion of the integrated model with a collision point matrix template, achieving high-precision collision localization in the context of automatic charging for electric vehicles.

4. Experimental Results and Discussion

Before validating the collision localization method, the setting of the hyperparameters is crucial, as it directly affects the performance and training process of the model. We shuffled D1 and utilized 80% of the shuffled D1 data as the training set and 20% for testing to select reasonable hyperparameters. The objective of hyperparameter tuning is to optimize the model’s performance, which involves achieving the best trade-off between localization accuracy and parameter scale. The proposed collision localization method consists of two parts: one part is the ESN used for adaptive feature extraction, and the other part is the SVM used for predicting the final results. Since the collision vibration signal, after passing through the ESN, results in initially high-dimensional features, directly inputting such high-dimensional features into the SVM for analysis would lead to an extremely slow processing speed. Therefore, after the ESN layer, the model introduces an FC network to better adapt the feature dimensions extracted by ESN to the requirements of SVM. In addition, to compare and validate the adaptability of the proposed model with the collision point matrix template, this work adopts common recurrent neural networks (RNNs), including long short-term memory (LSTM) networks and gated recurrent units (GRUs) [

27], as feature extractors for comparison. Both of these use the same single-layer structure as the ESN during usage, and the parameters of the FC network attached afterward are also the same. When setting the model’s hyperparameters, it is common to construct a reasonable hyperparameter search space, which helps limit the search range and improve search efficiency. In the hyperparameter tuning process, we initially optimized parameters for ESN, LSTM, and GRU combined with Softmax, respectively. Subsequently, we fixed the parameters of the aforementioned networks and focused on the selection of optimal parameters for SVM. To maintain a certain degree of fairness in the comparison, we utilized the average localization accuracy of ESN, LSTM, and GRU combined with SVM as metrics to guide the selection of optimal SVM parameters. During the practical implementation, we explored different values for hyperparameters based on the hyperparameter search space, testing from lower to higher parameter scales. To compare the performance of different parameter combinations, we conducted training on the dataset with five shuffles, obtaining average accuracy for comparison. If the average accuracy of a new parameter combination exceeded the previous one by more than 0.25%, we retained the new parameter combination, continuing this process until the entire screening was complete. The final specific hyperparameter settings are presented in

Table 3.

In [

24], the accuracy and the deviation of collision localization are utilized to evaluate the effectiveness of collision localization methods. This paper follows the same approach to assess the proposed collision localization method. In this section, 80% of the shuffled D1 is used as the training set, and 20% is used as the validation set. The proposed model and comparative models are trained using a five-fold cross-validation. For testing, two separate datasets, D2 and D3, isolated from D1, are used to evaluate the effectiveness of the proposed method. The results of the average accuracy of collision localization are shown in

Figure 6. From the graph, it is evident that the fusion methods with SVM outperform the non-fusion methods in terms of localization accuracy for different

s. The proposed ESN–SVM method achieves a collision localization accuracy exceeding 90% on both the D2 and D3 test sets, outperforming the LSTM–SVM and GRU–SVM methods. Additionally, a comparison between D2 and D3 reveals that models trained on a certain joint configuration exhibit some differences in collision localization performance under different joint configurations. It is noticeable that the collision localization model trained on D1 performs significantly better in D2 than in D3, mainly due to the smaller differences in joint configurations between D1 and D2 compared to D1 and D3. Moreover, there are notable differences in collision localization accuracy between the proposed method and the comparison methods across different testing sets: the maximum difference in collision localization accuracy exhibited by ESN–SVM, LSTM–SVM, and GRU–SVM on D2 and D3 test sets, for different

s, is 3.39%, 6.76%, and 6.26%, respectively, and the average difference in collision localization accuracy is 3.29%, 6.31%, and 5.25%, respectively. This suggests that ESN–SVM performs consistently better than LSTM–SVM and GRU–SVM on both D2 and D3 test sets. It indicates that in collision localization datasets with certain distribution differences, ESN–SVM exhibits stronger robustness and generalization capabilities compared to other fusion methods. From another perspective, it highlights that ESN–SVM, along with the proposed collision point matrix template, demonstrates better adaptability to collision localization in electric vehicle charging scenarios.

Furthermore, a qualitative analysis of collision localization deviations for the fusion methods is conducted. Since the size of the traditional confusion matrix will grow squarely as the number of categories increases, in the collision localization problem, due to the large number of individual categories, the traditional confusion matrix will become very large, making it difficult to visually display the performance of the model in relation to different individual categories. The proposed variant of the confusion matrix utilizes a three-dimensional bar heatmap to represent non-diagonal confusion in the traditional confusion matrix. This approach provides a clear and intuitive visualization of collision localization deviations.

Figure 7 shows the variant confusion matrix obtained by testing the fusion methods on D2 and D3. The figure illustrates that, for the proposed method and the compared fusion methods, confusion is primarily concentrated near the diagonal, indicating that collision localization deviations mainly occur between individual locations and their adjacent locations. This is attributed to the higher similarity in vibration signals caused by collisions in neighboring locations, posing a greater challenge for fusion collision localization methods in these scenarios. Additionally, the overall confusion level for the fusion model on D2 is weaker compared to D3, further confirming that variations in joint configurations do indeed impact collision localization.

Although the qualitative analysis of collision localization deviation helps one to understand the overall distribution of confusion among predicted locations, in practical applications, specific quantification of localization deviations and understanding the magnitude of these deviations are essential for guiding the use of collision localization strategies. In our work, quantitative analysis of localization deviations focuses on the fusion methods. Here, we selected the same models as in the qualitative analysis. The detailed results are presented in

Table 4, which primarily displays the maximum deviation and root mean square error (RMSE) of collision localization. When comparing the three methods, it is evident that ESN–SVM outperforms LSTM–SVM and GRU–SVM overall, in terms of RMSE and maximum deviation in collision localization. This result indicates that the features extracted based on the ESN method have the best compatibility with SVM, making them more suitable for collision localization scenarios based on the collision vibration signals. Additionally, it is important to note that when using the ESN–SVM method, the minimum value of the maximum deviation is 13.6 mm. This implies that even with deviations, the proposed method may still lead to instances of charging failure. Therefore, to ensure safety, the proposed collision localization method should be used in conjunction with appropriate collision protection methods.

5. Conclusions

In this study, we propose a novel data-driven collision localization method for the end effector of a manipulator using ESN and SVM. During the data collection process, we design a collision point matrix template suitable for automatic charging plug-in, transforming the problem of collision localization during the charging plug-in process into a classification task of collision vibration signals corresponding to different collision points. By utilizing the data collected through the collision point matrix template, which contains collision position information, we train the proposed ESN–SVM collision localization model. This model demonstrates an ability to effectively estimate collision contact positions under the different geometric characteristics of the manipulator, without requiring manual intervention in the feature extraction process. Simulated experimental results show promising value in locating collision positions during the charging plug-in process.

Generally, the method proposed in this paper achieves high-precision collision localization based on contact. In terms of collision localization accuracy, the proposed method achieves an average accuracy of 95.85%, significantly higher than non-fusion methods, indicating that the fusion approach contributes to enhancing the localization performance. In comparison with other fusion models, it is also evident that the collision localization accuracy varies less under different joint configurations, demonstrating that the ESN combined with SVM exhibits better generalization capabilities and stronger robustness compared to other fusion methods. Regarding localization deviation, the proposed ESN–SVM method demonstrates a minimal localization RMSE of only 0.83 mm, presenting a significant advantage over other fusion methods in terms of localization deviation. This suggests that the ESN-SVM model, in conjunction with the collision point matrix template, is more suitable for the charging plug-in collision localization problem.

It should be noted that, although the proposed method, on average, achieves an accurate estimation of collision location, there are instances where the method may fail to provide effective compensation for system deviations, as indicated by the maximum estimated deviation. Therefore, in future work, we will conduct targeted research on collision protection strategies tailored to the proposed collision localization method, aiming to enhance the safety of the charging plug-in process.