Modeling and Operating Characteristics of Excitation System for Variable Speed Pumped Storage Unit with Full-Size Converter

Abstract

1. Introduction

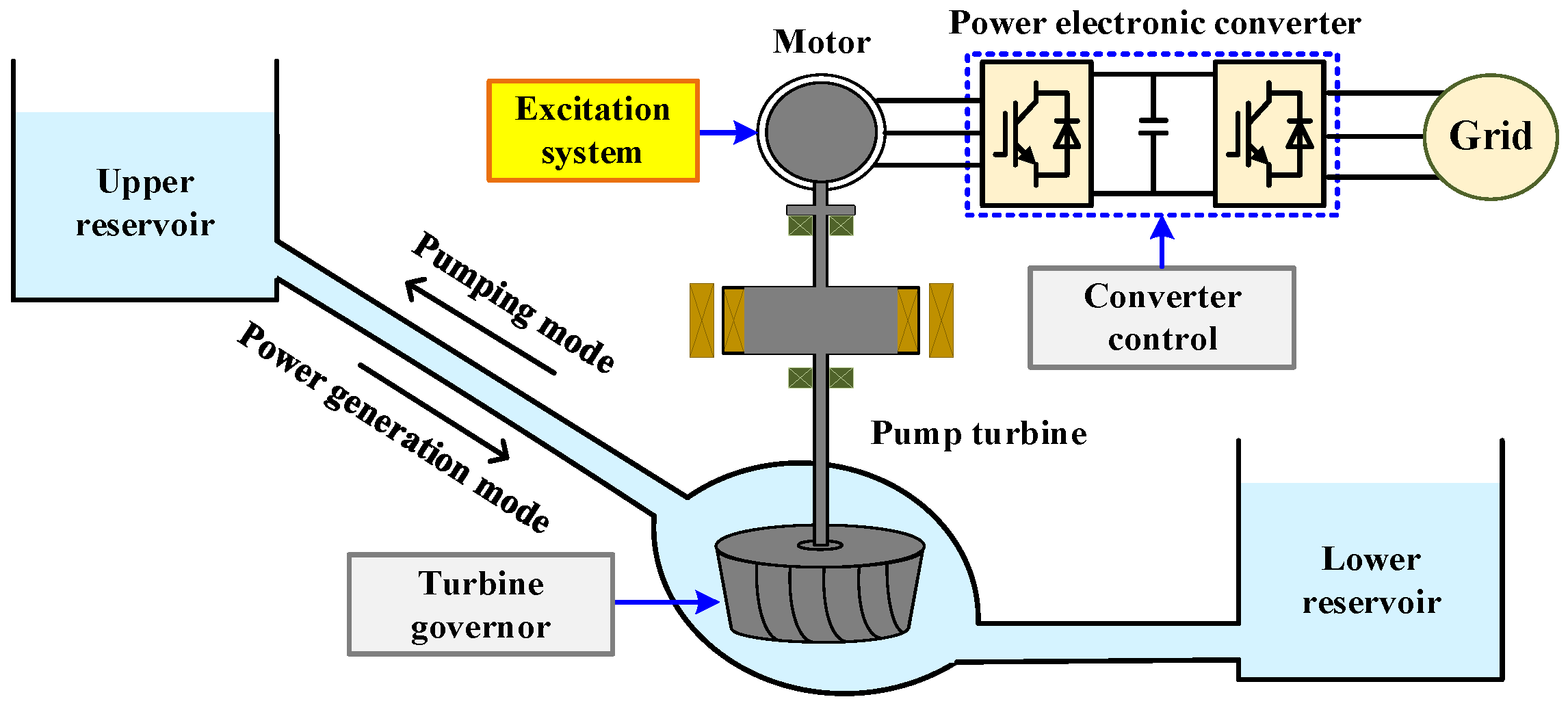

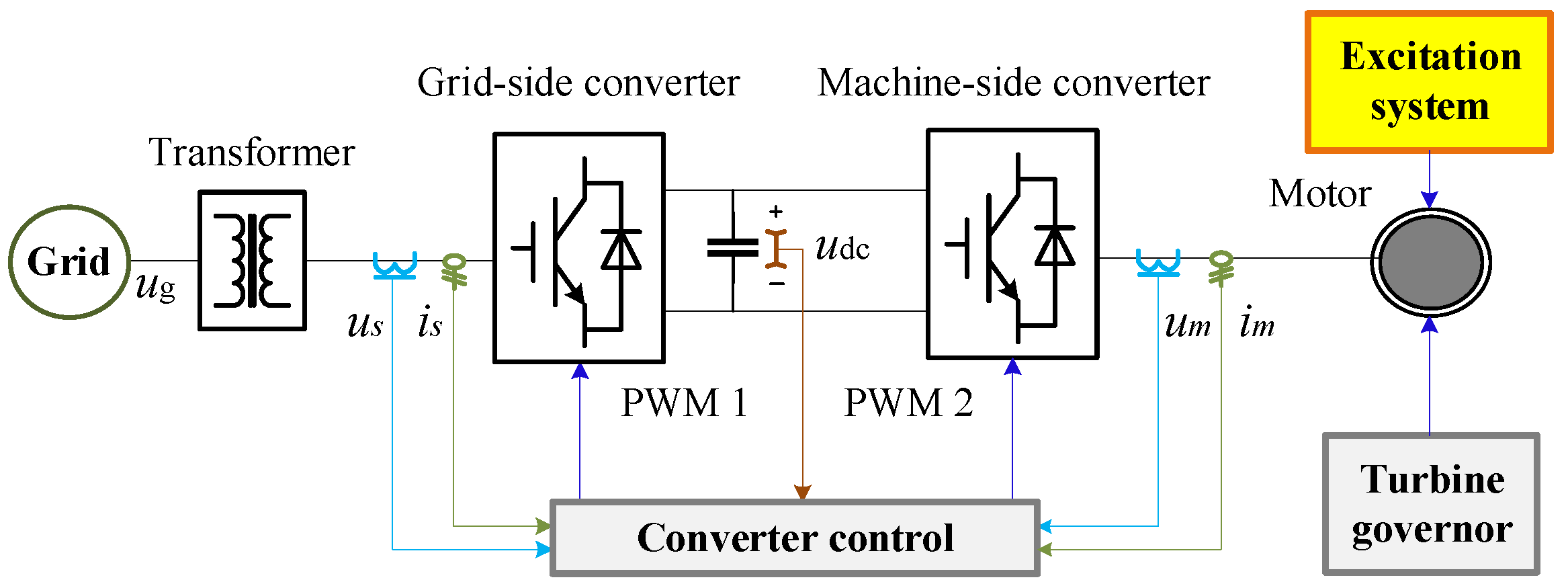

2. Structure of the FSC-VSPSU

3. Mathematical Models of the Excitation System

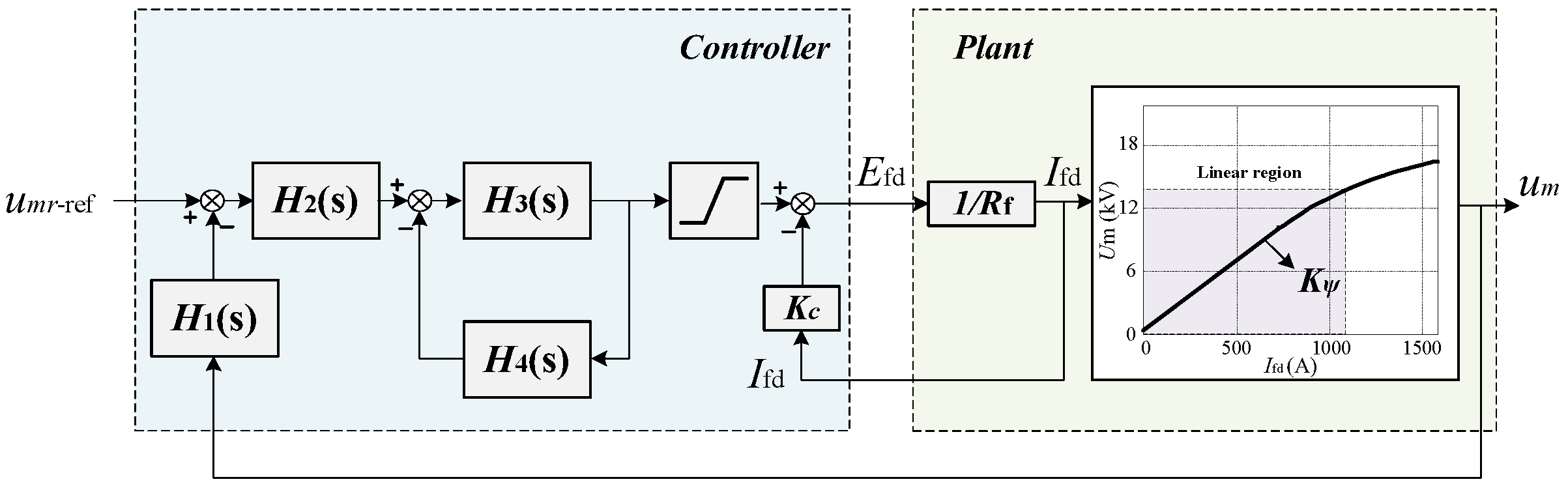

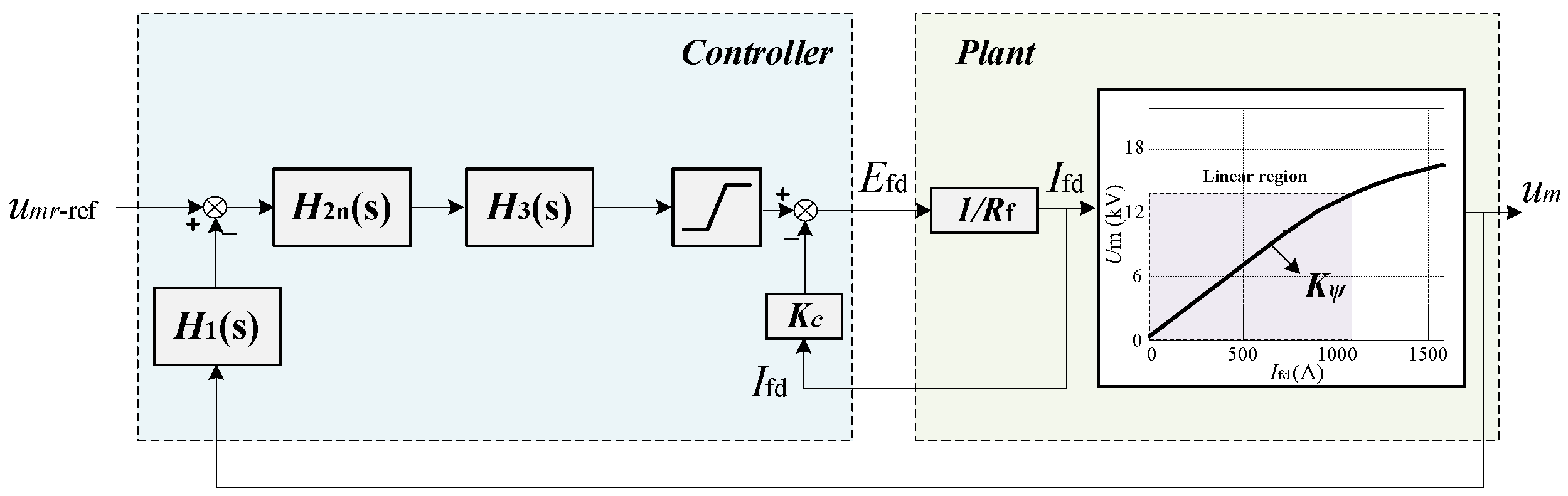

3.1. Structure of the Excitation System

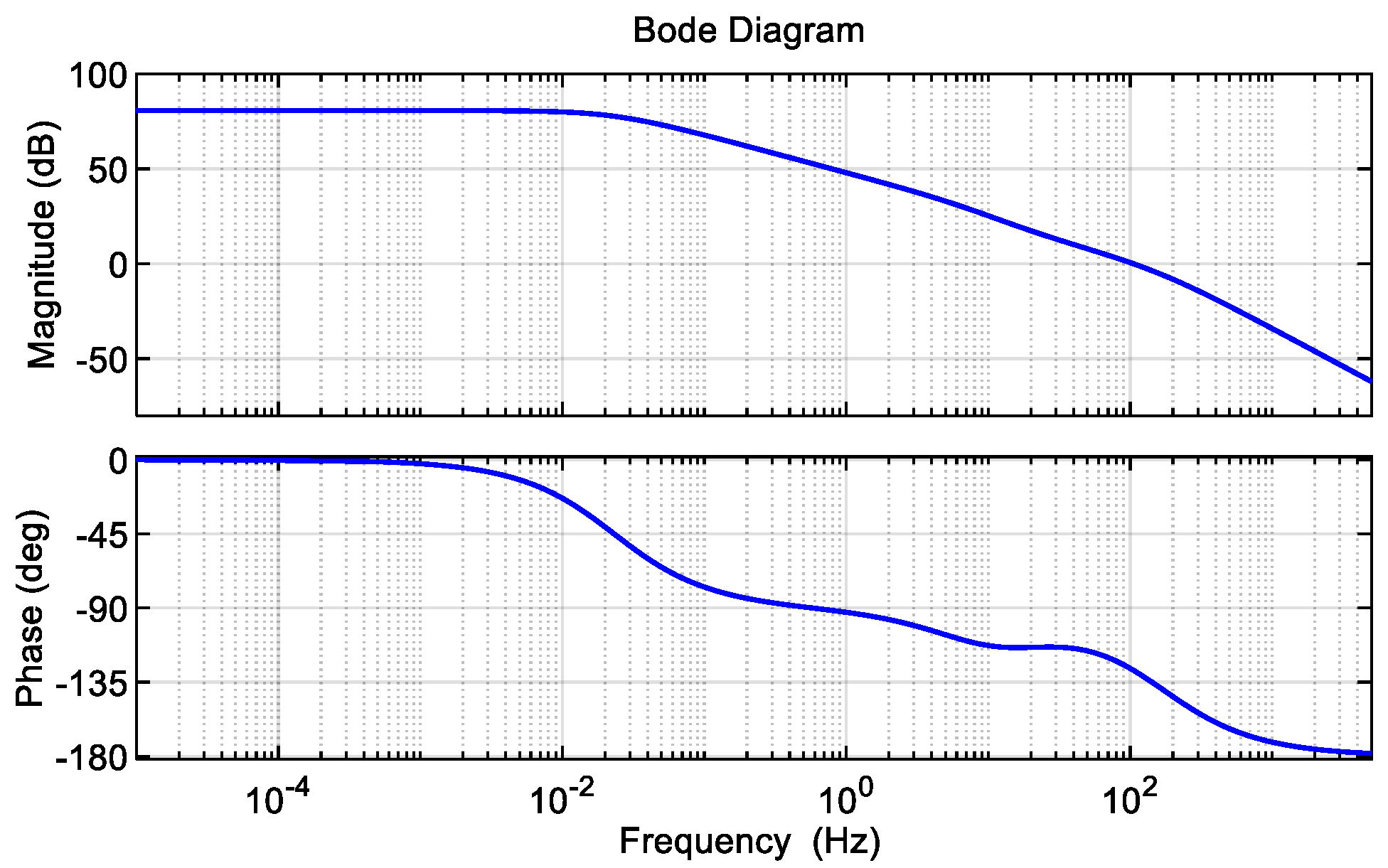

3.2. The Transfer-Function-Based Mathematical Model

4. Operating Characteristics of the Excitation System for the FSC-VSPSU

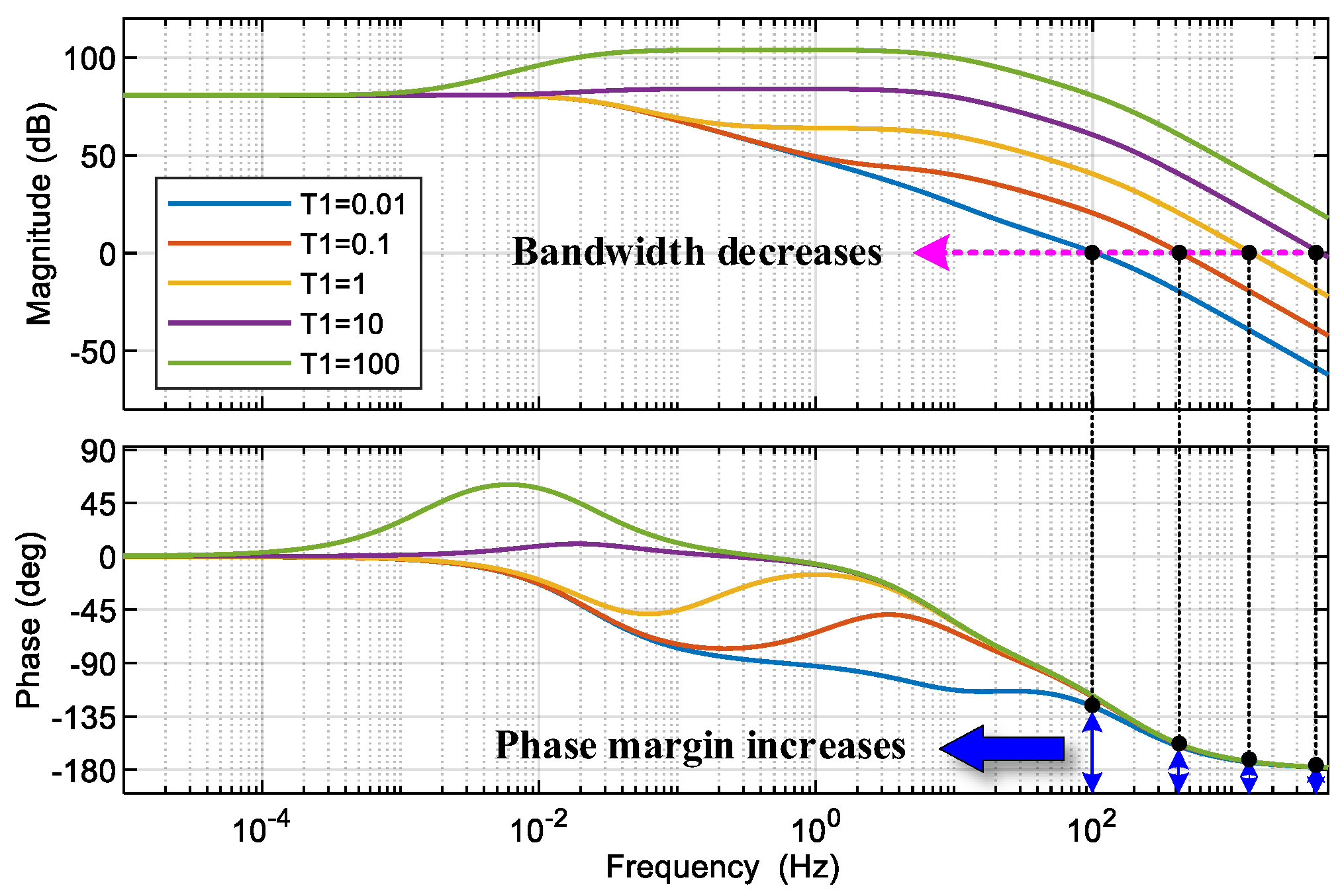

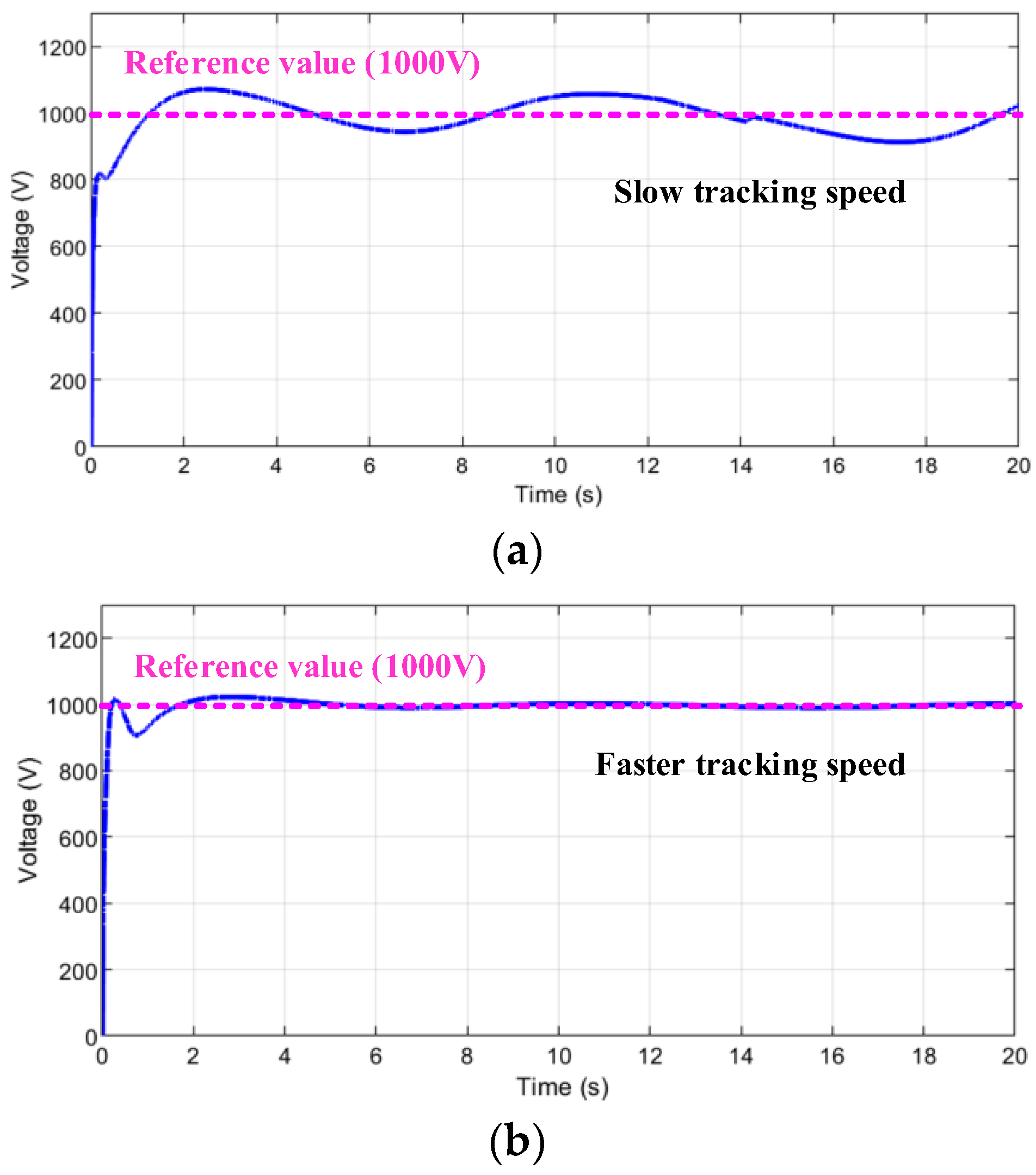

4.1. The Influence Rule of Time Constant T1

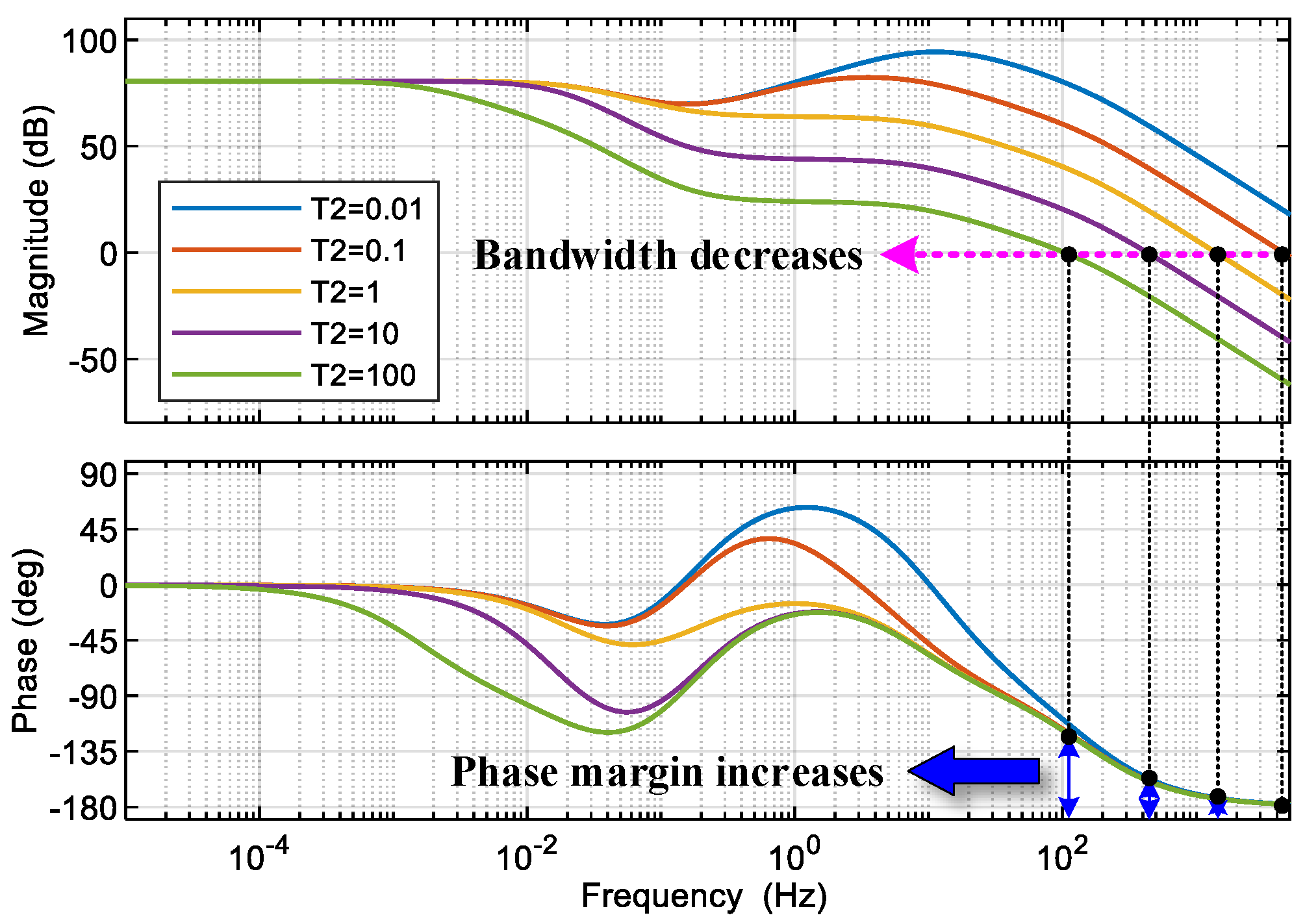

4.2. The Influence Rule of Time Constant T2

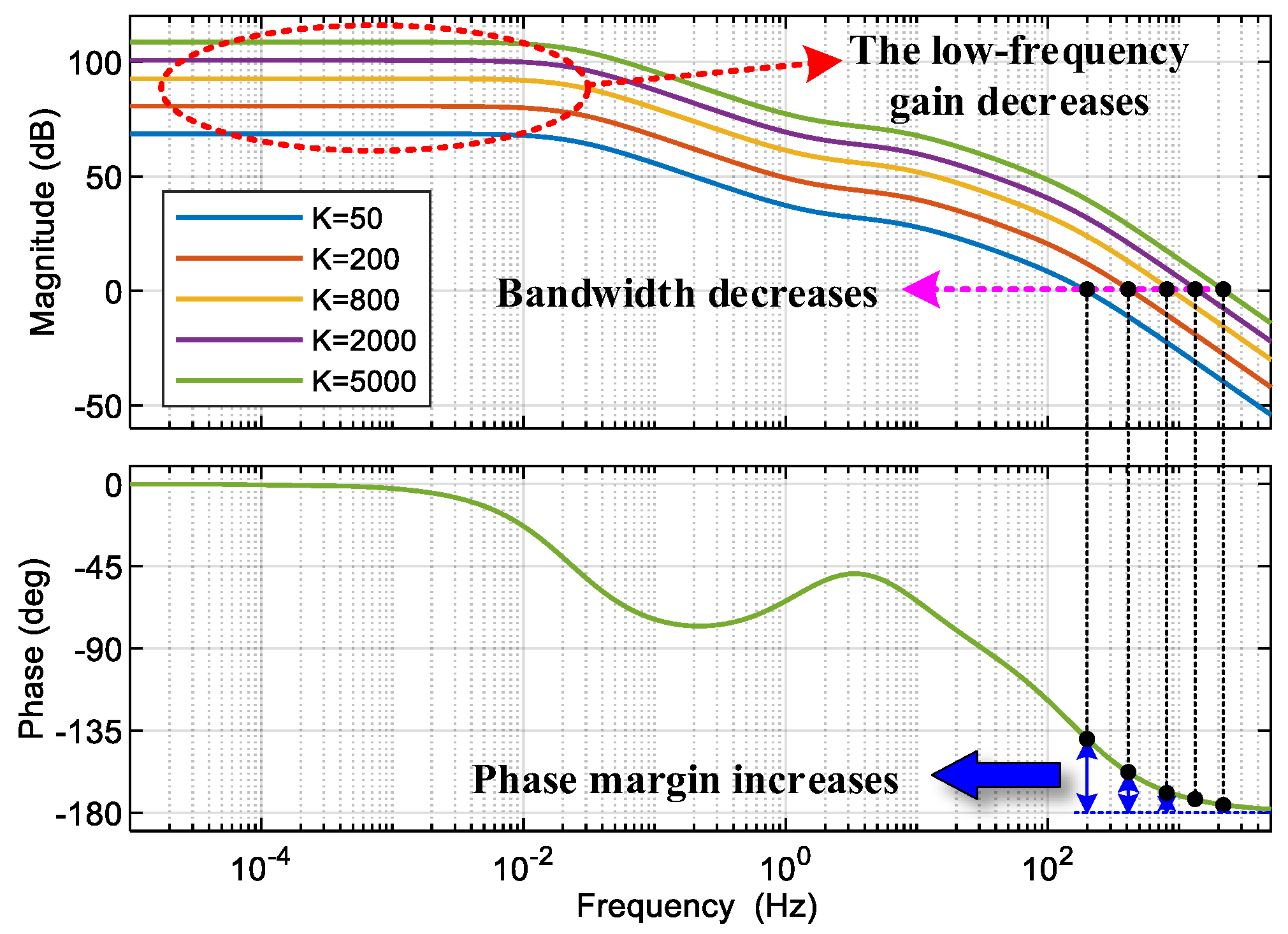

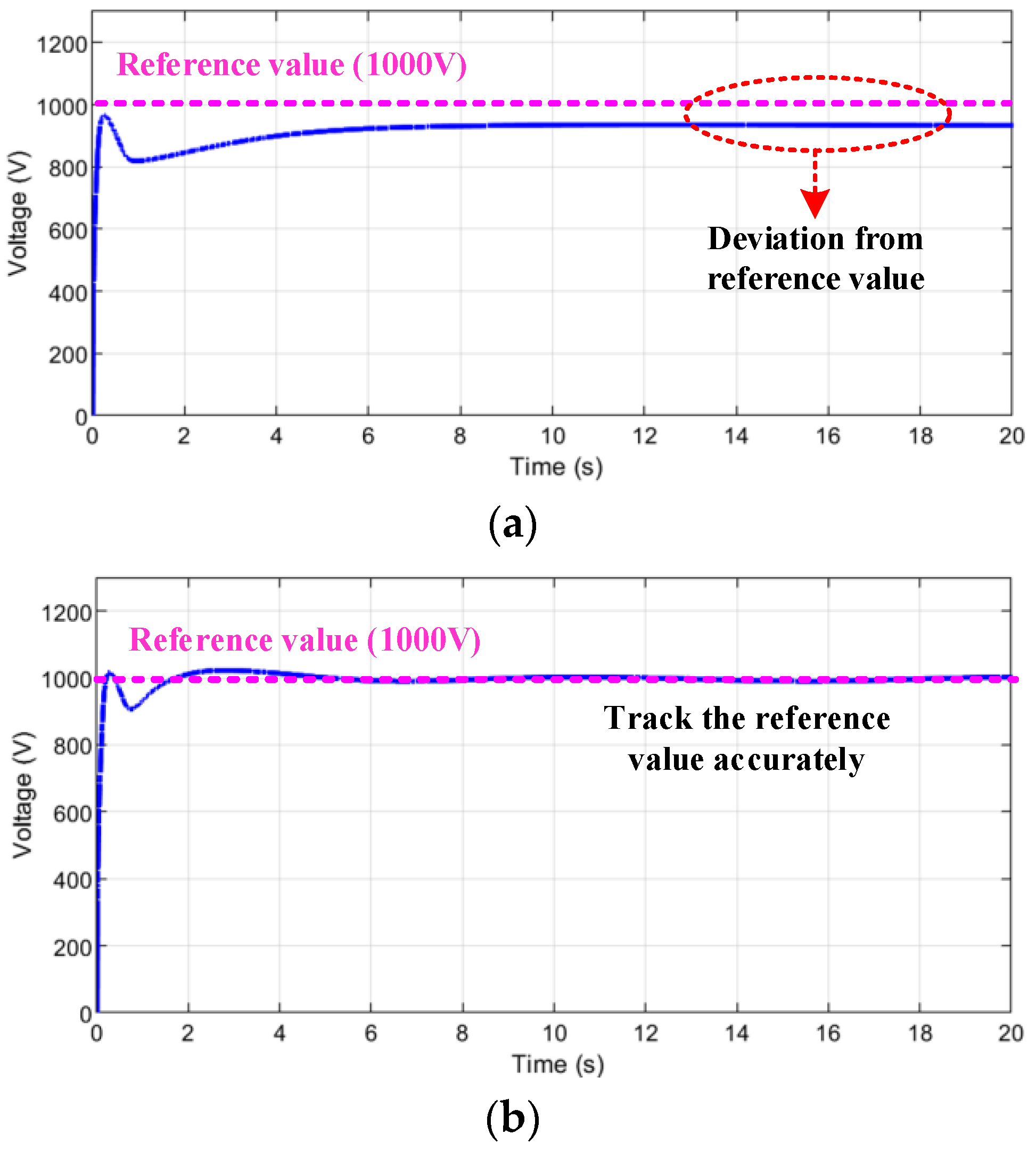

4.3. The Influence Rule of DC Gain K

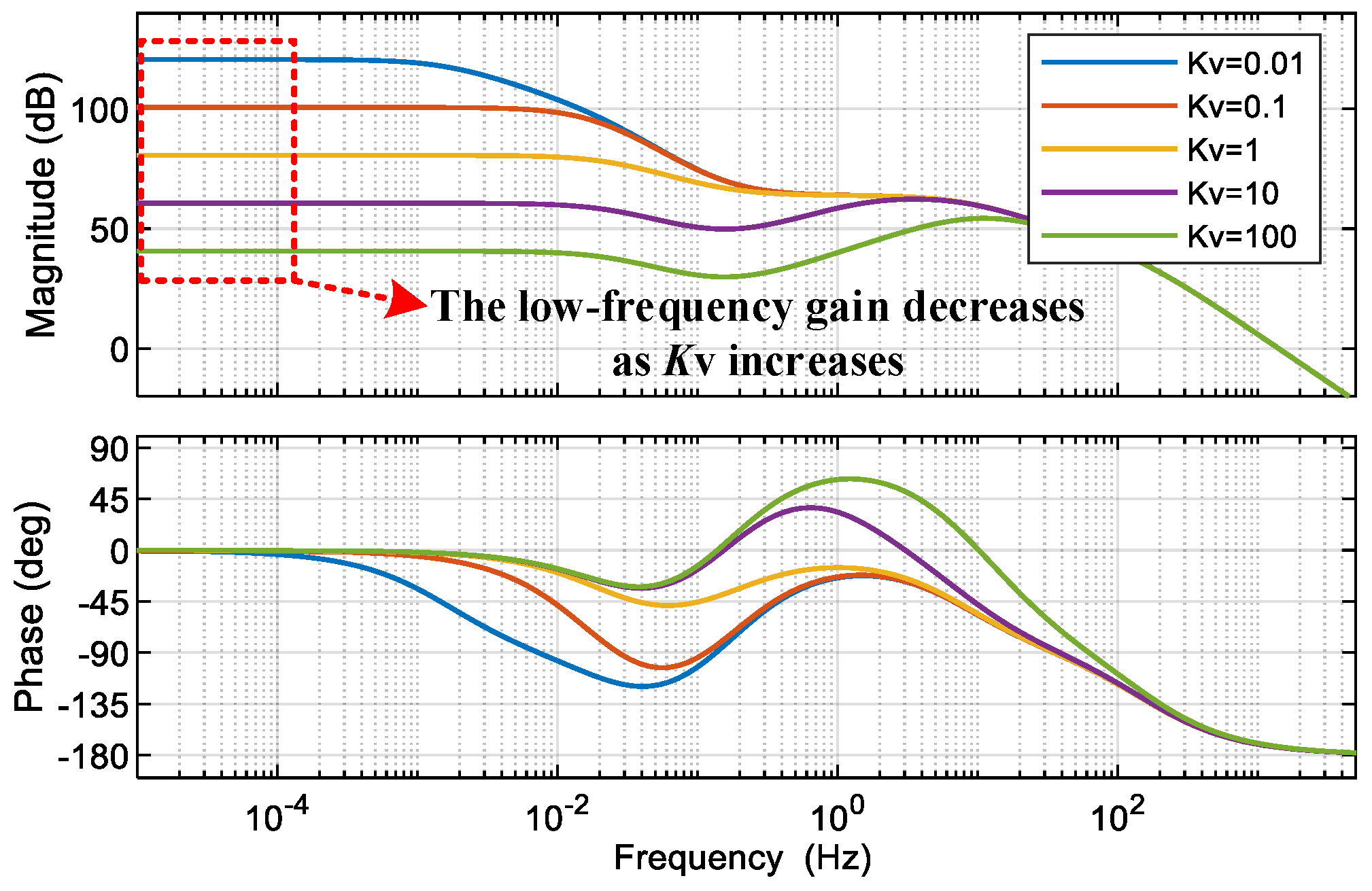

4.4. The Influence Rule of Integral Correction Selection Factor KV

4.5. The Influence Rule of Gain Kf of the Parallel Correction Link

4.6. Simplification of the Excitation System Structure

5. Simulation Validation

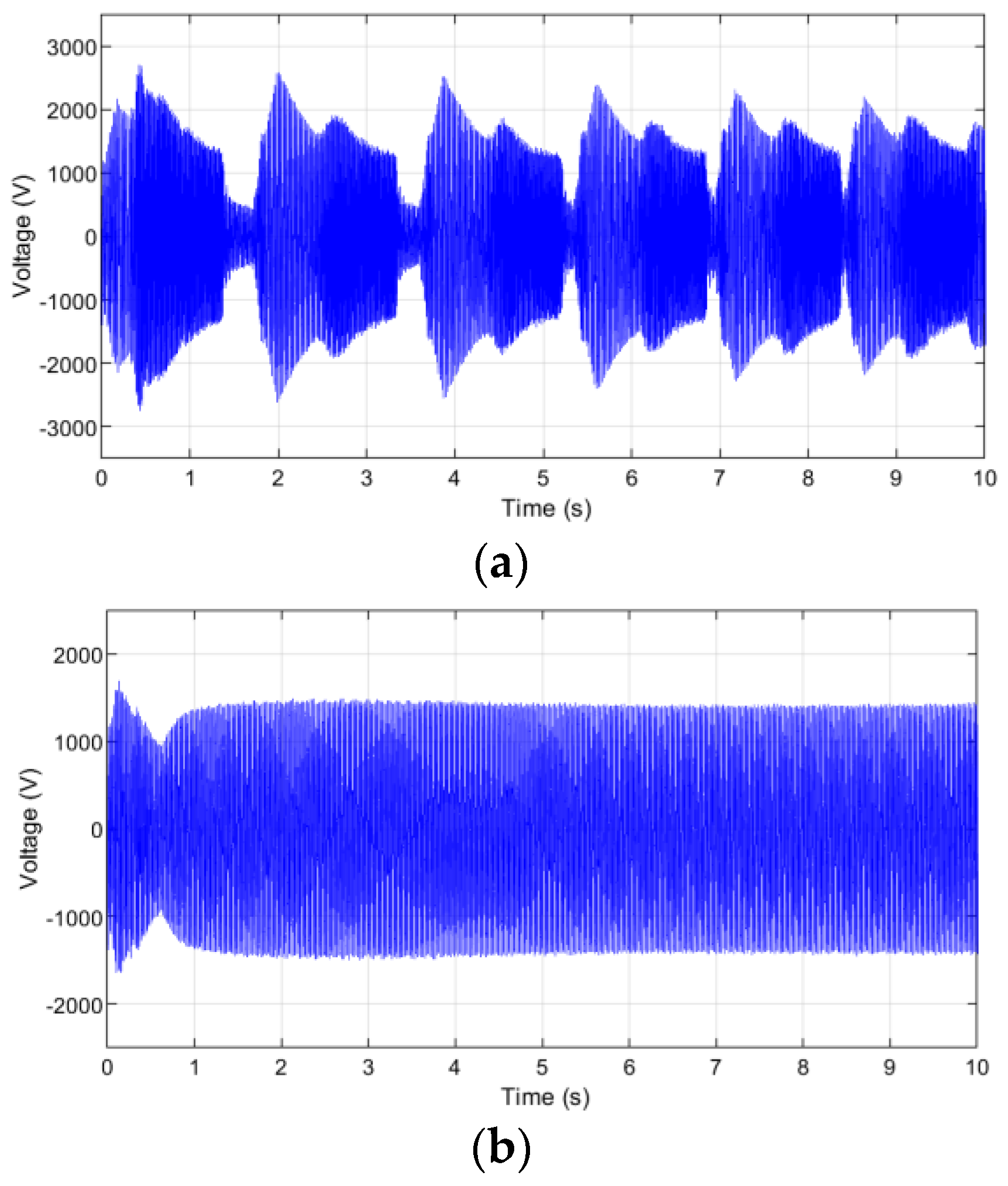

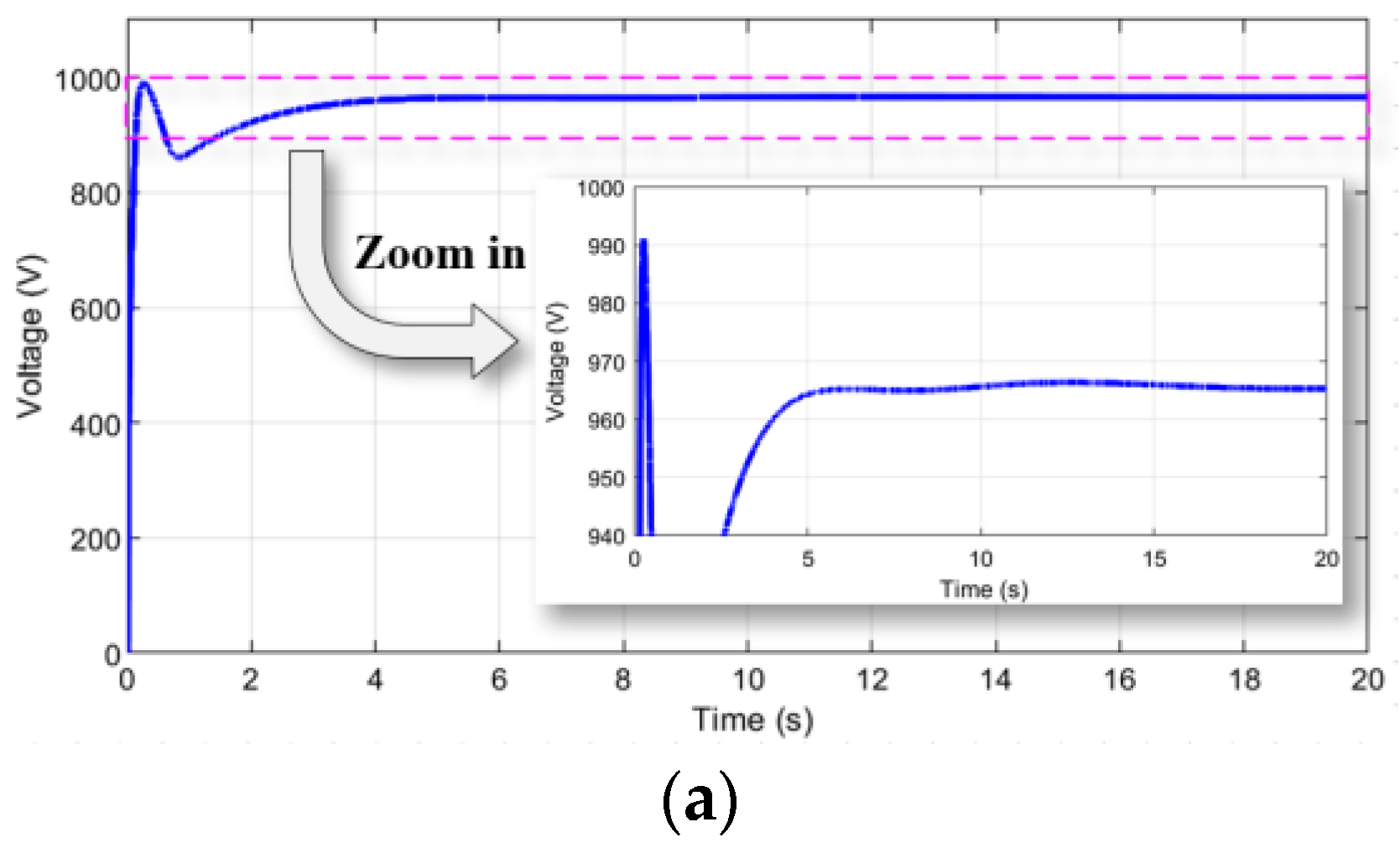

5.1. Verification of the Influence Rule of Time Constant T1

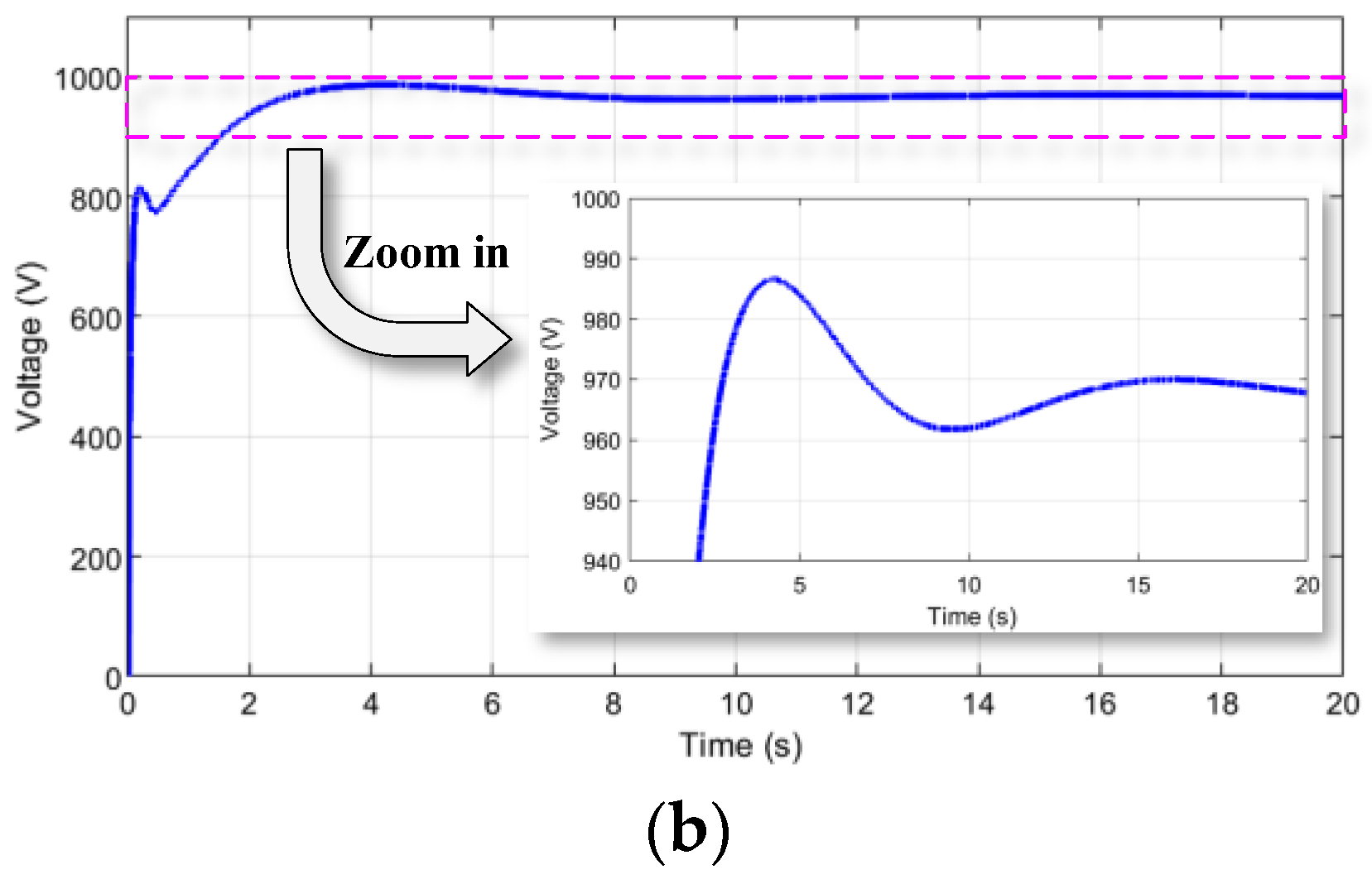

5.2. Verification of the Influence Rule of Time Constant T2

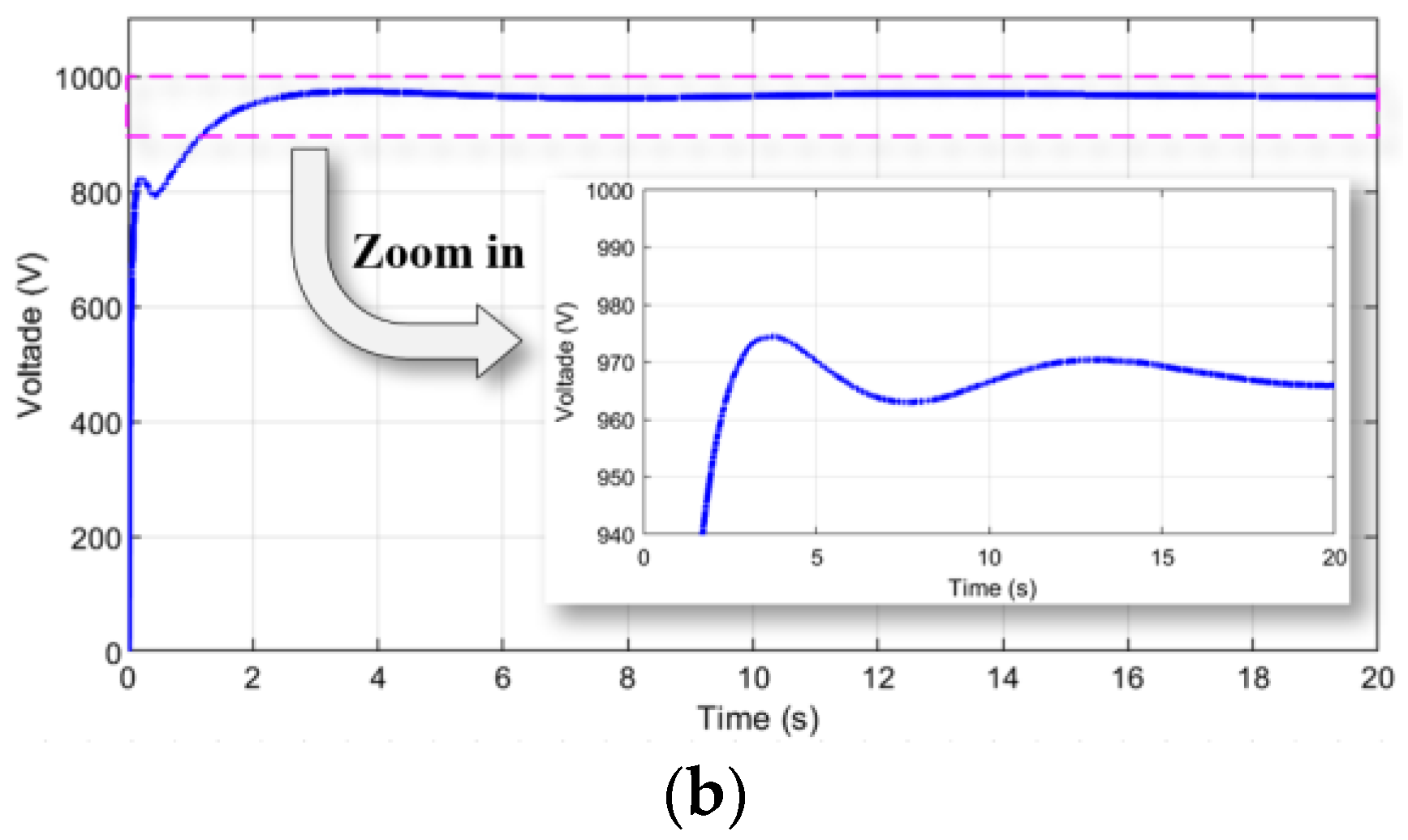

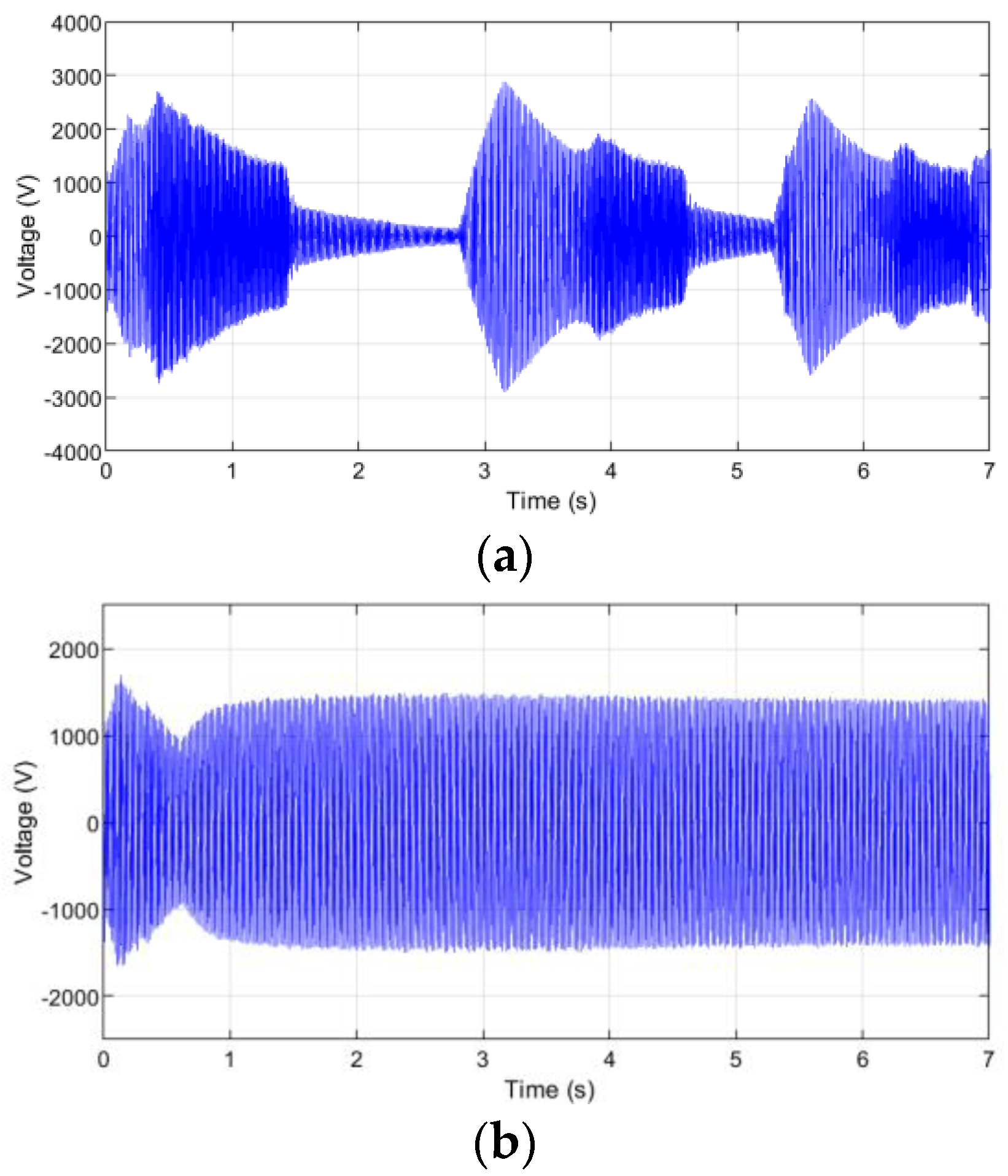

5.3. Verification of the Influence Rule of DC Gain K

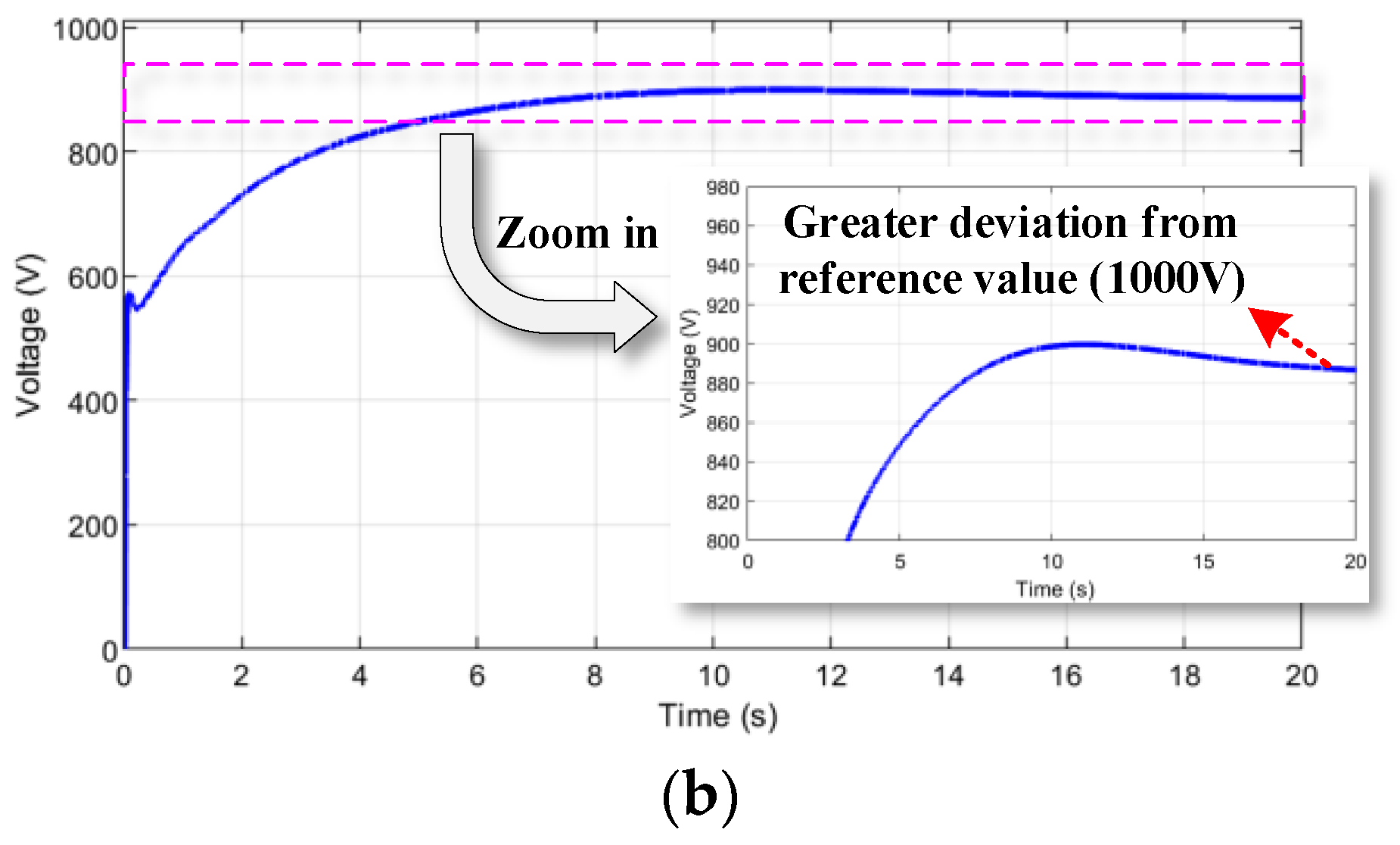

5.4. Verification of the Influence Rule of Integral Correction Selection Factor KV

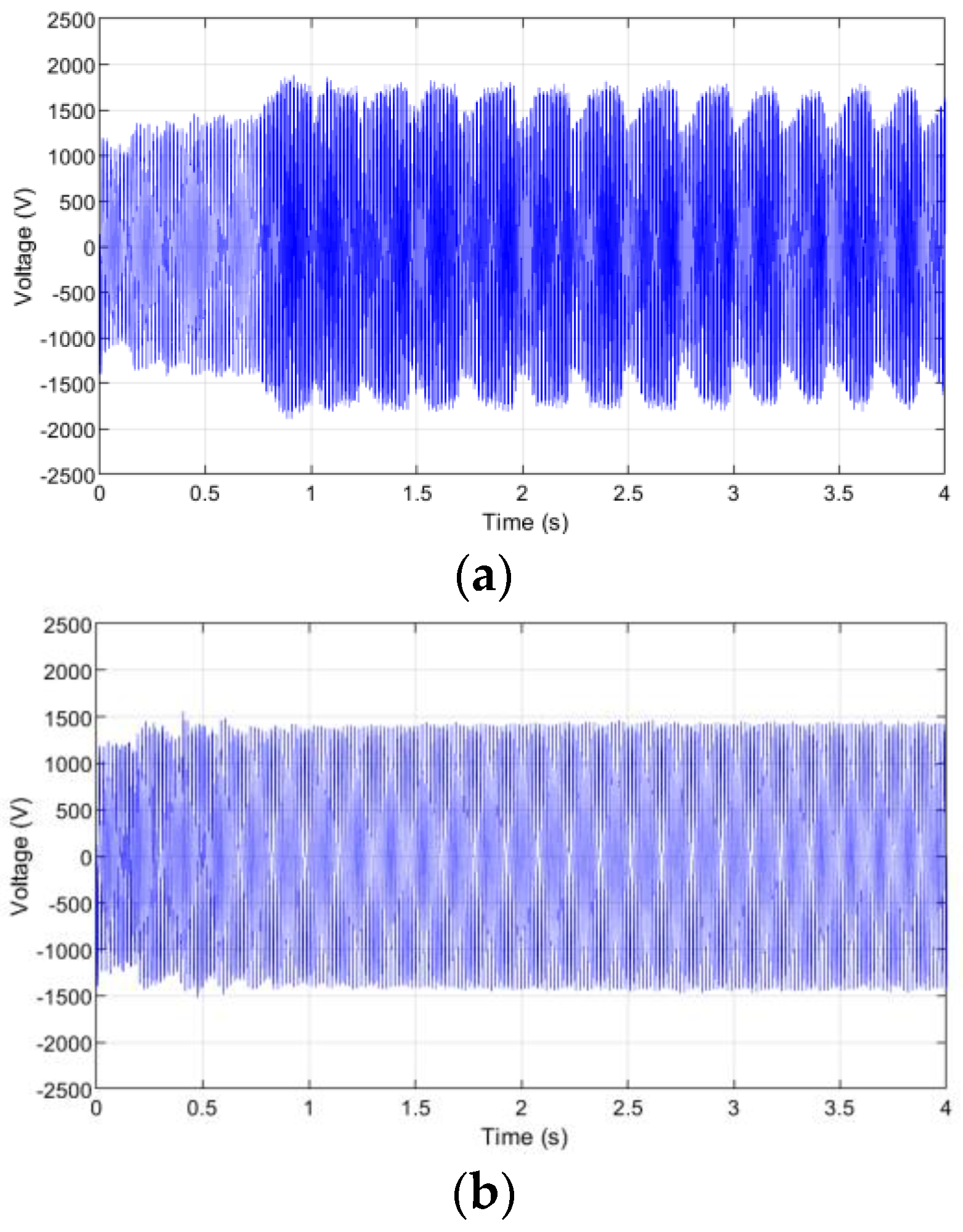

5.5. Verification of the Influence Rule of the Parallel Correction Link Gain Kf

5.6. Verification of the Simplification of the Excitation System Structure

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Yang, W.; Qi, H.; Shi, Z.; Geng, H. Coordinated power reserve control of wind farm for frequency regulation. IEEE Access 2023, 11, 55465–55473. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Y.; Huang, L.; Ying, F.; Li, F. Collection system topology for deep-sea offshore wind farms considering wind characteristics. IEEE Trans. Energy Convers. 2022, 37, 631–642. [Google Scholar]

- Hara, S.; Douzono, H.; Imamura, M.; Yoshioka, T. Estimation of photovoltaic cell parameters using measurement data of photovoltaic module string currents and voltages. IEEE J. Photovolt. 2022, 12, 540–545. [Google Scholar]

- Chen, J.; Zhao, Y.; Lin, H.; Wei, Y.; Liu, W.; Guo, Q.; Li, Y.; Mantooth, H.A. Analysis and Control of Cascaded Energy Storage System for Energy Efficiency and Power Quality Improvement in Electrified Railways. IEEE Trans. Transp. Electrif. 2023. [Google Scholar] [CrossRef]

- Chen, J.; Ge, Y.; Wang, K.; Hu, H.; He, Z.; Tian, Z.; Li, Y. Integrated Regenerative Braking Energy Utilization System for Multi-Substations in Electrified Railways. IEEE Trans. Ind. Electron. 2023, 70, 298–310. [Google Scholar]

- Zhao, Z.; Yang, J.; Yang, W.; Luo, H.; Peng, Y. Coordinated multi-objective optimization for multiple trade-offs in pumped outage condition of pumped storage system. IEEE Access 2019, 7, 161394–161411. [Google Scholar] [CrossRef]

- Liu, D.; Pan, J.; Zhang, H.; Wang, K.; Pan, F.; Zhu, J. A quantification method of promoting variable renewable energy accommodation by pumped storage power plant. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC), Nanjing, China, 27–29 May 2022; pp. 2407–2411. [Google Scholar]

- Luo, Y.; Shao, D.; Zhao, J.; Huang, K.; Li, X. Stability analysis of Tianchi pumped storage power station connected to central China Power Grid. In Proceedings of the 2022 7th Asia Conference on Power and Electrical Engineering (ACPEE), Virtual, 16–17 April 2022; pp. 606–612. [Google Scholar]

- Zhang, S.; Xiang, Y.; Liu, J.; Liu, J.; Yang, J.; Zhao, X.; Jawad, S.; Wang, J. A regulating capacity determination method for pumped storage hydropower to restrain PV generation fluctuations. CSEE J. Power Energy Syst. 2022, 8, 304–316. [Google Scholar]

- Tiwari, R.; Nilsen, R.; Mo, O. Control strategies for variable speed operation of pumped storage plants with full-size converter fed synchronous machines. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 61–68. [Google Scholar]

- Xin, C.; Minxiao, H.; Chao, Z. Power control analysis for variable speed pumped storage with full-size converter. In Proceedings of the IECON 2015-41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 001327–001332. [Google Scholar]

- Wang, W.; Wang, Z.; Yang, Z.; Ma, W.; Tang, F.; Wu, X.; Xiao, M. Methods of smoothing active power fluctuations of photovoltaic plants using the full-size converter based variable speed pumped storage unit. In Proceedings of the 2020 IEEE Power & Energy Society General Meeting (PESGM), Montreal, QC, Canada, 2–6 August 2020; pp. 1–5. [Google Scholar]

- Pan, P.; Ding, L.; Shi, H.; Chen, G. Multi-mode simulation modeling of full-size variable speed pumped storage system including the complete unit links. In Proceedings of the 2023 Panda Forum on Power and Energy (PandaFPE), Chengdu, China, 27–30 April 2023; pp. 13–17. [Google Scholar]

- Holzer, T.; Muetze, A.; Traxler-Samek, G.; Lecker, M.; Zerobin, F. Generator design possibilities for full-size converter operation of large pumped storage power plants. IEEE Trans. Ind. Appl. 2020, 56, 3644–3655. [Google Scholar]

- Chazarra, M.; Pérez-Díaz, J.I.; García-González, J. Optimal joint energy and secondary regulation reserve hourly scheduling of variable speed pumped storage hydropower plants. IEEE Trans. Power Syst. 2018, 33, 103–115. [Google Scholar] [CrossRef]

- Jian, Y.; Zhong, L.; Yi, F.; Guo, H.; Yang, H.; Xu, W.; Hu, J.; Wu, Y. Feasibility analysis of full power variable speed operation of pumped storage power station based on M3C converter. In Proceedings of the 2022 12th International Conference on Power and Energy Systems (ICPES), Guangzhou, China, 23–25 December 2022; pp. 440–444. [Google Scholar]

- Abdalla, O.H.; Han, M. Variable speed pumped storage based on the use of H-bridge cascaded multilevel converter. In Proceedings of the 7th International Power Electronics and Motion Control Conference, Harbin, China, 2–5 June 2012; pp. 402–405. [Google Scholar]

- Joseph, A.; Kim, S.; Lee, S.S.; Dominic, A.; Lee, K. Boost multi-level NPC-fed VS large rated asynchronous pumped storage hydro-generating unit. IET Electr. Power Appl. 2019, 13, 1488–1496. [Google Scholar]

- Ji, L.; Sun, J.; Zhou, M.; Tian, W. AC excitation control strategy of variable speed pumped storage units based on active disturbance rejection control. In Proceedings of the 6th International Conference on Renewable Power Generation (RPG), Wuhan, China, 19–20 October 2017; pp. 1195–1199. [Google Scholar]

- Yao, W.; Deng, C.; Peng, P. Optimal sizing of variable-speed seawater pumped storage based on maximum efficiency tracking. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–1 November 2020; pp. 374–379. [Google Scholar]

- Tiwari, R.; Nilsen, R.; Nysveen, A. Active NPC converter for variable speed operation of pumped storage hydropower plant. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 1211–1216. [Google Scholar]

- He, J.; Ji, K.; Lin, D.; Mei, G.; Xu, M.; Xia, H. Multivariable feedback linearizaton scheme for new excitation system based on full controlled device. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; pp. 1–5. [Google Scholar]

- Pramanik, M.A.H.; Roy, T.K.; Ghosh, S.K.; Anower, M.S.; Mahmud, M.A. An advanced excitation control scheme for a synchronous generator in a single machine infinite bus system based on detailed dynamical models. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Jaipur, India, 16–19 December 2020; pp. 1–6. [Google Scholar]

- Su, X.; Wang, G.; Qu, Z.; Fan, J.; Shang, G.; Bian, C. Research on the state evaluation model of a generator excitation system based on fuzzy comprehensive evaluation theory. In Proceedings of the 2021 IEEE 3rd International Conference on Power Data Science (ICPDS), Harbin, China, 26 December 2021; pp. 17–22. [Google Scholar]

| Symbol | Parameter | Value |

|---|---|---|

| Tc | Time constant of the sampling link | Tc = 0.001 |

| K | DC gain of the series correction link | K = 200 |

| KV | Integration correction selection factor | KV = 1 |

| T1 | Time constant of the series compensation link | T1 = 0.01 |

| T2 | T2 = 1 | |

| T3 | T3 = 1 | |

| T4 | T4 = 6.86 | |

| Ka | Gain of the power amplification link | Ka = 1 |

| Ta | Time constant of the power amplification link | Ta = 0.02 |

| Kf | Gain of the parallel correction link | Kf = 0 |

| Tf | Time constant of the parallel correction link | Tf = 1 |

| Rf | Resistance of the excitation winding | Rf = 0.1576 |

| Kψ | Mapping relationship between excitation current and motor-port voltage | Kψ = 0.02 |

| Tc | Time constant of the sampling link | Tc = 0.001 |

| K | DC gain of the series correction link | K = 200 |

| KV | Integration correction selection factor | KV = 1 |

| Symbol | Parameter | Value |

|---|---|---|

| ug | Power grid voltage | ug = 35 kV |

| fg | Power grid frequency | fg = 50 Hz |

| rt | Transformer ratio | rt = 35 kV:3.3 kV |

| udc | DC voltage | udc = 5.2 kV |

| um | Motor-port voltage | um = 1 kV |

| n | Mechanical speed | n = 1500 r/min |

| Pm | Active power | Pm = 1 MW |

| Qf | Reactive power | Qf = 0 Var |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, P.; Shi, H.; Chen, G.; Ding, L.; Zhang, Y.; Zha, X. Modeling and Operating Characteristics of Excitation System for Variable Speed Pumped Storage Unit with Full-Size Converter. Electronics 2024, 13, 505. https://doi.org/10.3390/electronics13030505

Pan P, Shi H, Chen G, Ding L, Zhang Y, Zha X. Modeling and Operating Characteristics of Excitation System for Variable Speed Pumped Storage Unit with Full-Size Converter. Electronics. 2024; 13(3):505. https://doi.org/10.3390/electronics13030505

Chicago/Turabian StylePan, Pengyu, Huabo Shi, Gang Chen, Lijie Ding, Yuanzhi Zhang, and Xiaoming Zha. 2024. "Modeling and Operating Characteristics of Excitation System for Variable Speed Pumped Storage Unit with Full-Size Converter" Electronics 13, no. 3: 505. https://doi.org/10.3390/electronics13030505

APA StylePan, P., Shi, H., Chen, G., Ding, L., Zhang, Y., & Zha, X. (2024). Modeling and Operating Characteristics of Excitation System for Variable Speed Pumped Storage Unit with Full-Size Converter. Electronics, 13(3), 505. https://doi.org/10.3390/electronics13030505