Development of an Adaptive Fuzzy-Neural Controller for Temperature Control in a Brick Tunnel Kiln

Abstract

1. Introduction

- (1)

- As far as the authors are aware, this is the first instance of a fuzzy neural network controller proposed for the BTK system, combining the capabilities of fuzzy logic and neural networks. The advanced control system aims to offer a robust and adaptable solution to optimize temperature levels while minimizing energy consumption for the BTK system.

- (2)

- The controller leverages sensor data, historical information, and real-time adjustments to optimize temperature control, taking into account variables such as fuel type, external environmental conditions, and furnace load.

- (3)

- Outstanding performance of the suggested methodology is exhibited via simulation and experimental results as compared with two controllers, i.e., PID and fuzzy controllers.

2. Modelling of the Brick Tunnel Kilns

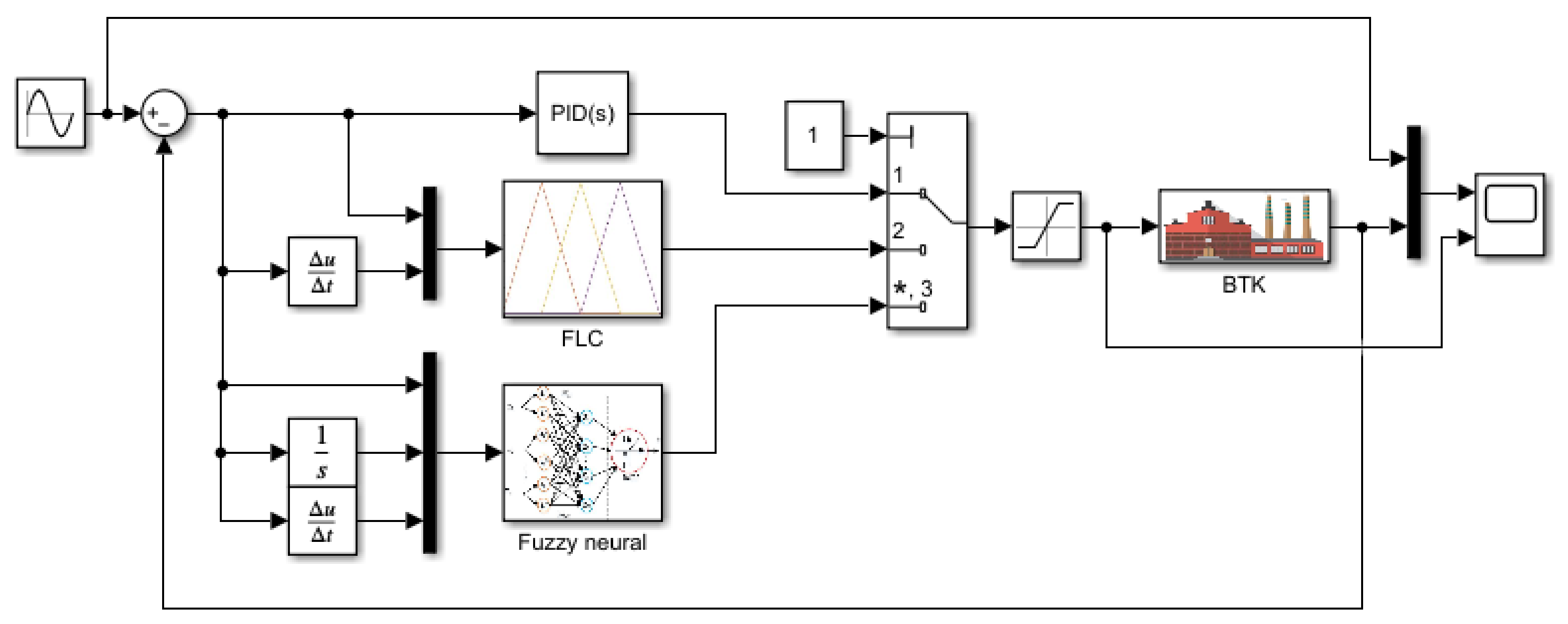

3. Controller Design

3.1. PID Controller

3.2. Fuzzy Logic Controller

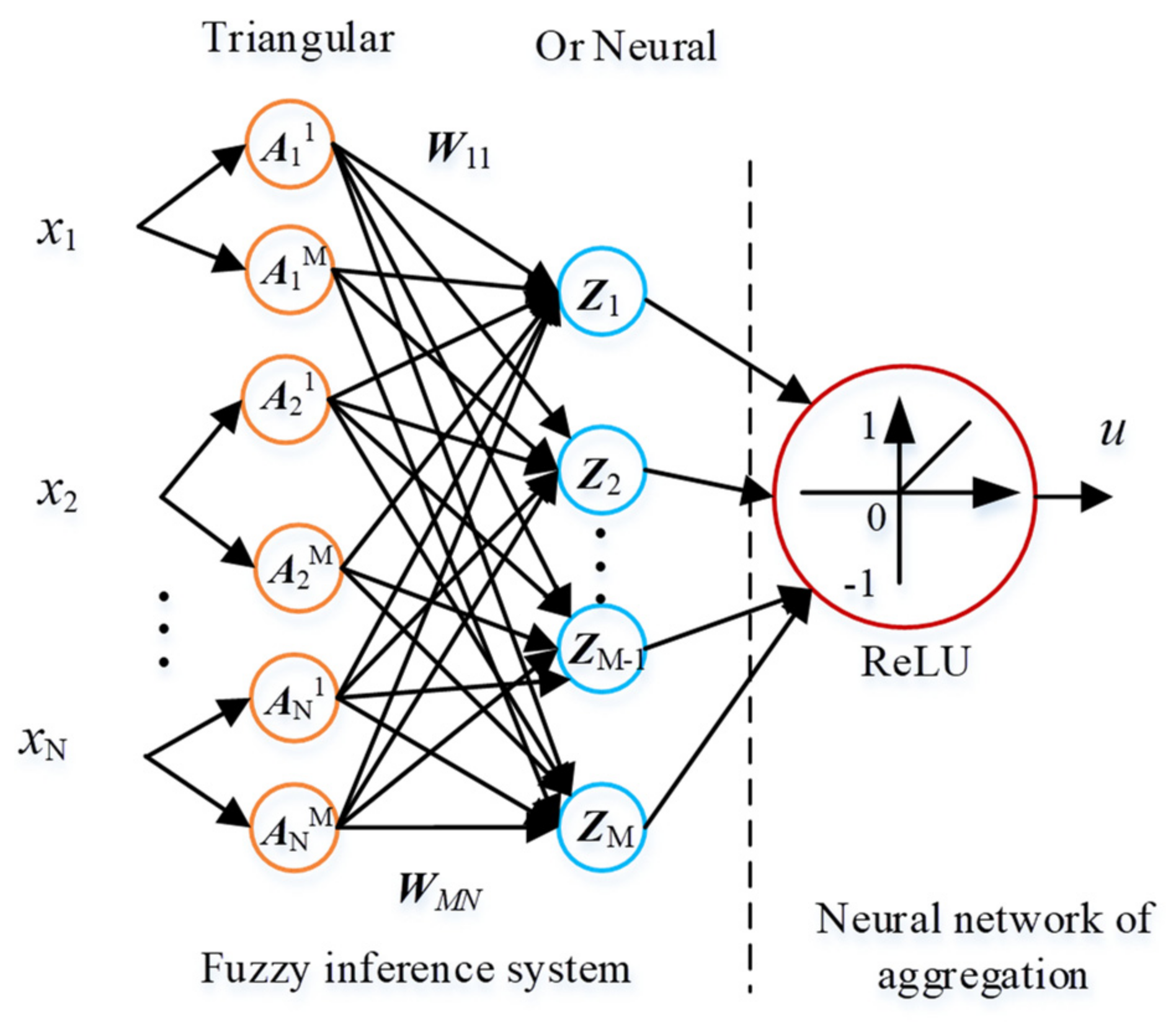

3.3. Fuzzy-Neural Controller

- Rule Rl: If x1(t) is , x2(t) is , and xn(t) is , then the output u (control signal) is Bi,

4. Simulation and Experimental Validation

4.1. Simulation Results

4.2. Experimental Verification

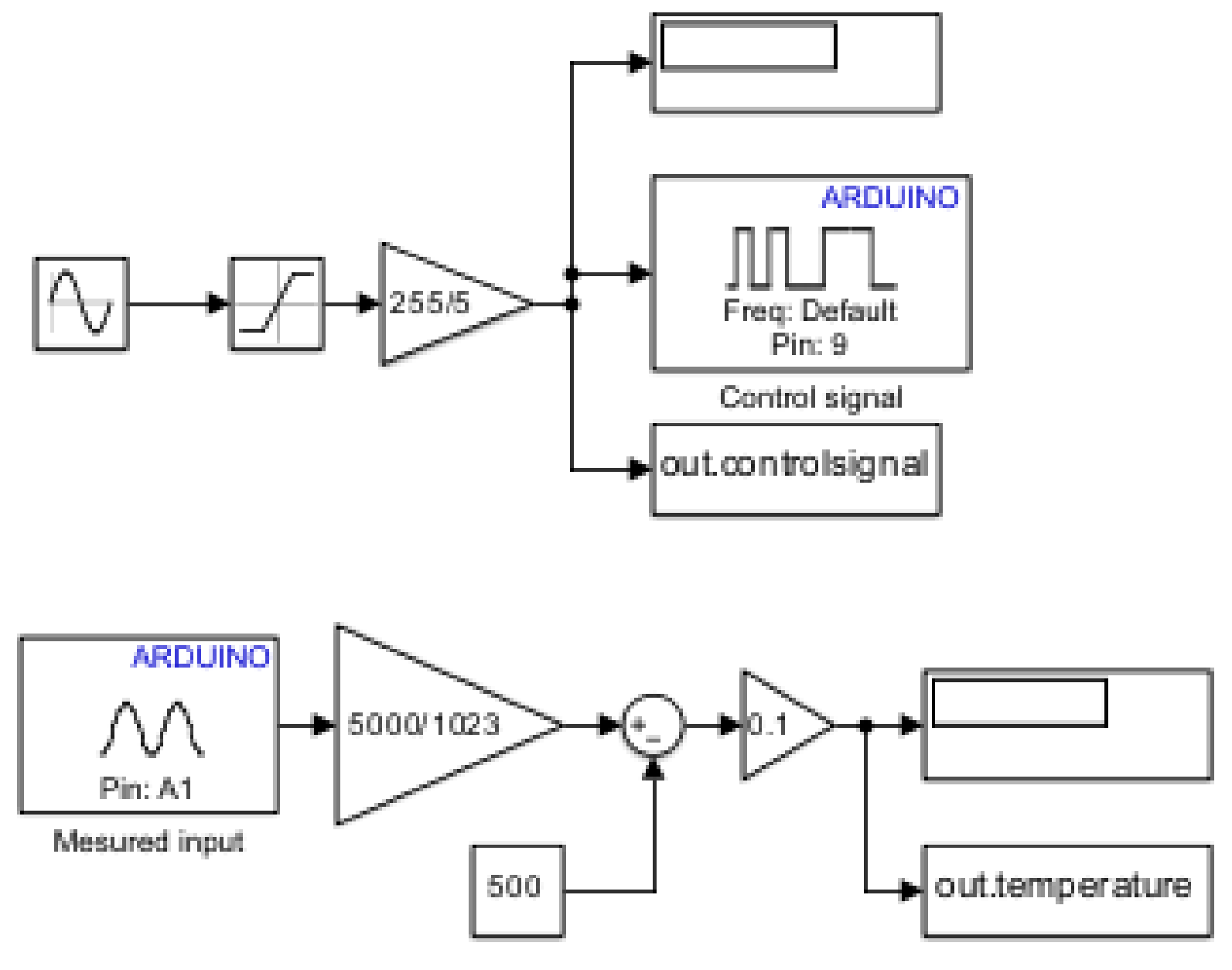

4.2.1. Experimental Setup

- Laptop: used to design and control the system.

- Arduino: receive program from Matlab; control the system.

- Temperature sensor TMP36: used to read the returned temperature and feed back to the main controller.

- SSR relay: used to control temperature bulbs.

- Incandescent light bulbs: act as a source of heat.

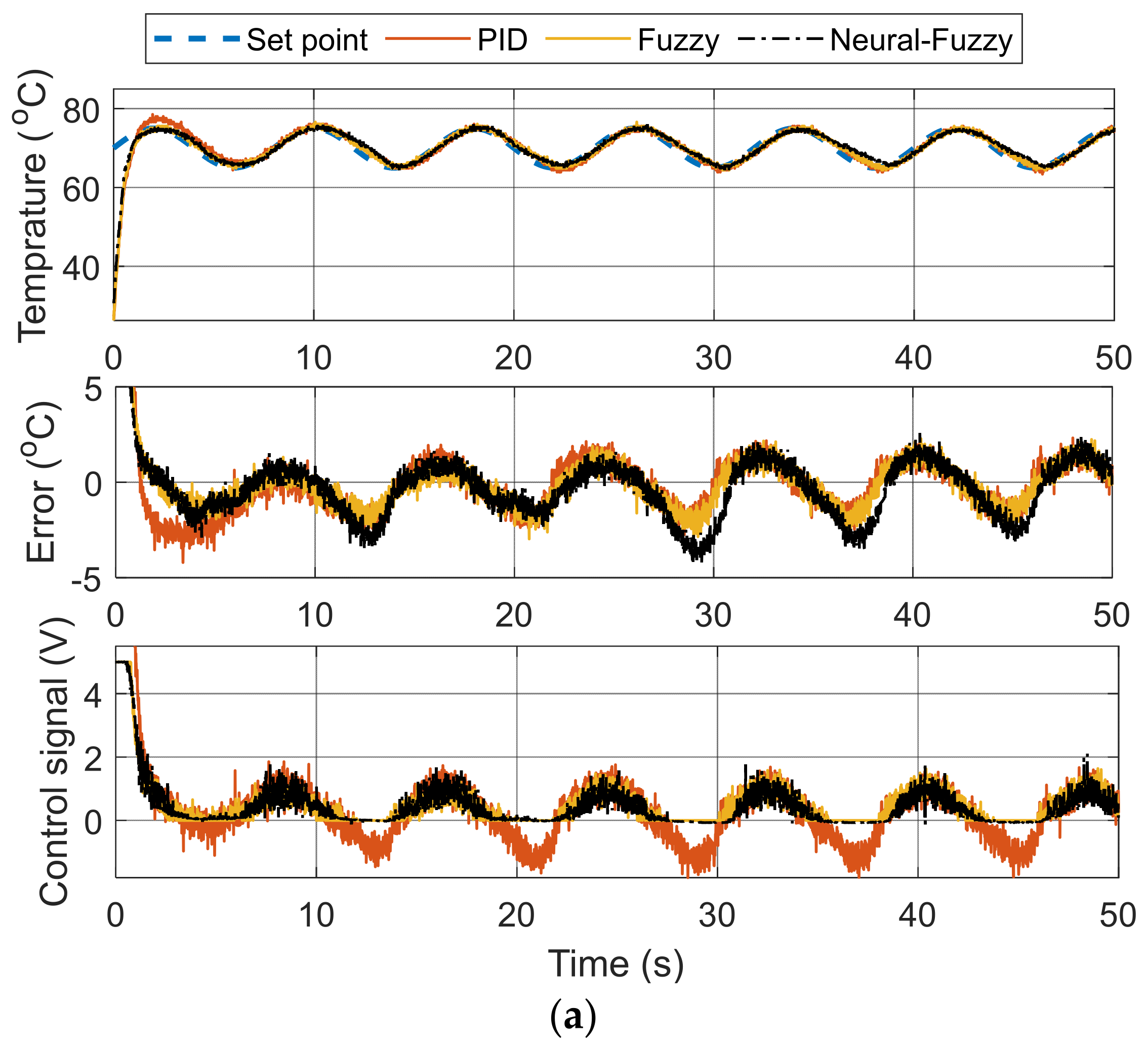

4.2.2. Experimental Results

- Case study 1:

- desired constant input (x1d = 60 °C)

- Case study 2:

- desired sinusoidal input (similar to simulation study)

- Case study 3:

- desired signal Builder waveform input

4.3. Performance Index Evaluation

4.3.1. Evaluation of the Simulation Result

4.3.2. Evaluation of the Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Darain, K.M.U.; Jumaat, M.Z.; Islam, A.S.; Obaydullah, M.; Iqbal, A.; Adham, M.I.; Rahman, M.M. Energy efficient brick kilns for sustainable environment. Desalination Water Treat. 2015, 2015, 105–114. [Google Scholar] [CrossRef]

- Refaey, H.; Almohammadi, B.A.; Abdel-Aziz, A.A.; Abdelrahman, H.; El-Ghany, H.A.; Karali, M.A.; Al-Dosoky, M. Transient thermal behavior in brick tunnel kiln with guide vanes: Experimental study. Case Stud. Therm. Eng. 2022, 33, 101959. [Google Scholar] [CrossRef]

- Da Silva Almeida, G.; da Silva, J.B.; e Silva, C.J.; Swarnakar, R.; de Araújo Neves, G.; de Lima, A.G.B. Heat and mass transport in an industrial tunnel dryer: Modeling and simulation applied to hollow bricks. Appl. Therm. Eng. 2013, 55, 78–86. [Google Scholar] [CrossRef]

- Victor, A.O.; Ejiogu, E. Hybrid Solar Thermal/Electricity Automated Oven. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 188. [Google Scholar] [CrossRef]

- De Rubeis, T.; Muttillo, M.; Nardi, I.; Pantoli, L.; Stornelli, V.; Ambrosini, D. Integrated Measuring and Control System for Thermal Analysis of Buildings Components in Hot Box Experiments. Energies 2019, 12, 2053. [Google Scholar] [CrossRef]

- Dugwell, D.R.; Oakley, D. A model of heat transfer in tunnel kilns used for firing refractories. Int. J. Heat Mass Transf. 1988, 31, 2381–2390. [Google Scholar] [CrossRef]

- Mancuhan, E.; Kucukada, K.; Alpman, E. Mathematical modeling and simulation of the preheating zone of a tunnel kiln. J. Therm. Sci. Technol. 2011, 31, 79–86. [Google Scholar]

- Durakovic, J.; Delalic, S. Temperature field analysis of tunnel kiln for brick production. Mater. Geoenviron. 2006, 53, 403–408. [Google Scholar]

- Refaey, H.; Abdel-Aziz, A.A.; Ali, R.; Abdelrahman, H.; Salem, M. Augmentation of convective heat transfer in the cooling zone of brick tunnel kiln using guide vanes: An experimental study. Int. J. Therm. Sci. 2017, 122, 172–185. [Google Scholar] [CrossRef]

- Yu, B. Dynamic Modeling of a Tunnel Kiln. Heat Transf. Eng. 1994, 15, 39–53. [Google Scholar] [CrossRef]

- Minnu Jayan, C.; Rini Jones, S.B.; Binu, L.S. A Survey on the Control Techniques used In Process Control. In Proceedings of the 2023 International Conference on Innovations in Engineering and Technology (ICIET), Muvattupuzha, India, 13–14 July 2023; pp. 1–6. [Google Scholar]

- Visan, D.A.; Lita, I.; Cioc, I.B. Temperature control system based on adaptive PID algorithm implemented in FPAA. In Proceedings of the 2011 34th International Spring Seminar on Electronics Technology (ISSE), Tratanska Lomnica, Slovakia, 11–15 May 2011. [Google Scholar]

- Hambali, N.; Ang, A.A.R.; Ishak, A.A.; Janin, Z. Various PID controller tuning for air temperature oven system. In Proceedings of the 2014 IEEE International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Kuala Lumpur, Malaysia, 25 November 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, D. A temperature monitor system with King View software based on single-chip microcomputer. J. Xian Univ. Sci. Technol. 2005, 25, 201–203. [Google Scholar]

- Qiu, X.; Gao, Y. Automatic Temperature Control System for the Large-Size Brick Kiln. In Advances in Technology and Management: Proceedings of the 2012 International Conference on Technology and Management (ICTAM 2012), International Convention Center Jeju, Jeju-Island, Korea; Kim, H., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; p. 165. [Google Scholar] [CrossRef]

- Singhala, P.; Shah, D.N.; Patel, B. Temperature Control using Fuzzy Logic. Int. J. Instrum. Control Syst. 2014, 4, 1–10. [Google Scholar]

- Jiang, W.; Jiang, X. Design of an Intelligent Temperature Control System Based on the Fuzzy Self-Tuning PID. Procedia Eng. 2012, 43, 307–311. [Google Scholar] [CrossRef]

- Palaniyappan, T.K.; Yadav, V.; Ruchira; Tayal, V.K.; Choudekar, P. PID Control Design for a Temperature Control System. In Proceedings of the 2018 International Conference on Power Energy, Environment and Intelligent Control (PEEIC), Greater Noida, India, 13–14 April 2018; pp. 632–637. [Google Scholar] [CrossRef]

- Guofang, G.; Zhengzhong, L. Design of Heating Furnace Temperature Control System Based on Fuzzy-PID Controller. In Information Engineering and Applications; Zhu, R., Ma, Y., Eds.; Lecture Notes in Electrical Engineering; Springer: London, UK, 2012; p. 154. [Google Scholar] [CrossRef]

- Efheij, H.; Albagul, A. Comparison of PID and Artificial Neural Network Controller in online of Real Time Industrial Temperature Process Control System. In Proceedings of the 2021 IEEE 1st International Maghreb Meeting of the Conference on Sciences and Techniques of Automatic Control and Computer Engineering MI-STA, Tripoli, Libya, 25–27 May 2021; pp. 110–115. [Google Scholar] [CrossRef]

- Stankovski, M.; Kolemisevska-Gugulovska, T.; Spasovski, M.; Milkovski, Z.; Kuzmanovska, P. Intelligent Control of a Tunnel Kiln for Clay-Brick Production. IFAC Proc. Vol. 2001, 34, 125–130. [Google Scholar] [CrossRef]

- Duan, Y.-h. The Design of Predictive Fuzzy-PID Controller in Temperature Control System of Electrical Heating Furnace. In Life System Modeling and Intelligent Computing, ICSEE LSMS 2010; Li, K., Fei, M., Jia, L., Irwin, G.W., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2010; p. 6329. [Google Scholar] [CrossRef]

- Trinh, H.-A.; Phan, V.-D.; Truong, H.-V.-A.; Ahn, K.K. Energy Management Strategy for PEM Fuel Cell Hybrid Power System Considering DC Bus Voltage Regulation. Electronics 2022, 11, 2722. [Google Scholar] [CrossRef]

- Van Nam, D.; Gon-Woo, K. Learning Type-2 Fuzzy Logic for Factor Graph Based-Robust Pose Estimation with Multi-Sensor Fusion. IEEE Trans. Intell. Transp. Syst. 2023, 24, 3809–3821. [Google Scholar] [CrossRef]

- Pham, D.-A.; Han, S.-H. Enhancing Underwater Robot Manipulators with a Hybrid Sliding Mode Controller and Neural-Fuzzy Algorithm. J. Mar. Sci. Eng. 2023, 11, 2312. [Google Scholar] [CrossRef]

- Van Nam, D.; Kim, G.-W. Online Self-Calibration of Multiple 2D LiDARs Using Line Features with Fuzzy Adaptive Covariance. IEEE Sens. J. 2021, 21, 13714–13726. [Google Scholar] [CrossRef]

- Zhao, M.; Wan, J.; Peng, C. Generalized predictive control using improved recurrent fuzzy neural network for a boiler-turbine unit. Eng. Appl. Artif. Intell. 2023, 121, 106053. [Google Scholar] [CrossRef]

- Phu, D.X.; Mien, V. Robust control for vibration control systems with dead-zone band and time delay under severe disturbance using adaptive fuzzy neural network. J. Frankl. Inst. 2020, 357, 12281–12307. [Google Scholar] [CrossRef]

- Kaya, S.; Mançuhan, E.; Küçükada, K. Modelling and optimization of the firing zone of a tunnel kiln to predict the optimal feed locations and mass fluxes of the fuel and secondary air. Appl. Energy 2009, 86, 325–332. [Google Scholar] [CrossRef]

- Oba, R.; Possamai, T.; Nicolau, V. Thermal analysis of a tunnel kiln used to produce roof tiles. Appl. Therm. Eng. 2014, 63, 59–65. [Google Scholar] [CrossRef]

- Phan, V.D.; Ahn, K.K. Fault-tolerant Control for an Electro-Hydraulic Servo System with Sensor Fault Compensation and Disturbance Rejection. Nonlinear Dyn. 2023, 111, 10131–10146. [Google Scholar] [CrossRef]

- Phan, V.D.; Trinh, H.-A.; Ahn, K.K. Finite-Time Command Filtered Control for Oxygen-Excess Ratio of PEM Fuel Cell Systems with Prescribed Performance. Mathematics 2023, 11, 914. [Google Scholar] [CrossRef]

| u | e | |||||

|---|---|---|---|---|---|---|

| VL | L | AV | H | VH | ||

| de | NB | L | L | AV | H | VH |

| NS | VL | L | AV | H | VH | |

| ZE | VL | VL | L | AV | H | |

| PS | VL | VL | L | H | H | |

| PB | L | L | AV | H | VH | |

| Criteria | Neural Network | Fuzzy Logic |

|---|---|---|

| Demonstrate knowledge | Not clear, difficult to explain, and difficult regulation | Clear and easy to check its works and fix change. |

| Learning ability | Able to learn through data sets. | Inability to learn, need for experience requirements of designer |

| Controller | RMSE [°C] | MAE [°C] | MSE [°C] |

|---|---|---|---|

| PID | 6.9222 | 15.2748 | 3.3202 |

| Fuzzy | 3.3363 | 12.3540 | 2.6211 |

| Fuzzy neural | 3.1362 | 12.1143 | 2.6006 |

| Controller | RMSE [°C] | MAE [°C] | MSE [°C] |

|---|---|---|---|

| PID | 1.8288 | 3.3444 | 0.4639 |

| Fuzzy | 2.1753 | 4.7320 | 0.5135 |

| Fuzzy neural | 1.7001 | 2.8903 | 0.3877 |

| Controller | RMSE [°C] | MAE [°C] | MSE [°C] |

|---|---|---|---|

| PID | 3.2364 | 10.4746 | 1.4054 |

| Fuzzy | 3.0923 | 9.5621 | 1.2288 |

| Fuzzy neural | 2.9407 | 8.6478 | 1. 3148 |

| Controller | RMSE [°C] | MAE [°C] | MSE [°C] |

|---|---|---|---|

| PID | 3.6306 | 13.1812 | 2.1694 |

| Fuzzy | 3.5385 | 12.5208 | 2.0202 |

| Fuzzy neural | 3.0097 | 9.0585 | 1.6396 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phan, V.D.; Nguyen, X.H.; Dinh, V.N.; Dang, T.S.; Le, V.C.; Ho, S.P.; Ta, H.C.; Duong, D.T.; Mai, T.A. Development of an Adaptive Fuzzy-Neural Controller for Temperature Control in a Brick Tunnel Kiln. Electronics 2024, 13, 342. https://doi.org/10.3390/electronics13020342

Phan VD, Nguyen XH, Dinh VN, Dang TS, Le VC, Ho SP, Ta HC, Duong DT, Mai TA. Development of an Adaptive Fuzzy-Neural Controller for Temperature Control in a Brick Tunnel Kiln. Electronics. 2024; 13(2):342. https://doi.org/10.3390/electronics13020342

Chicago/Turabian StylePhan, Van Du, Xuan Hung Nguyen, Van Nam Dinh, Thai Son Dang, Van Chuong Le, Sy Phuong Ho, Hung Cuong Ta, Dinh Tu Duong, and The Anh Mai. 2024. "Development of an Adaptive Fuzzy-Neural Controller for Temperature Control in a Brick Tunnel Kiln" Electronics 13, no. 2: 342. https://doi.org/10.3390/electronics13020342

APA StylePhan, V. D., Nguyen, X. H., Dinh, V. N., Dang, T. S., Le, V. C., Ho, S. P., Ta, H. C., Duong, D. T., & Mai, T. A. (2024). Development of an Adaptive Fuzzy-Neural Controller for Temperature Control in a Brick Tunnel Kiln. Electronics, 13(2), 342. https://doi.org/10.3390/electronics13020342