Digital Twin Modeling for Hydropower System Based on Radio Frequency Identification Data Collection

Abstract

1. Introduction

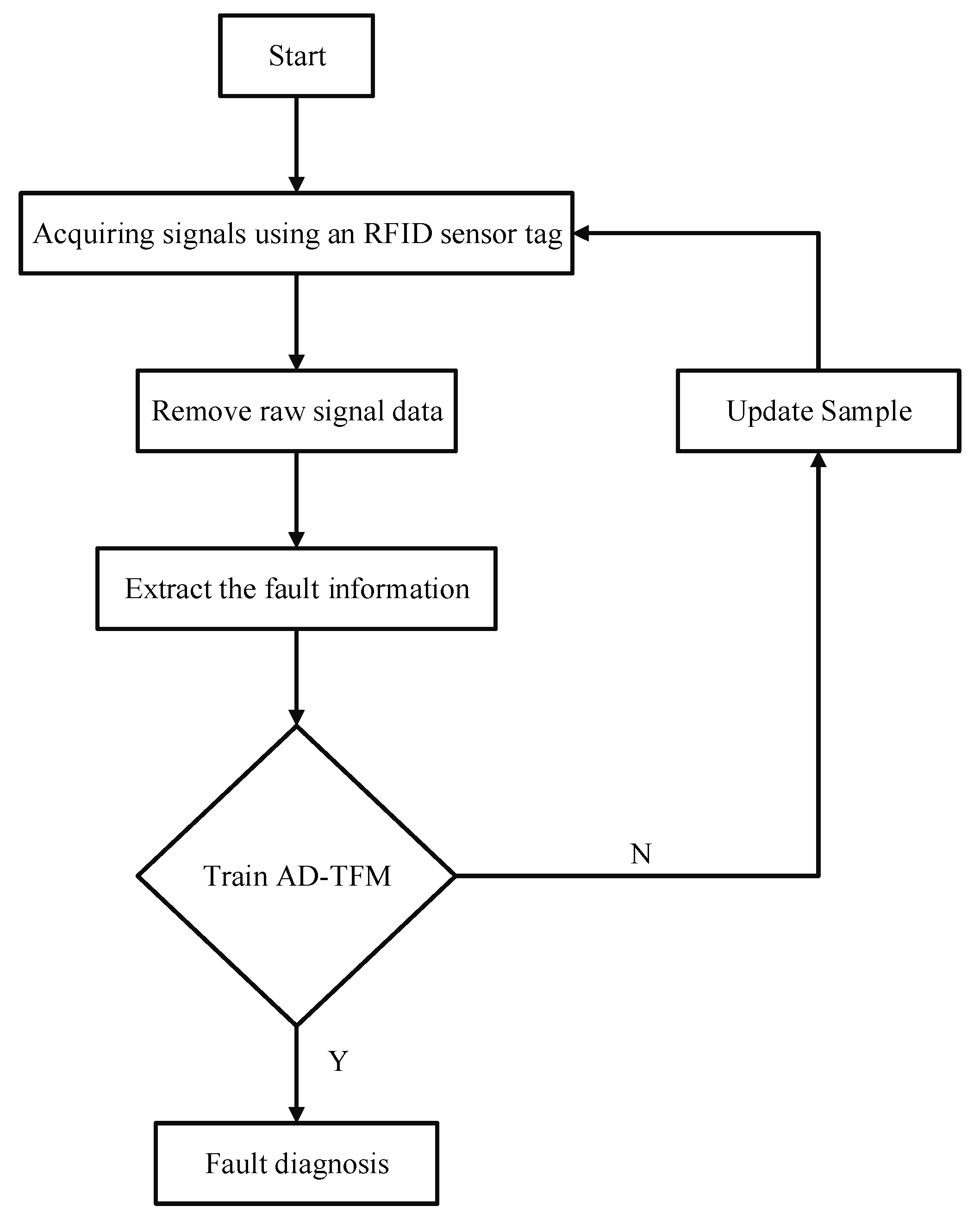

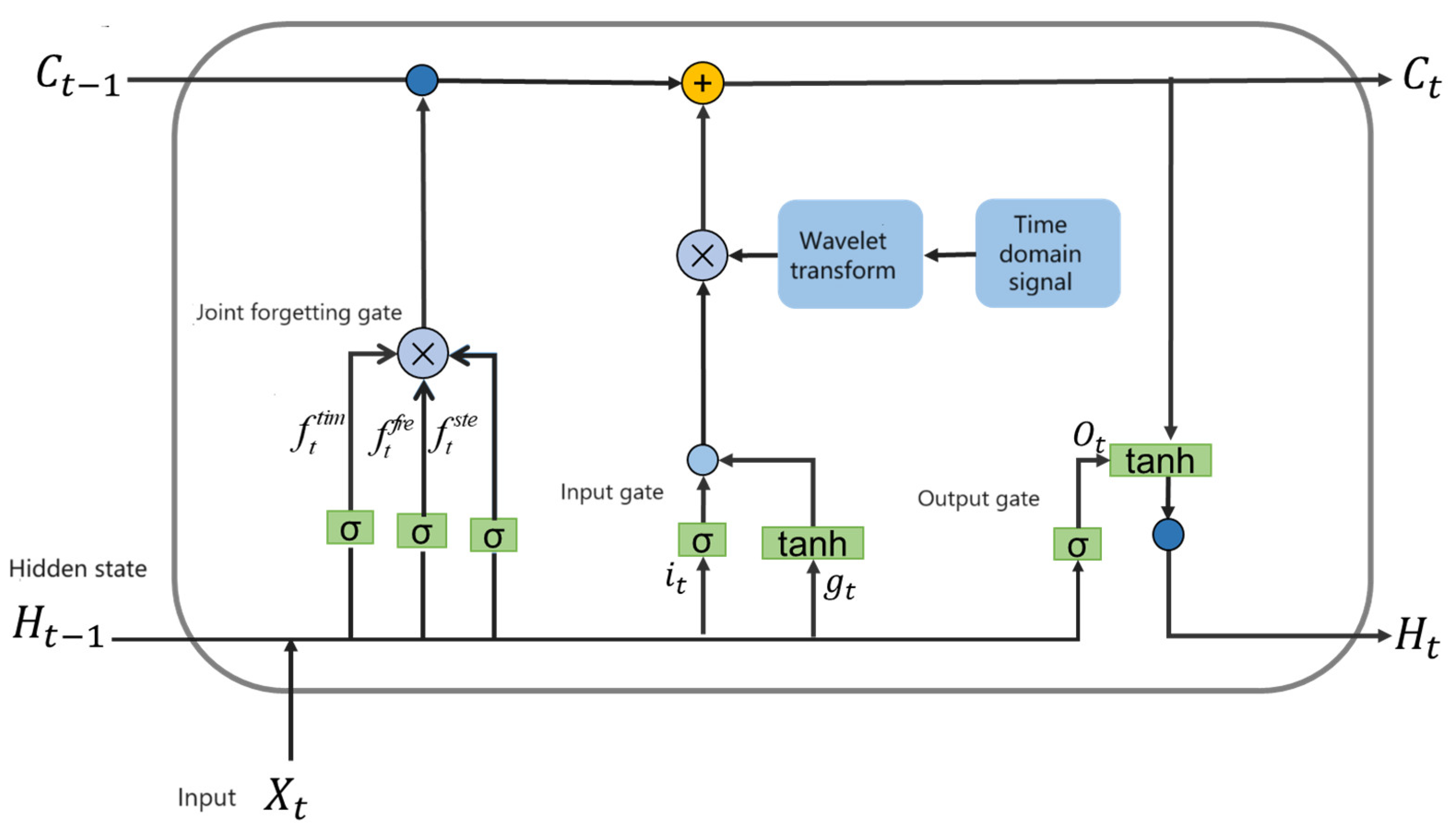

- Due to the increasing complexity of power systems and the huge amount of monitoring data with very few malfunctions, digital twins of hydropower equipment are a challenging topic. With the development of artificial intelligence, data-driven intelligent algorithms have been widely used in the fault detection of power systems [20]. Since power system fault information is positively correlated with time series, long short-term memory recurrent neural networks (LSTMs), which use contextual time series and shows good performance in time series prediction and classification, are applied to power system fault identification. This technique has also achieved good performance in time series estimation and classification [21,22]. Due to the lack of frequency domain analysis of LSTM, fault signals are non-stationary, and the fault data samples are scarce. A fault identification scheme based on LSTM cannot completely extract the features of non-stationary initial faults [23]. In order to solve the above problems as existing in LSTM, researchers have embedded adaptive wavelet transform into LSTM neurons to realize the transformation of time-domain signals to frequency-domain signals, and then proposed adaptive Time–Frequency Memory (AD-TFM) units. Based on the AD-TFM unit, the AD-TFM-AT model of a neural network with an attention mechanism is designed, and the AD-TFM-AT neural network can effectively classify the fault messages of a time series in power system faults after the training of data sets [24]. Our contributions are summarized as follows: digital twin technology is used to model and reconstruct the hydropower station’s primary equipment as well as the whole system.

- An optimization framework for the intelligent management and maintenance of hydropower stations as well as online monitoring is provided by the AD-TFM-AT neural network, which is utilized to perform unsupervised learning and fault identification of multi-dimensional fault signals.

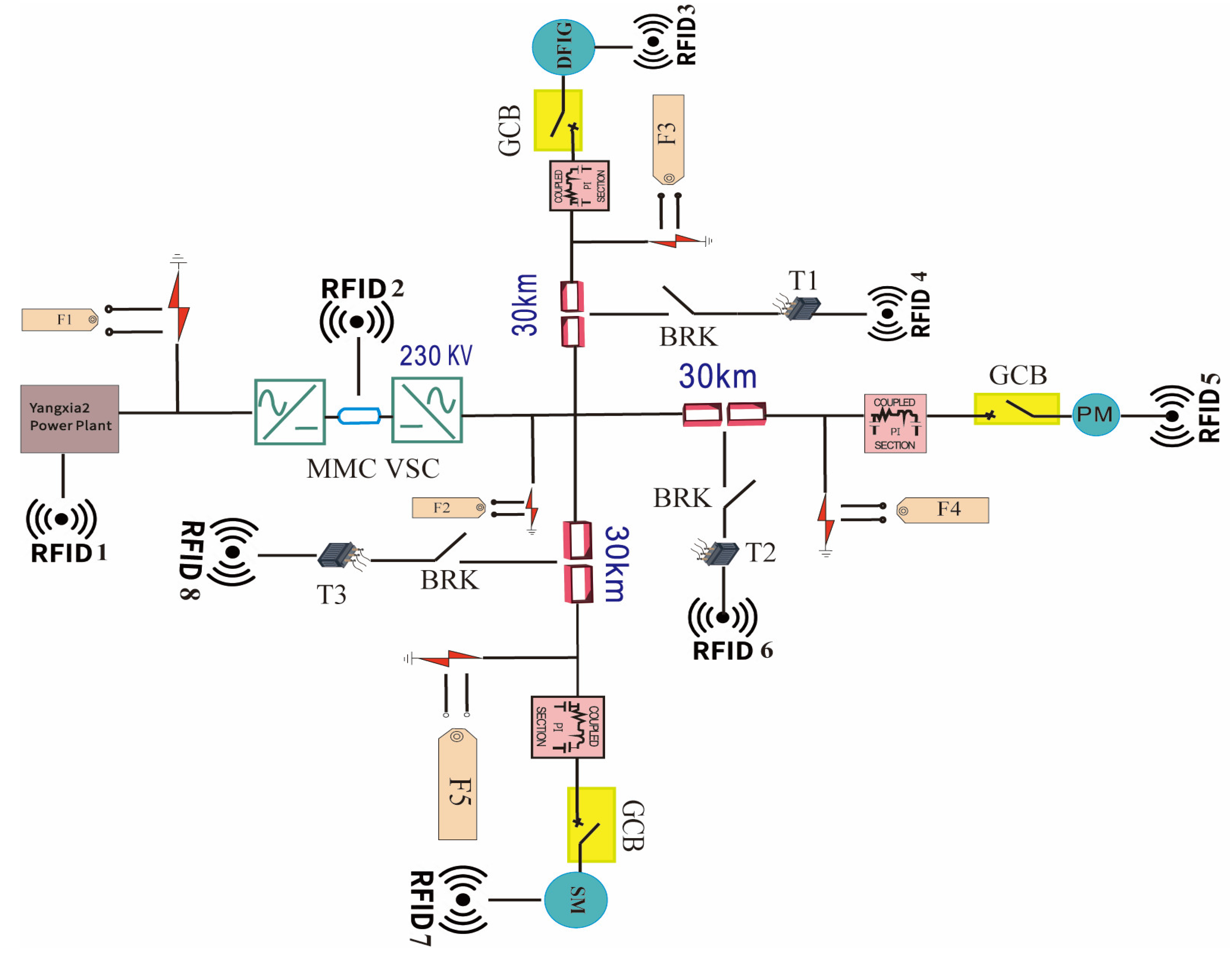

- RFID tags are used to collect the data in order to simulate the operations of a hydropower station’s digital system to collect multi-dimensional fault signal information.

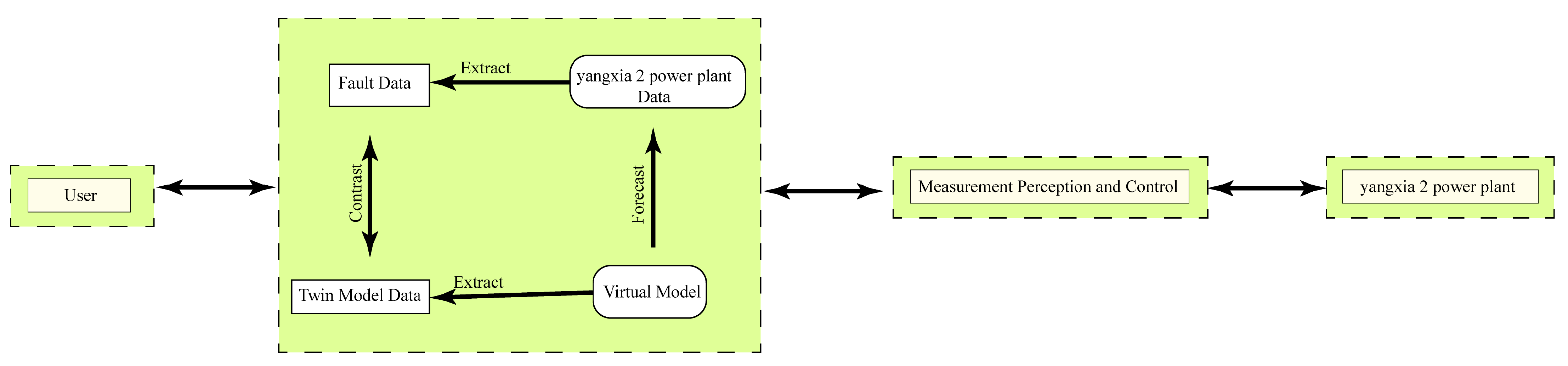

2. Digital Twin Model Architecture and Building

2.1. Digital Twin Model Architecture

- Client Use Domain: This layer facilitates the client’s interaction with the system, providing a user-friendly interface for monitoring and control.

- Digital Twin Layer: The core component responsible for modeling and data processing. It is divided into two sub-layers:

- ○

- Modeling: Handles virtualization and model management of the hydropower station.

- ○

- Service: Utilizes model analysis to address practical problems and improve decision-making.

- Interactive Layer: Manages the upload of measurement data from the hydropower station and the transmission of control instructions.

- Hydropower Station Layer: Represents the operational state of the hydropower station and interacts with the upper layers to ensure seamless data flow and operational control.

2.2. Digital Twin Model Building

3. Intelligent Fault Identification

3.1. Information Collection Principles of RFID

3.2. Construction of AD-TFM Neurons

3.2.1. Joint Forgetting Gate

3.2.2. Neuron Input Gate

3.2.3. Wavelet Transformation

3.2.4. Output Layer

3.3. Preprocessing of Fault Data

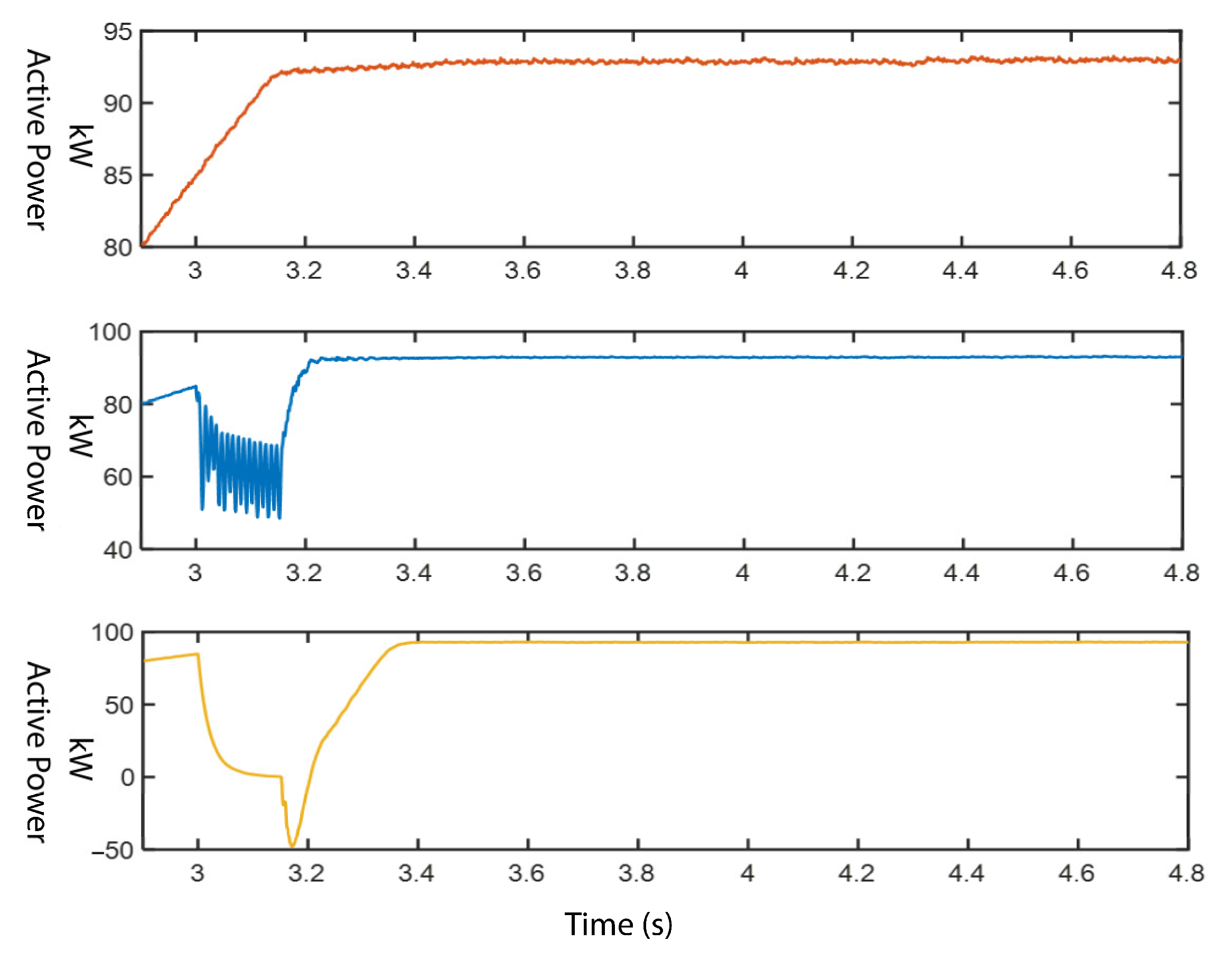

4. Training Results of AD-TFM Neural Network

5. Discussion and Limitation

5.1. Discussion

5.2. Limitation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, L.; Liu, S.; Xi, L.; Zhang, G.; Liu, Z.; Zeng, Q.; Lü, F.; Wang, Y. Research on the Short-Term Economic Dispatch Method of Power System Involving a Hydropower-Photovoltaic-Pumped Storage Plant. Electronics 2024, 13, 1282. [Google Scholar] [CrossRef]

- Jiang, T.; Shen, Z.; Liu, Y.; Hou, Y. Carbon Footprint Assessment of Four Normal Size Hydropower Stations in China. Sustainability 2018, 10, 2018. [Google Scholar] [CrossRef]

- Pan, H.; Luo, Z.; Hang, C.; Zheng, Y.; Feng, F.; Zheng, X. Optimization of Load Distribution Method for Hydropower Units Based on Output Fluctuation Constraint and Double-Layer Nested Model. Mathematics 2024, 12, 662. [Google Scholar] [CrossRef]

- Giraldo, S.; la Rotta, D.; Nieto-Londoño, C.; Vásquez, R.E.; Escudero-Atehortúa, A. Digital Transformation of Energy Companies: A Colombian Case Study. Energies 2021, 14, 2523. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Ma, Y. Prediction Model of Hydropower Generation and Its Economic Benefits Based on EEMD-ADAM-GRU Fusion Model. Water 2022, 14, 3896. [Google Scholar] [CrossRef]

- Lu, X.; Li, C.; Liu, D.; Zhu, Z.; Tan, X.; Xu, R. Comprehensive stability analysis of complex hydropower system under flexible operating conditions based on a fast stability domain solving method. Energy 2023, 274, 127368. [Google Scholar] [CrossRef]

- Usländer, T.; Baumann, M.; Boschert, S.; Rosen, R.; Sauer, O.; Stojanovic, L.; Wehrstedt, J.C. Symbiotic Evolution of Digital Twin Systems and Dataspaces. Automation 2022, 3, 378–399. [Google Scholar] [CrossRef]

- Chainikov, D.; Zakharov, D.; Kozin, E.; Pistsov, A. Studying Spatial Unevenness of Transport Demand in Cities Using Machine Learning Methods. Appl. Sci. 2024, 14, 3220. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin Certified: Employing Virtual Testing of Digital Twins in Manufacturing to Ensure Quality Products. Machines 2023, 11, 808. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, T.; Li, Z.; Bi, Q.; Liu, X.; Tian, K. Digital Twin Modeling Method for Hierarchical Stiffened Plate Based on Transfer Learning. Aerospace 2023, 10, 66. [Google Scholar] [CrossRef]

- Vieira, J.; Poças Martins, J.; de Almeida, N.M.; Patrício, H.; Morgado, J. Reshaping the Digital Twin Construct with Levels of Digital Twinning (LoDT). Appl. Syst. Innov. 2023, 6, 114. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Cheng, J.; Zhang, M.; Xu, W.; Qi, Q. Theory and technologies for cyber-physical fusion in digital twin shop-floor. Comput. Integr. Manuf. Syst. 2017, 23, 1603–1611. [Google Scholar]

- Zhou, Y. Research on Fault Prediction Method of EMU Traction Motor Based on Digital Twin Technology; Beijing Jiaotong University: Beijing, China, 2020. [Google Scholar]

- Grieves, M.W. Digital twins: Past, present, and future. In The Digital Twin; Springer International Publishing: Cham, Switzerland, 2023; pp. 97–121. [Google Scholar]

- Wang, H.; Ahmed, O.; Smith, B.T.; Bellgraph, B. Developing a digital twin for hydropower systems-An open platform framework. Int. Water Power Dam Constr. Mag. 2021, 81, 1818693. [Google Scholar]

- Wang, H.; Ou, S.; Dahlhaug, O.G.; Storli, P.-T.; Skjelbred, H.I.; Vilberg, I. Adaptively Learned Modeling for a Digital Twin of Hydropower Turbines with Application to a Pilot Testing System. Mathematics 2023, 11, 4012. [Google Scholar] [CrossRef]

- De Kooning, J.D.M.; Stockman, K.; De Maeyer, J.; Jarquin-Laguna, A.; Vandevelde, L. Digital Twins for Wind Energy Conversion Systems: A Literature Review of Potential Modelling Techniques Focused on Model Fidelity and Computational Load. Processes 2021, 9, 2224. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Z.; Shen, C.; Wu, J.; Zhao, A. A review of radio frequency identification sensing systems for structural health monitoring. Materials 2022, 15, 7851. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Pang, W.; Zhang, Z.; Wang, X. Short-term Load Forecasting of Online Learning Support Vector Machine based on Bayes Theory input feature Selection. Electr. Eng. China 2005, 25, 8–13. [Google Scholar]

- Deng, F.; Wen, K.; Xie, Z.; Liu, H.; Tong, J. External Breaking Vibration Identification Method of Transmission Line Tower Based on Solar-Powered RFID Sensor and CNN. Electronics 2020, 9, 519. [Google Scholar] [CrossRef]

- Ma, Y.; Oslebo, D.; Maqsood, A.; Corzine, K. DC Fault Detection and Pulsed Load Monitoring Using Wavelet Transform-Fed LSTM Autoencoders. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 7078–7087. [Google Scholar] [CrossRef]

- Skydt, M.R.; Bang, M.; Shaker, H.R. A probabilistic sequence classification approach for early fault prediction in distribution grids using long short-term memory neural networks. Measurement 2021, 170, 108691. [Google Scholar] [CrossRef]

- Liu, M.-D.; Ding, L.; Bai, Y.-L. Application of hybrid model based on empirical mode decomposition, novel recurrent neural networks and the ARIMA to wind speed prediction. Energy Convers. Manag. 2021, 233, 113917. [Google Scholar] [CrossRef]

- Li, Q.; Luo, H.; Cheng, H.; Deng, Y.; Sun, W.; Li, W.; Liu, Z. Incipient Fault Detection in Power Distribution System: A Time–Frequency Embedded Deep-Learning-Based Approach. IEEE Trans. Instrum. Meas. 2023, 72, 1–14. [Google Scholar] [CrossRef]

- Feng, R.; Xiang, X.; Xie, S.; Jiang, P. Sensing System for Mixed Inorganic Salt Solution Based on Improved Double Label Coupling RFID. IEEE Sens. J. 2023, 23, 13565–13574. [Google Scholar] [CrossRef]

- Wang, T.; He, Y.; Li, B.; Shi, T. Transformer fault diagnosis using self-powered RFID sensor and deep learning approach. IEEE Sens. J. 2018, 18, 6399–6411. [Google Scholar] [CrossRef]

- Wang, L.; Gu, T.; Tao, X.; Lu, J. Toward a wearable RFID system for real-time activity recognition using radio patterns. IEEE Trans. Mob. Comput. 2016, 16, 228–242. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, Y.; Pan, Y. Fault diagnosis of Rolling Bearing based on multi-sensor signal and Convolutional neural Network. J. Vib. Shock. 2020, 39, 172–178. [Google Scholar]

- Li, Z.; Zhang, M.; Li, L.; Guan, X. Fault Diagnosis of Microgrids Using Branch Convolution Neural Network and Majority Voting. In Proceedings of the 2022 IEEE International Conference on Communications, Control, and Computing Technologies for Smart Grids (SmartGridComm), Singapore, 25–28 October 2022; pp. 328–333. [Google Scholar]

- Li, C.; Wang, B. A Knowledge Graph Method towards Power System Fault Diagnosis and Classification. Electronics 2023, 12, 4808. [Google Scholar] [CrossRef]

| Methodology | Key Finding | References |

|---|---|---|

| Adaptive learning with recursive least squares algorithm | Developed dynamic models for digital twins that accurately mimic hydropower turbine dynamics | [16] |

| Systematic literature review and bibliometric–qualitative analysis | Highlights the need for integrated information systems in digital twins for watershed management | [15] |

| Rigorous method | Provides a comprehensive overview of digital twin applications, aiding in the identification of best practices | [14] |

| Virtual replica | Highlights the use of digital twins for design, production, prognostics, and health management | [17] |

| Fault Category | Fault One-Hot Label |

|---|---|

| Normal | 1000 |

| Single-phase short-circuit fault | 0100 |

| Two-phase short-circuit fault | 0010 |

| Three-phase short-circuit fault | 0001 |

| Fault Category | Accuracy | Recall Rate | F1-Score | Sample Size |

|---|---|---|---|---|

| Normal | 0.88 | 1.00 | 0.93 | 28 |

| Single-phase short-circuit fault | 1.00 | 0.91 | 0.95 | 79 |

| Two-phase short-circuit fault | 0.97 | 0.81 | 0.89 | 86 |

| Three-phase short-circuit fault | 0.84 | 0.99 | 0.91 | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Z.; Wang, Y.; Zhang, D.; Wen, L.; Liu, H.; Xiong, Z.; Wajid, K.; Feng, R. Digital Twin Modeling for Hydropower System Based on Radio Frequency Identification Data Collection. Electronics 2024, 13, 2576. https://doi.org/10.3390/electronics13132576

Cai Z, Wang Y, Zhang D, Wen L, Liu H, Xiong Z, Wajid K, Feng R. Digital Twin Modeling for Hydropower System Based on Radio Frequency Identification Data Collection. Electronics. 2024; 13(13):2576. https://doi.org/10.3390/electronics13132576

Chicago/Turabian StyleCai, Zhi, Yanfeng Wang, Dawei Zhang, Lili Wen, Haiyang Liu, Zhijie Xiong, Khan Wajid, and Renhai Feng. 2024. "Digital Twin Modeling for Hydropower System Based on Radio Frequency Identification Data Collection" Electronics 13, no. 13: 2576. https://doi.org/10.3390/electronics13132576

APA StyleCai, Z., Wang, Y., Zhang, D., Wen, L., Liu, H., Xiong, Z., Wajid, K., & Feng, R. (2024). Digital Twin Modeling for Hydropower System Based on Radio Frequency Identification Data Collection. Electronics, 13(13), 2576. https://doi.org/10.3390/electronics13132576