A Nonlinear Hybrid Modeling Method for Pump Turbines by Integrating Delaunay Triangulation Interpolation and an Improved BP Neural Network

Abstract

1. Introduction

2. Modeling and Modeling Evaluation of the PT

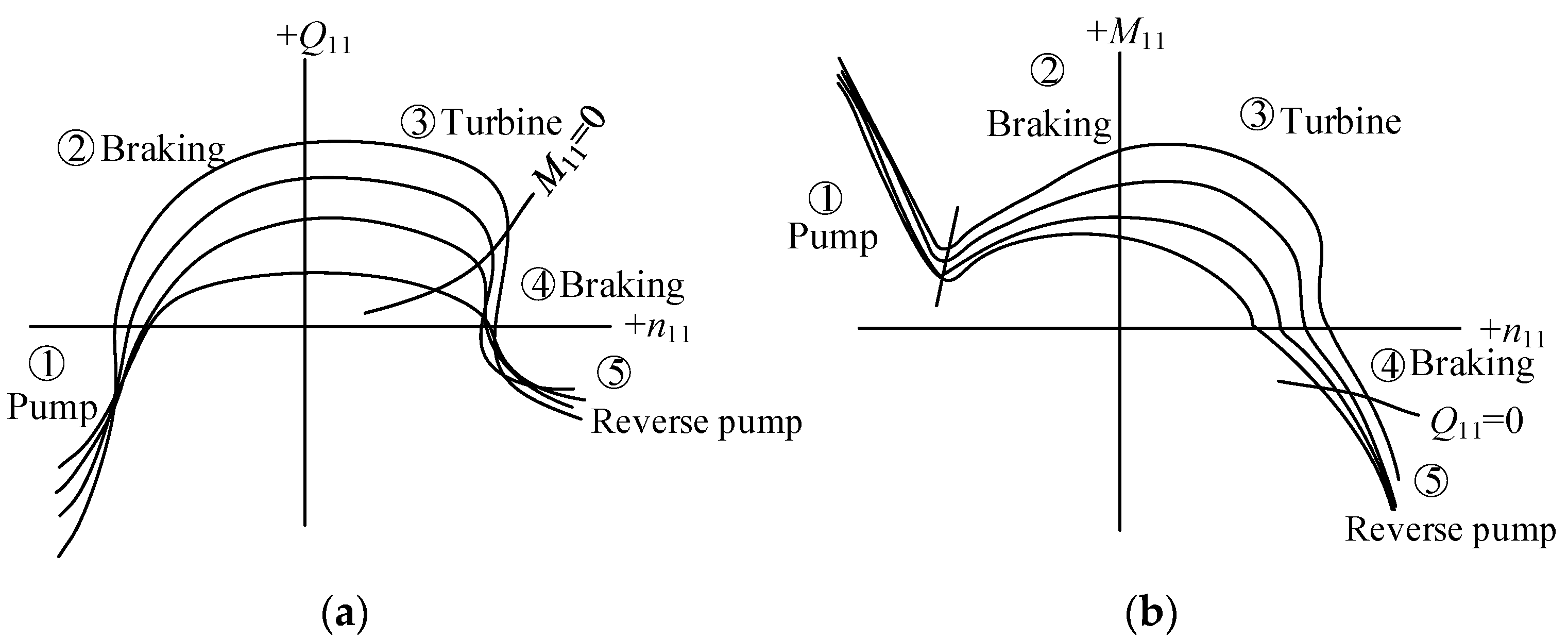

2.1. Modeling of the PT Based on the Complete Characteristic Curve

2.2. Modeling Evaluation Indicators

3. Nonlinear Hybrid Modeling Method for the PT

3.1. Delaunay Triangulation Interpolation

- (1)

- A super triangle containing all the measurement points is constructed and placed in a linked list of triangles.

- (2)

- The measurement points in the set are sequentially inserted. First, the triangle containing the insertion point in the circumcircle is identified. The insertion point is then connected to all the vertices of the triangle, completing the insertion of a point in the Delaunay triangle linked list.

- (3)

- Based on the characteristics of the Delaunay triangulation network’s external empty circles, the optimization criterion is used to optimize the newly formed local triangle to satisfy the Delaunay characteristics.

- (4)

- Steps (2)–(4) above are performed in a loop until all measurement points have been inserted, forming a complete irregular network.

- (5)

- Similarly, the points to be interpolated need to follow step (4), and the estimated values of the points can be calculated through linear interpolation.

3.2. IBP Optimized by the Mind Evolutionary Algorithm

3.3. Nonlinear Hybrid Modeling Method

4. Experimental Verification

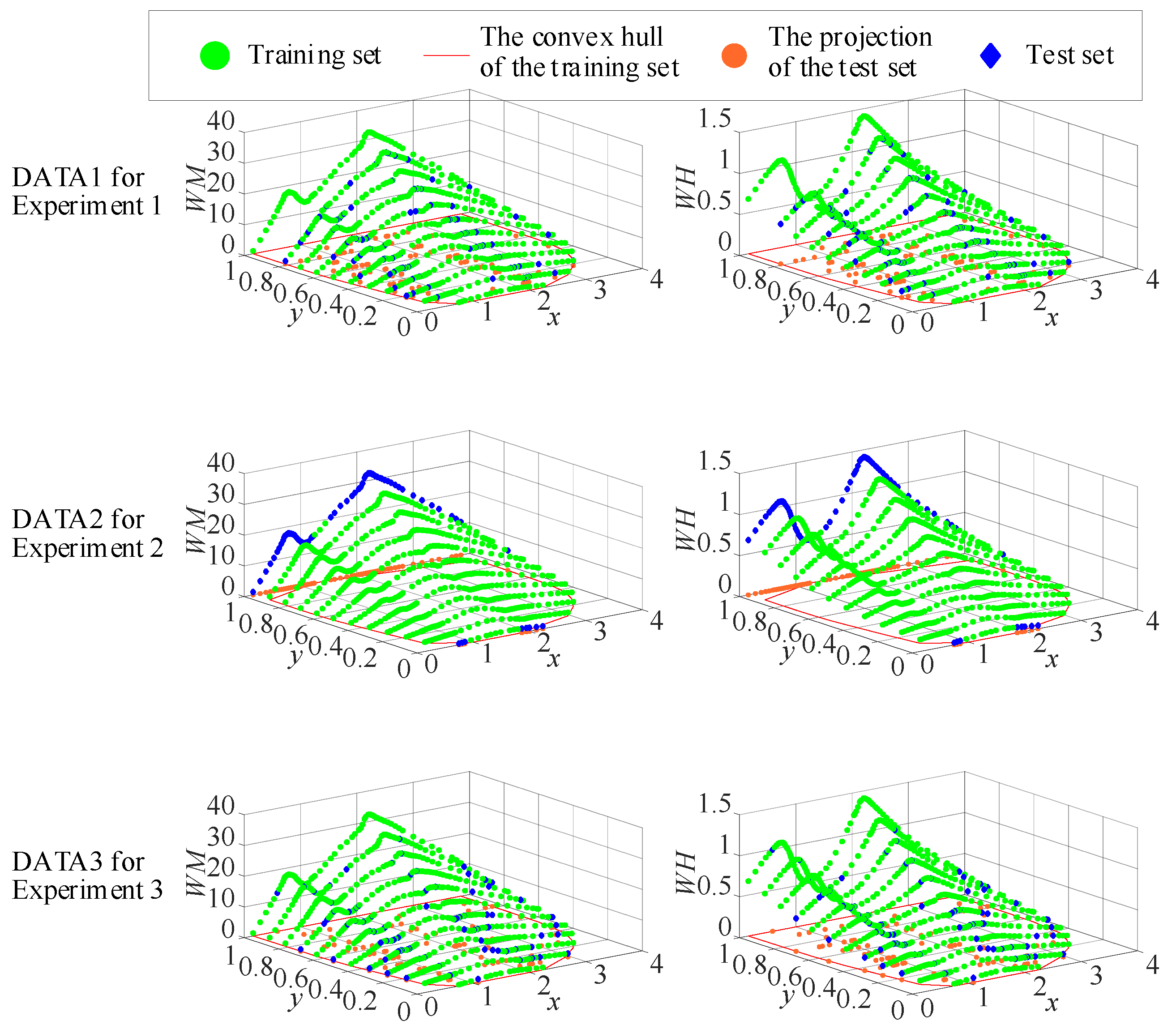

4.1. Experimental Data

4.2. Experiment 1: Inside the Convex Hull

4.3. Experiment 2: Outside the Convex Hull

4.4. Experiment 3: Partially Outside the Convex Hull

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- 2023 Statistical Review of World Energy[EB/OL]//Energy Institute. Available online: https://www.energyinst.org/statistical-review (accessed on 18 January 2024).

- European Electricity Review 2022[EB/OL]//Ember. Available online: https://ember-climate.org/insights/research/european-electricity-review-2022/#supporting-material (accessed on 18 January 2024).

- Hoffstaedt, J.P.; Truijen, D.P.K.; Fahlbeck, J.; Gans, L.H.A.; Qudaih, M.; Laguna, A.J.; De Kooning, J.D.M.; Stockman, K.; Nilsson, H.; Storli, P.-T.; et al. Low-head pumped hydro storage: A review of applicable technologies for design, grid integration, control and modelling. Renew. Sustain. Energy Rev. 2022, 158, 112119. [Google Scholar] [CrossRef]

- Xu, Z.; Deng, C.; Yang, Q. Flexibility of variable-speed pumped-storage unit during primary frequency control and corresponding assessment method. Int. J. Electr. Power Energy Syst. 2023, 145, 108691. [Google Scholar] [CrossRef]

- Chazarra, M.; Perez-Diaz, J.I.; Garcia-Gonzalez, J. Optimal Joint Energy and Secondary Regulation Reserve Hourly Scheduling of Variable Speed Pumped Storage Hydropower Plants. IEEE Trans. Power Syst. 2018, 33, 103–115. [Google Scholar] [CrossRef]

- Xu, Z.; Deng, C.; Yang, Q. A primary frequency control strategy for variable-speed pumped-storage plant in generating mode based on adaptive model predictive control. Electr. Power Syst. Res. 2023, 221, 109356. [Google Scholar] [CrossRef]

- Yao, W.; Deng, C.; Li, D.; Chen, M.; Peng, P.; Zhang, H. Optimal Sizing of Seawater Pumped Storage Plant with Variable-Speed Units Considering Offshore Wind Power Accommodation. Sustainability 2019, 11, 1939. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Theoretical model of energy performance prediction and BEP determination for centrifugal pump as turbine. Energy 2019, 172, 712–732. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, K.; Zhao, W. Nonlinear Modeling of Dynamic Characteristics of Pump-Turbine. Energies 2022, 15, 297. [Google Scholar] [CrossRef]

- Feng, C.; Mai, Z.; Wu, C.; Zheng, Y.; Zhang, N. Advantage of battery energy storage systems for assisting hydropower units to suppress the frequency fluctuations caused by wind power variations. J. Energy Storage 2024, 78, 109989. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, W.; Liu, Y.; Bao, Z.; Mao, Z.; Rashad, E.M. Modeling and Transient Response Analysis of Doubly-Fed Variable Speed Pumped Storage Unit in Pumping Mode. IEEE Trans. Ind. Electron. 2023, 70, 9935–9947. [Google Scholar] [CrossRef]

- Mohale, V.; Chelliah, T.R.; Hote, Y.V. Small Signal Stability Analysis of Damping Controller for SSO Mitigation in a Large Rated Asynchronous Hydro Unit. IEEE Trans. Ind. Appl. 2023, 59, 4914–4923. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, C.; Zhao, Y. Coordination Control between Excitation and Hydraulic System during Mode Conversion of Variable Speed Pumped Storage Unit. IEEE Trans. Power Electron. 2021, 36, 10171–10185. [Google Scholar] [CrossRef]

- Group, I.W. Hydraulic turbine and turbine control model for system dynamic studies. IEEE Trans. Power Syst. 1992, 7, 167–179. [Google Scholar]

- Sarasúa, J.I.; Pérez-Díaz, J.I.; Wilhelmi, J.R.; Sánchez-Fernández, J.Á. Dynamic response and governor tuning of a long penstock pumped-storage hydropower plant equipped with a pump-turbine and a doubly fed induction generator. Energy Convers. Manag. 2015, 106, 151–164. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, J.; Yang, W.; Hu, J.; Chen, M. A coordinated optimization framework for flexible operation of pumped storage hydropower system: Nonlinear modeling, strategy optimization and decision making. Energy Convers. Manag. 2019, 194, 75–93. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, Z.; Wang, L.; Zhang, Y. Data interpolation by Delaunay triangulation for the combined characteristic curve of a turbine. J. Hydroelectr. Eng. 2011, 30, 197–952. [Google Scholar]

- Li, J.; Chen, Q.; Chen, G. Study on synthetic characteristic curve processing of Francis turbine conbined with BP neural network. J. Hydroelectr. Eng. 2015, 34, 182–188. [Google Scholar]

- Pan, H.; Hang, C.; Feng, F.; Zheng, Y.; Li, F. Improved Neural Network Algorithm Based Flow Characteristic Curve Fitting for Hydraulic Turbines. Sustainability 2022, 14, 10757. [Google Scholar] [CrossRef]

- Cao, R.; Guo, W.; Qu, F. Hydraulic disturbance characteristics and power control of pumped storage power plant with fixed and variable speed units under generating mode. J. Energy Storage 2023, 72, 108298. [Google Scholar] [CrossRef]

- Suter, P. Representation of Pump Characteristics for Calculation of Water Hammer. Sulzer Tech. Rev. 1966, 4, 45–48. [Google Scholar]

- Dorfler, P.K. Improved Suter Transform for Pump-Turbine Characteristics. Int. J. Fluid Mach. Syst. 2010, 3, 332–341. [Google Scholar] [CrossRef]

- Zhang, C.; Peng, T.; Zhou, J.; Ji, J.; Wang, X. An Improved Autoencoder and Partial Least Squares Regression-Based Extreme Learning Machine Model for Pump Turbine Characteristics. Appl. Sci. 2019, 9, 3987. [Google Scholar] [CrossRef]

- IEC60193 1999; Hydraulic Turbines, Storage Pumps and Pump-Turbines–Model Acceptance Tests. European Committee for Standards: Brussels, Italy, 1991; Second edition 11-1999.

- Liu, Z.-M.; Zhang, D.-H.; Liu, Y.-Y.; Zhang, X. New Suter-transformation Method of Complete Characteristic Curves of Pump-turbines Based on the 3-D Surface. China Rural. Water Hydropower 2015, 1, 143–145+150+157. [Google Scholar]

- Weatherill, N.P.; Hassan, O. Efficient three-dimensional Delaunay triangulation with automatic point creation and imposed boundary constraints. Int. J. Numer. Methods Eng. 2010, 37, 2005–2039. [Google Scholar] [CrossRef]

- Waston, D.F. Computing the n-dimensional Delaunay tessellation with application to voronoi polytopes. Comput. J. 1981, 24, 167–172. [Google Scholar]

- Joe, B. Three-Dimensional Triangulations from Local Transformations. Siam J. Sci. Stat. Comput. 1989, 10, 718–741. [Google Scholar] [CrossRef]

- Yang, W.X.; Tse, P.W. Development of an advanced noise reduction method for vibration analysis based on singular value decomposition. Ndt Int. 2003, 36, 419–432. [Google Scholar] [CrossRef]

| Error | RMSE | MAPE (%) | R2 (%) | |

|---|---|---|---|---|

| Model | ||||

| IP | 3160.3143 | 88.4499 | 9.4724 | |

| BP | 244.8342 | 7.8279 | 95.9455 | |

| IBP | 196.9613 | 3.3978 | 94.5856 | |

| CNN | 268.3546 | 9.9853 | 93.4788 | |

| LSTM | 482.9481 | 11.8363 | 79.2922 | |

| RF | 475.0019 | 20.1417 | 80.5958 | |

| PHM | 152.2848 | 3.4479 | 97.6663 | |

| Model | IP | BP | IBP | CNN | LSTM | RF | PHM |

|---|---|---|---|---|---|---|---|

| Mean rank | 2.5611 | 3.8556 | 4.1833 | 5.2222 | 4.9556 | 4.9444 | 2.2778 |

| Sort | 2 | 3 | 4 | 7 | 6 | 5 | 1 |

| p-value | p = 5.8487 × 10−33 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Zhang, Y.; Zhang, Y.; Deng, C. A Nonlinear Hybrid Modeling Method for Pump Turbines by Integrating Delaunay Triangulation Interpolation and an Improved BP Neural Network. Electronics 2024, 13, 2573. https://doi.org/10.3390/electronics13132573

Yang Q, Zhang Y, Zhang Y, Deng C. A Nonlinear Hybrid Modeling Method for Pump Turbines by Integrating Delaunay Triangulation Interpolation and an Improved BP Neural Network. Electronics. 2024; 13(13):2573. https://doi.org/10.3390/electronics13132573

Chicago/Turabian StyleYang, Qiuling, Yangning Zhang, Yingchen Zhang, and Changhong Deng. 2024. "A Nonlinear Hybrid Modeling Method for Pump Turbines by Integrating Delaunay Triangulation Interpolation and an Improved BP Neural Network" Electronics 13, no. 13: 2573. https://doi.org/10.3390/electronics13132573

APA StyleYang, Q., Zhang, Y., Zhang, Y., & Deng, C. (2024). A Nonlinear Hybrid Modeling Method for Pump Turbines by Integrating Delaunay Triangulation Interpolation and an Improved BP Neural Network. Electronics, 13(13), 2573. https://doi.org/10.3390/electronics13132573