1. Introduction

As an important production mode [

1], distributed manufacturing has always been considered by experts and scholars with regards to its production efficiency, economic benefits, and social benefits. However, due to the large differences in production scale, production capacity, and regional differences among various factories, the distributed scheduling problem is mainly related to the study of the problem of job allocation and scheduling. These considerations achieve a better scheduling effect.

Aiming at the distributed scheduling problem of flow-shop and job-shop in traditional industry, many experts and scholars have carried out in-depth research from different research angles [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11]. Zhao et al. proposed a pure reactive scheduling method for updating scheduling strategies to deal with the interference of uncertainty in the arrival of new jobs on the shop floor [

2]. Delgoshaei et al. proposed a fuzzy-weighted NSGA-II (FW-NSGA-II) to address the developed non-linear fuzzy multi-objective dual resource-constrained scheduling problem [

3]. Song et al. used the genetic programming hyperheuristic algorithm to solve a class of distributed assembly permutation flow shop scheduling problems related to time and sequence [

4]. Chen et al. solved the distributed flow shop scheduling problem by constructing a heuristic algorithm and iterative greedy algorithm [

5]. Zhang et al. proposed an improved heuristic Kalman algorithm to solve the dynamic job-shop scheduling problem [

6]. Olmo A D et al. presented an indirect monitoring procedure and its application in AISI 1045 high-speed broaching for the unattended machine tool scheduling problem [

7].

For multi-variety, small-batch, and complex products, different from the distributed job scheduling problem, this paper studies the distributed integrated scheduling problem. It is a scheduling mode for part processing and assembly synchronically [

12,

13,

14,

15,

16,

17,

18] for the tree structure products with constraints between operations.

At present, in the existing resource-symmetric two-shop integrated scheduling problem, the research results include the balanced processing algorithm of two-shop scheduling processes [

13], the allied-critical path algorithm [

14], the neighborhood rendering algorithm [

15], and the timing-selected algorithm [

16]. Through improving horizontal parallel processing of schedulable operations, adopting the long-path method and the long-time method for key operations, neighborhood rendering strategy, and workshop selection strategy of the same equipment, these research results achieved good scheduling effect. However, the following major problems still remain.

The integrated scheduling problem is proved to be a NP-hard problem, and the intensity of continuous processing can be further improved in the existing two-workshop integrated scheduling algorithm.

On the basis of minimizing the time cost, the integrated scheduling optimization objective fails to fully and comprehensively consider the complex product properties and the comprehensive utilization of the objective situation of workshop equipment resources, thus increasing the migration frequency.

The equipment resources in the workshop have the problem of low utilization rate or even being idle.

In order to solve the above common problems, this paper proposed a two-workshop integrated scheduling algorithm based on process tree cycle decomposition. It consists of the following three strategies.

Sub-tree cycle decomposition strategy (SCDS). It decomposed the process tree into several operation strings, which could be scheduled together and reduced the number of operation migrations.

Operation weight-based scheduling strategy (OWSS). It comprehensively considers the factors of equipment priority and operation constraint degree, and it establishes scheduling operation set in descending order of weight value, which improves the tightness of operation in longitudinal processing.

Balanced workshop allocation strategy (BWAS). It is based on reducing the processing time difference between the two workshops to allocate the process set to be scheduled, so as to improve the utilization rate of the two vehicles.

2. Problem Description

Definition 1. Symmetric two-workshop. Two different workshops with the same equipment resource and layout.

Definition 2. Operation migration. If an operation is not processed in the same workshop as its immediate predecessor, then an operation migration is said to have occurred.

Definition 3. Integrated scheduling. A scheduling method that schedules the operations of jobs and assembly simultaneously.

Definition 4. Makespan. The completion time of the product is also the maximum completion time of the two workshops.

The symmetric two-workshop integrated scheduling problem can be described as: a single complex tree-structured product with n operations that can be produced by two workshops, f1 and f2, with the same equipment resource and layout. Each workshop contains m machines. The specific requirements are as follows:

(1) The processing structure of the complex product is a treelike structure, which can be represented by a processing tree.

(2) Each node of the tree represents an operation with three known information: operation number, machine type, and processing time.

(3) There are no machines of the same type in the same workshop.

(4) Each operation can only be processed on its specific type of machine in any workshop.

(5) An operation can only be processed after its immediate predecessors have completed.

The objective of our study is to minimize the makespan of products. The objective function is as follows.

The completion time of operation

i can be calculated with Equation (2):

where

is a Boolean variable;

Ci is the completion time of operation

i;

Si is the starting time of operation

i;

Pi is the processing time of operation

i;

,

.

The makespan of the product is the completion time of the last operation. Then,

According to the description and requirements, the constraints are as follows.

Constraint (4) ensures that an operation can only be processed after its predecessors on the same path of processing tree has completed. W is a given large positive integer, . Constraint (5) ensures that an operation can only be processed after other operations on the same machine have been completed. . Constraint (6) ensures that an operation can only be processed in one workshop. Constraint (7) ensures that all the information is significant.

3. Strategy Analysis and Design

3.1. Sub-Tree Cycle Decomposition Strategy (SCDS)

The main feature of the sub-tree decomposition is to divide the nodes in a complex graph, which is dominated by the treelike structure, into several finite and related node subsets according to some rules to decompose the graph into several relatively independent parts, and then we solve them separately, and finally we synthesize them to obtain the approximate optimal solution of the original problem [

19,

20,

21,

22,

23,

24].

For graph

,

denotes the set of all the points in the graph, and

denotes the set of all the edges in the graph. One of its corresponding decomposition trees

can be expressed as (

,

T), where

is a set of consecutive integers, and its number corresponds to the number of nodes in the decomposition tree.

is a subset of

, which corresponds to the

ith node in the decomposition tree [

25].

For the decomposition tree =(, T), let be two points of , and let and be the root nodes of the sub-tree corresponding to u and v on the decomposition tree . If , then and must be an ancestor-descendant relationship on the decomposition tree T, that is, the constraint relation of pre-tightening operation and post-tightening operation in the digraph. If a decomposition tree of graph can be expressed as an ordered pair , then the following conditions are met:

(1) ;

(2) For any data point , there must be a node on the sub-tree T, such that the node set satisfies ∈;

(3) , have , that is, two nodes of every edge in form a cut set.

The SCDS in this article is based on the cycle judgment of the operation attributes, such as the number of branches and the leaf nodes. The complex product process tree is decomposed into several sub-tree strings, of which the internal relations are under the priority constraints. The solution category of sub-trees is much smaller than that of the whole process tree. It can effectively avoid the long waiting time of equipment during the processing to achieve the optimization effect of reducing the overall processing time of complex products. The specific description is as follows:

Step 1: The complex product process tree is simplified into the directed graph according to the constraint relation between operations.

Step 2: Cycle decomposition:

(1) Determine whether the branch of the process tree is unique. If it is, it does not meet the conditions of complex products, therefore end and exit the procedure; if it is not, the branch root node of the process tree is taken as the cut set to decompose the process tree and establish the sub-tree operation string.

(2) Determine whether the sub-tree procedure string is a leaf node procedure. If it is, the decomposition is complete. If it is not, repeat (1).

Step 3: Decompose the complex product process tree into several sub-tree operation strings according to the determined cut set. According to the cut set, establish the sub-tree process sequence of the original complex product process tree.

3.2. Example of the SCDS

Assume that complex product

A consists of 25 operations

A1–

A25, which are processed on four machines,

M1,

M2,

M3, and

M4, in the integrated scheduling system. The processing process tree is shown in

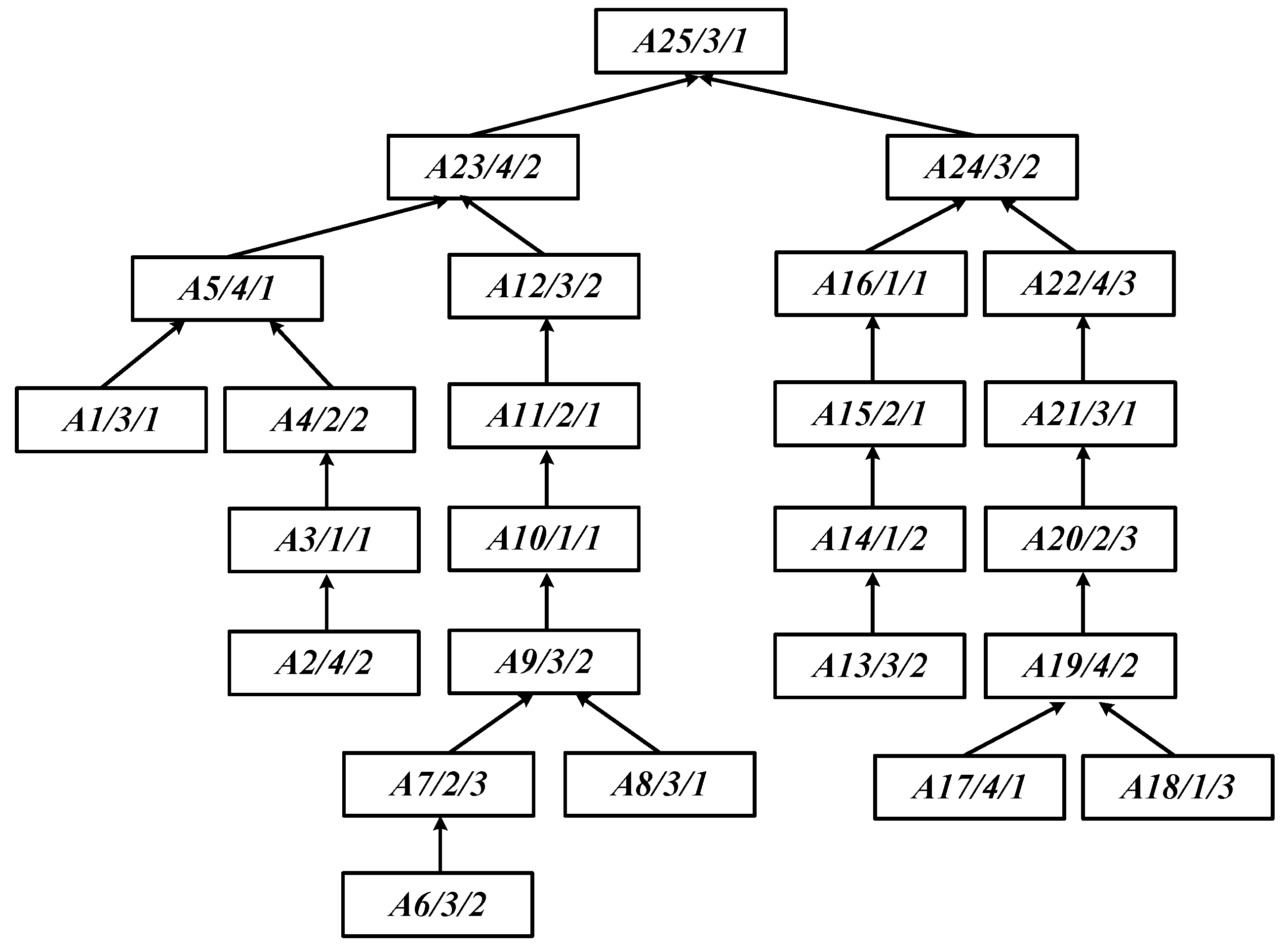

Figure 1. The demonstration process adopting the SCDS is as follows:

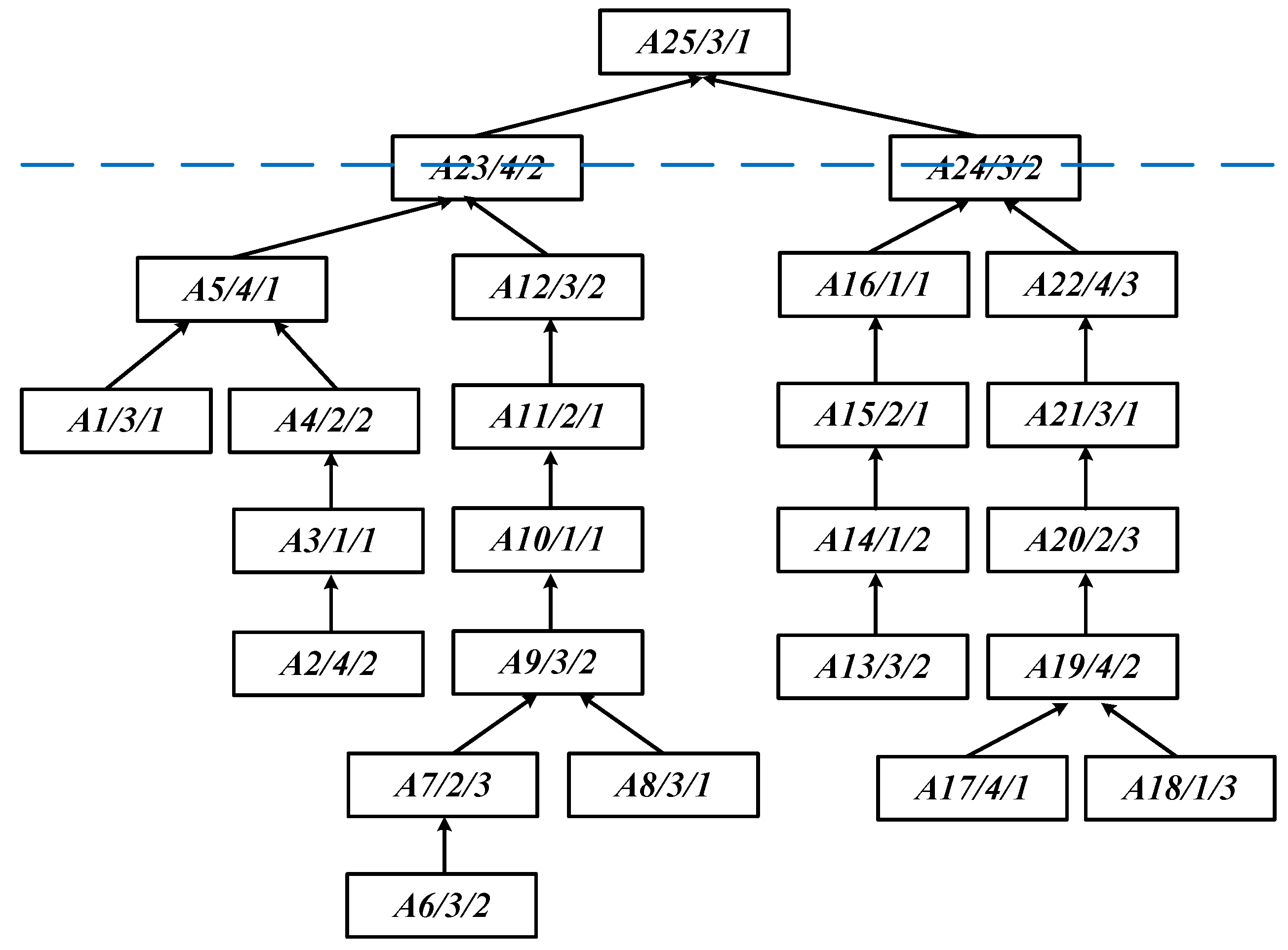

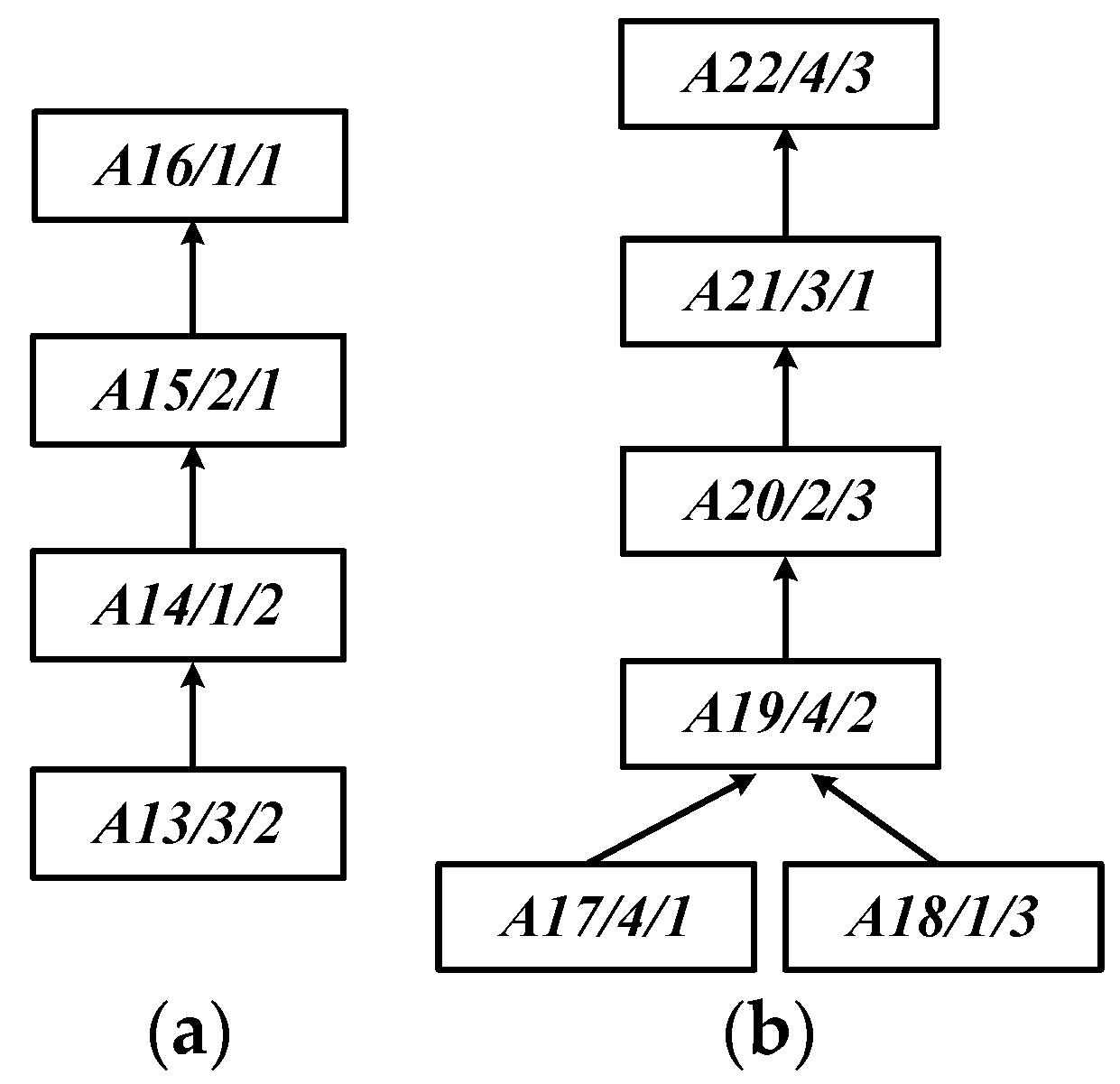

Step 1: As shown in

Figure 2, {

A23,

A24} is selected as the cut set to decompose complex products for the first time, and the operation strings,

TA1 and

TA2, are obtained as shown in

Figure 3a,b.

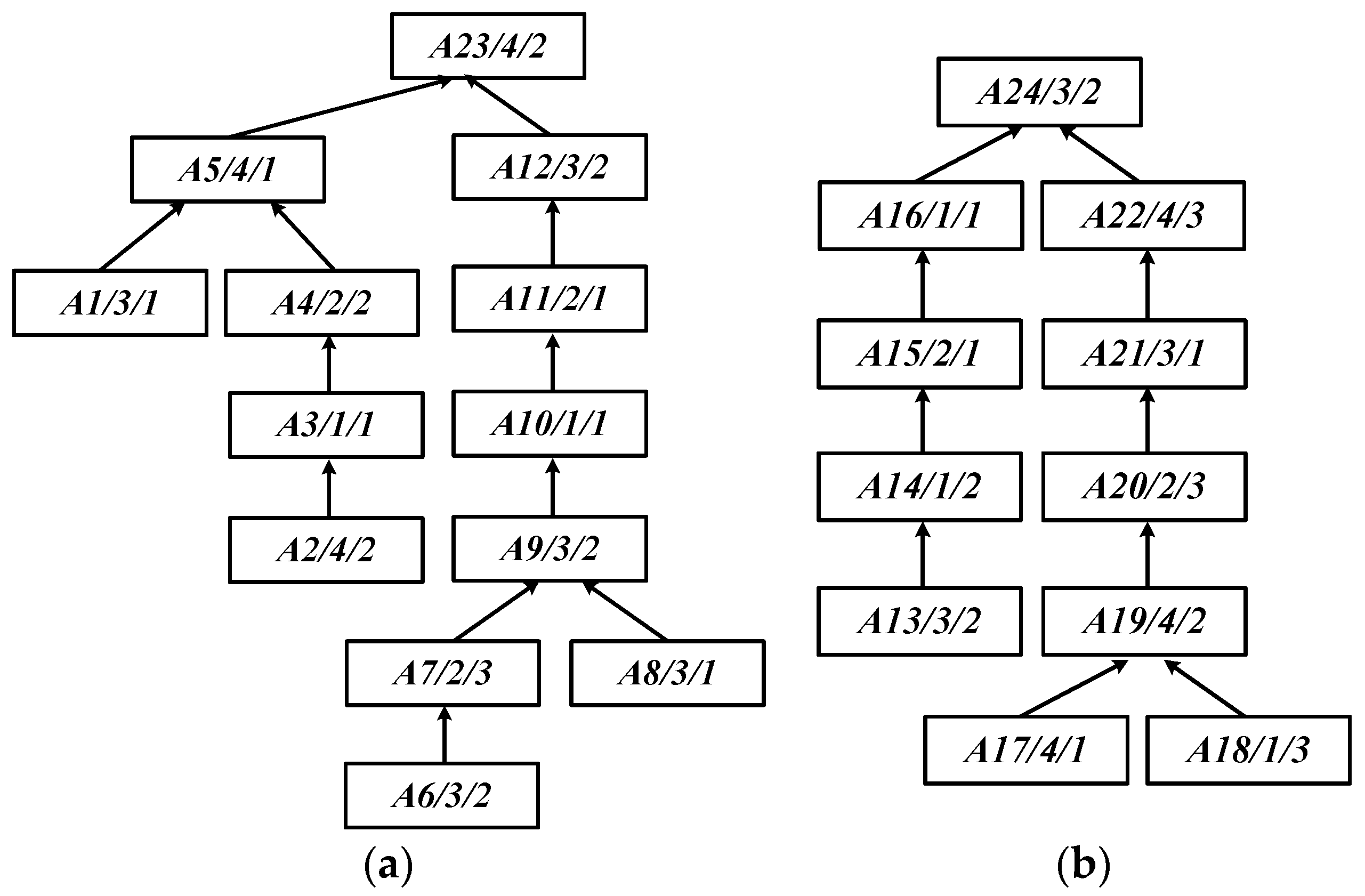

Step 2: the second decomposition of operation strings TA1 and TA2.

The branching number of operation string

TA1 and

TA2 is 2, so the operation string T

A1 takes

{A5,

A12} as the cut set for the second decomposition, and the obtained operation strings

TA11 and

TA12 are shown in

Figure 4a,b. The operation string

TA2 takes {

A16,

A22} as the cut set for the second decomposition, and the obtained operation strings

TA21 and

TA22 are shown in

Figure 5a,b. After the second decomposition, the branching number of the operation string

TA21 is 1, so the third decomposition will not be carried out. Currently, the operation string

TA21 = {A13,

A14,

A15,

A16}.

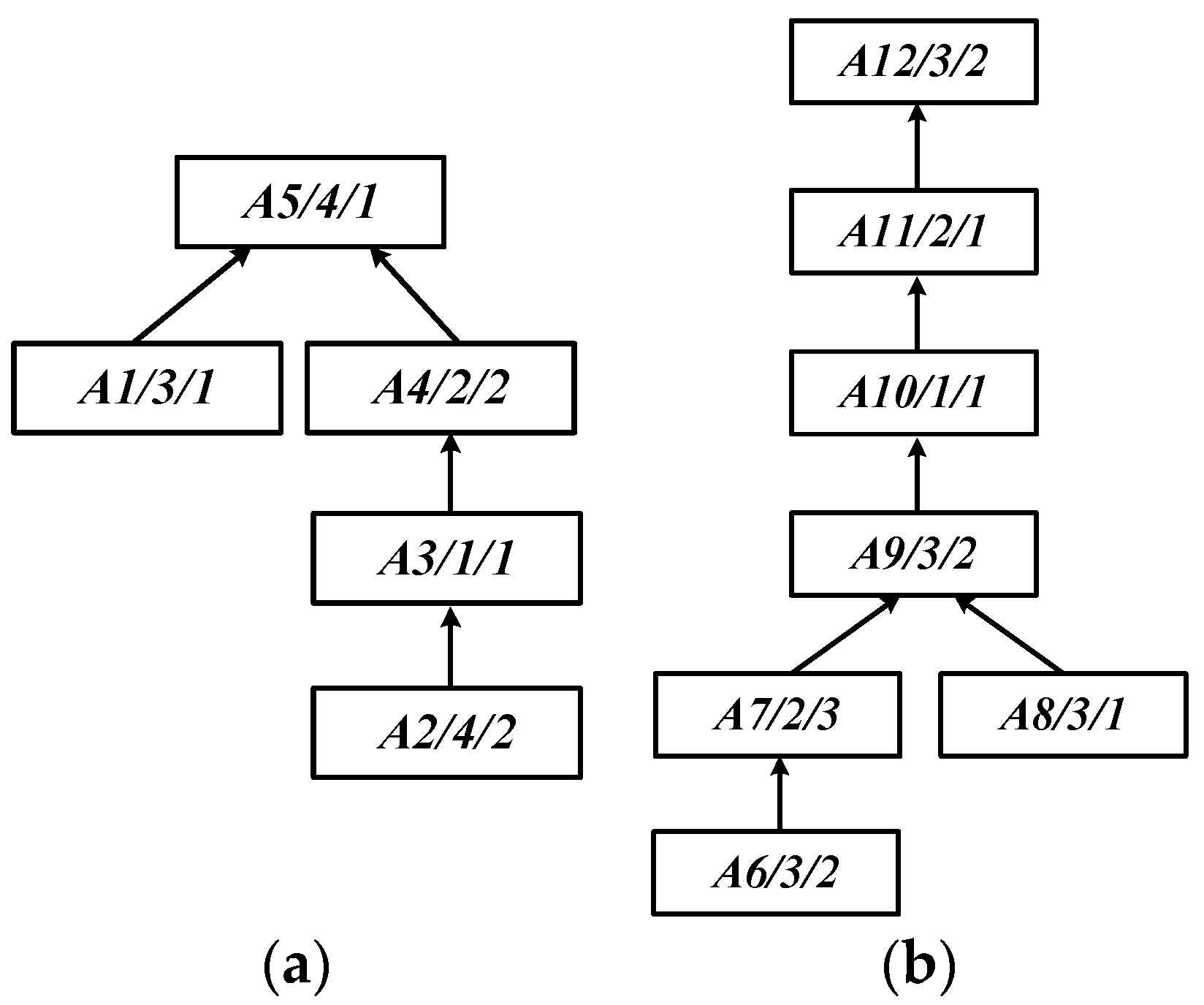

Step 3: the third decomposition of operation strings TA11, TA12, and TA22.

For TA11, the number of its branches is 2, so TA111 and TA112 are decomposed for the third time by taking the operation {A5} as the cut set. TA12 takes operation {A9} as a cut set to divide TA121 and TA121 for the third time. After the third decomposition, TA111 = {A1}, TA112 = {A2, A3, A4}, backtracking TA11={{A1}, {A2, A3, A4}, A5}, TA121 = {A6, A7}, TA122 = {A8}, and backtracking TA12 = {{A6, A7}, {A8}, A9, A10, A11, A12}. On the basis of TA11 and TA12, backtracking TA1 = {{{A1}, {A2, A3, A4}, A5}, {{A6, A7}, {A8}, A9, A10, A11, A12}, A23}.

After the third decomposition, TA2 = {{A13, A14, A15, A16}, {{A17, A18}, A19, A20, A21, A22}, A24}.

Step 4: According to the determined cut sets, the process tree of complex product A is decomposed into several operation strings circularity, as follows:

TA = {TA1, TA2} = {{TA11, TA12}, {TA21, TA22}} = {{TA111, TA112}, {TA121, TA122}}, {TA21}, {TA221, TA222}} = {{{{A1}, {A2, A3, A4}, A5}, {{A6, A 7}, {A8}, A9, A10, A11, A12}, A23}, {{A13, A14, A15, A16}, {{A17, A18}, {A19, A20, A21, A22}}, A24}, A25}.

3.3. Operation Weight-Based Scheduling Strategy (OWSS)

Definition 5. Layer priority.

Assuming that there are n layers in the processing tree of complex products, the priority of the root node operation is defined as 1, the priorities of all descendant node operations of the root node operation are defined as 2, and so on, until the priorities of all nodes of the nth layer are defined as n. The root node operation has the lowest priority, and the nth layer operations have the highest priorities [

26].

Definition 6. Equipment priority.

Assuming that the integrated scheduling system has m machines with equipment sequence , defined that the device with the largest number of operations has the highest equipment priority, the device with the second largest number of operations has the second highest equipment priority, and so on, the device with the smallest number of operations has the lowest equipment priority as 1, and the same equipment priority is allowed.

Definition 7. Constraint degree.

Taking a certain operation as the center, the sum of all the operations directly adjacent to it that have the constraint relationship of pre-tightening operation and post-tightening operation is defined the constraint degree of this operation.

Definition 8. Weight value.

The sum of the values of the layer priority, equipment priority, and operation constraint of an operation is defined as the weight value of this operation.

In the operation scheduling strategy, the operation weight-based scheduling strategy (OWSS) is proposed to fully consider the importance of special equipment in the integrated scheduling, that is, the influence of equipment with a large number of operations on the scheduling result. The OWSS takes all the factors, such as the layer priority of the operations, the equipment priority, and the constraint degree, as the consideration factors affecting the scheduling result. On the basis of both vertical and horizontal optimization, the operation strings are scheduled in descending order of weights to increase the intensity of continuous processing on the equipment in both workshops as far as possible and reduce the idle period of the devices. The specific description is as follows:

Step 1: According to the structural characteristics of the complex product process tree, determine the sequence of the process tree and calculate the layer priority of each operation.

Step 2: According to the attribute characteristics of the process tree of complex products, calculate the equipment priority, the constraint degree, and the weight value of each operation.

Step 3: Determine the operation string where the operation with the highest weight except the root node is located.

Step 4: Judge whether the operation string is unique. If it is, then go to Step 5. If it is not, the operation string in which the operation is located is scheduled in the descending order according to the priority of the operation layer.

Step 5: Judge whether there is an optimal scheduling time for the operation string. If it is, schedule this operation string at the optimal time. If it is not, then go to Step 6.

Step 6: Schedule the operation string, of which the operations have lower weights.

Step 7: Judge whether all the operation strings formed by the decomposition of the process tree of complex products have been scheduled. If they are, go to Step 8. If not, go to Step 4.

Step 8: Establish the scheduling sequence of operation strings, and the scheduling is finished.

3.4. Balanced Workshop Allocation Strategy (BWAS)

Let denotes the ith operation string in the operation string sequence, denotes the processing time of the operation string of operation i, and denotes the operation string of the operation with the largest weight. denotes the processing time of workshop at the current moment, denotes the processing time of workshop at the current moment. = min|,, and it denotes the current moment processing time difference between the two workshops. Then, BWAS is , and the detailed description is as follows:

Step 1: At the initial moment, both workshops are in the state of being processed, == 0;

Step 2: initialize = 0;

Step 3: In the scheduling sequence of operation strings, assign to any workshop, such as workshop , and calculate the current processing time of it.

Step 4: Assign the operation string of the operations with the second larger weight to another workshop , and calculate the current processing time of it.

Step 5: Calculate , , and of each operation string that is about to be assigned to f1 and f2. Update the value of .

Step 6: Assign operation string based on the principle of minimizing .

Step 7: Repeat Step 5 until each operation string is allocated.

Step 8: End.

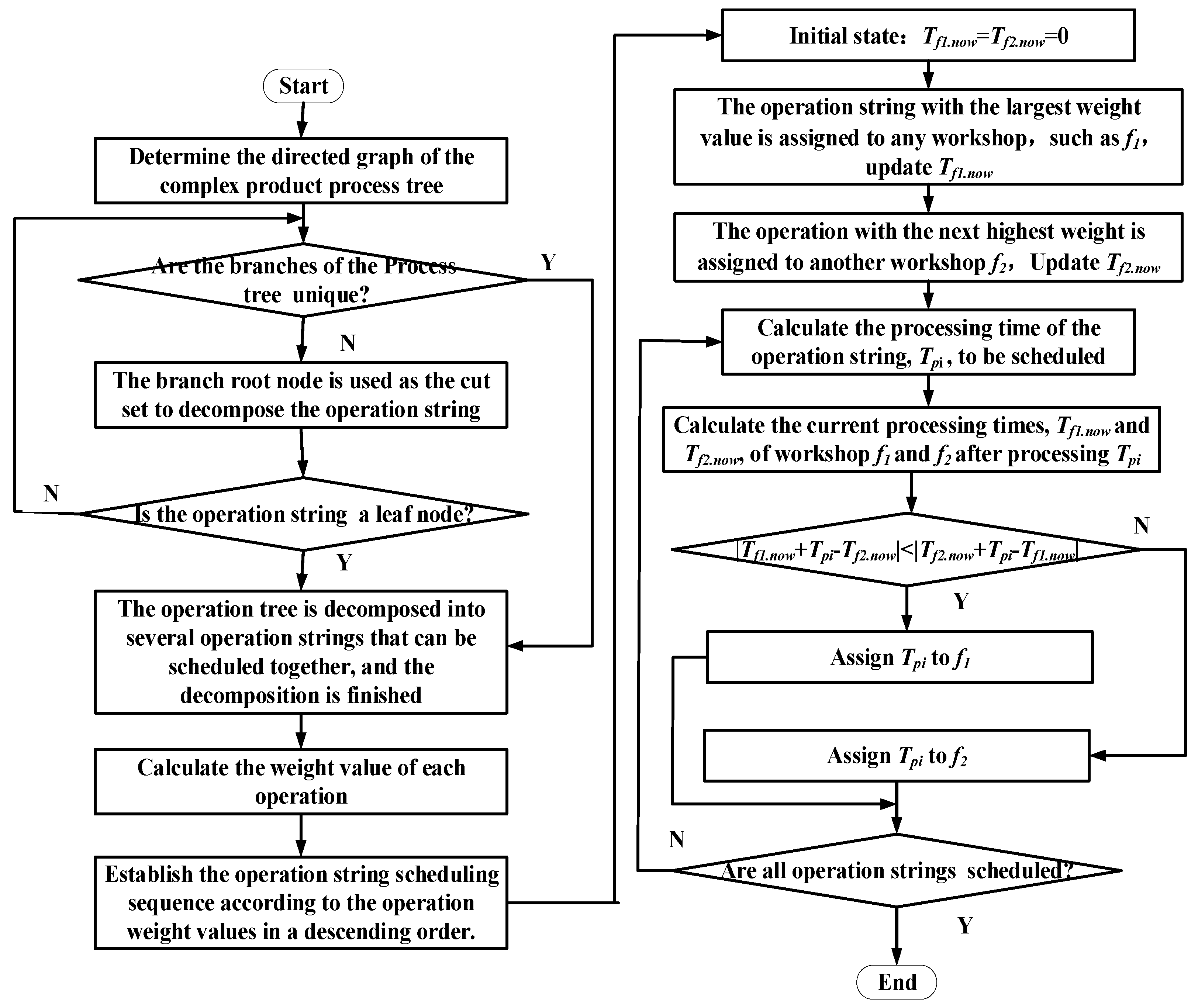

To sum up, the flowchart of the algorithm in this paper is shown in

Figure 7.

4. Algorithm Complexity Analysis

Assuming that the number of operations of the complex product, the processing time of each operation, and the number of machines in both workshops are all given, then the complexity analysis of the SCDS, the OWSS, and the BWAS in the proposed algorithm is as follows:

For the SCDS, the time complexity of determining the branches is , and the time complexity of determining the cut sets is also . The time complexity of recursive calls to sub-trees is . Therefore, the time complexity of the SCDS is . For the OWSS, the time complexity of the algorithm to determine the priority of the operation layer, the equipment priority, and the constraint degree is . The time complexity of calculating the weights is . According to the weight value to establish the operation sequence, the worst situation is that an operation needs to be compared with its predecessors and the successors, so the time complexity is . Therefore, the time complexity of the OWSS is . For the BWAS, the time complexities of calculating the scheduling time of the current time of the workshop, calculating the time difference between the scheduling times of both workshops, and allocating the operation string are all . Therefore, the time complexity of the BWAS is . Based on the above analysis, the time complexity of the proposed algorithm is .

5. Scheduling Example Analysis

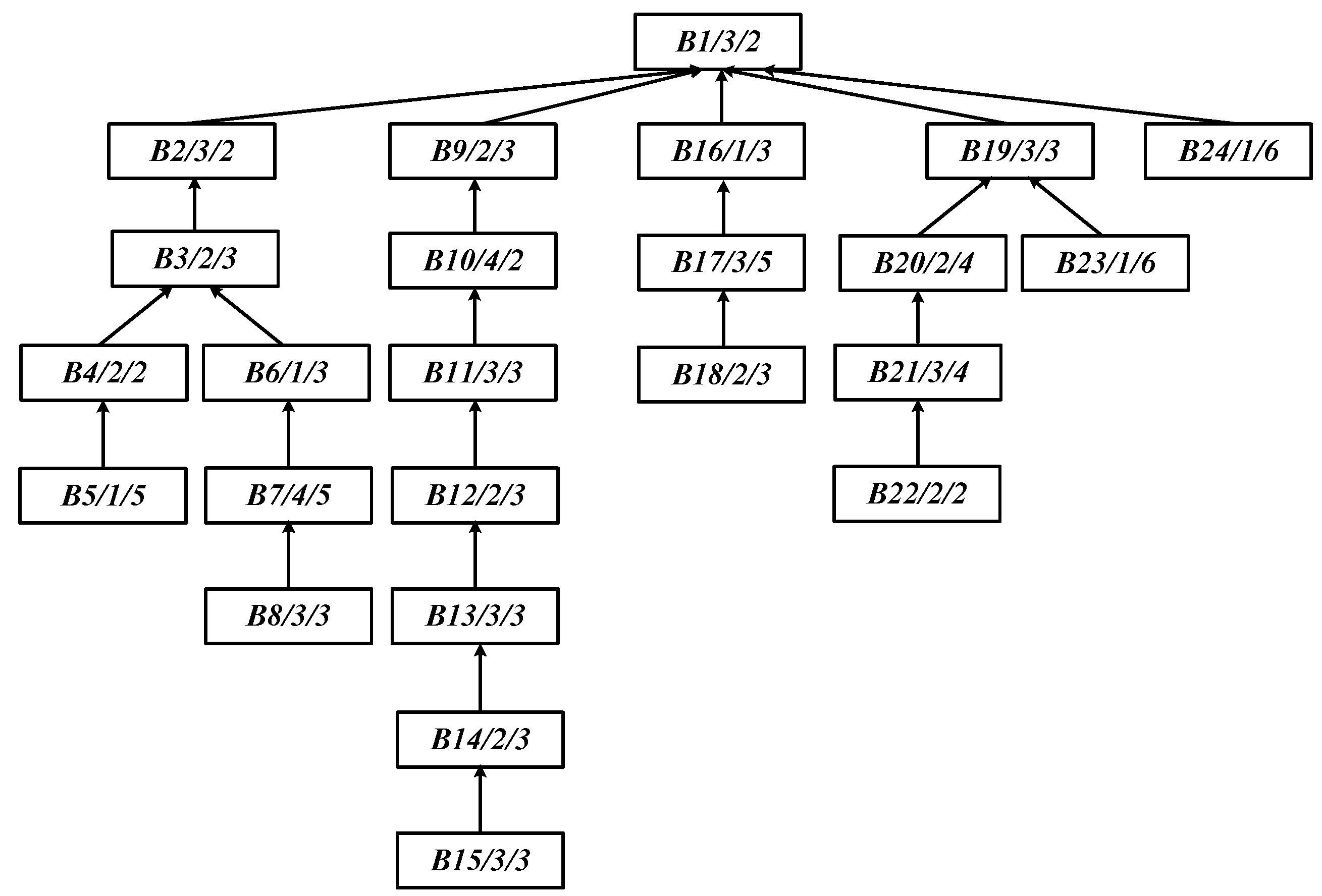

Assume that complex product

B consists of 24 operations, as shown in

Figure 8. It needs to be carried out in two workshops, and each workshop has four devices with exactly the same processing capacity.

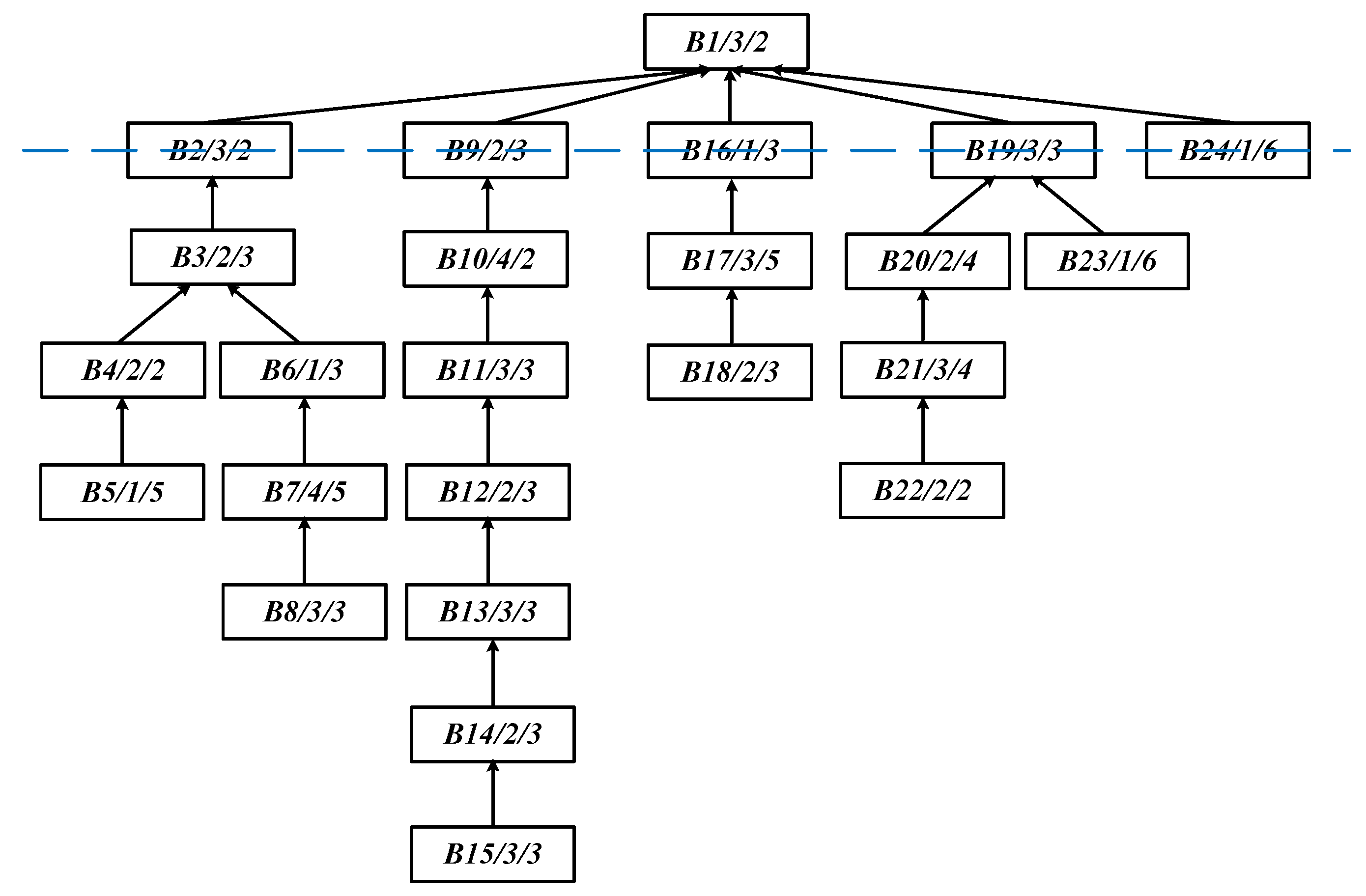

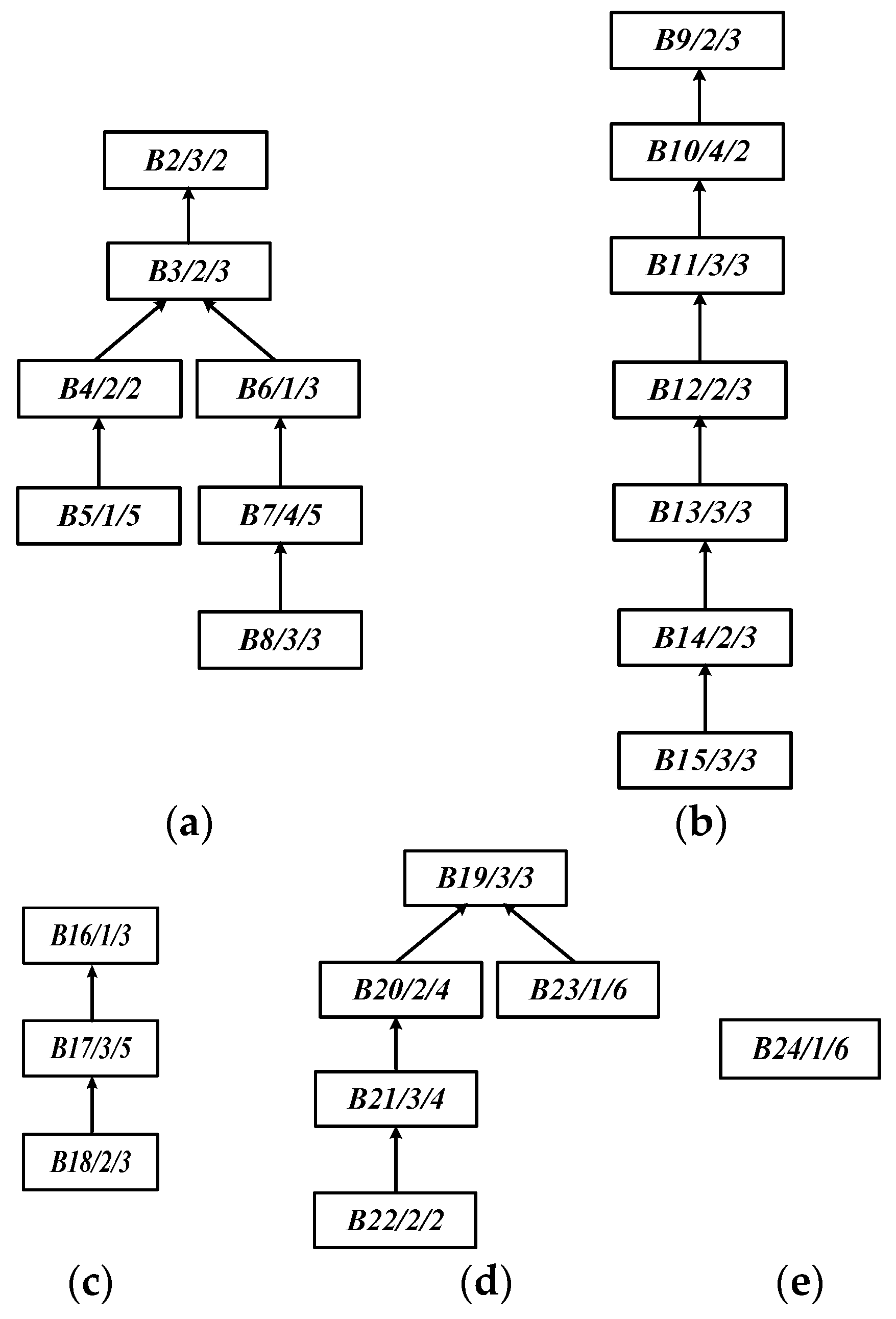

5.1. Cyclic Decomposition of Complex Product B

Step 1: As shown in

Figure 9, {

B2,

B9,

B16,

B19,

B24} is the cut set to decompose the complex product B shown in

Figure 8. The operation strings

TB1,

TB2,

TB3,

TB4, and

TB5 of each sub-tree obtained after the first decomposition are shown in

Figure 10a–e.

After the first decomposition, the number of the branches of TB2 with root node {B9} and TB3 with root node {B16} are both 1, and the decomposition is finished. TB5 with {B24} as the root node is the leaf node operation, and the decomposition is finished. At this point, TB2 = {B9, B10, B11, B12, Bl3, B14, B15}, TB3= {B16, B17, B18}, and TB5 = {B24}. The number of the branches of TB1 is 2, and the same is true for TB4, which requires a second decomposition.

Step 2: Decompose sub-trees TB1 and TB4 for the second time. TB1 is decomposed into TB11 and TB12 by taking {B3} as the cut set. At this time, the number of the branches of TB11 and the number of the branches of TB12 are 1, and the decomposition is finished. So far, TB1 = {TB11, TB12} = {{B4, B5}, {B6, B7, B8}, B3, B2}.

Similarly, taking {B19} as the cut set to decompose TB4 for the second time, TB4={TB41, TB42} = {{B20, B21, B22}, {B23}, B19} is obtained.

At this point, the cyclic decomposition of complex product B is completed, and the operation strings of each sub-tree are obtained as follows: TB = {TB1, TB2, TB3, TB4, TB5} = {{TB11, TB12}, TB2, TB3, {TB41, TB42}, TB5} = {{{B4, B5}, {B6, B7, B8}, B3, B2}, {B9, B10, B11, B12, B13, B14, B15}, {B16, B17, B18}, {{B20, B21, B22}, {B23}, B19}, {B24}}, B1}.

5.2. Process Scheduling Strategy for Complex Product B

In the integrated scheduling system for complex product

B shown in

Figure 8, there are five operations that need to be processed on

M1, eight operations on

M2, nine operations on

M3, and two operations on

M4. According to the definition of equipment priority, the equipment priority of

M3 is the highest, the equipment priority of

M2 is higher, the equipment priority of

M1 is lower, and

M4 has the lowest equipment priority.

Table 1 lists the priorities of each device.

During the integrated scheduling, the process structure of complex products can construct more complex products by means of virtual root nodes, so the processing scale and the complexity of products are not uniform. Meanwhile, due to the difference in the equipment resources, the layer priority, the equipment priority, and the constraint degrees of each operation are concrete numerical normalized before weight value calculation by the proposed algorithm. The purpose is to make no dimensional levels of data after calculation results so as not to result in the appearance of deviation. In this paper, we chose the Z-score standardized method, which is commonly used in data processing [

27]. For details, see

Table 2.

The operation weight-based scheduling strategy (OWSS) is based on the subtree decomposition strategy, so the schedulable operation string can only be the one with one branch. As the root node of subtree TB4, B19 has two branches, so it cannot be scheduled until its subtree TB41 and TB42 are scheduled. Similarly, B3 with two branches cannot be scheduled until operation string {B4, B5} and {B6, B7, B8} have been scheduled. Thus, the operation sequence sorted in descending order according to weights is as follows:

{B1, B15, Bl3 B14, B8, B11, B21, B19, B12, B3, B17, B4, B2, B22, B20, B6, B18, B9, B7, B5, B16, B10, B23, B24}. According to the sequence, the scheduling sequence of the operation string except the root node is established: TB = {B15, B14, B13, B12, B11, B10, B9}; {B8, B7, B6}; {B22, B21, B20}; {B5, B4}; {B18, B17, B16}; {B3, B2}; {B23}; {B19}; {B24}.

5.3. Workshop Allocation Strategy for Complex Product B

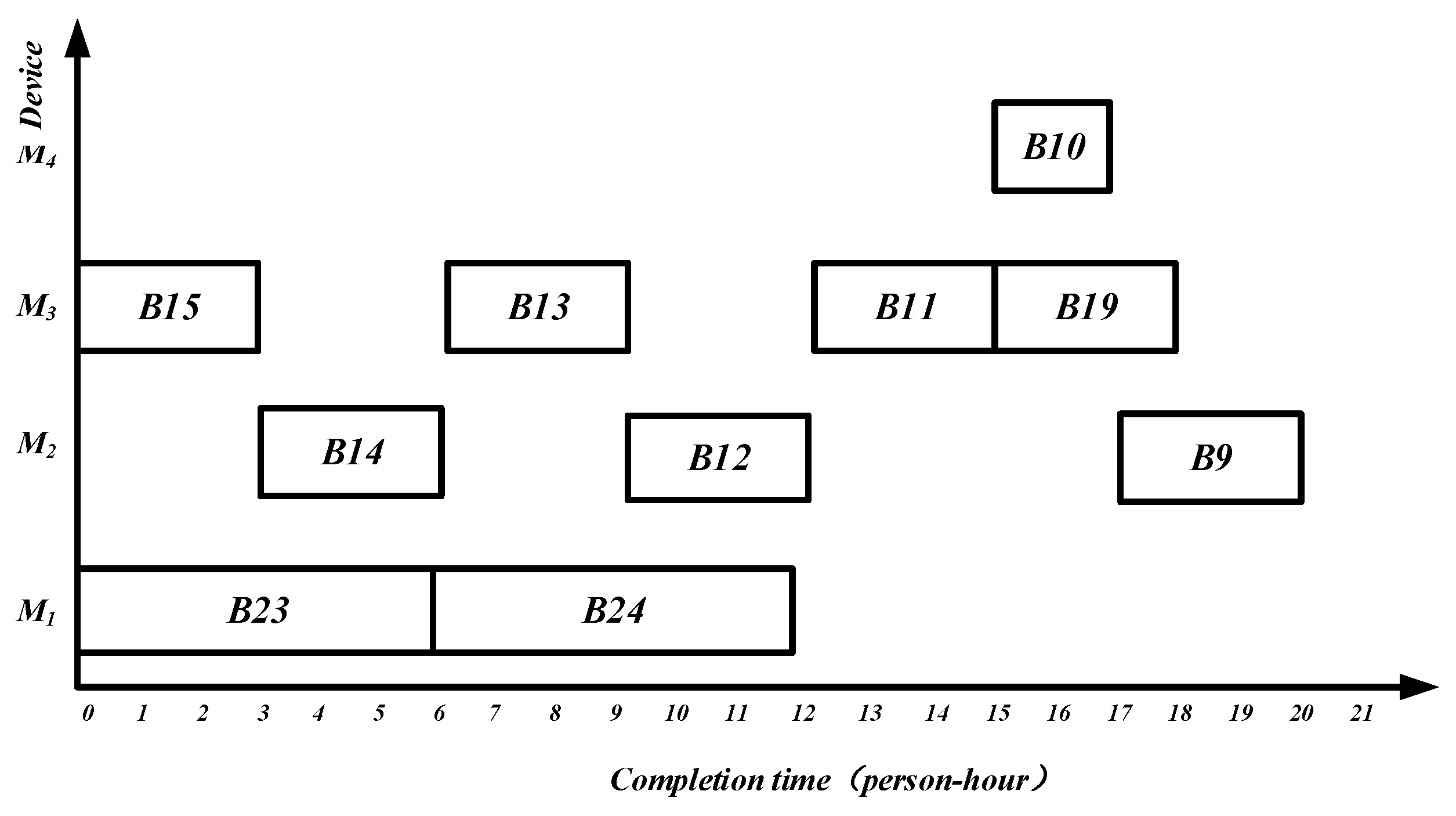

Step 1: Choose

TB2 = {

}, which contains operation {

} with the highest weight value, and then, assign it to any workshop, such as workshop

=

= 20 person-hours, as shown in

Figure 11. Update the scheduling sequence of operation strings:

TB = {

B8,

B7,

B6}; {

B22,

B21,

B20}; {

B5,

B4}; {

B18,

B17,

B16}; {

B3,

B2}; {

B23}; {

B19}; {

B24}.

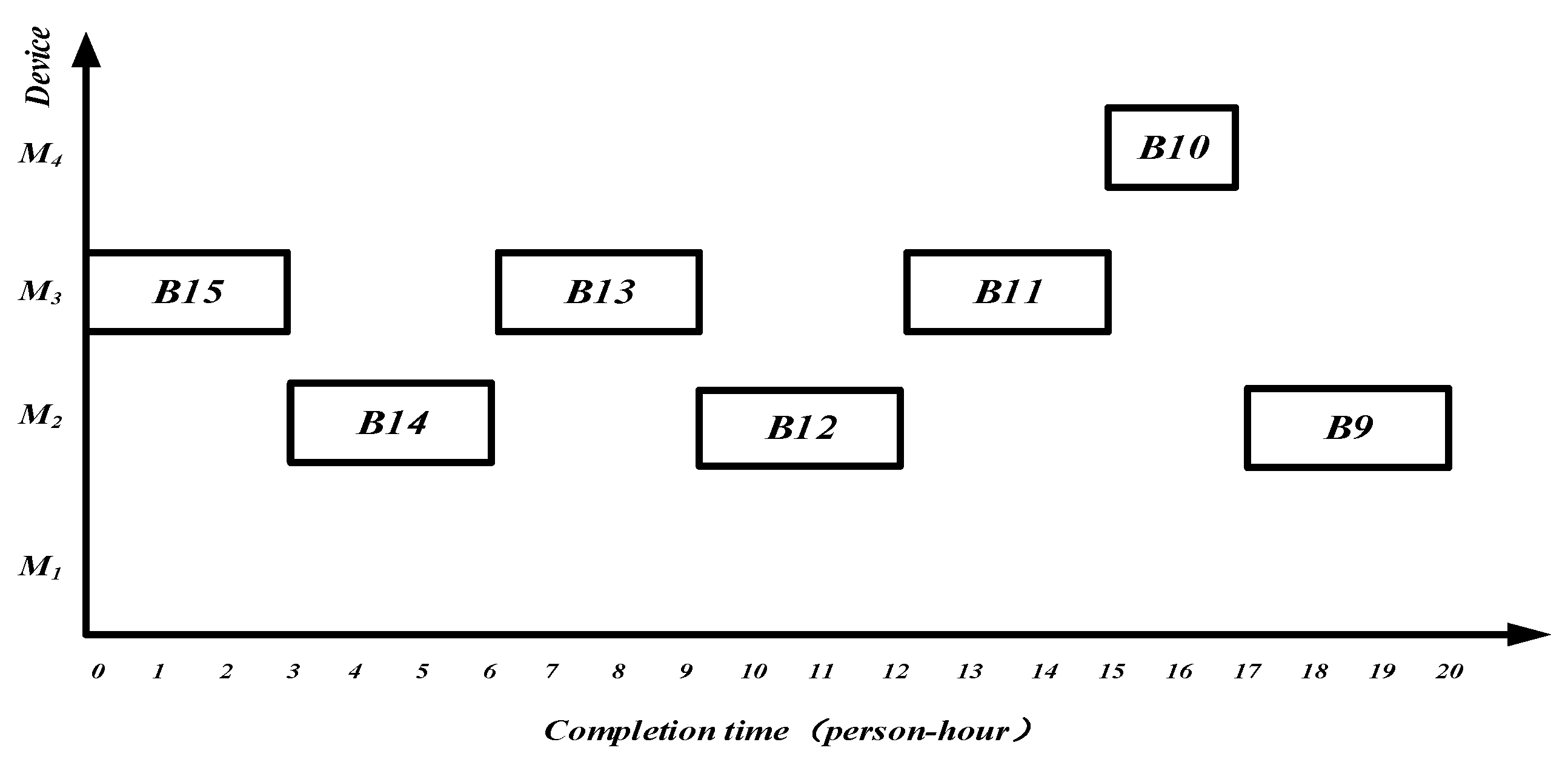

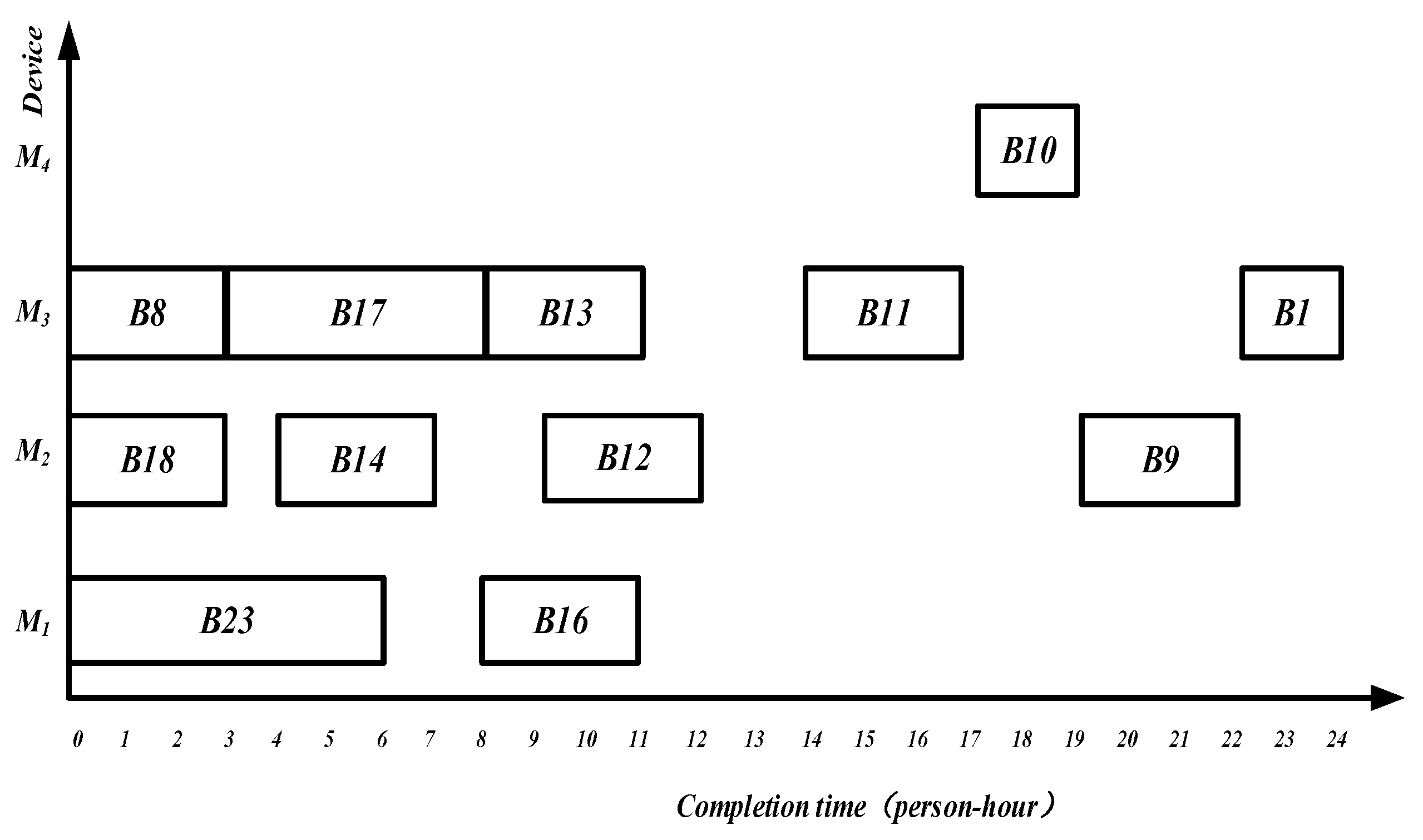

Step 2: Choose

TB12 = {

B8,

B7,

B6}, which contains {

B8} with the higher weight, and assign it to the other workshop

,

=

= 11 person-hours, as shown in

Figure 12. Update the scheduling sequence of operation strings:

TB = {

B22,

B21,

B20}; {

B5,

B4}; {

B18,

B17,

B16}; {

B3,

B2}; {

B23}; {

B19}; {

B24}.

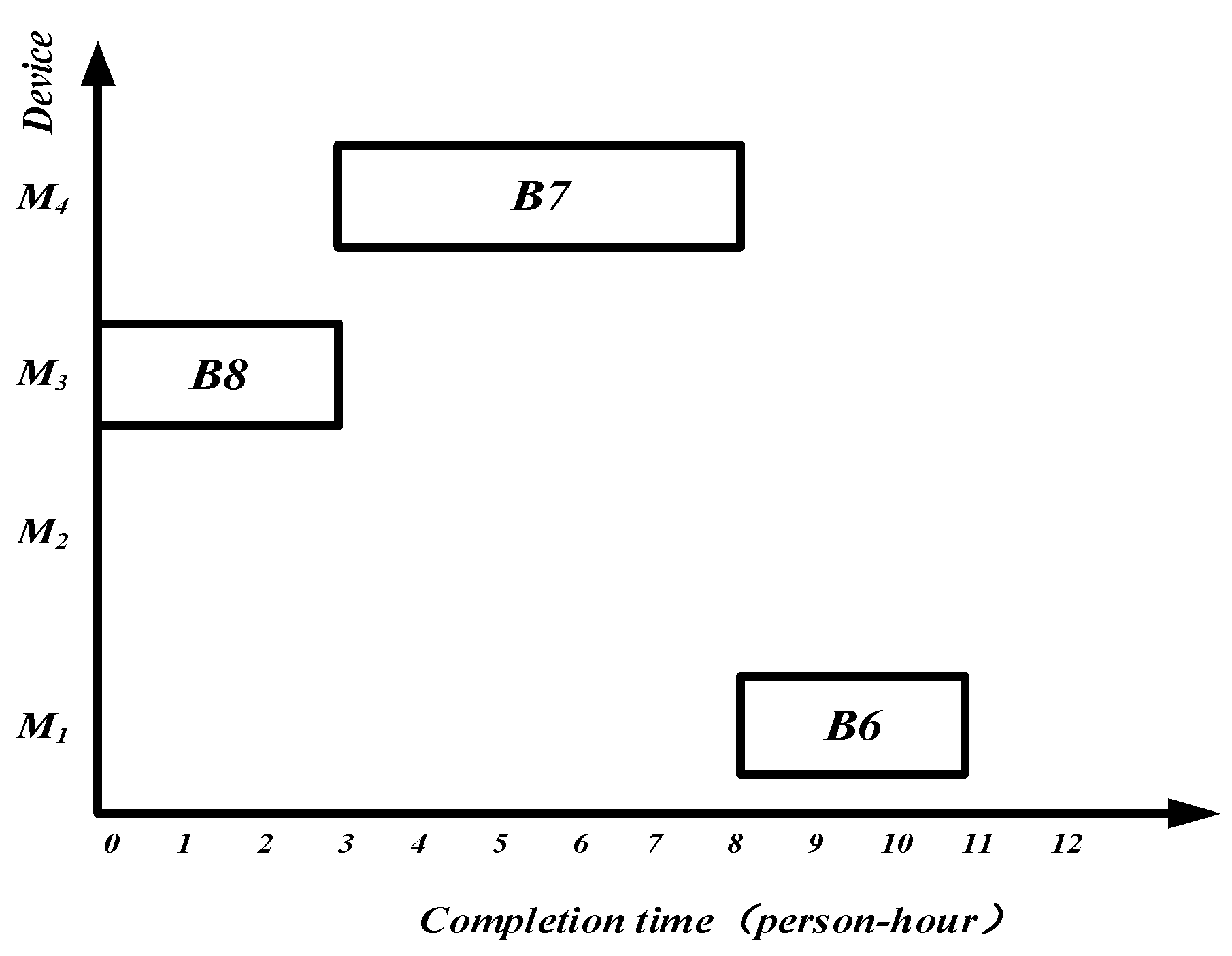

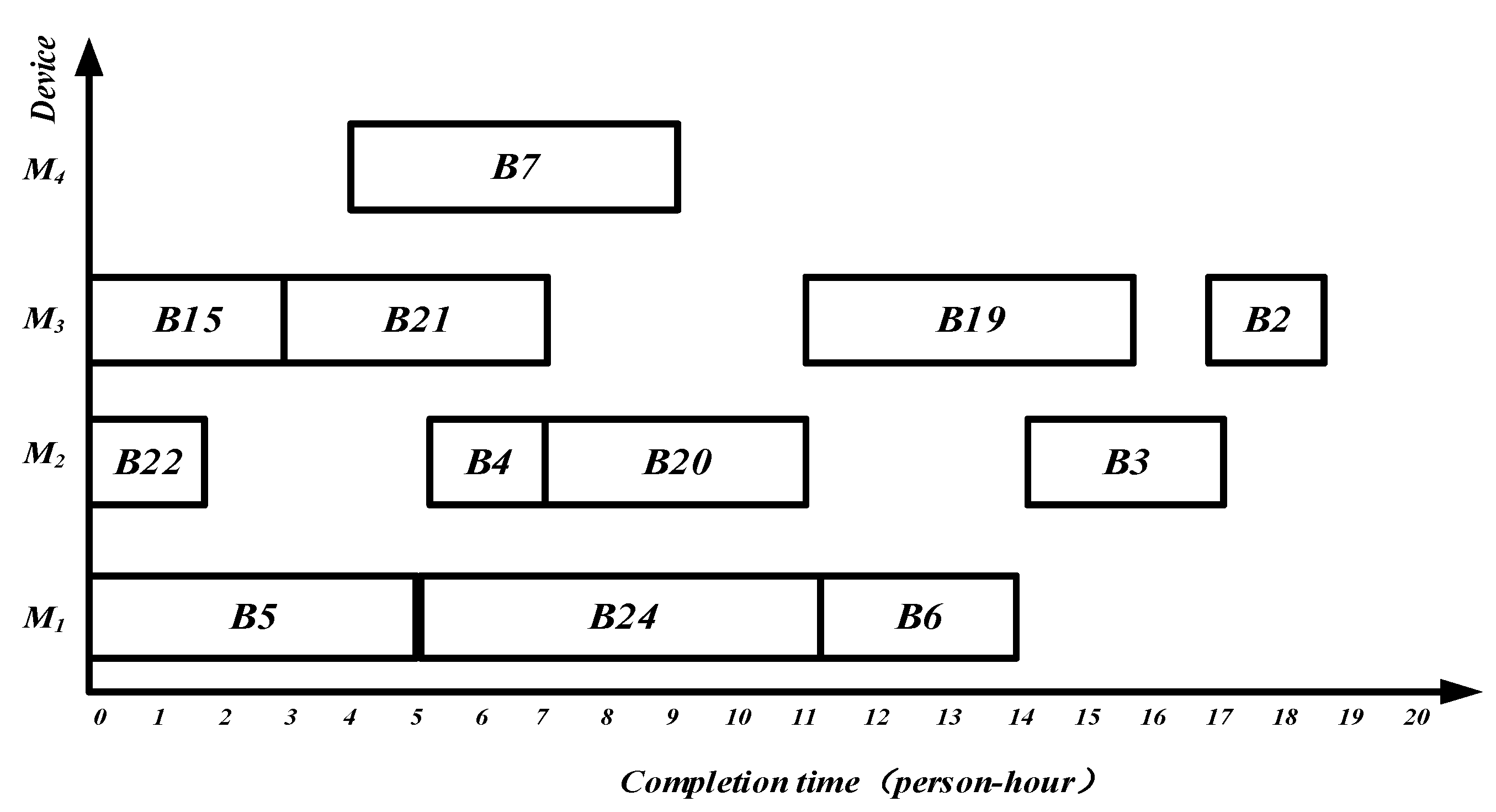

Step 3: Calculate the processing time

= 10 person-hours for

TB41 = {

B22,

B21,

B20} to be allocated in the sub-tree operation string sequence, and calculate the absolute value of the difference in the processing time between the two workshops that the sequence is assigned to, respectively, that is

=

10

= 19,

=

11

10

= 1. According to

{19,1} = 1,

TB41 is selected to be assigned to workshop

, as shown in

Figure 13. Update

and the scheduling sequence of operation strings:

TB = {

B5,

B4}; {

B18,

B17,

B16}; {

B3,

B2}; {

B23}; {

B19}; {

B24}.

Step 4: In the same way, the sub-tree operation strings, {

B5,

B4}, {

B18,

B17,

B16}, and {

B3,

B2}, are also assigned to

.

Figure 14 shows the scheduling Gantt chart for

. Update the scheduling sequence of operation strings:

TB = {

B23}; {

B19}; {

B24}.

= 20 person-hours,

= 16 person-hours.

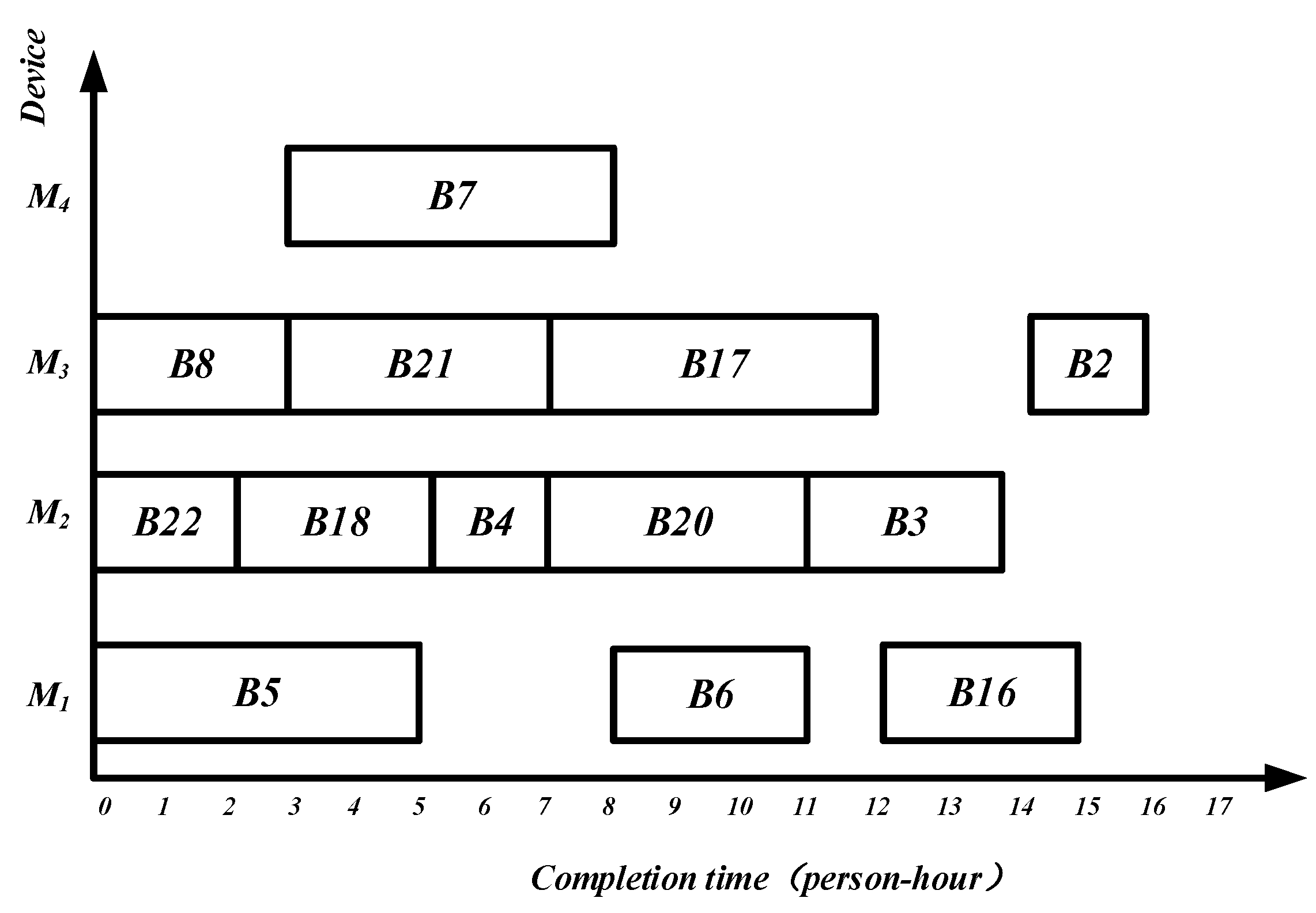

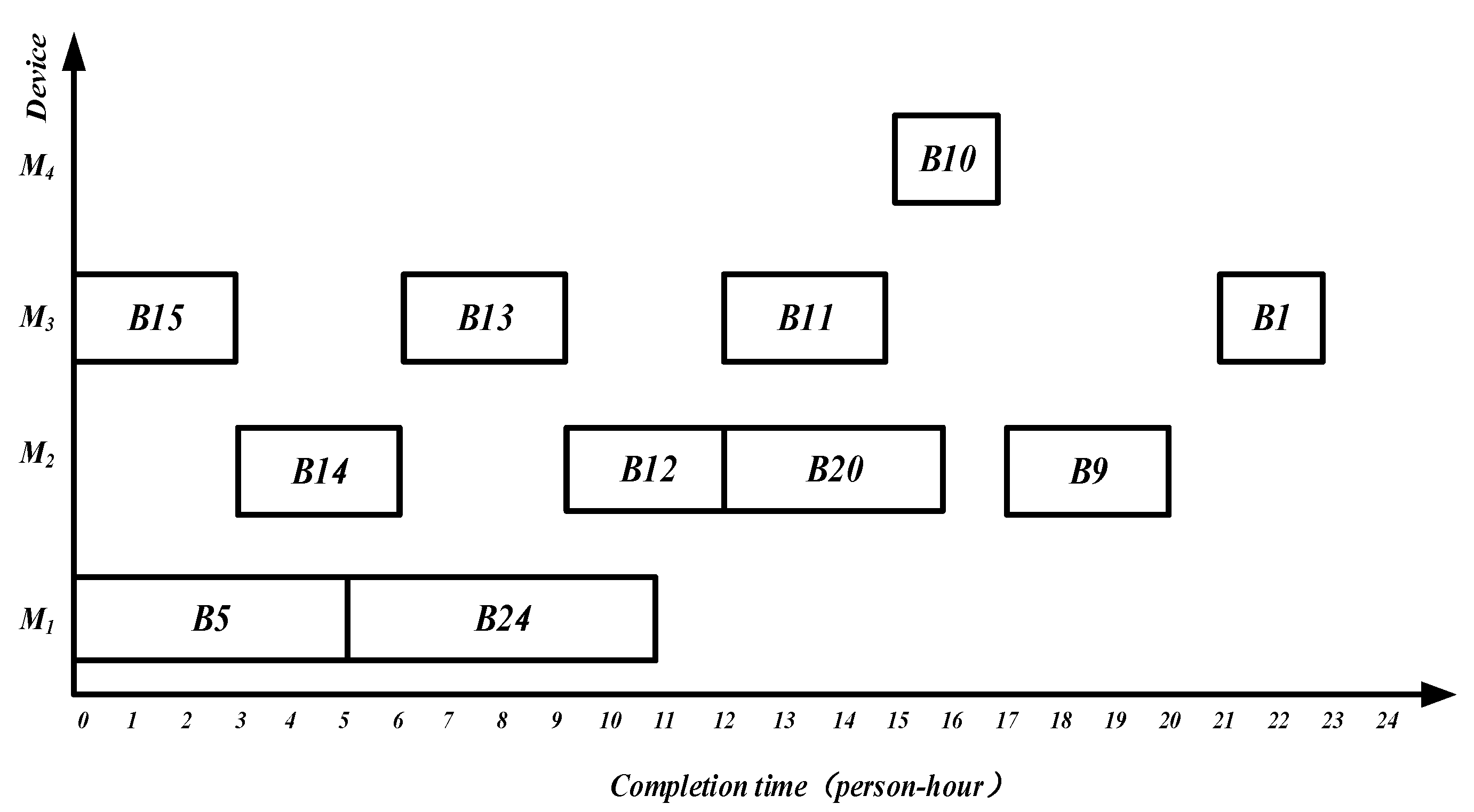

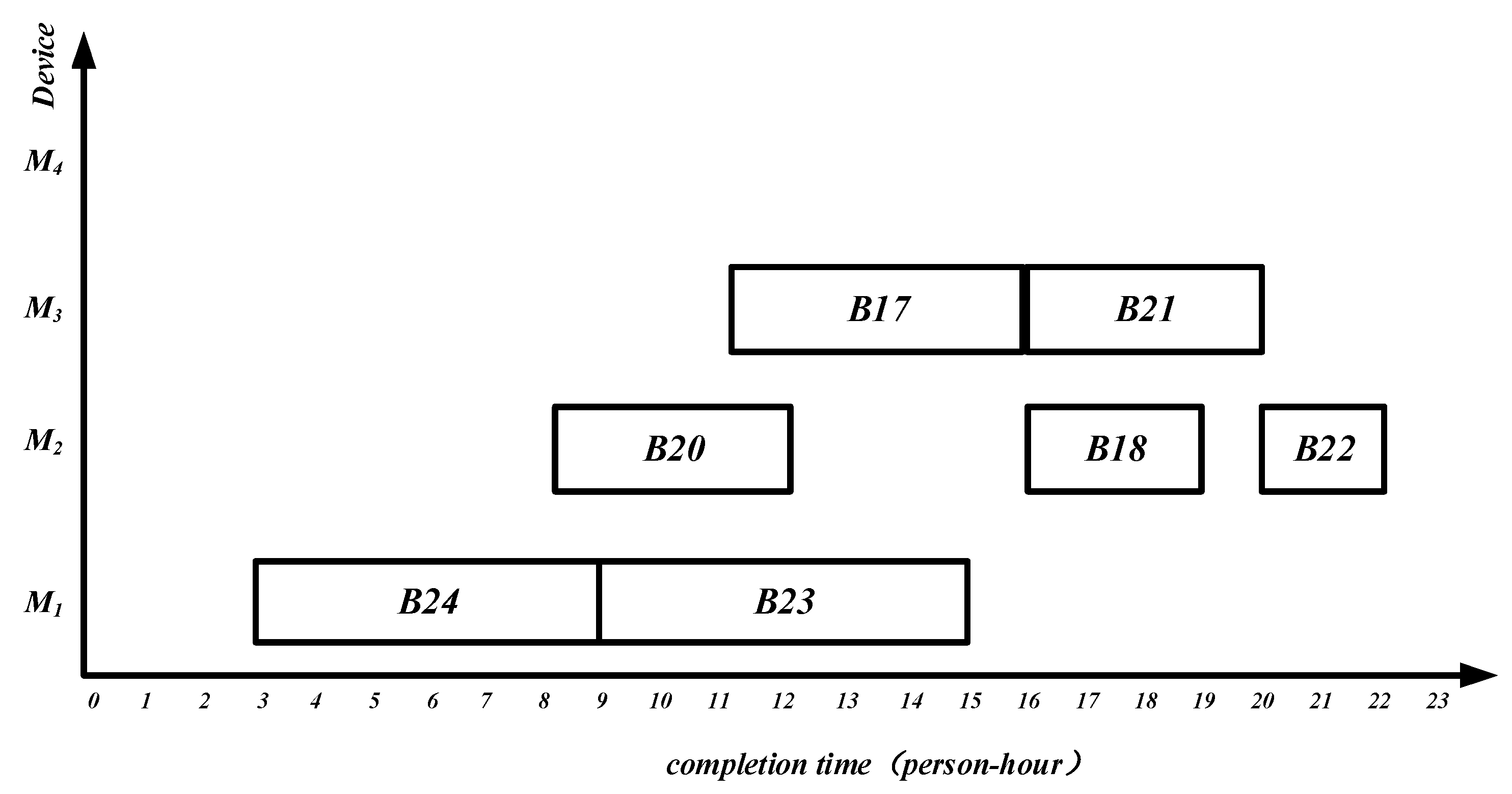

Step 5: At this time, the scheduling sequence of operation strings is

TB = {{

B23}, {

B19}, {

B24}}. Firstly, according to the definition of the optimal scheduling time, {

B23} and {

B24} as the operation string of leaf nodes can start to be scheduled at time

t = 0 on

M1. However, the weight of operation string {

B23} is greater than that of {

B24}, so {

B23} is scheduled earlier than {

B24}. Secondly, according to the principle that the absolute value of the processing time difference between the two workshops is the minimum, {

B23} and {

B24} to be scheduled are allocated to

. Finally, the root node operation {

B1} is allocated to

. The Gantt charts of complex product

B processed in the two workshops are shown in

Figure 15 and

Figure 16. The processing times are 20 person-hours and 18 person-hours, respectively. The makespan is 20 person-hours, which is the maximum of the two completion times.

6. Comparative Analysis of Algorithms

6.1. Case Results by Five Algorithms

Taking complex product

B, shown in

Figure 8, as an example, the STHIS-PTCD is, respectively, compared with the algorithms in PBP, ACPM, NR, and TS in the same research field. The results show that the STHIS-PTCD has a better scheduling effect in terms of production makespan, migration times, and equipment utilization of the resource-symmetric two-workshop integrated scheduling.

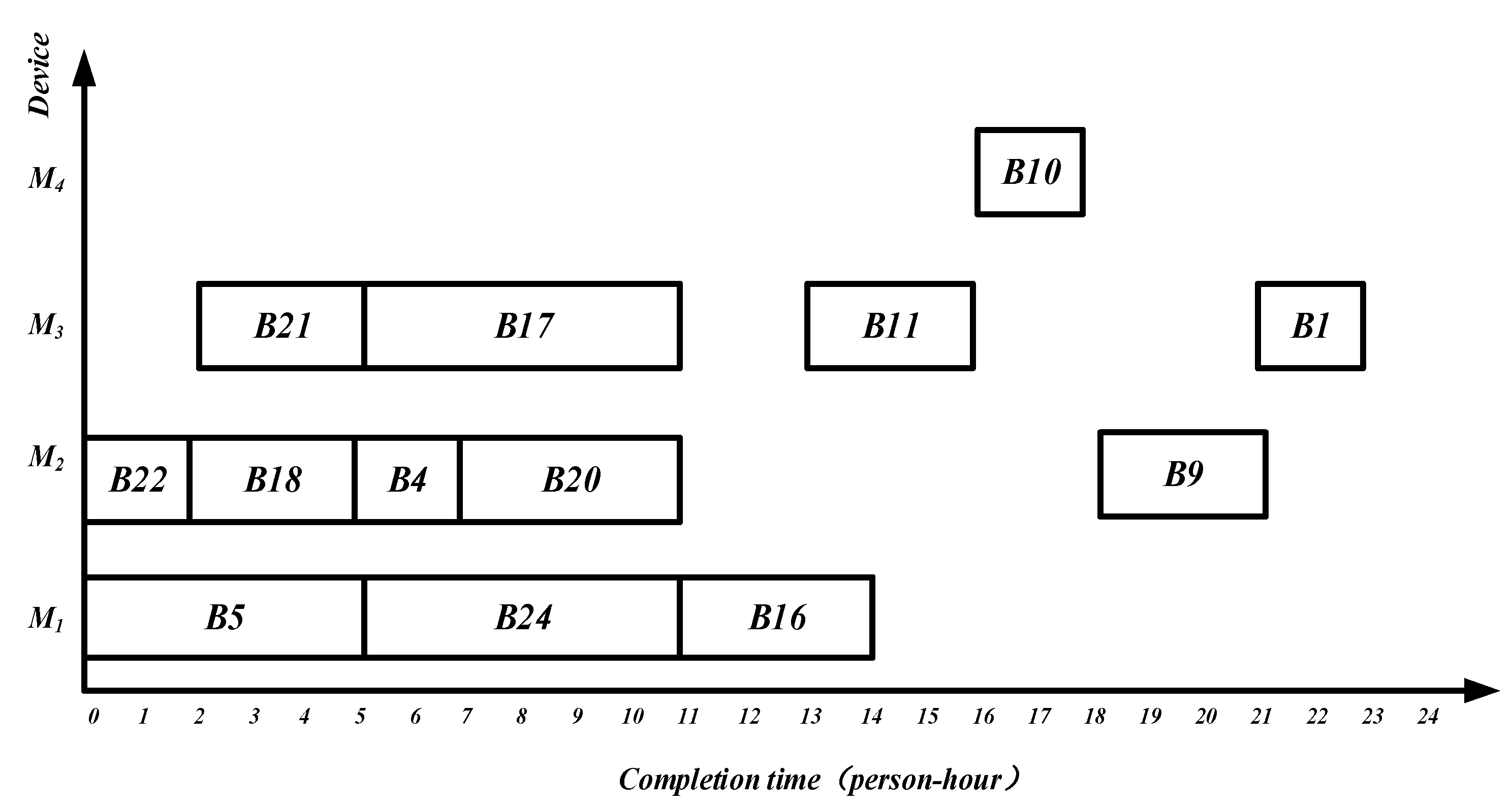

The PBP takes schedulable operations as the optimization object and establishes the scheduling algorithm through the idea of balanced processing. By using this algorithm, the scheduling Gantt chart of workshop

is shown in

Figure 17, which takes 24 person-hours. The scheduling Gantt chart of workshop

is shown in

Figure 18, which takes 19 person-hours. The makespan is 24 person-hours.

The ACPM adopts the allied critical path idea of longitudinal optimization. It divides the process tree of complex products into two cases to determine the workshop allocation scheme of operations through the threshold, which is two. One is less than two, and the other is not less than two. With this algorithm, the scheduling Gantt chart of workshop

is shown in

Figure 19, which takes 23 person-hours. The scheduling Gantt chart of workshop

is shown in

Figure 20, which takes 20 person-hours. The makespan is 23 person-hours.

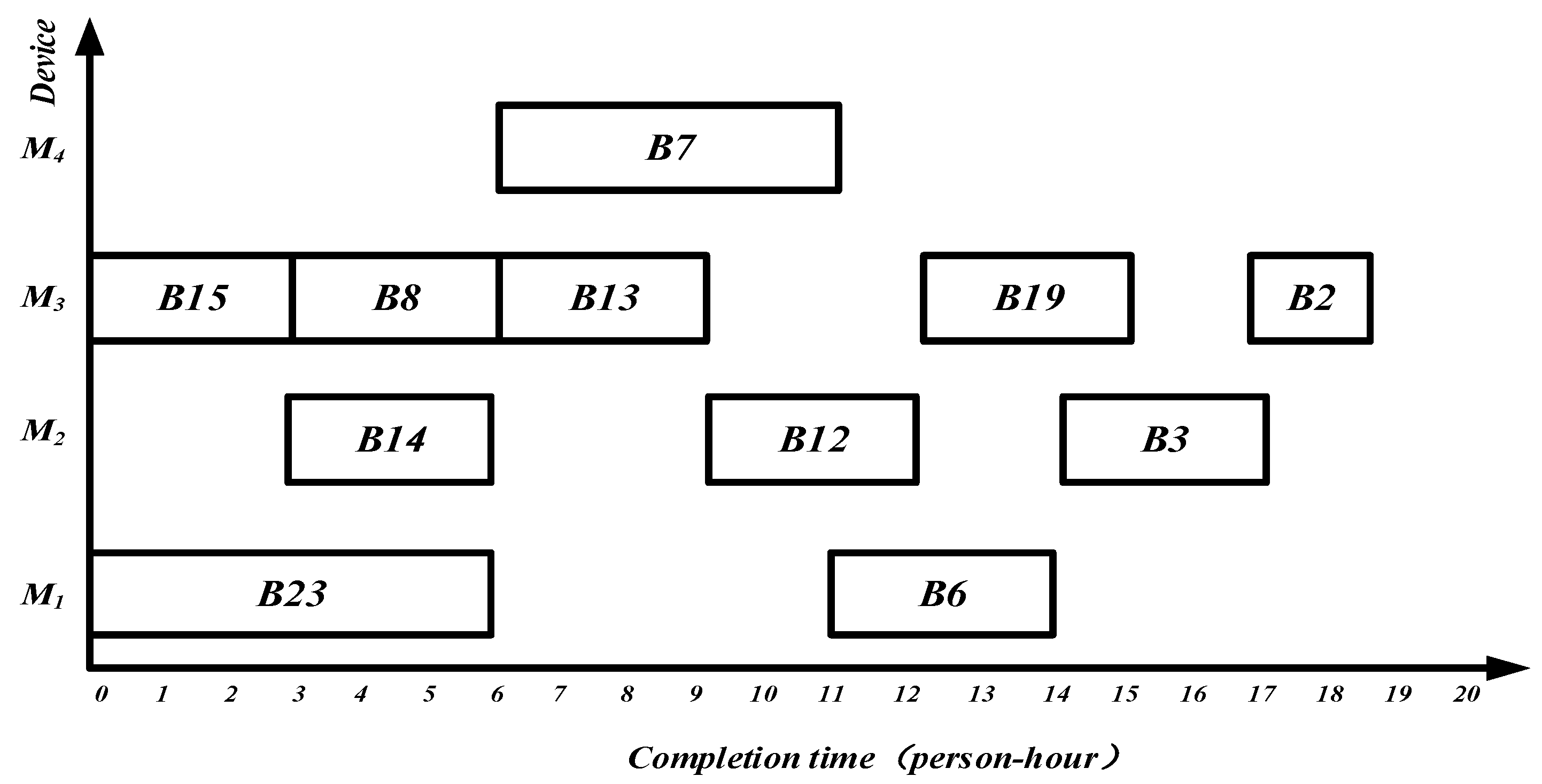

The NR also takes key equipment balance as the main idea. It uses the principles of neighborhood rendering and the same equipment operation in the same workshop to determine the operation allocation scheme. Inside the workshop, the operation scheduling scheme is determined according to the strategy of “dynamic critical path + short time”. With this algorithm, the scheduling Gantt chart of workshop

is shown in

Figure 21, which takes 23 person-hours. The scheduling Gantt chart of workshop

is shown in

Figure 22, which takes 19 person-hours. The makespan is 23 person-hours.

The TS “timing-selection” as the main idea of scheduling, which takes the descending order of the sum of operation paths in the sequence as the arrangement scheme, and it takes the minimum workshop completion time as the allocation scheme. With this algorithm, the scheduling Gantt chart of workshop

is shown in

Figure 23, which takes 22 person-hours. The scheduling Gantt chart of workshop

is shown in

Figure 24, which takes 22 person-hours. The makespan is 22 person-hours.

Now, the completion time and the average utilization rate of equipment in both workshops of the results obtained by the proposed algorithm are compared with the results obtained by the other four algorithms, as shown in

Table 3.

In the comparative analysis, we take complex product B as an example, and STHIS-PTCD has the shortest makespan, which is smaller than the other four algorithms. Additionally, the completion times are shortened by STHIS-PTCD in both and f. Meanwhile, among the five algorithms, STHIS-PTCD has the highest average workshop utilization rate, which fully improves the equipment utilization rate.

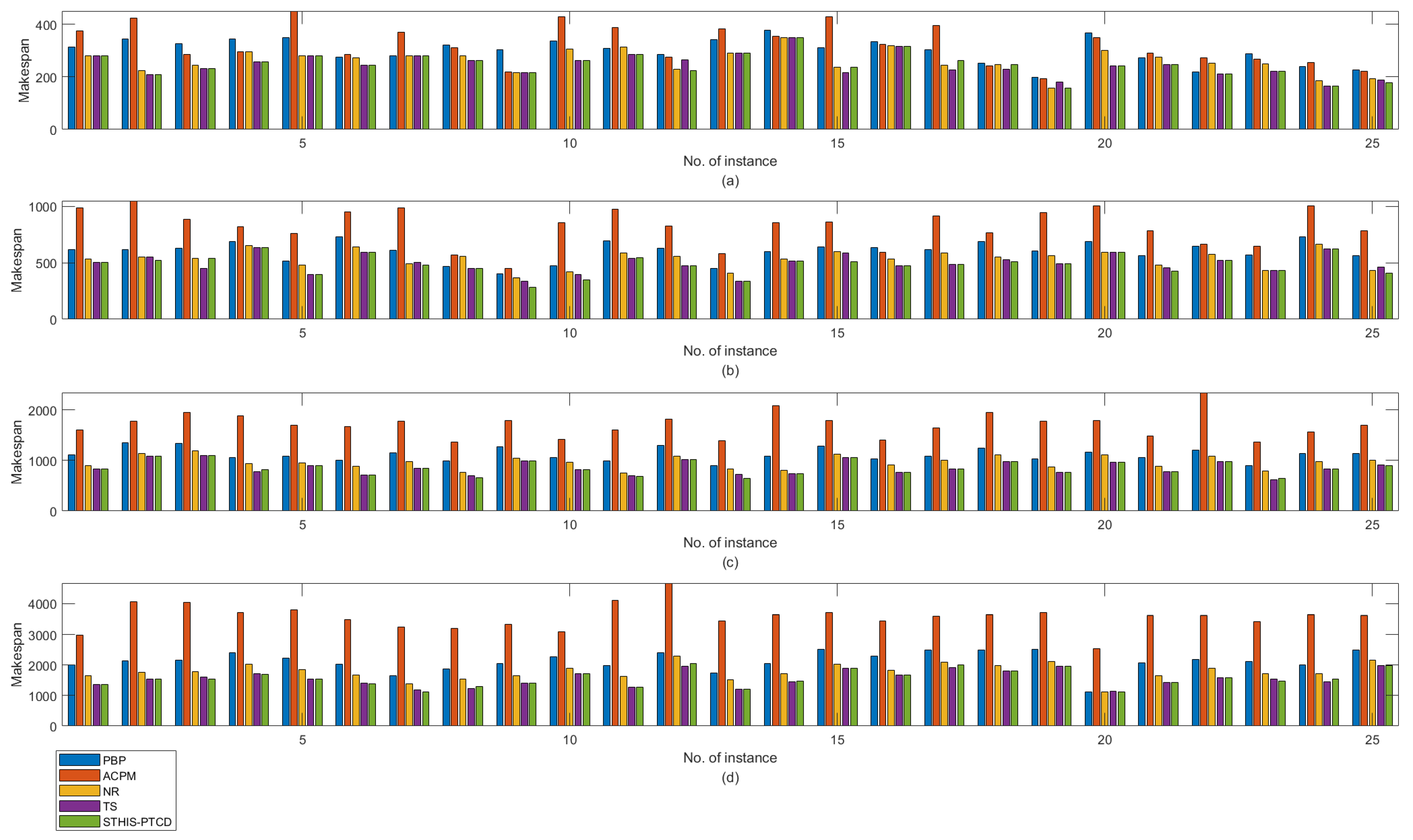

6.2. Experimental Results by Five Algorithms

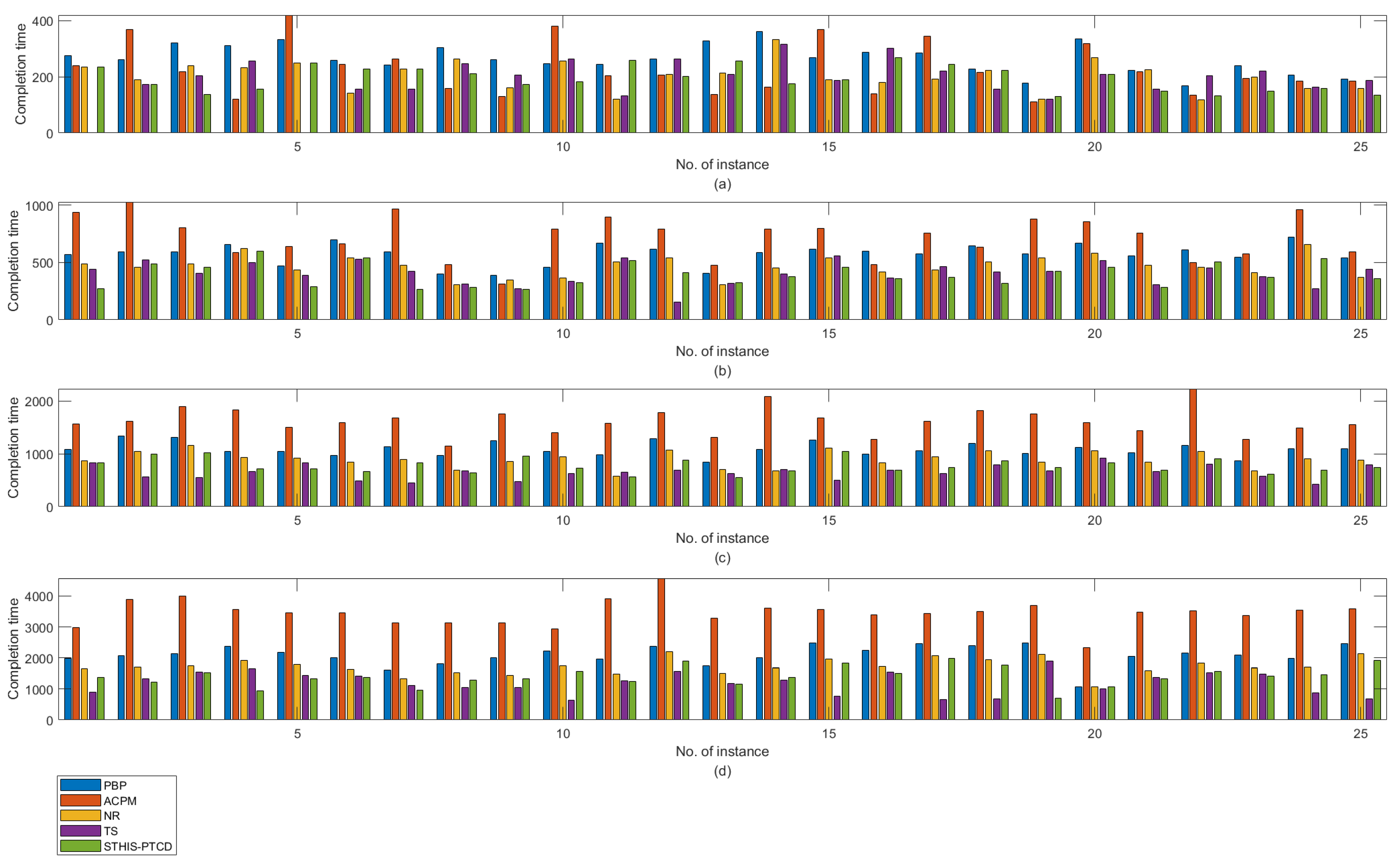

In order to verify the effectiveness of the STHIS-PTCD and its adaptability to complex products in symmetric two workshops, this paper randomly selects 100 instances with four operation scales, [20, 50, 100, 200], on five machines, and each scale with 25 instances. As the number of the machines is five, the average operations on each machine are [4, 10, 20, 40], which is in an ascending order. All the product instances are scheduled by the PBP, ACPM, NR, TS, and STHIS-PTCD, respectively. They are all implemented on Matlab 2019 on the same PC. The makespans of the 100 instances by five algorithms are given in

Figure 25 and

Table 4, and the results of the workshop with the shortest completion time are shown in

Figure 26 and

Table 4.

The results show that the performance of STHIS-PTCD always maintains a higher quality for each operation scale than that of the other four algorithms. Though the performance of TS is similar to it, the processing situation is more balanced than that of TS, which is reflected in the small difference between the completion times in two workshops.

In order to compare the performance of the other algorithms, we use the relative deviation index (RDI) as the measure.

where

R is the RDI value of an algorithm,

Cm is the makespan obtained by it, and

Cbest is the best makespan obtained by all the algorithms. The descriptive statistics are presented in

Table 5 for each operation scale. As shown, STHIS-PTCD finds the best solutions for 22, 23, 23, and 19 out of 25 instances of each test group. Additionally, STHIS-PTCD has a better RDI value, which is the smallest for 20 operations, 50 operations, and 100 operations. Although the TS is better than it for 200 operations, this is not by much.

Furthermore, we also use Wilcoxon matched-paired signed-rank test on the results, and they are listed in

Table 6. It shows that the differences between STHIS-PTCD and PBP, ACPM, and NR, which are significant with

p < 0.05, and the difference between STHIS-PTCD and TS is not significant with

p > 0.05.

Based on the above results, STHIS-PTCD performs the best.

6.3. Comparative Analysis of Scheduling Results

The main reasons why the STHIS-PTCD is the best are as follows:

(1) For the operations:

The algorithm in this paper takes “operation string” as the scheduling unit, which improves the intensity of synchronous scheduling of operations, and it effectively reduces the migration of operations between two workshops. Moreover, on the basis of ensuring sufficient parallel scheduling, the form of “string” further improves the optimization of longitudinal continuous processing of the integrated scheduling, which better makes up for the disadvantages of the existing integrated scheduling of two workshops, such as valuing horizontal relationships over vertical ones or valuing vertical relationships over horizontal ones.

PBP scheduled the operations after grouping them according to the corresponding equipment. When the operations with a constrained relationship on the longest path would not be assigned to the same workshop, not only the operation migration occurs between the two workshops, but also the lack of valuing horizontal relationships over vertical ones happens, as the scheduling of the leaf node operations is ignored. For example, {B15}, as a leaf node, cannot be scheduled in the same workshop with another operation string, {B14, B13, B12, B11, B10, B9}, which has the unique immediate predecessor and the immediate successor. It not only reduces the intensity of continuous processing, but it also adds an operation migration between the two workshops.

Although the ACPM is a classical vertical optimization idea, it neglects the effect of horizontal optimization. Thus, the parallel scheduling of operations is affected, and unnecessary operation migrations have happened. For example, {B20} and {B21} in the operation string {B20, B21, B22} have the constraint relationship of one branch. They could have been seamlessly processed in the same workshop, but they were distributed to two workshops, which increased the operation migrations and prolonged the overall completion time of complex products.

According to the NR, the operations of the operation group are equally allocated to workshops according to the descending order of parallel time. However, the equipment balancing strategy will produce unnecessary operation migration during the scheduling. The long-path strategy and the long-time strategy adopted for the key operations reduce the parallelism between operations. Moreover, it will reduce the intensity of continuous processing of operations on the same equipment no matter the relationship between the operation waiting to be scheduled whether the operation under scheduling is adjacent or with the same immediate successor. For example, in {B15, B14, Bl3, B12, B11, B10, B9}, {B15, B14, Bl3, B12} and {Bl1, B10, B9} are assigned to different workshops, which leads to the scheduling effect of splitting the longitudinal tightness of operations.

The TS first determines the arrangement scheme according to the descending order of the sum of the grouped operation paths. Then, it determines the scheme by the principle of the minimum processing time of the current partial product. Both the scheduling sequence and the allocation scheme of the algorithm take the processing time of the operations as the main consideration. It not only ignores the comprehensive control of parallel processing advantages, but it also takes insufficient consideration of the utilization of equipment resources. For example, M4 in workshop is completely idle during the whole scheduling process.

(2) For the equipment:

In the PBP, ACPM and NR, the key equipment is defined by the longest duration of the equipment. In contrast, the algorithm in this paper takes the number of the operations of the equipment as the defining standard. First, the definition category of special equipment in integrated scheduling is extended. Second, the proposed algorithm sets the equipment with the most operations as the standard and embodies the factors affecting the scheduling result, such as operation constraint relation and level, in the scheduling sequence of operation strings in the way of weight value. From the perspective of optimizing equipment resources, the problem of equipment resource waste or even being idle in the integrated scheduling of two-workshop is better solved. Thus, the goal of optimizing the overall effect of the integrated scheduling of two-workshop is achieved. For example, the TS and M4 in f2 are always in the inactive state in the whole product processing. In the STHIS-PTCD, the average equipment utilization rate of reaches 83.6%, which is 8.8% higher than the PBP, 6.4% higher than the ACPM, 22.9% higher than the NR, and 32.7% higher than the TS.

(3) For the workshops:

Among the workshops, the STHIS-PTCD assigns the operation string to be scheduled according to the minimum difference in completion time between the completed workshop and the uncompleted workshop. In a workshop, the optimal scheduling time strategy is adopted so that the operation string to be scheduled can start processing on the corresponding equipment as early as possible, and the horizontal parallelism of the integrated scheduling is improved, thus the total product processing time can be shortened on the whole. For example, in , the STHIS-PTCD makes {B23} and {B24} on M1 of process from time t = 0 according to the workshop balance strategy and the optimal scheduling time strategy, which not only reduces the number of operation migrations, but also shortens the processing time. In the PBP, the problem of reducing parallel optimization and migration occurs when the scheduling of leaf nodes is ignored in a workshop. For example, {B23} and {B24} are allocated to different workshops, respectively. Similarly, in the ACPM and NR, {B23} and {B24} are also allocated to different workshops, adding one operation migration. However, in the TS, {B24} starts to be processed at t = 3, 3 h later than the proposed algorithm. Another example is that the root node {B1} is allocated to with relatively less processing time according to the workshop balance strategy in this paper. Therefore, on the basis of shortening the total processing time of complex product B, the average utilization rate of workshop equipment is improved.