Multilayer Ceramic Capacitors: An Overview of Failure Mechanisms, Perspectives, and Challenges

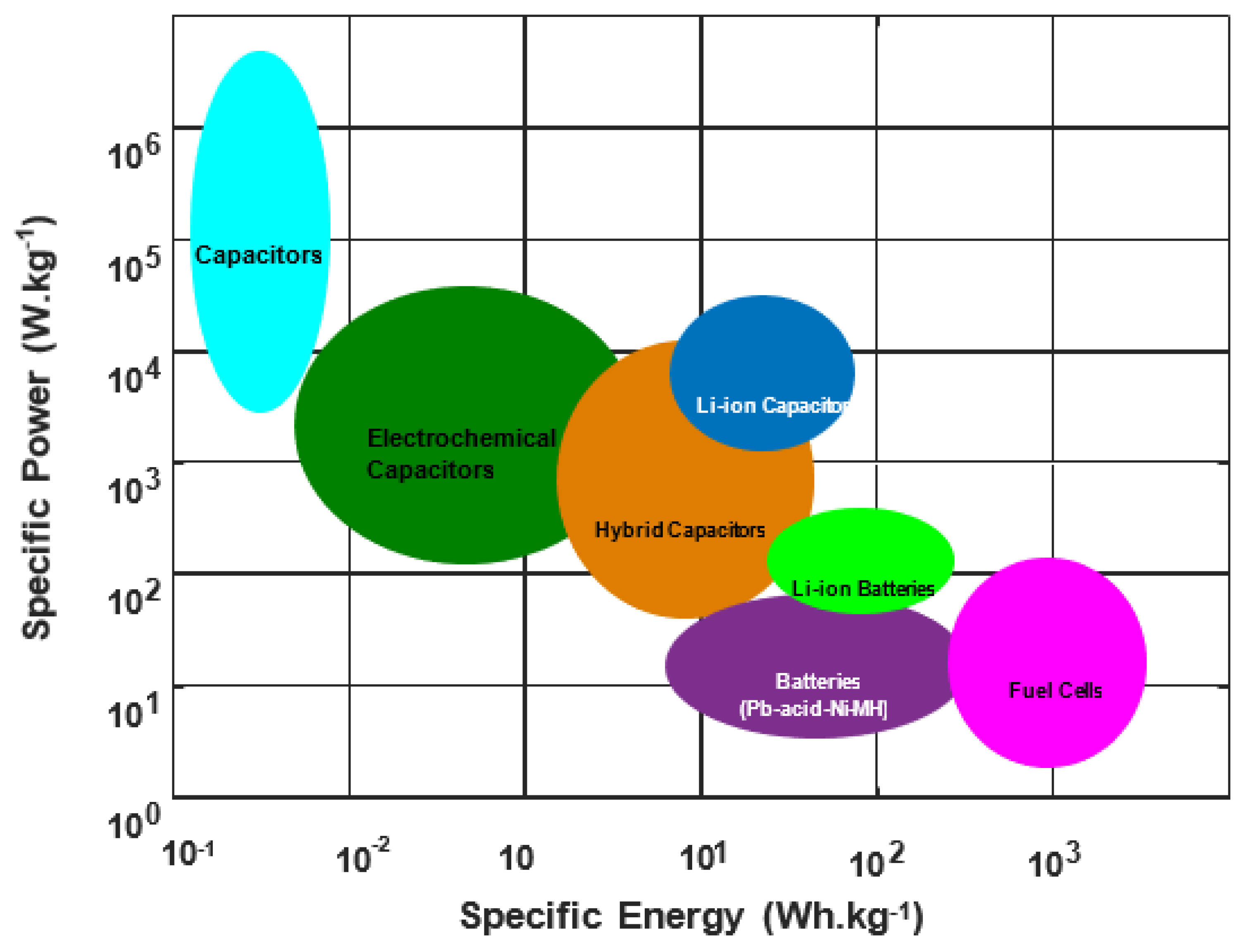

Abstract

:1. Introduction

- ○

- Ratted voltage, capacitances, price, volumetric efficiency, consistency and dependability of capacitances, longevity, and power density.

- ○

- Current ripple ratting and maximum peak current.

- ○

- Temperature range, insulating resistance, and leakage current.

- ○

- Capacitor performance and resonance frequency (capacitance dependency with frequency and temperature, as well as its internal resistance).

1.1. Basic Composition and the Concept of Energy Storage

1.2. Energy Storage Density

1.3. State-of-the-Art in Ceramics

- (1)

- The ability to compensate for a raising the BDS, by a decrease in inherent electrical characteristics, frequently by reducing layer thickness (see Section 1.4.1).

- (2)

- The market dominance of lead-free BT-based MLCCs, which are expected to continue to grow.

1.4. Bulk Ceramics

1.4.1. Lead-Based-Ceramics

- Lead-Based-Relaxor-Ferroelectrics

- Lead-Based-Antiferroelectrics

- (Pb,La)(Zr,Sn,Ti)O3(PLZST)

- (Pb,La)(Zr,Ti)O3 (PLZT)

- (Pb,La)(Zr,Sn)O3 (PLZS)

1.4.2. Lead-Free-Ceramics

- BaTiO3-Based-Ceramics

- SrTiO3-Based-Ceramics

- K0.5Na0.5NbO3-Based-Ceramics

- BiFeO3-Based-Ceramics

- Na0.5Bi0.5TiO3-Based-Ceramics

- AgNbO3-Based-Ceramics

- NaNbO3-Based-Ceramics

1.5. Glass Ceramics

1.6. Ceramic Multilayers

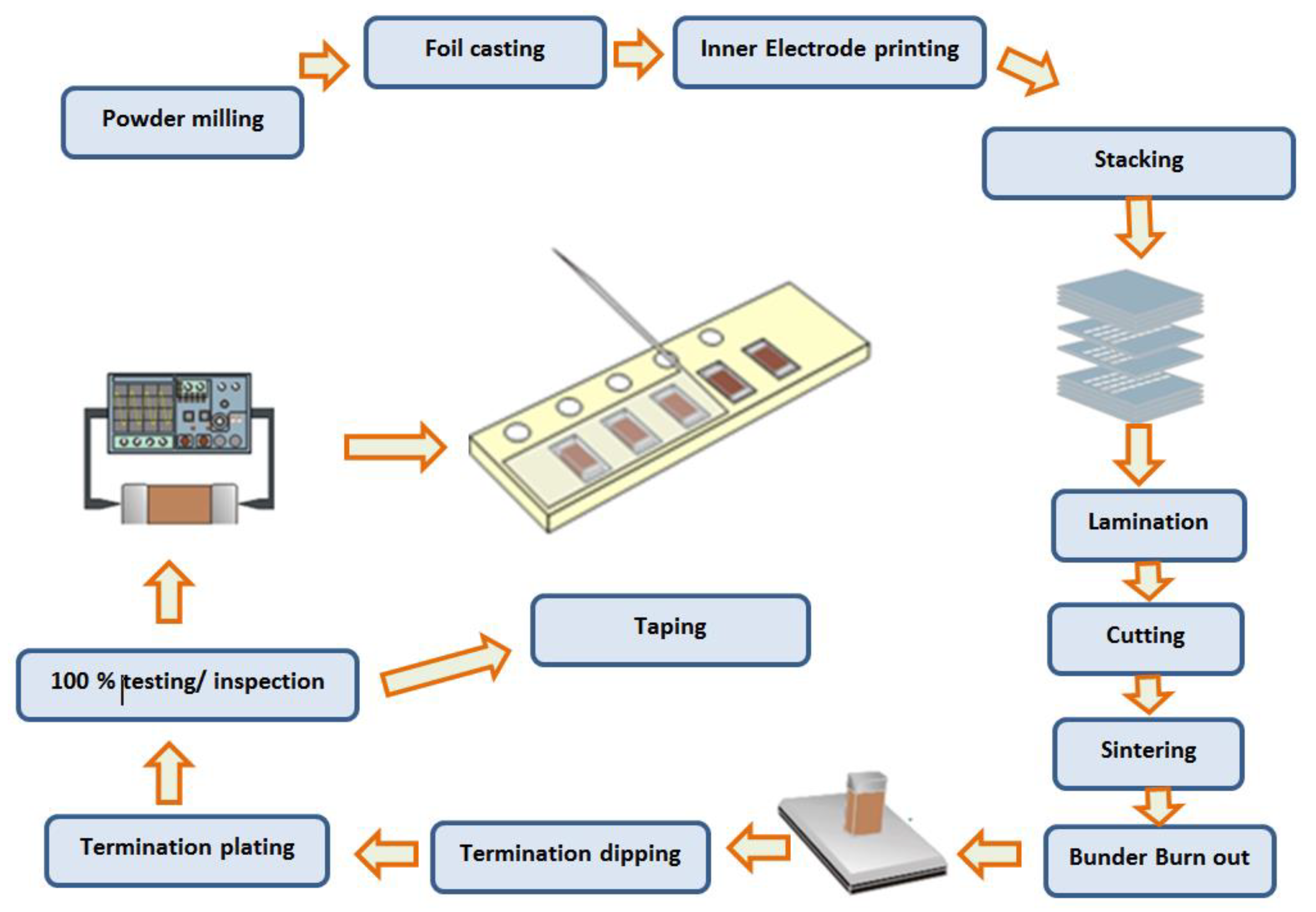

2. MLCC and Its Fabrication Process

- (1)

- The use of silver (Ag)/Pd alloy electrodes having a high Ag content (more than 70%) to achieve low temperature sintering of the dielectrics.

- (2)

- The use of base metals such as nickel (Ni) and copper (Cu) as internal electrodes by using a nonreducible dielectric that can be fired in a reducing atmosphere [109].

3. Reliability

4. MLCCs Failure Mechanisms, Testing Strategies and Fault Diagnosis

4.1. Humidity’s Impact on Electrical Characteristics’ Degradation

4.2. Consequences of Silver Ion Migration

4.3. Ceramic Capacitors’ Mechanism of Failure in High-Temperature Environments

4.4. Improvement of Electrode Materials

4.5. Fracture of Laminated Ceramic Capacitors

4.6. Analysis of Laminated Ceramic Capacitors’ Fractures

4.7. Melted of the Electrode Terminals of the Laminated Ceramic Capacitor

5. Conclusions and Outlook

- (1)

- The capacity to improve. To identify how to effectively control material and device fabrication conditions when scaled up, basic research must be undertaken. It must also be determined whether the cost gradients and the fine-tuning method used in small-scale energy storage MLCCs can be scaled up for production.

- (2)

- Compatibility with the electrode made of base metal. The internal electrode of contemporary, high-energy-density MLCCs is made of precious metals, however base metals must be used in their stead to significantly cut costs. The dielectric material must be anti-reducing or low burn in order to be compatible with base metal electrodes. Additionally, other concerns like high temperature, high frequency, and strong electric field must be addressed in order to retain high-energy storage performance under harsh circumstances.

- (3)

- Great reliability. MLCCs long-term suitability for high-quality industrial applications is determined by their great dependability. It is necessary to solve the performance decline and failure caused by the plurality of electrical, thermal, mechanical, and wet physics. Effective theories, models, approaches, experimental platforms, and simulation methodologies of rapid deterioration are needed for this.

- (4)

- Application-specific assessment and measurement. For the particular applications indicated above, the way energy-storage performance is currently measured and assessed differs from actual usage. As a result, the produced materials and gadgets cannot presently be used in actual applications. On the basis of collaboration between researchers and producers, appropriate standards should be set. Despite these difficulties, it is anticipated that high-energy-density MLCCs will eventually be produced because of their utility in intensive research and development.

- (5)

- By taking into account all the factors that might affect the state of operation or the state of health, these proposals give a great contribution to the evolution of the state of the MLCCs. However, certain methods cannot be used because of the limitations of technological circumstances. For instance, the excessively high breakdown voltage prevents in-site electron microscopy from directly seeing the dynamic destruction of microstructure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MLCCs | Multilayer Ceramic Capacitors |

| SAM | Scanning Acoustic Microscopy |

| ROHS | Restriction of the use of certain Hazardous Substances |

| COTS | Commercial Off-The-Shelf |

| Wrec | Recoverable Energy Storage Density |

| AFEs | Antiferroelectrics |

| RFEs | Relaxor-ferroelectrics |

| FEs | Ferroelectrics |

| Pr | Remnant polarization |

| BDS | Break-Down Strength |

| PNR | Polar Nanoregions |

| ESR | Equivalent Series Resistance |

| ESL | Equivalent Series Inductance |

| BDS | Breakdown Strength |

| PMN | Pb(Mg1/3Nb2/3)O3 |

| NN | NaNbO3 |

| ST | SrTiO3 |

| CT | CaTiO3 |

| AN | AgNbO3 |

| BT | BaTiO3 |

| KNN | (Na, K)NbO3 |

| BF | BiFeO3 |

| NBT | (Na, Bi)TiO3 |

| PLZT | (Pb, La)(Zr, Ti)O3 |

| PZT | (Pb)(Zr, Ti)O3 |

| PLZS | (Pb,La)(Zr,Sn)O3 |

| SBT | (Sr0.7Bi0.2)TiO3 |

| BMN | Bi(Mg2/3Nb1/3)O3 |

| BMH | Bi(Mg0.5Hf0.5) O3 |

| BLN | Bi(Li1/2Nb1/2)O3 |

| NBT | Na0.5Bi0.5TiO3 |

| BF | BiFeO3 |

| BT | BaTiO3 |

References

- Cardoso, A.J.M. Diagnosis and Fault Tolerance of Electrical Machines and Power Electronics; 2018; p. 376. ISBN 13: 978-1-78561-531-1. Available online: https://www.researchgate.net/publication/328676133_Diagnosis_and_Fault_Tolerance_of_Electrical_Machines_Power_Electronics_and_Drives (accessed on 1 February 2023).

- Yuan, Q.; Chen, M.; Zhan, S.; Li, Y.; Lin, Y.; Yang, H. Ceramic-Based Dielectrics for Electrostatic Energy Storage Applications: Fundamental Aspects, Recent Progress, and Remaining Challenges. Chem. Eng. J. 2022, 446, 136315. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. “Singing” Multilayer Ceramic Capacitors and Mitigation Methods—A Review. Sensors 2022, 22, 3869. [Google Scholar] [CrossRef]

- Pan, M.-J.; Randall, C.A. A brief introduction to ceramic capacitors. IEEE Electr. Insul. Mag. 2010, 26, 44–50. [Google Scholar] [CrossRef]

- Pithan, C.; Hennings, D.; Waser, R. Progress in the synthesis of nanocrystalline BaTiO3 powders for MLCC. Int. J. Appl. Ceram. Technol. 2005, 2, 1–14. [Google Scholar] [CrossRef]

- Ho, J.; Jow, T.R.; Boggs, S. Historical introduction to capacitor technology. IEEE Electr. Insul. Mag. 2010, 26, 20–25. [Google Scholar] [CrossRef] [Green Version]

- Kropp, J.; Bakran, M.-M. In-circuit-characterization of ceramic capacitor with anti-ferroelectric material for voltage source inverters. In Proceedings of the PCIM Europe 2016, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2016; pp. 1–8. [Google Scholar]

- Neumayr, D.; Bortis, D.; Kolar, J.W.; Koini, M.; Konrad, J. Comprehensive large-signal performance analysis of ceramic capacitors for power pulsation buffers. In Proceedings of the 2016 IEEE 17th Workshop on Control and Modeling for Power Electronics (COMPEL), Trondheim, Norway, 27–30 June 2016; pp. 1–8. [Google Scholar]

- Hao, H.; Liu, M.; Liu, H.; Zhang, S.; Shu, X.; Wang, T.; Yao, Z.; Cao, M. Design, fabrication and dielectric properties in core–double shell BaTiO3-based ceramics for MLCC application. RSC Adv. 2015, 5, 8868–8876. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Kim, J.; Tian, Z.; Fang, J.; Hur, K.H.; Li, L. High performance BaTiO3-based BME-MLCC nanopowder prepared by aqueous chemical coating method. J. Am. Ceram. Soc. 2012, 95, 1628–1633. [Google Scholar] [CrossRef]

- Kishi, H.; Mizuno, Y.; Chazono, H. Base-metal electrode-multilayer ceramic capacitors: Past, present and future perspectives. Jpn. J. Appl. Phys. 2003, 42, 1. [Google Scholar] [CrossRef]

- Dai, K.; Wang, X.; Niu, S.; Yi, F.; Yin, Y.; Chen, L.; Zhang, Y.; You, Z. Simulation and structure optimization of triboelectric nanogenerators considering the effects of parasitic capacitance. Nano Res. 2017, 10, 157–171. [Google Scholar] [CrossRef]

- Archangelo, K.C.; Guilardi, L.F.; Campanelli, D.; Valandro, L.F.; Borges, A.L.S. Fatigue failure load and finite element analysis of multilayer ceramic restorations. Dent. Mater. 2019, 35, 64–73. [Google Scholar] [CrossRef]

- Nagayoshi, M.; Matsubara, K.; Fujikawa, N. Analyses of microstructure at degraded local area in Ni-multilayer ceramic capacitors under highly accelerated life test. Jpn. J. Appl. Phys. 2020, 59, SPPC01. [Google Scholar] [CrossRef]

- Kalaiselvan, C.; Rao, L.B. Accelerated life testing of nano ceramic capacitors and capacitor test boards using non-parametric method. Measurement 2016, 88, 58–65. [Google Scholar] [CrossRef]

- Lall, P.; Dornala, K.; Suhling, J.; Deep, J.; Lowe, R. Effect of Dielectric Material on the Reliability of 3640 MLCC Capacitors under High-G Shock Loads. In Proceedings of the 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 28–31 May 2019; pp. 1037–1046. [Google Scholar]

- Lall, P.; Dornala, K.; Deep, J.; Lowe, R. Measurement and Prediction of Interface Crack Growth at the PCB-Epoxy Interfaces Under High-G Mechanical Shock. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; pp. 1097–1105. [Google Scholar]

- Lall, P.; Dornala, K.; Lowe, R.; Foley, J. Survivability assessment of electronics subjected to mechanical shocks up to 25,000 g. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 507–518. [Google Scholar]

- Lall, P.; Patel, K.; Lowe, R.; Strickland, M.; Blanche, J.; Geist, D.; Montgomery, R. Modeling and reliability characterization of area-array electronics subjected to high-g mechanical shock up to 50,000 g. In Proceedings of the 2012 IEEE 62nd Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2012; pp. 1194–1204. [Google Scholar]

- Prume, K.; Waser, R.; Franken, K.; Maier, H.R. Finite-Element Analysis of Ceramic Multilayer Capacitors: Modeling and Electrical Impedance Spectroscopy for a Nondestructive Failure Test. J. Am. Ceram. Soc. 2000, 83, 1153–1159. [Google Scholar] [CrossRef]

- Lee, S.P.; Kang, K.W. Analysis for deformation behavior of multilayer ceramic capacitor based on multiscale homogenization approach. J. Mech. Sci. Technol. 2018, 32, 2577–2585. [Google Scholar] [CrossRef]

- Xuhui, Z.; Kuahai, Y.; Hongyu, X.; Bin, L.; Xingguo, K. Failure analysis of multilayer ceramic capacitor structure under high G impact load. Electron. Compon. Mater. 2016, 35, 28–31. [Google Scholar]

- Collins, J.; Gourdin, G.; Foster, M.; Qu, D. Carbon surface functionalities and SEI formation during Li intercalation. Carbon N. Y. 2015, 92, 193–244. [Google Scholar] [CrossRef]

- Yao, Z.; Song, Z.; Hao, H.; Yu, Z.; Cao, M.; Zhang, S.; Lanagan, M.T.; Liu, H. Homogeneous/inhomogeneous-structured dielectrics and their energy-storage performances. Adv. Mater. 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Zhai, J.; Shen, B.; Zeng, H. Recent progress of ecofriendly perovskite-type dielectric ceramics for energy storage applications. J. Adv. Dielectr. 2018, 8, 1830005. [Google Scholar] [CrossRef] [Green Version]

- Hao, X. A review on the dielectric materials for high energy-storage application. J. Adv. Dielectr. 2013, 3, 1330001. [Google Scholar] [CrossRef]

- Zou, K.; Dan, Y.; Xu, H.; Zhang, Q.; Lu, Y.; Huang, H.; He, Y. Recent advances in lead-free dielectric materials for energy storage. Mater. Res. Bull. 2019, 113, 190–201. [Google Scholar] [CrossRef]

- Hong, K.; Lee, T.H.; Suh, J.M.; Yoon, S.-H.; Jang, H.W. Perspectives and challenges in multilayer ceramic capacitors for next generation electronics. J. Mater. Chem. C Mater. 2019, 7, 9782–9802. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, D.-W.; Lin, H.-B.; Zhao, Q.-L.; Zhang, D.-Q.; Cao, M.-S. Effect of ZnO whisker content on sinterability and fracture behaviour of PZT peizoelectric composites. J. Alloys Compd. 2010, 504, 123–128. [Google Scholar] [CrossRef]

- Wang, D.; Cao, M.; Yuan, J.; Zhao, Q.L.; Li, H.B.; Zhang, D.Q.; Agathopoulos, S. Enhanced Piezoelectric and Ferroelectric Properties of Nb2O5 Modified Lead Zirconate Titanate-Based Composites. J. Am. Ceram. Soc. 2011, 94, 647–650. [Google Scholar] [CrossRef]

- Wang, D.; Cao, M.; Zhang, S. Piezoelectric ceramics in the PbSnO3–Pb (Mg1/3Nb2/3) O3–PbTiO3 ternary system. J. Am. Ceram. Soc. 2011, 94, 3690–3693. [Google Scholar] [CrossRef]

- Zhao, Q.L.; Cao, M.S.; Yuan, J.; Lu, R.; Wang, D.W.; Zhang, D.Q. Thickness effect on electrical properties of Pb (Zr0.52Ti0.48) O3 thick films embedded with ZnO nanowhiskers prepared by a hybrid sol–gel route. Mater. Lett. 2010, 64, 632–635. [Google Scholar] [CrossRef]

- Zhang, T.F.; Tang, X.G.; Liu, Q.X.; Jiang, Y.P.; Huang, X.X.; Zhou, Q.F. Energy-storage properties and high-temperature dielectric relaxation behaviors of relaxor ferroelectric Pb (Mg1/3Nb2/3) O3–PbTiO3 ceramics. J. Phys. D Appl. Phys. 2016, 49, 095302. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, T.; Ye, J.; Wang, G.; Dong, X.; Withers, R.; Liu, Y. Antiferroelectrics for energy storage applications: A review. Adv. Mater. Technol. 2018, 3, 1800111. [Google Scholar] [CrossRef]

- Li, Y.; Sun, N.; Du, J.; Li, X.; Hao, X. Stable energy density of a PMN–PST ceramic from room temperature to its Curie point based on the synergistic effect of diversified energy. J. Mater. Chem. C Mater. 2019, 7, 7692–7699. [Google Scholar] [CrossRef]

- Perumal, R.N.; Athikesavan, V. Investigations on electrical and energy storage behaviour of PZN-PT, PMN-PT, PZN–PMN-PT piezoelectric solid solutions. J. Mater. Sci. Mater. Electron. 2019, 30, 902–913. [Google Scholar] [CrossRef]

- Li, Q.; Yao, F.-Z.; Liu, Y.; Zhang, G.; Wang, H.; Wang, Q. High-temperature dielectric materials for electrical energy storage. Annu. Rev. Mater. Res. 2018, 48, 219–243. [Google Scholar] [CrossRef]

- Bikyashev, E.A.; Ryush, I.O.; Reshetnikova, E.A. Structures of Pb1− xLax [Zr0.9Mg (0.1+ x)/3Nb (0.2− x)/3] O3 solid solutions, electrostriction and energy storage characteristics of a new antiferroelectric phase with disturbed translational symmetry. Ceram. Int. 2017, 43, 1429–1436. [Google Scholar] [CrossRef]

- Chao, M.; Liu, J.; Zeng, M.; Wang, D.; Yu, H.; Yuan, Y.; Zhang, S. High discharge efficiency of (Sr, Pb, Bi) TiO3 relaxor ceramics for energy-storage application. Appl. Phys. Lett. 2018, 112, 203903. [Google Scholar] [CrossRef]

- Qi, X.; Zhao, Y.; Sun, E.; Du, J.; Li, K.; Sun, Y.; Yang, B.; Zhang, R.; Cao, W. Large electrostrictive effect and high energy storage performance of Pr3+-doped PIN-PMN-PT multifunctional ceramics in the ergodic relaxor phase. J. Eur. Ceram. Soc. 2019, 39, 4060–4069. [Google Scholar] [CrossRef]

- Shkuratov, S.I.; Baird, J.; Antipov, V.G.; Hackenberger, W.; Luo, J.; Zhang, S.; Lynch, C.S.; Chase, J.B.; Jo, H.R.; Roberts, C.C. Complete stress-induced depolarization of relaxor ferroelectric crystals without transition through a non-polar phase. Appl. Phys. Lett. 2018, 112, 122903. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Sun, N.; Li, X.; Du, J.; Chen, L.; Gao, H.; Hao, X.; Cao, M. Multiple electrical response and enhanced energy storage induced by unusual coexistent-phase structure in relaxor ferroelectric ceramics. Acta Mater. 2018, 146, 202–210. [Google Scholar] [CrossRef]

- Jo, H.R.; Lynch, C.S. A high energy density relaxor antiferroelectric pulsed capacitor dielectric. J. Appl. Phys. 2016, 119, 024104. [Google Scholar] [CrossRef]

- Gao, J.; Liu, Y.; Wang, Y.; Wang, D.; Zhong, L.; Ren, X. High temperature-stability of (Pb0.9La0.1)(Zr0.65Ti0.35) O3 ceramic for energy-storage applications at finite electric field strength. Scr. Mater. 2017, 137, 114–118. [Google Scholar] [CrossRef]

- Li, B.; Liu, Q.; Tang, X.; Zhang, T.; Jiang, Y.; Li, W.; Luo, J. High energy storage density and impedance response of PLZT2/95/5 antiferroelectric ceramics. Materials 2017, 10, 143. [Google Scholar] [CrossRef] [Green Version]

- Yan, F.; Yang, H.; Ying, L.; Wang, T. Enhanced energy storage properties of a novel lead-free ceramic with a multilayer structure. J. Mater. Chem. C Mater. 2018, 6, 7905–7912. [Google Scholar] [CrossRef]

- Chen, S.; Wang, X.; Yang, T.; Wang, J. Composition-dependent dielectric properties and energy storage performance of (Pb, La)(Zr, Sn, Ti) O3 antiferroelectric ceramics. J. Electroceram. 2014, 32, 307–310. [Google Scholar] [CrossRef]

- Zhuo, F.; Li, Q.; Li, Y.; Gao, J.; Yan, Q.; Zhang, Y.; Chu, X.; Cao, W. Effect of A-site La3+ modified on dielectric and energy storage properties in lead zironate stannate titanate ceramics. Mater. Res. Express. 2014, 1, 045501. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Sun, N.; Hao, X. High energy-storage performance of PLZS antiferroelectric multilayer ceramic capacitors. Inorg. Chem. Front. 2020, 7, 756–764. [Google Scholar] [CrossRef]

- Xu, R.; Xu, Z.; Feng, Y.; Wei, X.; Tian, J.; Huang, D. Evaluation of discharge energy density of antiferroelectric ceramics for pulse capacitors. Appl. Phys. Lett. 2016, 109, 032903. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, X.; Liu, Y.; Cao, F.; Wang, G. Electric field tunable thermal stability of energy storage properties of PLZST antiferroelectric ceramics. J. Am. Ceram. Soc. 2017, 100, 2382–2386. [Google Scholar] [CrossRef]

- Xu, R.; Tian, J.; Zhu, Q.; Zhao, T.; Feng, Y.; Wei, X.; Xu, Z. Effects of La-induced phase transition on energy storage and discharge properties of PLZST ferroelectric/antiferroelectric ceramics. Ceram. Int. 2017, 43, 13918–13923. [Google Scholar] [CrossRef]

- Shen, J.; Wang, X.; Yang, T.; Wang, H.; Wei, J. High discharge energy density and fast release speed of (Pb, La)(Zr, Sn, Ti) O3 antiferroelectric ceramics for pulsed capacitors. J. Alloys Compd. 2017, 721, 191–198. [Google Scholar] [CrossRef]

- Zhang, Q.; Dan, Y.; Chen, J.; Lu, Y.; Yang, T.; Yao, X.; He, Y. Effects of composition and temperature on energy storage properties of (Pb, La)(Zr, Sn, Ti) O3 antiferroelectric ceramics. Ceram. Int. 2017, 43, 11428–11432. [Google Scholar] [CrossRef]

- Dan, Y.; Xu, H.; Zou, K.; Zhang, Q.; Lu, Y.; Chang, G.; Huang, H.; He, Y. Energy storage characteristics of (Pb, La)(Zr, Sn, Ti) O3 antiferroelectric ceramics with high Sn content. Appl. Phys. Lett. 2018, 113, 063902. [Google Scholar] [CrossRef]

- Dan, Y.; Xu, H.; Zhang, Y.; Zou, K.; Zhang, Q.; Lu, Y.; Chang, G.; Zhang, Q.; He, Y. High-energy density of Pb0. 97La0. 02 (Zr0.50Sn0.45Ti0.05) O3 antiferroelectric ceramics prepared by sol-gel method with low-cost dibutyltin oxide. J. Am. Ceram. Soc. 2019, 102, 1776–1783. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Wang, G.; Bao, W.; Li, J.; Li, L.; Mostaed, A.; Yang, H.; Ji, H.; Li, D.; Feteira, A.; et al. Superior energy density through tailored dopant strategies in multilayer ceramic capacitors. Energy Environ. Sci. 2020, 13, 2938–2948. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, Y.; Zou, K.; Chen, G.; Zhang, Y.; Li, H.; Lu, Y.; Zhang, Q.; He, Y. High energy density and efficiency in (Pb, La)(Zr, Sn, Ti) O3 antiferroelectric ceramics with high La3+ content and optimized Sn4+ content. Ceram. Int. 2019, 45, 24419–24424. [Google Scholar] [CrossRef]

- Zhao, Q.; Lei, H.; He, G.; Di, J.; Wang, D.; Tan, P.; Jin, H.; Cao, M. Effects of thickness on energy storage of (Pb, La)(Zr, Sn, Ti) O3 antiferroelectric films deposited on LaNiO3 electrodes. Ceram. Int. 2016, 42, 1314–1317. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Yang, T.; Zhang, S. Ultrahigh energy-storage density in antiferroelectric ceramics with field-induced multiphase transitions. Adv. Funct. Mater. 2019, 29, 1807321. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Hao, X. Ultra-high energy-storage density and fast discharge speed of (Pb 0.98− x La 0.02 Sr x)(Zr 0.9 Sn 0.1) 0.995 O3 antiferroelectric ceramics prepared via the tape-casting method. J. Mater. Chem. A Mater. 2019, 7, 11858–11866. [Google Scholar] [CrossRef]

- Yang, X.; Zhuo, F.; Wang, C.; Liu, Y.; Wang, Z.; Tailor, H.; He, C.; Long, X. High energy storage density and ultrafast discharge in lead lutetium niobate based ceramics. J. Mater. Chem. A Mater. 2019, 7, 8414–8422. [Google Scholar] [CrossRef]

- Chao, W.; Yang, T.; Li, Y. Achieving high energy efficiency and energy density in PbHfO3-based antiferroelectric ceramics. J. Mater. Chem. C Mater. 2020, 8, 17016–17024. [Google Scholar] [CrossRef]

- Hao, X.; Zhai, J.; Kong, L.B.; Xu, Z. A comprehensive review on the progress of lead zirconate-based antiferroelectric materials. Prog. Mater. Sci. 2014, 63, 1–57. [Google Scholar] [CrossRef]

- Haertling, G.H.; Land, C.E. Hot-pressed (Pb, La)(Zr, Ti) O3 ferroelectric ceramics for electrooptic applications. J. Am. Ceram. Soc. 1971, 54, 1–11. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M.; Sinclair, D.C.; Mustapha, K.B.; Acquaye, A.; Wang, D. Are lead-free piezoelectrics more environmentally friendly? MRS Commun. 2017, 7, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M.; Acquaye, A.; Wang, D.; Taylor, S.; Genovese, A. Integrated hybrid life cycle assessment and supply chain environmental profile evaluations of lead-based (lead zirconate titanate) versus lead-free (potassium sodium niobate) piezoelectric ceramics. Energy Environ. Sci. 2016, 9, 3495–3520. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Wang, G.; Murakami, S.; Fan, Z.; Feteira, A.; Zhou, D.; Sun, S.; Zhao, Q.; Reaney, I.M. BiFeO3-BaTiO3: A new generation of lead-free electroceramics. J. Adv. Dielectr. 2018, 8, 1830004. [Google Scholar] [CrossRef] [Green Version]

- Lai, X.; Hao, H.; Liu, Z.; Li, S.; Liu, Y.; Emmanuel, M.; Yao, Z.; Cao, M.; Wang, D.; Liu, H. Structure and dielectric properties of MgO-coated BaTiO3 ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 8963–8970. [Google Scholar] [CrossRef]

- Han, D.; Wang, C.; Lu, D.; Hussain, F.; Wang, D.; Meng, F. A temperature stable (Ba1–xCex)(Ti1–x/2Mgx/2) O3 lead-free ceramic for X4D capacitors. J. Alloys Compd. 2020, 821, 153480. [Google Scholar] [CrossRef]

- Li, Y.; Cao, M.; Wang, D.; Yuan, J. High-efficiency and dynamic stable electromagnetic wave attenuation for La doped bismuth ferrite at elevated temperature and gigahertz frequency. RSC Adv. 2015, 5, 77184–77191. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Cao, W.; Yuan, J.; Wang, D.; Cao, M. Nd doping of bismuth ferrite to tune electromagnetic properties and increase microwave absorption by magnetic–dielectric synergy. J. Mater. Chem. C Mater. 2015, 3, 9276–9282. [Google Scholar] [CrossRef]

- Wang, D.; Wang, M.; Liu, F.; Cui, Y.; Zhao, Q.; Sun, H.; Jin, H.; Cao, M. Sol–gel synthesis of Nd-doped BiFeO3 multiferroic and its characterization. Ceram. Int. 2015, 41, 8768–8772. [Google Scholar] [CrossRef]

- Li, Z.J.; Hou, Z.L.; Song, W.L.; Liu, X.D.; Wang, D.W.; Tang, J.; Shao, X.H. Mg-substitution for promoting magnetic and ferroelectric properties of BiFeO3 multiferroic nanoparticles. Mater. Lett. 2016, 175, 207–211. [Google Scholar] [CrossRef]

- Murakami, S.; Wang, D.; Mostaed, A.; Khesro, A.; Feteira, A.; Sinclair, D.C.; Fan, Z.; Tan, X.; Reaney, I.M. High strain (0.4%) Bi (Mg2/3Nb1/3) O3-BaTiO3-BiFeO3 lead-free piezoelectric ceramics and multilayers. J. Am. Ceram. Soc. 2018, 101, 5428–5442. [Google Scholar] [CrossRef]

- Hussain, F.; Khesro, A.; Lu, Z.; Wang, G.; Wang, D. Lead free multilayer piezoelectric actuators by economically new approach. Front. Mater. 2020, 7, 87. [Google Scholar] [CrossRef] [Green Version]

- Khesro, A.; Wang, D.; Hussain, F.; Sinclair, D.C.; Feteira, A.; Reaney, I.M. Temperature stable and fatigue resistant lead-free ceramics for actuators. Appl. Phys. Lett. 2016, 109, 142907. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for high-energy density capacitors: Current status and future perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Cai, Z.; Wu, L.; Zhu, C.; Li, L.; Wang, X. Perspectives and challenges for lead-free energy-storage multilayer ceramic capacitors. J. Adv. Ceram. 2021, 10, 1153–1193. [Google Scholar] [CrossRef]

- Jia, W.; Hou, Y.; Zheng, M.; Xu, Y.; Yu, X.; Zhu, M.; Yang, K.; Cheng, H.; Sun, S.; Xing, J. Superior temperature-stable dielectrics for MLCC s based on Bi0. 5Na0. 5TiO3-NaNbO3 system modified by CaZrO3. J. Am. Ceram. Soc. 2018, 101, 3468–3479. [Google Scholar] [CrossRef]

- Yuan, Q.; Cui, J.; Wang, Y.; Ma, R.; Wang, H. Significant enhancement in breakdown strength and energy density of the BaTiO3/BaTiO3@ SiO2 layered ceramics with strong interface blocking effect. J. Eur. Ceram. Soc. 2017, 37, 4645–4652. [Google Scholar] [CrossRef]

- Chen, L.; Sun, N.; Li, Y.; Zhang, Q.; Zhang, L.; Hao, X. Multifunctional antiferroelectric MLCC with high-energy-storage properties and large field-induced strain. J. Am. Ceram. Soc. 2018, 101, 2313–2320. [Google Scholar] [CrossRef]

- Tong, X.Y.; Yang, Y.T.; Song, M.W.; Zhou, J.J.; Wang, K.; Guan, C.L.; Liu, H.; Fang, J.Z. Energy-storage properties of low-temperature Co-fired BNT-ST/AgPd multilayer lead-free ceramic capacitors. J. Alloys Compd. 2020, 827, 154260. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.; Zhao, P.; Zhu, C.; Cai, Z.; Cen, Z.; Li, L.; Wang, X. Multifunctional BaTiO3-(Bi0.5Na0.5) TiO3-based MLCC with high-energy storage properties and temperature stability. J. Am. Ceram. Soc. 2019, 102, 4178–4187. [Google Scholar] [CrossRef]

- Lee, H.; Kim, J.R.; Lanagan, M.J.; Trolier-McKinstry, S.; Randall, C.A. High-Energy Density Dielectrics and Capacitors for Elevated Temperatures: Ca (Zr, Ti) O3. J. Am. Ceram. Soc. 2013, 96, 1209–1213. [Google Scholar] [CrossRef]

- Li, W.-B.; Zhou, D.; Xu, R.; Pang, L.-X.; Reaney, I.M. BaTiO3–Bi (Li0.5Ta0.5) O3, lead-free ceramics, and multilayers with high energy storage density and efficiency. ACS Appl. Energy Mater. 2018, 1, 5016–5023. [Google Scholar] [CrossRef]

- Li, W.B.; Zhou, D.; Xu, R.; Wang, D.W.; Su, J.Z.; Pang, L.X.; Liu, W.F.; Chen, G.H. BaTiO3-based multilayers with outstanding energy storage performance for high temperature capacitor applications. ACS Appl. Energy Mater. 2019, 2, 5499–5506. [Google Scholar] [CrossRef]

- Ogihara, H.; Randall, C.A.; Trolier-McKinstry, S. High-energy density capacitors utilizing 0.7 BaTiO3–0.3 BiScO3 ceramics. J. Am. Ceram. Soc. 2009, 92, 1719–1724. [Google Scholar] [CrossRef]

- Wang, D.; Fan, Z.; Zhou, D.; Khesro, A.; Murakami, S.; Feteira, A.; Zhao, Q.; Tan, X.; Reaney, I.M. Bismuth ferrite-based lead-free ceramics and multilayers with high recoverable energy density. J. Mater. Chem. A Mater. 2018, 6, 4133–4144. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.; Wang, H.; Zhao, P.; Chen, L.; Zhu, C.; Hui, K.; Li, L.; Wang, X. Significantly enhanced dielectric breakdown strength and energy density of multilayer ceramic capacitors with high efficiency by electrodes structure design. Appl. Phys. Lett. 2019, 115, 023901. [Google Scholar] [CrossRef]

- Cai, Z.; Zhu, C.; Wang, H.; Zhao, P.; Chen, L.; Li, L.; Wang, X. High-temperature lead-free multilayer ceramic capacitors with ultrahigh energy density and efficiency fabricated via two-step sintering. J. Mater. Chem. A Mater. 2019, 7, 14575–14582. [Google Scholar] [CrossRef]

- Li, J.; Li, F.; Xu, Z.; Zhang, S. Multilayer lead-free ceramic capacitors with ultrahigh energy density and efficiency. Adv. Mater. 2018, 30, 1802155. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Lu, Z.; Li, J.; Ji, H.; Yang, H.; Li, L.; Sun, S.; Feteira, A.; Yang, H.; Zuo, R.; et al. Lead-free (Ba, Sr) TiO3–BiFeO3 based multilayer ceramic capacitors with high energy density. J. Eur. Ceram. Soc. 2020, 40, 1779–1783. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, H.; Wu, L.; Chen, L.; Cai, Z.; Li, L.; Wang, X. High-performance relaxor ferroelectric materials for energy storage applications. Adv. Energy Mater. 2019, 9, 1803048. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, P.; Chen, L.; Wang, X. Effects of dielectric thickness on energy storage properties of 0.87 BaTiO3-0.13 Bi (Zn2/3 (Nb0.85Ta0.15) 1/3) O3 multilayer ceramic capacitors. J. Eur. Ceram. Soc. 2020, 40, 1902–1908. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Zhang, X.; Fan, Z.; Yang, F.; Feteira, A.; Zhou, D.; Sinclair, D.C.; Ma, T.; Tan, X.; et al. Ultrahigh energy storage density lead-free multilayers by controlled electrical homogeneity. Energy Environ. Sci. 2019, 12, 582–588. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Yang, H.; Ji, H.; Mostaed, A.; Li, L.; Wei, Y.; Feteira, A.; Sun, S.; Sinclair, D.C.; et al. Fatigue resistant lead-free multilayer ceramic capacitors with ultrahigh energy density. J. Mater. Chem. A Mater. 2020, 8, 11414–11423. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, P.; Chen, L.; Li, L.; Wang, X. Energy storage properties of 0.87 BaTiO3-0.13 Bi (Zn2/3 (Nb0.85Ta 0.15) 1/3) O3 multilayer ceramic capacitors with thin dielectric layers. J. Adv. Ceram. 2020, 9, 292–302. [Google Scholar] [CrossRef]

- Yu, D.; Dai, K.; Zhang, J.; Yang, B.; Zhang, H.; Ma, S. Failure mechanism of multilayer ceramic capacitors under transient high impact. Appl. Sci. 2020, 10, 8435. [Google Scholar] [CrossRef]

- Levikari, S.; Kärkkäinen, T.J.; Andersson, C.; Tamminen, J.; Silventoinen, P. Acoustic phenomena in damaged ceramic capacitors. IEEE Trans. Ind. Electron. 2017, 65, 570–577. [Google Scholar] [CrossRef]

- Li, J.; Shen, Z.; Chen, X.; Yang, S.; Zhou, W.; Wang, M.; Wang, L.; Kou, Q.; Liu, Y.; Li, Q.; et al. Grain-orientation-engineered multilayer ceramic capacitors for energy storage applications. Nat. Mater. 2020, 19, 999–1005. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Guo, L.; Zhu, W.; Li, C. Recent Advances in Multi-Material 3D Printing of Functional Ceramic Devices. Polymers 2022, 14, 4635. [Google Scholar] [CrossRef]

- Reinheimer, T.; Azmi, R.; Binder, J.R. Polymerizable ceramic ink system for thin inkjet-printed dielectric layers. ACS Appl. Mater. Interfaces 2019, 12, 2974–2982. [Google Scholar] [CrossRef]

- Wolf, A.; Rosendahl, P.L.; Knaack, U. Additive manufacturing of clay and ceramic building components. Autom. Constr. 2022, 133, 103956. [Google Scholar] [CrossRef]

- He, Q.; Jiang, J.; Yang, X.; Zhang, L.; Zhou, Z.; Zhong, Y.; Shen, Z. Additive manufacturing of dense zirconia ceramics by fused deposition modeling via screw extrusion. J. Eur. Ceram. Soc. 2021, 41, 1033–1040. [Google Scholar] [CrossRef]

- Wang, F.; Li, Z.; Lou, Y.; Zeng, F.; Hao, M.; Lei, W.; Wang, X.; Wang, X.; Fan, G.; Lu, W. Stereolithographic additive manufacturing of Luneburg lens using Al2O3-based low sintering temperature ceramics for 5G MIMO antenna. Addit. Manuf. 2021, 47, 102244. [Google Scholar] [CrossRef]

- Liu, K.; Zhou, C.; Hu, J.; Zhang, S.; Zhang, Q.; Sun, C.; Shi, Y.; Sun, H.; Yin, C.; Zhang, Y.; et al. Fabrication of barium titanate ceramics via digital light processing 3D printing by using high refractive index monomer. J. Eur. Ceram. Soc. 2021, 41, 5909–5917. [Google Scholar] [CrossRef]

- Gong, P.; Li, Y.; Xin, C.; Chen, Q.; Hao, L.; Sun, Q.; Li, Z. Multimaterial 3D-printing barium titanate/carbonyl iron composites with bilayer-gradient honeycomb structure for adjustable broadband microwave absorption. Ceram. Int. 2022, 48, 9873–9881. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Huang, C.; Hu, Y. Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. J. Eur. Ceram. Soc. 2020, 40, 5797–5809. [Google Scholar] [CrossRef]

- Zhang, D.; Hubing, T.H.; Ritter, A.; Patil, K. Electrical Behavior of Multi-Layer Ceramic Capacitors Damaged by Electrostatic Discharge. Investig. Electr. Compon. Fail. Affect. Veh. Electron. 2014, 62. [Google Scholar]

- Brown, D. Multilayer Ceramic Capacitors: Mitigating Rising Failure Rates. 2018, pp. 1–7. Available online: https://smtnet.com/library/index.cfm?fuseaction=view_article&article_id=2903&company_id=52094 (accessed on 1 February 2023).

| Capacitors Categories | Dielectric | Dielectric Constant (εr) | Dielectric Thickness (d) |

|---|---|---|---|

| Electrolyte | Aluminum Oxide | [8, 10] | [0.03, 0.7] μm |

| Tantalum Oxide | [23, 27] | [0.04, 0.5] μm | |

| Film | Polyester Film | ≅3.2 | [0.5, 2] μm |

| Ceramic | Barium Titanate | [0.5, 20] × 103 | [2, 3] μm |

| Titanium Oxide | [15, 250] | [2, 3] μm |

| Metals | Melting Point (°C) | Resistivity (mΩ) | Price Ratio |

|---|---|---|---|

| Ag | 961 | 1.62 | 3 |

| Cu | 1080 | 1.72 | 1 |

| Ni | 1453 | 6.9 | 1 |

| Pd | 1552 | 10.4 | 80 |

| Failure Modes | Schematic | Possible Reasons: | The Specific Performance | Countermeasures |

|---|---|---|---|---|

| Penetration of ceramic electrode edges (the breakdown point is at the edge of the silver surface) |  |

|

|

|

| The ceramic chip’s edge is cracked and damaged, or it is conducting along its edge (the breakdown point is on the side of the element) |  |

|

|

|

| The electrode’s ceramic chip has fractured (the breakdown point is at the center of the element, on the silver surface, and its surroundings). |  |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laadjal, K.; Cardoso, A.J.M. Multilayer Ceramic Capacitors: An Overview of Failure Mechanisms, Perspectives, and Challenges. Electronics 2023, 12, 1297. https://doi.org/10.3390/electronics12061297

Laadjal K, Cardoso AJM. Multilayer Ceramic Capacitors: An Overview of Failure Mechanisms, Perspectives, and Challenges. Electronics. 2023; 12(6):1297. https://doi.org/10.3390/electronics12061297

Chicago/Turabian StyleLaadjal, Khaled, and Antonio J. Marques Cardoso. 2023. "Multilayer Ceramic Capacitors: An Overview of Failure Mechanisms, Perspectives, and Challenges" Electronics 12, no. 6: 1297. https://doi.org/10.3390/electronics12061297

APA StyleLaadjal, K., & Cardoso, A. J. M. (2023). Multilayer Ceramic Capacitors: An Overview of Failure Mechanisms, Perspectives, and Challenges. Electronics, 12(6), 1297. https://doi.org/10.3390/electronics12061297