3.1. Energy Management Procedure

If we take into account only the power demand in the charging points, each EV will represent a consumption of approximately 28 kWh in terms of energy capacity [

11]. With this reference and assuming 100 EVs per day, the station ESS should have a capacity of around 2.8 MWh in its operating range, i.e., 40–90% of the SOC. This is an upper bound considering that ESS is responsible for delivering all the energy to the vehicles.

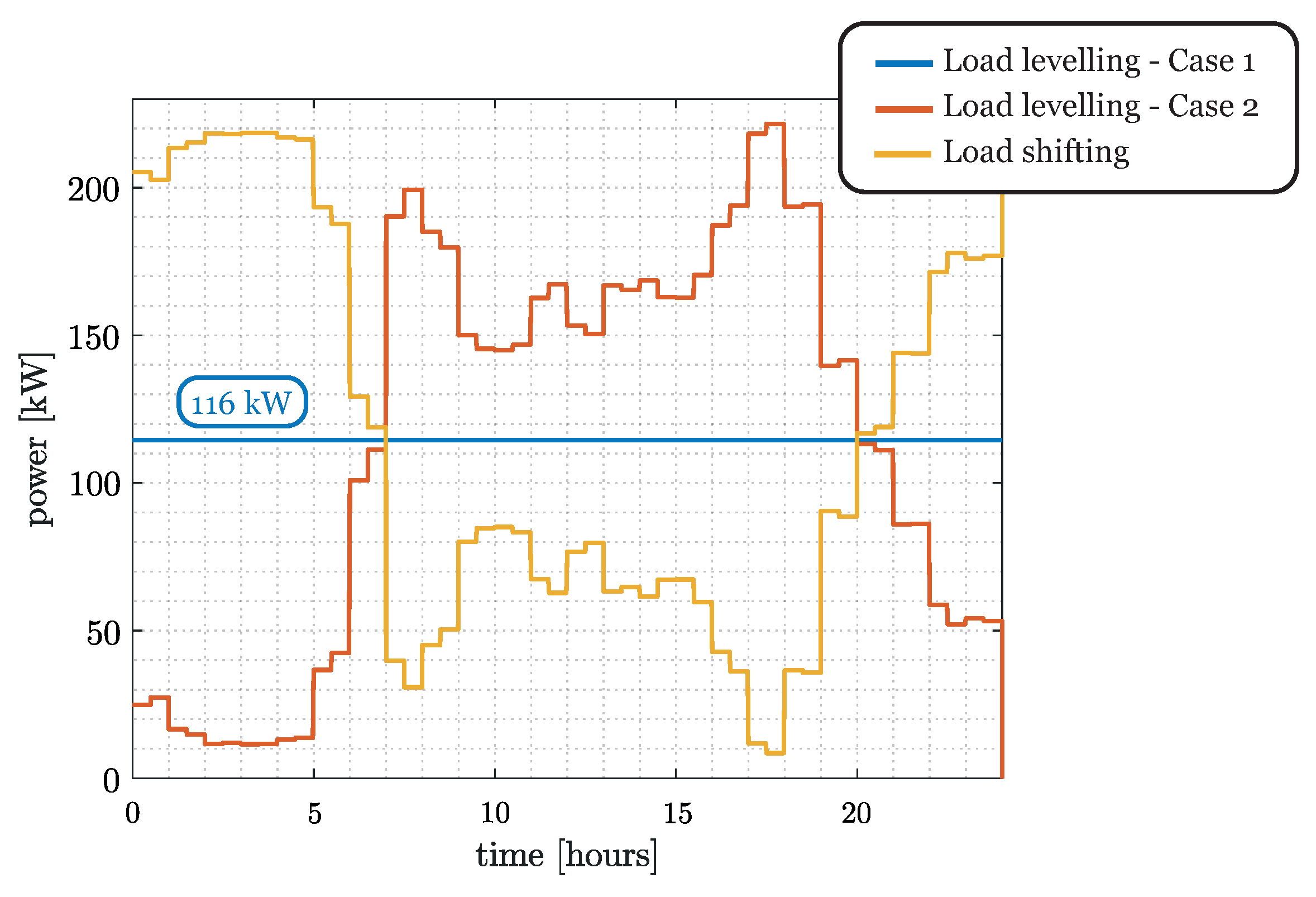

Nonetheless, it is necessary to use an appropriate energy and power distribution management procedure among ChPs, ESS, and SST in order to establish a reasonable value of the ESS capacity, considering the circumstances of the daily operation of the UFCS. In this sense, two different energy management strategies can be used, namely load leveling and load shifting.

Load leveling assigns the power distribution proportionally between SST and ESS, considering a consumption value that reflects a possible power demand per hour in one day of operation of the UFCS. In this work, we establish two types of load leveling for energy management. The first method is based on a continuous consumption profile and is equal to the daily mean power value demanded by the ChPs (Case 1), while the second one is based in the average consumption profile every 30 min (Case 2).

The load shifting approach is the opposite of the leveling technique, since the ESS stores energy in valley hours and delivers the energy during the service peaks, thus alleviating the demand on the grid. The load shifting is performed with respect to the 30 min average consumption used in the above-mentioned Case 2.

It is assumed in our study that the SST ensures a regular power delivery in both strategies.

Figure 5 shows the UFCS estimated consumption profiles according to the three management procedures described above. In reference [

11], the expected number of daily vehicles in the UFCS was 100 for the current traffic conditions. In order to consider a possible increase in that figure in the following years, we have considered in this paper 150 and 200 EVs per day, which represents an increment of 50% and 100% in the current capacity.

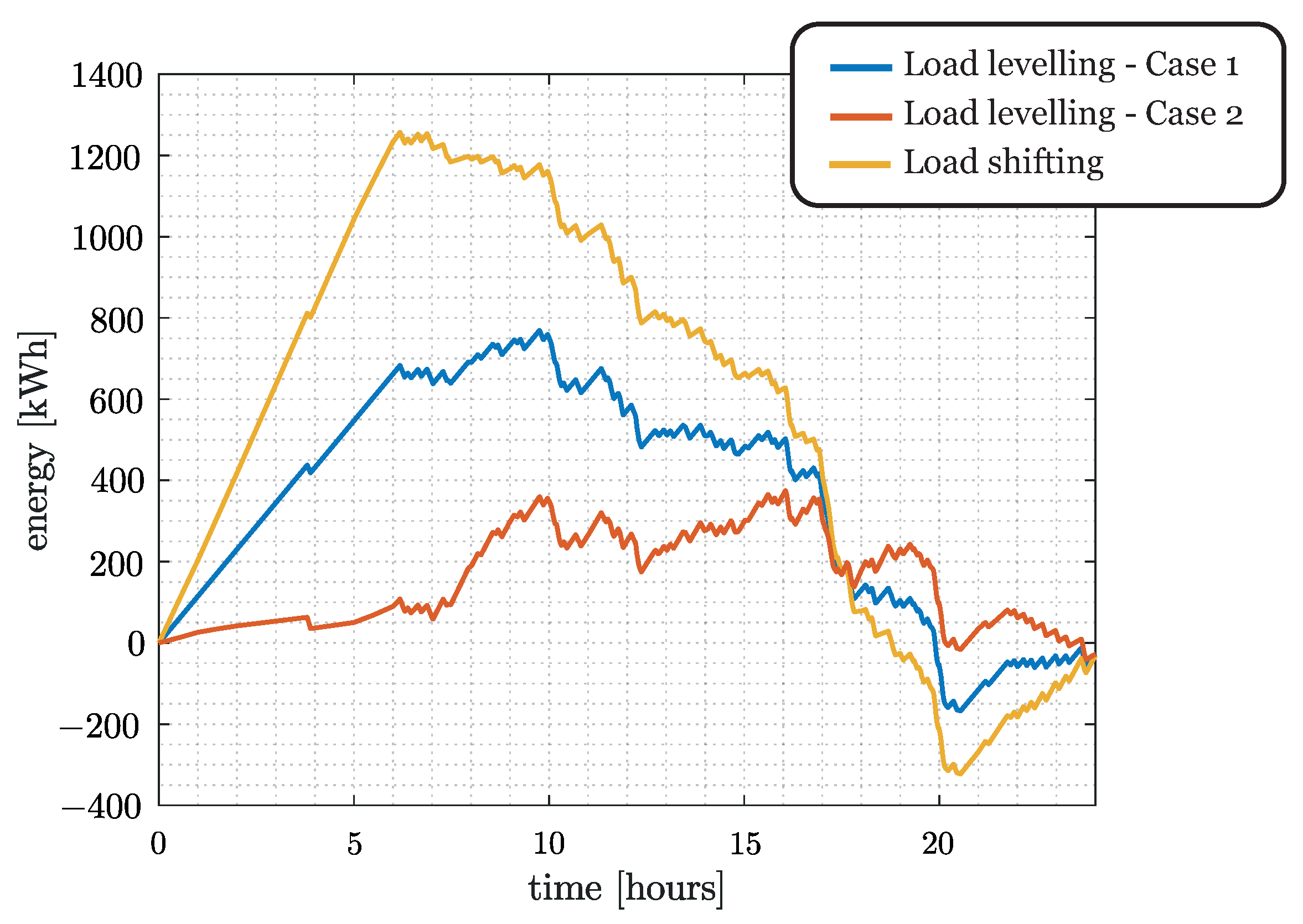

A first approach to computing the capacity can be carried out by establishing the difference between the expected demand profile of the station and the real demand in the ChPs. This calculation determines the total necessary energy in each management procedure but does not take account of the energy flow. We denominate this approach the static method, and it allows establishing an upper bound of the ESS sizing.

Table 3 shows the average results for 500 operating days predicted by simulation using the static method with each management policy. Note that the final capacity corresponds to the total capacity of the ESS, although in the design, only 50% of that value has to be considered as the operative range.

Figure 6 shows the energy flow dynamics generated in the ESS during UFCS operation according to the employed energy management procedure. Instead of considering the total amount of energy, a second approach based on

Figure 6 uses the ESS complete operation range during both charging and discharging processes and results in a smaller value of the capacity.

Different indexes can be used to calculate the capacity related to the operation range.

Figure 7 illustrates the dynamic behavior for one-day operation when the load shifting profile is used. The first hours correspond to the total load phase, which is followed by the delivery phase of that stored load to the ChPs as the day goes by. Thus, a capacity equal to the total range between two processes indicates the correct operation with respect to the selected management system.

Table 4 summarizes the obtained results on average for each management procedure using the dynamic method for a total range calculated after 500 operating days. It can be observed that there is a reduction in the calculated capacity with respect to the value estimated by the static approach.

Figure 6 shows a significant difference with respect to both maximum and minimum values of the energy flow dynamics. An indicator taking the largest value with respect to zero, i.e., the beginning of the day at 0 h, provides a partial range that corresponds to the minimum value required for UFCS operation.

Table 5 summarizes the obtained results on average for 500 operating days, considering the mentioned partial range.

In the performed simulations, the queue and power distribution management system ensures the availability of the service near 100%, in spite of the increase in the number of EVs.

Table 6 summarizes the waiting times and the dismissed vehicles over 500 operating days.

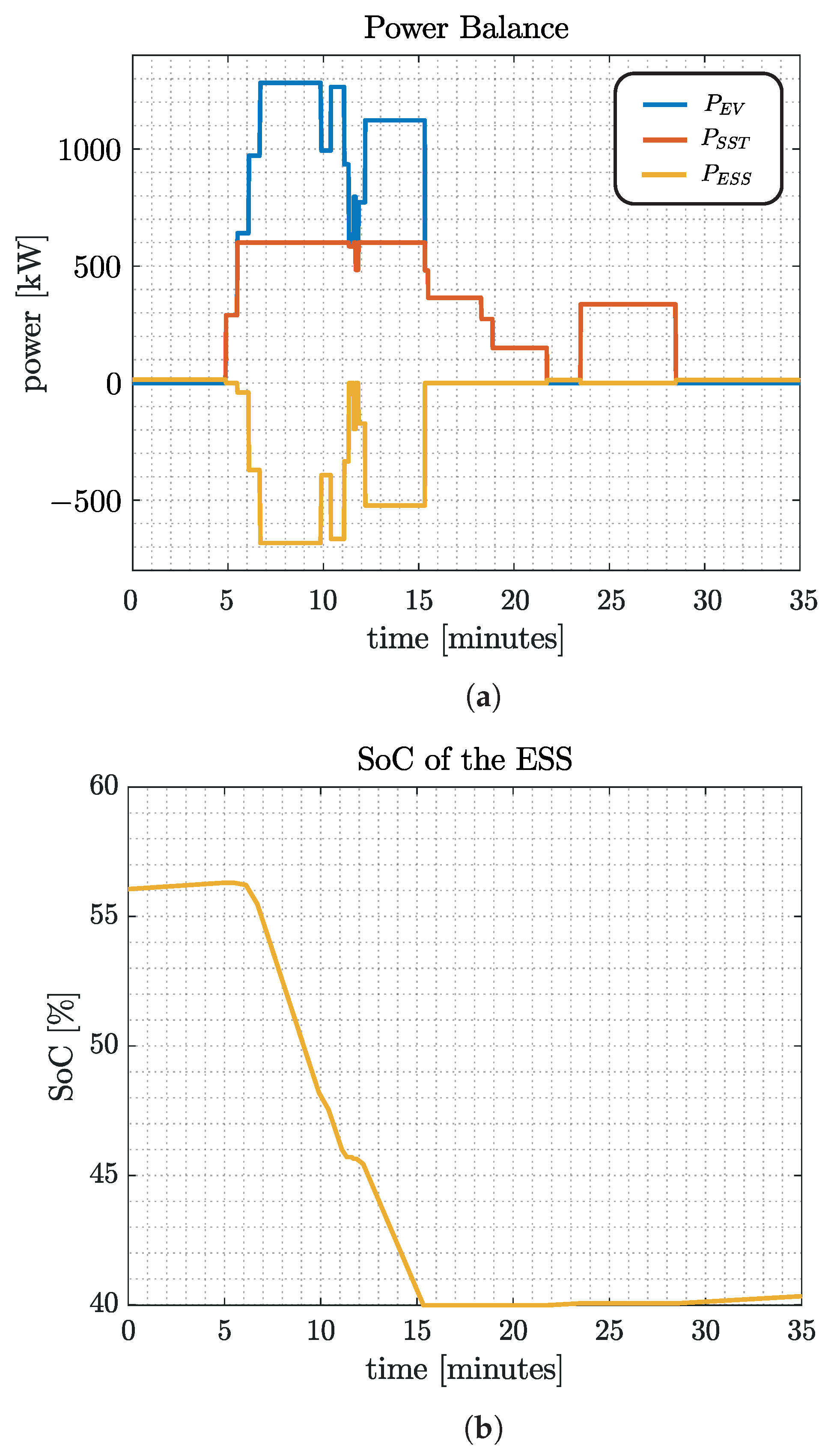

3.2. Event Simulation

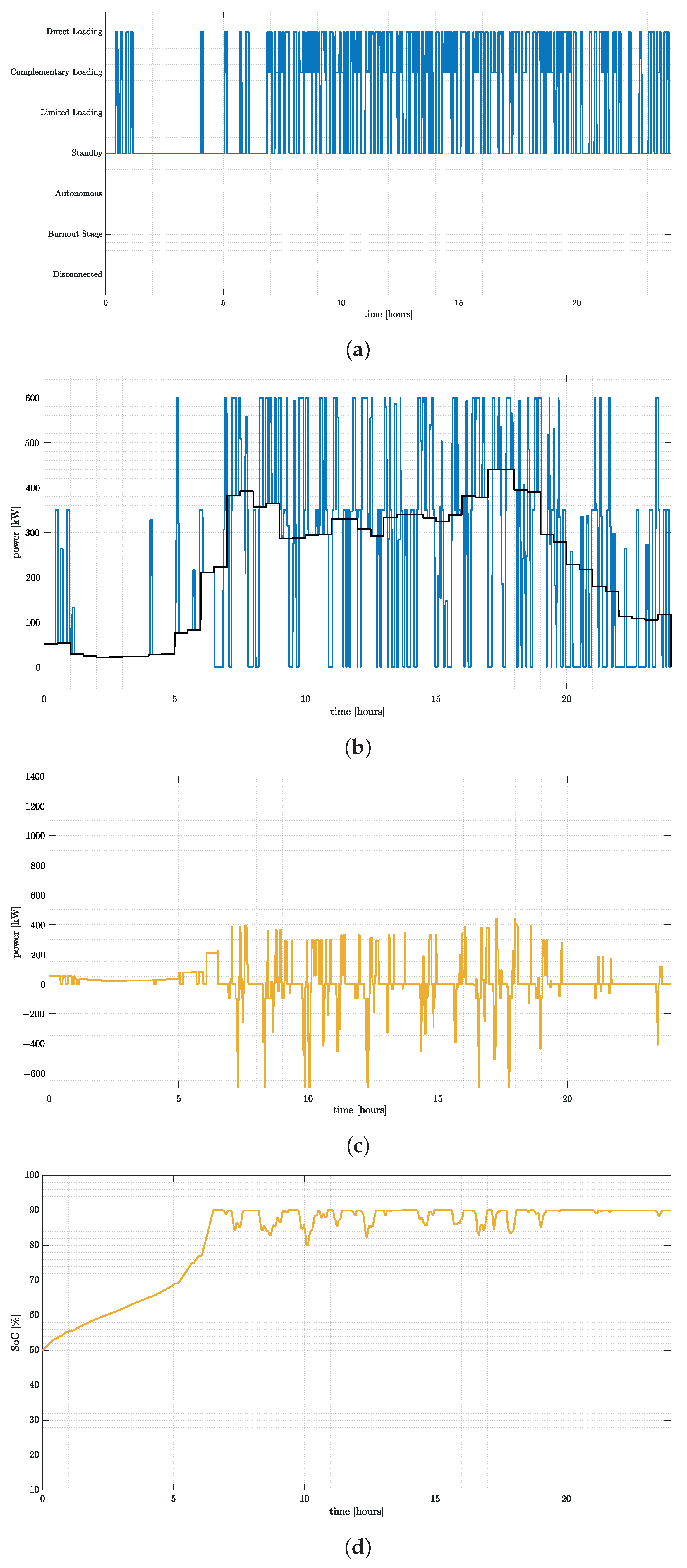

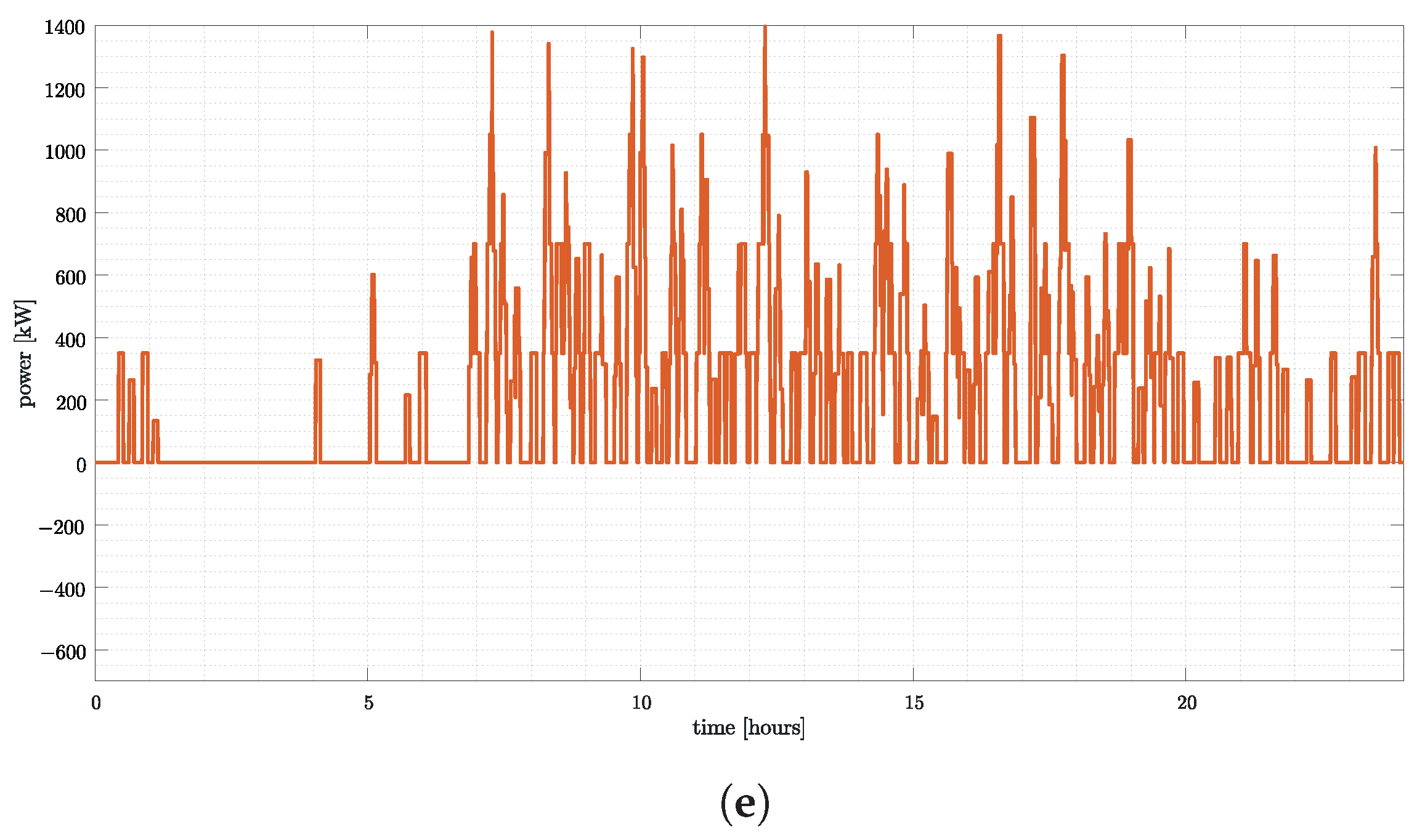

Figure 8 shows an operating day for 180 EVs under optimal operating conditions and reliable energy delivery. The energy management procedure corresponds to the load leveling case with a capacity assignment of 715 kWh for the ESS.

Figure 8a depicts the transition between the operating modes, where the direct charging, complementary charging, and standby are dominant. The average consumption of the SST profile shown in

Figure 8b follows the pattern established by the management policy, and is altered by the EVs’ arrival. It has to be pointed out that the UFCS never enters into limited charging mode since the SOC of the ESS (

Figure 8d) is above the expected values of its operating range.

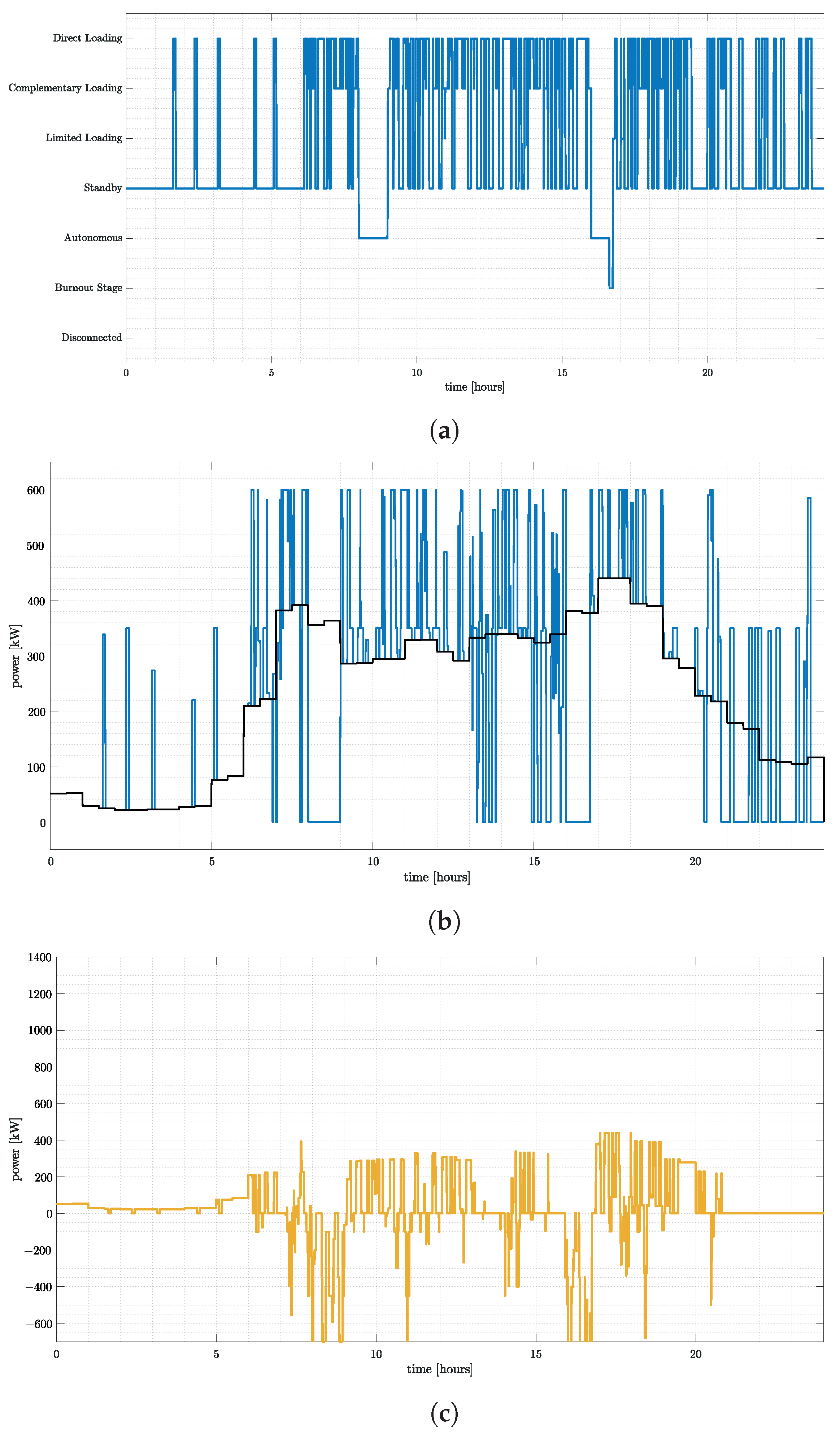

Figure 9 is a similar simulation to that of

Figure 8, but it includes two blackouts, which generates two fault alarms in the system, the first one of one hour duration occurring at 8 a.m. and the second one of 45 min at 4 p.m. These faults allow exploring the performance of the islanded modes and evaluating the ESS sizing.

During the SST disconnection at 8 a.m., only the autonomous mode was working. Nonetheless, during the SST disconnection at 4 p.m., after facing the peak of demand, the UFCS autonomous mode changed to burnout mode once the minimum value of the usable range was overtaken, i.e., .

The blackout ending and the availability of the SST lead the UFCS to the limited charging mode, waiting for the restoration of the ESS capacity, which takes place relatively fast. In spite of 1 h and 45 min working in islanded mode, the station could still offer the power demand without overloading the ESS and providing 100% of service.