Abstract

Highwall mining is a method that involves using a continuous highwall miner system (CHM) to extract coal from the remaining coal seams, which has proven to be an effective and safe method for extracting coal after open-pit mining. However, application cases globally have shown that the feasibility of highwall mining in open-pit coal mines is subject to geological conditions, mining techniques, and other factors. If application conditions are not suitable, equipment may be trapped under collapsed coal–rock masses and unable to be retrieved, resulting in severe safety issues for slope stability. To meet the real-world demand for extracting the remaining coal in open-pit coal mines in China, it is urgent to conduct a feasibility evaluation of highwall mining in these areas. This paper establishes a mathematical evaluation framework for assessing the feasibility of highwall mining by summarizing a large number of engineering application cases globally and analyzing various technical characteristics such as geological deposit conditions, mining techniques, and technical equipment. The analytic hierarchy process (AHP), fuzzy comprehensive evaluation (FCE) and variable weight theory (VWT) are utilized in conjunction to form this framework, which includes four secondary indicators: geological deposit factors, mining technique factors, safety impact factors, and economic evaluation factors, and 20 tertiary sub-indicators, along with their corresponding characteristic values. The feasibility sub-set is divided into four categories: infeasible, basically feasible, relatively feasible, and highly feasible, and the values of the sub-indicators strictly follow and represent these four levels of feasibility. Weight vectors for the sub-indicators are obtained through a judgment matrix established within the mathematical evaluation framework. The fuzzy relationship matrix of the sub-indicators is constructed using fuzzy mathematical membership functions, and the final feasibility evaluation is determined through two-level comprehensive evaluation. The accuracy of the model is verified using the characteristic parameters of open-pit coal mines under two different conditions (JZT coal mine in Inner Mongolia, China, and GC coal mine in Australia). The results demonstrate that the maximum evaluation membership degree for the JZT mine is 0.7113, belonging to the “highly feasible” level, while the GC mine is 0.3304, belonging to the “basically feasible” level, which aligns well with real-world usage, proving that the evaluation model can effectively reveal the performance and membership degree of each indicator in different application cases. By quantitatively characterizing the feasibility level of highwall mining technology under different application conditions, this evaluation model can provide scientific guidance for coal mining enterprises to introduce CHM for highwall mining operation in open-pit coal mines.

1. Introduction

Coal has been a long-term mainstay energy source in China, with the country currently having over 420 open-pit coal mines and a production output of about 950 million tons, making open-pit mining one of the significant coal extraction methods in China [1]. Due to limitations in mining technique and safety factors, a significant amount of coal cannot be effectively extracted after open-pit mining, resulting in the waste of coal resources as these coal seams become buried again under backfill [2,3]. Highwall mining operation employs CHM to conduct exploratory mining on residual coal seams at the highwall, ensuring slope safety and control over the overlying rock layer by pre-reserving supporting coal pillars between mining roadways. The entire system operates remotely outside the mine, without the need for personnel to enter the mining area, highlighting its features of high intelligence, simplified operation, high production efficiency, and low infrastructure investment. It has been fully promoted and applied in countries such as the United States, Australia, and India, proving to be a safe, efficient, economical, and environmentally friendly highwall coal extraction technology [4,5,6].

Statistics show that the maximum mining depth reached by overseas highwall mining technology is 500 m, with the highest monthly output reaching 124,000 tons. Coal mined using highwall mining machines in the United States accounts for about 4% of the country’s total annual coal production [7,8,9]. However, due to varying conditions in different mines, highwall mining technology has experienced several incidents of platform instability, landslides, and significant roof collapses in practical application [10,11,12]. Existing case studies indicate that the feasibility of highwall mining in open-pit mining areas is subject to geological condition, mining techniques, and other factors. If the conditions do not match, the application of highwall mining technology may lead to the equipment being buried under collapsed coal–rock masses, making it impossible to retrieve and posing significant risks to slope safety. At present, the recovery of highwall coal in open-pit coal mines in China using highwall mining technology is still in its initial stage, and the decision to use highwall mining technology often relies on empirical judgments based on engineering analogy. Given the significant number of open-pit coal mines in China and the pressing need to extract the remaining highwall coal, it is urgent to conduct feasibility studies on highwall mining technology for this purpose. Luo et al. [13] conducted research on the Hequ Open-Pit Coal Mine as a study subject. Based on the limit equilibrium method and finite element strength reduction method, they investigated the slope stability under various highwall mining schemes and calculated the potential economic benefits. Wang et al. [14] took a certain open-pit mine in Xinjiang as the research object, analyzing the slope stability coefficient under different highwall mining technologies. The aforementioned literature indicates that existing research mainly focuses on the safety and economic feasibility evaluation of highwall mining in specific open-pit mines, being unable to provide a general and comprehensive feasibility assessment of highwall mining technology and unable to offer scientific guidance for decision making in highwall coal recovery using highwall mining technology.

According to domestic and international engineering experience, by establishing the AHP-FCE model, the influencing factors of applying highwall mining technology are hierarchically and indexically analyzed, and its results are transformed into weight values to judge the space to which it belongs [15,16,17]. This method provides a new idea and solution for the feasibility evaluation of highwall mining technology. In recent years, evaluation methods using fuzzy mathematics have been applied in many areas of coal mine production. Duan et al. [18] selected nine evaluation indicators from economic, technological, and safety aspects to establish a hierarchical evaluation system, determining each index value. Using the AHP-TOPSIS method, they performed an optimal evaluation of the steep slope plan in the eastern part of Anjialing Open-Pit Mine, proposing the best plan for steep slope mining in the first mining area of Anjialing Mine. Ma et al. [19,20], based on geological structure, coal seam occurrence, roadway characteristics, and mining safety elements, established a multi-factor feasibility evaluation index system and quantified the range of each index value. And, using fuzzy mathematics, the analytic hierarchy process, and variable weight fuzzy theory, they achieved the adaptability evaluation of residual coal mining and bolter miners. Zhang et al. [21] proposed an evaluation index for the adaptability of intelligent mining working faces, consisting of four primary influencing factors and 16 secondary influencing factors including geological conditions, mining technical conditions, key technical conditions, and management and security conditions. Yu et al. [22] built an evaluation model for the adaptability of intelligent integrated mining through the analytic hierarchy process and evaluated the mining efficiency and safety aspects. In summary, mathematical fuzzy evaluations in the field of open-pit coal highwall mining feasibility are relatively rare.

Addressing the issue that existing research struggles to provide a general, applicable, and comprehensive evaluation system for the feasibility evaluation of highwall mining, and analogy judgments based on engineering experience often lead to decision-making errors and equipment incompatibility with mine conditions, the authors summarize a large number of engineering application cases globally, and by thoroughly analyzing the technical characteristics such as mine occurrence conditions and mining processes, a mathematical evaluation framework system for combining the AHP-FCE-VWT method is proposed. The system includes four secondary indicators: geological deposit factors, mining technique factors, safety impact factors, and economic evaluation factors. It also defines and determines 20 tertiary sub-indicators and the corresponding characteristic value conditions for these sub-indicators. Through the established mathematical evaluation framework, a judgment matrix is formulated to derive the weight vector of the sub-indicators. By utilizing the membership function of fuzzy mathematics, this relationship matrix of the sub-indicators is constructed. After two levels of comprehensive judgment, the final feasibility evaluation result is determined. The authors import the constructed mathematical evaluation model for the feasibility of highwall mining with two engineering cases to verify the accuracy of the model. The results show that the comprehensive evaluation model constructed in this paper presents good membership for different commentary subsets, and the evaluation results have a good fit with the actual field practice effects, which offers a preliminary quantitative analysis method for making decisions on whether open-pit coal mines should adopt highwall mining equipment for highwall coal recovery.

2. Preliminaries

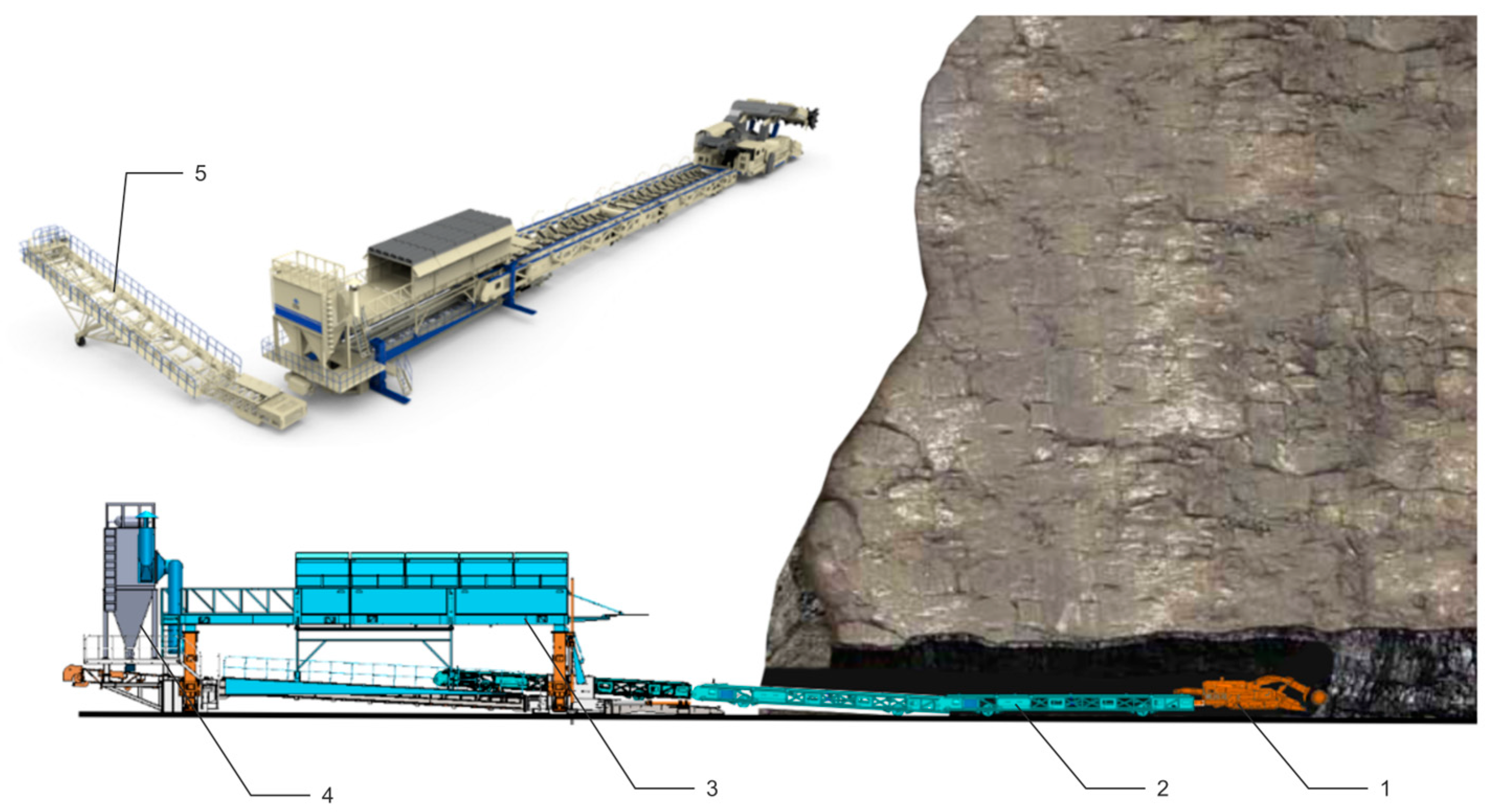

2.1. Technical Characteristics of Highwall Mining

The continuous highwall miner system (CHM) designed by Shanxi Tiandi Coal Machinery Co., Ltd. mainly includes a continuous highwall miner, multi-unit continuous conveyor belt system, stepping walking platform, pull-out ventilation and dust removal system, mobile unloading section, remote control system, and navigation and posture monitoring systems, as shown in Figure 1. During highwall mining operations, it is necessary to support the overlying rock layers by reserving coal pillars between the mining roadways, ensuring the stability of the slope [23]. Daily operators of highwall mining do not need to enter the mining roadways. All operations are carried out in the central control room outside the roadway, with personnel relying on the video acquisition devices placed at the front of the continuous highwall miner for coal cutting operations, forming a group of mining roadways perpendicular to the direction of the slope. The continuous highwall miner uses an inertial navigation system, cutting forward 12.5 m each time and connecting one section of the multi-unit continuous conveyor belt system until reaching the maximum mining depth of the roadway. After mining is finished, the walking platform drags the highwall miner and conveyor belt system out and successively separates the multi-unit continuous conveyor belt, waiting for all equipment to be dragged out of the mining roadway and moved to the next mining roadway by the stepping walking platform, for the next cycle of mining operations.

Figure 1.

Continuous highwall miner system (CHM) in open-pit coal mine. 1. continuous highwall miner; 2. multi-unit continuous conveyor belt system; 3. stepping walking platform; 4. pull-out ventilation and dust removal system; 5. mobile unloading section.

2.2. Evaluation Method Selection

The analytic hierarchy process (AHP) is a system analysis and decision-making method combining both qualitative and quantitative aspects. It applies the systems in consideration of decomposition followed by integration, breaking down complex problems into various levels and the corresponding influencing factors, forming an ordered recursive hierarchical structure [24]. Through pairwise comparison between factors, the relative weights of each factor to the upper level factors are determined, forming a judgment matrix with corresponding quantitative scale values. The final importance ranking of the lowest-level evaluation factors to the overall objective can be obtained through the synthesis within the hierarchical structure using quantitative data.

Fuzzy comprehensive evaluation (FCE) is an overall evaluation method for processes affected by multiple evaluation factors, characterized by the fuzziness of the evaluation factors, which are difficult to express with simple quantitative values.

The feasibility of highwall mining in open-pit coal mine is influenced by many factors, making it difficult to evaluate simply with quantitative values. As can be seen from the above analysis, AHP is not suitable for solving problems with many lowest-level factors. When there are too many influencing factors, AHP is cumbersome and consistency checking is difficult, while FCE does not provide a calculation method for the importance weight of evaluation factors [25]. Combining AHP with FCE can fully utilize the advantages of each. That is, by building a multi-level model through AHP and constructing a fuzzy judgment matrix from evaluation levels and influencing factors, and then using FCE to calculate the membership of each factor to different levels, the final membership under different schemes can be obtained. Compared with other single evaluation methods, this method has the characteristic of being less affected by the index system, coefficient values, and evaluation methods, and the evaluation result is more accurate.

Therefore, for the actual situation of the comprehensive evaluation of the feasibility of highwall mining in this paper, the authors propose the combination of AHP and FCE to construct a comprehensive evaluation model for the feasibility of highwall mining in open-pit coal mine, and the determination of the review subset to which it belongs through the maximum membership degree, thus achieving the feasibility evaluation.

3. Feasibility Evaluation Model of Highwall Mining

3.1. Construction of Feasibility Evaluation Model

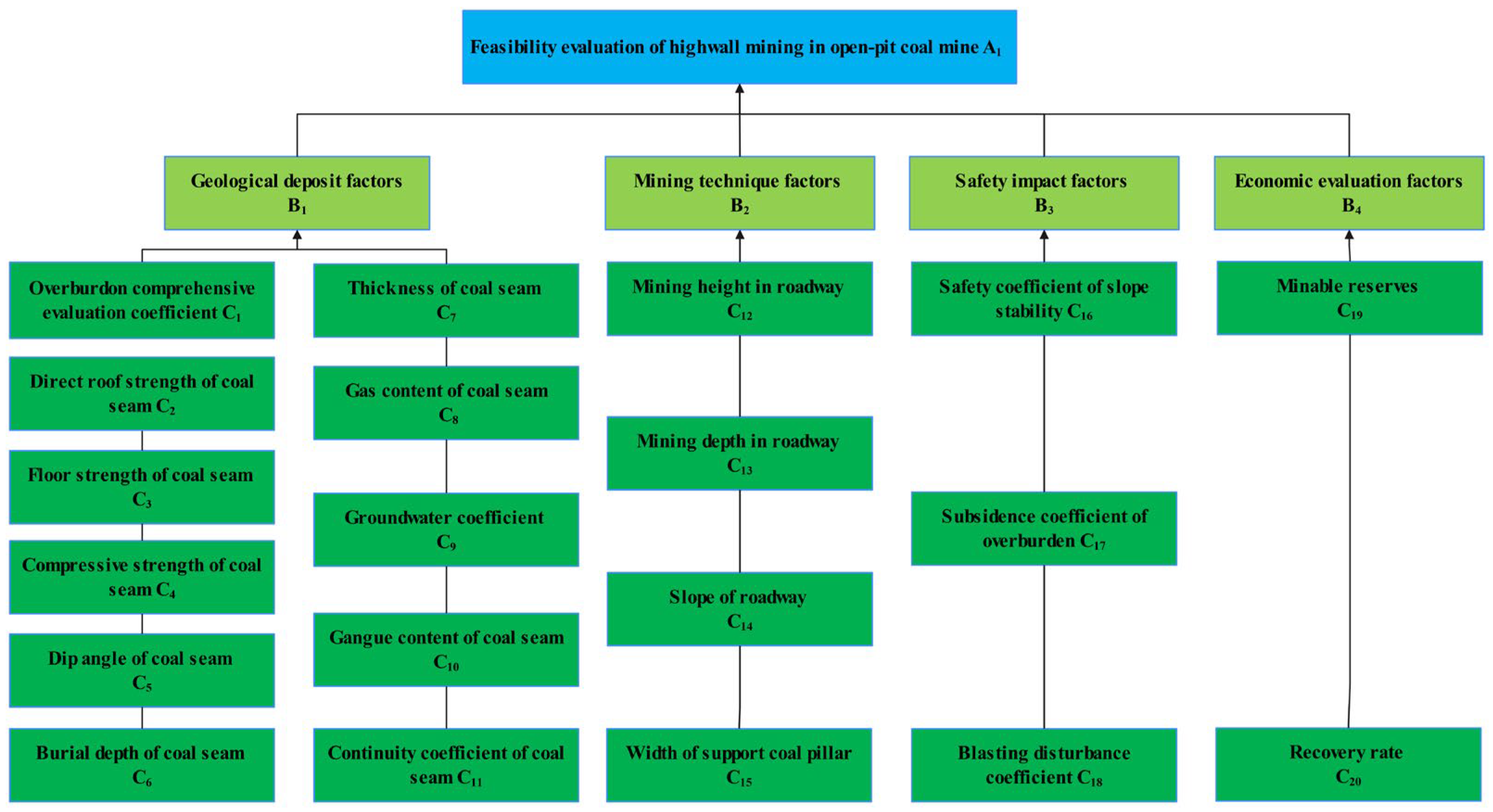

3.1.1. Construction of Evaluation Index System Based on AHP

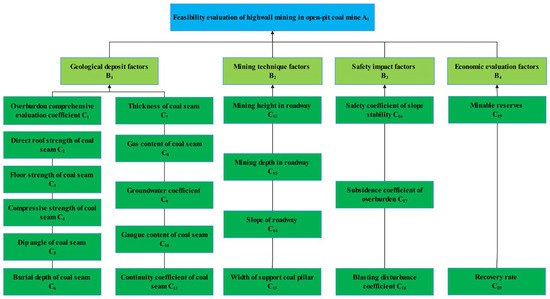

Through field research and a literature review, the authors studied a large number of domestic and international highwall mining application cases. Based on the AHP method, a comprehensive evaluation index system for the feasibility of highwall mining was established. The comprehensive evaluation system is divided into three levels: Level A (objective layer), Level B (index layer), and Level C (sub-index layer). Level A is the feasibility evaluation purpose of highwall mining in an open-pit coal mine. Level B indicators mainly include four aspects: geological deposit factors (B1), mining technique factors (B2), safety impact factors (B3), and economic evaluation factors (B4). Each type of sub-index in Level C is the specification of the corresponding B-level indicators, totaling 20 items. The index system for the feasibility evaluation of highwall mining in open-pit coal is shown in Figure 2.

Figure 2.

Feasibility evaluation index system for highwall mining in open-pit coal mine.

3.1.2. Quantification of Evaluation Indicators

The evaluation index system mainly serves to evaluate whether the highwall mining in open-pit coal is feasible. As the evaluation results are fuzzy, according to the evaluation level requirements, the conditional feasibility evaluation of the model is divided into four levels, with the comment set V = {infeasible, basically feasible, relatively feasible, and highly feasible}.

As can be seen from Figure 2, the feasibility evaluation index system for highwall mining is divided into three levels: A, B, and C. Level B includes four influencing factors, specifically geological deposit factors (B1), mining technique factors (B2), safety impact factors (B3), and economic evaluation factors (B4). Among them, the geological deposit factors (B1) include a total of 11 evaluation elements: C1−C11. The mining technique factors (B2) include a total of four evaluation elements: C12−C15. The safety impact factors (B3) mainly include three evaluation elements: C16−C18. And the economic evaluation factors (B4) mainly include two evaluation elements: C19−C20. The quantified values of C-layer indicators in different comment sets are shown in Table 1 below.

Table 1.

Quantitative values of C-layer indicators in different comment sets.

- (1)

- Geological deposit factors

The evaluation indicators for geological deposit factors (B1) are overlying rock comprehensive evaluation coefficient (C1), direct roof strength of coal seam (C2), floor strength of coal seam (C3), compressive strength of coal seam (C4), dip angle of coal seam (C5), burial depth of coal seam (C6), thickness of coal seam (C7), gas content of coal seam (C8), groundwater coefficient (C9), gangue content of coal seam (C10), and continuity coefficient of coal seam (C11).

The overlying rock comprehensive evaluation coefficient (C1) reflects the soft and hard degree of the top plate coal wall in the highwall mining field. The formula for calculating the overlying rock comprehensive evaluation coefficient is as follows [26]:

where represents the thickness of the stratified overburden and is the lithological evaluation coefficient of the stratified overburden, with data primarily obtained by calculating the columnar diagram of the mining area’s bottom layer.

- (2)

- Mining technique factors

The evaluation indicators for mining technique factors (B2) are mining height in roadway (C12), mining depth in roadway (C13), slope of roadway (C14), and width of support coal pillar (C15). Since the EML340 continuous highwall miner developed by Shanxi Tiandi Coal Machinery Co., Ltd. (Shanxi, China) has a cutting drum width of 3.3 m, the mining width element is not considered this time. Numerous studies have shown that mining depth, the width of the support coal pillar, and other mining technological elements have a significant impact on the stability of the highwall mining slope [27,28,29].

- (3)

- Safety impact factors

The evaluation indicators for safety impact factors (B3) are safety coefficient of slope stability (C16), subsidence coefficient of overburden (C17), and blasting disturbance coefficient (C18). Based on the actual working conditions of highwall mining, the recommended safety coefficient of slope stability (C16) is ≥1.20 [30]. The subsidence coefficient of overburden (C17) refers to the ratio of rock layer subsidence caused by overburden pressure to overburden thickness. Considering the surface geological features, the higher the allowable subsidence coefficient of overburden, the higher the feasibility of highwall mining. As the blasting shock wave acts on the support coal pillar in the open-pit mining area, the instantaneous dynamic stress response generated will weaken the strength of the support coal pillar, thereby endangering the safety of the slope, hence the use of the blasting disturbance coefficient (C18) to describe the disturbance of the blasting seismic waves to highwall mining [31].

- (4)

- Economic evaluation factors

The evaluation indicators for economic evaluation factors (B4) are minable reserves (C19) and recovery rate (C20). When the coal seam reserves are low, choosing highwall mining technology does not make economic sense. Generally, highwall mining processes need to reserve support coal pillars and permanent isolation coal pillars to ensure slope safety. The larger the recovery rate, the better the economic benefits. The formula for calculating the recovery rate is as follows [32]:

where represents the highwall recovery rate, represents the mining width, represents the width of the support coal pillar, represents the width of the permanent isolation coal pillar, represents the number of support coal pillars, and represents the loss of coal seam thickness due to mining with the highwall miner.

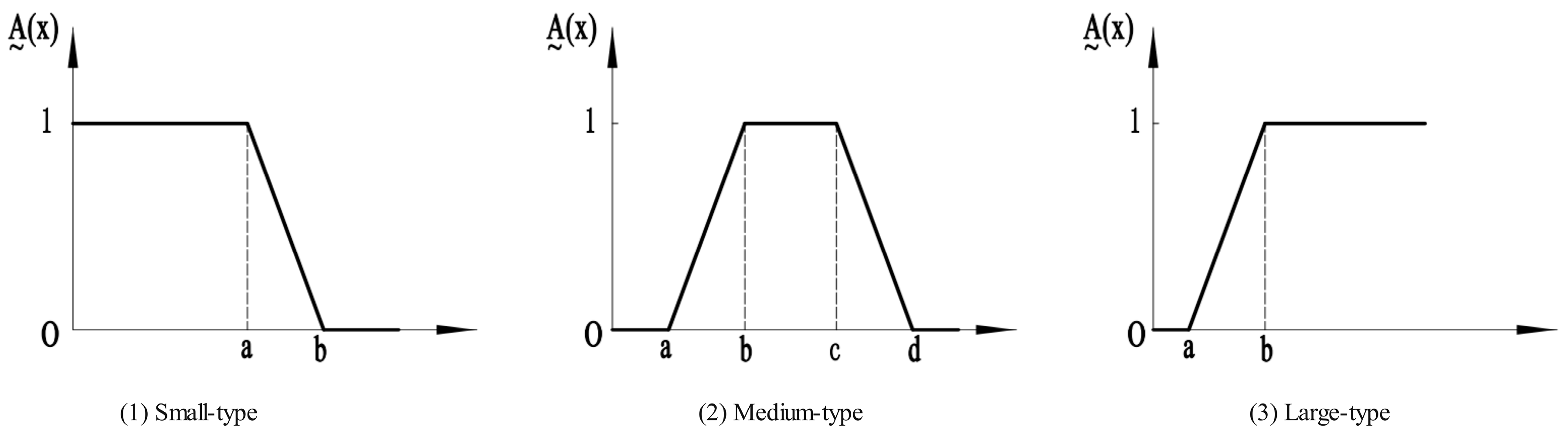

3.1.3. Determination of Membership Function

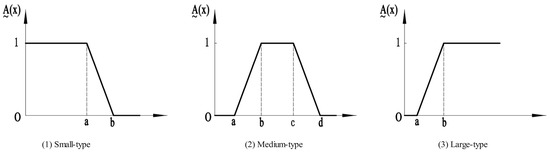

In fuzzy mathematics, the membership function describes the fuzzy distribution of the target evaluation factors in a fuzzy set. In specific applications, it is often necessary to process the original values of various indicators using the membership function and calculate the degree of membership, that is, unify the values of different dimensions to the membership degree in the [0, 1] interval. Therefore, the sum of the degrees of membership of each indicator in various comment sets is 1. The commonly used fuzzy distributions include the small-type fuzzy distribution, large-type fuzzy distribution, and medium-type fuzzy distribution, each suitable for describing fuzzy sets leaning toward small, large, and medium values, respectively. The membership functions in the fuzzy function are divided into two major types based on curve type: linear and non-linear. The former includes rectangles, triangles, trapezoids, etc., and the latter includes k-order parabolas, T-distributions, normal distributions, Cauchy distributions, etc. [33]. This article uses the relatively simple-to-calculate trapezoidal distribution, the expression of its membership function is as follows, and the function image is shown in Figure 3.

Figure 3.

Membership function of trapezoidal distribution.

- (1)

- Small-type:

- (2)

- Medium-type:

- (3)

- Large-type:

Based on the quantitative intervals of the C-level indicators in different evaluation levels in Table 1 and combined with the application cases of highwall mining engineering practices globally, the membership functions of each indicator are constructed. Due to space limitations, only the membership function of B1 is listed, as shown in Table 2. Since a trapezoidal membership function is used, a situation where the indicator value is 0 might occur, leading to an inability to calculate. To avoid the aforementioned situation, a common method is to take a smaller value as a substitute and accordingly subtract this value from other non-zero memberships, ensuring that the sum of the membership degrees of all indicators is 1. For convenience, this value is taken as 0.0001 [34,35].

Table 2.

Membership functions of each sub-indicator of geological occurrence elements.

3.2. Determination of Weight Vector for Indicator Layer

3.2.1. Construction of the Judgment Matrix

Using the AHP method, the authors constructed the judgment matrix based on the indicator system built in Figure 2. Taking the B1 layer as an example, the specific method is to arrange the 11 C-level indicators belonging to the B1 layer in sequence in the first row and the first column to construct the initial square matrix. Each value in the matrix is assigned by the scale of importance, that is, two factors are compared pairwise to determine their relative importance and represented by suitable scale values, typically using 1–9 and its reciprocals as scale values. The authors, based on a large number of domestic and international side-slope mining application cases, constructed the judgment matrices as follows:

3.2.2. Consistency Test of the Judgment Matrix

A chaotic judgment matrix may lead to decision-making errors, necessitating a consistency test of the judgment matrix to ensure the reliability of subsequent ranking and decision making. The purpose of the consistency test is to prevent logical errors such as “A is extremely more important than B, B is extremely more important than C, and C is extremely more important than A”. If the matrix fails the consistency test, it should be readjusted until it meets the conditions [36]. The steps for the consistency test are as follows:

- (1)

- Calculation of consistency index :

Table 3.

The calculation results of the consistency index.

- (2)

- Calculation of Consistency Ratio

When the value of is less than 0.1, it is considered that the judgment matrix has passed the consistency check. Otherwise, the judgment matrix needs to be adjusted until the conditions are met.

where is the average random consistency index, which is related to the order of the judgment matrix. The values of and the calculation results of the are shown in Table 4.

Table 4.

Values of RI and calculation results of CR.

As shown in Table 4, all the values of the judgment matrices are less than 0.1, all passing the consistency check, proving that the constructed judgment matrices are reasonable and reliable, with satisfactory consistency.

3.2.3. Single-Level Weight Vector

Based on the judgment matrix, we can calculate the importance ranking of the lower-level factors to the upper-level factors. This article uses the eigenvalue method [37], that is, calculating the eigenvalues and eigenvectors of the judgment matrix. The eigenvector corresponding to the largest eigenvalue is normalized as the weight vector.

Using Matlab R2022b software, the initial weight vectors of the index layer elements relative to the target layer indices can be calculated as

To avoid the unreasonable impact caused by the internal discrepancies among various indicators in the constant weight model, variable weight theory (VWT) [38,39] is introduced to integrate the status values of each indicator. The core idea is that the weight of the indicators can change with the change in the variable weight values. Considering the possibility of an excessive membership degree for some factors belonging to the lowest language level in the feasibility evaluation in the fuzzy matrix obtained according to the membership function, it is believed that their factor status needs adjustment. This paper adopts the method of performing the Hadamard product and normalization on the initial weight vector and the status vector for adjustment. In this paper, the maximum membership degree is stipulated to be no more than 0.4. The calculation formula for the state impact vector is as follows [40]:

where is the adjustment level and is state impact vector.

The formula for the variable weight objective weight vector is as follows:

where represents the initial weight vector.

3.3. Comprehensive Evaluation and Decision Making

The hierarchical sorting results are synthesized to obtain the weight vector of the sub-index layer to the overall goal. The basic steps are to calculate the sorting weights of the lower-level elements to the overall goal from the bottom up, layer by layer. Finally, we can recursively calculate the weight vector of the lowest level elements to the overall goal and use this as the basis for decision making.

The comprehensive evaluation result is , and the calculation process is as follows:

where represents the comprehensive objective weight vector and is the fuzzy relation matrix.

4. Feasibility Evaluation Validation of Engineering Cases

In Inner Mongolia, China, the JZT coal mine adopted the CHM from the Shanxi Tiandi Coal Machinery Co., Ltd. for an engineering practice in highwall coal recovery. The GC coal mine in Australia utilized the CHM from SHM for highwall mining operations [41]. Based on the actual conditions of the two mining areas, the quantified values for each indicator in layer C were determined, with indicator values as shown in Table 1. According to the mathematical model for evaluating the feasibility of highwall mining established in this paper, a comprehensive feasibility evaluation was conducted separately for the two mining areas.

4.1. Feasibility Evaluation of JZT Open-Pit Mine in Inner Mongolia, China

- I.

- Level I comprehensive fuzzy evaluation

- i.

- Comprehensive fuzzy evaluation vector of geological deposit factor B1

- (1)

- Constant weight comprehensive coefficient.

- (2)

- Construct a fuzzy relation matrix according to the membership function.

- (3)

- According to the fuzzy relation matrix, it is found that the lowest evaluation level of C5 is higher than 0.4. Therefore, calculate its status impact vector according to Formula (8).

- (4)

- Calculate its variable weight vector according to Formula (9).

- (5)

- Determine the final comprehensive fuzzy evaluation vector according to Formula (10).

- ii.

- Comprehensive fuzzy evaluation vector of mining technique factor B2

- (1)

- Determine the initial weight vector of the comprehensive evaluation index system.

- (2)

- Construct a fuzzy relation matrix according to the membership function.

- (3)

- According to the fuzzy relation matrix, there is no lowest level membership degree greater than 0.4. Determine the status impact vector according to Formula (8).

- (4)

- Obtain the comprehensive fuzzy evaluation vector according to Formula (9).

- (5)

- Determine the final comprehensive fuzzy evaluation vector according to Formula (10).

- iii.

- Comprehensive fuzzy evaluation vector of safety impact factor B3

Repeat calculation steps 1–5 to obtain the comprehensive fuzzy evaluation vector of safety factor B3.

- iv.

- Comprehensive fuzzy evaluation vector of economic evaluation factors B4

Repeat calculation steps 1–5 to obtain the comprehensive fuzzy evaluation vector of economic evaluation factor B4.

- II.

- Level II comprehensive fuzzy evaluation

- (1)

- Determine the constant weight vector of the comprehensive evaluation index system.

- (2)

- Construct a fuzzy relation matrix according to the comprehensive judgment results of Level I.

- (3)

- According to the fuzzy relation matrix, there is no lowest level membership degree greater than 0.4. Determine the status impact vector according to Formula (8).

- (4)

- Obtain the comprehensive fuzzy evaluation vector according to Formula (9).

- (5)

- Determine the final comprehensive fuzzy evaluation vector according to Formula (10).

It is known from the above that, according to the principle of evaluation membership degree, the maximum evaluation membership degree value for JZT mine is 0.7113, belonging to the “highly feasible” level.

In practical use, the Inner Mongolia JZT coal mine uses the EML340 CHM for mining the 9# coal seam, as shown in Figure 4. The coal seam roof is medium-fine grained sandstone with an average compressive strength of about 40 Mpa. The false roof is mudstone, belonging to a weak-to-semi-hard rock layer, and the slope is stable. In the engineering project, the equipment has been in operation for 6 months without any significant coal–rock collapses affecting the machinery. The overall performance of the equipment has been satisfactory, with over 300,000 tons of material excavated, resulting in significant economic and societal benefits.

Figure 4.

Engineering case of highwall mining in JZT Mine, Inner Mongolia, China.

4.2. Comprehensive Evaluation of GC Open-Pit Mine in Australia

The calculation of the fuzzy comprehensive evaluation of the Australian GC mine is the same as the comprehensive evaluation process of the JZT coal mine. The comprehensive fuzzy evaluation vector of the Australian GC mine can be calculated as follows.

This implies that the maximum evaluation membership degree value for the Australian GC mine is 0.3304, belonging to the “basically feasible” level.

The coal seam thickness of the Australian GC coal mine is between 2 and 3 m, and the uniaxial compressive strength (UCS) of the coal seam is about 3.3 MPa. The roof is a weak mudstone to medium-strength silty sandstone layer. During the mining process, roof collapses occurred frequently, mainly manifested as delamination and plate-like block detachment from cross-joints. According to statistics, due to frequent roof collapse accidents, about 66% of the time is spent on equipment withdrawal and re-entry operations, and the real-world application results are unsatisfactory.

In summary, through comparative analysis of the actual use of highwall mining in the open-pit coal mine under the two different conditions mentioned above, it is demonstrated that the feasibility evaluation model of highwall mining in the open-pit coal mine built in this article is in good agreement with the actual application conditions, which proves the evaluation model can effectively reveal the performance and membership degree of each indicator under different commentary sets in application cases with significant differences in mine conditions.

5. Conclusions

The application of highwall mining technology in open-pit mining areas requires certain requirements such as geological conditions and mining processes. If the requirements are not met, it may result in the equipment becoming inoperable and potentially cause slope instability issues. Regarding the current reliance on manual categorization based on experience to determine the feasibility of highwall mining, this paper introduces a novel feasibility assessment method. This method aims to offer a general applicable and comprehensive approach to evaluating the feasibility of highwall mining, assisting coal mine engineers in more conveniently quantifying the feasibility assessment. The major conclusions include:

- (1)

- This paper proposes a mathematical evaluation framework for combining the AHP-FCE-VWT method to realize the feasibility evaluation for highwall mining in an open-pit coal mine by thoroughly analyzing the technical characteristics, such as mine occurrence conditions and mining processes. Based on a large number of field practice cases globally of highwall mining operation, four major indicators are established, namely geological deposit factors, mining technique factors, safety impact factors, and economic evaluation factors. In association with these, 20 sub-indicators and the corresponding characteristic value conditions for these sub-indicators are constructed.

- (2)

- The feasibility evaluation comment set can be categorized into four types, namely: infeasible, basically feasible, relatively feasible, and highly feasible. The values of the sub-indicators strictly follow and combine these four levels of feasibility characterization. A judgment matrix is established through a mathematical evaluation framework to derive the weight vector of the sub-indicators. Additionally, a fuzzy relationship matrix of the sub-indicators is constructed using fuzzy mathematical membership functions. Through a two-level comprehensive judgment and based on the principle of maximum membership, the final feasibility membership degree can be calculated.

- (3)

- This study validates the rationality of the feasibility evaluation model through two real engineering cases of highwall mining in open-pit coal mines. Based on the actual working conditions of two mines (JZT coal mine in Inner Mongolia, China, and GC mine in Australia), their 20 sub-indicators are quantified and input into the feasibility evaluation model for calculation. The calculated results show that the maximum membership degree of the JZT coal mine is 0.7113, which is categorized as “highly feasible”, while the feasibility membership degree of the GC coal mine is 0.3304, which falls under “basically feasible”. An analysis of engineering practices confirms that the results are consistent with real-world application scenarios.

The research results show that feasibility evaluation framework established in this paper can effectively reveal the performance and membership degree of each indicator under different evaluation sets in the case of significant differences in the two mine conditions, aligning well with the actual on-site usage effects. Moreover, the established comprehensive mathematical framework provides a systematic and objective basis for evaluating the feasibility and effectiveness of highwall mining technology in open-pit coal mines. The evaluation model quantitatively characterizes the feasibility level of highwall mining technology under various technical conditions of open-pit coal mines. This enhances the accuracy of the feasibility evaluation decision-making process, offers scientific guidance for coal mines considering the adoption of highwall mining technology, and assists enterprises in further improving mining efficiency and safety.

Due to constraints in time and resources, certain mining techniques, such as backfill mining and layered extraction of thick coal seams, have not been fully incorporated into the feasibility assessment criteria. Future research will aim to enrich the corresponding index system, further enhancing the comprehensiveness and accuracy of the feasibility evaluation for highwall mining.

Author Contributions

Conceptualization, D.S. and B.W.; formal analysis, D.S., J.P., A.W. and Y.N.; writing—original draft preparation, D.S.; visualization, D.S. and Z.G.; project administration, B.W. and Z.G.; funding acquisition, D.S., B.W., J.P., A.W. and Y.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China National Key R&D Program (Grant No. 2020YFB1314000), Research Project Supported by Shanxi Scholarship Council of China (Grant No. 2022-186), National Natural Science Foundation of China (62006148), National Undergraduate Innovation and Entrepreneurship Training Program (20230014), and the 21st Undergraduate Innovation and Entrepreneurship Training Program of Shanxi University (202210108012), Shanxi Province Key R&D Program (Grant No. 202202100401012).

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

This study was completed at the National Engineering Laboratory for Coal Mining & Excavation Machinery Equipment, and the authors would like to thank the laboratory for its assistance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yang, T.; Wang, H.; Dong, X.; Liu, F.; Zhang, P.; Deng, W. Current situation, problems and countermeasures of intelligent evaluation of slope stability in open pit. J. China Coal Soc. 2020, 45, 2277–2295. [Google Scholar]

- Wang, R.; Yan, S.; Bai, J.; Chang, Z.; Zhao, T. Theoretical analysis of damaged width & instability mechanism of rib pillar in open-pit highwall mining. Adv. Civ. Eng. 2019, 2019, 1–15. [Google Scholar]

- Chen, Y.; Shimada, H.; Sasaoka, T.; Hamanaka, A.; Matsui, K. Research on exploiting residual coal around final end-walls by highwall mining system in China. Int. J. Min. Reclam. Environ. 2013, 27, 166–179. [Google Scholar] [CrossRef]

- Shen, B.; Duncan, F. Review of highwall mining experience in Australia and a case study. Aust. Geomech. 2001, 36, 25–32. [Google Scholar]

- Shimada, H.; Chen, Y.; Hamanaka, A.; Sasaoka, T.; Shimada, H.; Matsui, K. Application of highwall mining system to recover residual coal in End-walls. Procedia Earth Planet. Sci. 2013, 2013, 311–318. [Google Scholar] [CrossRef][Green Version]

- Liu, W.; Wang, L.; Fu, Q. SHM highwall mining technology and key issues of application. Coal Eng. 2012, 2012, 1–4. [Google Scholar]

- Boeut, S.; Laowattanabandit, P.; Fujji, Y. Extracting residual coal by auger highwall mining at Mae Tan Coal Mine, Thailand. In Proceedings of the Spring Meeting of MMIJ Hokkaido Branch, Hokkaido University, Sapporo, Japan, 16 June 2017; pp. 59–60. [Google Scholar]

- Zipf, R.; Bhatt, S. Analysis of practical ground control issues in highwall mining. In Proceedings of the 23rd International Conference on Ground Control in Mining, Morgantown, WV, USA, 1 July 2004; pp. 210–219. [Google Scholar]

- Tian, Y.; Tu, L.; Lu, X.; Zhou, W.; Jiskani, I.M.; Liu, F.; Cai, Q. Stability analysis of multi-layer highwall mining: A sustainable approach for thick-seam open-pit mines. Sustainability 2023, 15, 3603. [Google Scholar] [CrossRef]

- Elmouttie, M.; Karekal, S. A framework for geotechnical hazard analysis in highwall mining entries. Procedia Eng. 2017, 2017, 1203–1210. [Google Scholar] [CrossRef]

- Sasaoka, T.; Karian, T.; Hamanaka, A.; Shimada, H.; Matsui, K. Application of highwall mining system in weak geological condition. Int. J. Coal Sci. Technol. 2016, 3, 311–321. [Google Scholar] [CrossRef]

- Prakash, A.; Kumar, A.; Singh, B. Highwall mining: A critical appraisal. Minetech 2015, 36, 17–30. [Google Scholar]

- Luo, K.; Ma, L.; Liu, C.; Lv, G.; Shi, L.; Xu, T.; Xue, F. Feasibility analysis of end slope and steep mining technology in Hequ Open-pit Mine. Coal Eng. 2022, 54, 19–25. [Google Scholar]

- Wang, S.; Liu, F.; Hu, G. Study on end slope shearer mining feasibility in Xinjiang Open-pit Mine. Opencast Min. Technol. 2022, 37, 22–26. [Google Scholar]

- Li, J.; Deng, C.C.C.; Xu, J.; Ma, Z.; Shuai, P.; Zhang, L. Safety risk assessment and management of Panzhihua Open Pit (OP)-Underground (UG) Iron Mine based on AHP-FCE, Sichuan Province, China. Sustainability 2023, 15, 4497. [Google Scholar] [CrossRef]

- Dong, G.; Wei, W.; Xia, X.; Woźniak, M.; Damaševičius, R. Safety risk assessment of a Pb-Zn mine based on fuzzy-grey correlation analysis. Electronics 2020, 9, 130. [Google Scholar] [CrossRef]

- Xiao, L.; Li, F.; Niu, C.; Dai, G.; Qiao, Q.; Lin, C. Evaluation of water inrush hazard in coal seam roof based on the AHP-CRITIC composite weighted method. Energies 2023, 16, 114. [Google Scholar] [CrossRef]

- Duan, L.; Guo, S.; Han, L.; Wei, H. Research on optimal selection of steep slope mining based on AHP-TOPSIS method. Coal Technol. 2022, 41, 18–22. [Google Scholar]

- Ma, J.; Song, D. Mathematical evaluation on the applicability of bolter miners based on variable weight fuzzy theory. J. China Coal Soc. 2023, 48, 2579–2589. [Google Scholar]

- Ma, J. Study on feasibility evaluation of continuous mining of residual coal based on variable weight fuzzy theory. Coal Sci. Technol. 2021, 49, 30–37. [Google Scholar]

- Xiu, Z.; Nie, W.; Cai, P.; Chen, D.; Zhang, X. Study on intelligent adaptability evaluation of intelligent coal mining working face based on ANP and matter-element extension model. J. Min. Strat. Control Eng. 2022, 5, 023037. [Google Scholar]

- Yu, J.; Zhu, L.; Xu, G. Safety and high efficiency adaptability evaluation of coal mine intelligent fully-mechanized mining face. Coal Sci. Technol. 2019, 47, 60–65. [Google Scholar]

- Ding, X.; Li, F.; Fu, T. Overburden movement and failure law of coalface in end slope and the slope stability control method. J. China Coal Soc. 2021, 46, 2883–2894. [Google Scholar]

- Nezarat, H.; Sereshki, F.; Ataei, M. Ranking of geological risks in mechanized tunneling by using Fuzzy Analytical Hierarchy Process (FAHP). Tunn. Undergr. Space Technol. 2015, 50, 358–364. [Google Scholar] [CrossRef]

- Fayaz, M.; Ullah, I.; Park, D.H.; Kim, K.; Kim, D. An integrated risk index model based on hierarchical fuzzy logic for underground risk assessment. Appl. Sci. 2017, 7, 1037. [Google Scholar] [CrossRef]

- Peng, S.S. Advances in Coal Mine Ground Control; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Ross, C.; Conover, D.; Baine, J. Highwall mining of thick, steeply dipping coal a case study in geotechnical design and recovery optimization. Int. J. Min. Sci. Technol. 2019, 29, 777–780. [Google Scholar] [CrossRef]

- Porathur, J.; Karekal, S.; Palroy, P. Web pillar design approach for highwall mining extraction. Int. J. Rock Mech. Min. Sci. 2013, 64, 73–83. [Google Scholar] [CrossRef]

- Perry, K.; Raffaldi, M.; Harris, K. Influence of highwall mining progression on web and barrier pillar stability. Min. Eng. 2015, 67, 59–67. [Google Scholar]

- Zhu, Q.; Wang, B.; Zhao, X.; Liu, C.; Yu, Q.; Zhang, L.; Sang, G. Effect of coalbed methane well fracturing on slope stability of open-pit coal mine: A case study of Shengli East No. 2 open-pit coal mine. Adv. Civ. Eng. 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, Y.; Cao, L.; Fu, T.; Wang, D.; Wang, L.; Cai, M.; Li, L. Parameter design of coal pillar in highwall mining under the action of dynamic-static load. Coal Sci. Technol. 2023, 51, 53–62. [Google Scholar]

- Yu, M. Stability Mechanism Study of Coal Pillar and Slope Body under Strip Mining of End-Slope Coal. Ph.D. Dissertation, China University of Mining and Technology, Xuzhou, China, 2018. [Google Scholar]

- Chen, C.; Huang, H.; Zhao, B.; Shu, D.; Wang, Y. The research of AHP-based credit rating system on a blockchain application. Electronics 2023, 12, 887. [Google Scholar] [CrossRef]

- Chen, H.; Guo, Q.; Wang, L.; Meng, X. Evaluation of slope stability within the influence of mining based on combined weighting and finite cloud model. Energy Explor. Exploit. 2023, 41, 636–655. [Google Scholar] [CrossRef]

- Chen, J.; Li, H.; Hu, Z.; Liu, K.; Hou, Y. Evaluation Index for IVIS Integration Test under a Closed Condition Based on the Analytic Hierarchy Process. Electronics 2022, 11, 3830. [Google Scholar] [CrossRef]

- Yi, J.; Guo, L. AHP-Based network security situation assessment for industrial internet of things. Electronics 2023, 12, 3458. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision-making with the AHP: Why is the principal eigenvector necessary. Eur. J. Oper. Res. 2003, 145, 85–89. [Google Scholar] [CrossRef]

- Li, H. Factor spaces and mathematical frame of knowledge representation—Variable weights analysis. Fuzzy Syst. Math. 1995, 9, 1–9. [Google Scholar]

- Liu, W. Balanced function and its application to variable weight synthesizing. Syst. Eng. Theory Pract. 1997, 17, 58–64. [Google Scholar]

- Huang, W.; Wang, Z. Comprehensive evaluation model of fuzzy analytic hierarchy process with variable weight for underground coal gasification. J. Xi’an Univ. Sci. Technol. 2017, 37, 500–507. [Google Scholar]

- Porathur, J.L.; Roy, P.P.; Shen, B.; Karekal, S. Highwall Mining: Applicability, Design & Safety; CRC Press/Balkema: Leiden, The Netherlands, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).