Explicit Representation of Mechanical Functions for Maintenance Decision Support

Abstract

:1. Introduction

- Machine learning is essentially data-driven. However, it is usually associated with a lack of available data for model training, making the training process difficult [4].

- Machine learning algorithms usually do not have physical explanations regarding the trained models [10].

- Most machine learning methods reported in the literature focus on the maintained items rather than adopting a system-wide perspective [11], which means that they insufficiently reflect maintenance requirements in specific operational contexts.

2. State of the Art

2.1. Determining Maintenance Requirements

2.2. Knowledge-Based Diagnostics and Prognostics

2.3. Classification of Mechanical Functions

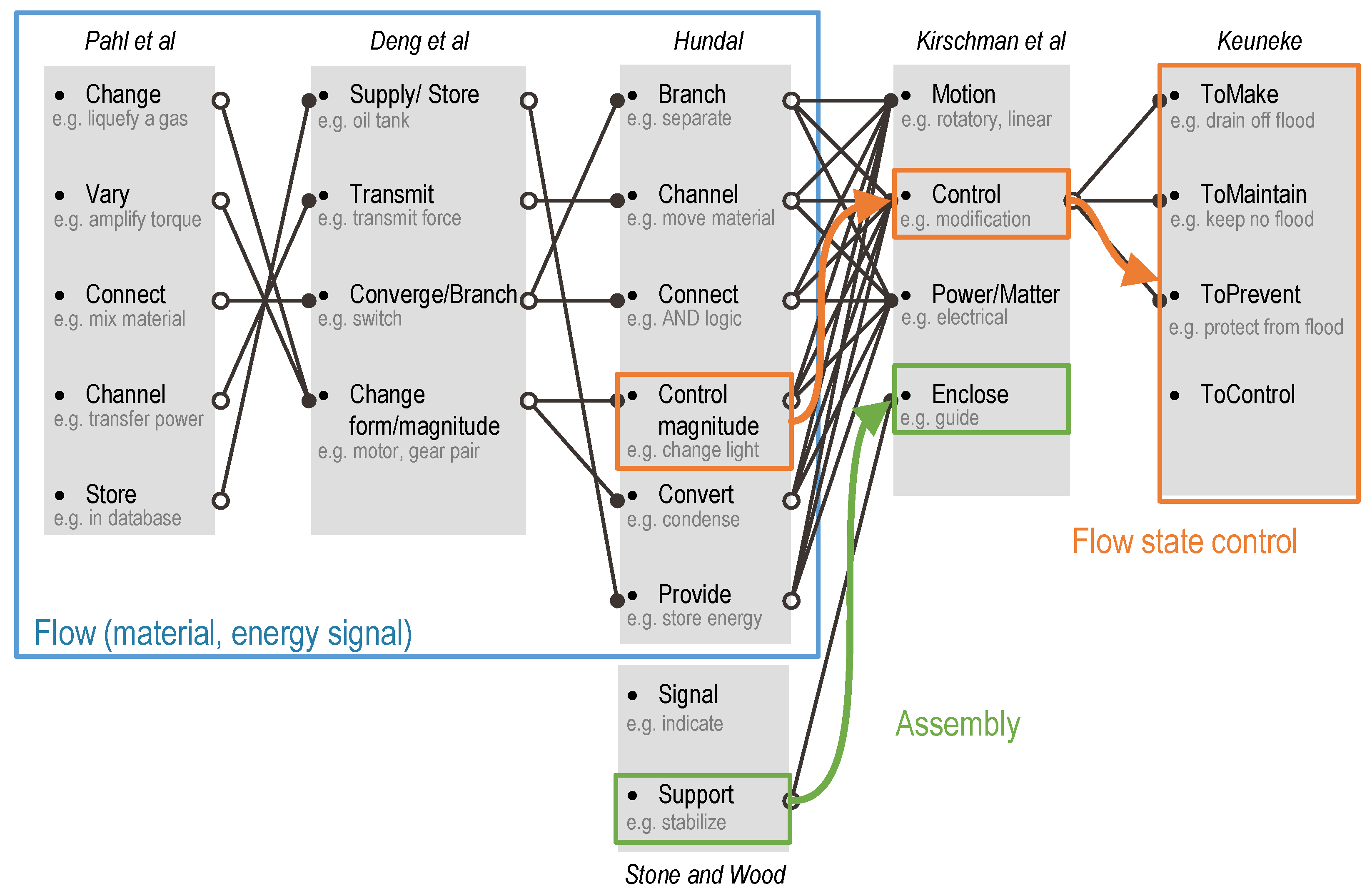

- Pahl et al. [31] developed five high-level functions, i.e., generally valid subfunctions, which are defined according to the relationships between inputs and outputs regarding the change in type, magnitude, number, place, and time. The corresponding functions are change, vary, connect, channel, and store.

- Deng et al. [32]’s classification is derived from work reported by Pahl et al. [31] but uses different vocabulary for the formulation. Mechanical functions are classified into four categories according to whether they are related to supply/store, transmit, converge/branch, or change form/magnitude of material or energy.

- Hundal [33] broke down the classifications proposed by Pahl et al. [31] and Deng et al. [32] and generated six mechanical function classes that can address flows of material, energy, and signal. On this basis, Stone and Wood [34] also included signal and support. Note that signal here only refers to how a status signal is manifested or used, apart from which control signals can also be processed on the basis of six basic functions. Support means that the signal does not satisfy the functionality required by the product but provides support for the other mechanical functions.

- Kirschman et al. [35] did not specify the verb form of mechanical functions but focused more on the object form. Four templates for defining mechanical functions were proposed, which are related to motion, power/matter, control, or enclosure.

- Keuneke [36] did not make a distinction from the viewpoint of material, energy, or signal flow, instead focusing on the state change. There are four function types, i.e., ToMake, ToMaintain, ToPrevent, and ToControl, among which ToControl has the power to execute the other three functions.

- Functions of various flows as defined by Pahl et al. [31];

- Conditions for flow functions;

- Control functions if control equipment is involved.

2.4. Literature Review for Functional Modeling Methods

- Verb–noun pairs are how people imply function in ordinary language.

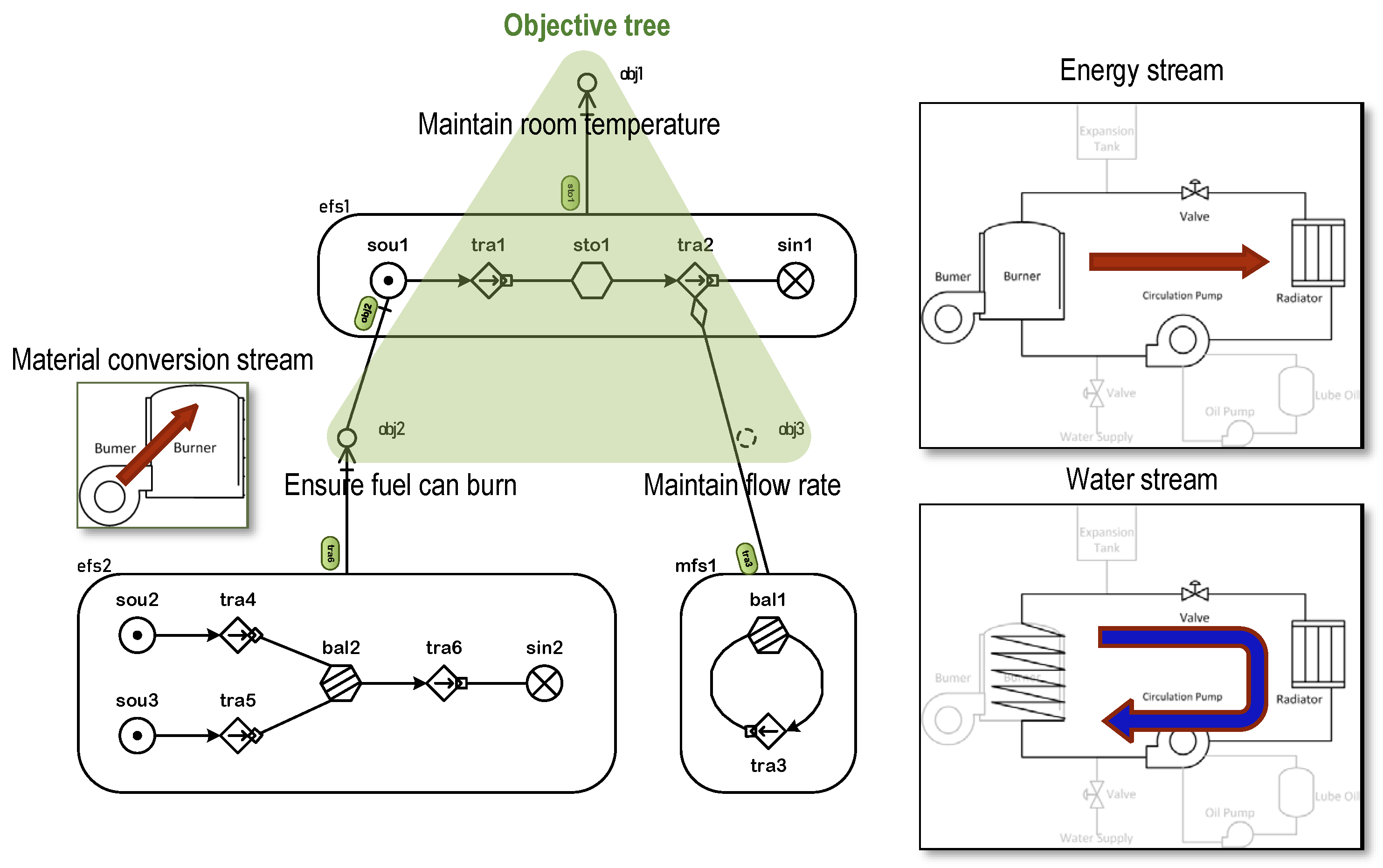

- Input–output (I–O) flow transformation defines a function as a relation between input and output of flow, which is relevant to the flow-term functions shown in Figure 2. Transformation from input flow to output flow can be recognized as a task purpose, i.e., function.

- Input–output (I–O) state transformation characterizes function as a sequential change from the initial state to the ending state, as state change usually occurs when the function is being delivered.

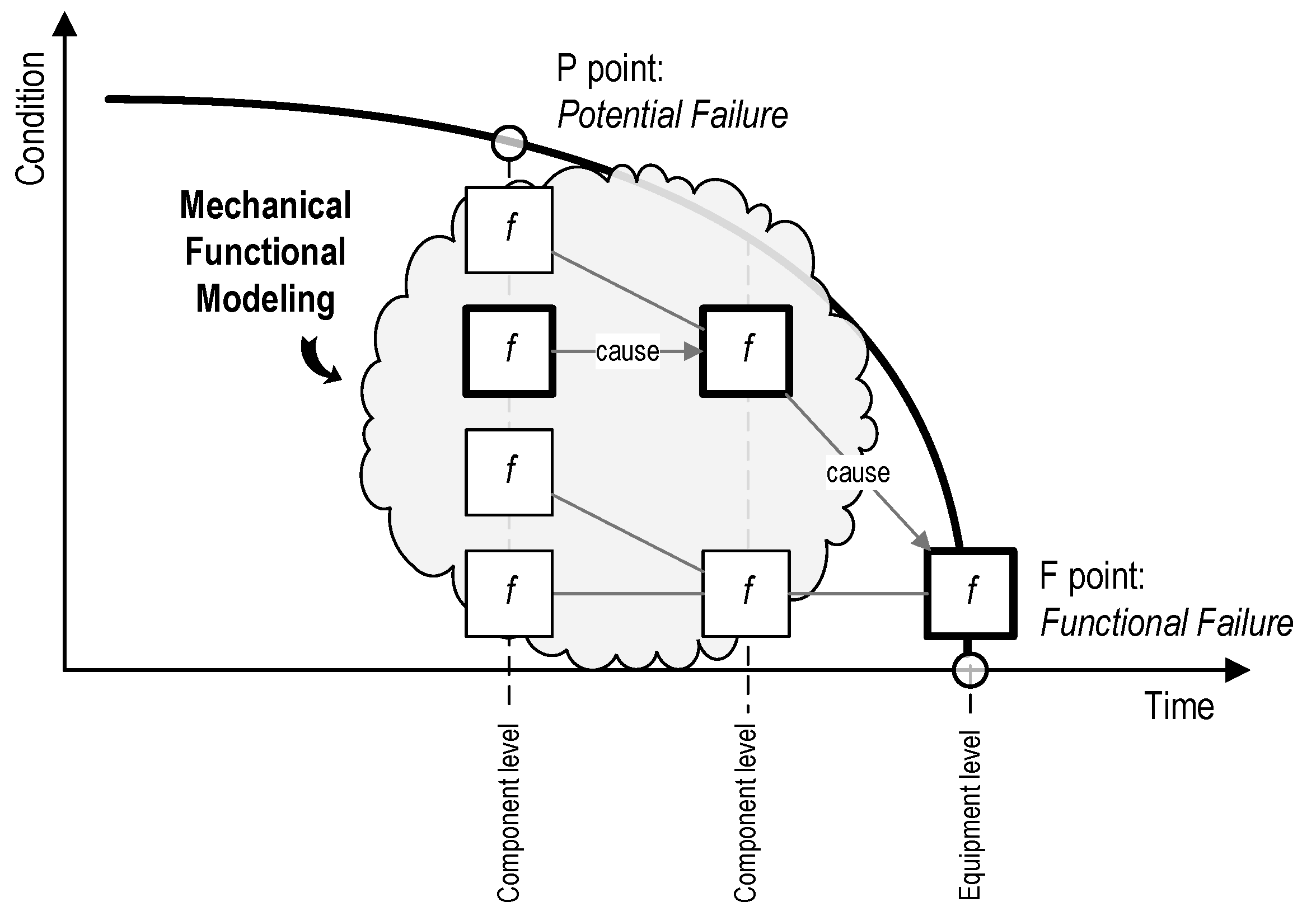

3. Mechanical Functional Modeling

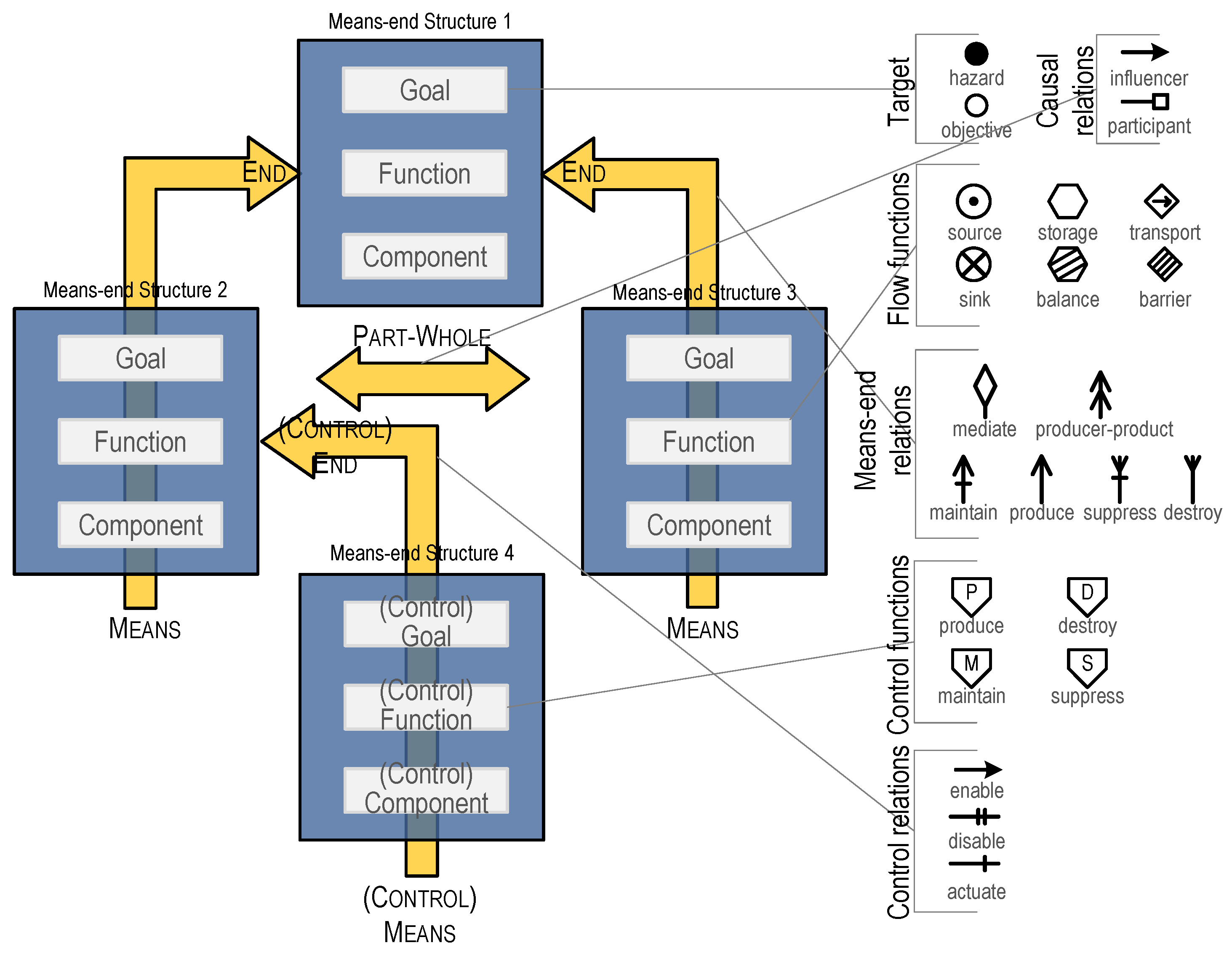

3.1. MFM

3.2. Problem with the Process-Oriented Approach

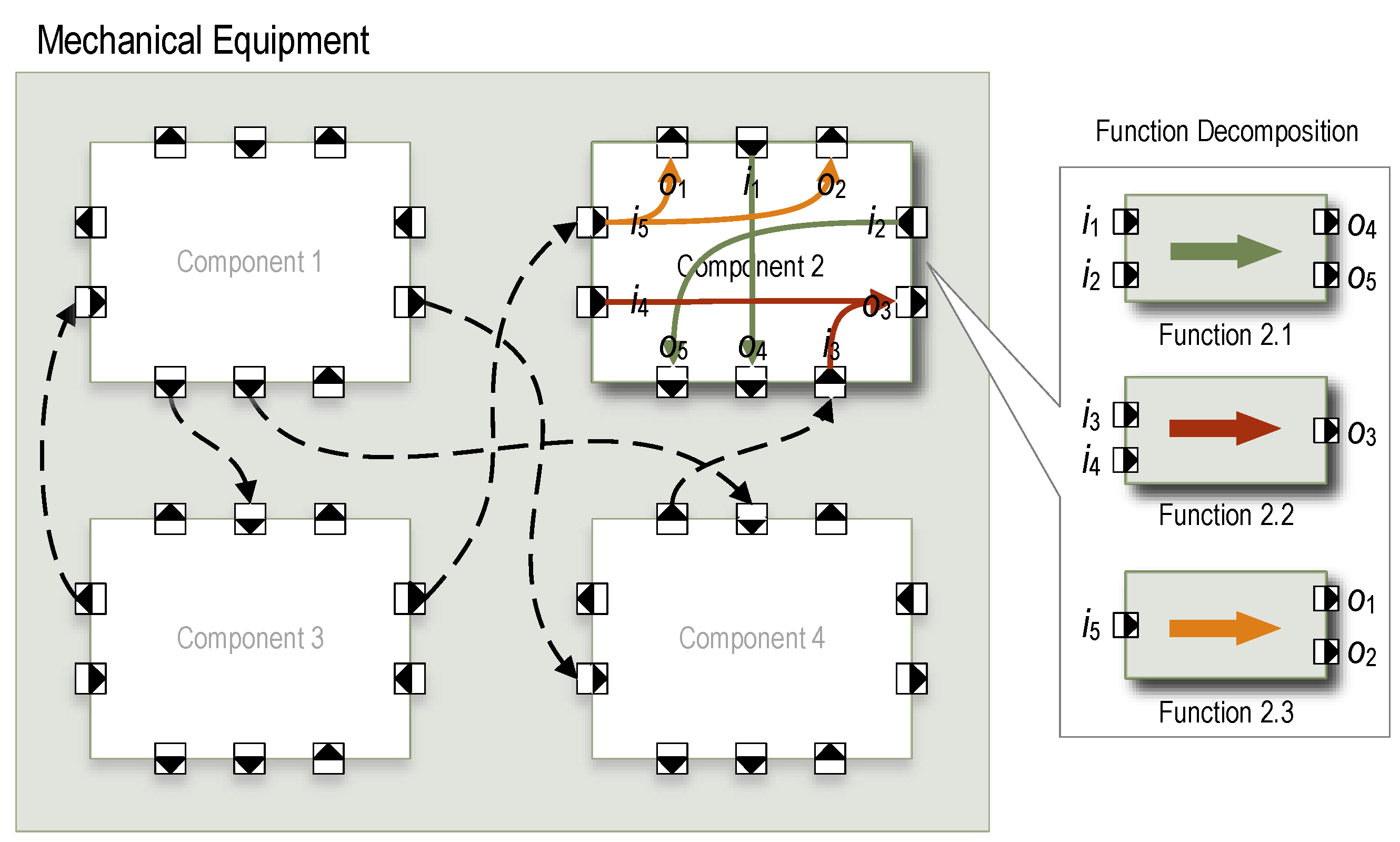

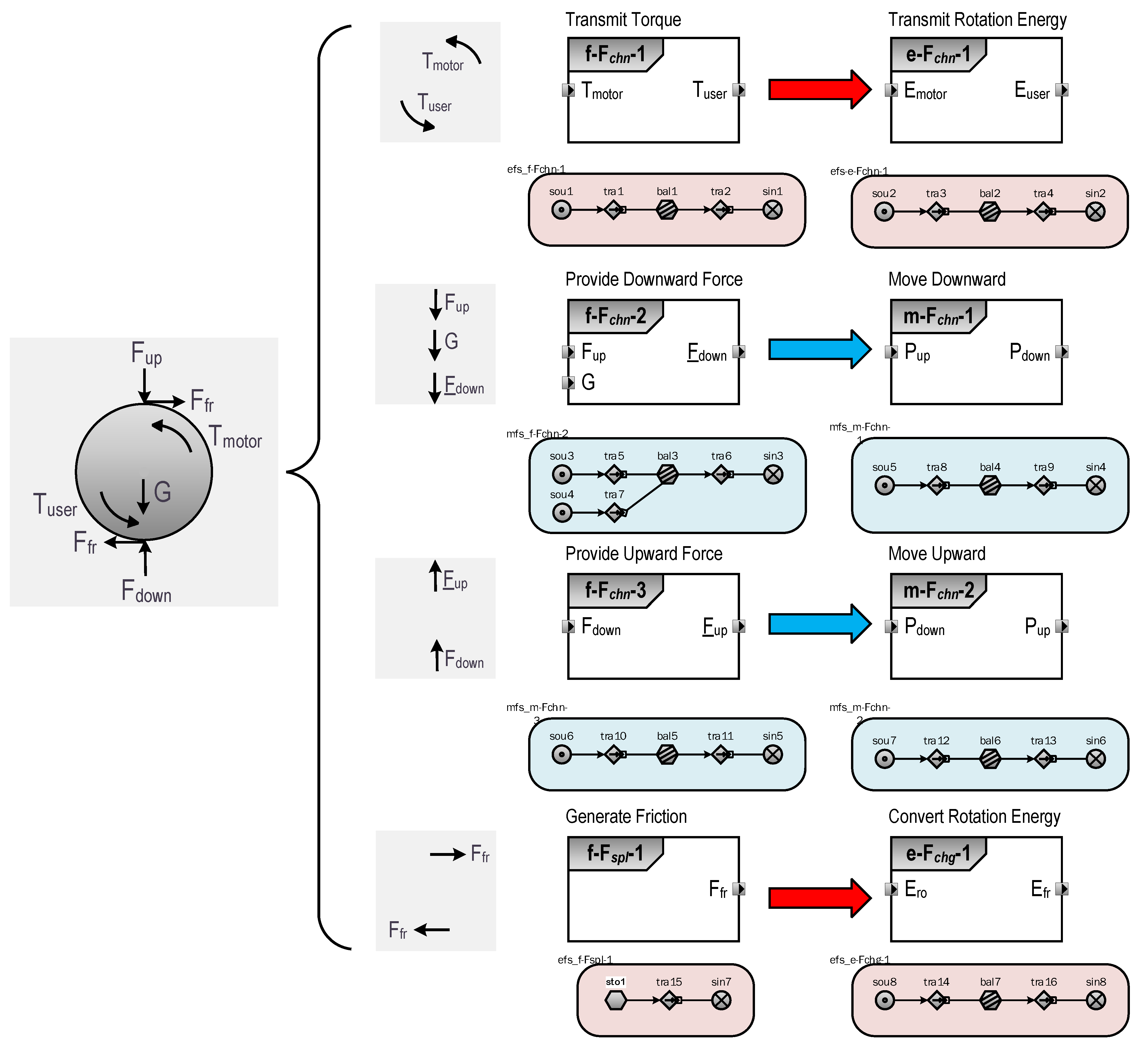

3.3. Component-Oriented Functional Modeling

3.3.1. Function Decomposition

3.3.2. Mechanical Function Patterns

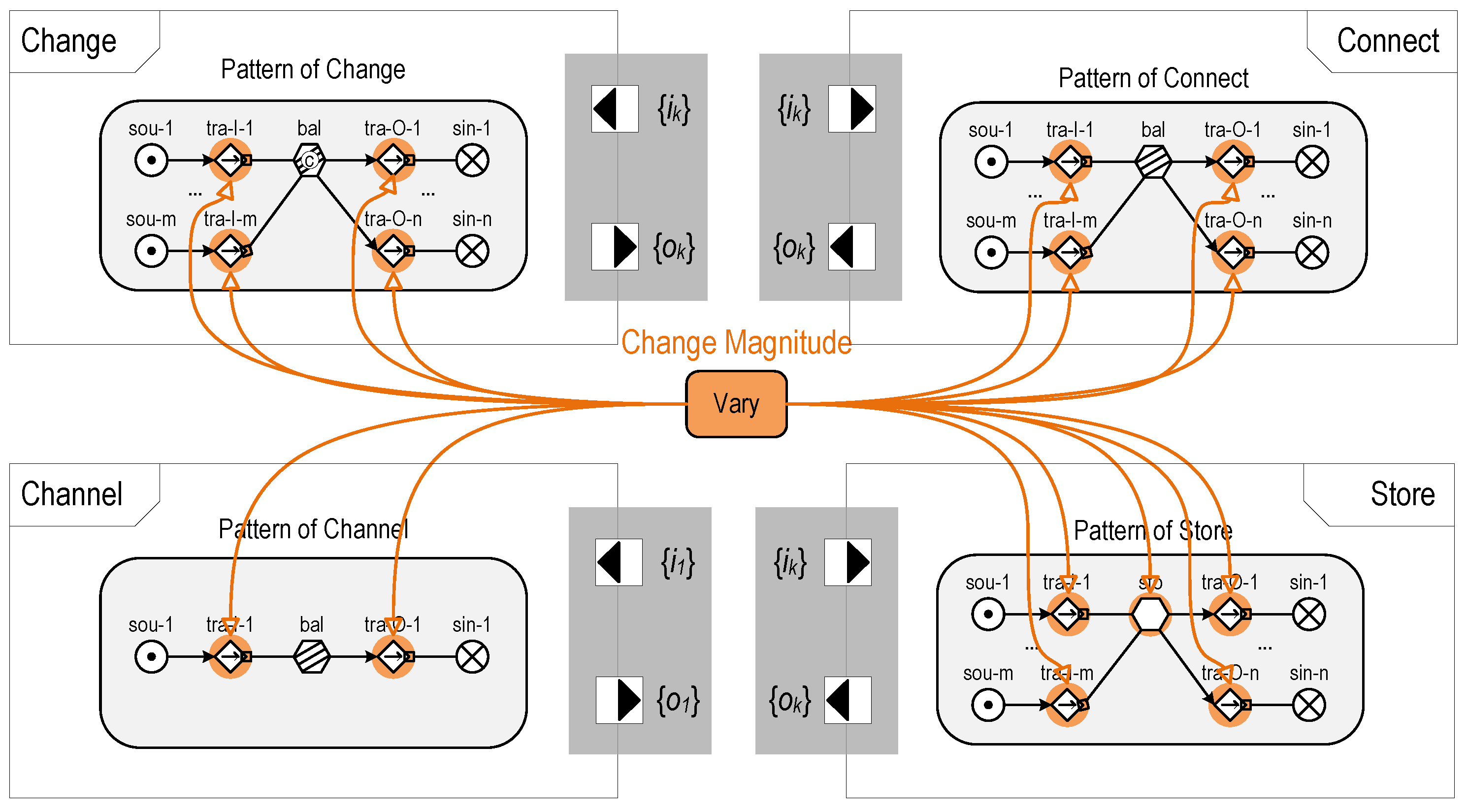

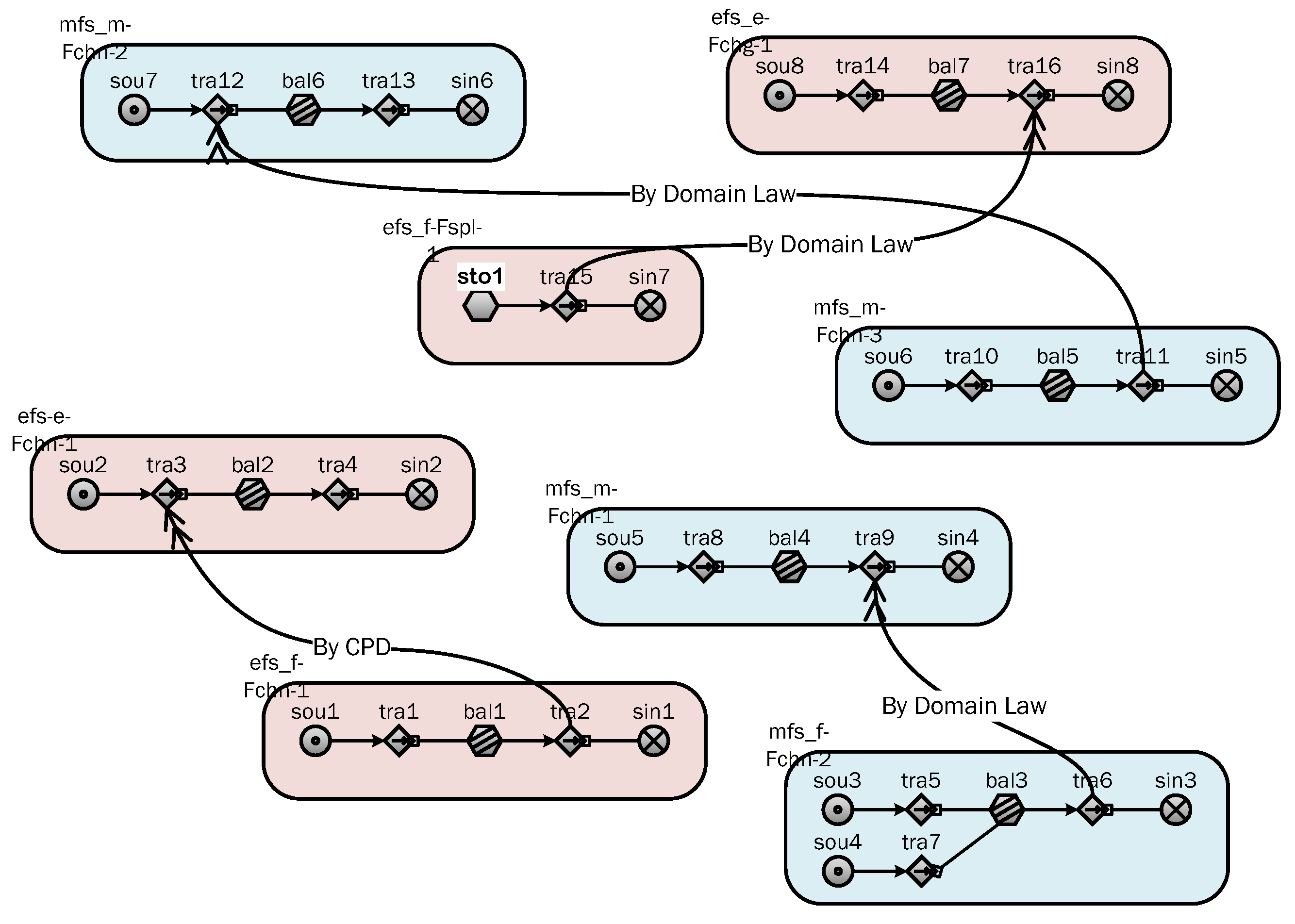

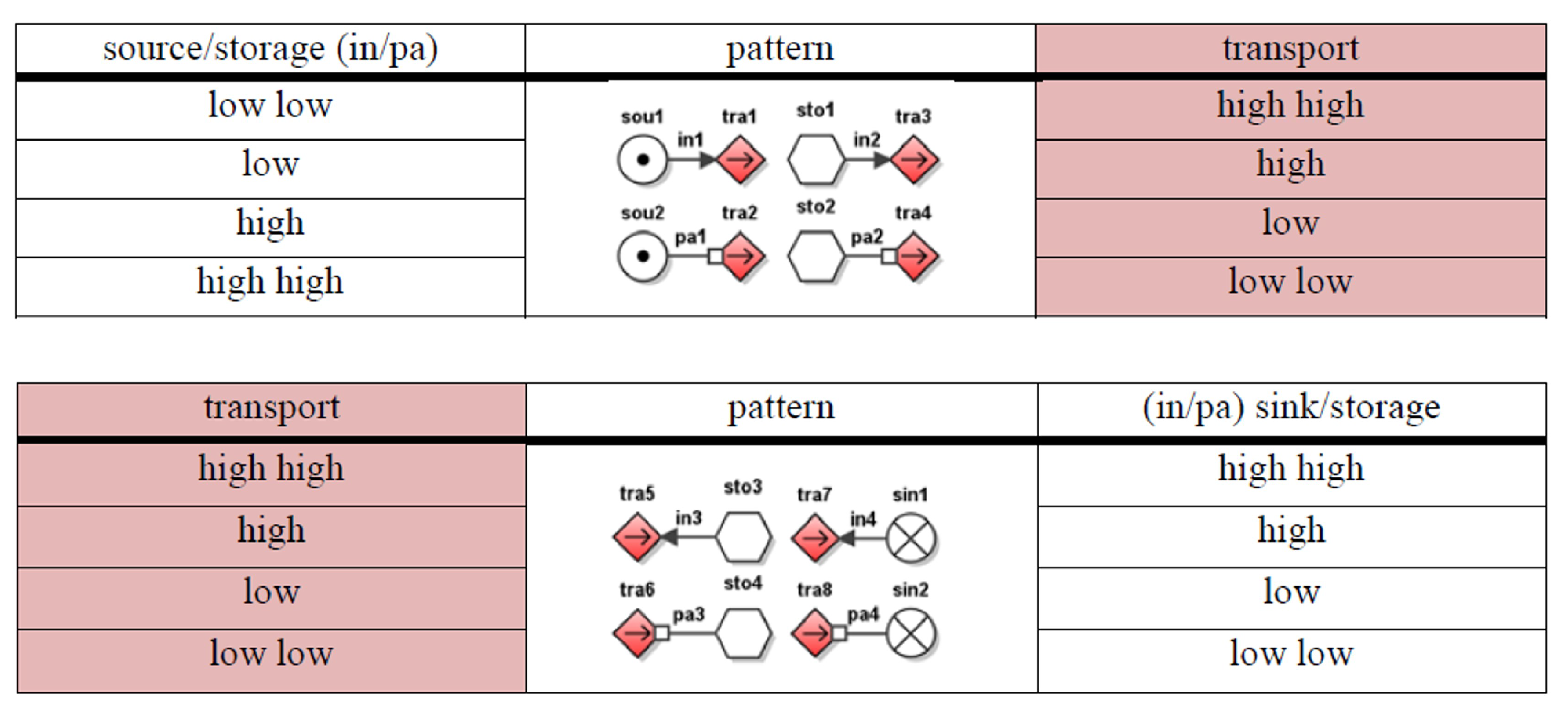

- The function of change () can be expressed as flow, indicating that the form of the flow object being processed has been converted from inputs to outputs. But it should be noted that the objective type—either mass or energy—does not change, which allows inputs and outputs to be included in the same mass flow structure or energy flow structure. The pattern shown in Figure 7 consists of several source–transport that represent input flows before their types change and several pairs transport–sink pairs the represent output flows after the change. A balance function is used to connect inputs and outputs.

- The connect function () expressed below can have more than one input and output, but the flow object does not change its type or form. The converge () and branch () functions are also defined within this pattern depending on the number of input flows and output flows. The pattern shown in Figure 7 has the same form as . The difference is that neither the type nor form changes from input flows to output flows.

- The channel function () is a flow transmitting objects from only one input to only one output, during which time the object does not change its type or form. A balance is used to connect upstream and downstream flows.

- The store function () indicates object accumulation, which can be switched to Supply () if there is no input. However, it does not involve a change in object type or form.

3.3.3. Relations between Mechanical Functions

- By-CPD, i.e., Causal process description, which is the causal knowledge that people compile through problem-solving experience, making it goal-dependent. It is usually couched in terms of common sense or scientific ontology. For example, closing a switch causes voltage to be applied between terminals.

- By-Function-of<>, where the blank can be filled with a device component, which means that it is the function of the component that causes the transition.

- By-Domain-Law, which corresponds to mathematical equations that embody scientific laws and express relations between state variables. For example, according to Ohm’s law, voltage ‘causes’ a current.

- By-Qualifier, which corresponds to a conditional relation that is required for the transition to take place. This usually happens for a support function, where a state, e.g., support force, must hold for another state transition.

3.4. Coupling between Mechanical Functional Modeling and Process Functional Modeling

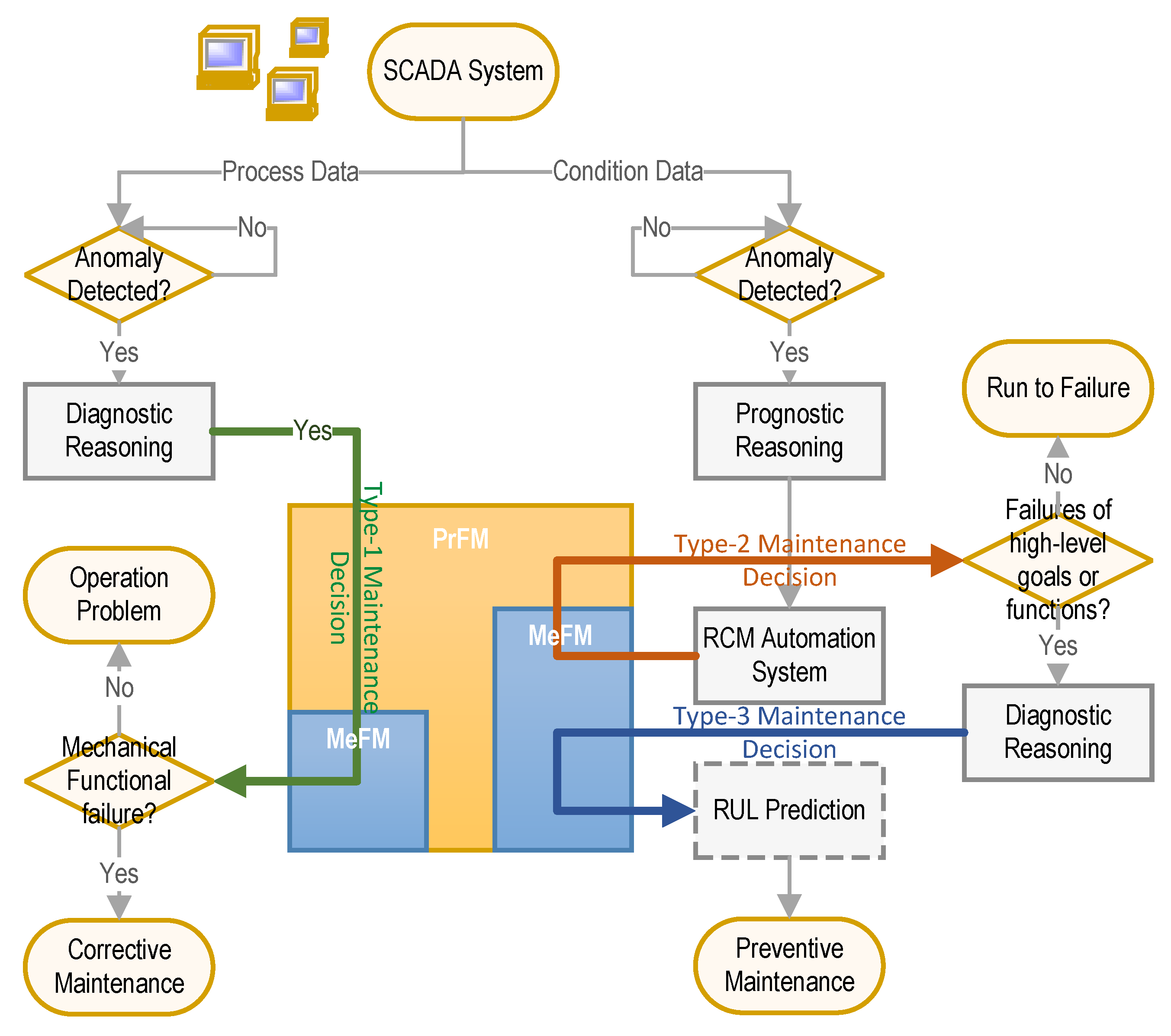

4. A Framework of Optimized CBM Combined with RCM

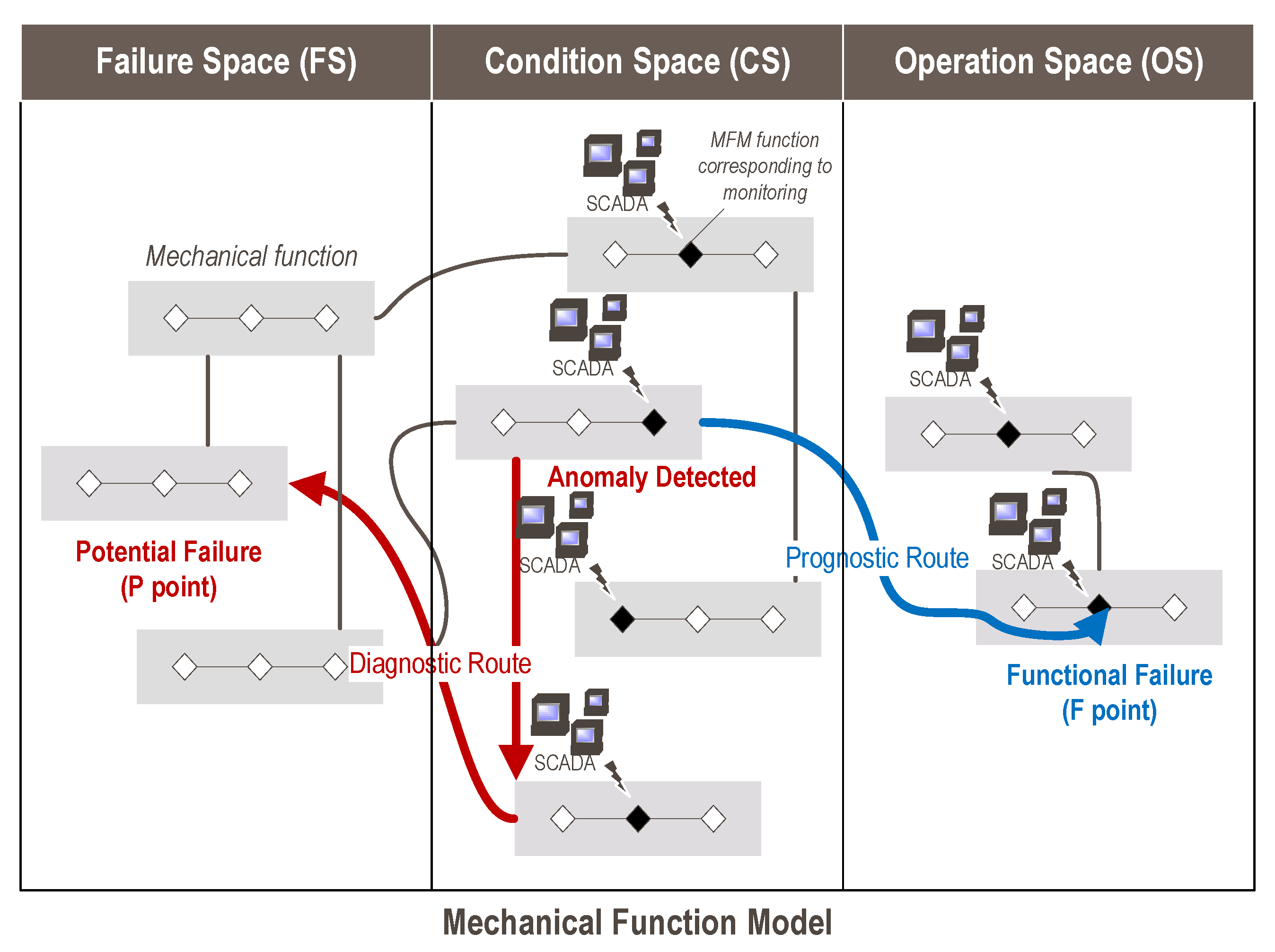

- Type-1 Maintenance Decision: Diagnostic reasoning PrFM → MeFM identifies mechanical failures that have already occurred (green arrow).

- Type-2 Maintenance Decision: Prognostic reasoning MeFM → PrFM via the RCM automation system indicates whether CBM is necessary (red arrow).

- Type-3 Maintenance Decision: Diagnostic reasoning MeFM → MeFM identifies potential mechanical failures (blue arrow).

4.1. Causal Reasoning of MFM

4.2. RCM Automation System

4.3. Diagnostic and Prognostic Reasoning at the Mechanical Level

- Operation space (OS) includes the mechanical functions that can accommodate the operation monitoring data, which, in general, measure the overall performance of equipment. Failures of those mechanical functions are considered functional failures.

- Condition space (CS), covers the mechanical functions that can accommodate the sensor data that are related to the health condition of equipment.

- Failure space (FS) does not link to any sensor data but can relate to them through causal relations. Failures of mechanical functions in this area can propagate to functions that are monitored.

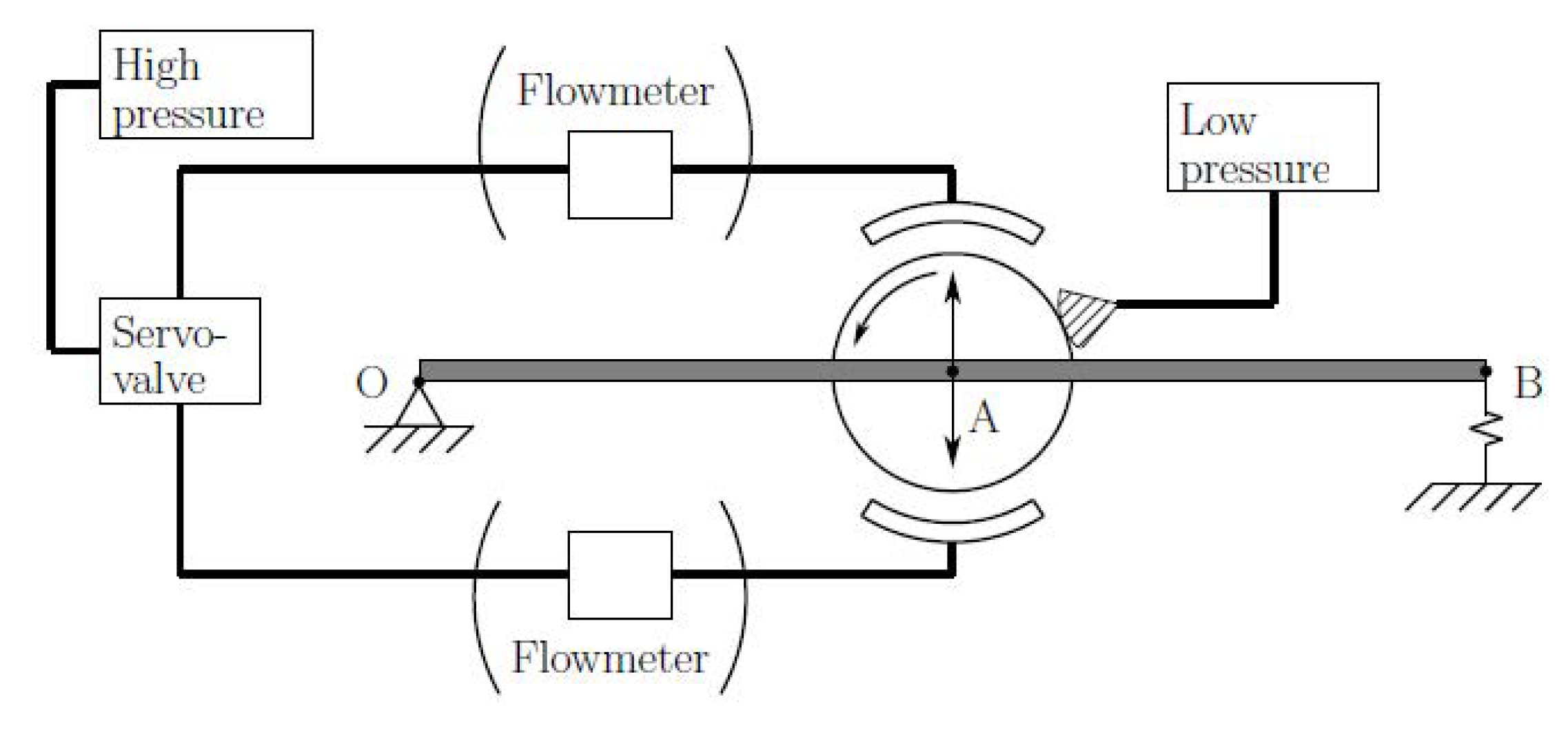

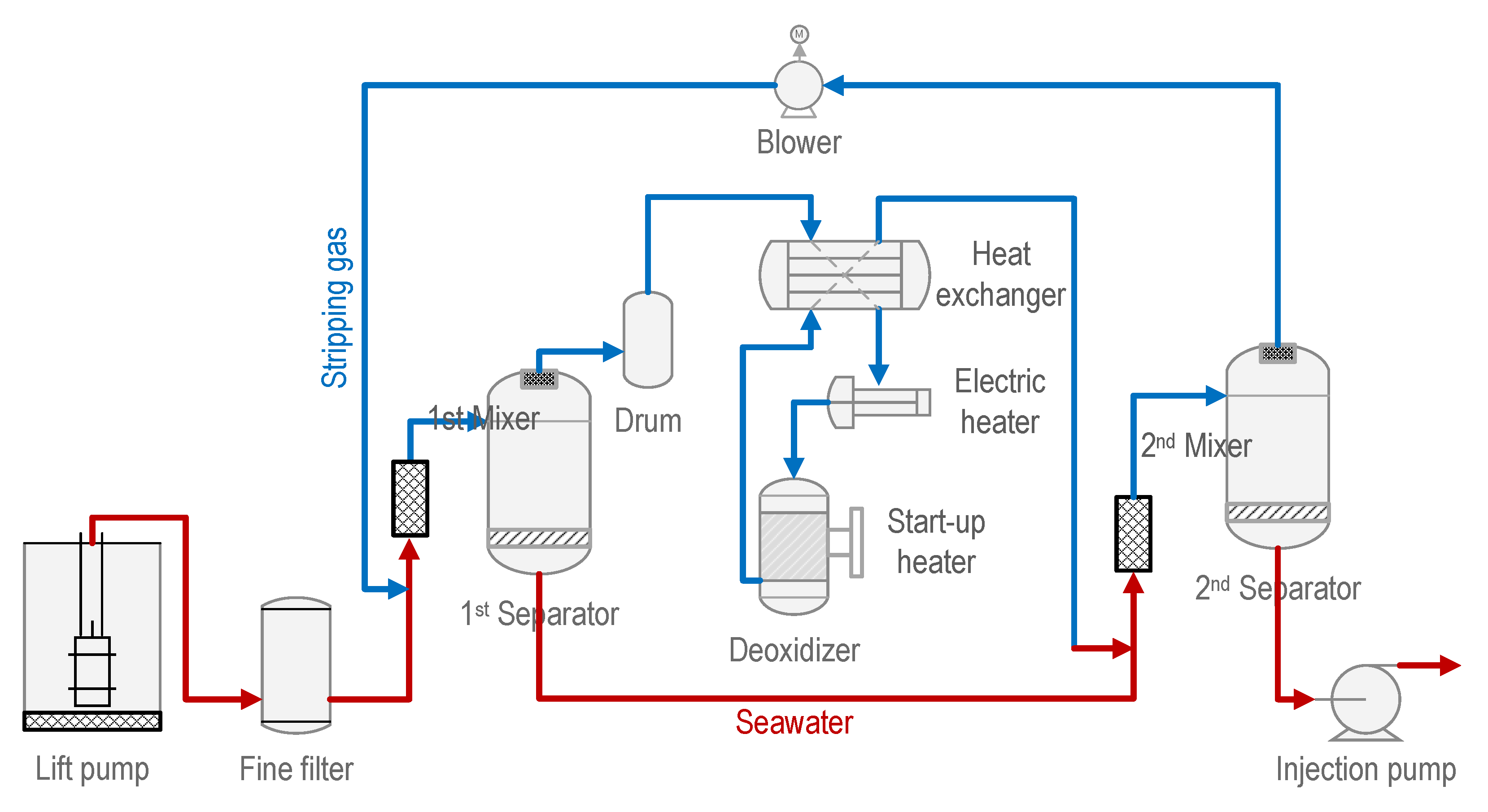

5. Case Study

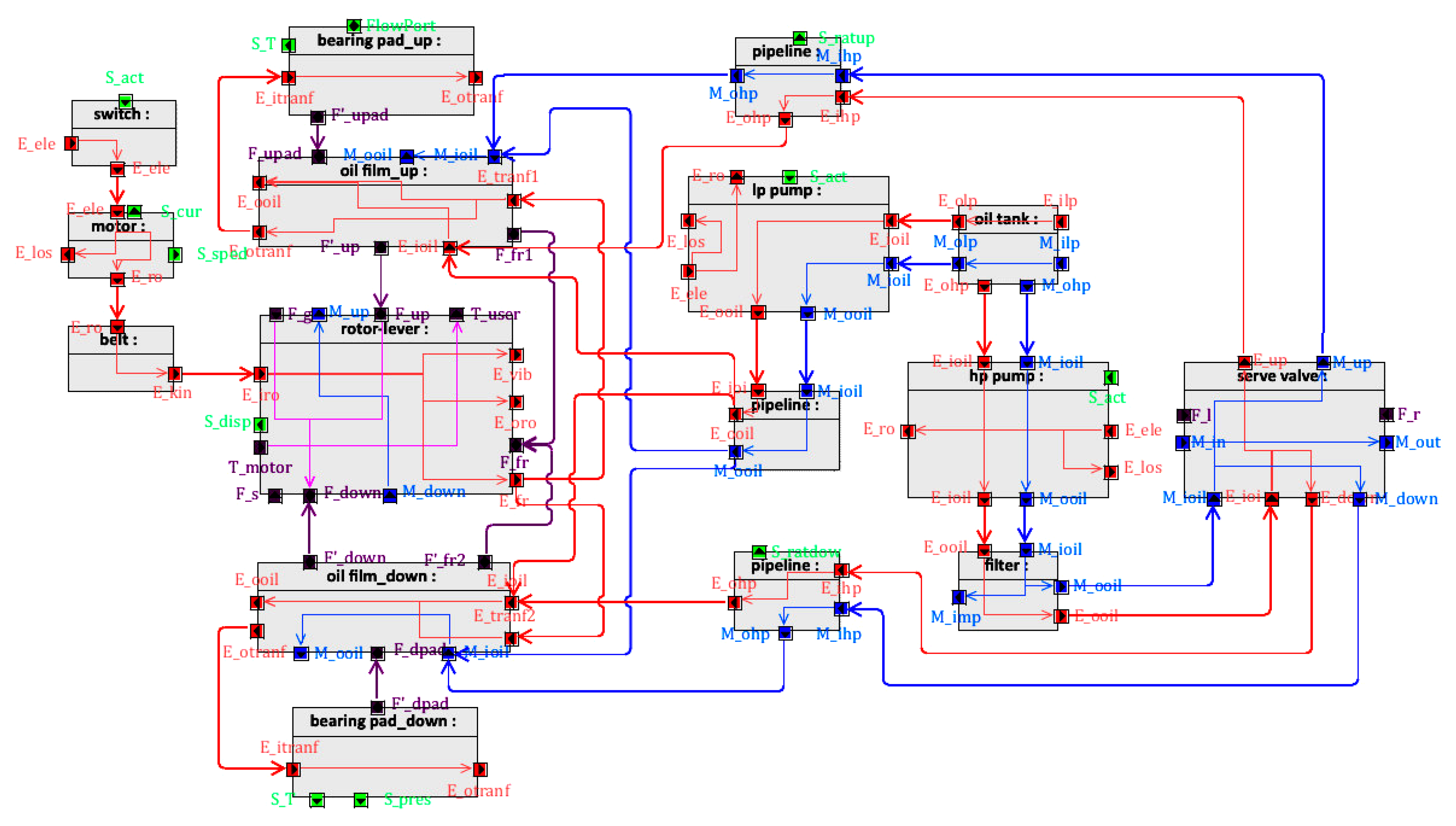

5.1. Description of the Test Apparatus

5.2. Input–Output Analysis

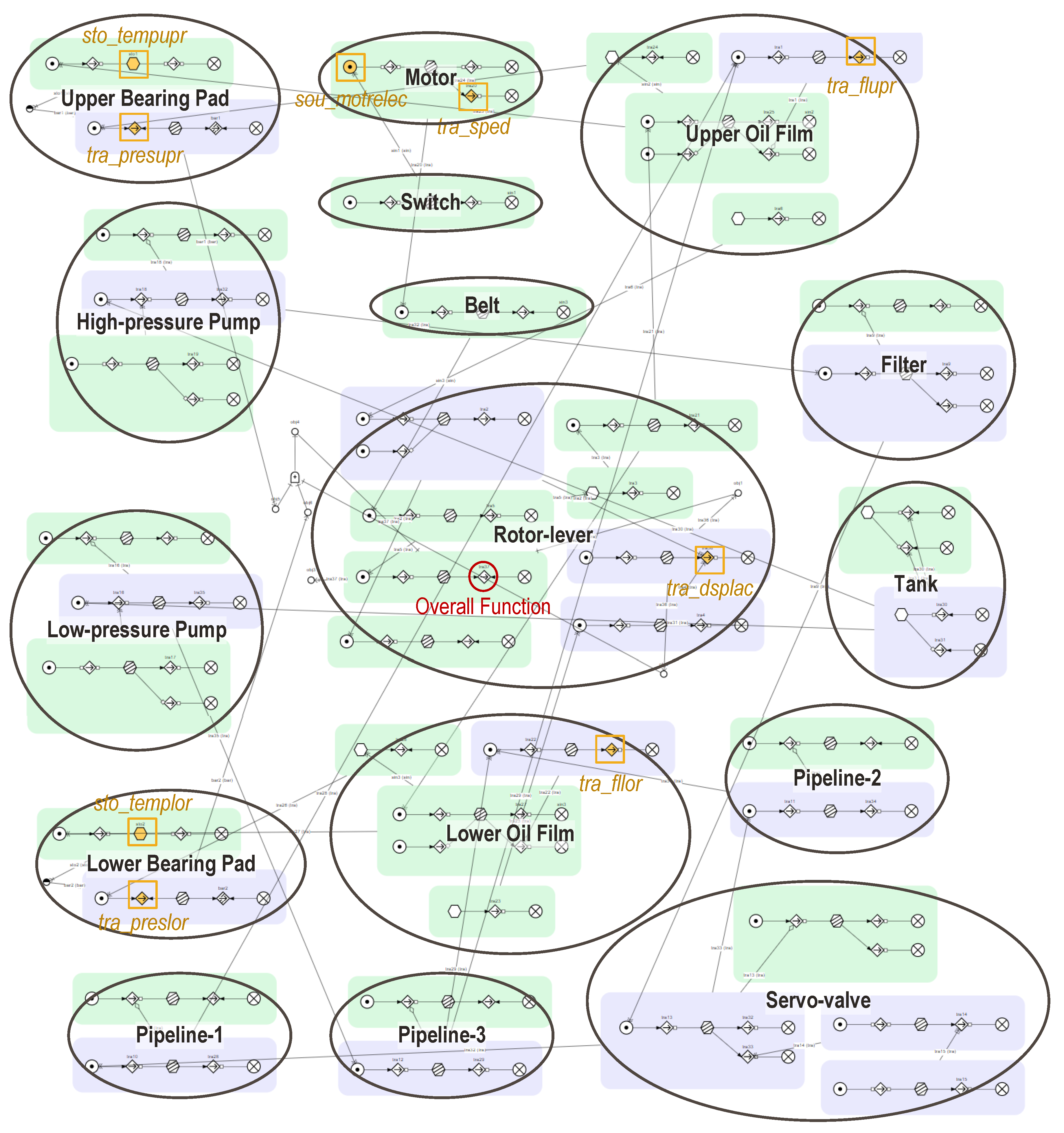

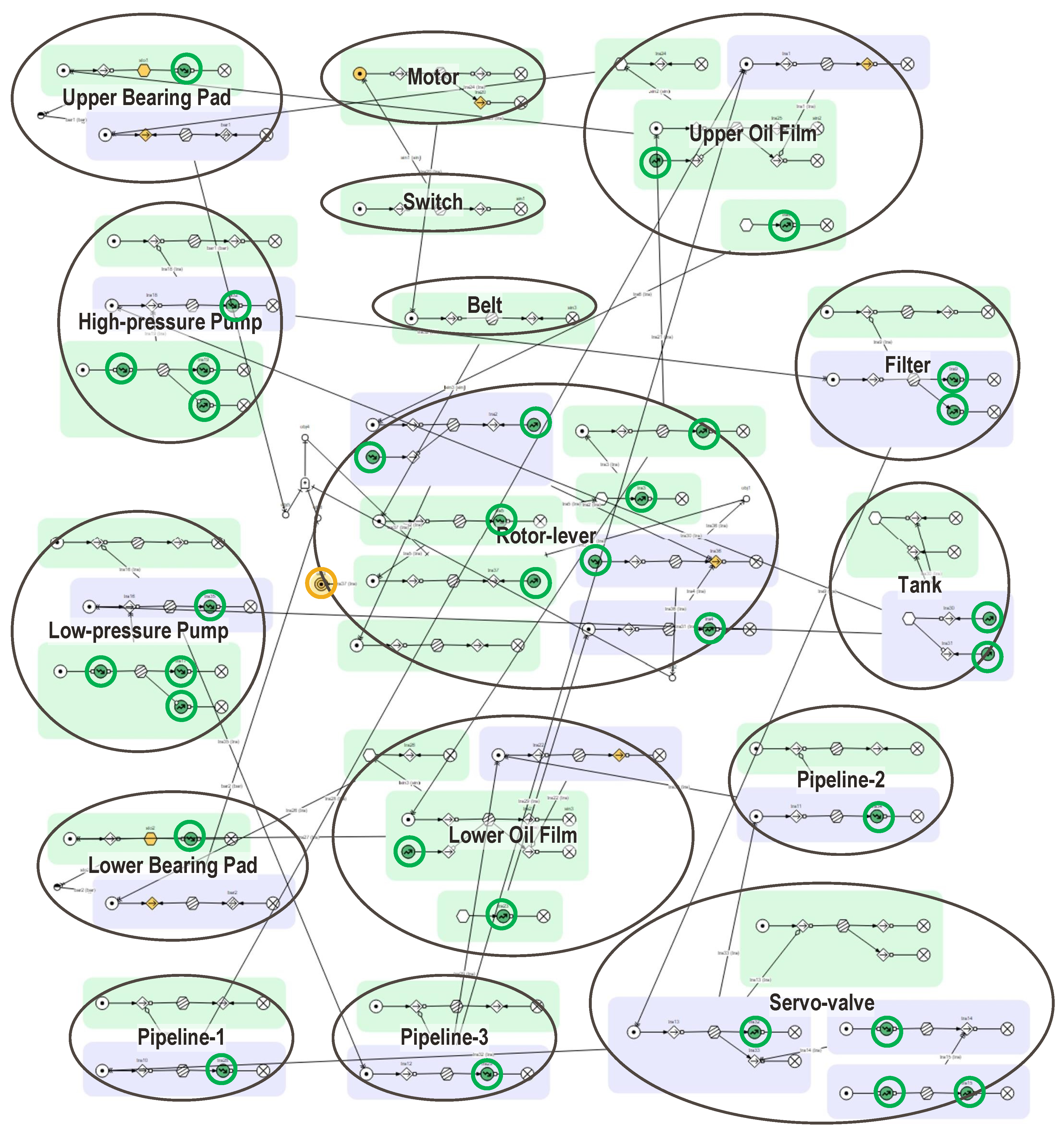

5.3. MFM Model

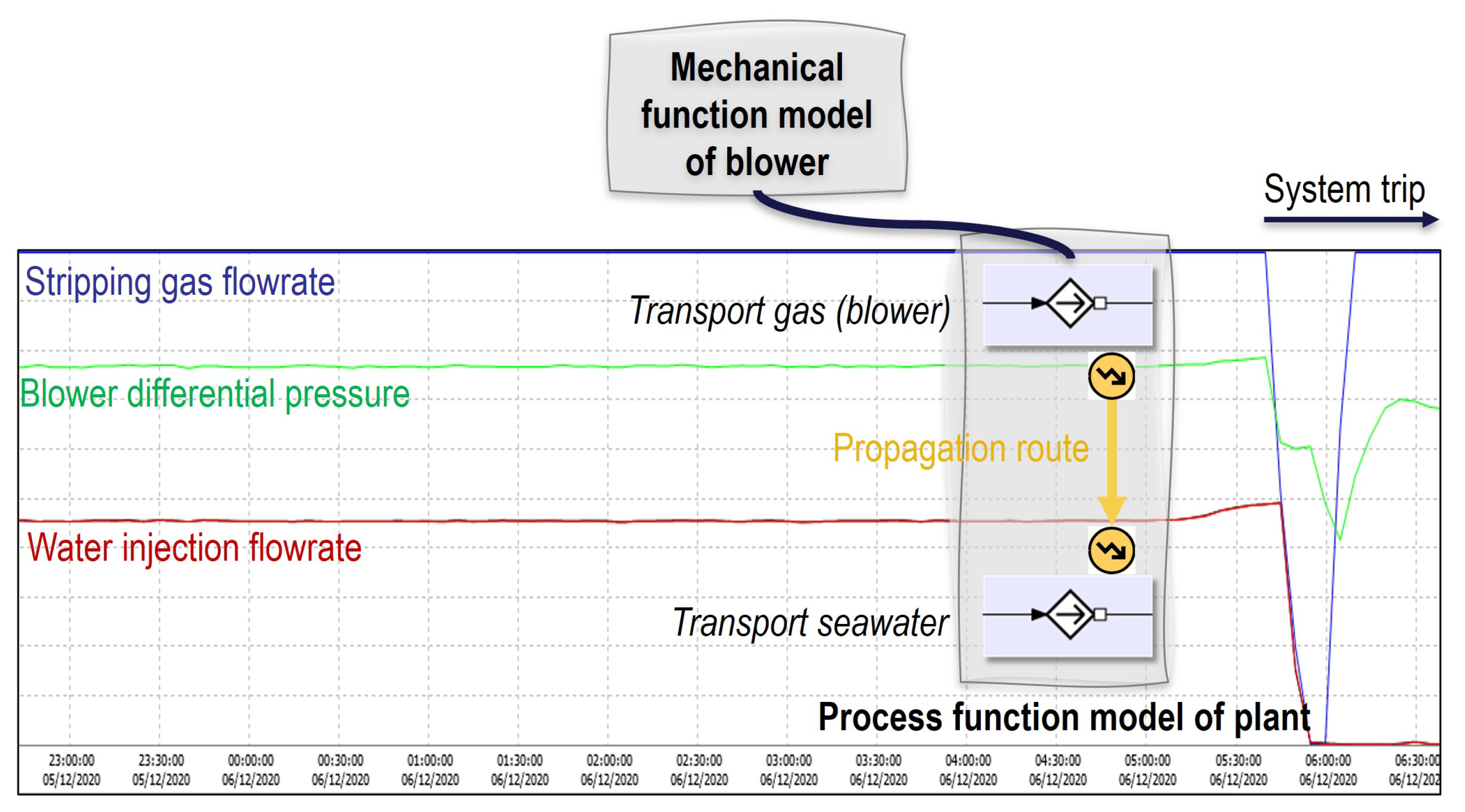

5.4. Reasoning for Maintenance Decision Support

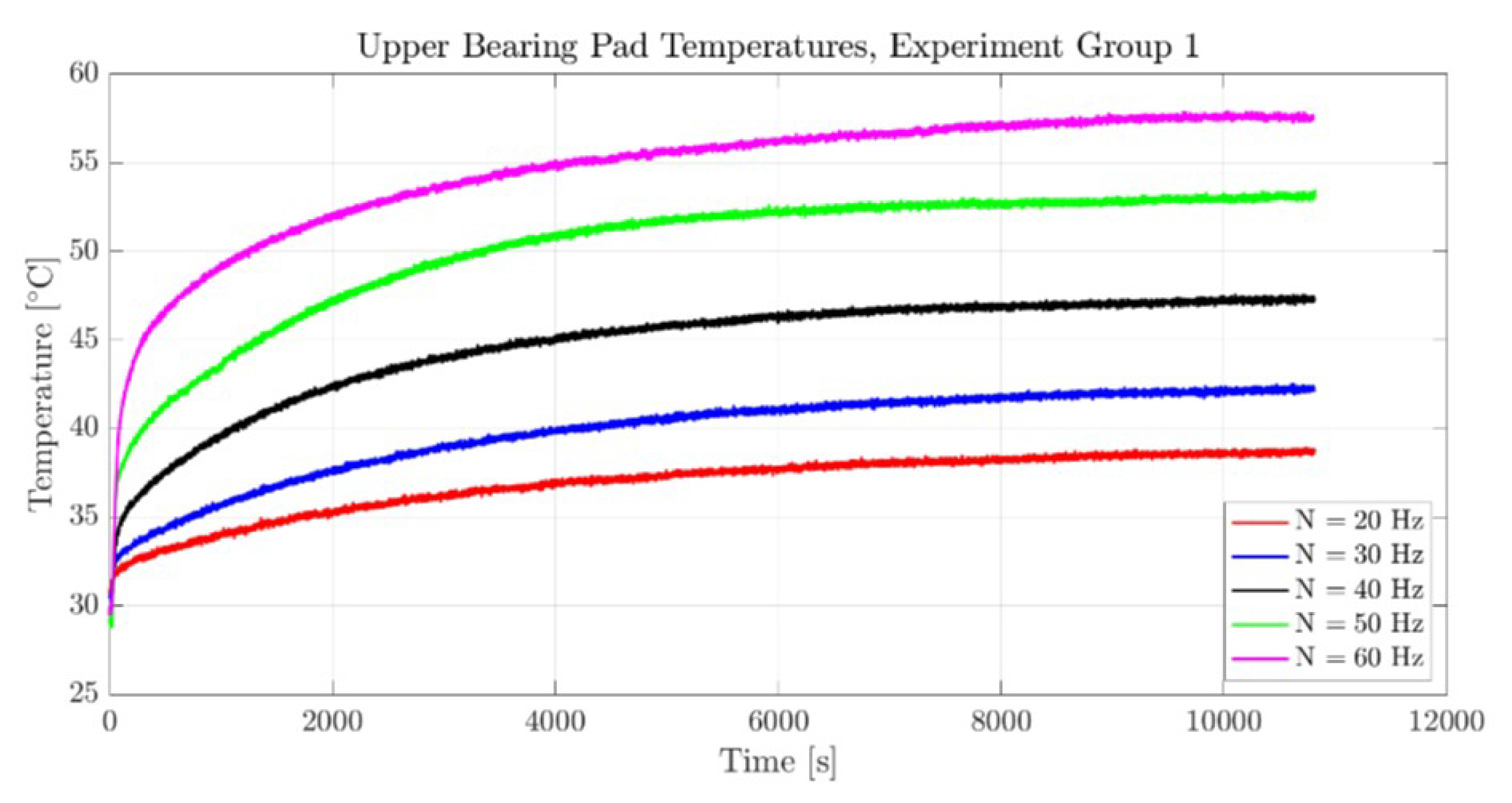

5.4.1. Problem Statement

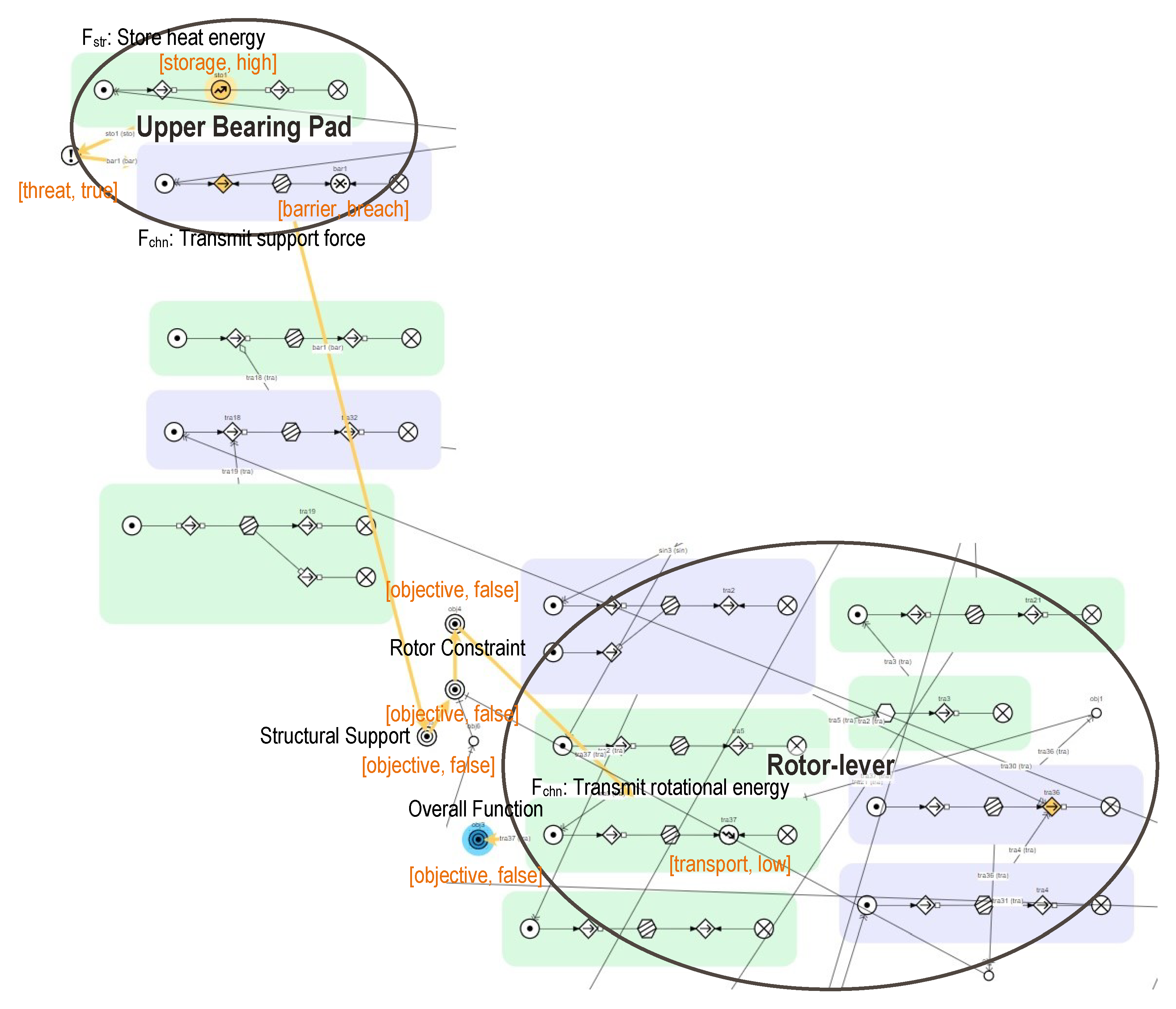

5.4.2. Type 1 Maintenance Decision

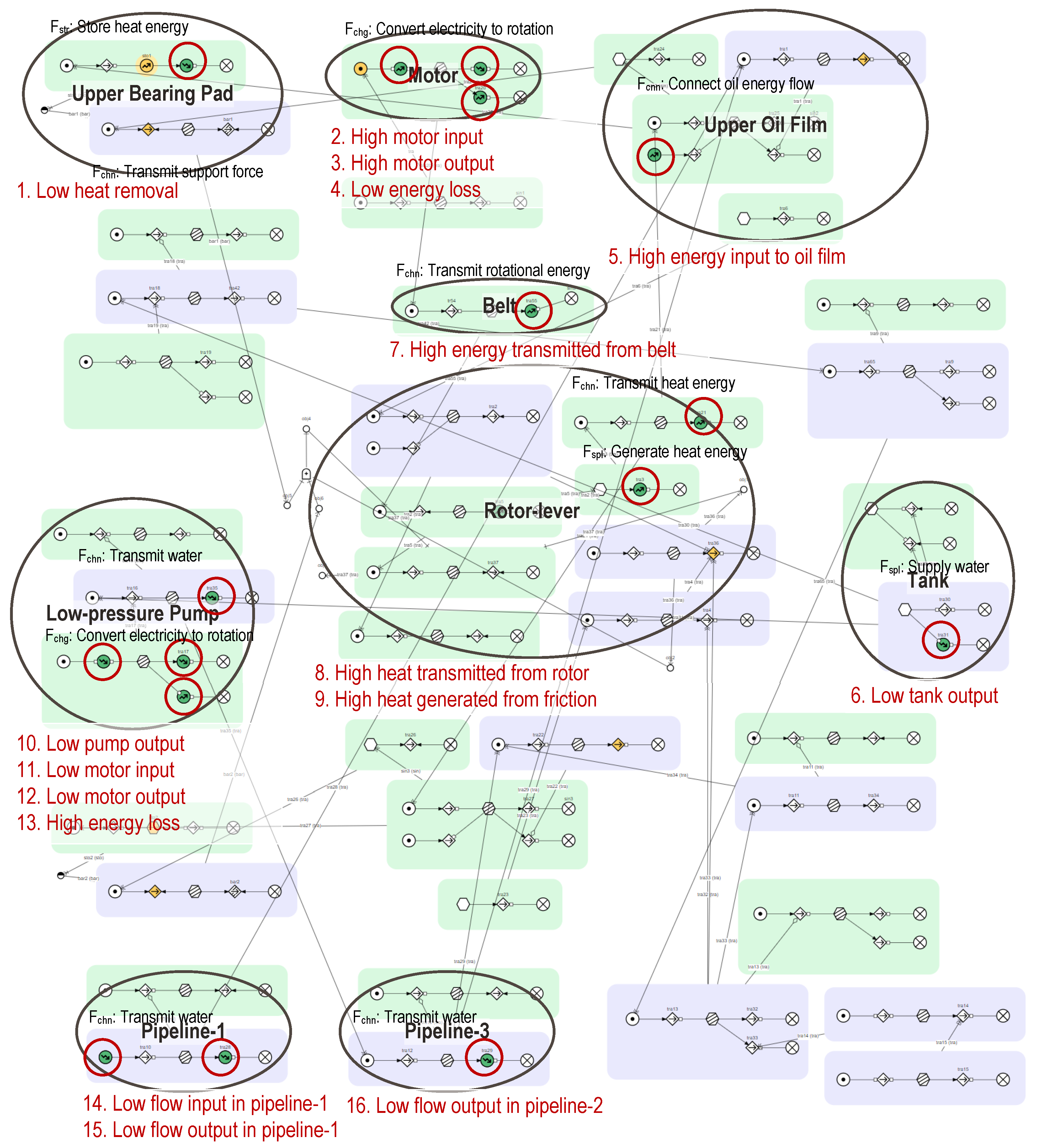

5.4.3. Type 2 and 3 Maintenance Decisions

Results Evaluation

6. Discussion

- A new functional modeling method suitable for the features of mechanical equipment was been proposed. However, we implicitly assume that the causal reasoning rules used for diagnostics and prognostics do not change after extending the modeling range, which brings up the question of how the causality between represented mechanical functions can be validated. Model validation is a common problem in MFM. For example, Nielsen et al. [51] proposed a causality validation method that also assumes that rules are invariant, despite making a comparison between causal reasoning in MFM and stochastic causality analysis in order to modify the causal relations used in the function model. Although it remains to be investigated whether new rules exist in the representation of mechanical functions, using new set of rules also increases the difficulty of developing such a rule-based reasoning system because under the unified model basis, it is difficult for a computer to determine which set of rules should be used. The solution may lie in using existing modeling syntax and semantics to adapt the newfound rules.

- There is still a gap between what the proposed method can offer and what is required by CBM. On the one hand, from the perspective of diagnostics, the potential failure identified in MFM is only implied in the corresponding component and mechanical function. How the failure is developed is not explicitly described. For example, assuming that MFM identifies “low transmit torque” as a potential failure, it is unclear how this failure is generated and how it should be eliminated by maintenance. In order to further identify the failure mechanism, failure modes, mechanisms, and effects analysis (FMMEA) [52] may be used as an additional knowledge source, which can be integrated into the mechanical functional modeling to represent possible degradation processes. In addition, ranking between different failure candidates is also required. On the other hand, from the perspective of prognostics, the method is limited to predicting the qualitative consequences rather than RUL, which is directly related to the maintenance decision. This limitation is due to the feature of instantaneous reasoning of MFM, which means that time is not considered in the influence propagation. To extend the capability of time prediction, the the temporal aspect of both functions and relations in MFM should be taken into account, allowing the consequence reasoning based on MFM not only to predict consequences of a potential mechanical failure but also to predict how long it takes to reach functional failure.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBM | Condition-based maintenance |

| CPD | Causal process description |

| MFM | Multilevel flow modeling |

| MeFM | Mechanical function model |

| RCM | Reliability-centered maintenance |

| FBD | functional block diagram |

| FMMEA | Failure modes, mechanisms, and effects analysis |

| PHM | Prognostics and health management |

| PrFM | Process function model |

| RC | Root cause |

| SCADA | Supervisory control and data acquisition |

References

- Peng, Y.; Dong, M.; Zuo, M.J. Current status of machine prognostics in condition-based maintenance: A review. Int. J. Adv. Manuf. Technol. 2010, 50, 297–313. [Google Scholar] [CrossRef]

- Nowlan, F.S.; Heap, H.F. Reliability-Centered Maintenance, AD/A066 579; Technical Report; US Department of Commerce: Springfield, VA, USA, 1978.

- Kim, N.H.; Choi, J.H.; An, D. Prognostics and Health Management of Engineering Systems: An Introduction; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Pecht, M.; Gu, J. Physics-of-failure-based prognostics for electronic products. Trans. Inst. Meas. Control 2009, 31, 309–322. [Google Scholar] [CrossRef]

- Azadeh, A.; Ebrahimipour, V.; Bavar, P. A fuzzy inference system for pump failure diagnosis to improve maintenance process: The case of a petrochemical industry. Expert Syst. Appl. 2010, 37, 627–639. [Google Scholar] [CrossRef]

- Steurtewagen, B.; Van den Poel, D. Adding interpretability to predictive maintenance by machine learning on sensor data. Comput. Chem. Eng. 2021, 152, 107381. [Google Scholar] [CrossRef]

- Ochella, S.; Shafiee, M.; Dinmohammadi, F. Artificial intelligence in prognostics and health management of engineering systems. Eng. Appl. Artif. Intell. 2022, 108, 104552. [Google Scholar] [CrossRef]

- Surucu, O.; Andrew, S.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Brotherton, T.; Jahns, G.; Jacobs, J.; Wroblewski, D. Prognosis of Faults in Gas Turbine Engines. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 25 March 2000; pp. 163–171. [Google Scholar] [CrossRef]

- Sarazin, A.; Bascans, J.; Sciau, J.b.; Song, J.; Supiot, B.; Montarnal, A.; Lorca, X.; Truptil, S. Expert system dedicated to condition-based maintenance based on a knowledge graph approach: Application to an aeronautic system. Expert Syst. Appl. 2021, 186, 115767. [Google Scholar] [CrossRef]

- DS/EN 13306:2017; Maintenance—Maintenance Terminology. Dansk Standard: Nordhavn, Denmark, 2017.

- Song, M.; Zhang, X.; Lind, M. Automatic identification of maintenance significant items in reliability centered maintenance analysis by using functional modeling and reasoning. Comput. Ind. Eng. 2023, 182, 109409. [Google Scholar] [CrossRef]

- Lind, M. Modeling goals and functions of complex industrial plants. Appl. Artif. Intell. 1994, 8, 259–283. [Google Scholar] [CrossRef]

- Song, M.; Reinartz, C.; Zhang, X.; Thunem, H.P.J.; McDonald, R. MFM-based alarm root-cause analysis and ranking for nuclear power plants. Nucl. Eng. Technol. 2023, 55, 4159–4176. [Google Scholar] [CrossRef]

- Song, M.; Gofuku, A.; Lind, M. Model-based and rule-based synthesis of operating procedures for planning severe accident management strategies. Prog. Nucl. Energy 2020, 123, 103318. [Google Scholar] [CrossRef]

- Kim, J.; Zhao, X.; Shah, A.U.A.; Kang, H.G. System risk quantification and decision making support using functional modeling and dynamic Bayesian network. Reliab. Eng. Syst. Saf. 2021, 215, 107880. [Google Scholar] [CrossRef]

- Erden, M.S.; Komoto, H.; Van Beek, T.J.; D’Amelio, V.; Echavarria, E.; Tomiyama, T. A review of function modeling: Approaches and applications. Artif. Intell. Eng. Des. Anal. Manuf. 2008, 22, 147–169. [Google Scholar] [CrossRef]

- Thunem, H.J. Current status of the MFM suite for diagnostic and prognostic reasoning of industrial process plants. In Proceedings of the 28th International European Safety and Reliability Conference, ESREL 2018, Trondheim, Norway, 17–21 June 2018; pp. 1011–1016. [Google Scholar]

- Song, M.; Zhang, X. Condition-based Maintenance with Functional Modeling: Challenges and Opportunities. In Proceedings of the 31st European Safety and Reliability Conference, ESREL 2021, Angers, France, 19–23 September 2021; pp. 2241–2248. [Google Scholar]

- Smith, A.M.; Hinchcliffe, G.R. RCM-Gateway to World Class Maintenance; Butterworth-Heinemann: Oxford, UK, 2003. [Google Scholar]

- Ochella, S.; Shafiee, M.; Sansom, C. Adopting machine learning and condition monitoring P-F curves in determining and prioritizing high-value assets for life extension. Expert Syst. Appl. 2021, 176, 114897. [Google Scholar] [CrossRef]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems - Reviews, methodology and applications. Mech. Syst. Signal Process. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K. A review on lubricant condition monitoring information analysis for maintenance decision support. Mech. Syst. Signal Process. 2019, 118, 108–132. [Google Scholar] [CrossRef]

- Sikorska, J.Z.; Hodkiewicz, M.; Ma, L. Prognostic modelling options for remaining useful life estimation by industry. Mech. Syst. Signal Process. 2011, 25, 1803–1836. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Kavuri, S.N. A review of process fault detection and diagnosis part II: Qualitative models and search strategies. Comput. Chem. Eng. 2003, 27, 313–326. [Google Scholar] [CrossRef]

- Kurtoglu, T.; Tumer, I.Y. A graph-based fault identification and propagation framework for functional design of complex systems. J. Mech. Des. 2008, 130, 051401. [Google Scholar] [CrossRef]

- L’Her, G.; Van Bossuyt, D.L.; O’Halloran, B.M. Prognostic systems representation in a function-based Bayesian model during engineering design. Int. J. Progn. Health Manag. 2020, 8, 1–23. [Google Scholar] [CrossRef]

- O’Halloran, B.M.; Papakonstantinou, N.; Giammarco, K.; Van Bossuyt, D.L. A graph theory approach to predicting functional failure propagation during conceptual systems design. Syst. Eng. 2021, 24, 100–121. [Google Scholar] [CrossRef]

- Chandrasekaran, B.; John, J.; Richard, B. What are ontologies, and why do we need them? IEEE Intell. Syst. Appl. 1999, 14, 20–26. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Springer: London, UK, 2007. [Google Scholar]

- Deng, Y.; Britton, G.A.; Tor, S.B. A design perspective of mechanical function and its object-oriented representation scheme. Eng. Comput. 1998, 14, 309–320. [Google Scholar] [CrossRef]

- Hundal, M. A systematic method for developing function structures, solutions and concept variants. Mech. Mach. Theory 1990, 25, 243–256. [Google Scholar] [CrossRef]

- Stone, R.B.; Wood, K.L. Development of a functional basis for design. J. Mech. Des. 2000, 122, 359–370. [Google Scholar] [CrossRef]

- Kirschman, C.; Fadel, G.; Jara-Almonte, C. Classifying functions for mechanical design. J. Mech. Des. 1998, 120, 475–482. [Google Scholar] [CrossRef]

- Keuneke, A.M. Device representation the significance of functional knowledge. IEEE Expert 1991, 6, 22–25. [Google Scholar] [CrossRef]

- Chandrasekaran, B. Functional representation: A brief historical perspective. Appl. Artif. Intell. 1994, 8, 173–197. [Google Scholar] [CrossRef]

- Chakrabarti, A.; Blessing, L. Special issue: Representing functionality in design. Artif. Intell. Eng. Des. Anal. Manuf. 1996, 10, 251–253. [Google Scholar] [CrossRef]

- Deng, Y. Function and behavior representation in conceptual mechanical design. Artif. Intell. Eng. Des. Anal. Manuf. 2002, 16, 343–362. [Google Scholar] [CrossRef]

- Umeda, Y.; Tomiyama, T. Functional reasoning in design. IEEE Expert 1997, 12, 42–48. [Google Scholar] [CrossRef]

- Gero, J.S. Design prototypes: A knowledge representation schema for design. AI Mag. 1990, 11, 26–36. [Google Scholar] [CrossRef]

- Chandrasekaran, B.; Josephson, J.R. Function in device representation. Eng. Comput. 2000, 16, 162–177. [Google Scholar] [CrossRef]

- Industrial Processes. Available online: https://en.wikipedia.org/wiki/Industrial_processes (accessed on 24 September 2023).

- Wu, J.; Lind, M.; Zhang, X.; Pardhasaradhi, K.; Pathi, S.K.; Myllerup, C.M. Knowledge acquisition and representation for intelligent operation support in offshore fields. Process Saf. Environ. Prot. 2021, 155, 415–443. [Google Scholar] [CrossRef]

- Zhang, X. Assessing Operational Situations. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, 2015. [Google Scholar]

- Zhao, M.; Chen, Y.; Chen, L.; Xie, Y. A state–behavior–function model for functional modeling of multi-state systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 2302–2317. [Google Scholar] [CrossRef]

- Chandrasekaran, B. Functional representation and causal processes. Adv. Comput. 1994, 38, 73–143. [Google Scholar] [CrossRef]

- Niu, G.; Yang, B.S.; Pecht, M. Development of an optimized condition-based maintenance system by data fusion and reliability-centered maintenance. Reliab. Eng. Syst. Saf. 2010, 95, 786–796. [Google Scholar] [CrossRef]

- IAEA. On-Line Monitoring for Improving Performance of Nuclear Power Plants. Part 2, Process and Component Condition Monitoring and Diagnostics; International Atomic Energy Agency: Vienna, Austria, 2008. [Google Scholar]

- Rumpe, B.; Berroth, J.; Jacobs, G.; Spuetz, K.; Zerwas, T.; Guist, C.; Kohl, J. Modeling mechanical functional architectures in SysML. In Proceedings of the 23rd ACM/IEEE International Conference on Model Driven Engineering Languages and Systems, Virtual Event, 16–23 October 2020; pp. 79–89. [Google Scholar]

- Nielsen, E.K.; Kirchhübel, D.; Jørgensen, T.M. Monte Carlo Simulations for probabilistic validation of consequence reasoning from Multilevel Flow Modelling. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Vienna, Austria, 8–11 September 2020; pp. 1351–1354. [Google Scholar] [CrossRef]

- Hendricks, C.; Williard, N.; Mathew, S.; Pecht, M. A failure modes, mechanisms, and effects analysis (FMMEA) of lithium-ion batteries. J. Power Sources 2015, 297, 113–120. [Google Scholar] [CrossRef]

| Causal Link | MFM Relation * | Type | Scope |

|---|---|---|---|

| By-CPD |  | Device-centric Environment-centric | Knowledge about goal achievement that one function can ‘cause’ another. |

| By-Function-of<> |  | Environment-centric | Functions of different components interact with one another by providing/receiving the same flow. |

| By-Domain-Law |  | Device-centric Environment-centric | The causal relations between variables are governed by domain laws. |

| By-Qualifier |  | Environment-centric | An objective achieved by one function can enable another. |

| Environment-centric | An objective achieved by one function can disable another. |

| Measurement | MFM |

|---|---|

| Displacement of the lever () | tra_dsplac |

| Pressure of the upper pad () | tra_presupr |

| Force of the upper pad () | |

| Temperature of the upper pad () | sto_tempupr |

| Pressure of the lower pad ( | tra_preslor |

| Force of the lower pad () | |

| Temperature of the lower pad () | sto_templor |

| Flow rate at the upper pad () | tra_flupr |

| Flow rate at the lower pad () | tra_fllor |

| Rotational speed () | tra_sped |

| Motor current | sou_motrelec |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, M.; Santos, I.F.; Zhang, X.; Wu, J.; Lind, M. Explicit Representation of Mechanical Functions for Maintenance Decision Support. Electronics 2023, 12, 4267. https://doi.org/10.3390/electronics12204267

Song M, Santos IF, Zhang X, Wu J, Lind M. Explicit Representation of Mechanical Functions for Maintenance Decision Support. Electronics. 2023; 12(20):4267. https://doi.org/10.3390/electronics12204267

Chicago/Turabian StyleSong, Mengchu, Ilmar F. Santos, Xinxin Zhang, Jing Wu, and Morten Lind. 2023. "Explicit Representation of Mechanical Functions for Maintenance Decision Support" Electronics 12, no. 20: 4267. https://doi.org/10.3390/electronics12204267

APA StyleSong, M., Santos, I. F., Zhang, X., Wu, J., & Lind, M. (2023). Explicit Representation of Mechanical Functions for Maintenance Decision Support. Electronics, 12(20), 4267. https://doi.org/10.3390/electronics12204267