1. Introduction

Due to weather and external factors, aircraft are highly vulnerable to damage during service. Thus, routine damage detection is of great significance to aviation safety [

1]. Both composite and metal materials have played significant roles in aircraft. As the material basis of the key structure in the aircraft, composite materials are accounting for an increasing proportion in aircraft due to their low weight and better specific strength [

2], specific stiffness, and fatigue resistance, and the metal L-shaped structure is still an important part of the aircraft structure. In civil aircraft, composite materials comprise approximately 25% and 12% of Boeing 737 and C919 aircraft, respectively. Composite materials in the military aircraft F-22 account for approximately 24% [

3]. As the earliest structure adopted by modern aircraft, metal materials have high strength and strong reliability. Combined with cost factors, the key structural components that need to bear large loads are still dominated by metal structures, and metal materials are still irreplaceable in structural parts such as body parts, joints and shafts. Composites are usually laminated structures with multiple layers laid on top of each other, and the damage usually occurs inside the structure (desticking or delamination between the layers). Once the damage occurs, the performance of the composite material is significantly reduced, and even leads to the failure of the original function and structure, resulting in flight safety accidents. Although metals are generally highly reliable, internal and external fatigue cracks can still occur in key structural components under heavy loads.

In light of the aforementioned issues, it is imperative to implement a range of detection techniques to identify damage and characterize defects in the crucial components of the aircraft, particularly for those hidden parts within the interior or in confined spaces. Ultrasonic detection is highly suitable for the detection of this type of defect. Ultrasonic detection has a certain level of irreplaceability in NDT, and can detect defects through its penetration characteristics in the interior of the detection object or in locations where the object is difficult to detect. Improvements in ultrasonic defect detection can be achieved through imaging technology, which has advantages in its underlying principles. For instance, the study of inverse scattering has the potential to enhance imaging technology. Mathematical analysis and numerical simulations are determined for object reconstruction using limited data in 2D full rectangular geometry [

4]. Based on fixed transmitter/receiver pair transducers, the use of reflection and transmission observation data for inverse scattering imaging has improved medical ultrasound imaging [

5]. Through these improvements, there may be drawbacks such as the need for the industrial sector to consider costs for large-scale production. Detecting large objects like aircraft and automobiles requires the UT parameters to be adjusted to accommodate their unique acoustic characteristics. In some cases, the probe may need to be replaced entirely, such as when detecting wave-fiber winding structures and CFRP. With the ongoing enhancements to mathematical algorithms and deep learning algorithms, the algorithmic program designed for cost savings exhibits improved compatibility and can be implemented in a range of detection systems. Using artificial intelligence techniques for damage detection holds promise for the future.

The damage detection algorithm uses non-destructive testing technology to detect the tested object, and obtains damage detection images such as the image sequence using the infrared and ultrasonic detection C-scan data. The data format could be a one-dimensional signal, such as THz-TDS signals in terahertz detection [

6]. The damage is identified through the visual analysis method or mathematical analysis method. With the development of artificial intelligence, in the field of nondestructive testing, more deep learning algorithms have been applied to infrared [

7], ultrasonic [

8,

9], eddy current [

10], ray [

11] and other detection methods to achieve automatic and intelligent damage detection. In the UT-related literature, there are several exemplary machine learning techniques that have been applied. With a great deal of research focusing on noise, an ultrasonic detection database was established, encompassing a diverse range of defect types and noise levels, and the classification of noisy ultrasonic signals by CNN was undertaken to enhance the performance and suitability of welding defect classification [

12]. The ultrasound and noise, which were received from the counterbore, planer, and volumetric weldment, were divided in accordance with the autoencoder network [

13]. Well-known methods in the field of linear system transformation and digital signal processing, such as Fourier transform, wavelet transform, and Laplace transform, are also used to process ultrasonic signal recognition. The STFT-CNN method [

14] is employed to measure the thickness of the coating, as well as the bonding state of the coating. The coating’s status is then automatically classified by a CNN. Laser ultrasonic testing is a popular method. Although the laser ultrasonic detection technology has cost limitations, it has certain advantages in terms of resolution and imaging speed [

15,

16]. The laser ultrasonic signals were transformed into scalograms (images) using wavelet transform [

17] and then analyzed using a pretrained CNN to measure the width of defects. Five types of wavelet basis functions, including db4 and morse, were utilized and evaluated. An innovative approach [

18] combining the Laplace transform and the B-spline wavelet on interval (BSWI) finite element method is presented to reduce the element count whilst simultaneously increasing the time integration interval. However, almost all current research on the damage target detection of deep learning algorithms is based on specific detection data with labels obtained by specific detection means. The end-to-end convolutional neural network structure with supervised learning is usually deployed for training and testing, which requires more defect image data as labels for training. These studies additionally demonstrate the requirement for machine learning within the PAUT domain. However, the small number of defect samples has become a difficulty of the defect detection scheme.

The defect recognition of ultrasonic detection data can be regarded as not only a target detection task, but also an anomaly detection task. In other words, unsupervised learning, which identifies data points that are significantly different from normal ultrasonic data or behavior patterns, has high interpretability, but its difficulty lies in the unclear boundary between normal and abnormal situations. Anomaly recognition research is more suitable for the pattern recognition of non-visual tasks, such as fraud detection, financial risk management, etc. A common dataset format for detection realization is also vital. A general anomaly detection dataset should include normal data and abnormal data, and in order to measure whether it is abnormal information, a consistent abnormal data label is required to identify the corresponding abnormal data orientation. To solve this problem, a method that uses the Gaussian Mixture Model (GMM) to learn the normal data distribution is proposed [

19], which solves the problems caused by inaccessible exception labels and inconsistent data types in anomaly detection. An MVTec dataset [

20] consisting of 15 different industrial scenarios is proposed with a clear structure and no complex data format conversion, which is widely used in various tasks related to anomaly detection and optimization [

21]. EfficienctAD [

22] uses lightweight feature extractors and student–teacher methods to train student networks to predict normal image features, and designs student networks with training loss constraints. Reverse distillation [

23] uses a teacher–encoder and student–decoder structure with a student–decoder structure opposite to the teacher–decoder structure to increase the differentiation between abnormal and normal states. A discriminant training method [

24] has been proposed, called DRAEM, with a reconstructed anomaly embedding model that can directly locate anomalies. Instead of requiring additional complex post-processing of the network output, this method is able to be trained using simple and general exceptions. The network learns the joint representation of the abnormal image and its anomaly-free reconstruction while learning the decision boundary between normal and abnormal examples.

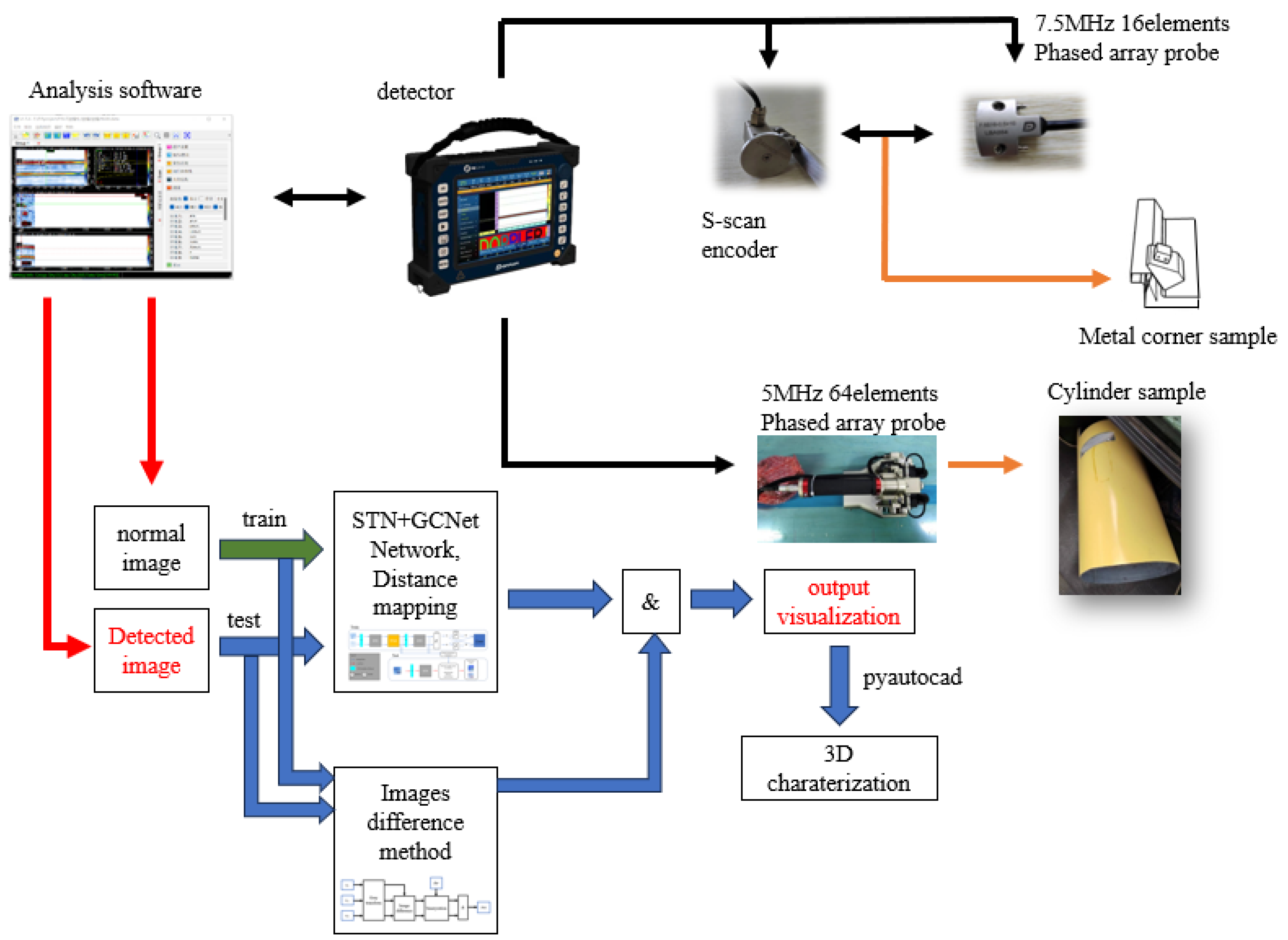

For non-destructive testing, it is urgent to develop a new intelligent testing technology based on fewer samples and no supervision. This paper takes anomaly detection as the starting point in order to solve the defect detection problem in the case of small samples, and to solve the problem of false detection in the phased array S-scan data, relying on an ultrasonic nondestructive testing self-focusing probe, wheel probe, and corresponding encoder (which is totally different from the encoder in the proposed network) to conduct scanning detection. Based on the contrast learning method, intelligent detection technology can solve the problem of defect images caused by few samples. The detection technology only needs to bring normal detection samples into training, without the corresponding defect samples. The contributions of this paper are as follows:

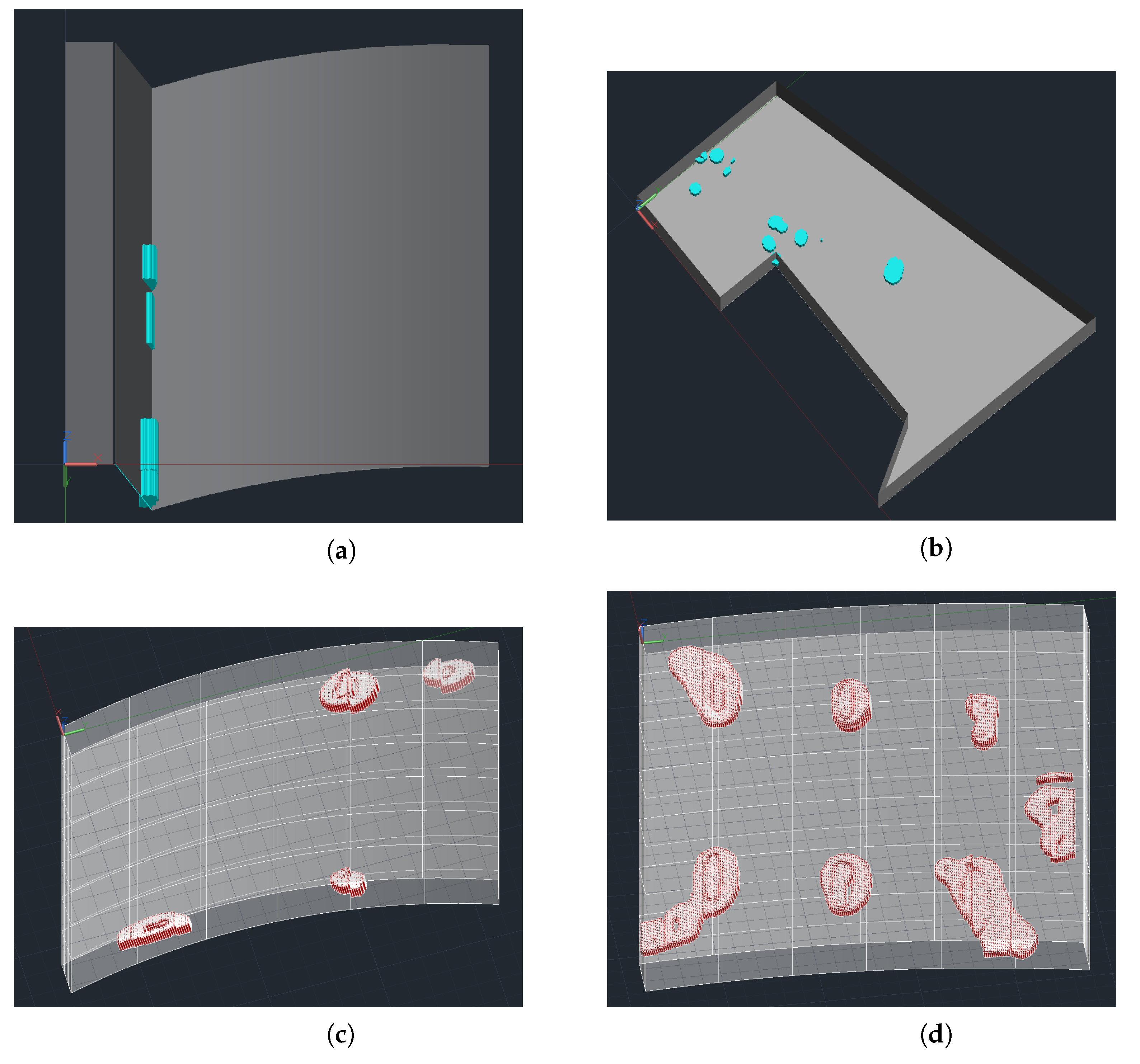

This study realizes defect detection through the supervision of non-defect data with no output label. According to the detection results, three-dimensional defect characterization under several geometric structures is realized through the pyautocad module.

A contrast learning strategy was adopted. The test image and homologous normal detection images under the corresponding detection modes (L-shaped structure or cylinder structure) were provided to obtain the positioning defects through Mahalanobis distance calculation.

Two trainable CNN-based modules, STN and GCnet, were introduced to further enhance the detection and characterization effect of the whole method. The ablation experiment and performance comparison verified the necessity and rationality of the module structure.

The rest of the paper is structured as follows:

Section 2 summarizes the defect detection procedure and proposed method with STN and GCNet block based on PAUT.

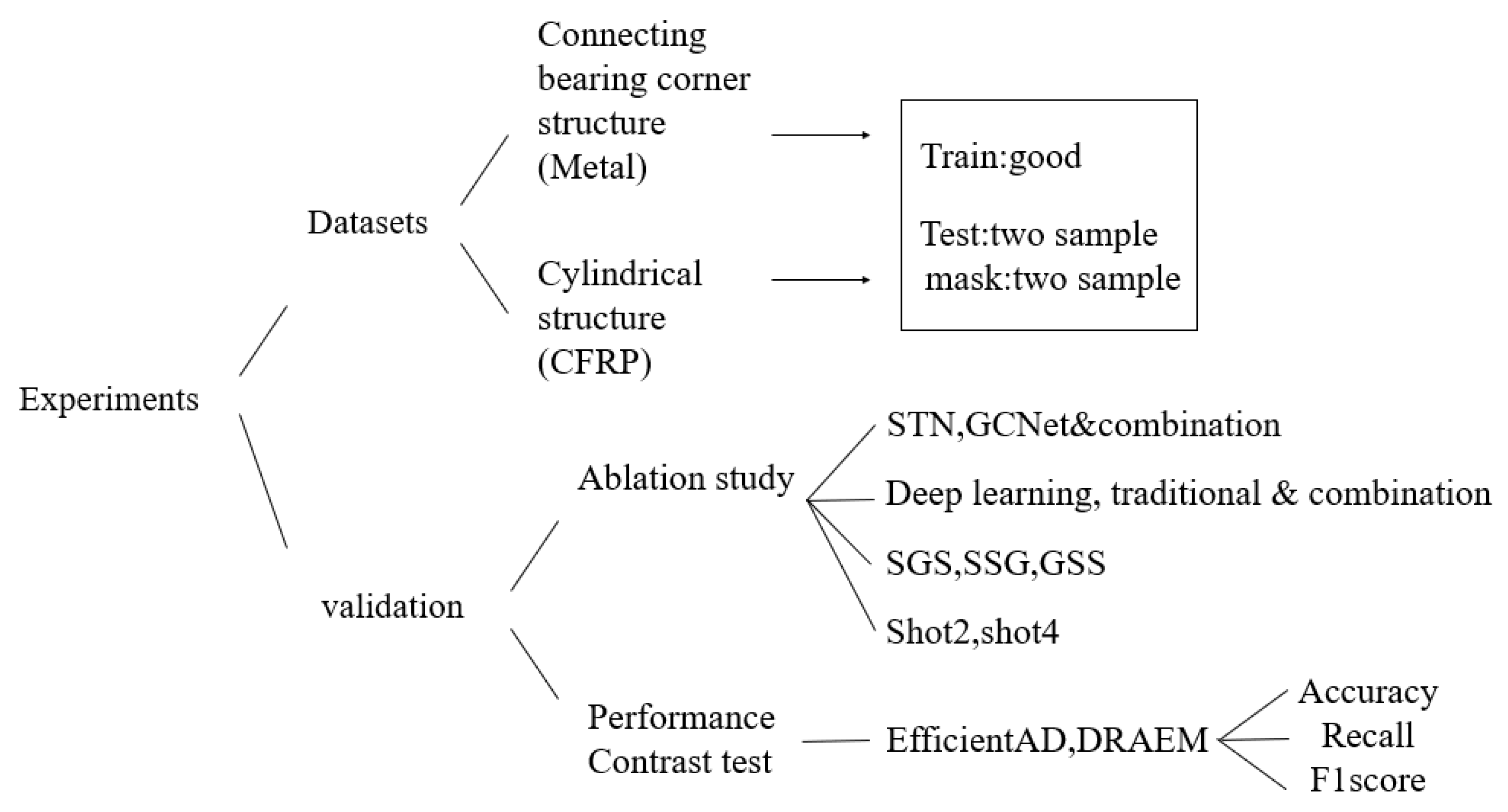

Section 3 introduces the experiments, including an ablation study, a performance comparison of four samples with three other state-of-the-art methods, and 3D characterization.

Section 4 summarizes the research findings and offers future research directions.

2. Proposed Method

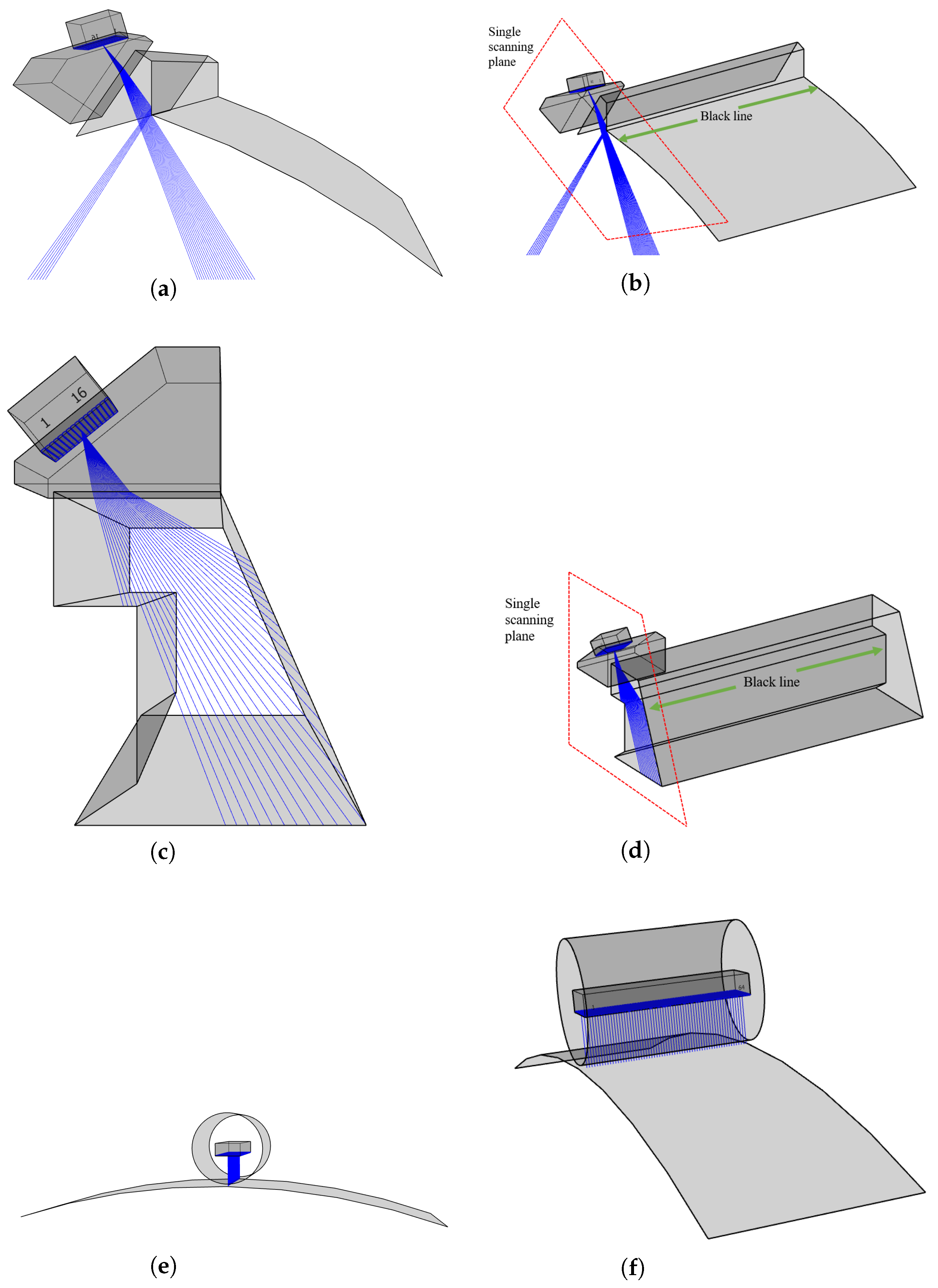

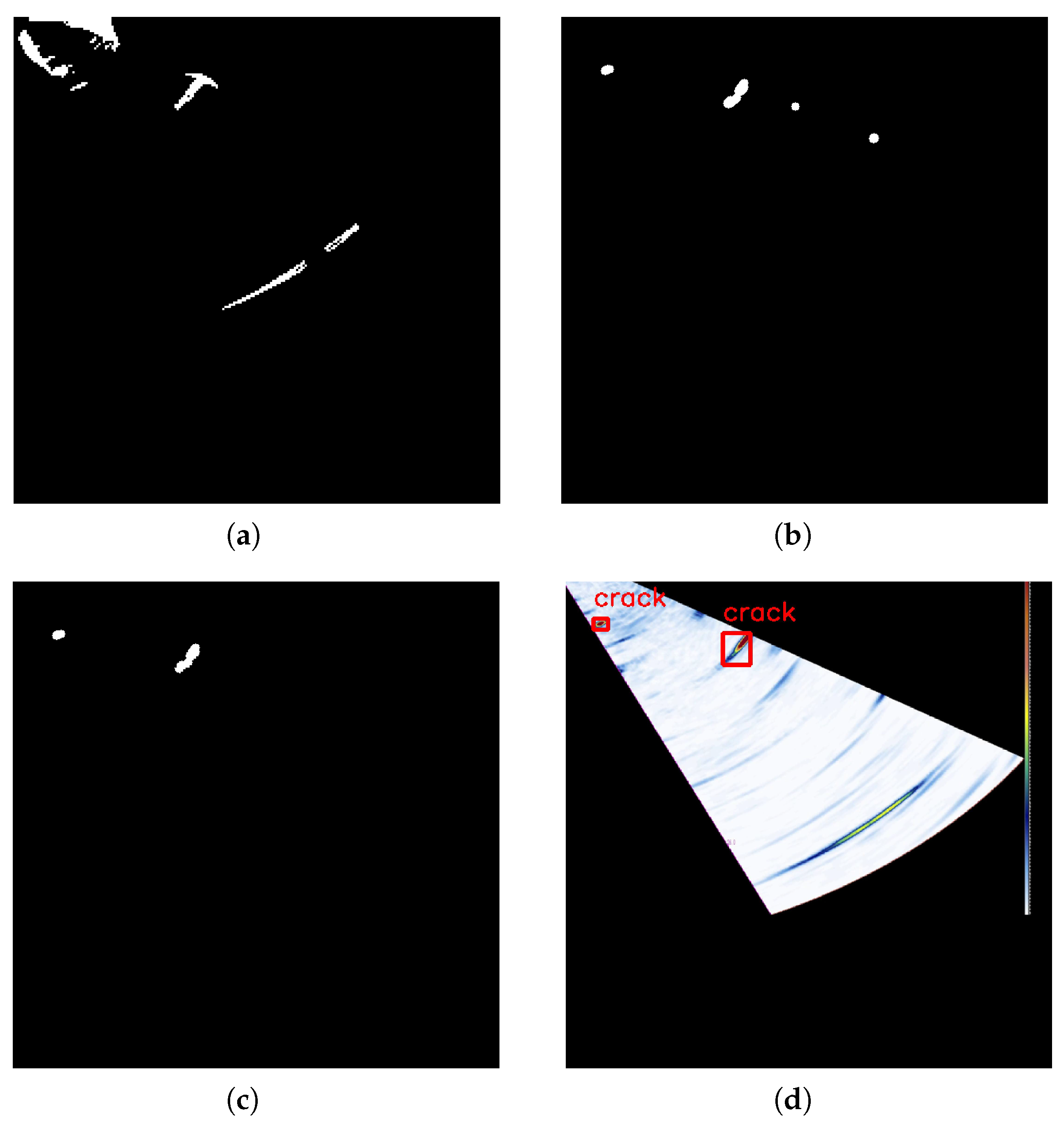

This research focuses on the defect detection and characterization of the L-shaped structure and cylinder structure. A program diagram in pseudo-code was created to clarify the defect detection process of this study. The pseudo-code was developed based on the network after training convergence, with an input of S-scan images corresponding to metal structure detection or C-scan images corresponding to CFRP detection; It represents the image to be detected. The output Ot was segregated into Ot1 for image difference output and Ot2 for Mahalanobis distance calculation based on contrast learning. Mid means the intermediate components in programs or mathematical operations. Mid5t means the final intermediate input by the test image, and then Mid5t is used for the distance calculation. In [B,C,H,W], B, C, H, and W represent the batch size, channel, height, and width of the variable. T relates to the transposition of one matrix. There are also some functions in the pseudo-code; difference(*), STN+GCNet(*), unfold(*), concat(*), fold(*), covariance(*), inverse matrix(*), and sqrt(*) represent the image difference method mentioned in the paper, intermediate characteristic quantity of the contrast learning network, tensor expansion operation, tensor concatenation operation, tensor folding operation, covariance matrix, inverse matrix, and root square value, respectively. The training of the corresponding network will be discussed further in relation to the contrast learning network. After the network is introduced, two improved CNN-based modules will be explained.

Section 2.2 accounts for the distance map calculation, aimed at defect visualization.

Section 3.4 will introduce the three-dimensional characterization. In the L-shaped structure task, the traditional method is used, while in the cylinder structure task, only the contrast learning network is used to extract the features for detection.

2.1. Feature Extraction Method

2.1.1. Dual-Normal Detection Image Difference Method

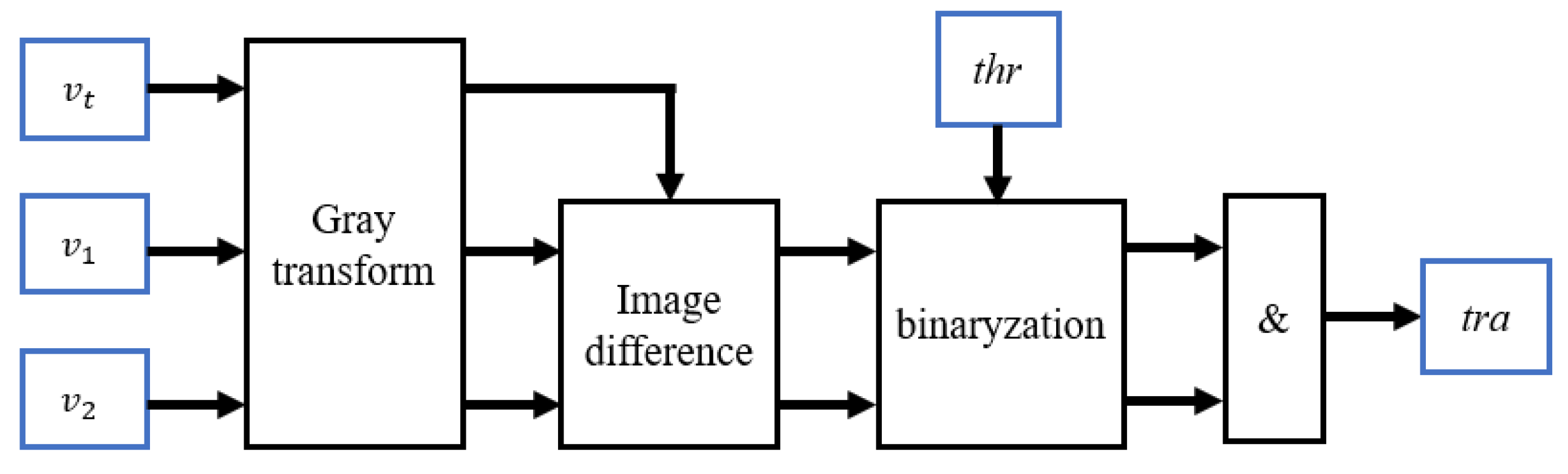

The simple and practical traditional method of defect detection should not be abandoned entirely. Traditional defect detection methods are introduced, including image difference and binarization processing. Three images are input, including two images with randomly selected normal testing results from normal ultrasonic detection datasets, and one image of ultrasonic data to be detected, and the image difference method is carried out after gray-scale transformation. While

,

is the output result, the mathematical expression of threshold processing is shown in Equation (

1), and the dual-normal detection image processing method adopted in this study is shown in Equation (

2).

is the threshold.

v represents a kind of image.

and

are two randomly selected images of the normal state, and

is the test image to be detected. After the image difference method, two feature tensors with the same dimensions as the image gray-scale transformation are output. The same threshold is set for binary processing. The output image is obtained by the Hadamard product of two image dimension variables.

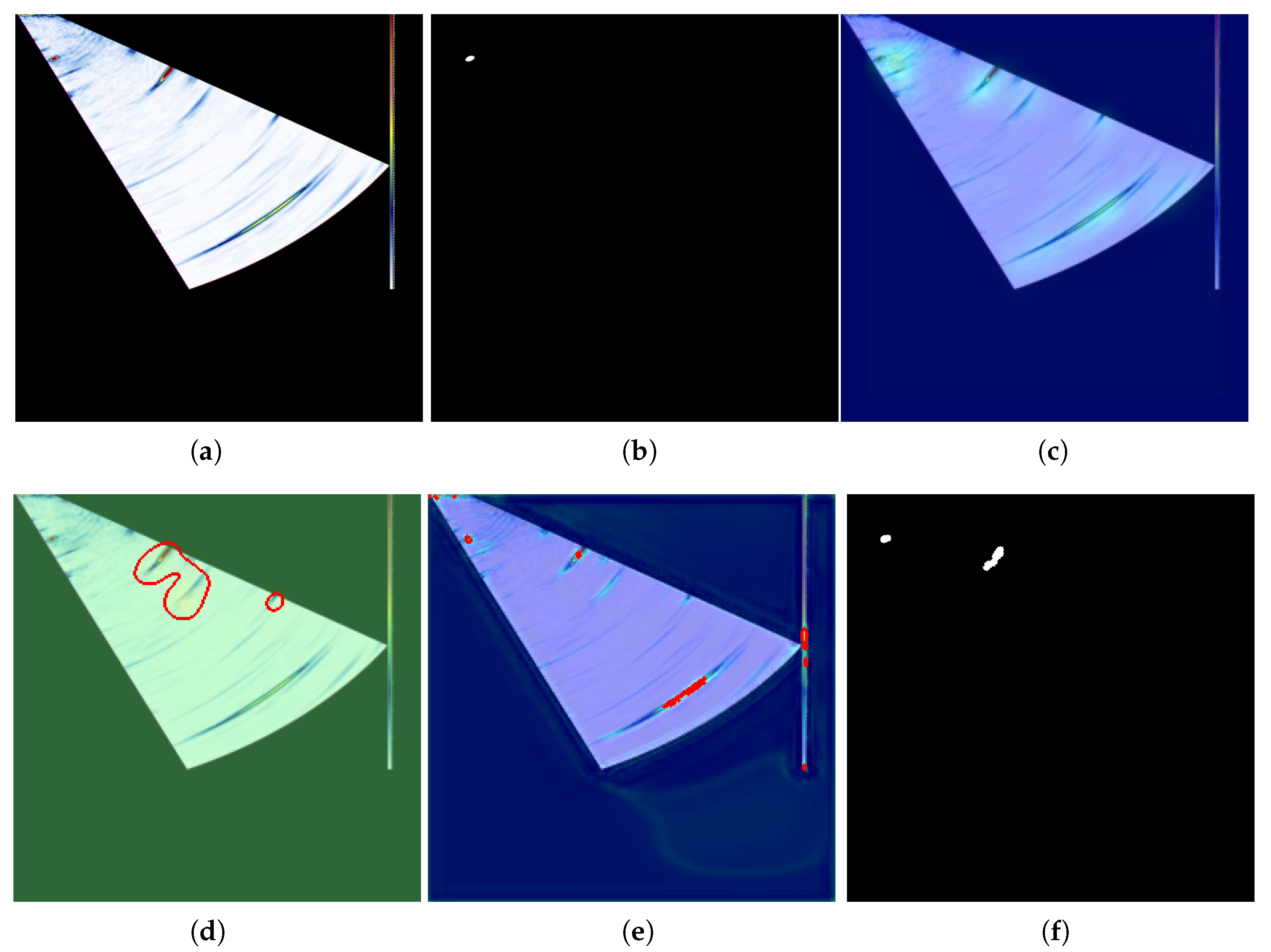

Figure 1 depicts this improved difference calculation process. In this paper, the traditional method is combined with the contrast learning network to improve the defect detection effect of the S-scan data, and only the contrast learning method is used for the cylinder structure.

2.1.2. Contrast Learning Network Method

The normal sample’s common characteristics are identified through contrast learning. Accordingly, defects are located and detected by measuring the distance.

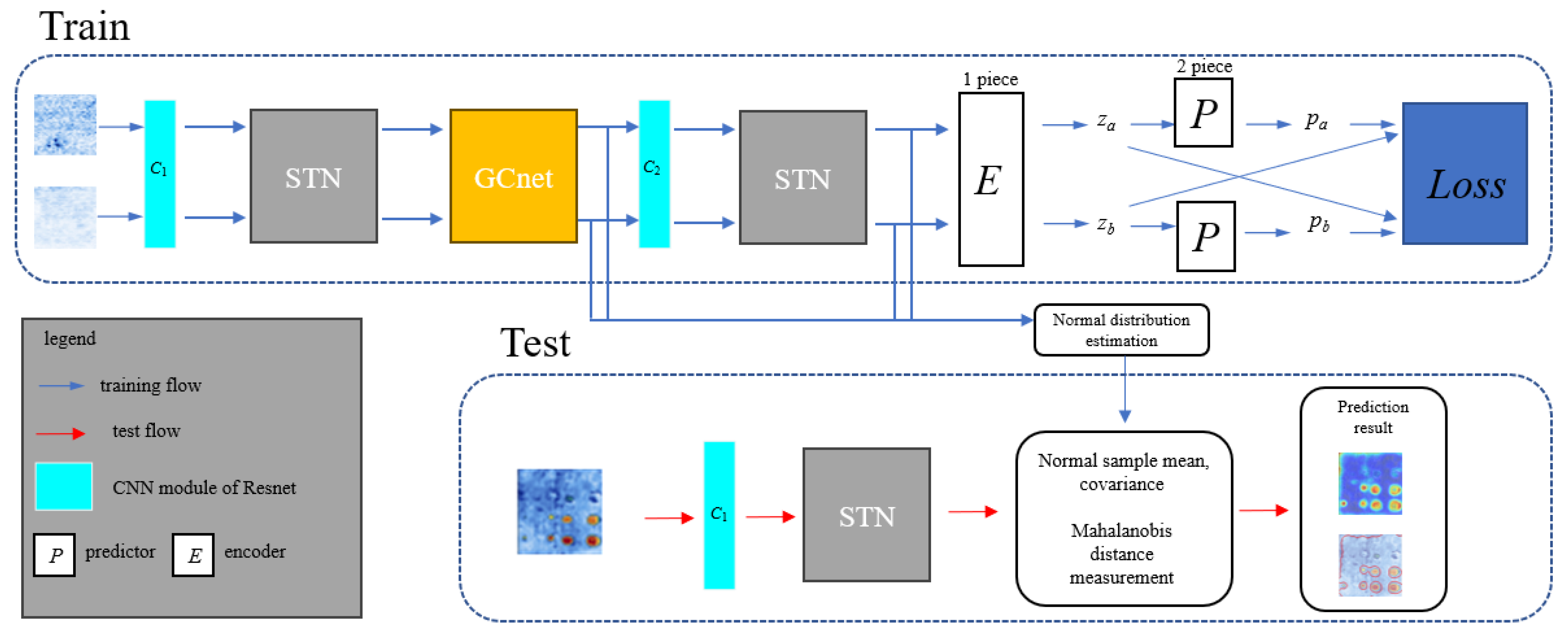

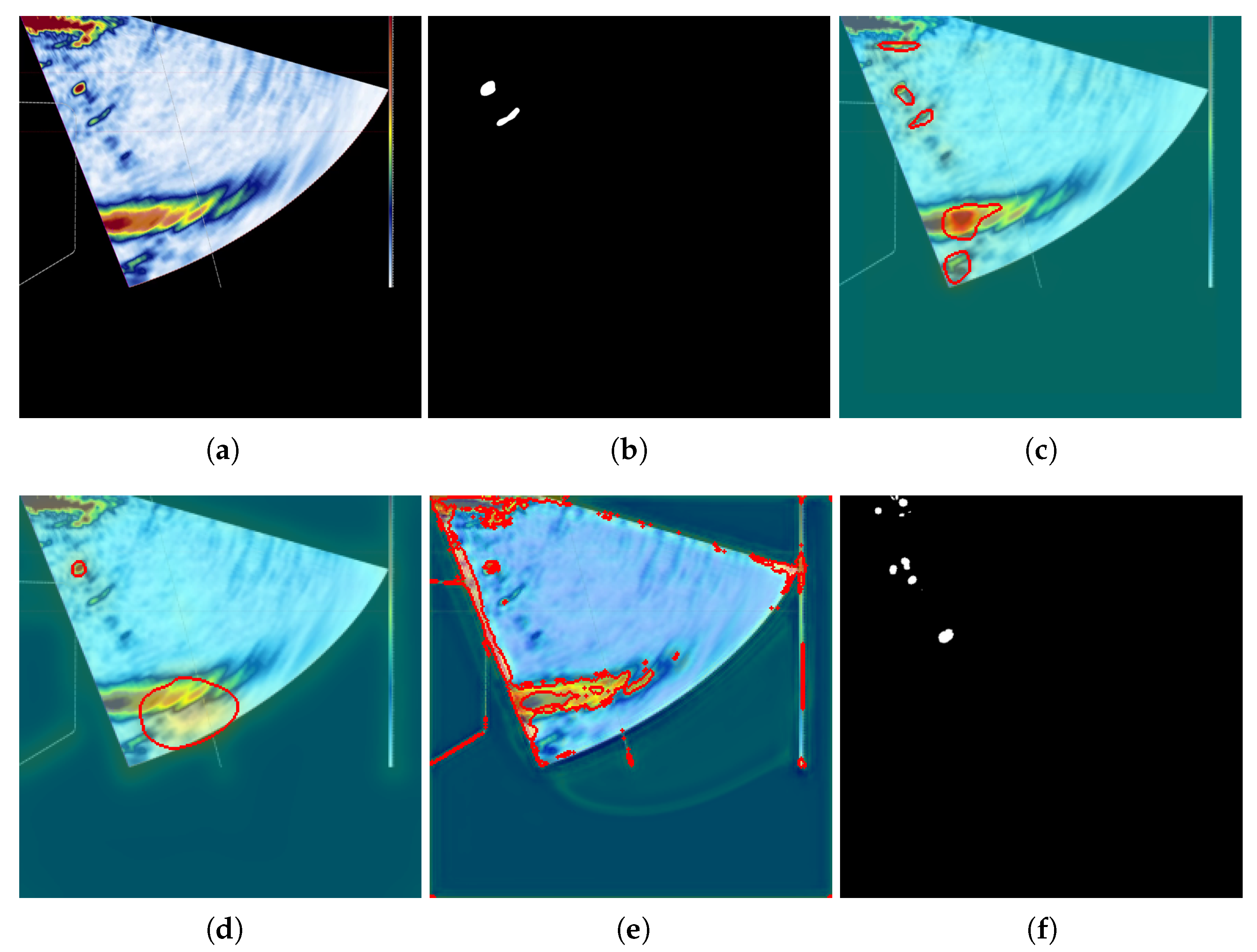

Figure 2 illustrates the proposed network’s overall structure for contrast learning and distance map calculation. The purpose of establishing the contrast learning network is to utilize the pretraining network and the enhanced feature extraction ability of the network after the STN module and GCNet module. In

Figure 2, the corresponding normal detection C-scan data of the plane plate are taken as the input and output legend, and the network relies on the Resnet18 pretrained structure. The last convolutional block in the original design of ResNet is removed, the STN module and GCNet module are incorporated into the pretrained Resnet18 structure, and the encoder and predictor are inserted into the tail end of the pretrained structure. The encoder is mainly composed of convolution, batch regularization, and relu modules, which are seen as one piece in

Figure 2, and the encoder and predictor are composed of one and two pieces, respectively. The intermediate layer of batch regularization applied to the neural network replaces the dropout structure of the original pretrained structure and accelerates the training process. The dimensionality of the feature map is unchanged after passing through the encoder and predictor. The specific steps of data forwarding are as follows: the normal image set is input to the network in the form of random normal image pairs, and the network output is based on the function of cosine loss to make the network converge. There are some differences between network training and testing. After training, the network can retain the mapping synthesis feature information of normal samples, and a limited number of images that identify defects can be entered into the network to extract the abnormal features of the defects. Then, the defects can be located and segmented through distance graph calculation, as described in

Section 2.2.

and

are the output vectors of the encoder corresponding to the two input images, and

and

are the output vectors of the predictor head corresponding to the two input images. Cosine loss is calculated based on these vector features, as shown in Equation (

4). Cosine loss, when formulated as given in Equation (

3), has the distance measurement property, and the loss function established on this basis can make the network converge to form the ability to extract common features.

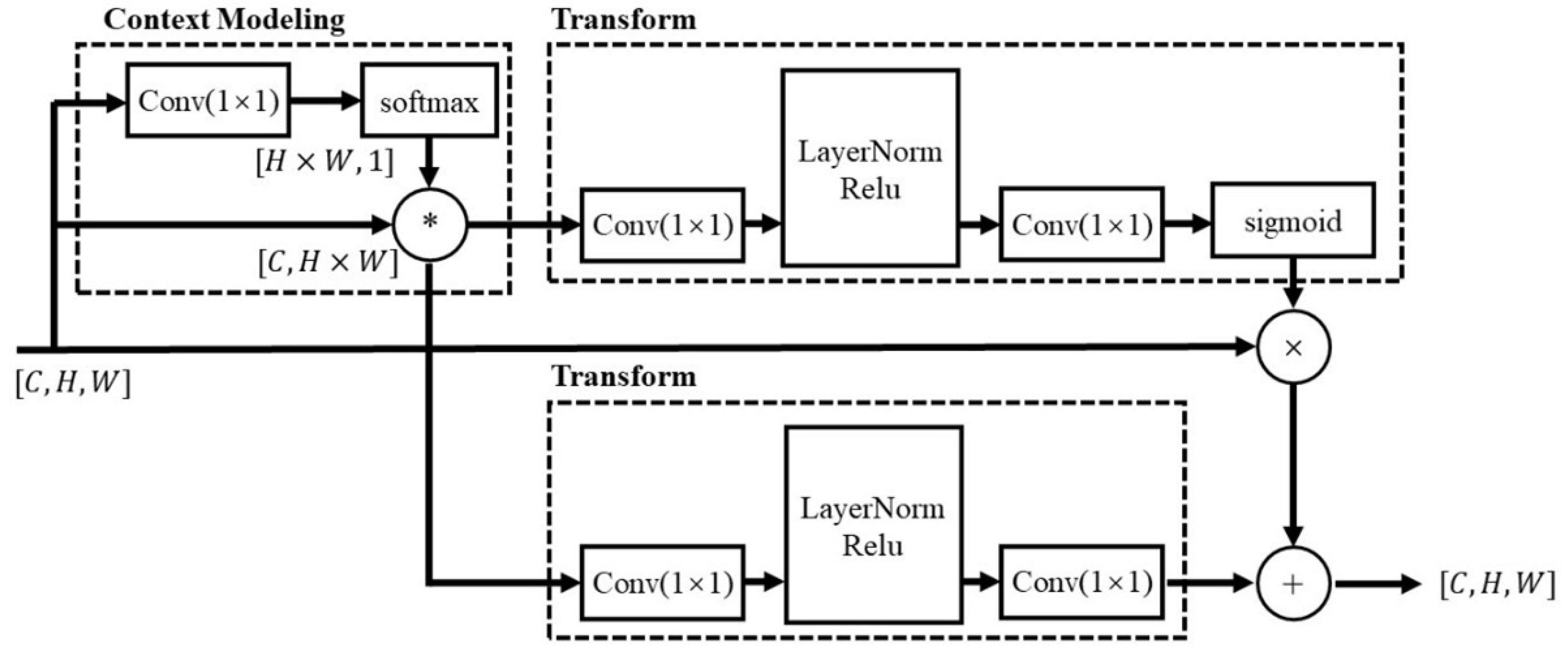

2.1.3. GCNet Block

GCNet is a convolutional network structure [

25,

26]. Due to the distance between the input and output dimensions, this structure can easily be combined with visual tasks to improve subjective and objective performance. This network structure combines the advantages of both SENet and NLNet. It can not only use the global context modeling capability of NLNet [

27], but can also be as lightweight as SENet [

28]. In other words, the addition of GCNet will not hinder the training and testing of the original network structure. The dimension transformation relationship of the structure diagram and feature diagram is shown in

Figure 3, which can be expressed by the mathematical relationship of Equations (

5) and (

6).

In Equation (

6),

and

represents the input and output of GCNet, respectively,

is the

convolution for

, and

represents the weight of the global attention pool. exp() relates to the exponential operation in the softmax calculation.

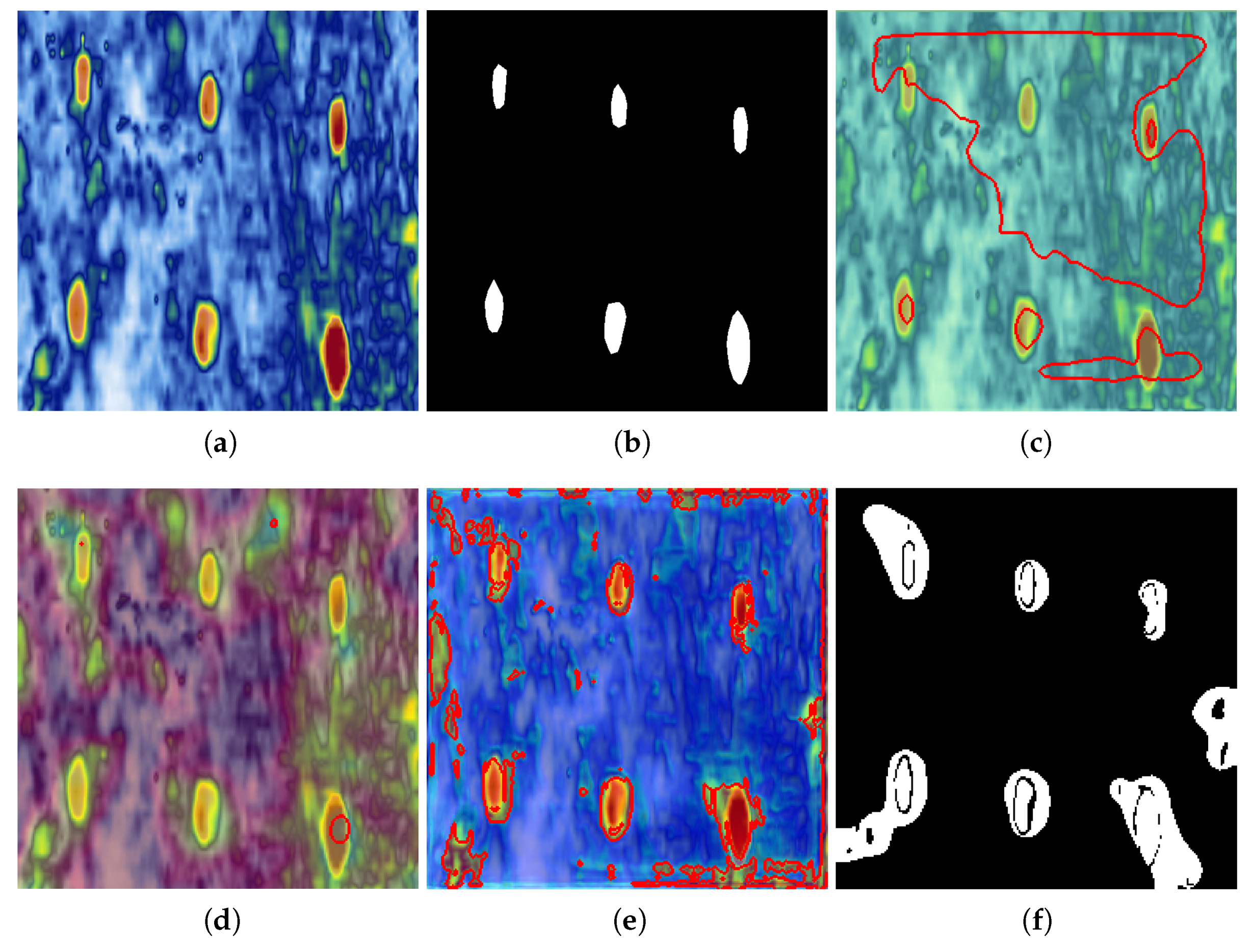

is reshaped to the tensor dimension by (C, H × W). After the synthesis by one output channel convolution of the input feature map, the tensor becomes (1, H × W). Then, the weight of each position in the (1, H × W) tensor is reflected through softmax, and the global attention weight is obtained by the matrix product with each channel input of the original input feature map. In other words, as shown by the output of context modeling in

Figure 3, the weight of global attention mainly reflects the importance of the location, and the determination of defects in the S-scan detection data is also related to the channel characteristics of image data. The GCNet structure extracts channel characteristics through bottleneck transformation, that is, the ‘transform’ given in bold font in

Figure 3. In Equation (

5),

, the bottleneck transformation is structurally similar to the autoencoder structure, and both of them have the same characteristics of small middle feature dimensions, the difference being that the dimension reduced by the bottleneck transformation is the channel dimension. In this study, two sets of bottleneck transforms are used and the sigmoid module is added to one of them. By reducing the convolution of feature map channels and the convolution of channel number reduction, a new feature map is obtained by dot multiplication and added to the original feature map. The feature map introduces the spatial channel feature information of the original feature map in a lightweight network way.

2.1.4. Spatial Transformer Network

The STN structure is based on affine transformation [

29]. In terms of results, affine transformations have the same effect as common data augmentation, such as translation, scaling, rotation, and flipping. However, data augmentation focuses on the random transformation, which will boost the generalization performance in the training process. The affine transformation describes the image data transformation with a unified expression, which has a clear expression, and has the feasibility of integrating with the network structure compared with the data enhancement.

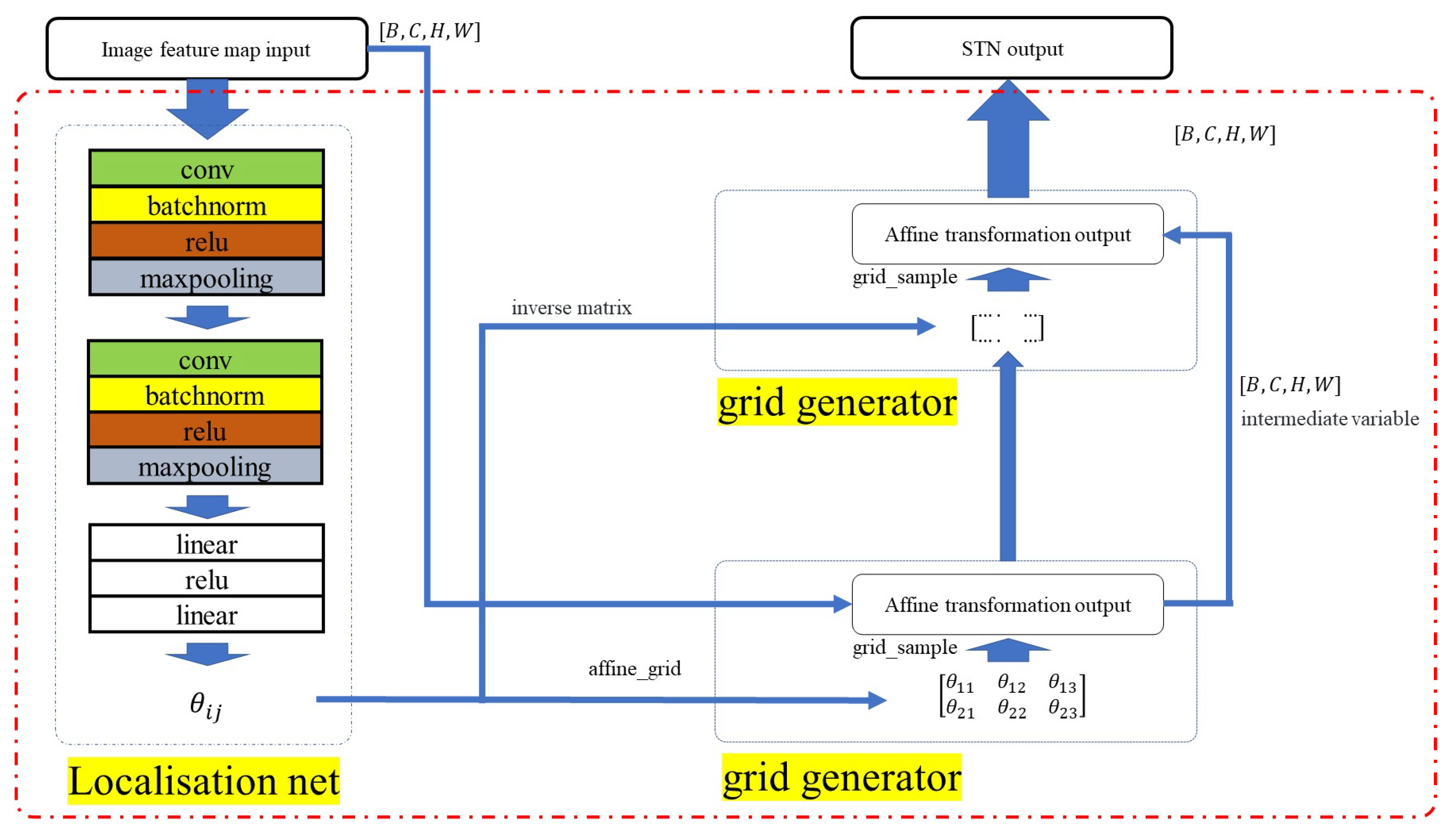

The STN structure introduces spatial geometric transformations such as translation, scaling, and rotation into the convolutional network structure. In this study, the introduction of the STN structure can better perceive the internal public features of input data, which is conducive to the natural wave extraction of S-scan detection data. The structure diagram of STN is shown in

Figure 4. The specific structure of the network in the red box has something in common with GCNet: the consistency of the input and output dimensions. The structure in

Figure 4 is divided into two parts according to the original paper [

24]: the localization net and grid generator. The localization net consists of a trainable convolution network and linear connection layer, including batchnorm2d, relu and maxpooling layers and a linear connection layer. The linear connection layer consists of a linear layer and relu layer. The network outputs six parameters, set as

, which is connected to the grid generator.

constructs the affine transformation matrix, referred to as

a in Equation (

7), according to affine transformation method.

A and

depict the pixel value mapping process according to the affine transformation matrix

a and

. The pixel coordinate relationship corresponding to the affine transformation can be represented by Equations (

8) and (

9).

Equation (

7) expresses the coordinate correspondence before and after the affine transformation of the image, that is, the pixel value of the original image before the affine transformation determines the pixel position according to its pixel position and the affine transformation matrix.

,

,

, and

correspond to the image rotation transformation parameters in the affine transformation.

and

correspond to the image translation parameters,

represent the transformed coordinates, and

represent the coordinates before transformation.

According to the position correspondence relationship in the affine transformation represented by this affine transform matrix, bilinear interpolation is used to solve the decimal problem in the calculation of pixel coordinates, and on this basis, the pixel value filling of the image after affine transformation is completed. In order to retain the characteristics of the image and avoid the obvious discontinuity at the boundary after filling, the reflection filling is adopted. When interpolating the boundaries of an image feature tensor, it fills the edge values of the image or tensor into the extended region in a mirror image. The input of the grid generator at the second layer is composed of the inverse matrix of the affine transformation parameter matrix and the output image feature of the affine transformation at the first layer, and the pixel value after the second layer’s affine transform is filled in the same way. The final output of the STN module is provided by the second layer affine transform output image feature.

2.2. Defect Map Calculation

According to the defect-free normal detection image set composed of different normal images, considering the relatively small amount of data in the training stage and in order to reduce the loss of information in the network, two output points are set on the network. The feature map of the two output points is synthesized (

10). The

function corresponds to lines 3 through 9 of the pseudo-code in Algorithm 1. The mean and covariance characteristic quantities are called the normal distribution parameters, and the distance we need is calculated using Equation (

11).

| Algorithm 1 Pseudocode for defect detection of PAUT using improved contrast learning |

Input It(S-scan or C-scan data detected image) with shape [B,C,H,W],In(N normal images randomly selected by normal image set) with shape [B,C,H,W] Output Ot(An image of the same size as the input image) with shape [B,C,H,W],Ot1 produced by dual-normal detection images difference meth,Ot2 produced by deep learning network.

- 1:

Ot1 = difference(It,In) ▹ only for L-shaped and inner structure - 2:

(xn and yn,xt and yt) = STN+GCNet(In,It) - 3:

- 4:

Mid1 (shape:[B,C1,H*W/(16*16)]) = unfold(x,kernel size=4,stride=4) - 5:

Mid1 reshape to Mid2(shape:[B,C2,C1/C2,H/16,W/16]) - 6:

y (shape:[B,Cy,H/16,W/16]) repeats C1/C2 times to Mid3 (shape:[B,Cy,C1/C2,H/16,W/16]) - 7:

Mid4 = concat(Mid2,Mid3) (Mid4 shape:[B,C3,C1/C2,H/16,W/16]) (Mid2(x),Mid3(y):synthesise two output points(xn and yn,xt and yt) by STN+GCNet) - 8:

Mid4 reshape to Mid5(Mid5 shape:[B,C3*C1/C2,H/16,W/16]) - 9:

Mid5 = fold(Mid4,kernelsize=4) and reshape to[B,C3,H*W/(4*4)] - 10:

- 11:

Mn = mean() - 12:

for

to

do - 13:

Cov[:,:,i] = Covariance(In1[:,:,i].T) - 14:

end - 15:

for

to

do - 16:

Cov1[:,:,i] = Inverse matrix(Cov[:,:,i]) - 17:

distance[i,:] = sqrt[(Mid5t-Mn[:,:,i]).T*Cov1[:,:,i]*(Mid5t-Mn[:,:,i])] - 18:

end - 19:

distance reshape to [B,H/4,W/4] interpolate to [B,H,W],Ot2

|

In Equation (

10),

T represents the transpose,

represents the feature vector after the image passes through the network,

is the mean value of the vector, and the subscript m,n maps the corresponding position of the original size map.

is the corresponding covariance matrix. The mean and covariance values provided relate to the computation of the mean and covariance shown in the latter portion, from line 11 to line 19 in pseudo-code Algorithm 1. The diagonal element of the covariance image matrix represents the difference between pixel values and at corresponding positions of the input image, and the non-diagonal element represents the correlation between different pixel values. Therefore, it can be seen that the average value and covariance feature map can represent the main features of the images in the normal detection image set without defects. According to the network loss function, the feature quantity between the normal detection images is relatively close. When the abnormal detection image is input into the network, the vector data with large difference from the normal feature quantity will be obtained at the two output points, that is, the abnormal detection image will be far away from the normal distribution of the normal distribution parameters at the corresponding position of the defect. In this paper, Mahalanobis distance is applied to calculate the image point by point, and the threshold processing is used to help locate the defects. D represents the defect’s distance measurement, which measures the possibility between defect or normal situation, and Mahalanobis distance is calculated according to Equation (

9). The larger the D value of a certain position, the higher probability of defects exists at that position.

4. Discussion and Conclusions

In this paper, two common aircraft structures, namely the CFRP cylinder plate and metal corner bearing structure, are studied using ultrasonic detection result recognition. The contrast learning model with pretrained weights is applied to the defect identification of ultrasonic detection data, and the STN and GCNet structures are used to further enhance the feature extraction ability. In the actual phased array ultrasonic detection process, the defect judgment of the phased array S-scan data image usually only focuses on the specified area. For example, within a certain gate range, as long as the echo occurs at a specified position within the gate range, it can be identified as a defect. This method is applied to a new sample, based on finished acoustic analysis. However, this method focuses on covering the global scope of the S-scan image in the absence of acoustic analysis. Any anomalies in the range of the S-scan image will be identified as defects. This method only needs to detect the image normally to provide the structure’s natural wave information, and the size and range of the natural wave usually fluctuate during the scanning process, so it is difficult to determine the defects through a simple image difference method. The experimental results show that the combination of the image difference method and contrast learning model is more suitable than using only one method to solve the problem of the difficult identification of S-scan image defects, and has surpassed some state-of-the-art methods in the AD field. On the basis of the wheel probe, the data format of surface plate defect identification is not vastly different from that of the panel parts, and can be identified directly through the contrast learning network. There are also some limitations of the work presented in this paper. More threshold processing is used in the testing process, which is unfavorable for the overall generalization performance of the method.