Power Transformer Fault Diagnosis Based on Improved BP Neural Network

Abstract

:1. Introduction

2. Transformer Fault Analysis and Detection

2.1. Common Faults of Transformers

2.1.1. Electrical Fault

2.1.2. Thermal Failure

2.2. Dissolved Gas Analysis in Oil

2.2.1. Principle of Dissolved Gas Generation in Power Transformers

- (a)

- Decomposition of insulating oil

- (b)

- Decomposition of solid insulating materials

- (c)

- Other sources

2.2.2. Gas Generation in Transformer Oil

- (a)

- Judge according to gas concentration

- (a)

- Judge according to the gas production rate

2.2.3. Dissolved Gas Composition in Oil

2.2.4. Dissolution of Gases

2.3. Transformer Fault Diagnosis Method

2.3.1. Traditional Transformer Fault Diagnosis Method

- (a)

- Characteristic gas method

- (b)

- Ratio method

- 1.

- IEC triple-ratio method

- 2.

- No coding ratio method

2.3.2. Intelligent Diagnosis Method

3. Model Construction Based on Improved BP Neural Network

3.1. SVM Classifier

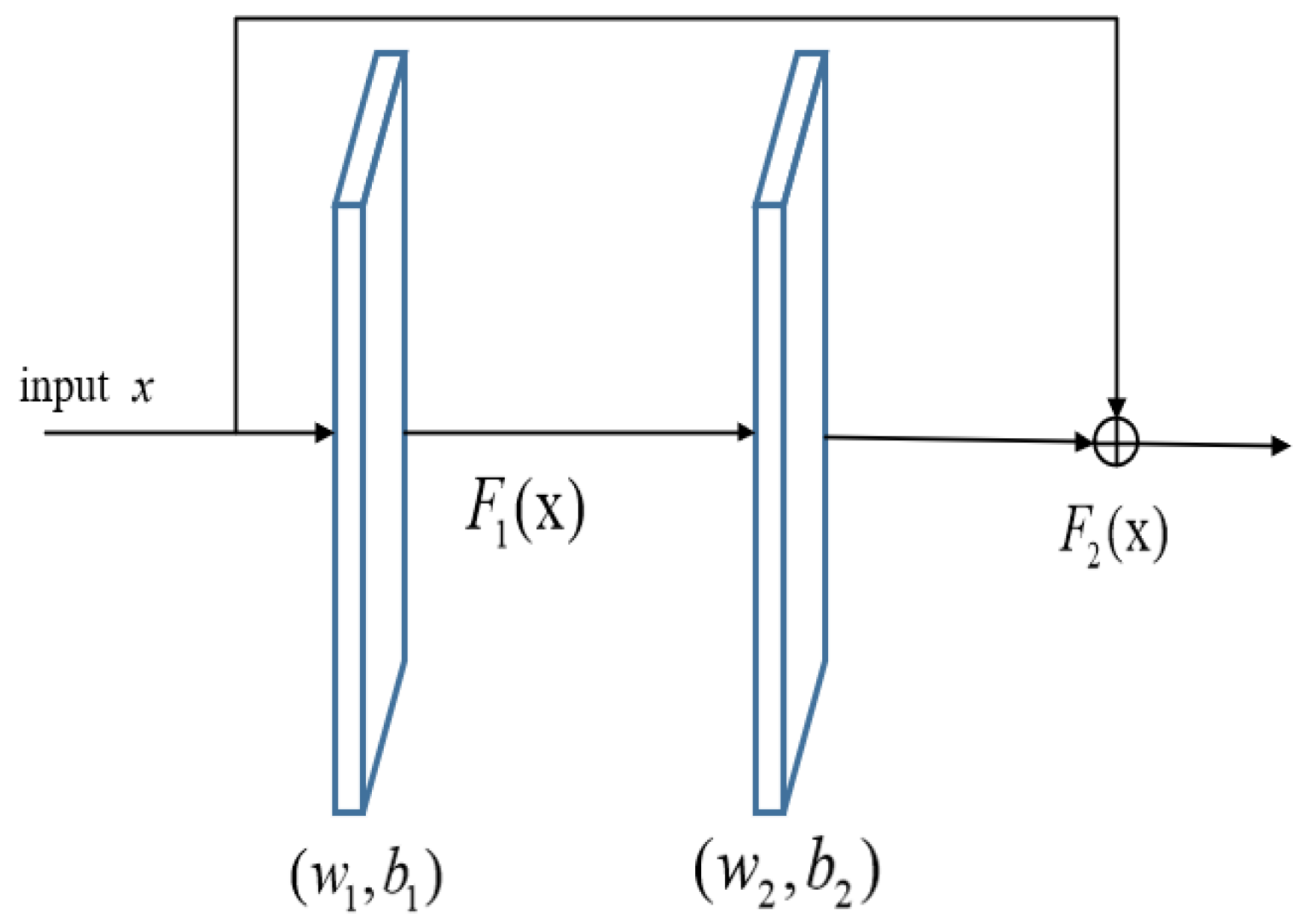

3.2. Residual Network Module

3.3. Improved Model Structure of BP Neural Network

- (a)

- The output of the jth neuron of the l layer of the hidden layer is

- (b)

- Extract the feature vectors , of module V and module VI. and their corresponding category labels in the improved BP neural network to form a new training set , .

- (c)

- Use the new training set formed in step (b) to train the models TSVM1 and TSVM2 respectively, and the trained models are SVM1 and SVM2.

- (d)

- Input the validation set data into the network to extract the feature vectors and of the V. residual module and . residuals respectively, and then use SVM1 and SVM2 to diagnose the feature vectors and , respectively, and output the corresponding accuracy and .

- (e)

- If , calculate the weights of the eigenvectors according to Equation (15).

- (f)

- Update the feature vectors and of modules V and in step (b) to and , according to the new weights and obtained in step (e).

- (g)

- According to the expected output of the i-group sample of the output layer, the calculation error is ; see Equation (16).

4. Transformer Fault Diagnosis Based on Improved BP Neural Network

4.1. Fault Feature Selection

4.2. Data Normalization

4.3. Fault Type Code

4.4. Filter Training Samples

- (a)

- Euler distance is a commonly used metric to calculate the natural length between vectors and is calculated as follows:

- (b)

- The Pearson coefficient is a morphologically similar quantity, which solves the problem that the covariance is affected by dimensions. Its value range is [0,2], and the calculation formula is as follows:

4.5. Data Sampling Block

4.6. Distributed Training

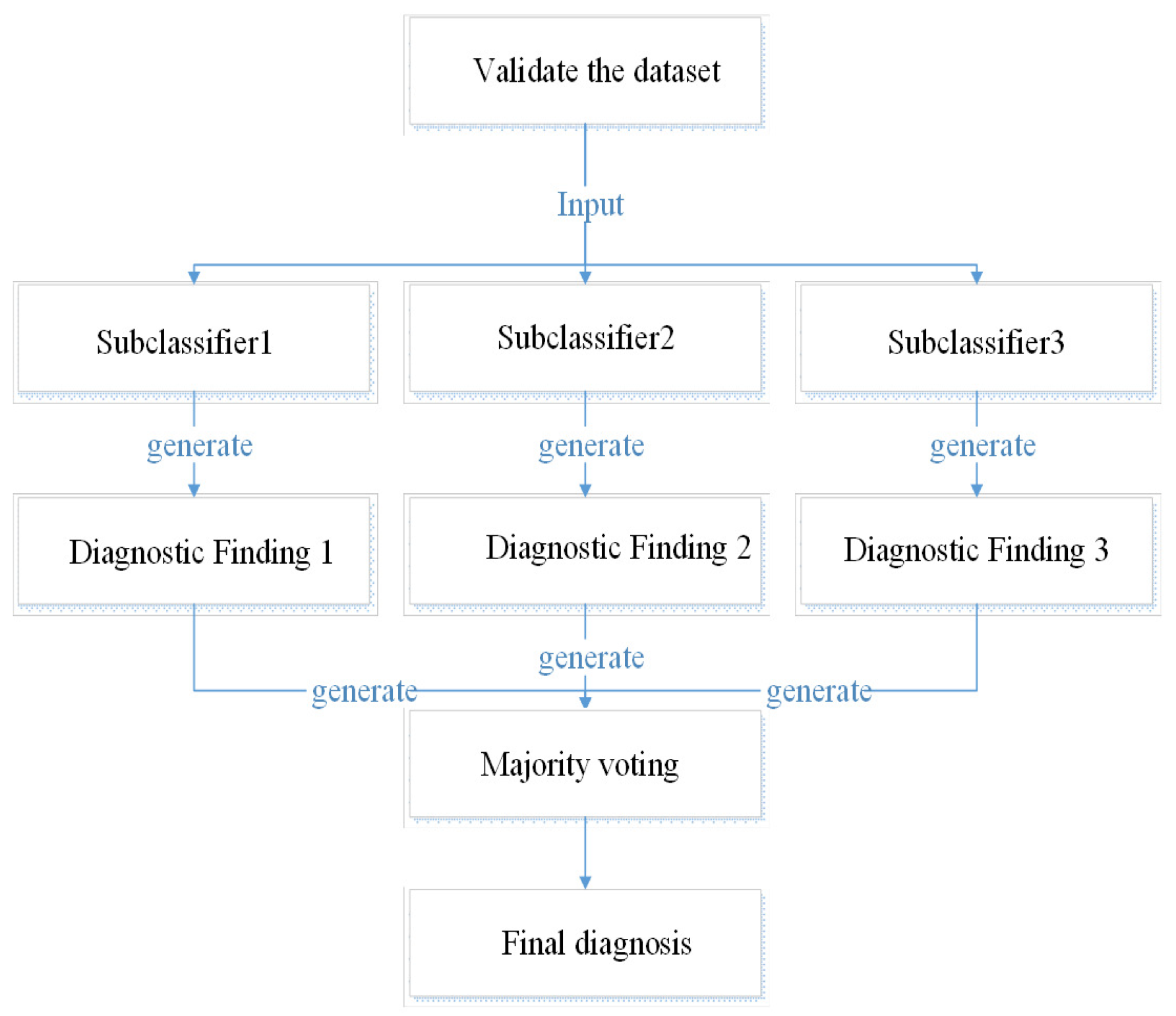

4.7. Model Diagnosis

5. Experimental Testing and Analysis

5.1. Data Sample Selection and Preprocessing

5.2. Analysis of Transformer Fault Diagnosis Results

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BP | Back Propagation |

| DGA | Dissolved Gas Analysis |

| SVM | Support Vector Machine |

| IEC | International Electrotechnical Commission |

| Bi-LSTM | Bi-directional Long Short-Term Memory |

References

- Equbal, M.; Khan, S.A.; Islam, T. Transformer incipient fault diagnosis on the basis of energy-weighted DGA using an artificial neural network. Turk. J. Electr. Eng. Comput. 2018, 26, 77–88. [Google Scholar] [CrossRef]

- Wang, D.; Lei, Q. Fault diagnosis of power transformer based on BR-DBN. Electr. Power Autom. Equip. 2018, 38, 129–135. [Google Scholar]

- Maofa, G.; Yanni, L.; Laihe, W.; Baoye, S.; Wenqiang, Z. Fault diagnosis of power transformers based on chaos particle swarm optimization BP neural network. Electr. Meas. Instrum. 2016, 53, 13–16. [Google Scholar]

- Feng, Z.; Shuo, L. Fault Diagnosis of Traction Transformer Based on DGA and Improved Association Degree Model. High Volt. Appar. 2015, 51, 41–45. [Google Scholar]

- Zhang, W.; Yuan, J.; Zhang, T.; Zhang, K. An improved three-ratio method for transformer fault diagnosis using B-spline theory. Proc. CSEE 2014, 34, 4129–4136. [Google Scholar]

- Yang, X.; Chen, W.; Li, A.; Yang, C.; Xie, Z.; Dong, H. BA-PNN-based methods for power transformer fault diagnosis. Adv. Eng. Inform. 2019, 39, 178–185. [Google Scholar] [CrossRef]

- Weihua, Z.; Jinsha, Y.; Shan, W. A caculation method for transformer fault basic probability assignment based on improved three-ratio method. Power Syst. Prot. Control 2015, 43, 115–121. [Google Scholar]

- Li, Y.; Shu, N. Transformer fault diagnosis based on fuzzy clustering and complete binary tree support vector machine. Trans. China Electrotech. Soc. 2016, 31, 64–70. [Google Scholar]

- Kari, T.; Gao, W.; Zhao, D.; Abiderexiti, K.; Mo, W.; Wang, Y.; Luan, L. Hybrid feature selection approach for power transformer fault diagnosis based on support vector machine and genetic algorithm. IET Gener. Transm. Distrib. 2018, 12, 5672–5680. [Google Scholar] [CrossRef]

- Yuan, F.; Guo, J.; Xiao, Z. A transformer fault diagnosis model based on chemical reaction optimization and twin support vector machine. Energies 2019, 12, 960. [Google Scholar] [CrossRef]

- Xiao, Y.; Pan, W.; Guo, X.; Bi, S.; Lin, S. Fault Diagnosis of Traction Transformer Based on Bayesian Network. Energies 2020, 13, 4966. [Google Scholar] [CrossRef]

- Zeng, B.; Guo, J.; Zhu, W.; Xiao, Z.; Yuan, F.; Huang, S. A Transformer Fault Diagnosis Model Based On Hybrid Grey Wolf Optimizer and LS-SVM. Energies 2019, 12, 4170. [Google Scholar] [CrossRef]

- Yang, Z. “Guidelines for Dissolved Gas Analysis and Fault Diagnosis of Transformers”—A Discussion on Transformer Fault Diagnosis. Transformer 2008, 45, 24–27. [Google Scholar]

- Zhu, Y.; Yin, J. Study on application of multi-kernel learning relevance vector machines in fault diagnosis of power transformers. IEEE Inst. Electr. Electron. Eng. 2013, 33, 68–74. [Google Scholar]

- Hanbo, Z.; Wei, W.; Xiaogang, L.; Linan, W.; Yuquan, L.; Jinhua, H. Fault diagnosis method of power transformers using multi-class LS-SVM and improved PSO. High Volt. Eng. 2014, 40, 3424–3429. [Google Scholar]

- Shijun, H.; Ju, Z.; Jigui, M. Fault Diagnosis of Transformer Based on Particle Swarm Optimization-Based Support Vector Machine. Electr. Meas. Instrum. 2014, 51, 71–75. [Google Scholar]

- Ali, M.S.; Abu Bakar, A.H.; Omar, A.; Abdul Jaafar, A.S.; Mohamed, S.H. Conventional methods of dissolved gas analysis using oil-immersed power transformer for fault diagnosis: A review. Electr. Power Syst. Res. 2023, 216, 109064. [Google Scholar] [CrossRef]

- Taha, I.; Hoballah, A.; Ghoneim, S. Optimal Ratio Limits of Rogers’ Four-Ratios and IEC 60599 Code Methods Using Particle Swarm Optimization Fuzzy- Logic Approach. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 222–230. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, H.; Liu, S. Research on Digital Twin Modeling Technology for Transformer Protection. Power Syst. Technol. 2022, 46, 4982–4992. [Google Scholar]

- Yuan, J.; Xu, P.; Li, L. Prediction of transformer oil- paper insulation aging based on BP neural networks with the chicken swarm optimization algorithm. J. Electr. Power Sci. Technol. 2020, 35, 33–41. [Google Scholar]

- Wang, B.; Yang, Y.; Zhang, S. Fault diagnosis of support vector machine transformer based on improved BP neural network. Electr. Meas. Instrum. 2019, 56, 53–58. [Google Scholar]

- Li, P.; Hu, G. Transformer fault diagnosis method based on the fusion of improved neural network and ratio method. High Volt. Eng. 2022, 7, 1–9. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, B.; Cao, W. Application of locust optimized neural network in transformer fault diagnosis. Power Syst. Clean Energy 2021, 37, 17–23. [Google Scholar]

- Xian, R.; Fan, H.; Li, F. Power Transformer Fault Diagnosis Based on Improved GSA-SVM Model. Smart Power 2022, 50, 50–56. [Google Scholar]

- Xiong, Y.; Liao, X.; Ke, F. Life cycle cost analysis of main transformer based on the multi-system data fusion. J. Electr. Power Sci. Technol. 2020, 35, 3–11. [Google Scholar]

- Fu, H.; Ren, R.; Yan, Z.; Ma, Y. Fault Diagnosis Method of Power Transformers Using Multi-kernel RVM and QPSO. Gaoya Dianqi/High Volt. Appar. 2017, 53, 131–135+141. [Google Scholar]

- Song, Z.J.; Wang, J. Transformer Fault Diagnosis Based on BP Neural Network Optimized by Fuzzy Clustering and LM Algorithm. High Volt. Appar. 2013, 49, 54–59. [Google Scholar]

- Li, X.; Chen, Z.; Fan, X. Fault Diagnosis of Transformer Based on BP Neural Network and ACS-SA. High Volt. Appar. 2018, 54, 134–139+146. [Google Scholar]

- Yuan, P.; Mao, J.; Xiao, F. Grid Fault Diagnosis Based on Improved Genetic Optimization BP Neural Network. J. Electr. Power Syst. Autom. 2017, 29, 118–122. [Google Scholar]

- Wu, R.; Li, C. Design of Transformer Fault Intelligent Diagnosis System. In Proceedings of the 2021 International Conference on Networking Systems of AI (INSAI), Shanghai, China, 19–20 November 2021; pp. 293–296. [Google Scholar] [CrossRef]

- Zhao, W. Study for Transformer Fault Diagnosis and Forecast Based on Data Mining. Master’s Thesis, North China Electric Power University, Beijing, China, 2009. [Google Scholar]

- Huang, Y.; Huang, S. Condition Maintenance of Power Generation Equipment; China Power Press: Beijing, China, 2000. [Google Scholar]

- Du, J. Transformer Fault Diagnosis Expert System. Master’s Thesis, North China Electric Power University, Beijing, China, 2003. [Google Scholar]

- Crowley, T.H.; Hagman, W.H.; Tabors, R.D.; Cooke, C.M. Expert system for on-line monitoring of large power transformers. Expert Syst. Appl. Electr. Power Ind. 1990, 1, 629–660. [Google Scholar]

- Yin, J. Research on Fault Diagnosis Method of Oil-immersed Power Transformers Based on Correlation Vector Machine. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2013. [Google Scholar]

- Liu, C.; Wu, J.; Gao, Y. Transformer Fault Diagnosis Based on BP Neural Network and Bee Colony Algorithm. Industrialization 2020, 10, 7–11. [Google Scholar]

- Fu, B.; Wng, Q. Transformer fault diagnosis based on adaptive Particle swarm optimization BP neural network. J. Huaqiao Univ. 2013, 34, 262–266. [Google Scholar]

- Han, Q. Research on Transformer Fault Diagnosis Based on the Optimization of BP Neural Network Using the Bouguebird Algorithm. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2019. [Google Scholar]

- Zeng, Z.; Zhang, H.; Yang, T.; Zeng, X.; Zeng, C. Power transformer incipient fault diagnosis based on neural network optimized by combined ant colony optimization. Electrotech. Appl. 2019, 38, 43–49. [Google Scholar]

| Fault Type | Cause |

|---|---|

| Low-temperature overheating (≤300 ) | The output of the transformer exceeds the rated value, causing the core temperature to rise rapidly; The transformer cooling device does not work properly; The ambient temperature rises or the ambient temperature around the transformer rises, or the environment around the transformer is not conducive to heat dissipation. |

| Medium- temperature overheating (300 –700 ) | Medium-temperature overheating (300 –700 ) |

| High-temperature overheating (>700 ) | Insufficient pressure of electric shock; There is an oil sludge film between the dynamic and static contacts; Burns on the contact surface; Mechanical damage to insulation during manufacturing; Insulation aging or debris in the oil, blocking the oil passage and causing high-temperature damage to the insulation; Through-the-loop short-circuit fault joint heat, due to the insulation damage of the pressure ring screw or the pressure ring contact touching the iron core. Due to the circulating current, magnetic leakage makes the iron parts eddy current larger. |

| Partial discharge | The air humidity around the transformer is too large, and the insulation of some areas of the transformer body is not strong enough, or the transformer insulation is damaged during installation, resulting in partial discharge of the transformer; The oil level of the transformer drops, causing the live parts inside the transformer to not be covered by the insulating oil, resulting in partial discharge of the transformer. |

| Low-energy discharge | There are more impurities in oil-immersed transformer oil that cause low-energy discharge; The metal parts inside the transformer are disconnected due to poor manufacturing, transportation, installation technology, etc., and the levitation potential causes low-energy discharge. |

| High-energy discharge | Coil-to-turn insulation breakdown; Overvoltage causes internal flashover; arcing caused by lead breakage; Tap changer arcing and capacitive screen breakdown. |

| Gas Composition | Ethylene | Ethane | Acetylene | Methane | Total Hydrocarbons | |

|---|---|---|---|---|---|---|

| Critical value | 150 | 65 | 35 | 5 | 45 | 150 |

| Gas Composition | Closed (mL/d) | Open (mL/d) |

|---|---|---|

| Total hydrocarbons | 12 | 6 |

| Acetylene | 0.2 | 0.1 |

| Fault Type | Main Ingredients | Minor Gas Components |

|---|---|---|

| The insulating oil is overheated | , | , |

| Teinsulatin Oylis Ofheited | , , | , , |

| Insulating oil and paper arc discharge | , , , | , , |

| Arc discharge in insulating oil | , , | , |

| Akdi Shegin in Suratingil | , , | , , |

| Low energy discharge in insulating oil | , |

| Standard | Temperature | |||||||

|---|---|---|---|---|---|---|---|---|

| GB/T17623.1998 | 50 | 0.06 | 0.12 | 0.92 | 0.39 | 1.02 | 1.46 | 2.3 |

| IEC60599.1999 | 50 | 0.05 | 0.12 | 1 | 0.4 | 0.9 | 1.4 | 1.8 |

| Serial Number | Nature of the Failure | Characteristic Gas Characteristics |

|---|---|---|

| 1 | General overheating failure | Total hydrocarbons are too high, < 5 L/L |

| 2 | Severity overheating failure | high total hydrocarbons > 5 L/L, However, did not constitute the main component of total hydrocarbons, and the content was high |

| 3 | Partial discharge | Total hydrocarbons are not high, >100 L/L, This accounts for the main component of total hydrocarbons |

| 4 | Patialdi | Total hydrocarbons are not high, > 10 L/L, Totahid Rocabens–Anotte Sea |

| 5 | Arcing | The total hydrocarbon content is high, the content is high, and the content is high, but it is not the main component |

| Gas Ratio Range | Ratio Encoding Range | ||

|---|---|---|---|

| / | / | ||

| <0.1 | 0 | 1 | 0 |

| ≥0.1∼<1 | 1 | 0 | 0 |

| ≥1∼<3 | 1 | 2 | 1 |

| ≥3 | 2 | 2 | 2 |

| Nature of the Failure | Typical Example | |||

|---|---|---|---|---|

| Low-temperature overheating (<300 ) | <0.1 | Independent | <1 | The winding oil passage is blocked, and the iron core is short-circuited |

| Medium-temperature overheating | <0.1 | Independent | 1<ratio<3 | Tap changer lead connector contact |

| (300–700 ) | Poor, iron core multi-point grounding bureau | |||

| High-temperature overheating (>) | <0.1 | Independent | >3 | Local short circuit |

| High-energy discharge | 0.1 < ratio < 3 | <1 | Independent | Short-circuit circumference between winding turns and cake rooms, screen discharge, load tap and switch |

| High-energy discharge and overheating | 0.1 < ratio < 3 | >1 | Independent | The selector switch cuts off the current |

| Low-energy discharge | >3 | <1 | Independent | Fence dendritic discharge, tap |

| Low-energy discharge and overheating | >3 | >1 | Independent | The switch is misaligned, and the selector switch is not in place |

| Algorithm | Peculiarity |

|---|---|

| Characteristic gas method | This can visually determine whether there is a latent fault, but cannot determine the type and status of the fault |

| Ratio method | Simple and convenient, but the encoding will be missing, and the coding information corresponding to the fault state cannot be found |

| Fuzzy theory | This can better deal with the uncertainty and ambiguity between fault types and symptoms, but can determine the membership function based on experience. Rhere is more human intervention, and there is a lack of a convincing objective basis |

| Expert system | A large amount of experimental data and monitoring information can be comprehensively evaluated and analyzed, but expert knowledge is difficult to express in rules, and the reasoning of expert systems has some uncertainties |

| Support vector machine | This is mainly used for binary classification problems, and is not effective for multi-classification problems |

| BP neural network | There is a clear input–output relationship, and it has a good effect in multi-classification |

| Transformer Status | Encode |

|---|---|

| normal | (1,0,0,0,0,0) |

| Low-energy discharge | (0,1,0.0.0.0) |

| High-energy discharge | (0,0,1,0.0.0) |

| Medium- and low-temperature overheating | (0,0,0,1,0,0) |

| High-temperature overheating | (0,0,0,0,1,0) |

| Partial discharge | (0,0,0,0.0,1) |

| Model | SVM | Residual Network Module | Precision/% |

|---|---|---|---|

| BP neural network | × | × | 87.2 |

| ✓ | × | 91.3 | |

| × | ✓ | 89.8 | |

| ✓ | ✓ | 92.7 |

| Model | Test Set Diagnostic Accuracy/% | Average Diagnostic Accuracy/% | ||

|---|---|---|---|---|

| Improved residual BP neural network | 91.52 | 92.26 | 93.75 | 92.51 |

| Traditional shallow BP neural networks | 87.94 | 88.69 | 90.18 | 89.94 |

| Traditional deep BP neural networks | 86.16 | 86.90 | 87.50 | 86.85 |

| Model | Test Set Diagnostic Accuracy/% | Average Diagnostic Accuracy/% | ||

|---|---|---|---|---|

| Improved residual BP neural network | 91.07 | 90.18 | 89.88 | 90.38 |

| Traditional shallow BP neural networks | 85.71 | 84.82 | 83.33 | 84.62 |

| Traditional deep BP neural networks | 83.93 | 83.03 | 82.74 | 83.23 |

| Serial Number | Gas Content/(L/L) | The Actual Failure Type | Predict the Result (Ours) | IEC_60599 | Duval Triangle | Rogers Methods | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 14.67 | 3.68 | 10.54 | 2.71 | 0.2 | normal | ||||

| 2 | 27 | 90 | 42 | 63 | 0.2 | Medium and low temperature overheating | ||||

| 3 | 73 | 12.3 | 3.33 | 27.1 | 47.9 | Partial discharge | ||||

| 4 | 135 | 466 | 70 | 502 | 9 | High temperature overheating | ||||

| 5 | 119 | 25 | 12 | 55 | 84 | High energy discharge | ||||

| 6 | 80 | 20 | 6 | 20 | 62 | Low energy discharge | ||||

| Algorithm | Correct Rate (%) |

|---|---|

| SVM | 85 |

| Bi-LSTM | 89 |

| Traditional BP neural network | 87 |

| Our method | 92 |

| Algorithm | Model Diagnostic Accuracy (\%) | Average Percentage (%) | |

|---|---|---|---|

| Dataset Is Error-Free | Dataset Error | ||

| SVM | 85 | 73 | 12 |

| Bi-LSTM | 89 | 72 | 17 |

| Traditional BP neural network | 87 | 71 | 16 |

| Our method | 92 | 86 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Wu, H.; Zheng, J.; Zhang, J.; Liu, Z. Power Transformer Fault Diagnosis Based on Improved BP Neural Network. Electronics 2023, 12, 3526. https://doi.org/10.3390/electronics12163526

Jin Y, Wu H, Zheng J, Zhang J, Liu Z. Power Transformer Fault Diagnosis Based on Improved BP Neural Network. Electronics. 2023; 12(16):3526. https://doi.org/10.3390/electronics12163526

Chicago/Turabian StyleJin, Yongshuang, Hang Wu, Jianfeng Zheng, Ji Zhang, and Zhi Liu. 2023. "Power Transformer Fault Diagnosis Based on Improved BP Neural Network" Electronics 12, no. 16: 3526. https://doi.org/10.3390/electronics12163526

APA StyleJin, Y., Wu, H., Zheng, J., Zhang, J., & Liu, Z. (2023). Power Transformer Fault Diagnosis Based on Improved BP Neural Network. Electronics, 12(16), 3526. https://doi.org/10.3390/electronics12163526