Adaptive Quantization Range Division Technique for Electronic Control Data Compression in CNC Machine Tools

Abstract

1. Introduction

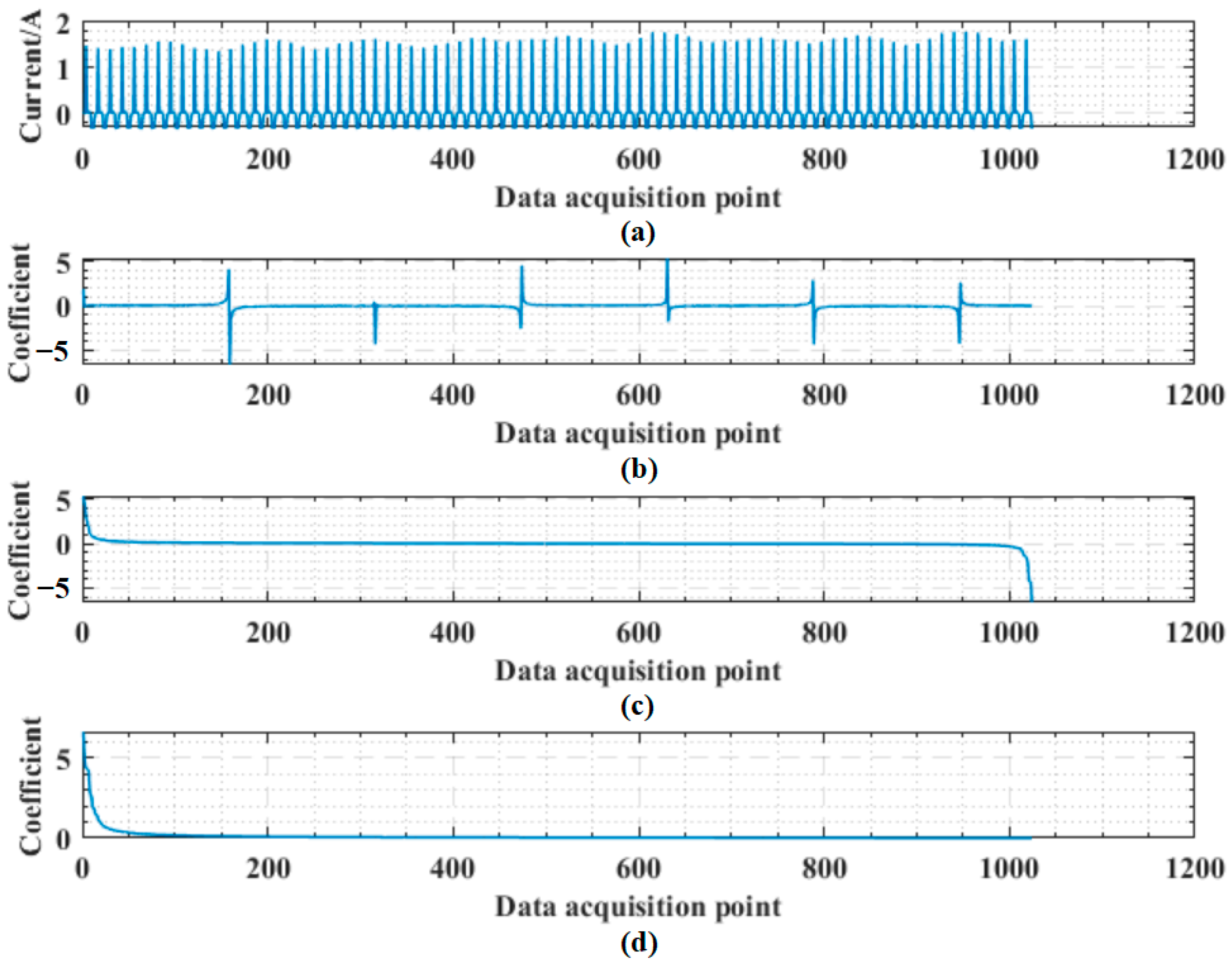

1.1. Background and Motivation

1.2. Contribution

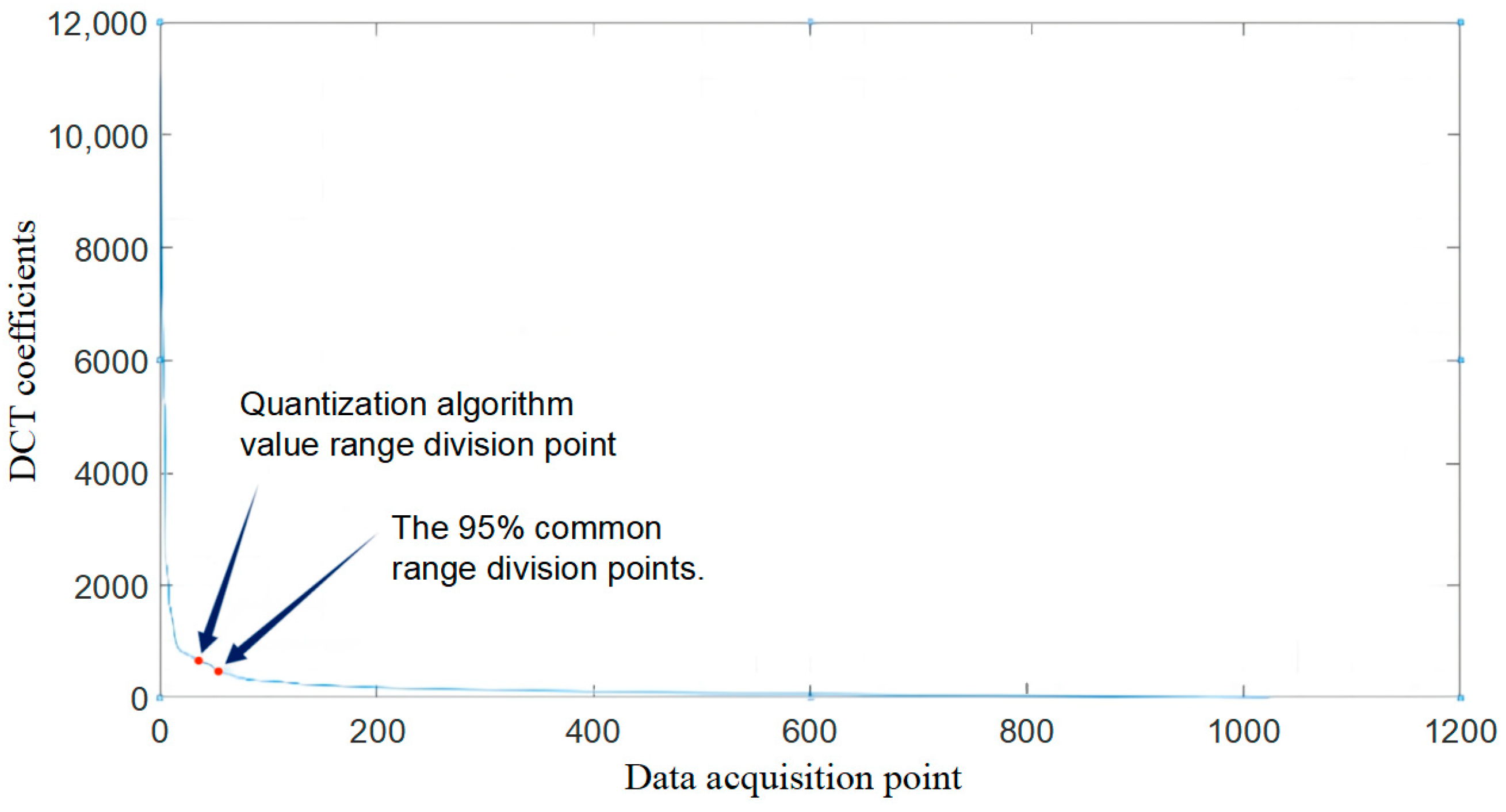

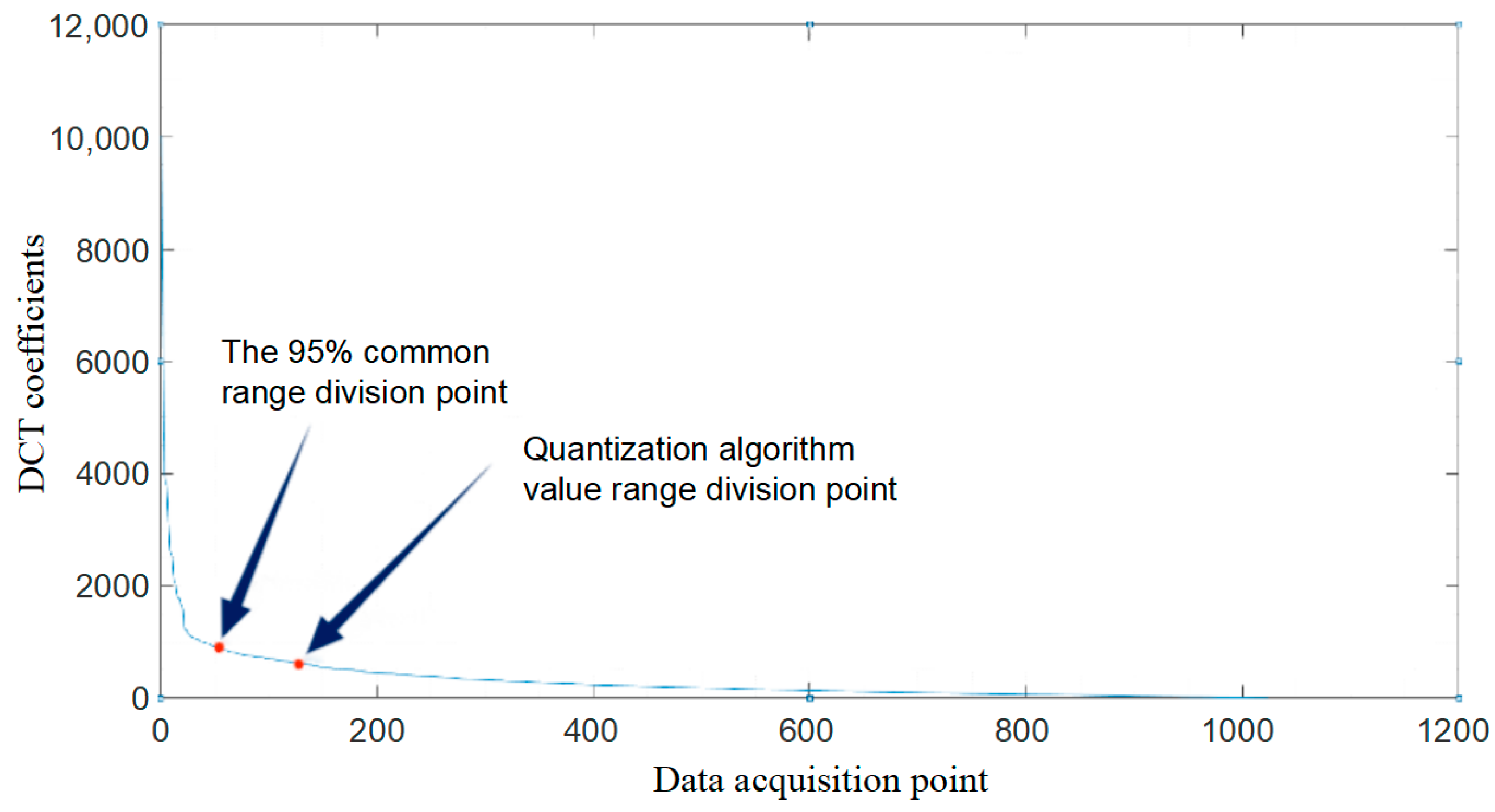

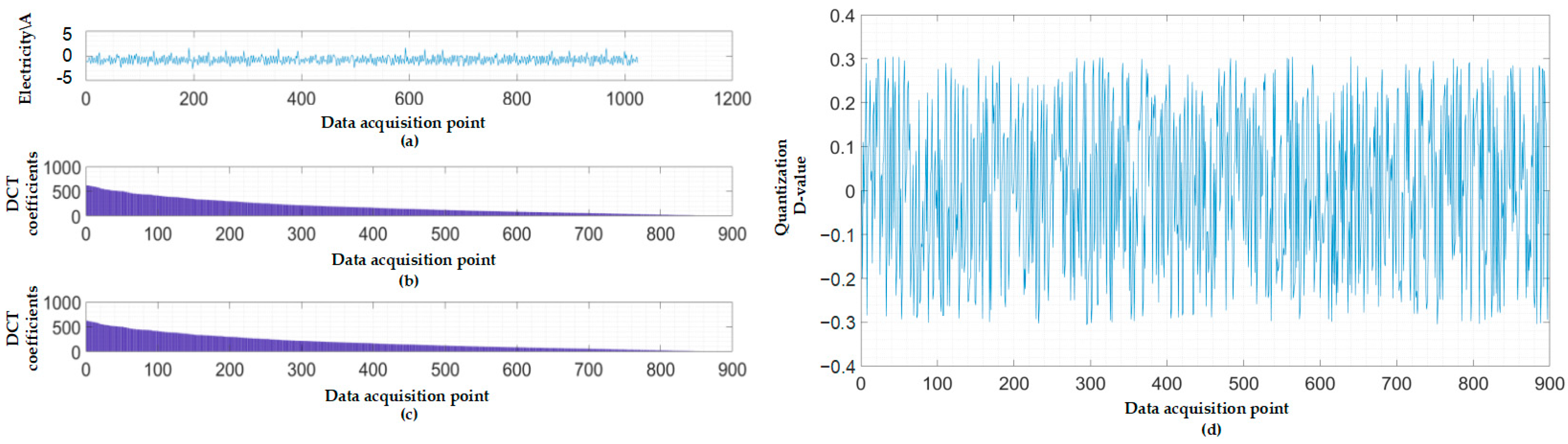

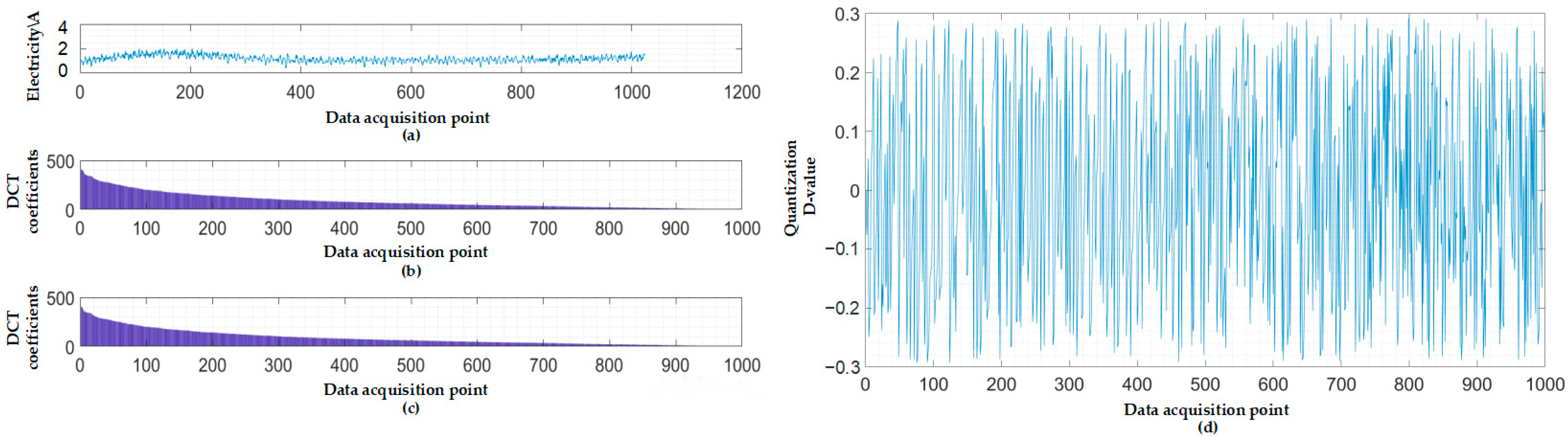

- A sparse-domain quantization interval threshold determination method based on the discrete cosine transform is proposed for use in the field of CNC machine tools, which can improve the efficiency and quality of compression-aware methods of CNC machine tools under different working conditions.

- Previous methods have typically used a fixed value or percentage for quantization; however, this approach lacks scientific justification. This article abandons the fixed-value quantization approach and instead proposes a distortion rate evaluation formula for determining the quantization interval, thereby ensuring compression accuracy.

- Aiming at the electronic data of CNC machine tools processed by DCT, this paper proposed an algorithm to quickly calculate the value range division and determine the quantization step size. This algorithm can optimize the compression effect under different working conditions of CNC machine tools.

1.3. Organization of the Paper

2. Related Work

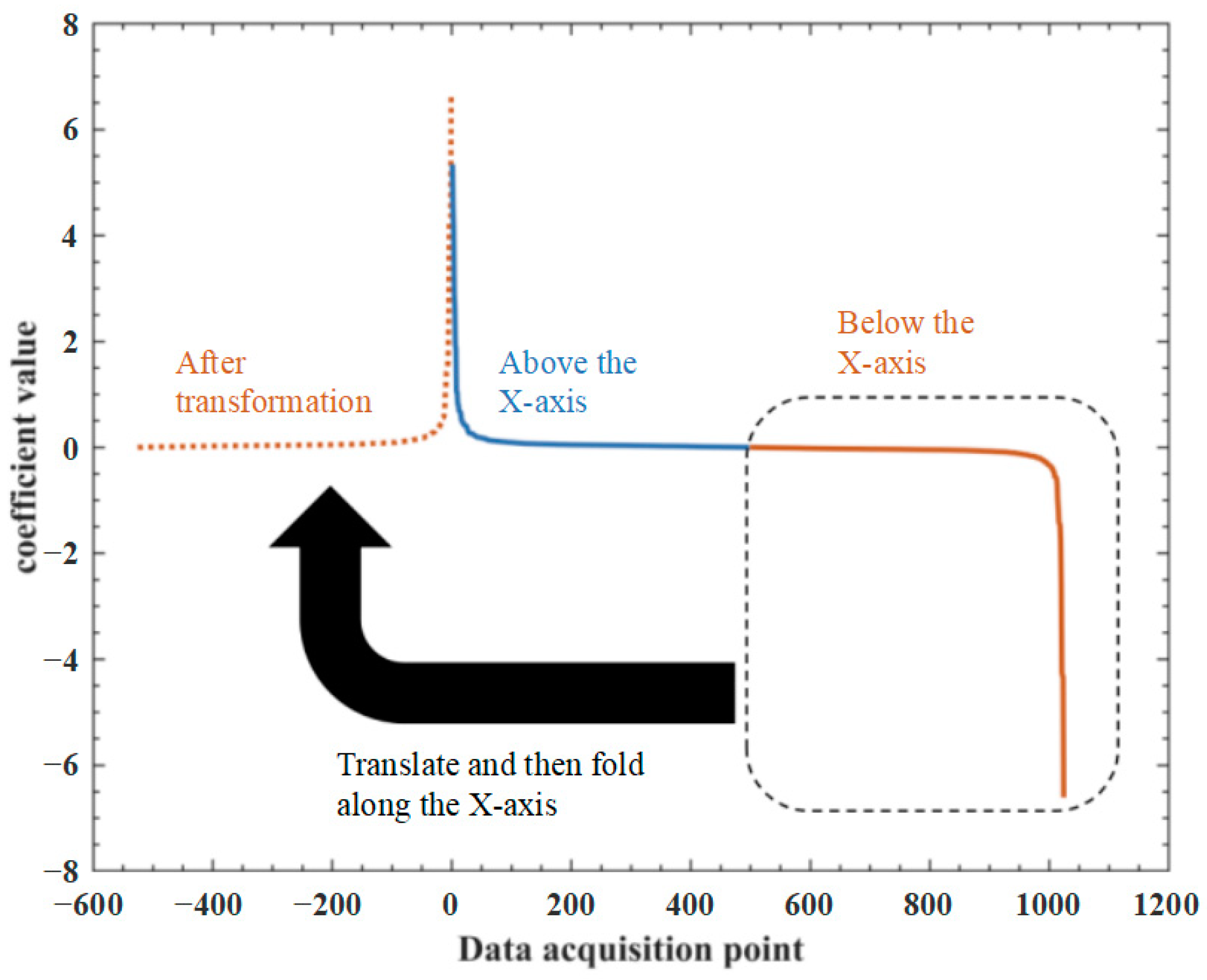

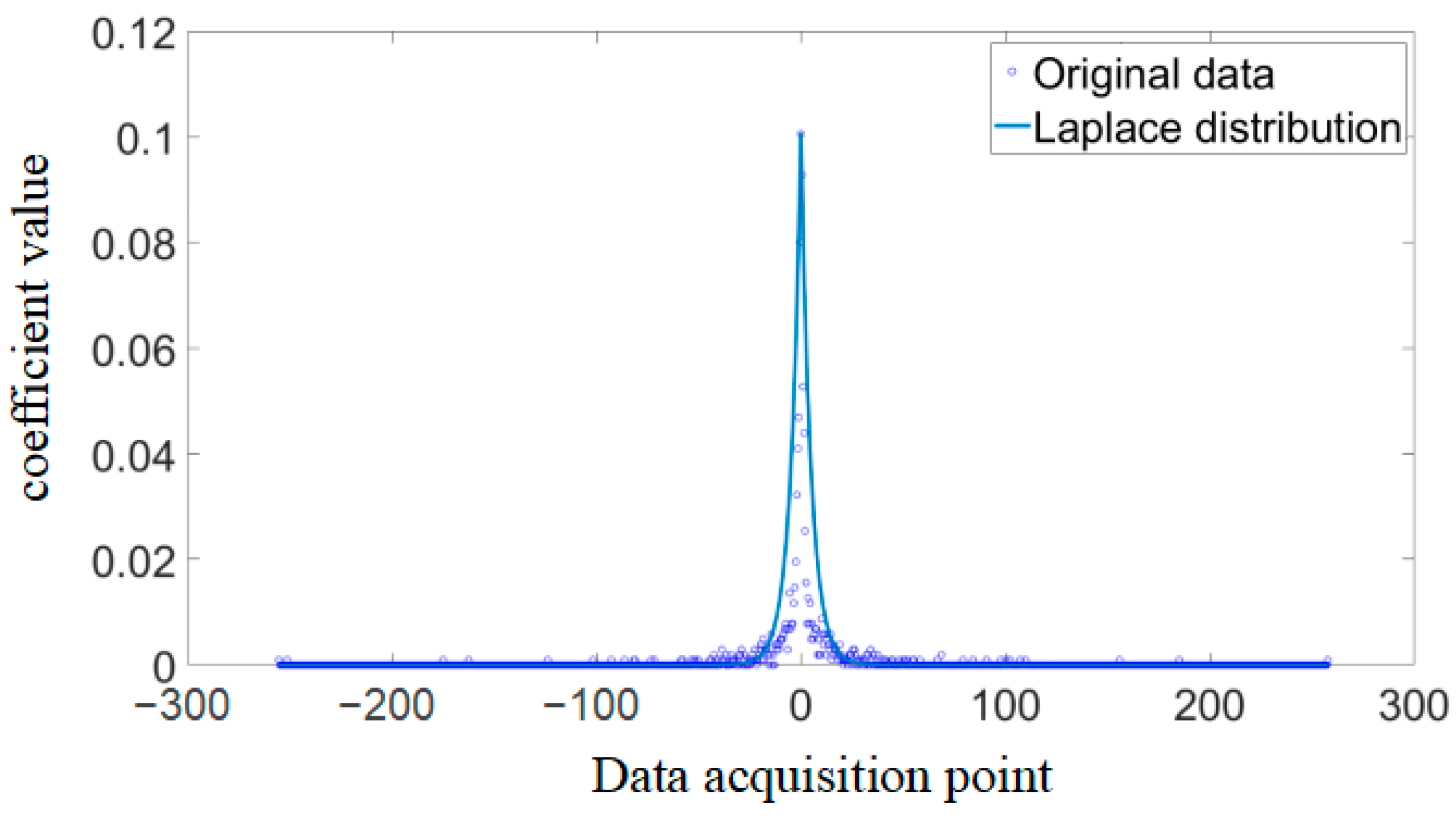

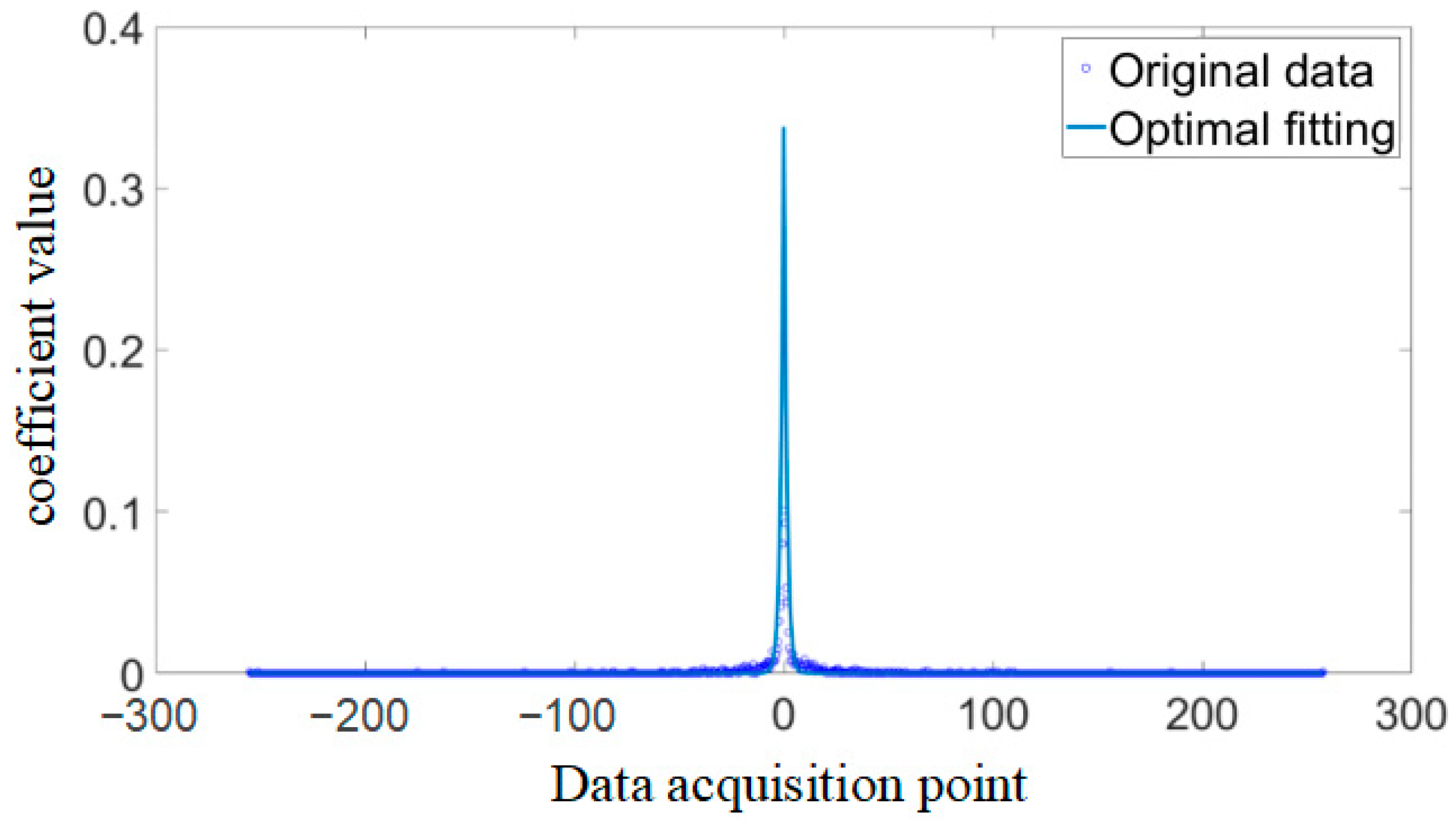

3. Proposed Scheme

| Algorithm 1: Quantization Algorithm | |

| Input: Set of raw CNC machine tool spindle current signal samples Current; Threshold θ; Initial quantization step ; 0.9 Output: Quantization interval; Quantization step | |

| 1: | function QA(Current, θ, ,) |

| 2: | Randomly extract a data segment containing 1024 points in Current, denoted as Sample(−). |

| 3: | Sample(−) was processed by DCT, denoted as Sample(DCT). |

| 4: | Sort the absolute values of Sample(DCT) in descending order, denoted as SortedSample(DCT). //Conform to the data processing form |

| 5: | Compute according to Equation (4) with quantization step and SortedSample(DCT). //Get the initial quantization step and distortion rate |

| 6: | While θ < do |

| 7: | = |

| 8: | Compute distortion rate according to Equation (4) with quantization step and SortedSample(DCT). |

| 9: | EndWhile //Get the quantization interval and step size |

| 10: | end function |

4. Experiments and Evaluation

4.1. Experimental Settings

4.2. Experimental Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-heuser, B.; Wang, L. Industry 4.0 and industry 5.0inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Sofic, A.; Rakic, S.; Pezzotta, G.; Markoski, B.; Arioli, V.; Marjanovic, U. Smart and resilient transformation of manufacturing firms. Processes 2022, 10, 2674. [Google Scholar] [CrossRef]

- Salunkhe, O.; Berglund, A.F. Industry 4.0 enabling technologies for increasing operational flexibility in final assembly. Int. J. Ind. Eng. Manag. 2022, 13, 38–48. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of things in industries: A survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Khan, W.; Rehman, M.; Zangoti, H.; Afzal, M.; Armi, N.; Salah, K. Industrial internet of things: Recent advances, enabling technologies and open challenges. Comput. Electr. Eng. 2020, 81, 106522. [Google Scholar] [CrossRef]

- Haoran, Z.; Jianhua, L.; Hui, X.; Cunbo, Z.; Tian, M.; Jinshan, L.; Bin, W. 3D visualization real-time monitoring method for digital twin workshop. Comput. Integr. Manuf. Syst. 2019, 25, 1432–1443. [Google Scholar]

- Hendrawan, Y.M.; Simba, K.R.; Uchiyama, N. Iterative learning contouring controller based on trajectory generation with linearly interpolated contour error estimation and bézier reposition trajectory for computerized numerical control machine tool feed drive systems. Adv. Mech. Eng. 2019, 11, 168781401986810. [Google Scholar] [CrossRef]

- Wang, W.; Tian, G.; Chen, M.; Tao, F.; Zhang, C.; Ai-ahmari, A.; Li, Z.; Jiang, Z. Dual-objective program and improved artificial bee colony for the optimization of energy-conscious milling parameters subject to multiple constraints. J. Clean. Prod. 2020, 245, 118714. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward new-generation intelligent manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Shi, W.; Cao, J.; Zhang, Q.; Li, Y.; Xu, L. Edge computing: Vision and challenges. IEEE Internet Things J. 2016, 3, 637–646. [Google Scholar] [CrossRef]

- Passian, A.; Buchs, G.; Seck, C.M.; Marino, A.M.; Peters, N.A. The concept of a quantum edge simulator: Edge computing and sensing in the quantum era. Sensors 2022, 23, 115. [Google Scholar] [CrossRef] [PubMed]

- Sonmez, C.; Ozgovde, A.; Ersoy, C. Edgecloudsim: An environment for performance evaluation of edge computing systems. In Proceedings of the 2017 Second International Conference on Fog and Mobile Edge Computing (FMEC), Valencia, Spain, 8–11 May 2017. [Google Scholar] [CrossRef]

- Xu, D.; Li, Q.; Zhu, H. Energy-saving computation offloading by joint data compression and resource allocation for mobile-edge computing. IEEE Commun. Lett. 2019, 23, 704–707. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y. A physics-constrained dictionary learning approach for compression of vibration signals. Mech. Syst. Signal Process. 2021, 153, 107434. [Google Scholar] [CrossRef]

- Silva LR, M.; Filho LM, D.A.; Duque, C.A. Sparse representation algorithm applied to power systems signal compression. Int. Trans. Electr. Energy Syst. 2019, 29, e2693. [Google Scholar] [CrossRef]

- Ghaffari, A. Image compression-encryption method based on two-dimensional sparse recovery and chaotic system. Sci. Rep. 2021, 11, 369. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.; Gao, L.; Li, X. A new deep transfer learning based on sparse auto-encoder for fault diagnosis. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 136–144. [Google Scholar] [CrossRef]

- Tang, Z.; Chen, Z.; Bao, Y.; Li, H. Convolutional neural network-based data anomaly detection method using multiple information for structural health monitoring. Struct. Control Health Monit. 2019, 26, e2296. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, J.; Bo, L.; Li, H.; Zhang, H.; Zhong, Z.; Yuan, D. Singular vector sparse reconstruction for image compression. Comput. Electr. Eng. 2021, 91, 107069. [Google Scholar] [CrossRef]

- Kalluri, M.; Jiang, M.; Ling, N.; Zheng, J.; Zhang, P. Adaptive rd optimal sparse coding with quantization for image compression. IEEE Trans. Multimed. 2019, 21, 39–50. [Google Scholar] [CrossRef]

- Erb, W. Graph wedgelets: Adaptive data compression on graphs based on binary wedge partitioning trees and geometric wavelets. IEEE Trans. Signal Inf. Process. Over Netw. 2023, 9, 24–34. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Zhou, H.; Xiang, H.; Zhu, Z.; Li, Y.; Lee, C.; Xu, G. Cps modeling of cnc machine tool work processes using an instruction-domain based approach. Engineering 2015, 1, 247–260. [Google Scholar] [CrossRef]

- Shen, P.; Huang, B.; Wang, L. Range division and linearization algorithm for a class of linear ratios optimization problems. J. Comput. Appl. Math. 2019, 350, 324–342. [Google Scholar] [CrossRef]

- Li, X.; Zhang, P.; Hui, E.; Chen, G. Based on embedded zerotree wavelet coding data compression algorithm research of nc machine tool control system. In Proceedings of the 2019 4th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Hohhot, China, 25–27 October 2019. [Google Scholar] [CrossRef]

- Liu, M.; Yao, Y.; Du, J. An efficient machine tool control instruction compression method for networked numerical control systems. Robot. Comput.-Integr. Manuf. 2021, 67, 102027. [Google Scholar] [CrossRef]

- Sabbagh, R.; Cai, Z.; Stothert, A.; Djurdjanovic, D. Physically inspired data compression and management for industrial data analytics. Front. Comput. Sci. 2020, 2, 41. [Google Scholar] [CrossRef]

- Lin, X.; Wang, L.; Liu, F.; Zhang, Z. Data Compression Method for Computerized Numerical Control Reliability Data. J. Chin. Comput. Syst. 2017, 38, 2202–2206. [Google Scholar]

- Yuan, X.; Cai, Z. Ichv: A new compression approach for industrial images. IEEE Trans. Ind. Inform. 2022, 18, 4427–4435. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Z.; Zhang, H.; Yang, G.; Wang, K. Fog-based optimized kronecker-supported compression design for industrial iot. IEEE Trans. Sustain. Comput. 2020, 5, 95–106. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, Y.; Jin, X.; Chen, Y.; Gao, C. Task offloading for edge computing in industrial internet with joint data compression and security protection. J. Supercomput. 2023, 79, 4291–4317. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, S.; Zheng, X.; Ruan, X. Layered adaptive compression design for efficient data collection in industrial wireless sensor networks. J. Netw. Comput. Appl. 2019, 129, 37–45. [Google Scholar] [CrossRef]

- Bagherian, M.; Chehade, S.; Whitney, B.; Passian, A. Classical and quantum compression for edge computing: The ubiquitous data dimensionality reduction. Computing 2023, 105, 1419–1465. [Google Scholar] [CrossRef]

- Mahdaoui, A.E.; Ouahabi, A.; Moulay, M.S. Image denoising using a compressive sensing approach based on regularization constraints. Sensors 2022, 22, 2199. [Google Scholar] [CrossRef] [PubMed]

| Type of Machine Tool | Type of Machining Condition | Size of Data (bit) | Average Relative Error (Empirical Method) | Average Relative Error (Improved Method) | Compression Ratio (Empirical Method) | Compression Ratio (Improved Method) | PSNR (Improved Method) (dB) | Running Time (s) |

|---|---|---|---|---|---|---|---|---|

| CNC machining center | Stable processing | 32,768 | 6.35% | 4.75% | 28.81% | 25.73% | 50.7366 | 0.1143 |

| Fluctuating conditions | 32,768 | 5.39% | 4.39% | 36.53% | 32.52% | 52.3241 | 0.2081 | |

| Normal processing | 32,768 | 5.95% | 4.35% | 33.79% | 31.41% | 53.2647 | 0.1432 | |

| Abnormal processing | 32,768 | 5.85% | 3.85% | 23.98% | 20.74% | 39.0981 | 0.1896 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Zhou, H.; Yang, J.; Hui, E.; Dai, C. Adaptive Quantization Range Division Technique for Electronic Control Data Compression in CNC Machine Tools. Electronics 2023, 12, 3387. https://doi.org/10.3390/electronics12163387

Hu W, Zhou H, Yang J, Hui E, Dai C. Adaptive Quantization Range Division Technique for Electronic Control Data Compression in CNC Machine Tools. Electronics. 2023; 12(16):3387. https://doi.org/10.3390/electronics12163387

Chicago/Turabian StyleHu, Weiqi, Huicheng Zhou, Jianzhong Yang, Enming Hui, and Chaoren Dai. 2023. "Adaptive Quantization Range Division Technique for Electronic Control Data Compression in CNC Machine Tools" Electronics 12, no. 16: 3387. https://doi.org/10.3390/electronics12163387

APA StyleHu, W., Zhou, H., Yang, J., Hui, E., & Dai, C. (2023). Adaptive Quantization Range Division Technique for Electronic Control Data Compression in CNC Machine Tools. Electronics, 12(16), 3387. https://doi.org/10.3390/electronics12163387