Abstract

The development of agricultural farming has evolved from traditional agricultural machinery due to its efficiency and autonomy. Intelligent agricultural machinery is capable of autonomous driving and remote control, but due to its limited perception of farmland and field obstacles, the assistance of unmanned aerial vehicles (UAVs) is required. Although existing intelligent systems have greater advantages than traditional agricultural machinery in improving the quality of operations and reducing labor costs, they also produce complex operational planning problems. Especially as agricultural products and fields become more diversified, it is necessary to develop an adaptive operation planning method that takes into account the efficiency and quality of work. However, the existing operation planning methods lack practicality and do not guarantee global optimization because traditional planners only consider the path commands and generate the path in the rectangular field without considering other factors. To overcome these drawbacks, this paper proposes a novel and practical collaborative path planning method for intelligent agricultural machinery based on unmanned aerial vehicles. First, we utilize UAVs for obstacle detection. With the field information and operation data preprocessed, automatic agricultural machinery could be assisted in avoiding obstacles in the field. Second, by considering both the historical state of the current operation and the statistics from previous operations, the real-time control of agricultural machinery is determined. Therefore, the K-means algorithm is used to extract key control parameters and discretize the state space of agricultural machinery. Finally, the dynamic operation plan is established based on the Markov chain. This plan can estimate the probability of agricultural machinery transitioning from one state to another by analyzing data, thereby dynamically determining real-time control strategies. The field test with an automatic tractor shows that the operation planner can achieve higher performance than the other two popular methods.

1. Introduction

With the rapid development of positioning technology, automatic navigation technology, and other related technologies, the automatic driving technology of agricultural machinery has been widely adopted in agricultural production, leading to a significant improvement in labor productivity and land output rate [1,2]. The unmanned driving and unmanned operation developed based on the automatic driving of agricultural machinery are more conducive to reducing labor costs and improving operation quality [3]. However, compared to the automatic driving of agricultural machinery, the unmanned driving of agricultural machinery imposes higher requirements on control commands such as implement lifting, engine speed, and operation path. These requirements are necessary to ensure the safety and reliability of agricultural machinery [4]. In order to effectively utilize intelligent agricultural machinery, it is crucial to develop a command-based operation plan that can adapt to various fields, agronomic requirements, and machinery specifications.

However, agricultural machinery requires the global information of the field to perform operations. Currently, autonomous operation planning methods for agricultural machinery can be classified into three types according to different methods for detecting fields: manual mapping-based methods, radar-based methods, and vision-based methods. Manual mapping-based methods are too inefficient. Radar-based methods [5] use lidar, ultrasonic radar, or millimeter wave radar mounted on agricultural machinery to extract field information from environmental point clouds [6]. Despite its high performance, no matter what type of radar is used, it is relatively expensive and requires high computing power for the real-time processing of cluttered point cloud data [7]. Vision-based methods [8,9,10] use cameras mounted on agricultural machinery to obtain field information. Cameras are inexpensive and widely used [11], but if the field is uneven, the camera will shake and cause performance degradation [12]. Neither vision-based nor radar-based methods have access to global information of the field as their sensing devices are mounted on agricultural machinery. Since the UAV has a wide field of view, it can provide a wide range of high-precision ground sensing information, which can address the lack of global information.

In addition to using UAVs to address the lack of global information of fields, another challenge that needs to be considered is how to plan the operation of agricultural machinery. In terms of the information used, most existing methods use only field and agricultural machinery information. On the basis of field and agricultural machinery information, this paper focuses on mining the historical operation data of agricultural machinery. When the same model of agricultural machinery operates on the same field, the operation plan should remain the same as long as the size and shape of the field remain the same. If these machines are driven by professional operators, then in theory the big data of these operations should hide the operational thinking of these operators, who tend to be experienced indigenous people with professional training and who tend to be flexible in choosing efficient operation plans. After a long period of agricultural production, these plans have often been shown to be able to adapt themselves to the local operating environment, climatic conditions, and cultivating habits. With the development of various sensors, it has become possible to record these operation data [13]. These big data can be analyzed to provide effective operation plans for future re-operations. As the times of operations increase, the operation plans mined from more historical operation data will become more and more reliable and efficient. The practicability of the plans excavated from the historical plans that have been practiced in the past is ensured.

The paper has made the following contributions:

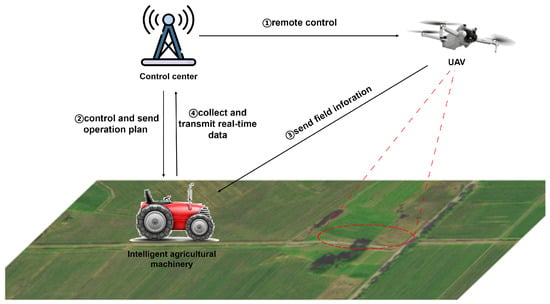

- A collaborative path planning method for intelligent agricultural machinery based on unmanned aerial vehicles is proposed, and the method is applied to an agricultural field exploration scenario. Based on this, a UAV collaborative intelligent combat system is proposed, where the control center generates the best field operation guidance plan and sends it to the agricultural machinery and UAV to remotely control them, and the agricultural machinery and UAV send back the detected field information to the control center in real-time.

- We proposed a method to extract both the core parameters and the discretized state space based on the K-means clustering algorithm and the silhouette coefficient. The real-time control of agricultural machinery is determined by considering both the historical state of the current operation and the statistics from previous operations. Therefore, the K-means algorithm is used to extract key control parameters and discretize the state space of agricultural machinery.

- A dynamic agricultural machinery operation plan based on the Markov chain is established, which has the characteristics of field adaptability, agronomic adaptability, and machinery adaptability. In this study, engine speed, implement position, and other control parameters are introduced to solve the integrity problem of intelligent agricultural machinery field operations. In addition, UAVs are used to assist agricultural machinery avoid obstacles.

- The experimental results show that compared with the popular adjacent method and block circle method, our method is more efficient in terms of the operation area ratio and operation distance ratio.

The remainder of this paper is organized as follows. Section 2 briefly describes the relevant research background. Section 3 expounds on the proposed method, including the K-means algorithm and operation plan based on the Markov chain. Section 4 analyzes the effectiveness and performance of the method. Section 5 provides an overview and summary of the previous sections, proposes limitations, and proposes future research approaches, and the conclusion follows in Section 6.

2. Related Work

The main goal of agricultural machinery operation planning is to guide agricultural machinery to achieve full coverage of the field efficiently [14]. At present, the research focus in this field is mainly on route planning [15], headland turning, and obstacle avoidance. In terms of route planning, after Bochtis et al. [16] improved the farm efficiency of the machine by minimizing the total non-working travel distance, Conesa-Muñoz et al. [17] established a route combination optimization method by comprehensively considering vehicles with different features, the variability of the field, the probability of tank refueling, and other factors, and Rodias et al. [18] proposed an optimization and evaluation model to reduce energy requirements. Plessen et al. [19] proposed a path planning approach based on the circular pattern with the total distance as the indicator. Utamima et al. [20] suggested the usage of the evolutionary estimation of distribution algorithm and evolutionary hybrid neighborhood search for solving agricultural routing planning. In terms of headland turning, Boryga et al. [21] proposed a method that involves the application of polynomic transition curves for trajectory planning on the headlands. Cariou et al. [22] designed a turning method based on segments of closures. In terms of obstacle handling, Zhou et al. [23] divided the field into blocks and used the ant colony algorithm approach to optimize the sequence that the blocks worked. Li et al. [24] proposed an obstacle avoidance controller based on a nonlinear model of predictive control.

First, most of the existing research on operation plans revolves around a single problem (e.g., route planning, headland turning, or obstacle avoidance problems), and there is insufficient research on other control information of agricultural machinery such as implement lifting. There are also few operation plans available for completing a full operation task, which cannot meet the demand for the autonomous operation of intelligent agricultural machinery. Second, most plans are often modeled in an idealized or specific scenario, so it is difficult to cover some constraints in other scenarios. Some fields have restricted access. Therefore, it is also necessary to adjust the sequence of strip operations to avoid additional non-working distances. It is also necessary to adjust the spacing of the strips for the subsoiling operation to match the subsequent seeding operation. These constraints are often difficult to enumerate and seriously affect the practicality of the operation plans. Third, the properties of farmland vary around the world. For example, there are many shapes, such as circles and rectangles. In this case, an operation plan that works for a rectangular field must not work for a circular field, which also leads to the poor practicality of the operation plan. In response to the above shortcomings, we extracted operational plans from the historical operational data of agricultural machinery, and UAVs were used to help agricultural machinery avoid obstacles.

In recent years, UAVs have been widely used in agriculture [25,26]. UAVs are aircraft that are capable of flying without human control. UAVs are typically operated and navigated by remote control or by pre-programmed autonomous systems. They can carry a variety of sensors, cameras, communications equipment, and other payloads for a variety of missions and applications [27,28,29]. UAVs come in a variety of types and sizes and can range from small micro drones to large drones. UAVs have a wide range of applications. They are used in military applications for reconnaissance, surveillance, and military missions, as well as in civilian applications such as aerial photography, logistics, disaster monitoring, and agriculture. According to different tasks, UAV control systems can be divided into trajectory tracking-based control systems and path following-based control systems [30]. The difference between them is that trajectory tracking control requires UAVs to arrive at a predetermined location within a predetermined time according to the expected trajectory, while path following control does not have specific requirements regarding the arrival time [31,32]. In this sense, path following-based control systems are suitable for tasks without temporal requirements, such as ground target tracking [33]. In the Agriculture 4.0 field, the complementary role of UAVs and intelligent agricultural machinery has been recognized as catalytic to operations efficiency, human safety and health, and environmental stewardship. Specifically, Mammarella et al. [34] articulated several scenarios and proposed the concept of heterogeneous cooperation between unmanned systems in vineyards. This paper proposes a UAV collaborative intelligent combat system.

3. Methodology

This section describes the methods we proposed in detail, including the system model, data acquisition and preprocessing, operation plan based on the Markov chain, and main algorithm description and analysis.

3.1. System Model

The system model is shown in Figure 1. The cloud server in the control center is responsible for remote control of agricultural machinery and UAVs, and UAVs send the detected field information to the agricultural machinery. During the operation of agricultural machinery, the UAV needs to detect a circular area centered on the agricultural machinery in real-time (the radius is determined by the performance of the unmanned aerial vehicle) and send information to the agricultural machinery to handle sudden obstacles. In addition, in order to prevent the UAV from detecting oversized obstacles in real-time (the size of obstacles may exceed the detection range of UAV), the UAV needs to conduct complete detection of the target field before the agricultural machinery starts operation and to send suspicious obstacle information to the agricultural machinery. During operation, intelligent agricultural machinery utilizes path tracking control technology [35] to operate according to the predetermined path obtained from the operation plan, while the UAV utilizes ground target tracking control technology [33] to always follow the intelligent agricultural machinery. The path tracking control of agricultural machinery refers to calculating the expected front wheel angle of the agricultural machinery based on the deviation between the real-time position of the agricultural machinery and the preset expected operation path, thereby controlling the steering of the agricultural machinery to drive along the expected path. The ground target tracking of UAVs refers to using visual information obtained by the camera of UAVs to automatically adjust the rotation and pitch angles of the airborne pan tilt, so that the tracked moving target remains at the center of the camera’s image and transmits the image and position information back to the ground control center.

Figure 1.

Intelligent operation system collaborated by UAVs.

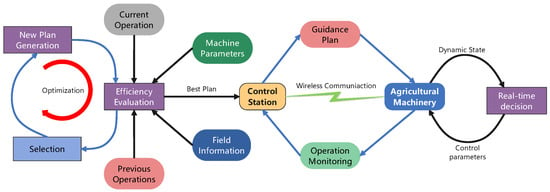

The process of creating, evolving, and implementing the operation plan designed in this paper is shown in Figure 2. The first one is the control center, which is responsible for generating the best operation guidance plan on the field based on the previous agricultural machinery operation data (engine speed, equipment height, GPS location, etc.) and field information and sending the guidance plan to the agricultural machinery after it starts a new operation on the field. The second is the agricultural machinery, which receives the guidance operation plan from the control center before each operation starts, combines its dynamic status (such as GPS positioning, etc.) with the guidance plan sent from the control center during the operation, decides on the control parameters of the agricultural machinery in real-time, and sends the operation data monitored by the monitoring equipment to the control center in real-time through wireless communication after completing the operation for the improvement of the operation plan. For ease of expression, the agricultural machinery or machinery referred to below are all intelligent agricultural machinery. The main notations used in this study are listed in Table 1.

Figure 2.

Process of creating, evolving, and implementing the operation plan.

Table 1.

Main notations used in this study.

3.2. Data Acquisition and Preprocessing

In this section, we will demonstrate how to collect field information and operation data for preprocessing.

3.2.1. Data Acquisition

The data collected in this system consists of two parts. The first part is the field contour information and field obstacle information, both of which are measured by UAVs. The second part is the historical operation data of agricultural machinery such as engine speed, driving speed, implement position, and GPS location. These data, which are closely related to operations, are collected by the sensors mounted on agricultural machinery and sent to the cloud server at the control center by the vehicle terminal via the wireless network at a fixed frequency.

3.2.2. Field Gridding and Obstacle Marking

The field consists of a polygon enclosed by a series of GPS coordinate points (including longitude and latitude). The rectangles that can just cover the whole field are divided into grids with several vertical lines and horizontal lines, and the grids are labelled from left to right and from top to bottom as 1 to r. After knowing the GPS coordinates of the four vertices of this rectangle, the latitude and longitude of the center point of each grid can be calculated. In this way, we can obtain the driving trajectories by recording the grids and the order in which they are traversed. The first reason for field gridding is that the trajectories of agricultural machinery appear smoother along the center of the grid after gridding than if we recorded the trajectories directly using high-precision latitudes and longitudes. The second reason is that fewer values can be used to record the trajectories of agricultural machinery, and by reducing the two-dimensional latitude and longitude to a one-dimensional numbering, the locations of agricultural machinery can be represented by only r values. Although the gridding of the field inevitably introduces an accuracy loss, such an accuracy loss is acceptable as long as the grid size is reasonable.

When compared with the handheld GNSS (global navigation satellite system) module or tripod-based total station, UAVs can achieve higher efficiency and can be applied to large-area operations [36]. So, we use UAVs to detect obstacles and mark the grids where the obstacles are located.

3.2.3. Sensors Data Preprocessing

In this paper, whenever agricultural machinery performs an operation task on the field, it sends a data point to the control center at a fixed frequency in sequence, which contains the data measured by the sensors installed in the machinery. Due to the presence of various perturbations, sensor data inevitably suffer from errors and some data points are irrelevant to the operation task. These operation data need to be pre-processed before they are used to obtain operation plans.

For sensor data other than GPS data, this paper considers data loss caused by device fault or other physical reasons, such as implementer position. Since such missing values may occur consecutively over a period of time, but these sensor data are important for guiding the operation of agricultural machinery, these data points cannot be removed directly. In Section 3.2.2, the field map has gridded, and, after several operation times on the field, plenty of data points already exist on the same grid, so a very simple approach is that the average of previous valid data on the same grid can be taken as the interpolation result of these missing data.

Next is the processing of GPS data. GPS sensor data, which are subject to significant errors due to satellite measurements, rely on satellite measurements. The data points that need to be processed are shown below:

Points out of the field: When agricultural machinery is active at the edge of the field or out of the field of operation, many GPS location points may be acquired beyond the field of operation due to satellite signal drift. These data points are irrelevant to this operation and need to be removed.

Static points: It is necessary to remove points where the GPS location data remain constant over a long period of time. These data are generated for various reasons (such as the need for a short break by the operator), and these static points are not related to the operational tasks. If this part of the data is not processed, it will bias the operation plan.

Drifting points: GPS sensors are known to be sometimes unstable. During normal operation, the GPS location data may suddenly drift to a location that cannot be reached by the machinery in a short period of time, and in order to reduce the overall data bias, the original data can be optimized by removing these drifting data points.

Then, the solutions for processing the above three kinds of odd points are provided in detail.

Removing points out of the field: This task can be converted to determining whether a point is in a polygon. A well-known method is the PNPoly algorithm, and its principle is that if a ray has an odd number of intersections with a polygon, the start of the ray is inside the polygon [37].

Removing static points: A very simple approach would be to simply remove static points whose driving speed is zero, but as mentioned earlier, it is also possible for a static GPS receiver to generate some drifting data, and the speed of these data points is often not zero, so even after filtering based on only some simple conditions, these points cannot be removed. Next, we describe how we remove these error data points.

Removing drifting points: Sometimes GPS receivers make errors in the driving speed or position, known as drift points, and these anomalous data points may have incorrect values for driving speed, longitude, and latitude compared to the normal data points, but these drifting points cannot be screened by normal data processing methods.

Since the speed of the agricultural machinery operating on the field is almost constant, it is possible to determine whether each data point is a drifting point based on its distance from the data point at the previous moment, defining the moving distance of each data point as the true distance of the point from the data point at the previous moment. Then, the moving distance of the drifting point tends to be much larger than the moving distance of the data points in the previous normal moments. Since it is only necessary to compare the relationship between the size of the distance moved by the data points to a certain extent without calculating the distance precisely, it can be assumed that the earth is a perfect sphere and its radius is R. According to the great-circle distance[38], it is not difficult to compute the actual distance between and via:

Then, the moving distance of the data point is shown as follows:

Then, the method to determine whether the data point is a drifting point is as follows:

where N and Z are user parameters, indicating that the absolute value of the difference between the moving distance of the drifting point and the average moving distance of the previous N data points exceeds threshold Z. Two drifting points may lean together, so when a drifting point is detected, it should be removed from the operation data before starting the drifting point detection of the next data point to prevent it from affecting the drifting point detection of the next data point.

3.3. Operation Plan Based on Markov Chain

For a given moment in the operation of agricultural machinery, although there is a strong continuity in the operation of the agricultural machinery, the greatest influence on the state of the agricultural machinery at that moment is the state of the agricultural machinery at the preceding moment. For a long continuous operation process, with the stable performance of agricultural machinery, the transition matrix of the agricultural machinery state during the whole operation process can be inferred from the changes of the agricultural machinery state in two adjacent moments, and this matrix is getting closer to the ideal operation plan as the number of agricultural machinery operations increases. It can be seen that the above agricultural machinery operation scenario is closer to the Markov stochastic process [39], so the Markov chain [39] can be used to construct a probabilistic model to guide the agricultural machinery to complete the operation task.

In order to facilitate the representation of the start and end moments of agricultural machinery operation, it is stipulated that the entry of agricultural machinery into the field indicates the start of the operation task, and the departure of agricultural machinery from the field indicates the end of the operation task. In addition, for the convenience of expression, this paper only considers the scenario of the same model of agricultural machinery operating on the same field, i.e., a one-to-one case. The real scene is many-to-many, but it can be deduced by analogy.

3.3.1. Mathematical Representation of Operation Plans

The state vector of the agricultural machinery used in the experimental part of this paper contains state variables such as the current location, engine speed, and implement position. However, in order to improve the generalization ability of the model to apply to various models and types of agricultural machinery, the dimensionality of the agricultural machinery state vector is set to an undefined parameter d. The state vector of agricultural machinery is then represented as follows:

where t denotes the moment and t is a positive integer.

In Section 3.2.2, the field has been gridded. When the agricultural machinery works on the field, it will pass through many grids and record these grids in turn; if a total of m grids are passed, then the state change of the agricultural machinery can be expressed as a time state sequence: . If the field has a fixed entry, then the grid numbers in its starting and ending states should be determined. Assuming that the first element of the vector is the grid number, should represent the other sensor data, and their values are the mean values of for all data points within grid in this operation. Thus, this time state sequence can characterize the operation plan of this operation.

3.3.2. Core Control Parameters Extraction and State Space Discretization

During a subsoiling operation, the position of the subsoiler only has a few core values regularly, such as the position of the operating phase and the position of the turning phase; other data are often intermediate values of the adjustment process, and these intermediate values are not very meaningful for the operational task, so it is necessary to extract these few key control parameters. The fact that most of the state variables in the state vector in Equation (5) belong to continuous values, such as engine speed, leads to the state space also being continuous, and there are infinitely many states in the continuous state space, which makes the use of the Markov model difficult. For example, when the current wheel rotation angle is 198 but only 197 and 196 may appear in the historical operation data, then it is impossible to find the next control command of the agricultural machinery according to the Markov model; in fact, 198 has the same meaning as 197 and 196, and these three values should be grouped together. Therefore, it is necessary to discretize the state space, transform the continuous space into a finite discrete space, group values with similar meaning into a single category, and ignore values of control parameters and errors that not be relevant to the operation task. The gridding of the map in Section 3.2.2 is also a discretization step. So, in this paper, we propose a method to extract both the core parameters and the discretized state space based on the k-means clustering algorithm and the silhouette coefficient.

The discretization of the state space of the agricultural machinery can be decomposed as a discretization of each continuous value in the state space, with one and only one core control parameter in each discrete interval. The k-means clustering algorithm is widely used in data mining, where its purpose is to classify records with the same data structure based on a classification criterion, in order to obtain several sets of similar records [40]. The silhouette coefficient is a way that combines both cohesiveness and separation to evaluate the effectiveness of clustering [41].

The specific steps for extracting key control parameters and discretizing the state space are as follows:

P1. Initialize two parameters: .

P2. Run the k-means clustering algorithm with parameters and calculate the silhouette coefficients of all clustering results.

P3. Choose the value of K that maximizes as the number of discrete intervals.

P4. The centers of all clusters are ordered from the smallest to largest value as .

P5. The obtained K discrete intervals are ,..., ; one center exists in each interval as a key control parameter, where L and U are user parameters indicating the minimum and the maximum possible number of discrete intervals.

After discretizing each continuous variable in Equation (5), if in Equation (5) has values, then there can be up to discrete states in the state space, where n represents the total number of discrete states in the state space of agricultural machinery. From there, the state of agricultural machinery can be labeled as , where denotes the i-th state of the agricultural machinery. It is important to note that .

3.3.3. K-Step Transfer Probability Matrix and Planning

The operation planning problem of agricultural machinery has been successfully converted into a point-to-point prediction problem of state change of agricultural machinery. The points correspond to the states in the Markov chain, there are n states in total, and the transfer probability matrix is an matrix.

The element in the ith row and jth column of the one-step transition probability matrix represents the probability of transition from state to state and obviously can be obtained by counting the historical operation data.

Among a large number of real operation data available, the number of times the agricultural machinery is transferred from state to state is counted and denoted by . Then, the formula of is:

In this way, the one-step probability transition matrix P is obtained, and the recurrence relationship can be obtained according to the C-K equation [39]:

Thus, an arbitrary k-step transfer probability matrix can be obtained:

The next state of the agricultural machinery should be determined by the historical state of the present operation and the statistics of the previous operations. Clearly, the historical state of agricultural machinery closer to the present has a greater influence on the decision of the next state, while the historical states too far away can be ignored. In this way, we can empirically preserve the historical states of the k moments. Historical states beyond k steps have little influence on the next state of the agricultural machinery and can be ignored. In this way, we obtain a formula for the decision value of the next possible agricultural machinery state based on the Markov chain:

where t is the time of the next state, is the time of the previous state of the next state, and so on. Each element in represents the predicted value of the possibility of the corresponding state as the next state. This predictive value is only a relative value, and it is unnecessary to follow that the cumulants are one. is a matrix with only one element being 1 and the rest being 0; if the number of the j-th column is 1, it means that the state at the t-th time before the next time is state . are the weights, representing the importance of the first states for determining the next state, according to the previous assumptions: .

After is calculated by Equation (9), it is necessary to further process and set all the elements in corresponding to the grid that is not adjacent to the current grid where the agricultural machinery is located to 0. In this way, it is sufficient to select the state corresponding to the largest element in as the next ideal state of the agricultural machinery. However, if there are obstacles on the grid of the ideal state, the operation planner will malfunction. If the obstacles are fixed and unchanging (such as utility poles), the handling of these obstacles is often relatively simple because these obstacles are also faced in past operations, but some temporary obstacles (such as haystacks) need special treatment. Firstly, we mark the current grid of the agricultural machinery as . Secondly, we assume that the agricultural machinery will continue to operate under ideal conditions until it reaches , which is unobstructed. Finally, we generate an obstacle avoidance path between and , and the agricultural machinery continues to operate from . Fortunately, the research of field obstacle avoidance is already fairly in-depth [42], and the obstacle avoidance path is not investigated by this paper. Therefore, there will be no further explanation here.

The operational task is completed when the agricultural machinery goes to the exit of the field, and then a decision should be made as to whether to include it in the calculation of the one-step transition matrix P. The inclusion of data from an efficient operation plan will improve the transition matrix and vice versa. Of course, this screening task can be completed by an expert (e.g., an experienced agricultural machinery operator) or a computer program can evaluate it based on indicators such as the area of the operation and the distance of the operation. When performing the screening in the experimental part of this paper, it is required that the direction of the operational strips must be the same as the direction of the operational strips that have already been used in the model. The number of operation strips must not become smaller since the higher the number of strips, the larger the operation area and the higher the field utilization in general.

3.3.4. Main Algorithm Description and Analysis

The two main phases are contained in our algorithm: calculating the 1 to the k step transition matrix, for counting the historical operation data and planning the next state and for planning the next operation command of agricultural machinery according to the Markov chain. Pseudo-codes of the two phases are shown in Algorithm 1 and Algorithm 2, respectively.

| Algorithm 1: Calculate 1 to k step transition matrixes. |

|

| Algorithm 2: Plan the next state. |

|

Algorithm 1 first calculates the one-step transition probability matrix based on the state transition times matrix and then calculates the step transition probability matrix according to Equation (8). The time complexity of multiplying and P is , which requires matrix multiplications, so the time complexity of Algorithm 1 is .

Algorithm 2 first calculates according to Equation (9) and then sets all the elements in corresponding to the grid that is not adjacent to the current grid where the agricultural machinery is located at 0; the state corresponding to the maximum value in is the result. A total of matrix additions and matrix multiplications are required to obtain , so the time complexity of multiplying with is . The time complexity of the step to remove the states that are impossible to occur at the next moment is , and the time complexity of the final step to select the highest probability is . So, the time complexity of Algorithm 2 is .

In order to avoid problems caused by network delays and to reduce the computational pressure on the vehicle terminals, both algorithms are run separately. Considering that the k-step transition matrix can be computed in advance, after each operation, the data preprocessing, state-space discretization, and computation of the k-step transition matrix are all computed and saved by the cloud server in the control center. Before each agricultural machinery starts operation, the cloud server will send the transition matrix to the agricultural machinery through wireless communication, and the agricultural machinery only needs to run Algorithm 2. Therefore, only the time complexity of Algorithm 2 can be considered in the whole system, which is .

The largest space occupation among all steps of the two algorithms is the k-step transition matrix, so the space complexity of all steps is .

4. Experiments and Results

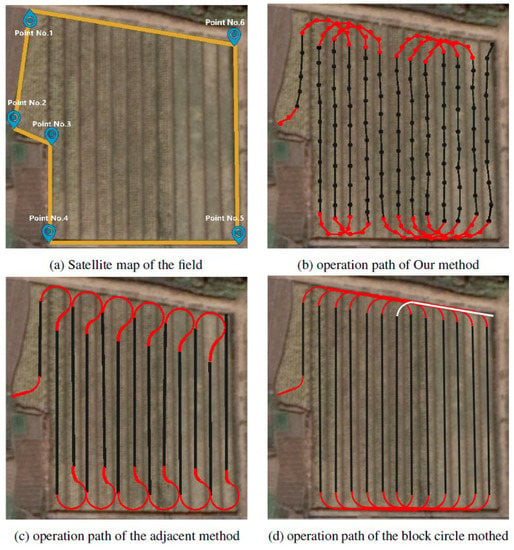

In order to assess the effectiveness and performance of the method, a field in Yangxiang Town, Wuxi City, China with a total area of 0.427 hm2 was selected as the test area. The shape of the field, illustrated in Figure 3a, is characterized by six contour vertexes, as detailed in Table 2. Grid the rectangle surrounding the field in Figure 3a with lines 1 m apart to obtain 3360 grids. In addition, it is stipulated that agricultural machineries can only enter and exit from and . To compare the proposed method, the adjacent method [43] and the block circle method [20] were employed as control groups in this experiment due to their popularity. The adjacent method utilizes a bulb-type turning technique for adjacent strip operations, while the block circle method divides the field into several standard blocks and one remaining block, facilitating single-arc turning and nesting operations.

Figure 3.

Satellite map of the field and operation paths of three methods.

Table 2.

Mapping points of field outline in field tests.

The hardware environment of the cloud server in the control center is Intel(R) Xeon(R) Platinum 8163 CPU @2.50 GHz with 8 G memory. The software environment is CentOS Linux release 7.8.2003. The tractor autonomous driving and operation unit mainly includes tractor, subsoiler, vehicle control, and monitoring terminal. The tractor model is DF1004, and its minimum turning radius is 3.3 m. Through the integration of the high-precision agricultural machinery automatic driving system, it can perform path tracking, equipment lifting, and other functions, and the hardware environment of the vehicle terminal used is Qualcomm585 @2.84 GHz with 4 G memory. The agricultural machinery operating parameters are as in Table 3. These operation parameters are determined by the agricultural machinery and the field, and since we only use one model of agricultural machinery and one field, these parameters are fixed. k = 3, in Algorithm 2.

Table 3.

Operation parameters.

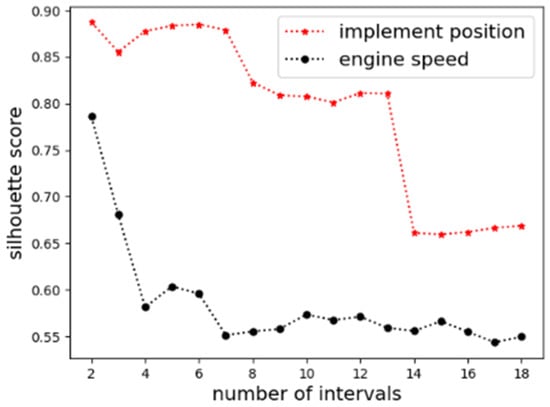

The cloud server collected the related data generated from nine manually driven DF1004 tractors for subsoiling operations. The format of each data point is shown in Table 4, and it was sent to the cloud server by the vehicle terminal at a frequency of one data point every two seconds. After the data preprocessing, the state vector of the agricultural machinery includes three variables: the grid number where it is located, the location of the implement, and the speed of the transmitter. The discretization algorithm in Section 3.3.2 is executed for the implement position and engine speed, respectively, with parameters and . Figure 4 shows the results of the k-means algorithm, its horizontal axis represents the number of discrete intervals (the number of cluster centers), and its vertical axis represents the contour coefficient. The maximum silhouette coefficient corresponds to the optimal number of discrete intervals. The optimal number of discrete intervals for the implement position is 2. The two cluster centers obtained are 388 and 923 after rounding, so the discrete intervals of engine speed are and . Obviously, 388 is the position where the implement descends in the operation phase of the agricultural machinery, while 923 is the position where the implement is lifted in the turning phase of the agricultural machinery. The optimal number of discrete intervals for the engine speed is 2. The two cluster centers obtained are 807 and 1309 after rounding, so the discrete intervals of implement position are and . Obviously, 1309 is the engine speed in the operation stage, while 807 is the engine speed in the turning stage.

Table 4.

Format of data points.

Figure 4.

Silhouette coefficients when the number of intervals ranges from 2 to 18.

4.1. Execution Time Evaluation

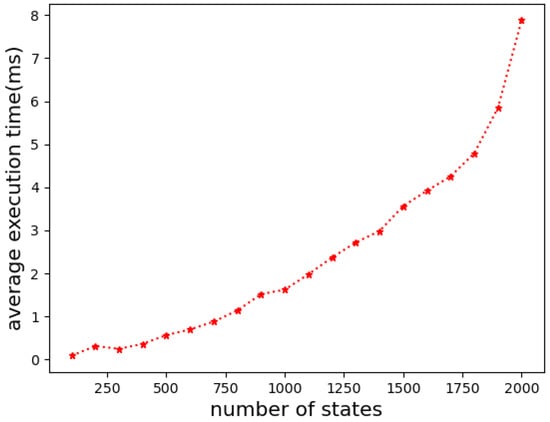

Since the running time of Algorithm 2 is critical for the overall system, it is essential to test the execution time of Algorithm 2 in this section. We conducted experiments using the Python programming language on the mentioned vehicle terminal. As the size of the fields increases, the number of states also increases. The input data for the algorithm is randomly generated with . Since the algorithm mainly involves matrix operations, we did not assign 0 to the elements in that correspond to states that are impossible to reach. We evaluated the execution time of Algorithm 2 by varying the number of states from 100 to 2000. The experimental results are depicted in Figure 5; its horizontal axis represents the input parameter n (total number of states) of Algorithm 2, and its vertical axis represents the execution time of Algorithm 2. Even when the number of states reaches 2000, the time is still under 8ms. The results show that the execution time of Algorithm 2 is very short and will not affect agricultural machinery operations.

Figure 5.

Execution time of Algorithm 2 when the number of states varies from 200 to 2000.

4.2. Operation Path

Figure 3c,d represent the simulation experiment data for the adjacent method and block circle method, respectively. Figure 3b is the trajectory generated by agricultural machinery using our method. Each data point is sent to the cloud server by the vehicle terminal. The time interval between each coordinate point is two seconds. If the implement position is greater than 655.5, it is marked red; otherwise, it is marked black. It can be observed that the tractor correctly lifted the subsoiler during the turning phase and lowered the subsoiler during the operation phase.

The turning area of the adjacent method is too large, while the block circle method has a small turning area but consumes extra distance when leaving the field at the end of the operation due to its failure to consider the exit restriction (the extra distance has been marked using white lines in Figure 3d). The proposed approach astutely selected the operation sequence of the operation strips, resulting in a successful departure from the field coinciding with the completion of the operation.

4.3. Operation Efficiency

In this paper, we evaluated the efficiency of our method by considering area and distance indicators [44,45]. The corresponding results are presented in Table 5. Comparative analysis reveals that our method outperforms the adjacent method significantly in terms of the operation area ratio and operation distance ratio. While the operation area ratio of our method is comparable to that of the block circle method, the operation distance ratio is notably superior. This indicates that our approach effectively reduces the turning area and non-working distance, demonstrating its feasibility and high efficiency. The slightly lower working area ratio of our method compared to the block circle method can be attributed to occasional instances where operators do not closely follow the field boundary during urning.

Table 5.

Format of data points.

5. Discussion

Operation planning is closely related to the operation effectiveness of intelligent agricultural machinery. Traditional methods often rely on manual mapping, radar, and visual methods to detect fields, which are either inefficient or costly and cannot obtain global information about the fields. However, the method proposed in this paper utilizes UAVs to obtain the global information of field, which greatly improves efficiency. In addition, we obtain efficient and practical operation plans by mining historical agricultural machinery operation data.

We analyzed the execution time of Algorithm 2, and the results showed that the execution time of Algorithm 2 does not affect the agricultural machinery operation. When the number of states continues to expand, even though n is very large, the states that can be reached from one state are limited, so the states that can be reached in step k are also limited. Assuming that k is 3, the movement range of agricultural machinery is only within the circle when the current grid is the center and the radius is fewer than three grids. Therefore, when n is too large, we need to extract the states that can be reached in k steps to construct the matrix instead of all states to reduce the running time of the program.

It can be observed from the operation path that our planner has successfully controlled the agricultural machinery to complete the operation and achieve good performance. The plan mined from the big data willingly chose the operation sequence of the operation strips and succeeded in leaving the field at the same time as ending the operation.

In addition, this paper also analyzed the operating area ratio and operating distance ratio, and the experimental results showed that our approach achieved better performance compared to the other two methods. The turning area of the adjacent method is too large. The block circle method has a small turning area but consumes an extra distance for leaving the field at the end of the operation due to its failure to consider the exit restriction (the extra distance has been marked using white lines in Figure 3d). The plan mined from the big data wisely chose the operation sequence of the operation strips and succeeded in leaving the field at the same time as ending the operation.

Although the proposed method performs well in experiments, there are some limitations. Our method mainly focuses on utilizing UAVs assist in the planning of intelligent agricultural machinery while neglecting the planning of UAVs. In future work, we will study the planning of UAVs to further improve the performance of the entire intelligent operation system.

6. Conclusions

In this paper, we propose a collaborative path planning method for intelligent agricultural machinery based on unmanned aerial vehicles. On the basis of field information and agricultural machinery operation data acquisition and preprocessing, the K-means clustering algorithm is used to extract core control parameters and state space discretization. A dynamic agricultural machinery operation plan based on the Markov chain is established, which has the characteristics of field adaptability, agronomic adaptability, and machinery adaptability. In this study, engine speed, implement position, and other control parameters are introduced to solve the integrity problem of intelligent agricultural machinery field operations. In addition, UAVs are used to help agricultural machinery avoid obstacles. The experimental results show that compared with the popular adjacent method and block circle method, our method is more efficient in terms of the operation area ratio and operation distance ratio.

Author Contributions

M.S., conceptualization, experimental design, data collection and analysis, and implementation of the computer code and writing the original draft; X.F., determination of the methodology, building of the architecture, guiding of the experimental process, and revision of the paper; S.P., design of the method and revision of the draft; X.S., revision of the manuscript; and L.J., visualization and curation of the data. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. U1736216).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yin, X.; Wang, Y.; Chen, Y.; Jin, C.; Du, J. Development of autonomous navigation controller for agricultural vehicles. Int. J. Agric. Biol. Eng. 2020, 13, 70–76. [Google Scholar] [CrossRef]

- Kelc, D.; Stajnko, D.; Berk, P.; Rakun, J.; Vindiš, P.; Lakota, M. Reduction of environmental pollution by using RTK-navigation in. Int. J. Agric. Biol. Eng. 2019, 12, 173–178. [Google Scholar]

- Yang, X. A survey on smart agriculture: Development modes, technologies, and security and privacy challenges. IEEE/CAA J. Autom. Sinica 2021, 8, 273–302. [Google Scholar] [CrossRef]

- Fountas, S.; Mylonas, N.; Malounas, I.; Rodias, E.; Hellmann Santos, C.; Pekkeriet, E. Agricultural robotics for field operations. Sensors 2020, 20, 2672. [Google Scholar] [CrossRef] [PubMed]

- Malavazi, F.B.; Guyonneau, R.; Fasquel, J.B.; Lagrange, S.; Mercier, F. LiDAR-only based navigation algorithm for an autonomous agricultural robot. Comput. Electron. Agric. 2018, 154, 71–79. [Google Scholar] [CrossRef]

- Higuti, V.A.H.; Velasquez, A.E.B.; Magalhaes, D.V.; Becker, M.; Chowdhary, G. Under canopy light detection and ranging-based autonomous navigation. J. Field Robot. 2019, 36, 547–567. [Google Scholar] [CrossRef]

- Zhang, C.; Yong, L.; Chen, Y.; Zhang, S.; Ge, L.; Wang, S. A rubber-tapping robot forest navigation and information collection system based on 2D LiDAR and a gyroscope. Sensors 2019, 19, 2136. [Google Scholar] [CrossRef] [PubMed]

- Torres-Sospedra, J.; Nebot, P. A new approach to visual-based sensory system for navigation into orange groves. Sensors 2011, 11, 4086–4103. [Google Scholar] [CrossRef]

- Radcliffe, J.; Cox, J.; Bulanon, D.M. Machine vision for orchard navigation. Comput. Ind. 2018, 98, 165–171. [Google Scholar] [CrossRef]

- Sharifi, M.; Chen, X.Q. A novel vision based row guidance approach for navigation of agricultural mobile robots in orchards. In Proceedings of the 2015 6th International Conference on Automation, Robotics and Applications (ICARA), Queenstown, New Zealand, 17–19 February 2015; pp. 251–255. [Google Scholar]

- Stefas, N.; Bayram, H.; Isler, V. Vision-based monitoring of orchards with UAVs. Comput. Electron. Agric. 2019, 163, 104814. [Google Scholar] [CrossRef]

- Lyu, H.K.; Park, C.H.; Han, D.H.; Kwak, S.; Choi, B. Orchard free space and center line estimation using Naive Bayesian classifier for unmanned ground self-driving vehicle. Symmetry 2018, 10, 355. [Google Scholar] [CrossRef]

- Colao, A.F.; Richetti, J.; Bramley, R.G.V.; Lawes, R.A. How will the next-generation of sensor-based decision systems look in the context of intelligent agriculture? A case-study. Field Crops Res. 2021, 270, 108205. [Google Scholar] [CrossRef]

- Lu, E.; Xu, L.; Li, Y.; Tang, Z.; Ma, Z. Modeling of working environment and coverage path planning method of combine harvesters. Int. J. Agric. Biol. Eng. 2020, 13, 132–137. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, Y.; Yang, J.; Li, D.; Wang, Y.; Zhao, R. Many-objective evolutionary algorithm based agricultural mobile robot route planning. Comput. Electron. Agric. 2022, 200, 107274. [Google Scholar] [CrossRef]

- Bochtis, D.; Vougioukas, S. Minimising the non-working distance travelled by machines operating in a headland field pattern. Biosyst. Eng. 2008, 101, 1–12. [Google Scholar] [CrossRef]

- Conesa-Muñoz, J.; Bengochea-Guevara, J.M.; Andujar, D.; Ribeiro, A. Route planning for agricultural tasks: A general approach for fleets of autonomous vehicles in site-specific herbicide applications. Comput. Electron. Agric. 2016, 127, 204–220. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Busato, P.; Bochtis, D.; Sørensen, C.G.; Zhou, K. Energy savings from optimised in-field route planning for agricultural machinery. Sustainability 2017, 9, 1956. [Google Scholar] [CrossRef]

- Plessen, M.M.G. Partial field coverage based on two path planning patterns. Biosyst. Eng. 2018, 171, 16–29. [Google Scholar] [CrossRef]

- Utamima, A.; Reiners, T.; Ansaripoor, A.H. Optimisation of agricultural routing planning in field logistics with evolutionary hybrid neighbourhood search. Biosyst. Eng. 2019, 184, 166–180. [Google Scholar] [CrossRef]

- Boryga, M.; Kołodziej, P.; Gołacki, K. Application of polynomial transition curves for trajectory planning on the headlands. Agriculture 2020, 10, 144. [Google Scholar] [CrossRef]

- Cariou, C.; Gobor, Z.; Seiferth, B.; Berducat, M. Mobile robot trajectory planning under kinematic and dynamic constraints for partial and full field coverage. J. Field Robot. 2017, 34, 1297–1312. [Google Scholar] [CrossRef]

- Zhou, K.; Jensen, A.L.; Sørensen, C.; Busato, P.; Bothtis, D. Agricultural operations planning in fields with multiple obstacle areas. Comput. Electron. Agric. 2014, 109, 12–22. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Yu, Z.; Zhang, B.; Zhang, N. Dynamic trajectory planning and tracking for autonomous vehicle with obstacle avoidance based on model predictive control. IEEE Access 2019, 7, 132074–132086. [Google Scholar] [CrossRef]

- Radoglou-Grammatikis, P.; Sarigiannidis, P.; Lagkas, T.; Moscholios, I. A compilation of UAV applications for precision agriculture. Comput. Netw. 2020, 172, 107148. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, R.; Chen, L.; Zhang, L.; Zhang, H.; Zhao, C. Semantic segmentation and path planning for orchards based on UAV images. Comput. Electron. Agric. 2022, 200, 107222. [Google Scholar] [CrossRef]

- Alzahrani, B.; Oubbati, O.S.; Barnawi, A.; Atiquzzaman, M.; Alghazzawi, D. UAV assistance paradigm: State-of-the-art in applications and challenges. J. Netw. Comput. Appl. 2020, 166, 102706. [Google Scholar] [CrossRef]

- Erwin, P.; Bruce, G.; Alena, O.; Niels, A.; James, C. Optimization approaches for civil applications of unmanned aerial vehicles (UAVs) or aerial drones: A survey. Networks 2018, 72, 411–458. [Google Scholar]

- Shakhatreh, H.; Sawalmeh, A.; Fuqaha, A.A.; Guizani, M. Unmanned aerial vehicles (UAVs): A survey on civil applications and key research challenges. IEEE Access 2019, 7, 48572–48634. [Google Scholar] [CrossRef]

- Zuo, Z.; Liu, C.; Han, Q.L. Unmanned aerial vehicles: Control methods and future challenges. IEEE/CAA J. Autom. Sinica 2022, 9, 601–614. [Google Scholar] [CrossRef]

- Zhao, J.W.H. High-order sliding mode observer-based trajectory tracking control for a quadrotor UAV with uncertain dynamics. Nonlinear Dyn. 2020, 102, 2583–2596. [Google Scholar] [CrossRef]

- Fari, S.; Wang, X.; Roy, S.; Baldi, S. Addressing unmodeled path-following dynamics via adaptive vector field: A UAV test case. IEEE Trans. Aerosp. Electron. Syst. 2019, 56, 1613–1622. [Google Scholar] [CrossRef]

- Li, B.; Wu, Y. Path planning for UAV ground target tracking via deep reinforcement learning. IEEE Access 2020, 8, 29064–29074. [Google Scholar] [CrossRef]

- Mammarella, M.; Comba, L.; Biglia, A.; Dabbene, F.; Gay, P. Cooperation of unmanned systems for agricultural applications: A theoretical framework. J. Biosyst. Eng. 2021, 223, 61–80. [Google Scholar] [CrossRef]

- He, J.; Hu, L.; Wang, P.; Liu, Y.; Man, Z.; Tu, T.; Luo, X. Path tracking control method and performance test based on agricultural machinery pose correction. Comput. Electron. Agric. 2022, 200, 107185. [Google Scholar] [CrossRef]

- Du, M.; Li, H.; Roshanianfard, A. Design and experimental study on an innovative UAV-LiDAR topographic mapping system for precision land levelling. Drones 2022, 6, 403. [Google Scholar] [CrossRef]

- Pnpoly-Point Inclusion in Polygon Test. Available online: https://wrfranklin.org/Research/Short_Notes/pnpoly.html (accessed on 23 July 2023).

- Great Circle. Available online: https://mathworld.wolfram.com/GreatCircle.html (accessed on 23 July 2023).

- Ross, S.M. Introduction to Probability Models, 11th ed.; Academic Press: New York, NY, USA, 2008; pp. 187–259. [Google Scholar]

- Hartigan, J.A.; Wong, M.A. Algorithm AS 136: A k-means clustering algorithm. J. R. Stat. Soc. Ser. C Appl. Stat. 1979, 28, 100–108. [Google Scholar] [CrossRef]

- Rousseeuw, P.J. Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 1987, 20, 53–65. [Google Scholar] [CrossRef]

- Cheng, C.; Sha, Q.; He, B.; Li, G. Path planning and obstacle avoidance for AUV: A review. Ocean Eng. 2021, 235, 109355. [Google Scholar] [CrossRef]

- Evans, I.V.J.T.; Pitla, S.K.; Luck, J.D.; Kocher, M. Row crop grain harvester path optimization in headland patterns. Comput. Electron. Agric. 2020, 171, 105295. [Google Scholar] [CrossRef]

- Nilsson, R.S.; Zhou, K. Method and bench-marking framework for coverage path planning in arable farming. Biosyst. Eng. 2020, 198, 248–265. [Google Scholar] [CrossRef]

- Nilsson, R.S.; Zhou, K. Decision support tool for operational planning of field operations. Agronomy 2020, 10, 229. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).