Parameters Identification of a Permanent Magnet DC Motor: A Review

Abstract

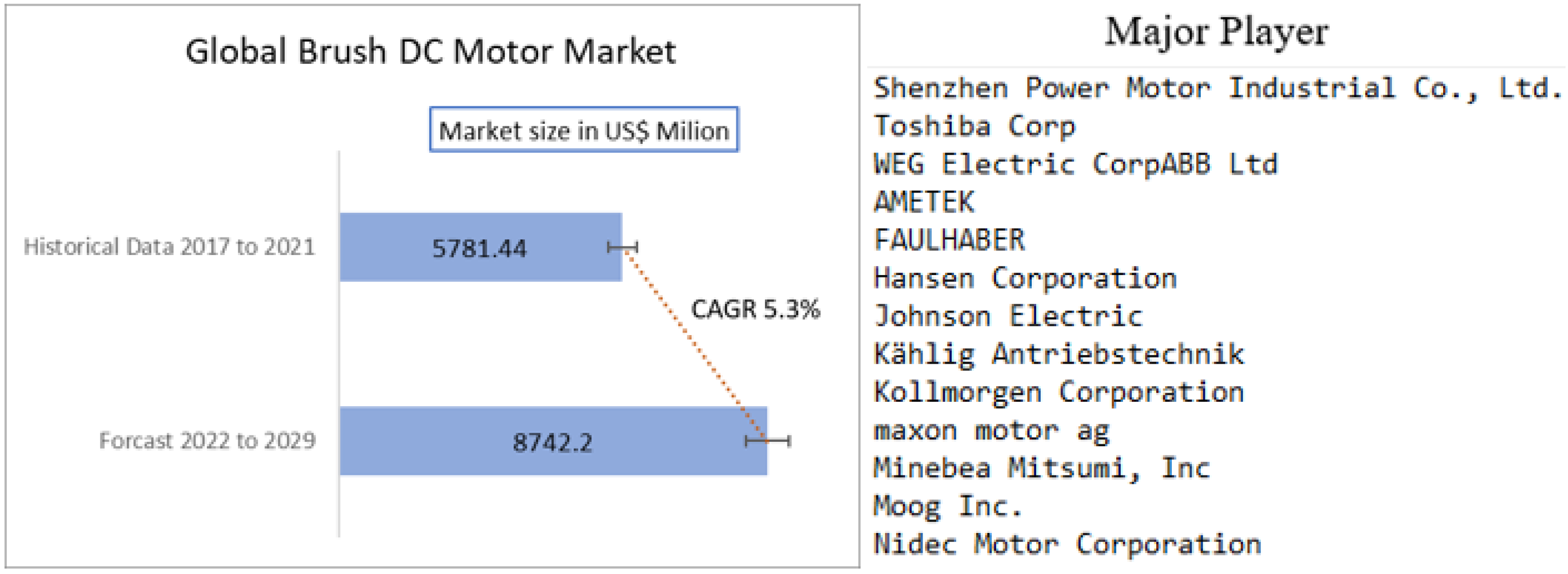

:1. Introduction

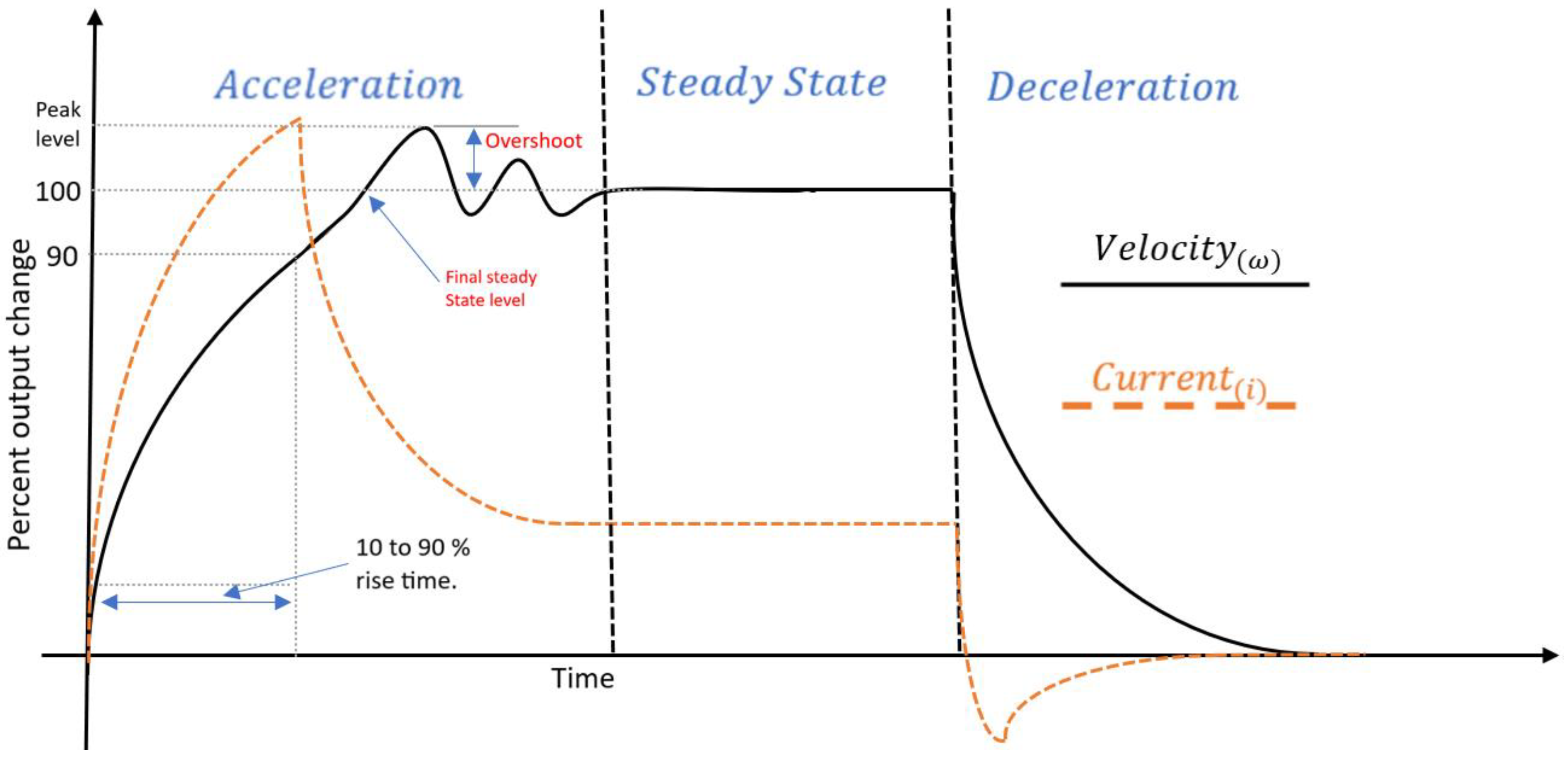

2. DC Motor Dynamic Response and Parameter Estimation

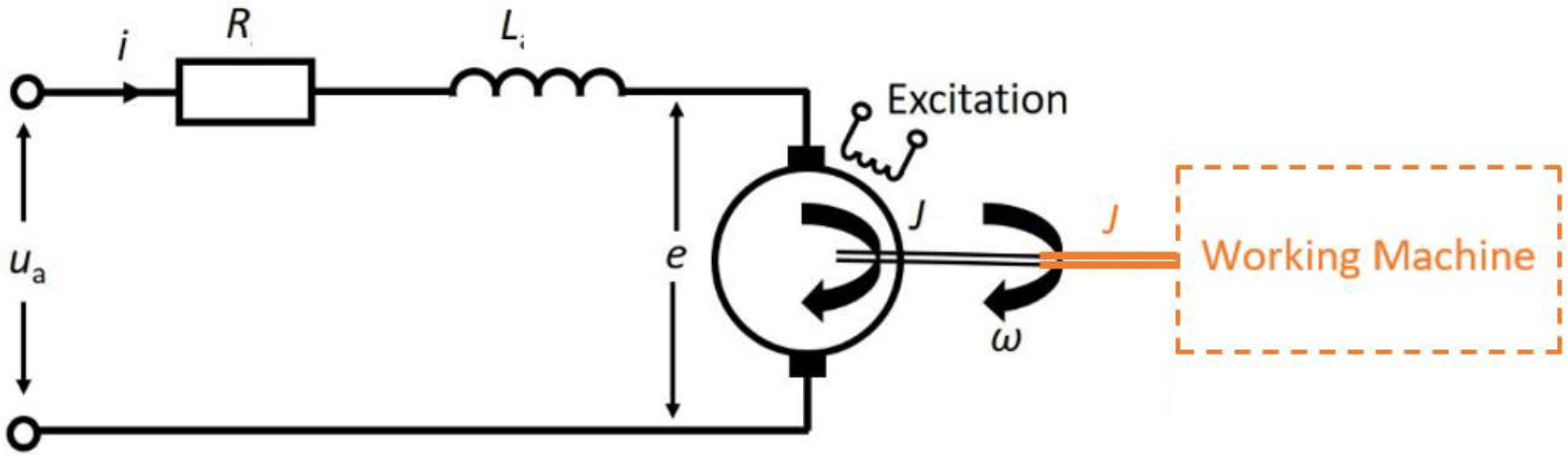

2.1. DC Motor Mathematical Model of DC Motor

2.2. Least Squares Method

2.3. Metaheuristics Algorithms

2.3.1. Differential Evolution (DE)

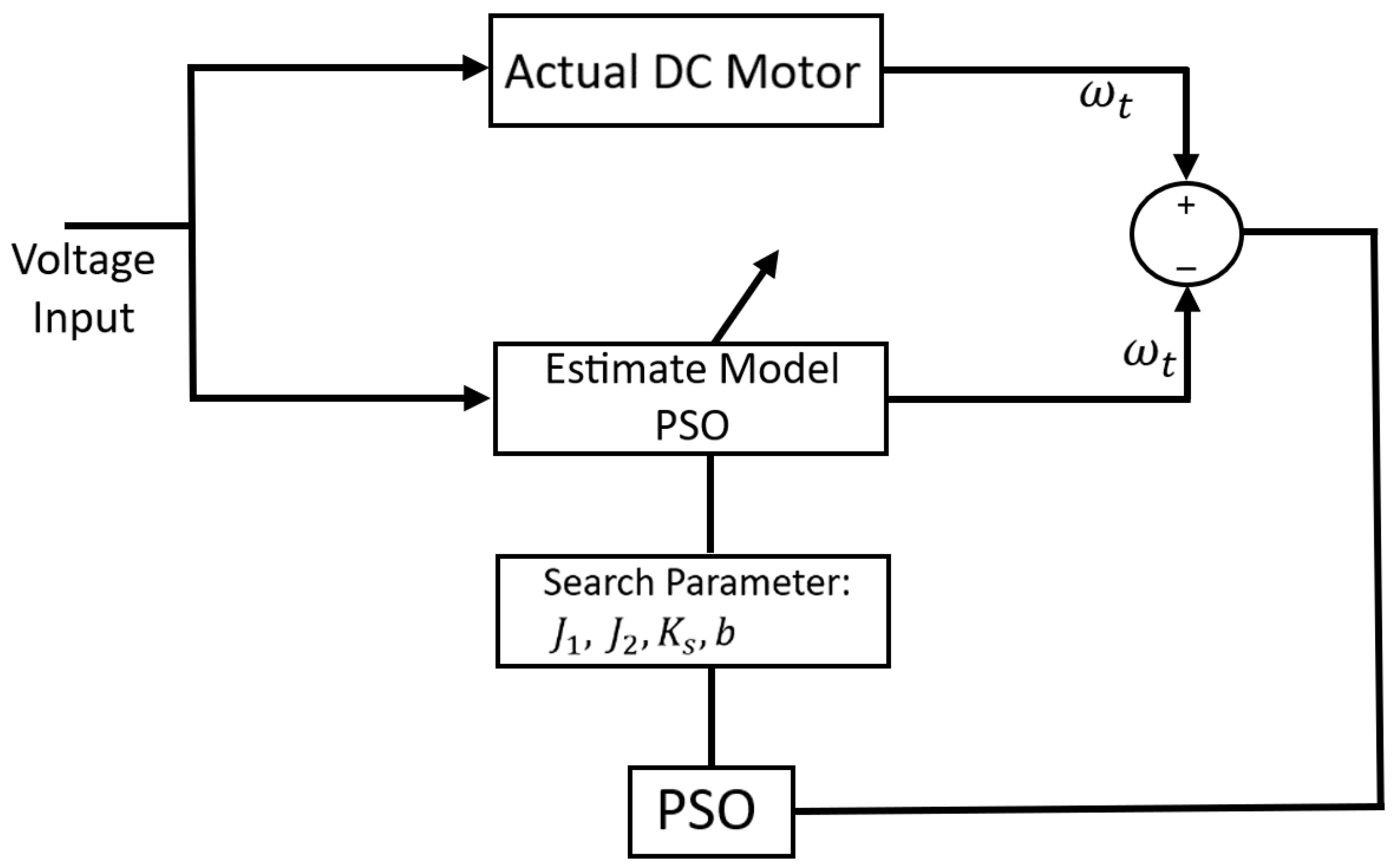

2.3.2. Particle Swarm Optimization (PSO)

2.3.3. Cuckoo Search Optimization (CSO)

3. Discussion

3.1. Least Squares Method

3.2. Differential Evolution

3.3. Particle Swarm Optimization

3.4. Cuckoo Search Optimization

3.5. Quantitative Comparison of Computational Costs

3.5.1. Least Squares Method

3.5.2. Differential Evolution (DE)

3.5.3. Particle Swarm Optimization (PSO)

3.5.4. Cuckoo Search Optimization (CSO)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maximize Market Research. Global Brush DC Motors Market—Industry Analysis and Forecast (2020–2027). 2021. Available online: https://www.maximizemarketresearch.com/market-report/global-brush-dc-motors-market/71704/ (accessed on 22 May 2023).

- Batool, A.; Ain, N.U.; Amin, A.A.; Adnan, M.; Shahbaz, M.H. A comparative study of DC servo motor parameter estimation using various techniques. Automatika 2022, 63, 303–312. [Google Scholar] [CrossRef]

- Usman, H.M.; Mukhopadhyay, S.; Rehman, H. Permanent magnet DC motor parameters estimation via universal adaptive stabilization. Control Eng. Pract. 2019, 90, 50–62. [Google Scholar] [CrossRef]

- Wu, W. DC Motor Parameters Identification Using Speed Step Response. Model. Simul. Eng. 2012, 2012, 189757. [Google Scholar] [CrossRef] [Green Version]

- Adewusi, S. Modeling and Parameters Identification of a DC Motor Using Constraint Optimization Technique. IOSR J. Mech. Civ. Eng. 2016, 13, 46–56. [Google Scholar]

- Hadef, M.; Mekideche, M.R. Parameter identification of a separately excited dc motor via inverse problem methodology. Turk. J. Electr. Eng. Comp. Sci. 2009, 17, 99–106. [Google Scholar] [CrossRef]

- Shanmuga, N.B.; Mythile, A.; Pavithra, S.; Nivetha, N. Parameter Identification of a DC Motor. Int. J. Sci. Technol. Res. 2020, 9, 2. [Google Scholar]

- Amiri, M.S.; Ibrahim, M.F.; Ramli, R. Optimal parameter estimation for a DC motor using genetic algorithm. Int. J. Power Electron. Drive Syst. 2020, 11, 1047–1054. [Google Scholar] [CrossRef]

- Dupuis, A.; Ghribi, M.; Kaddouri, A. Multiobjective genetic estimation of DC motor parameters and load torque. In Proceedings of the 2004 IEEE International Conference on Industrial Technology, 2004. IEEE ICIT ’04., Hammamet, Tunisia, 8–10 December 2004; Volume 3, pp. 1511–1514. [Google Scholar] [CrossRef]

- Wu, W. DC motor identification using speed step responses. In Proceedings of the IEEE American Control Conference (ACC), Baltimore, MD, USA, 30 June–2 July 2010; pp. 1937–1941. [Google Scholar]

- Awoda, M.L.; Ramzy, S.A. Parameter Estimation of a Permanent Magnets DC motor. Iraqi J. Electr. Electron. Eng. 2019, 15, 28–36. [Google Scholar] [CrossRef]

- Lin, Y.-H. Improvement and Implementation of Model Identification for Permanent Magnet DC Motors. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2020. [Google Scholar]

- Arshad, S.; Qamar, S.; Jabbar, T.; Malik, A. Parameter Estimation of a DC Motor Using Ordinary Least Squares and Recursive Least Squares Algorithms. In Proceedings of the 8th International Conference on Frontiers of Information Technology, Islamabad, Pakistan, 12–13 December 2010. [Google Scholar] [CrossRef]

- Li, M.; Ma, Y. Parameter Identification of DC Motor based on Compound Least Square Method. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 12–14 June 2020; pp. 1107–1111. [Google Scholar] [CrossRef]

- Ivanov, D.V.; Sandler, I.L.; Chertykovtseva, N.V.; Mitroshin, D.I.; Ivanova, O.S.; Kormakov, A.A. Identification of Parameters of DC Motor of Independent Excitation by Noisy Data. In Proceedings of the 2021 3rd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA), Lipetsk, Russia, 10–12 November 2021; pp. 194–198. [Google Scholar] [CrossRef]

- Gao, D.; Wu, S.; Yu, J.; Wang, M.; Wang, Y. Parameter identification of DC motor model based on improved dynamic forgetting factor recursive least squares method. In Proceedings of the 2022 IEEE 8th International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Melaka, Malaysia, 26–28 September 2022; pp. 282–286. [Google Scholar] [CrossRef]

- Hsueh, P.-W.; Tseng, C.-M.; Lin, Y.-H. Improvement of Model Identification for Permanent Magnet DC Servo Motors. In Proceedings of the 18th International Conference on Automation Technology (Automation 2021), Online, 6–8 July 2021. [Google Scholar]

- Jesenik, M.; Hamler, A.; Trbušić, M.; Trlep, M. The Use of Evolutionary Methods for the Determination of a DC Motor and Drive Parameters Based on the Current and Angular Speed Response. Mathematics 2020, 8, 1269. [Google Scholar] [CrossRef]

- Rodríguez-Molina, A.; Villarreal-Cervantes, M.G.; Aldape-Pérez, M. Optimal Adaptive Control of a DC Motor Using Differential Evolution Variants. In Proceedings of the 2017 IEEE 7th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Honolulu, HI, USA, 31 July–4 August 2017; pp. 283–288. [Google Scholar] [CrossRef]

- Sands, T. Nonlinear-Adaptive Mathematical System Identification. Computation 2017, 5, 47. [Google Scholar] [CrossRef] [Green Version]

- Poon, J.; Jain, P.; Spanos, C.; Panda, S.K.; Sanders, S.R. Fault Prognosis for Power Electronics Systems Using Adaptive Parameter Identification. IEEE Trans. Ind. Appl. 2017, 53, 2862–2870. [Google Scholar] [CrossRef]

- Serradilla, F.; Canas, N.; Naranjo, J.E. Optimization of the Energy Consumption of Electric Motors through Metaheuristics and PID Controllers. Electronics 2020, 9, 1842. [Google Scholar] [CrossRef]

- Ren, L.; Lin, G.; Zhao, Y.; Liao, Z. Smart Collaborative Performance-Induced Parameter Identification Algorithms for Synchronous Reluctance Machine Magnetic Model. Sustainability 2021, 13, 4379. [Google Scholar] [CrossRef]

- Rahman, M.S.; Lukman, G.F.; Hieu, P.T.; Jeong, K.I.; Ahn, J.W. Optimization and Characteristics Analysis of High Torque Density 12/8 Switched Reluctance Motor Using Metaheuristic Gray Wolf Optimization Algorithm. Energies 2021, 14, 2013. [Google Scholar] [CrossRef]

- Puangdownreong, D.; Hlungnamtip, S.; Thammarat, C.; Nawikavatan, A. Application of flower pollination algorithm to parameter identification of DC motor model. In Proceedings of the IEEE International Electrical Engineering Congress (IEECON), Pattaya, Thailand, 8–10 March 2017; pp. 1–4. [Google Scholar]

- Hafez, I.; Dhaouadi, R. Parameter Identification of DC Motor Drive Systems using Particle Swarm Optimization. In Proceedings of the 2021 International Conference on Engineering and Emerging Technologies (ICEET), Istanbul, Turkey, 27–28 October 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Mughal, M.A.; Khan, M.; Shah, A.A.; Almani, A.A. DC Motor Parameter Estimation Using Chaotic Initialized Particle Swarm Optimization. In Proceedings of the International Conference on Electromechanical Control Technology and Transportation (ICECTT), Chongqing, China, 19–21 January 2018. [Google Scholar] [CrossRef]

- Sankardoss, V.; Geethanjali, P. PMDC motor parameter estimation using bio-inspired optimization algorithms. IEEE Access 2017, 5, 11244–11254. [Google Scholar] [CrossRef]

- Srivastava, A.; Das, D.K.; Rai, A.; Raj, R. Parameter Estimation of a Permanent Magnet Synchronous Motor using Whale Optimization Algorithm. In Proceedings of the 2018 Recent Advances on Engineering, Technology and Computational Sciences (RAETCS), Allahabad, India, 6–8 February 2018; pp. 1–6. [Google Scholar]

- Balamurugan, K.; Mahalakshmi, R. Analysis of Brushless DC Motor Using Deep Neural Network and BAT Algorithm. In Advances in Smart System Technologies; Suresh, P., Saravanakumar, U., Hussein Al Salameh, M.S., Eds.; Springer: Singapore, 2021; pp. 51–60. [Google Scholar]

- Tabish, M.; Kalam, A.; Zayegh, A. Robot DC Servo Motor Parameters Estimation in a closed loop Using BAT Optimisation Algorithm. In Proceedings of the 2019 International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Swat, Pakistan, 24–25 July 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Liu, Z.H.; Li, X.H.; Wu, L.H.; Zhou, S.W.; Liu, K. GPU-Accelerated Parallel Coevolutionary Algorithm for Parameters Identification and Temperature Monitoring in Permanent Magnet Synchronous Machines. IEEE Trans. Ind. Inform. 2015, 11, 1220–1230. [Google Scholar] [CrossRef]

- Rubaai, A.; Kotaru, R. Online identification and control of a DC motor using learning adaptation of neural networks. IEEE Trans. Ind. Appl. 2000, 36, 935–942. [Google Scholar] [CrossRef]

- Da Silva, M.F.; Bastos, F.F.; Da Silva Casillo, D.S.; Casillo, L.A. Parameters identification and analysis of brushless direct current motors. IEEE Lat. Am. Trans. 2016, 14, 3138–3143. [Google Scholar] [CrossRef]

- Hadef, M.; Bourouina, A.; Mekideche, M. Parameter identification of a DC motor via moments method. Iran. J. Electr. Comput. Eng. 2008, 7, 159–163. [Google Scholar]

- Mamani, G.; Becedas, J.; Feliu-Batlle, V.; Sira-Ramirez, H. Open-loop algebraic identification method for a DC motor. In Proceedings of the IEEE European Control Conference (ECC), Kos, Greece, 2–5 July 2007; pp. 3430–3436. [Google Scholar]

- Sendrescu, D. Parameter identification of a DC motor via distribution-based approach. In Proceedings of the 17th IEEE International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 27–30 August 2012; pp. 17–22. [Google Scholar]

- Galijašević, S.; Mašić, Š.; Smaka, S.; Akšamović, A.; Balić, D. Parameter identification and digital control of speed of a permanent magnet DC motor. In Proceedings of the 23rd IEEE International Symposium on Information, Communication and Automation Technologies (ICAT), Sarajevo, Bosnia and Herzegovina, 27–29 October 2011. [Google Scholar]

- Rodríguez-Abreo, O.; Hernandez-Paredes, J.M.; Rangel, A.F.; Fuentes-Silva, C.; Velásquez, F.A.C. Parameter Identification of Motors by Cuckoo Search Using Steady-State Relations. IEEE Access 2021, 9, 72017–72024. [Google Scholar] [CrossRef]

- Rodríguez-Abreo, O.; Rodríguez-Reséndiz, J.; Álvarez-Alvarado, J.M.; García-Cerezo, A. Metaheuristic Parameter Identification of Motors Using Dynamic Response Relations. Sensors 2022, 22, 4050. [Google Scholar] [CrossRef] [PubMed]

- Narula, N.S.; Bhatnagar, A.; Kumar, V.; Rana, K.P.S. A teacher learning based optimization approach to tune backstepping controller for a single-link flexible-joint manipulator. In Proceedings of the 2nd International Conference on Communication, Control and Intelligent Systems (CCIS), Mathura, India, 18–20 November 2016; pp. 159–164. [Google Scholar]

- Singh, K.S.M.J.; Elamvazuthi, I.; Shaari, K.Z.K.; Lima, F.V. PID tuning control strategy using cuckoo search algorithm. In Proceedings of the 2015 IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015; pp. 129–133. [Google Scholar]

- Singh, K.S.M.J.; Elamvazuthi, I.; Shaari, K.Z.K.; Perumal, N. Development of PID controller tuning tool based on cuckoo search algorithms. In Proceedings of the IEEE 3rd International Symposium in Robotics and Manufacturing Automation (ROMA), Kuala Lumpur, Malaysia, 28 August–1 September 2017; pp. 1–5. [Google Scholar]

- Srivastava, D.; Singh, Y.; Sahoo, A. Auto tuning of RNN hyperparameters using cuckoo search algorithm. In Proceedings of the 12th International Conference on Contemporary Computing (IC), Noida, India, 8–10 August 2019; pp. 1–5. [Google Scholar]

- Wu, C.Y.; Tasi, M.C.; Mao, S.H. Characteristics measurement of direct-drive brushless DC motors without using dynamometers. In Proceedings of the 2009 International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Jamal, A.; Rahman, M.T.; Al-Ahmadi, H.M.; Ullah, I.; Zahid, M. Intelligent intersection control for delay optimization: Using meta-heuristic search algorithms. Sustainability 2020, 12, 1896. [Google Scholar] [CrossRef] [Green Version]

- Schaffer, J.D.; Roebber, P.J.; Evans, C. Development and evaluation of an evolutionary programming-based tropical cyclone intensity model. Mon. Weather. Rev. 2020, 148, 1951–1970. [Google Scholar] [CrossRef] [Green Version]

- Zahir, A.; Alhady, S.S.N.; Wahab, A.; Ahmad, M. Objective functions modification of GA optimized PID controller for brushed DC motor. Int. J. Electr. Comput. Eng. 2020, 10, 2426. [Google Scholar] [CrossRef]

- Özcan, E.; Drake, J.H.; Altıntaş, C.; Asta, S. A self-adaptive multimeme memetic algorithm co-evolving utility scores to control genetic operators and their parameter settings. Appl. Soft Comput. 2016, 49, 81–93. [Google Scholar] [CrossRef] [Green Version]

- Mehr, A.D.; Nourani, V.; Kahya, E.; Hrnjica, B.; Sattar, A.M.; Yaseen, Z.M. Genetic programming in water resources engineering: A state-of-the-art review. J. Hydrol. 2018, 566, 643–667. [Google Scholar] [CrossRef]

- Li, S.; Gu, Q.; Gong, W.; Ning, B. An enhanced adaptive differential evolution algorithm for parameter extraction of photovoltaic models. Energy Convers. Manag. 2020, 205, 112443. [Google Scholar] [CrossRef]

- Montiel, O.; Castillo, O.; Melin, P.; Díaz, A.R.; Sepúlveda, R. Human evolutionary model: A new approach to optimization. Inf. Sci. 2007, 177, 2075–2098. [Google Scholar] [CrossRef]

- Rahman, I.; Mohamad-Saleh, J. Hybrid bio-Inspired computational intelligence techniques for solving power system optimization problems: A comprehensive survey. Appl. Soft Comput. 2018, 69, 72–130. [Google Scholar] [CrossRef]

- Yu, H.; Tan, Y.; Zeng, J.; Sun, C.; Jin, Y. Surrogate-assisted hierarchical particle swarm optimization. Inf. Sci. 2018, 454, 59–72. [Google Scholar] [CrossRef]

- Uthayakumar, J.; Metawa, N.; Shankar, K.; Lakshmanaprabu, S. Financial crisis prediction model using antcolony optimization. Int. J. Inf. Manag. 2020, 50, 538–556. [Google Scholar] [CrossRef]

- Chen, J.; Yu, W.; Tian, J.; Chen, L.; Zhou, Z. Image contrast enhancement using an artificial bee colony algorithm. Swarm Evol. Comput. 2018, 38, 287–294. [Google Scholar] [CrossRef]

- Al-Betar, M.A.; Awadallah, M.A. Island bat algorithm for optimization. Expert Syst. Appl. 2018, 107, 126–145. [Google Scholar] [CrossRef]

- Chen, H.; Yang, C.; Heidari, A.A.; Zhao, X. An efficient double adaptive random spare reinforced whale optimization algorithm. Expert Syst. Appl. 2019, 154, 113018. [Google Scholar] [CrossRef]

- Li, M.; Zhao, H.; Weng, X.; Han, T. Cognitive behavior optimization algorithm for solving optimization problems. Appl. Soft Comput. 2016, 39, 199–222. [Google Scholar] [CrossRef]

- Feng, Z.-K.; Liu, S.; Niu, W.-J.; Li, S.-S.; Wu, H.-J.; Wang, J.-Y. Ecological operation of cascade hydropower reservoirs by elite-guide gravitational search algorithm with Levy flight local search and mutation. J. Hydrol. 2020, 581, 124425. [Google Scholar] [CrossRef]

- Xing, B.; Gao, W.-J. Electromagnetism-like Mechanism Algorithm, Innovative Computational Intelligence: A Rough Guide to 134 Clever Algorithms; Springer: Berlin/Heidelberg, Germany, 2014; pp. 347–354. [Google Scholar] [CrossRef]

- Taser, A.E.; Guney, K.; Kurt, E. Circular antenna array synthesis using multiverse optimizer. Int. J. Antennas Propag. 2020, 2020, 3149826. [Google Scholar] [CrossRef]

- Neggaz, N.; Ewees, A.A.; Elaziz, M.A.; Mafarja, M. Boosting salp swarm algorithm by sine cosine algorithm and disrupt operator for feature selection. Expert Syst. Appl. 2019, 145, 113103. [Google Scholar] [CrossRef]

- Chung, Y.; Char, I.; Neiswanger, W.; Kandasamy, K.; Nelson, A.O.; Boyer, M.D.; Kolemen, E.; Schneider, J. Offline contextual bayesian optimization for nuclear fusion. arXiv 2020, arXiv:2001.01793. [Google Scholar]

- Wang, H.; Wang, W.; Zhou, X.; Sun, H.; Zhao, J.; Yu, X.; Cui, Z. Firefly algorithm with neighborhood attraction. Inf. Sci. 2017, 382, 374–387. [Google Scholar] [CrossRef]

- Luu, T.V.; Nguyen, N.S. Parameters extraction of solar cells using modified JAYA algorithm. Optik 2019, 203, 164034. [Google Scholar] [CrossRef]

- Wagan, A.I.; Shaikh, M.M. A new metaheuristic optimizationalgorithm inspired by human dynasties with an application to the wind turbine micrositing problem. Appl. Soft Comput. 2020, 90, 106176. [Google Scholar] [CrossRef]

- Shukla, A.K.; Singh, P.; Vardhan, M. An adaptive inertia weight teaching-learning-based optimization algorithm and itsapplications. Appl. Math. Model. 2020, 77, 309–326. [Google Scholar] [CrossRef]

- Askari, Q.; Younas, I.; Saeed, M. Political Optimizer: A novel socio-inspired meta-heuristic for global optimization. Knowl.-Based Syst. 2020, 195, 105709. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution-a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Nápoles, G.; Grau, I.; Bello, R. Constricted Particle Swarm Optimization based Algorithm for Global Optimization. Polibits 2012, 46, 5–11. [Google Scholar] [CrossRef]

- Sengupta, S.; Basak, S.; Peters, R.A. Particle Swarm Optimization: A Survey of Historical and Recent Developments with Hybridization Perspectives. Mach. Learn. Knowl. Extr. 2018, 1, 157–191. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Hefny, H.A.; Azab, S.S. Chaotic particle swarm optimization. In Proceedings of the 2010 The 7th International Conference on Informatics and Systems (INFOS), Cairo, Egypt, 28–30 March 2010; pp. 1–8. [Google Scholar]

- Yang, X.S.; Deb, S. Engineering Optimisation by Cuckoo Search. Int. J. Math. Model. Numer. Optim. 2010, 1, 330–343. [Google Scholar] [CrossRef]

- Ahmad, M.F.; Isa, N.A.M.; Lim, W.H.; Ang, K.M. Differential evolution: A recent review based on state-of-the-art works. Alex. Eng. J. 2022, 61, 3831–3872. [Google Scholar] [CrossRef]

- Moharam, A.; El-Hosseini, M.A.; Ali, H.A. Design of optimal PID controller using hybrid differential evolution and particle swarm optimization with an aging leader and challengers. Appl. Soft Comput. 2016, 38, 727–737. [Google Scholar] [CrossRef]

- Zhang, J.-H.; Zhang, Y.; Zhou, Y. Path planning of mobile robot based on hybrid multi-objective bare bones particle swarm optimization with differential evolution. IEEE Access 2018, 6, 44542–44555. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Yang, H. Self-adaptive mutation differential evolution algorithm based on particle swarm optimization. Appl. Soft Comput. 2019, 81, 105496. [Google Scholar] [CrossRef]

- Boks, R.; Wang, H.; Bäck, T. A modular hybridization of particle swarm optimization and differential evolution. In Proceedings of the 2020 Genetic and Evolutionary Computation Conference Companion (2020), Cancún, Mexico, 8–12 July 2020; pp. 1418–1425. [Google Scholar]

- Dash, J.; Dam, B.; Swain, R. Design and implementation of sharp edge FIR filters using hybrid differential evolution particle swarm optimization. AEU-Int. J. Electron. Commun. 2020, 114, 153019. [Google Scholar] [CrossRef]

- Choi, Z.C.; Ang, K.M.; Lim, W.H.; Tiang, S.S.; Ang, C.K.; Solihin, M.I.; Juhari, M.R.M.; Chow, C.E. Hybridized Metaheuristic Search Algorithm with Modified Initialization Scheme for Global Optimization. In Proceedings of the Advances in Robotics, Automation and Data Analytics: Selected Papers from ICITES 2020, Bangkok, Thailand, 13–14 May 2021; Springer: Cham, Switzerland; Volume 1350, p. 172. [Google Scholar] [CrossRef]

- Mlakar, U.; Potočnik, B.; Brest, J. A hybrid differential evolution for optimal multilevel image thresholding. Expert Syst. Appl. 2016, 65, 221–232. [Google Scholar] [CrossRef]

- Lin, H.; Siu, S.W. A hybrid cuckoo search and differential evolution approach to protein–ligand docking. Int. J. Mol. Sci. 2018, 19, 3181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Z.; Ding, S.; Jia, W. A hybrid optimization algorithm based on cuckoo search and differential evolution for solving constrained engineering problems. Eng. Appl. Artif. Intell. 2019, 85, 254–268. [Google Scholar] [CrossRef]

- Chi, R.; Su, Y.; Qu, Z.; Chi, X. A hybridization of cuckoo search and differential evolution for the logistics distribution center location problem. Math. Probl. Eng. 2019, 2019, 7051248. [Google Scholar] [CrossRef]

- Xia, J.; Zheng, L. A hybrid algorithm based on cuckoo search and differential evolution for numerical optimization. Computing 2020, 4, 1–8. [Google Scholar] [CrossRef]

- Gao, W.-F.; Huang, L.-L.; Wang, J.; Liu, S.-Y.; Qin, C.-D. Enhanced artificial bee colony algorithm through differential evolution. Appl. Soft Comput. 2016, 48, 137–150. [Google Scholar] [CrossRef]

- Zhou, J.; Yao, X. DE-caABC: Differential evolution enhanced context-aware artificial bee colony algorithm for service composition and optimal selection in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2016, 90, 1085–1103. [Google Scholar] [CrossRef]

- Haohao, C.; Xiaohui, Q.I.; Sen, Y. Obstacle Avoidance and Path Planning for Quadrotor based on Differential Evolution-Artificial Bee Colony Algorithm. J. Phys. Conf. Ser. 2018, 1087, 022030. [Google Scholar] [CrossRef]

- Najari, S.; Gróf, G.; Saeidi, S.; Gallucci, F. Modeling and optimization of hydrogenation of CO2: Estimation of kinetic parameters via Artificial Bee Colony (ABC) and Differential Evolution (DE) algorithms. Int. J. Hydrogen Energy 2019, 44, 4630–4649. [Google Scholar] [CrossRef]

- Zorarpacı, E.; Özel, S.A. Differentially private 1R classification algorithm using artificial bee colony and differential evolution. Eng. Appl. Artif. Intell. 2020, 94, 103813. [Google Scholar] [CrossRef]

- Trivedi, A.; Srinivasan, D.; Biswas, S.; Reindl, T. A genetic algorithm–differential evolution based hybrid framework: Case study on unit commitment scheduling problem. Inf. Sci. 2016, 354, 275–300. [Google Scholar] [CrossRef]

- Thakshaayene, J.; Kavitha, D. Unit commitment using hybrid genetic algorithm with differential evolution. In Proceedings of the 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 21–22 April 2017; pp. 1–6. [Google Scholar]

- Li, Y.; Wang, S.; Hong, X.; Li, Y. Multi-objective task scheduling optimization in cloud computing based on genetic algorithm and differential evolution algorithm. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 4489–4494. [Google Scholar]

- Rahmat, N.; Aziz, N.; Mansor, M.; Musirin, I. Optimizing economic load dispatch with renewable energy sources via differential evolution immunized ant colony optimization technique. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 2012. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Xue, Y.; Lu, X.; Jia, S. Differential-evolution-based coevolution ant colony optimization algorithm for Bayesian network structure learning. Algorithms 2018, 11, 188. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.; Xu, K.; Wang, X. Cloud computing resource scheduling based on improved differential evolution ant colony algorithm. In Proceedings of the 2019 International Conference on Data Mining and Machine Learning (2019), Beijing, China, 8–11 November 2019; pp. 171–177. [Google Scholar]

- Tian, D. Particle Swarm Optimization with Chaos-based Initialization for Numerical Optimization. Intell. Autom. Soft Comput. 2018, 24, 331–342. [Google Scholar] [CrossRef]

- Fister, I.; Yang, X.S.; Fister, D.; Fister, I. Cuckoo Search: A Brief Literature Review. In Cuckoo Search and Firefly Algorithm. Studies in Computational Intelligence; Yang, X.S., Ed.; Springer: Cham, Switzerland, 2014; Volume 516. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Description |

|---|---|

| ν(t) | Applied voltage to the motor (V) |

| τ(t) | Motor’s produced torque (Nm) |

| ω(t) | Rotor angular velocity (rad/s) |

| Ea(t) | Voltage in the Back EMF (V) |

| i | Current consumed by the motor (A) |

| TL | Torque at load (Nm) |

| R | Armature resistance (Ω) |

| L | Armature inductance (H) |

| Kt | The mechanical constants’ equal values |

| Ke | Back EMF |

| K | The mechanical and electrical constants’ equal values |

| B | Coefficient of friction () |

| J | Moment of inertia (Nm) |

| Parameter | Value | Nonlinear Least Squares (NLS) | Pattern Search (PS) |

|---|---|---|---|

| R | 1.107 | 1.0591 | 0.27302 |

| L | 0.120016 | 0.1 | 0.0028285 |

| K | 0.02497621 | 0.03728 | 0.018262 |

| B | 0.0007815 | 0.0011448 | 0.00078149 |

| J | 0.000121 | 0.0009 | 0.00012102 |

| Parameter | Value | Acceleration Method | Least Squares Method |

|---|---|---|---|

| R | 2.8 | None | 0.7636 |

| L | 0.003 | None | 0.00076356 |

| 0.2311 | 0.2159 | 0.2115 | |

| 0.23 | 0.2159 | 0.2115 | |

| B | 0.00019 | 0.0001181 | 0.0001157 |

| J | 0.00015 | 0.1465 | 0.0014 |

| 0.04 | 0.9442 | 0.9248 |

| Parameter | Method | |||||

|---|---|---|---|---|---|---|

| Use Value (Simulation) | GA | DE/Rand/ 1/Exp | DE/Best/ 1/Bin | TLBO | ABC | |

| R | 42.5 | 37.34 | 42.5 | 43.58 | 42.5 | 42.48 |

| L | ||||||

| 0.4781 | 0.6782 | 0.4781 | 0.4773 | 0.4781 | 0.4781 | |

| J | ||||||

| Parameter | Value | STD PSO | Error | CIW PSO | Error | AIWF PSO | Error | CI PSO | Error |

|---|---|---|---|---|---|---|---|---|---|

| 0.00274 | 0.0034 | 25.18% | 0.00271 | 0.89% | 0.0029 | 8.73% | 0.00275 | 0.56% | |

| 0.00256 | 0.0018 | 27.05% | 0.00258 | 0.957% | 0.00239 | 9.33% | 0.00254 | 0.61% | |

| 43.4560 | 41.129 | 5.35% | 43.49 | 0.093% | 43.233 | 0.45% | 41.7134 | 4.01% | |

| 0.0550 | 0.1 | 150.0% | 0.04036 | 0.924% | 0.03852 | 9.66% | 0.04755 | 18.88% |

| Parameter | Actual | CIPSO | SPSO |

|---|---|---|---|

| J | 0.01 | 0.0102 | 0.0110 |

| B | 0.1 | 0.1 | 0.104 |

| K | 0.01 | 0.0101 | 0.014 |

| R | 1 | 1.007 | 1.0901 |

| L | 0.5 | 0.503 | 0.508 |

| MSE | 1.399 × 10−16 | 2.080 × 10−12 |

| Parameter | Nominal Value | Steiglitz–McBride | Modify CSO | ||

|---|---|---|---|---|---|

| Value | Error | Value | Error | ||

| R | 3.1363 | 3.0031 | 4.44% | 3.0112 | 3.99% |

| K | 0.048774 | 0.0477 | 2.25% | 0.049203 | 0.88% |

| L | 0.01307 | 0.013556 | 3.72% | 0.01144 | 12.41% |

| J | 0.01% | 4.99% | |||

| B | 16.35% | 0.02% | |||

| Test | Algorithm | R% | K% | L% | J% | B% |

|---|---|---|---|---|---|---|

| Test 1 | 1.557 | 0.355 | 6.721 | 2.317 | 0.182 | |

| 1.473 | 0.173 | 0.591 | 0.397 | 0.173 | ||

| 15.081 | 3.801 | 55.18 | 12.917 | 0.34 | ||

| 0.012 | 0.001 | 0.21 | 0.225 | 0.001 | ||

| 0.252 | 0.029 | 0.068 | 0.29 | 0.029 | ||

| 0.008 | 0.001 | 0.041 | 0.027 | 0.001 | ||

| Test 2 | 0.262 | 0.161 | 4.03 | 0.198 | 0.077 | |

| 0.653 | 0.076 | 4.476 | 0.3 | 0.076 | ||

| 5.623 | 0.396 | 55.18 | 20.54 | 0.899 | ||

| 0.013 | 0.001 | 0.194 | 0.225 | 0.001 | ||

| 0.198 | 0.023 | 1.084 | 0.226 | 0.023 | ||

| 0.022 | 0.002 | 0.069 | 0.098 | 0.002 | ||

| Test 3 | 1.445 | 0.02 | 3.555 | 0.508 | 0.391 | |

| 1.355 | 0.159 | 1.391 | 0.383 | 0.159 | ||

| 20.539 | 0.572 | 55.18 | 168.091 | 12.048 | ||

| 0.014 | 0.002 | 0.3 | 0.225 | 0.002 | ||

| 3.137 | 0.376 | 9.907 | 3.56 | 0.376 | ||

| 0.004 | 0.001 | 0.212 | 0.215 | 0.001 | ||

| Test 4 | 13.269 | 2.785 | 53.598 | 66.302 | 0.375 | |

| 1.233 | 0.141 | 0.437 | 0.082 | 0.141 | ||

| 63.585 | 21.087 | 57.78 | 55.245 | 35.513 | ||

| 0.151 | 0.018 | 0.191 | 0.241 | 0.018 | ||

| 0.369 | 0.043 | 5.891 | 3.551 | 0.043 | ||

| 0.241 | 0.028 | 0.269 | 0.251 | 0.028 |

| Test | Algorithm | R% | K% | L% | J% | B% |

|---|---|---|---|---|---|---|

| Test 1 | 29.525 | 4.733 | 61.008 | 70.75 | 5.774 | |

| 0.244 | 0.054 | 5.024 | 0.755 | 0.054 | ||

| 9.779 | 2.48 | 3.253 | 4.529 | 5.228 | ||

| 0.087 | 0.02 | 0.667 | 0.829 | 0.02 | ||

| 0.203 | 0.045 | 0.086 | 0.264 | 0.045 | ||

| 0.025 | 0.005 | 0.024 | 0.023 | 0.005 | ||

| Test 2 | 5.792 | 1.448 | 19.533 | 6.69 | 1.554 | |

| 2.773 | 0.64 | 18.245 | 1.454 | 0.64 | ||

| 9.55 | 1.637 | 28.856 | 17.807 | 0.466 | ||

| 0.06 | 0.013 | 0.703 | 0.823 | 0.013 | ||

| 0.307 | 0.069 | 0.632 | 0.459 | 0.069 | ||

| 0.053 | 0.012 | 0.025 | 0.013 | 0.012 | ||

| Test 3 | 11.298 | 1.53 | 67.539 | 192.484 | 2.66 | |

| 0.936 | 0.206 | 8.692 | 0.601 | 0.206 | ||

| 6.186 | 0.08 | 65.769 | 162.739 | 6.26 | ||

| 0.121 | 0.027 | 0.637 | 0.836 | 0.027 | ||

| 0.291 | 0.065 | 10.56 | 5.329 | 0.065 | ||

| 0.028 | 0.006 | 0.551 | 0.102 | 0.006 | ||

| Test 4 | 4.496 | 0.966 | 12.593 | 12.692 | 0.737 | |

| 2.004 | 0.436 | 4.146 | 0.37 | 0.436 | ||

| 35.942 | 14.237 | 161.4 | 28.31 | 6.117 | ||

| 0 | 0 | 0.665 | 0.809 | 0 | ||

| 4.296 | 0.909 | 13.716 | 11.149 | 0.909 | ||

| 0.113 | 0.025 | 0.035 | 0.556 | 0.025 |

| Parameter | Simulink | Actual Motor |

|---|---|---|

| ✓ | |

| ✓ |

| Different Evolution with | Years |

|---|---|

| PSO (Particle swarm optimization) | 2016 [77], 2018 [78], 2019 [79], 2020 [80,81], 2021 [82] |

| CS (Cuckoo Search) | 2016 [83], 2018 [84], 2019 [85,86], 2020 [87] |

| ABC (Artificial bee colony) | 2016 [88], 2017 [89], 2018 [90], 2019 [91], 2020 [92] |

| GA (Genetic algorithm) | 2016 [93], 2017 [94], 2018 [95] |

| ACO (Ant colony optimization) | 2017 [96], 2018 [97], 2019 [98] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazdi, M.F.; Hsueh, P.-W. Parameters Identification of a Permanent Magnet DC Motor: A Review. Electronics 2023, 12, 2559. https://doi.org/10.3390/electronics12122559

Fazdi MF, Hsueh P-W. Parameters Identification of a Permanent Magnet DC Motor: A Review. Electronics. 2023; 12(12):2559. https://doi.org/10.3390/electronics12122559

Chicago/Turabian StyleFazdi, Mohamad Farid, and Po-Wen Hsueh. 2023. "Parameters Identification of a Permanent Magnet DC Motor: A Review" Electronics 12, no. 12: 2559. https://doi.org/10.3390/electronics12122559

APA StyleFazdi, M. F., & Hsueh, P.-W. (2023). Parameters Identification of a Permanent Magnet DC Motor: A Review. Electronics, 12(12), 2559. https://doi.org/10.3390/electronics12122559