1. Introduction

The most fundamental component of a power system is the ability to provide power demand at the lowest possible operational cost while adhering to various technological, economic, and certain system constraints [

1]. The optimal power flow (OPF) plays a vital role as an important tool to discover the optimal decision variables of a power network to minimize intended objectives. Since the introduction of the OPF problem by Carpintier in 1962 [

2], many researchers proposed various approaches including quadratic programming [

3], nonlinear programming [

4], interior point [

5], and Newton algorithm [

6,

7] to solve this nonlinear and non-convex problem. However, these traditional approaches cannot provide competitive results in the case of multi-objective nonlinear functions as they mostly sink into the local optimum. Hence, designing optimizers with effective search strategies which can deal with such complexities and provide competitive results is still an open issue for solving the OPF problem.

Metaheuristic algorithms are a subset of stochastic algorithms that have been employed for solving complex problems such as feature selection [

8,

9,

10,

11,

12], engineering [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26], community detection [

27,

28,

29,

30], and continuous optimization [

31,

32,

33,

34,

35,

36,

37] problems. Metaheuristic algorithms employ stochastic techniques to discover the promising areas by exploring the search space in early iterations and improve solutions quality by exploiting the promising areas in the final iterations. The main categorization of the metaheuristic algorithms is depending on the source of inspiration which divides them into the evolutionary and the swarm intelligence (SI) algorithms [

38]. The evolutionary algorithms mostly mimic natural biological evolution and reproduction to improve the randomly generated solutions. Genetic algorithm (GA) [

39], differential evolution (DE) [

40], and evolution strategies (ES) [

41] are prominent optimizers inspired by evolutionary concepts. As the evolutionary approach has proven to be a promising procedure, many researchers proposed improved versions of GA and DE algorithms for solving various problems [

42,

43,

44,

45].

The collective and cooperative behavior of biological organisms including fishes, birds, terrestrial animals, and insects is the basis of developing SI algorithms to solve optimization problems. The particle swarm optimization (PSO) [

46] is a well-known SI algorithm that mimics the navigation behavior of bird flocks’ for generating solutions in optimization tasks. Dorigo et al. [

47] simulated the collective behavior of some ants in nature by proposing the ant colony optimization (ACO) algorithm. The krill herd (KH) algorithm [

48] is a successful simulation of the herding behavior of krill individuals which consists of three phases including krill random diffusion, foraging activity, and movement. The grey wolf optimizer (GWO) proposed by Mirjalili et al. [

49] is also a SI algorithm based on the pack hierarchy approach to organizing the wolves based on their strength and responsibilities into four groups. The chimp optimization algorithm (ChOA) [

50] mimics the social and sexual behavior of chimps to solve optimization problems. Starling murmuration optimizer (SMO) [

51] is a recently proposed SI algorithm that models the stunning murmuration of starlings to solve the continuous and engineering optimization tasks. The SMO algorithm proposes a dynamic multi-flock and three search strategies including whirling, diving, and separating to provide the proper diversity throughout the population and strike a balance between search strategies.

The moth-flame optimization (MFO) [

52] is a novel SI algorithm that simulates the spiral movement of moths around the light sources at night to perform optimization. Among numerous metaheuristic algorithms, the MFO stands out for its ease of use and low computational complexity. As a result, the MFO is used to solve a broad range of real-world problems, such as feature selection [

53,

54,

55,

56,

57,

58], and constraint engineering problems [

59,

60,

61,

62,

63,

64,

65,

66]. The MFO algorithm has an interesting concept of flames to preserve the best solutions, also it has an efficient global search strategy to explore the search space. However, the MFO suffers from weak exploitation and imbalance between search strategies which prevents it from converging toward the promising zone. Conversely, the whale optimization algorithm (WOA) [

67] mathematically modeled the humpback whales’ hunting behavior using three search strategies. The search strategies proposed in WOA provide sufficient exploitation for different optimization tasks [

68,

69,

70,

71,

72,

73,

74,

75]. However, they cannot satisfy the needs of the exploration during the complex optimization tasks. Although many metaheuristic algorithms including MFO and WOA have been used to address the OPF problem, they are mostly not scalable or not suitable for handling multi-objective cases.

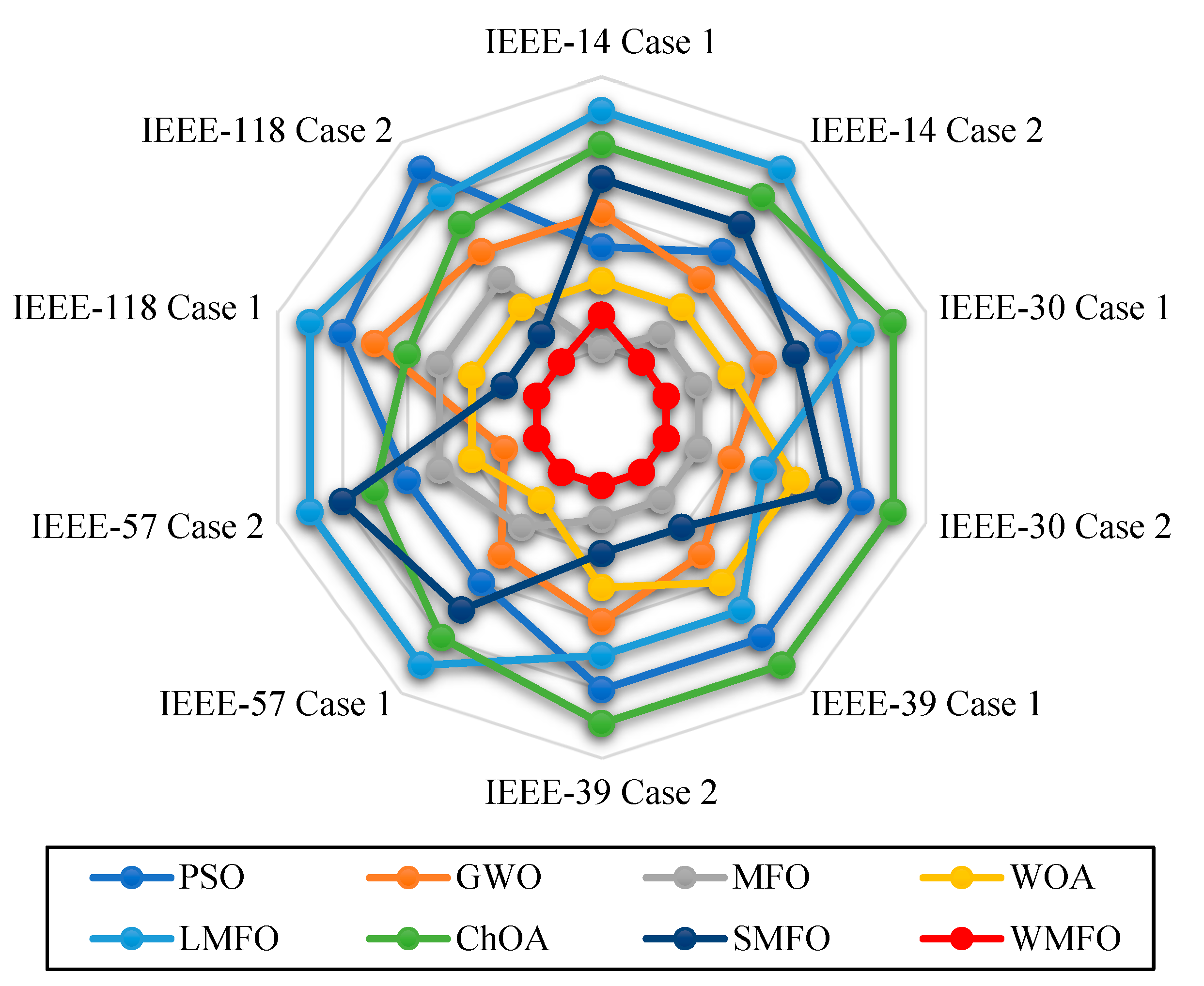

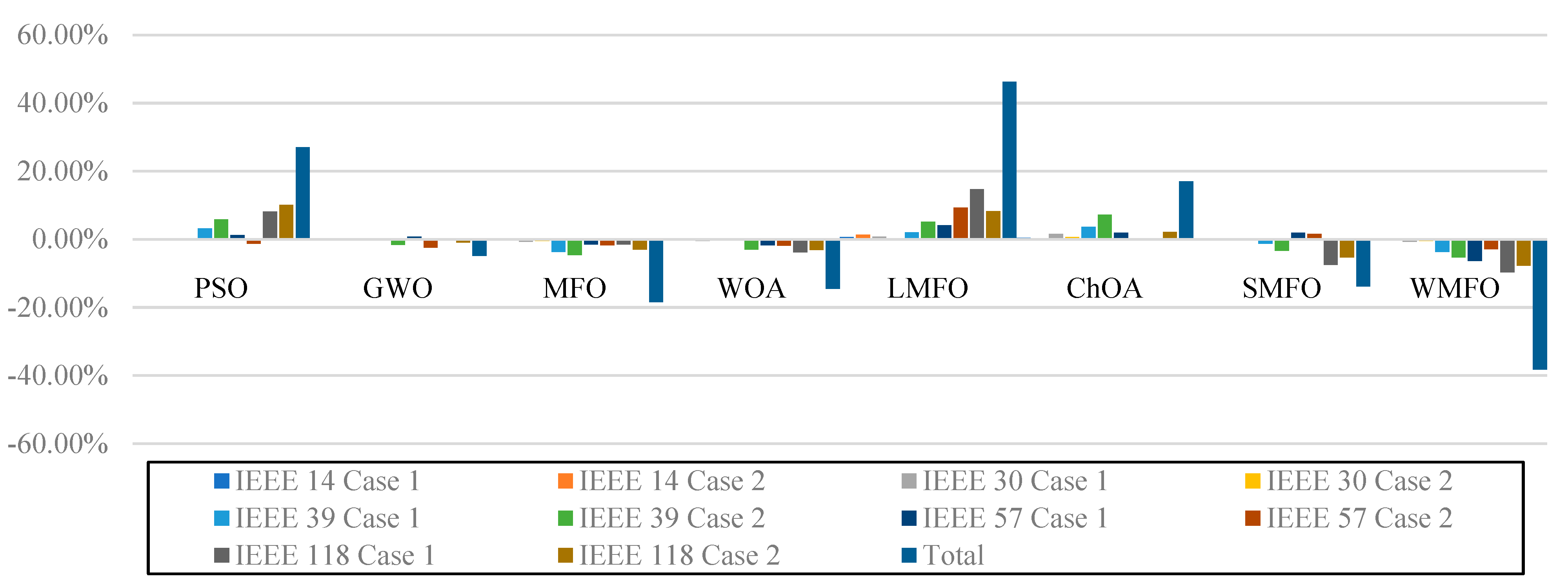

Therefore, this study is devoted to proposing an effective hybridizing of WOA with a modified MFO algorithm (WMFO) for solving the OPF problem. In this algorithm, first, a population partitioning mechanism is introduced to divide a population between search strategies. Then, the proposed WMFO algorithm is evolved using the WOA and modified MFO movement strategies. A greedy selection operator is considered as the acceptance criteria of the new positions by comparing their previous fitness and the new ones. Moreover, a randomized boundary handling method is used to return the solutions that have violated the permissible boundaries of search space. Moreover, to bypass the local optimum traps, a self-memory mechanism is defined for each search agent to preserve the best so far experience. Finally, the performance of the proposed WMFO algorithm is evaluated to solve diverse power system scale sizes including the standard IEEE 14-bus, IEEE 30-bus, IEEE 39-bus, IEEE 57-bus, and IEEE 118-bus test systems. The simulation results are compared to seven prominent optimization algorithms including PSO [

46], GWO [

49], MFO [

52], WOA [

67], Levy-flight moth-flame optimization (LMFO) [

76], chimp optimization algorithm (ChOA) [

50], and moth-flame optimizer with sine cosine mechanisms (SMFO) [

77]. According to the test results, WMFO outperforms other comparative algorithms in solving different power system scale sizes in both single and multi-objective cases of the OPD problem. The main contributions of this study are summarized as follows.

Proposing an effective hybridizing of WOA with a modified MFO to solve OPF problems with diverse power system scale sizes.

Proposing a population partitioning mechanism to divide a population between search strategies.

Introducing a modification of the canonical MFO using a self-memory mechanism to preserve the best so far experience.

Applying a randomized boundary handling method to return the solutions that have violated the permissible boundaries.

Applying a greedy selection operator to assess the acceptance criteria of new solutions.

The experiments’ results prove that the WMFO provides the best results in solving different scales of standard IEEE test systems compared to competitor algorithms.

The paper is organized as follows. A literature overview of the related works is included in

Section 2. The formulation and objective functions of the OPF problem are presented in

Section 3. The moth-flame and whale optimization algorithms are presented in

Section 4. The proposed WMFO algorithm is comprehensively presented in

Section 5. A rigorous evaluation of the effectiveness of the WMFO on the OPF problem is provided in

Section 6. Statistical analysis is presented in

Section 7. Ultimately,

Section 8 summarizes the conclusions and suggests future works.

2. Related Works

The optimal power flow (OPF) problem is formulated as a complex nonlinear nonconvex constrained optimization problem with different objectives and a variety of IEEE bus test systems [

78]. Many traditional methods, such as quadratic programming [

79], linear and nonlinear programming [

4,

80], and Newton algorithm [

6] have been applied to solve the OPF problem. Although, these methods are not suitable for solving practical systems due to the characteristics of nonlinear functions such as value-point effect and prohibited operating zones. Moreover, increasing the number of system buses intensifies the mentioned complexities and leads the algorithm toward sinking in local minimum solutions [

81,

82].

Recently, many metaheuristic optimization algorithms such as particle swarm optimization (PSO) [

83], ant colony optimization (ACO) [

84], shuffled frog leaping (SFL) [

85], differential evolution (DE) [

86], biogeography-based optimization (BBO) [

87], gravitational search algorithm (GSA) [

88], firefly algorithm (FA) [

89], teaching-learning-based optimization (TLBO) [

90], grey wolf optimizer (GWO) [

91], ant lion optimizer (ALO) [

92], moth-flame optimization (MFO) [

93], crow search algorithm (CSA) [

94], salp swarm algorithm (SSA) [

95], Levy spiral flight equilibrium optimizer (LSFEO) [

96], and jellyfish search optimizer (JS) [

97], have been applied as significant problem solvers to cope with the weaknesses of the traditional algorithms in solving the OPF problem benchmarks. Moreover, many researchers applied metaheuristic algorithms to solve real power systems [

98,

99].

Sivasubramani et al. [

100] proposed a multi-objective harmony search (MOHS) algorithm to solve the OPF problem. To identify the Pareto optimum front, the MOHS algorithm uses a rapid elitist non-dominated sorting and crowding distance. Then, a fuzzy-based mechanism is performed for selecting a compromise solution from the Pareto set. Improved particle swarm optimization (IPSO) [

101] proposed a pseudo-gradient and the constriction factor to direct the particle’s velocity. The purpose of the pseudo-gradient is to identify the particle’s orientation so that they may swiftly converge to the best solution. Sinsuphan et al. [

102] presented the improved harmony search method (IHS) by proposing a modification of the pitch adjustment rate to solve OPF problems with five standard IEEE test systems including 6-bus, 14-bus, 30-bus, 57-bus, and 118-bus. A hybrid algorithm based on a modified imperialistic competitive algorithm and teaching-learning algorithm named MICA–TLA [

103] is proposed for solving the OPF problem. The results of the simulation were tested on the IEEE 30-bus and IEEE 57-bus test systems with various objective functions. In another study, Ghasemi et al. [

78] introduced three modified techniques of the imperialistic competitive algorithm (ICA) based on three new actions that may occur to any colony for solving the OPF problem. The introduced techniques were justified in different cases of the IEEE 57- bus test system. Radosavljevic et al. [

104] proposed a hybridization of particle swarm optimization and gravitational search algorithms (PSOGSA) to find a proper solution in power systems. The PSOGSA takes advantage of the social thinking of the PSO and the local search ability of the GSA.

An improved artificial bee colony (IABC) [

105] optimizer is developed by orthogonal learning (OL) to empower the exploitation ability of the canonical ABC in solving the OPF problem. Fatima Daqaq et al. [

106] brought up a multi-objective backtracking search algorithm (MOBSA) to solve the OPF problem. The MOBSA can solve the highly constrained objectives and find the best solution from all Pareto optimal solution set using a fuzzy membership technique integrated into the BSA algorithm. Li et al. [

107] proposed a boosted adaptive differential evolution (JADE) with a self-adaptive penalty constraint management approach (EJADE-SP) to find the best solution to the OPF issue. The EJADE-SP algorithm used the crossover rate sorting mechanism to let individuals inherit more good genes, and re-randomizing parameters to sustain the population diversity and the effectiveness of the search. Furthermore, to speed up convergence, the EJADE-SP employs a dynamic population reduction method and a self-adaptive penalty constraint management technique to cope with various constraints. Nadimi et al. [

108] brought up the improved grey wolf optimizer (I-GWO) using dimension learning-based hunting (DLH) search strategy. The DLH strategy maintains the diversity and equilibriums between local and global searches by constructing a neighborhood for each wolf. In [

109], the slime mold algorithm (SMA) is used to solve the multi-objective OPF. The SMA mimics the oscillation mode of slime mold in nature and utilizes adaptive weights to mimic the process of providing positive and negative feedback in slime mold propagation waves.

Meng et al. [

110] introduced a crisscross search-based grey wolf optimizer (CS-GWO) to solve IEEE test systems including 30-bus and 118-bus. The CS-GWO algorithm improved the hunting operation in GWO by incorporating a greedy operator and the horizontal crossover operator was then used to refine the positions of the top three wolves. Moreover, to preserve population variety and prevent premature convergence, the vertical crossover operator is used. Abd el-Sattar et al. [

111] proposed an improved salp swarm algorithm (ISSA) for improving the movement strategies in canonical SSA to solve different OPF problems including 30, 57, and 118-bus test systems. ISSA utilizes a random mutation strategy to improve the exploration process and an adaptive process to enhance the exploitation process. In [

112], a boosted whale optimization algorithm named EWOA-OPF is developed to boost the global search capability of the WOA in solving the OPF problem by employing Levy motion in the encircling phase and utilizing Brownian motion to work with a canonical bubble-net attack. Kahraman et al. [

113] proposed an effective method by introducing a crowding distance-based Pareto archiving strategy to solve the multi-objective OPF problem. Akdag et al. [

98] introduced the improved Archimedes optimization algorithm (IAOA) using the dimension learning-based strategy to build a neighborhood and spread the information flow between search agents.

5. Proposed Algorithm

The ability to strike a balance between exploitation and exploration abilities is a crucial feature for any SI algorithm. As discussed earlier, the concept of the flame introduced in the MFO algorithm is regarded as an effective approach for maintaining the balance between exploration and exploitation by linearly decreasing the number of flames throughout the iterations. However, MFO inherently suffers from inefficient exploitation ability which results in stagnating in far from promising areas or premature convergence into local optima. On the other hand, the experimental results [

116] reveal that the WOA benefits from efficient exploitation ability, while its exploration and the balance between search strategies are not sufficient to handle complex real-world problems, especially in the OPF problem. Therefore, this study is devoted to proposing a hybridization of whale and moth-flame optimization (WMFO) to effectively solve the OPF problem. The proposed WMFO introduces a population partitioning mechanism, movement strategies, randomized boundary handling, and a greedy selection operator.

Suppose the matrix

as a finite set of positions in iteration

t such that the vector

denotes the position of

i-th individual in the D-dimensional search space. In the first iteration, the matrix

is initiated using Equation (28),

where

is the value of d-dimension,

randd is a random number between intervals 0 and 1, and

ubd and

lbd are the upper bound and lower bound for d-dimension. For the rest of the iterations, the matrix

is updated using movement search strategies in the proposed WMFO algorithm. Algorithm 1 presents the WMFO pseudo-code.

| Algorithm 1. The pseudocode of the proposed WMFO algorithm |

| Input: Dimension size (D), Maximum iterations (MaxIt), and Number of search agents (N). |

| Output: The global best solution. |

| 1. | Begin |

| 2. | Initialize the population |

| 3. | Set the self-memory mechanism for each search agent using Definition 2. |

| 4. | Calculating the fitness values. |

| 5. | Set t = 1. |

| 6. | While t ≤ MaxIt |

| 7. | Constructing two subpopulations PopMFO and PopWOA using Definition 1. |

| 8. | If t = = 1 then |

| 9. | Constricting the matrix flames by ascending ordered the fitness values. |

| 10. | Else |

| 11. | Updating F(t) and OF(t) by the sorted search agents from matrices F(t) and X(t). |

| 12. | End If |

| 13. | For i = 1: N |

| 14. | If i ∈ PopMFO then |

| 15. | Computing the FlameNum (t) using Equation (20). |

| 16. | If i ≤ FlameNum (t) |

| 17. | Computing Di based on Equation (19). |

| 18. | Updating the new position of Xi (t + 1) using Equations (18). |

| 19. | Else |

| 20. | Computing δi (t) based on Equation (31). |

| 21. | Updating the new position of Xi (t + 1) using Equations (30). |

| 22. | End If |

| 23. | Else |

| 24. | If p < 0.5 then |

| 25. | If |A| ≥ 1 then |

| 26. | Updating the new position of Xi (t + 1) using Equation (27). |

| 27. | Else |

| 28. | Updating the new position of Xi (t + 1) using Equation (22). |

| 29. | End If |

| 30. | Else |

| 31. | Updating the new position of Xi (t + 1) using Equation (26). |

| 32. | End If |

| 33. | End If |

| 34. | Checking and applying randomized boundary handling using Equation (32). |

| 35. | Computing the fitness values, and updating Xbesti based on Definition 2. |

| 36. | End for |

| 37. | Applying the greedy selection operator using Equation (33). |

| 38. | Updating the global best solution. |

| 39. | t = t + 1. |

| 40. | End while |

Definition 1 (Population partitioning mechanism). Given Pop = {PopMFO, PopWOA} is a finite set of two distinct subpopulations PopMFO and PopWOA with predefined capacity к. First, the members of the population are shuffled using a discrete uniform distribution and then divided between two matrices PopMFO and PopWOA such that PopMFO = {X1…Xк} and PopWOA = {Xк+1…XN}, where N represents the number of population. In this mechanism, each subpopulation evolves independently which causes the individuals to explore the search space from different perspectives. Hence, the flow of improper information is slowed down within the population and decreases the risk of premature convergence.

Movement strategies: The WMFO employs two movement strategies for evolving subpopulations PopWOA and PopMFO. The subpopulation PopWOA is updated using the WOA movement strategies while subpopulation PopMFO is updated based on the modified MFO movement strategy.

WOA movement strategies: The WMFO employs the canonical WOA’s movement strategies to update the positions of subpopulation Pop

WOA using Equation (29), where

Xi (

t + 1) represents the next position of

i-th search agent and

.

Modified MFO movement strategy: The proposed WMFO evolves the subpopulation Pop

MFO using Equation (30), where

b is the constant value,

k is a random value between intervals [−1, 1], and

Fj denotes the

j-th flame such that index

j is computed using Equation (20).

is computed using Equation (31), where

Xbesti is the position of the self-memory mechanism defined using Definition 2.

Definition 2 (Self-Memory mechanism).

Let SM = {SM1 … SMi … SMN} is a finite set of N search agents’ memories. The SMi is denoted by SMi = (Xbesti, Fbesti), where Xbesti represents the best position of Xi so far acquired, and Fbesti denotes the fitness of Xbesti. In the first iteration, Xbesti (t = 1) ← Xi (t = 1) and Fbesti (t = 1) ← OXi (t = 1). For the remaining iterations (t > 1), Xi and Fbesti are updated based on the best so far solution obtained by each Xi.

Randomized boundary handling: The canonical MFO and WOA use a simple mechanism for boundary limiting which assigns a value equal to its corresponding lower bound (

lbd) if the

d-th dimension of a search agent is less than the value of

lbd. Conversely, a value equal to the corresponding upper bound (

ubd) is given to the

d-th dimension of a search agent if it is found to be greater than

ubd. Although this boundary limiting method works efficiently for linear and convex problems, it leads the algorithm toward stagnation in the case of multi-objective nonlinear functions such as the OPF problem. Hence, to avoid stagnation, a randomized-based variable boundary limiting is introduced in the proposed WMFO based on Equation (32), where

xid denotes the value of

d-th dimension of

i-th search agent, and

r is a random value between intervals 0 and 1.

Greedy selection operator: WMFO employs the selection operator to evaluate the acceptance criteria of new solutions by comparing the fitness of new solutions

OX(

t + 1) with the fitness of previous population

OX(

t) using Equation (33).

6. Experimental Evaluation

In this section, first, a sensitivity analysis is conducted on the modified MFO, WOA, and the proposed WMFO to investigate the exploration and exploitation abilities. Then, the numerical efficiency of the proposed WMFO is scrutinized using simulation studies carried out on two scenarios based on five IEEE bus test systems consisting of IEEE 14-bus, IEEE 30-bus, IEEE 39-bus, IEEE 57-bus, and IEEE 118-bus test systems, where MATPOWER [

117] is used for load flow calculation. The acquired results are then compared with five well-known metaheuristic algorithms including particle swarm optimization (PSO) [

46], grey wolf optimizer (GWO) [

49], moth-flame optimization (MFO) [

52], whale optimization algorithm (WOA) [

67], chimp optimization algorithm (ChOA) [

50], and two enhanced variants of MFO, Levy-flight moth-flame optimization (LMFO) [

76], and synthesis of MFO with sine cosine mechanisms (SMFO) [

77]. The parameters of the competitor algorithms were set the same as the recommended settings in their works, which are reported in

Table 1.

The proposed WMFO and other comparative algorithms were run 20 times separately on Intel Core i7 (2.60 GHz) and 24 GB of RAM using MATLAB R2020 to ensure that all comparisons are fair. The maximum number of iterations (

MaxIt) and population size were set to (

D × 10

4)/

N for the sensitivity analysis tests, where

D and

N are dimensions of the problem and 100, respectively. For the IEEE bus test systems, the

MaxIt and

N are set to 200 and 50, respectively. The best values of control variables (DVs) and objective variables are tabulated in

Table 2,

Table 3,

Table 4,

Table 5,

Table 6,

Table 7,

Table 8,

Table 9,

Table 10 and

Table 11,

Table A1 and

Table A2.

6.1. Impact Analysis of Hybridizing WOA and Modified MFO

The exploration and exploitation abilities of the WOA, modified MFO, WMFO are investigated on several test functions selected from the CEC 2018 benchmark suite [

118]. The first function F

1 is a unimodal function, which can be employed to assess the exploitation ability of the algorithms. The test function F

9 is a multimodal function with many local optima, that is employed to investigate the exploration ability. Test functions 12, 14, and 19 are hybrid and 22, 25, 28, and 30 are composition functions that are suitable for evaluating the algorithms’ ability to prevent local optima and to strike balance between exploration and exploitation. The plotted convergence of these functions is presented in

Figure 1.

Analyzing convergence behavior of the test function F1 shows that the convergence trend of the modified MFO is hampered by local optimum after the initial iterations, while the WOA maintained its descent slope till the half of iterations, which shows its better exploitation ability compared to the modified MFO. On the contrary, the proposed WMFO converges toward the global solution by effectively exploiting the search space in the early iterations. The test function F9 shows that the modified MFO has better exploration than the WOA, and the proposed hybridization of WOA and modified MFO achieves superior results by effectively exploring the search space. The convergence behavior of hybrid and composition functions reveals that although WOA and modified MFO cannot maintain the balance between their search strategies, the proposed hybridization of them maintains the balance between exploitation and exploration and bypasses the local optimum effectively.

6.2. IEEE Bus Test Systems

The IEEE 14-bus, IEEE 30-bus, IEEE 39-bus, IEEE 57-bus, and the IEEE 118-bus test systems are employed to test the simulation effect of the WMFO for solving the OPF problem in two different Cases of single and multi-objective.

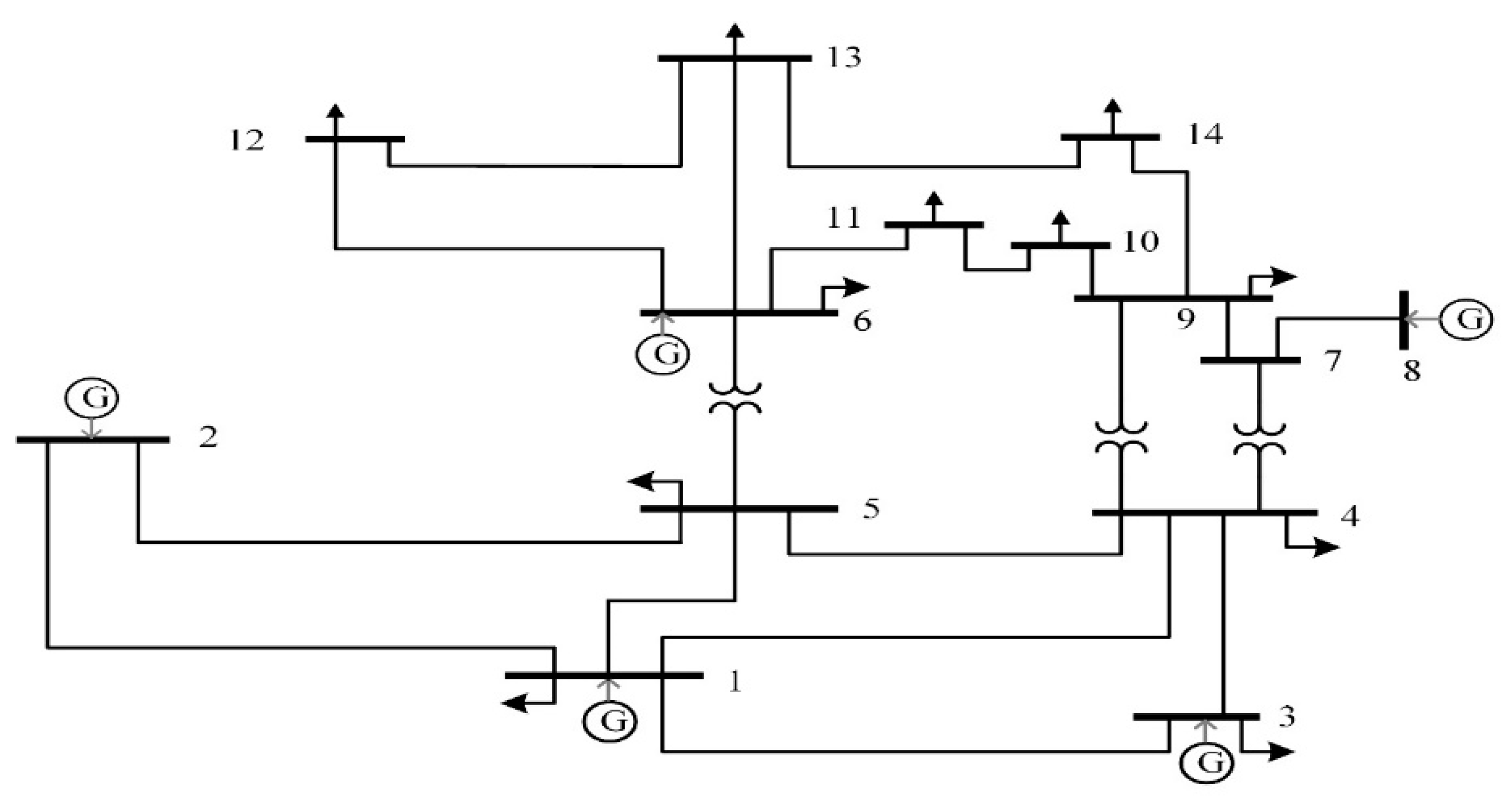

6.2.1. IEEE 14-Bus Test System

The IEEE 14-bus test system is regarded as the first test system for evaluating the performance of the WMFO.

Figure 2 illustrates the IEEE 14-bus test system, which consists of five generator buses, three transformers, nine load buses, and 20 transmission lines. The bus data, limitations, and cost coefficients are presented in [

119]. The transformer tap’s minimum and maximum boundaries are set to 0.9 and 1.1 p.u. The lower and upper limit voltages for all generator buses have been set at 0.94 and 1.06 p.u.

To establish an effective comparison,

Table 2 and

Table 3 present the detailed outcomes of the objective functions, transmission losses, and active and reactive power outputs of generators for both Cases 1 and 2. Moreover,

Figure 3 illustrates the convergence behavior of the obtained fitness of the algorithms over the course of iterations on the IEEE 14-bus standard test system. As illustrated in

Table 2, in terms of overall cost, both MFO and WMFO provide superior outcomes than other algorithms. For Case 2,

Table 3 shows that the WMFO’s results are superior to those of other algorithms.

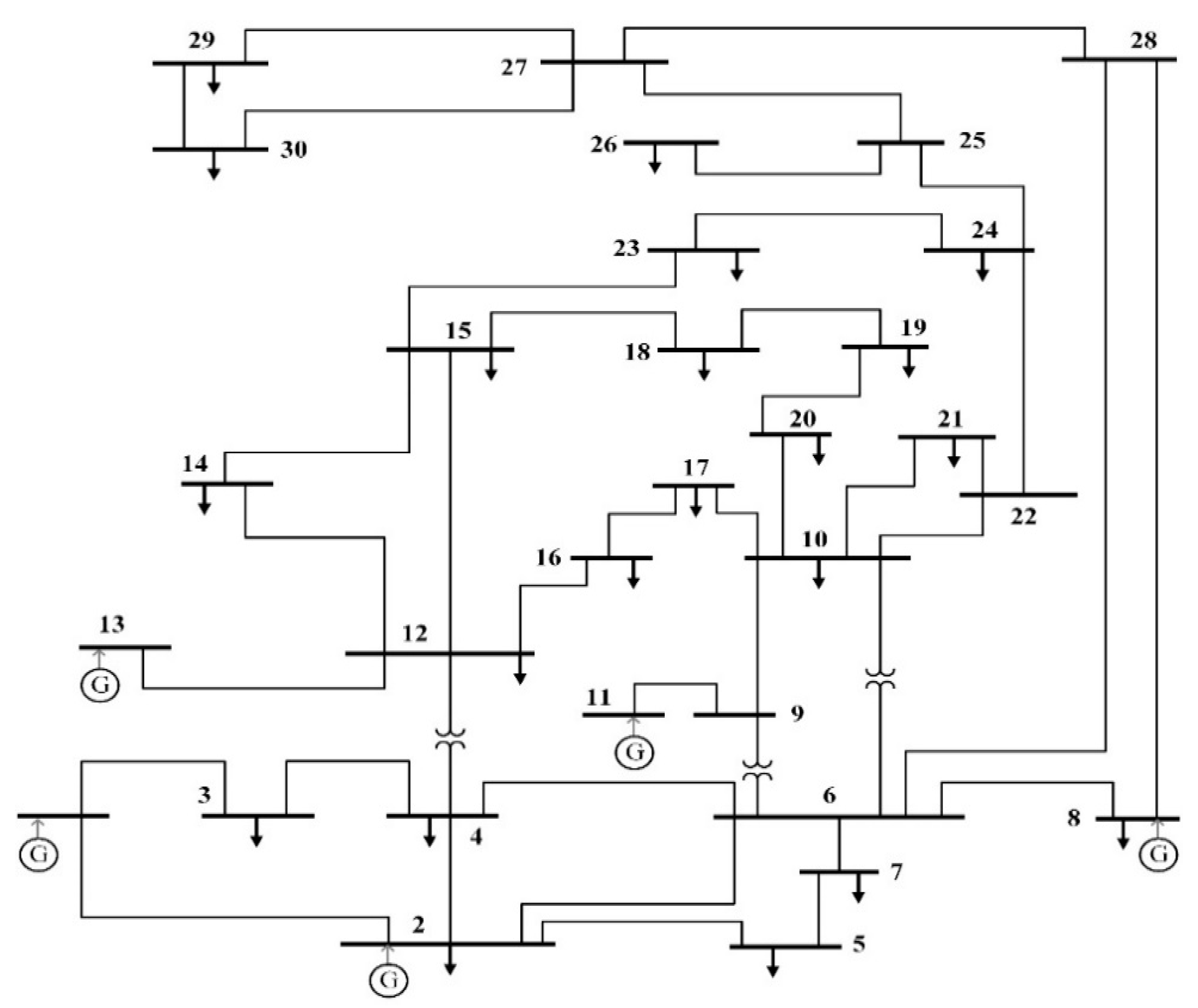

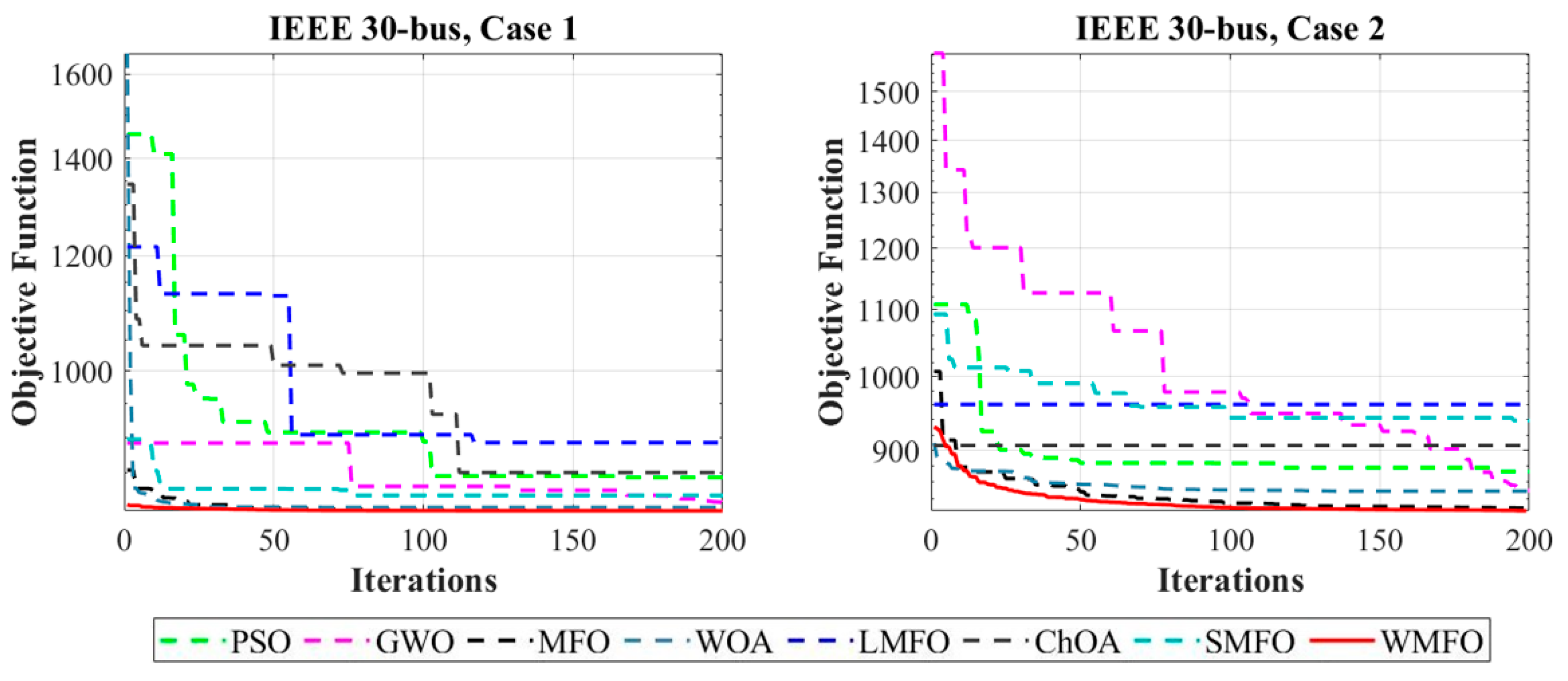

6.2.2. IEEE 30-Bus Test System

Figure 4 depicts a single-line diagram of the IEEE 30-bus test system. Six generators are used on buses 1, 2, 5, 8, 11, and 13, and on lines 6–9, 6–10, 4–12, and 28–27 there are four transformers installed. The branch, bus, and generator data are taken from [

120]. The minimum and maximum limits of the transformer tap are adjusted to 0.9 and 1.1 p.u. The shunt

VAR compensations have lower and upper values of 0.0 and 0.05 p.u. For all generator buses, the lower and upper limit voltages have been adjusted to 0.95 and 1.1 p.u.

Table 4 and

Table 5 illustrate the optimal control variable values including total cost of fuel, voltage deviations, and power loss for Cases 1 and 2.

Figure 5 shows the obtained fitness’ convergence trait for both Cases. It is clear to observe that WMFO provides the minimum total fuel cost of 800.603 (

$/h) and 804.209 (

$/h) for Case 1 and Case 2.

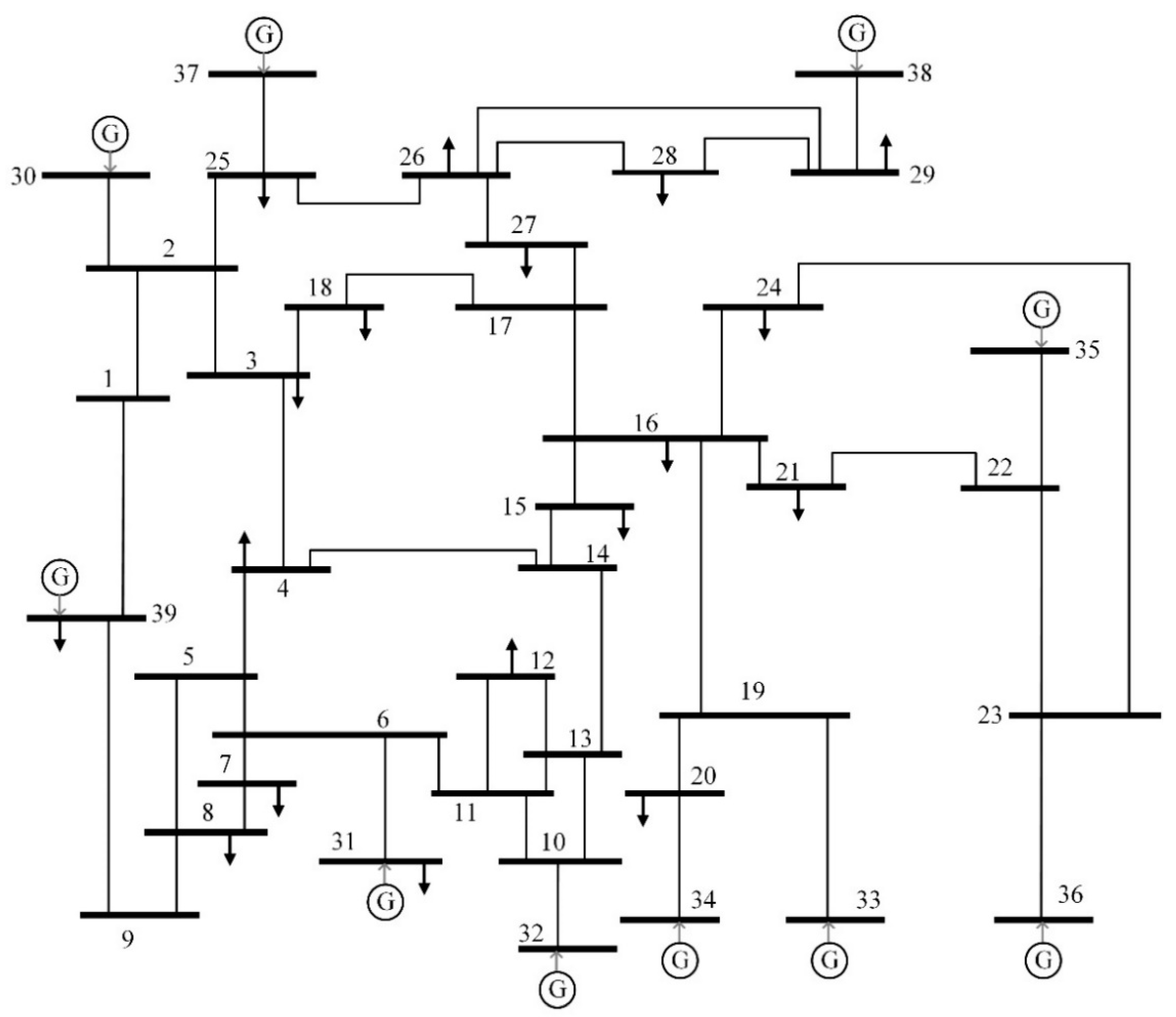

6.2.3. IEEE 39-Bus Test System

This test system contains ten generators on buses 30, 31, 32, 33, 34, 35, 36, 37, 38, and 39, and twelve transformers between buses 12–11, 12–13, 6–31, 10–32, 19–33, 20–34, 22–35, 23–36, 25–37, 2–30, 29–38, and 19–20, as shown in

Figure 6. The bus data, branch data, and cost coefficients are taken from MATPOWER [

117]. For all generator buses, the lower and upper limit voltages are considered to be 1.06 and 0.94. The minimum and maximum limits of the transformer tap are adjusted to 0.9 and 1.1 p.u. The tabulated results in

Table 6 and

Table 7 prove the superiority of the WMFO in minimizing the total fuel cost to 34,486.183 for Case 1 and 34,487.119 for Case 2. The convergence trait of WMFO, canonical MFO, and the other competitor algorithms are depicted in

Figure 7.

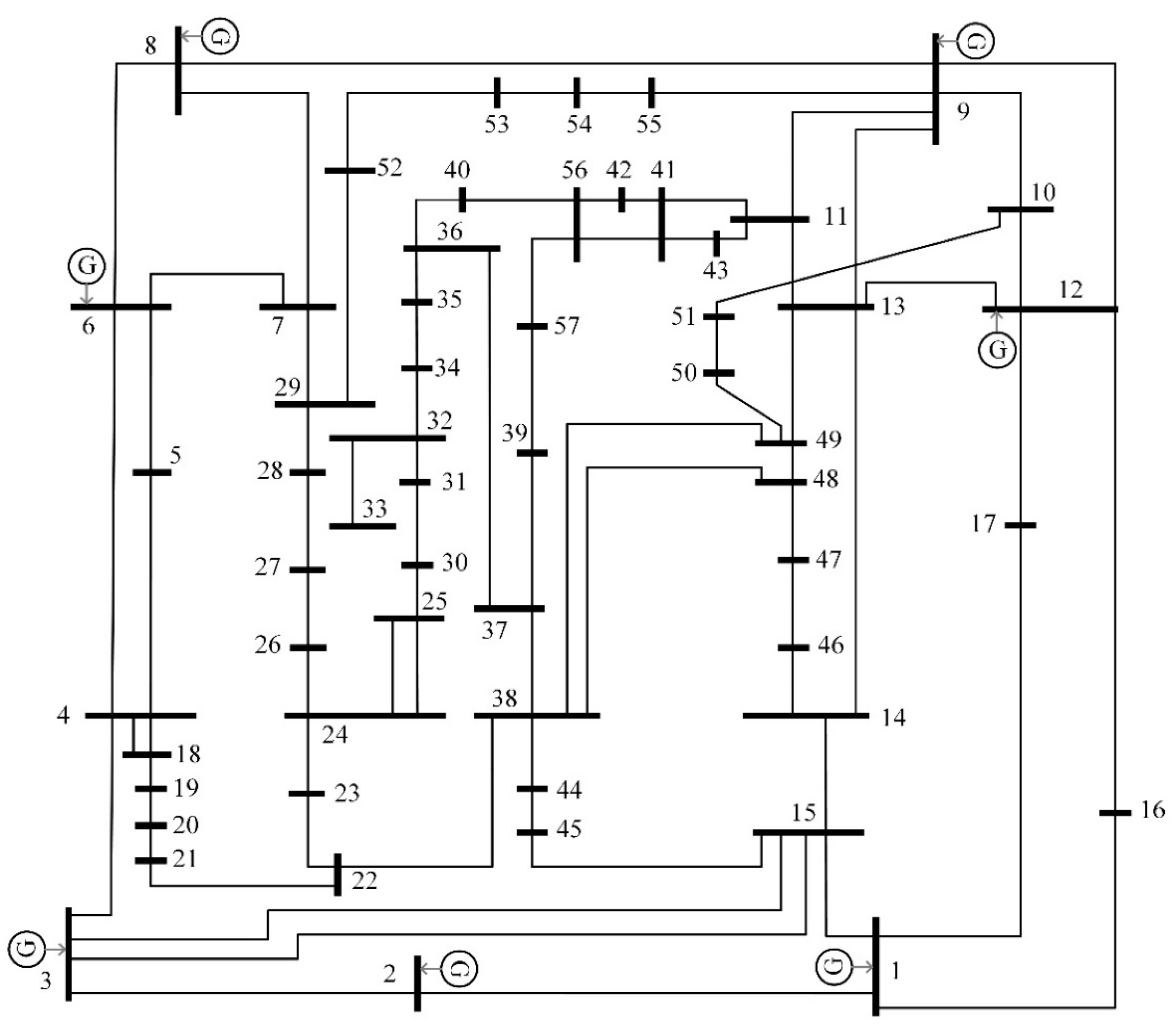

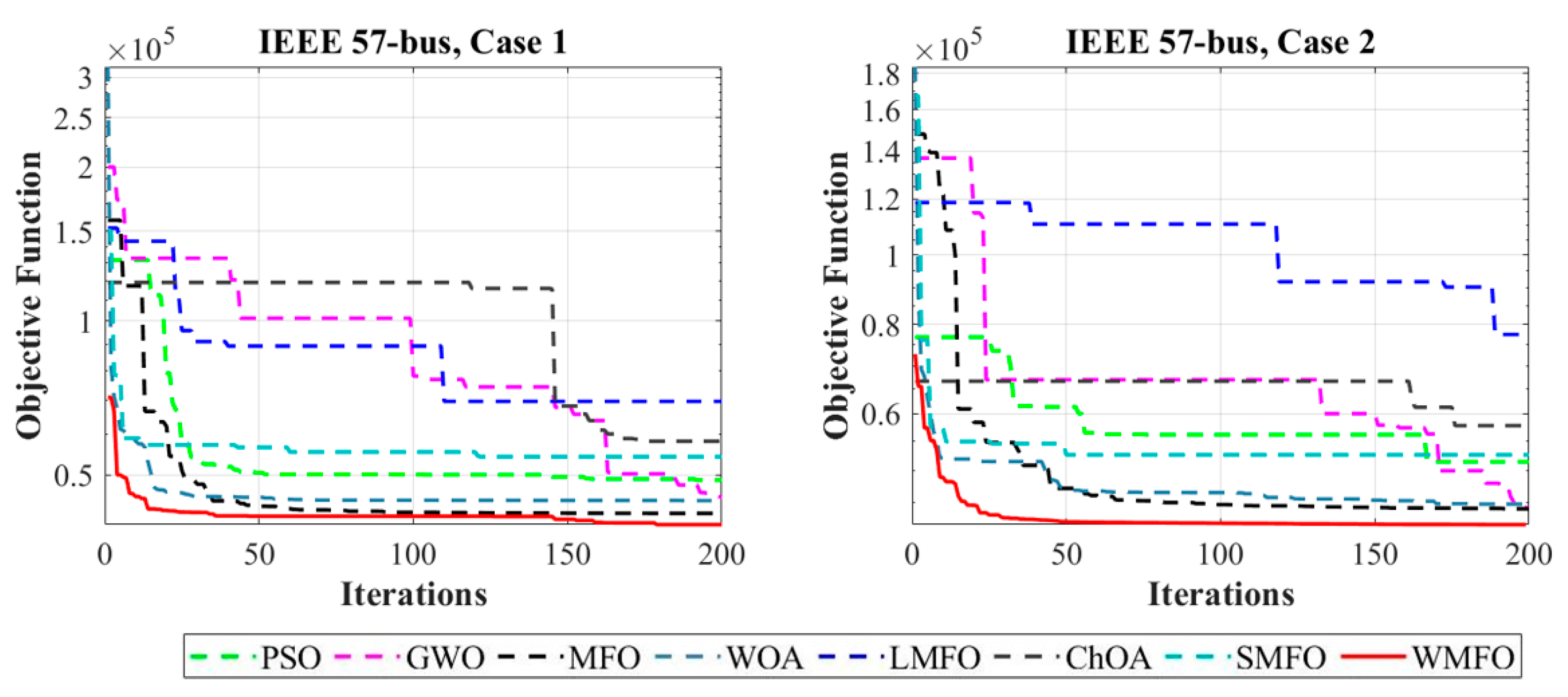

6.2.4. IEEE 57-Bus Test System

The IEEE 57-bus test system is depicted in

Figure 8, and it has seven generators at the buses 1, 2, 3, 6, 8, 9, 12, and 15 branches under load tap setting transformer branches and 80 transmission lines. Shunt reactive power sources are located at buses 18, 25, and 53. The upper bounds and lower bounds of real power generations and the cost coefficients are presented in [

121]. The upper and lower bounds for voltages of tap setting transformer variables and all generator buses are considered to be 1.1–0.9 in p.u. Shunt reactive power sources have maximum and lowest values of 0.0 and 0.3 in p.u. The voltages of all load buses have maximum and minimum values of 1.06 and 0.94 in p.u.

Table 8 and

Table 9 indicate that the best fuel cost values gained using the proposed WMFO are 39,359.123 (

$/h) for Case 1 and 41,811.734 (

$/h) for Case 2, which are significantly lower than the best fuel cost results obtained by comparative algorithms. The convergence traits of the best fuel cost acquired by the algorithms for this test system are illustrated in

Figure 9.

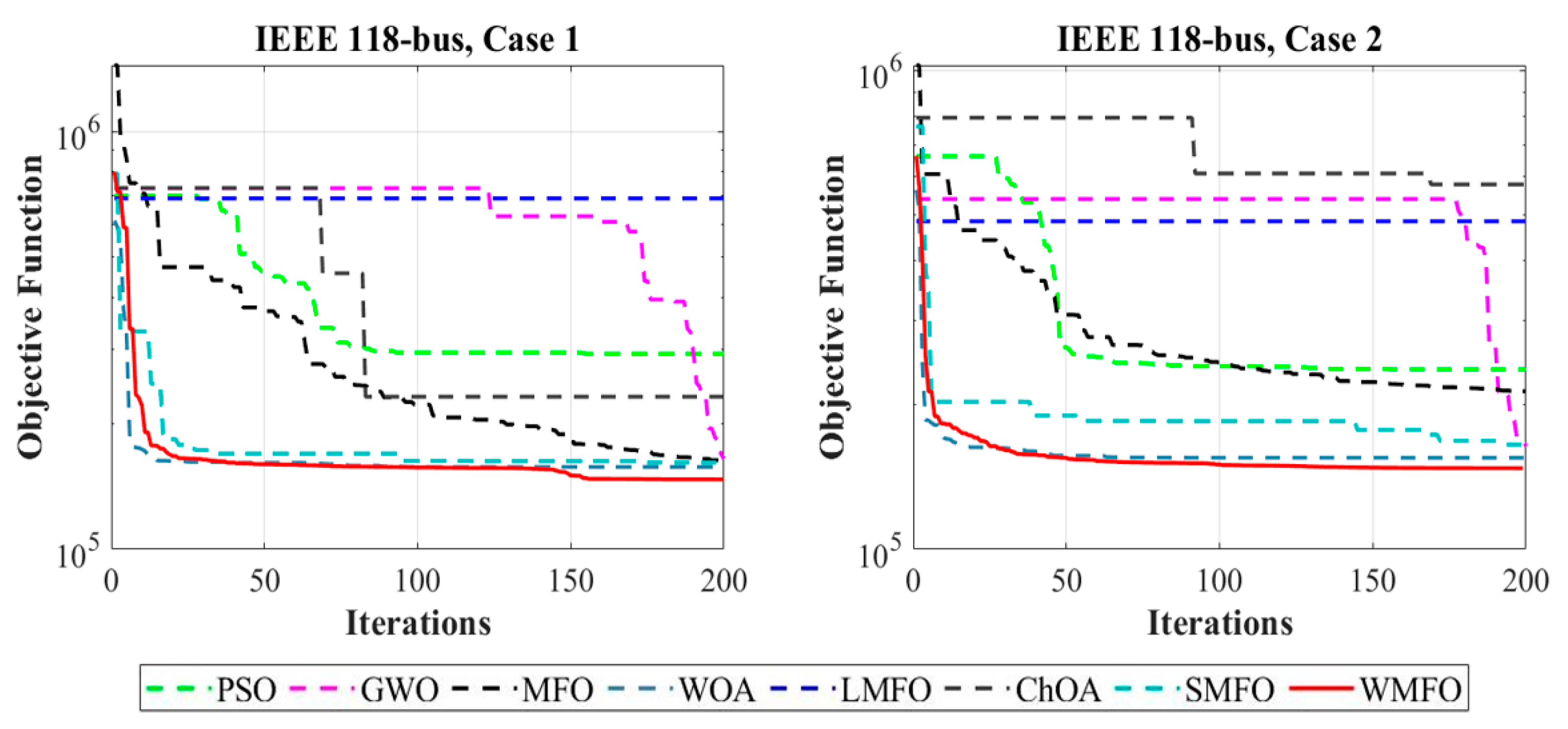

6.2.5. IEEE 118-Bus Test System

The ability of the proposed WMFO in solving a larger power system is evaluated by the IEEE 118-bus test system. The cost coefficients, branch, and bus data are taken from MATPOWER [

117]. This bus test system contains 54 generators, 186 branches, 9 transformers, 2 reactors, and 12 capacitors. This system contains 129 control variables in total, as follows: there are 54 generator active powers and bus voltages are available, as well as nine transformer tap settings and twelve shunt capacitors reactive power injections. The voltage limit for all buses is 0.94 to 1.06 p.u. Transformer tap settings are tested in the range of 0.90–1.10 p.u. Shunt capacitors’ available reactive powers vary from 0 to 30 MVAR. As Cases 1 and 2 in this experiment include too many design factors, the summary of the results is reported in

Table 10 and

Table 11, while the detailed results of MFO, WMFO, and the proposed WMFO are tabulated in

Table A1 and

Table A2 in

Appendix A. The results tabulated in

Table 10 and

Table 11 reveal that the WMFO provides the best fuel cost values. The cost value for Case 1 is 136,452.876 (

$/h) and for Case 2 is 136,147.702 (

$/h), which are significantly lower than the results acquired by competitor algorithms.

Figure 10 and

Figure 11 also show the single-line diagram of the IEEE 118-bus test system and the convergence curves of the algorithms’ acquired fitness.

8. Conclusions and Future Works

This paper proposed an effective hybridizing of whale and moth-flame optimization algorithms (WMFO) to solve the optimal power flow (OPF) problem. The population is equally partitioned among two algorithms using the population partitioning mechanism. A self-memory mechanism is defined for each search agent to preserve their best experiences and update their positions based on the average best-experienced position of the whole population. Moreover, randomized boundary handling is introduced to effectively apply the boundary limiting conditions. Furthermore, the WMFO employs a greedy selection operator to evaluate the acceptance criteria of new positions. The impact analysis on convergence curves shows that the WMFO explores the search space in the first iterations, then it keeps improving the quality of the solution in the course of iterations. This convergence behavior reveals that the WMFO inherits the exploitation of the WOA, while it takes advantage of the explorative movements of the modified MFO. The effectiveness and scalability of the proposed algorithm in solving the OPF problem have been assessed and investigated on the IEEE 14-bus, 30-bus, 39-bus, 57-bus, and 118-bus test systems to optimize the OPF’s single and multi-objective functions within the limits of the system. The obtained results are then compared against five well-known metaheuristic algorithms and two improved variations of the MFO to validate the results. The comparison of results reveals that the proposed WMFO outperforms competitor algorithms in solving single and multi-objective problems in various power system scale sizes by reducing the total cost 38.26% more than the average of the total cost gained by the competitor algorithms. The maximum amount of cost reduction compared to the average value of contender algorithms is 14,820.55 ($/h) gained by the WMFO on the IEEE 118-bus test system Case 1. Furthermore, the average amount of reduced cost gained by the WMFO on ten different OPF problems equals 33,722.24 ($/h) or 295 million dollars a year, which shows the economic viability of the proposed method in solving the OPF problem. In future research, WMFO can be employed to solve various problems in power systems such as FACTS devices and electrical load forecasting.