Optimum of Grain Loss Sensors by Analyzing Effects of Grain Collision Attitude on Signal Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Grain Sample Preparation

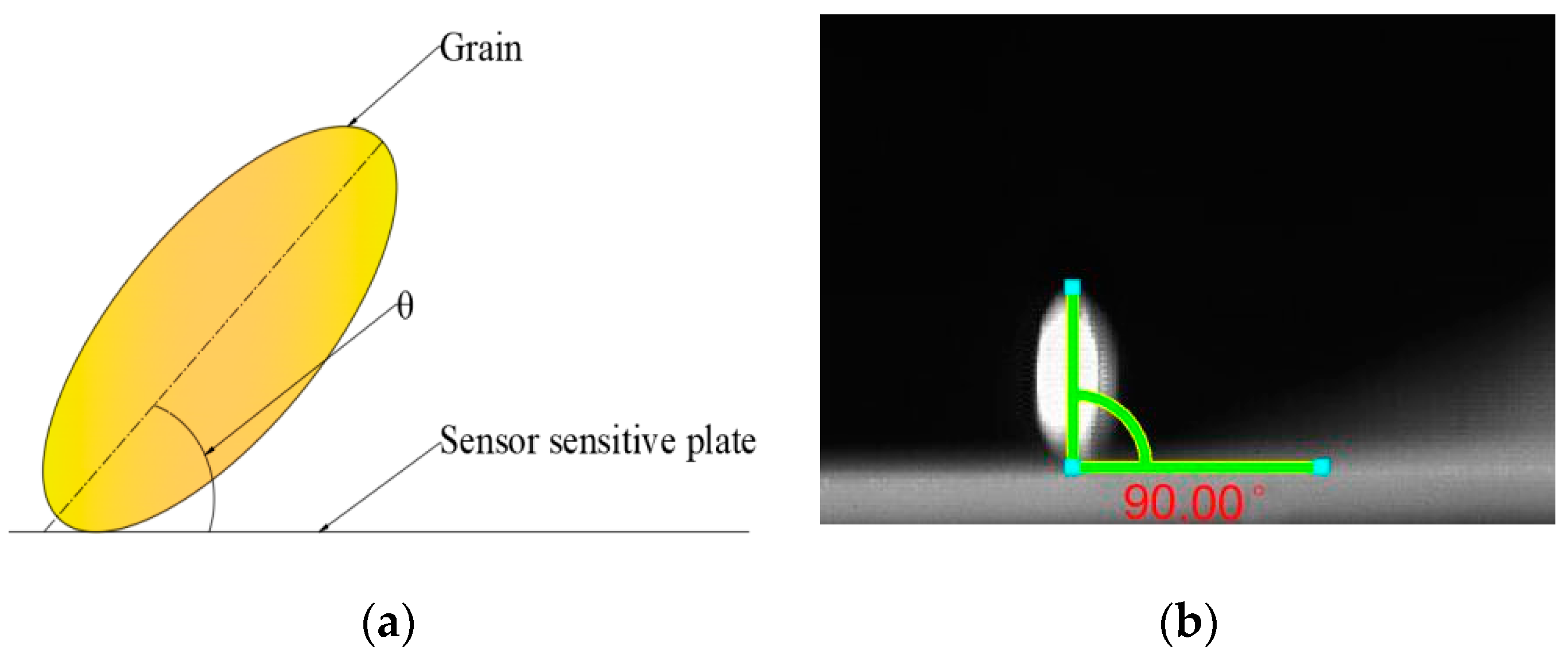

2.2. Grain Collision Information Collection

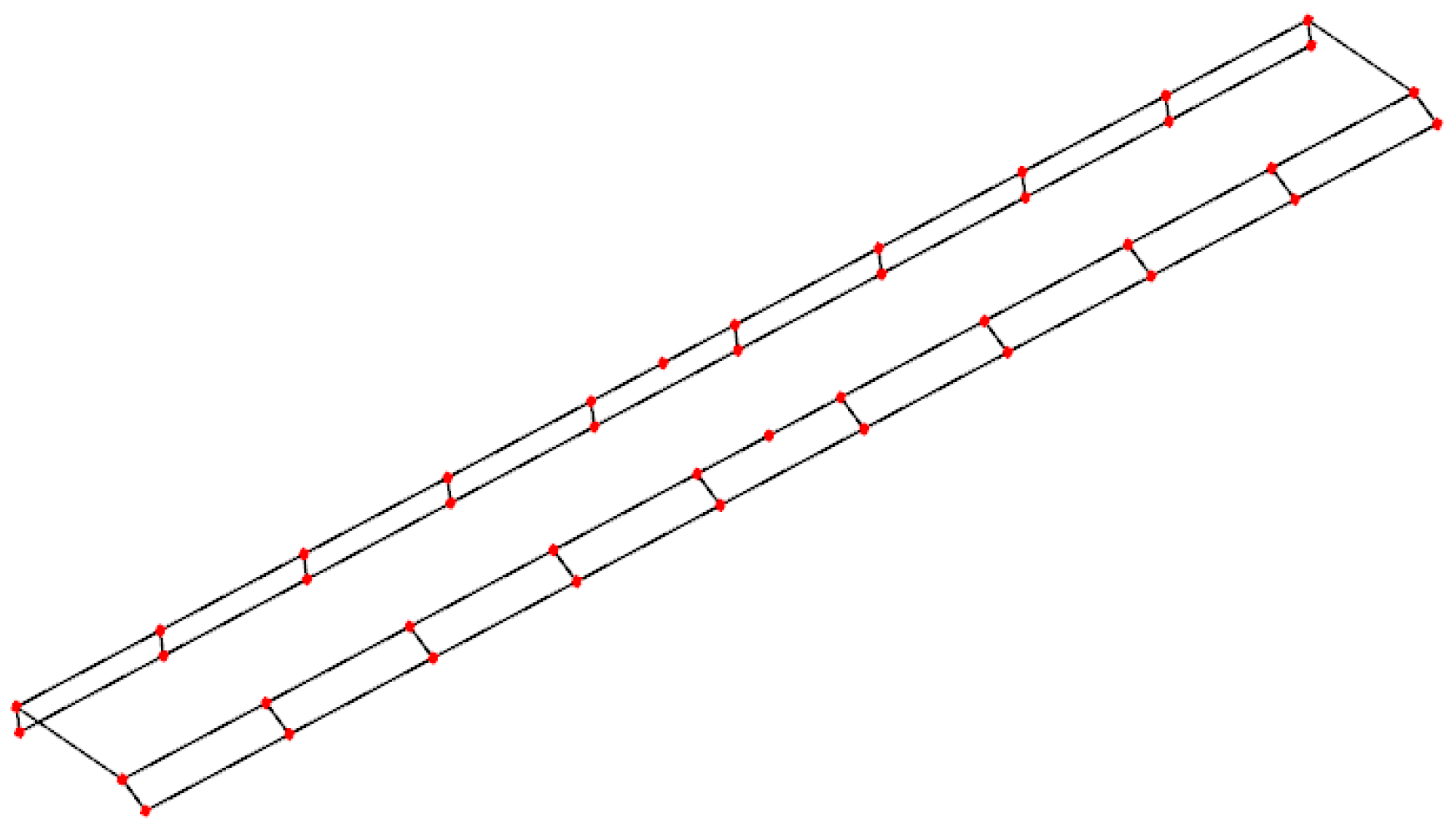

2.3. Partially Constrained Damping Design of the Sensor

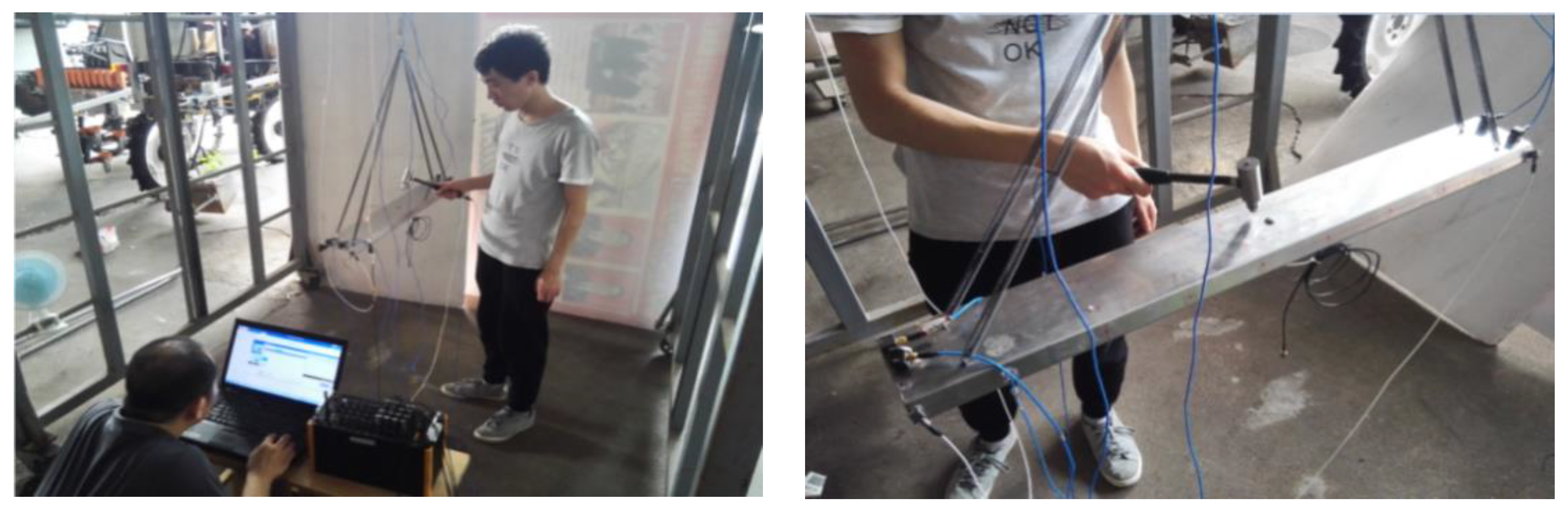

2.4. Field Experiment

3. Results and Discussion

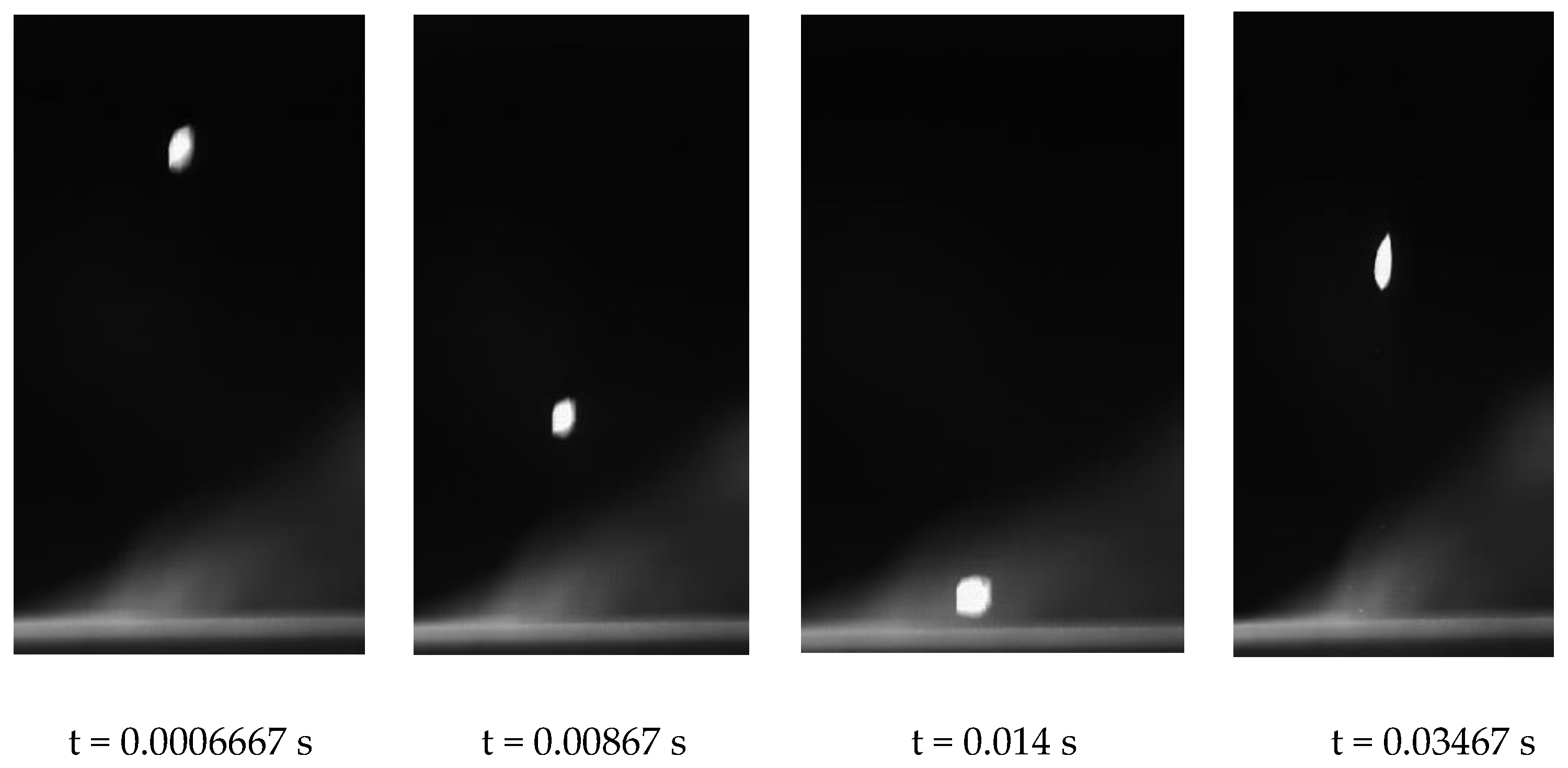

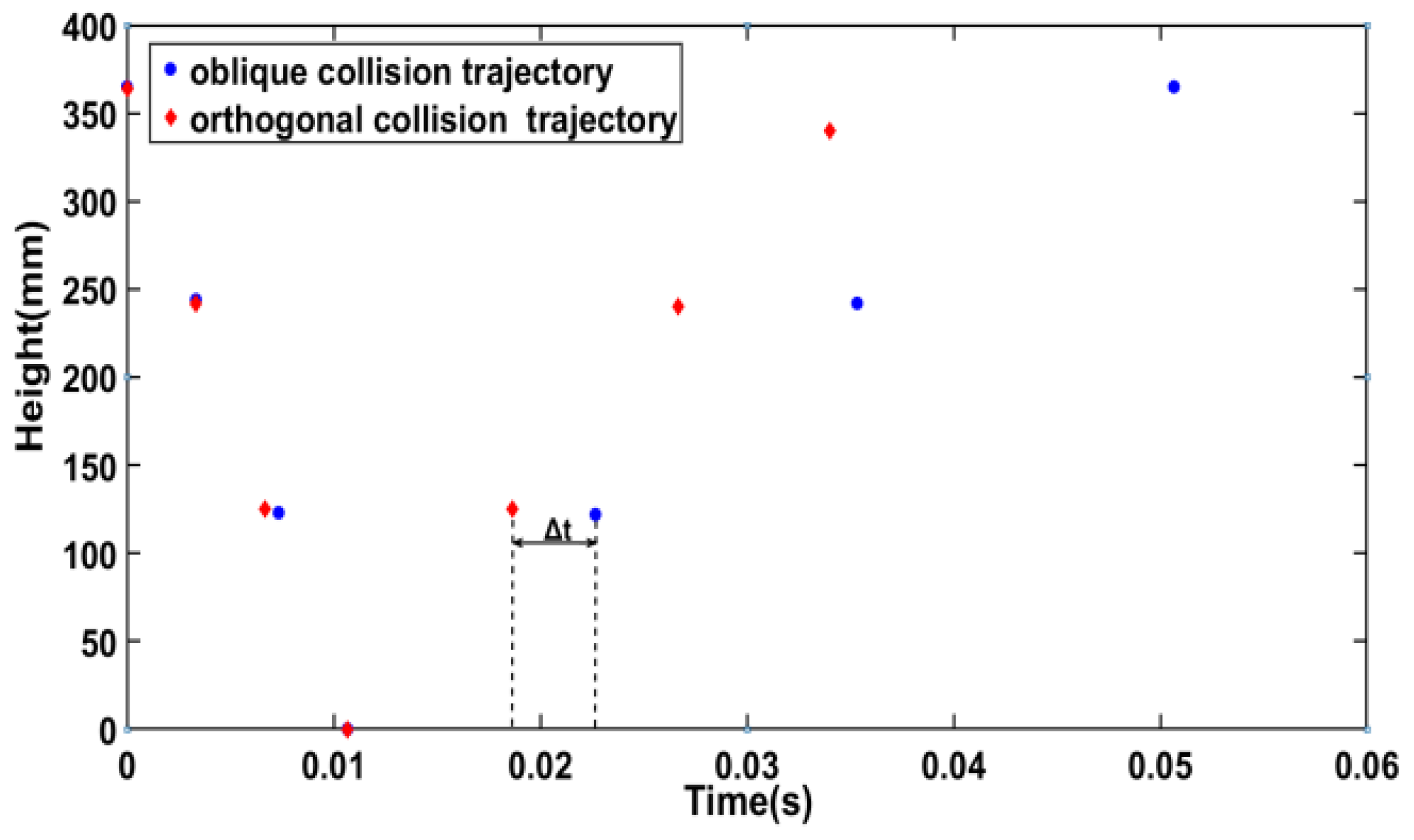

3.1. Grain Trajectory Analysis

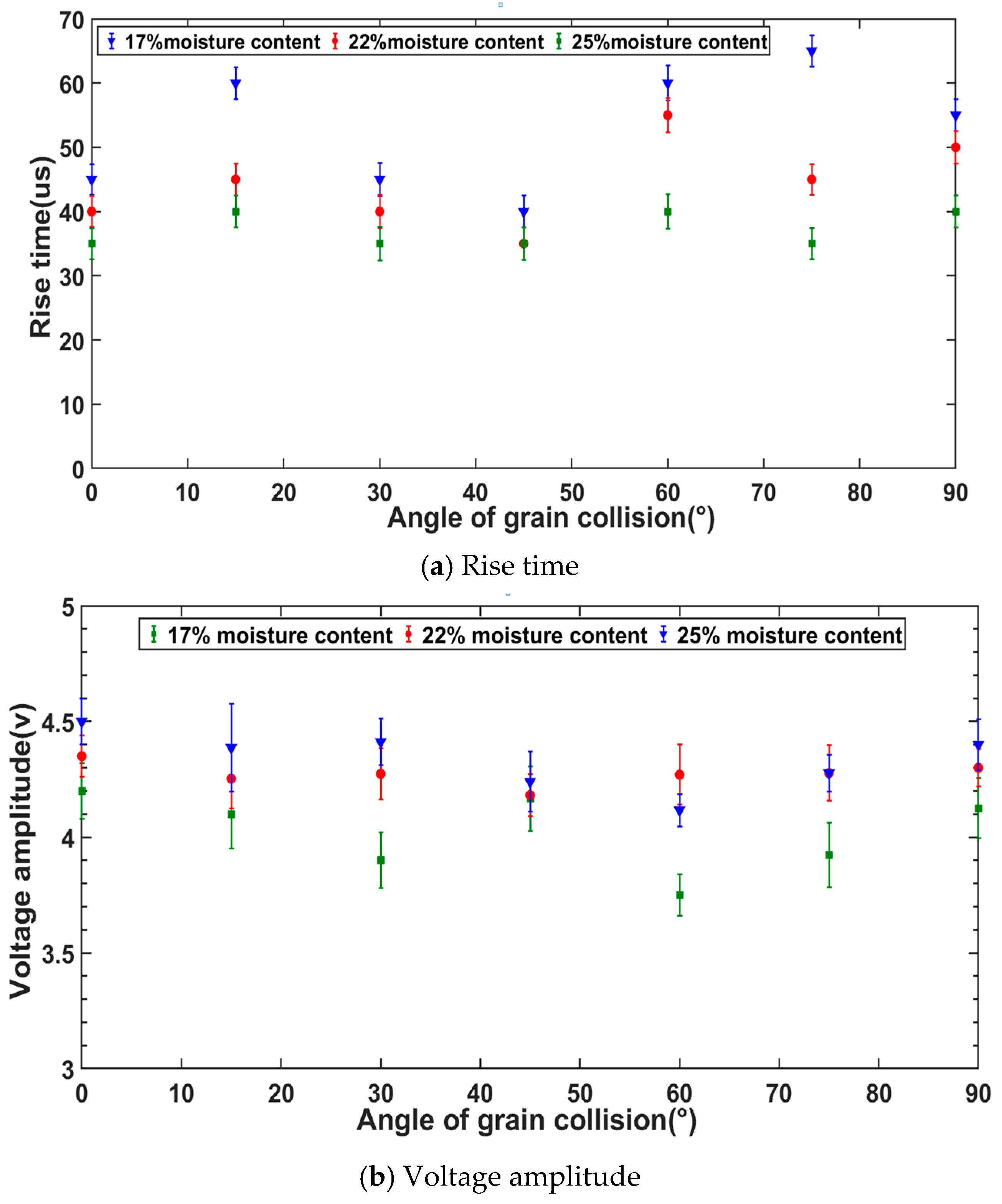

3.2. Grain Collision Signal Characteristics Analysis

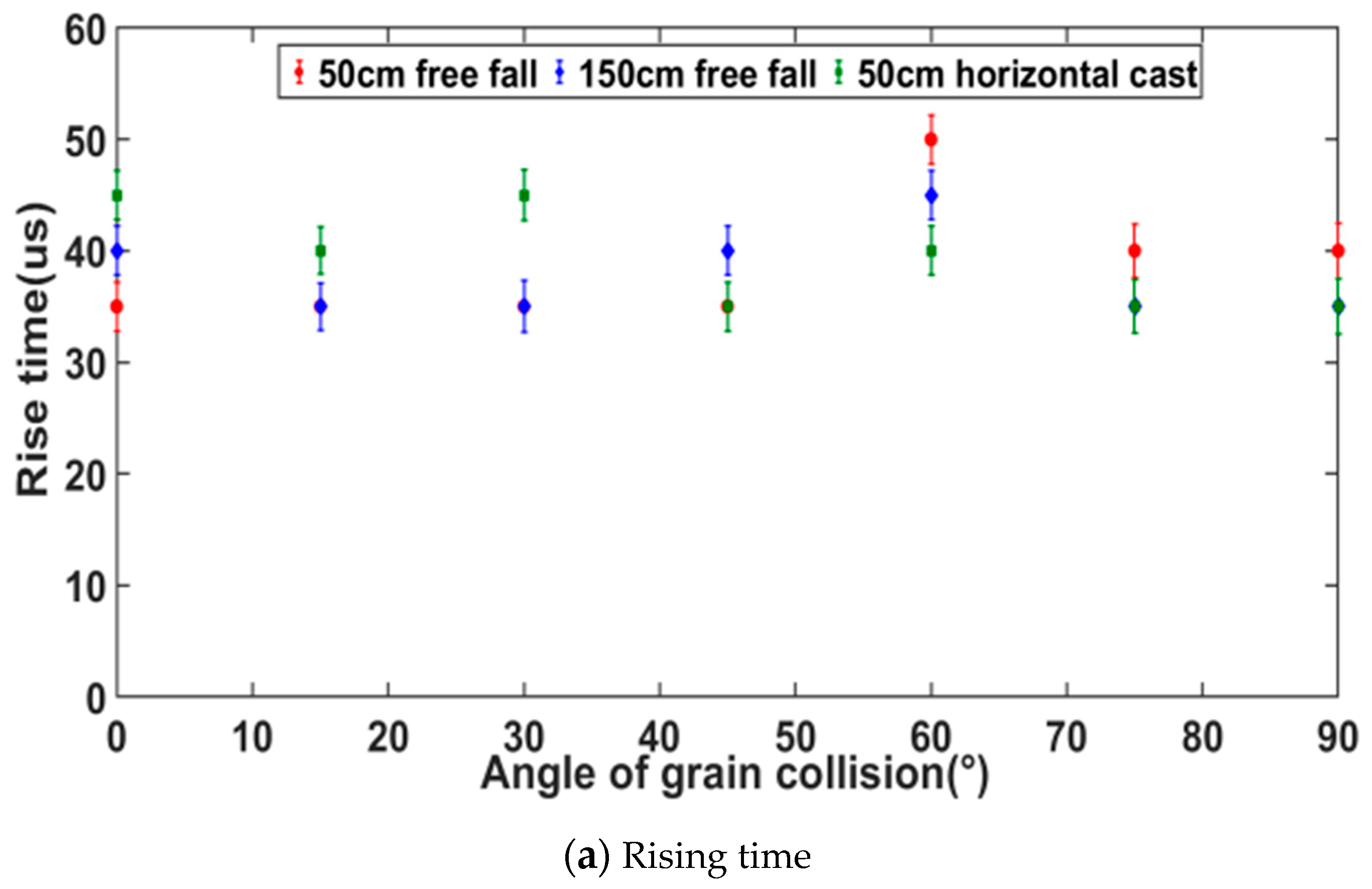

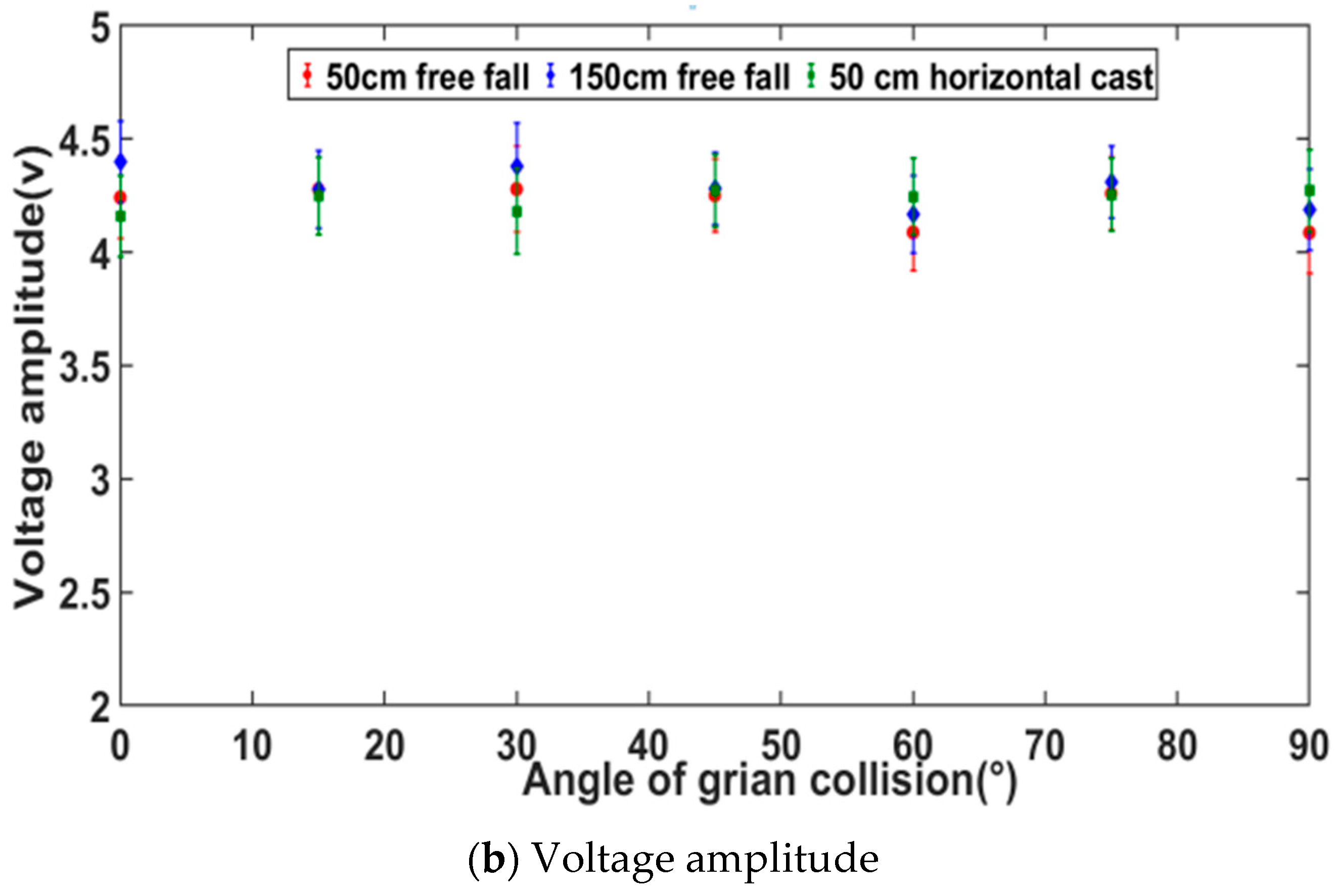

3.3. Effects of Collision Velocity on Signal Rise Time and Voltage Amplitude

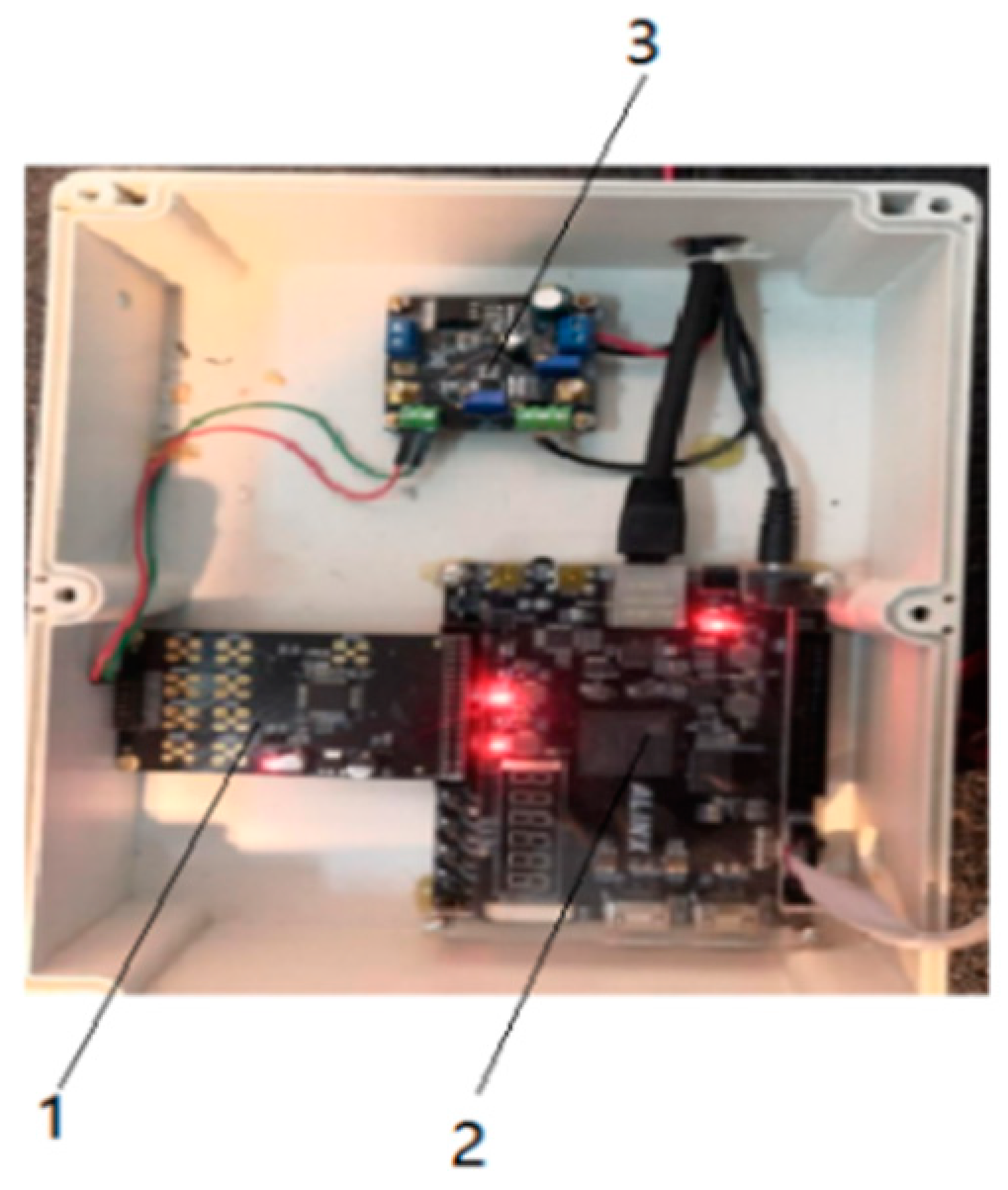

3.4. Design of Signal Process Circuit

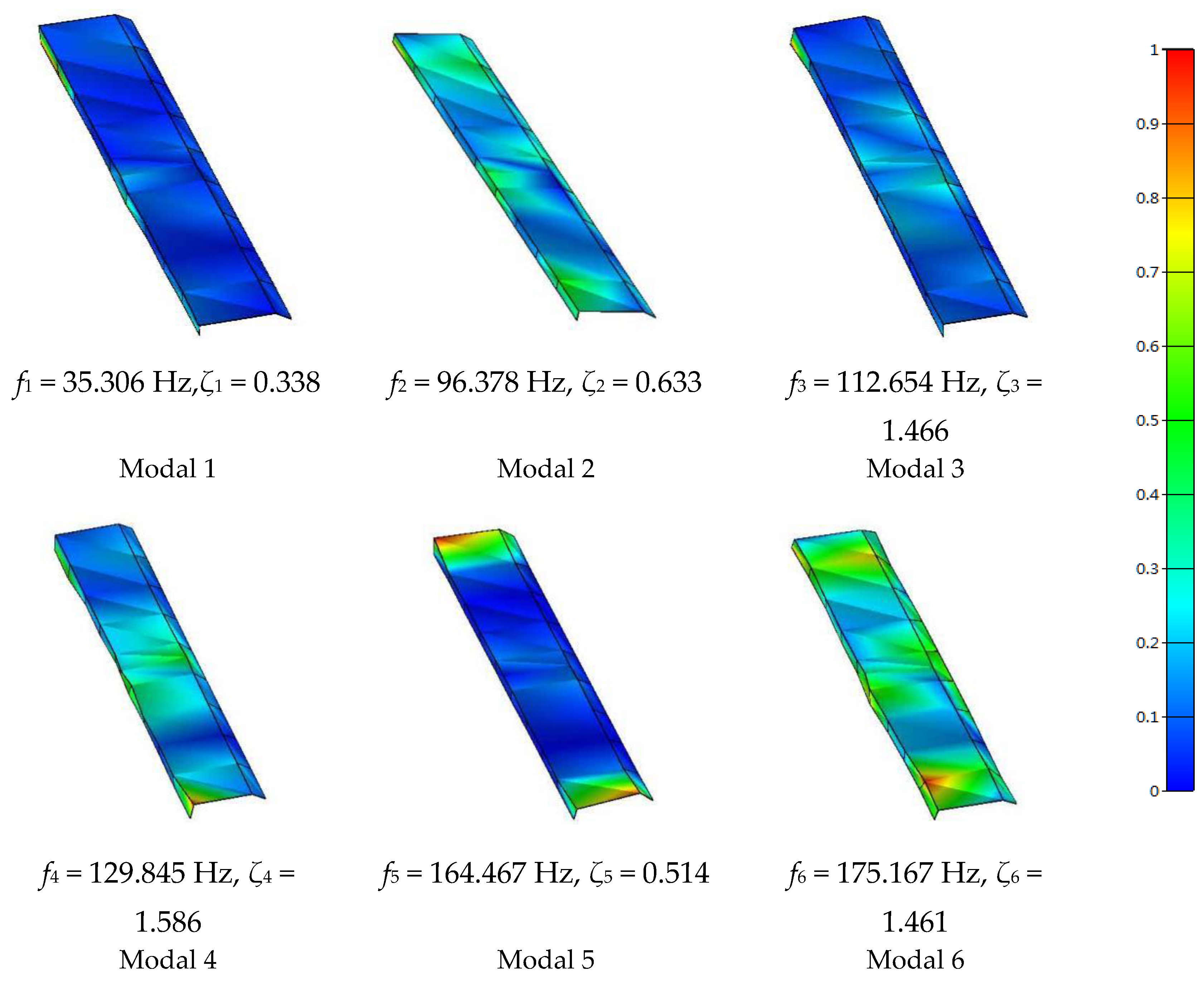

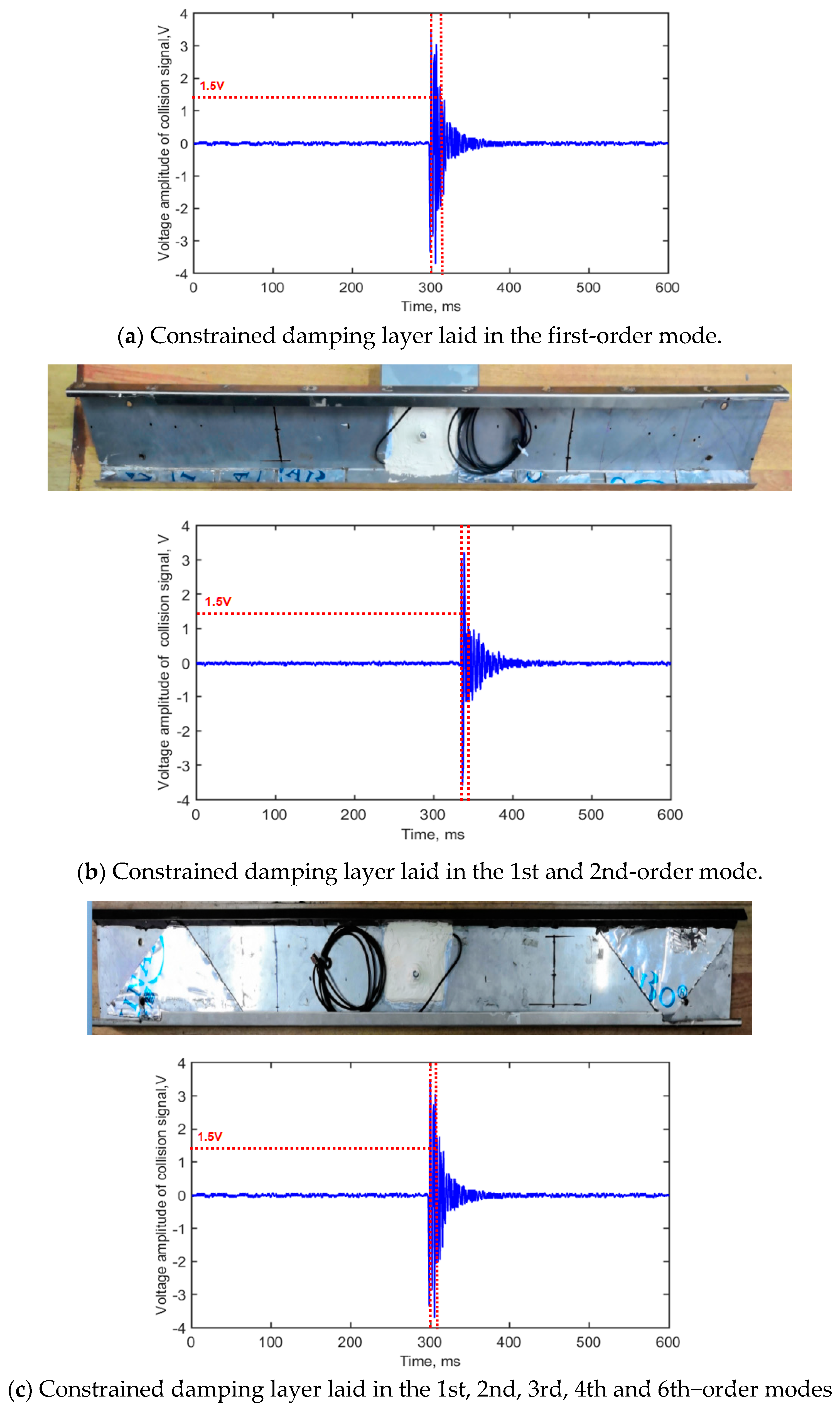

3.5. Determination of the Location of the Viscomaterial Damping Layer

3.6. Field Experiment Result Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, Z.W.; Li, Y.M.; De Baerdemaeke, J.; Xu, L.Z.; Saeys, W. Development and testing of a multi- duct cleaning device for tangential- longitudinal flow rice combine harvesters. Biosyst. Eng. 2019, 182, 95–106. [Google Scholar] [CrossRef]

- Strubbe, G.J.I. Grain Loss Monitors for Harvesting Machines. U.S. Patent 5,046,362, 10 September 1991. [Google Scholar]

- Ni, J.; Mao, H.P.; Tian, Y.C. Design and experimentation of sensitive element of piezoelectric crystal sensor array for grain cleaning loss. Afr. J. Biotechnol. 2011, 36, 6913–6919. [Google Scholar]

- Zhao, Z.; Li, Y.M.; Liang, Z.W. Optimum design of grain impact sensor utilising polyvinylidene fluoride films and a floating raft damping structure. Biosyst. Eng. 2012, 112, 227–235. [Google Scholar] [CrossRef]

- Wei, C.; Li, M.; Yu, L.J. Study on grain cleaning loss monitoring of combine harvester based on Kalman Filter. Agric. Mech. Res. 2016, 38, 23–27. [Google Scholar]

- Wang, Z.; Che, D.; Bai, X.P. Design and experiment of cleaning loss monitoring device for corn combined harvester. Trans. Chin. Soc. Agric. Mach. 2018, 49, 100–108. [Google Scholar]

- Nie, X. Design and Implementation of On-Line Detection Software System for Harvest Loss of Rice and Wheat Combine Harvester. Master’s Thesis, Zhejiang University, Hangzhou, China, 1 June 2021; pp. 90–91. [Google Scholar]

- Zhang, X.; Loc, V.Q. Modeling the dependence of the coefficient of restitution on the impact velocity in elasto-plastic collisions. Int. J. Impact Eng. 2002, 27, 317–341. [Google Scholar] [CrossRef]

- Wojtkowski, M.; Pecen, J.; Horabik, J.; Molenda, M. Rapeseed impact against a flat surface: Physical testing and DEM simulation with two contact models. Powder Technol. 2010, 198, 61–68. [Google Scholar] [CrossRef]

- Yigit, A.S.; Christoforou, A.P.; Majeed, M.A. A nonlinear visco-elastoplastic impact model and the coefficient of restitution. Nonlinear Dyn. 2011, 66, 509–521. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Y.M.; Liang, Z.W.; Gong, Z.Q. DEM simulation and physical testing of rice seed impact against a grain loss sensor. Biosyst. Eng. 2013, 116, 410–419. [Google Scholar]

- Xu, L.Z.; Wei, C.C.; Liang, Z.W. Development of rapeseed cleaning loss monitoring system and experiments in a combine harvester. Biosyst. Eng. 2019, 178, 118–130. [Google Scholar] [CrossRef]

- Du, X.W.; Ji, J.T.; Jin, X.; Li, C.; Yang, X.L. Research on divider losses with high-speed photography for foxtail millet harvesting. Future Gener. Comput. Syst. 2018, 88, 55–60. [Google Scholar] [CrossRef]

- Nakra, B.C. Vibration control in machines and structures using viscoelastic damping. J. Sound Vib. 1998, 211, 449–466. [Google Scholar] [CrossRef]

- Kessissoglou, N.J. Active attenuation of the wave transmission through an L-plate junction. J. Acoust. Soc. Am. 2000, 110, 267–277. [Google Scholar] [CrossRef]

- Cao, Z.Y. Vibration Theory of Plates and Shells; China Railway Press: Beijing, China, 1989; pp. 154–196. [Google Scholar]

- Feng, Y.C.; Zhan, H.; Tang, S.M. Design for vibration control with constrained partial damping based on modal analysis. Ship Sci. Technol. 2011, 33, 22–26. [Google Scholar]

- Aumjaud, P.; Smith, C.W.; Evans, K.E. A novel viscoelastic damping treatment for honeycomb sandwich structures. Compos. Struct. 2015, 119, 322–332. [Google Scholar] [CrossRef]

- Liang, Z.W.; Xu, L.Z.; De Baerdemaeke, J.; Li, Y.M.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

| Components | Parameters | Range | Manufacturer |

|---|---|---|---|

| Acceleration sensor of 356A16 (3-directional) | Sensitivity | 100 mv/g | PCB, USA |

| Response frequency range | 0.3–6 000 Hz | ||

| Range | ±50 g pk | ||

| Lateral sensitivity | <5% | ||

| DH5902 vibration signal acquisition and processing system | Signal channel | 32 | Donghua testing company, China |

| Sampling bandwidth | 100 k Hz | ||

| Distortion factor | <0.5% | ||

| AD resolution | 16 bit | ||

| 086D05 exciting hammer | Sensitivity Range | 0.23 mV N−1 ±22,000 N pk | PCB, USA |

| Tests No. | Forward Speed, m/s | Grain Cleaning Losses | Relative Error/% | |||

|---|---|---|---|---|---|---|

| Sensor | Manual | |||||

| Total Amount/g | Ratio/% | Total Mass/g | Ratio/% | |||

| 1 | 1.33 | 1225.7 | 0.110 | 1288.2 | 1.16 | 4.85 |

| 2 | 1.21 | 956.5 | 0.086 | 997.8 | 0.90 | 4.12 |

| 3 | 1.04 | 484.0 | 0.043 | 503.8 | 0.45 | 3.94 |

| 4 | 0.96 | 408.3 | 0.037 | 423.8 | 0.38 | 3.56 |

| 5 | 0.87 | 366.6 | 0.033 | 379.2 | 0.34 | 3.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liang, Z.; Zhu, F.; Liu, C. Optimum of Grain Loss Sensors by Analyzing Effects of Grain Collision Attitude on Signal Characteristics. Electronics 2022, 11, 3187. https://doi.org/10.3390/electronics11193187

Li J, Liang Z, Zhu F, Liu C. Optimum of Grain Loss Sensors by Analyzing Effects of Grain Collision Attitude on Signal Characteristics. Electronics. 2022; 11(19):3187. https://doi.org/10.3390/electronics11193187

Chicago/Turabian StyleLi, Jun, Zhenwei Liang, Fangyu Zhu, and Chuanchao Liu. 2022. "Optimum of Grain Loss Sensors by Analyzing Effects of Grain Collision Attitude on Signal Characteristics" Electronics 11, no. 19: 3187. https://doi.org/10.3390/electronics11193187

APA StyleLi, J., Liang, Z., Zhu, F., & Liu, C. (2022). Optimum of Grain Loss Sensors by Analyzing Effects of Grain Collision Attitude on Signal Characteristics. Electronics, 11(19), 3187. https://doi.org/10.3390/electronics11193187