Recent Progress in Fabrication and Physical Properties of 2D TMDC-Based Multilayered Vertical Heterostructures

Abstract

:1. Introduction

2. Fabrication Methods of 2D TMDC-Based Multilayered vdWs HSs

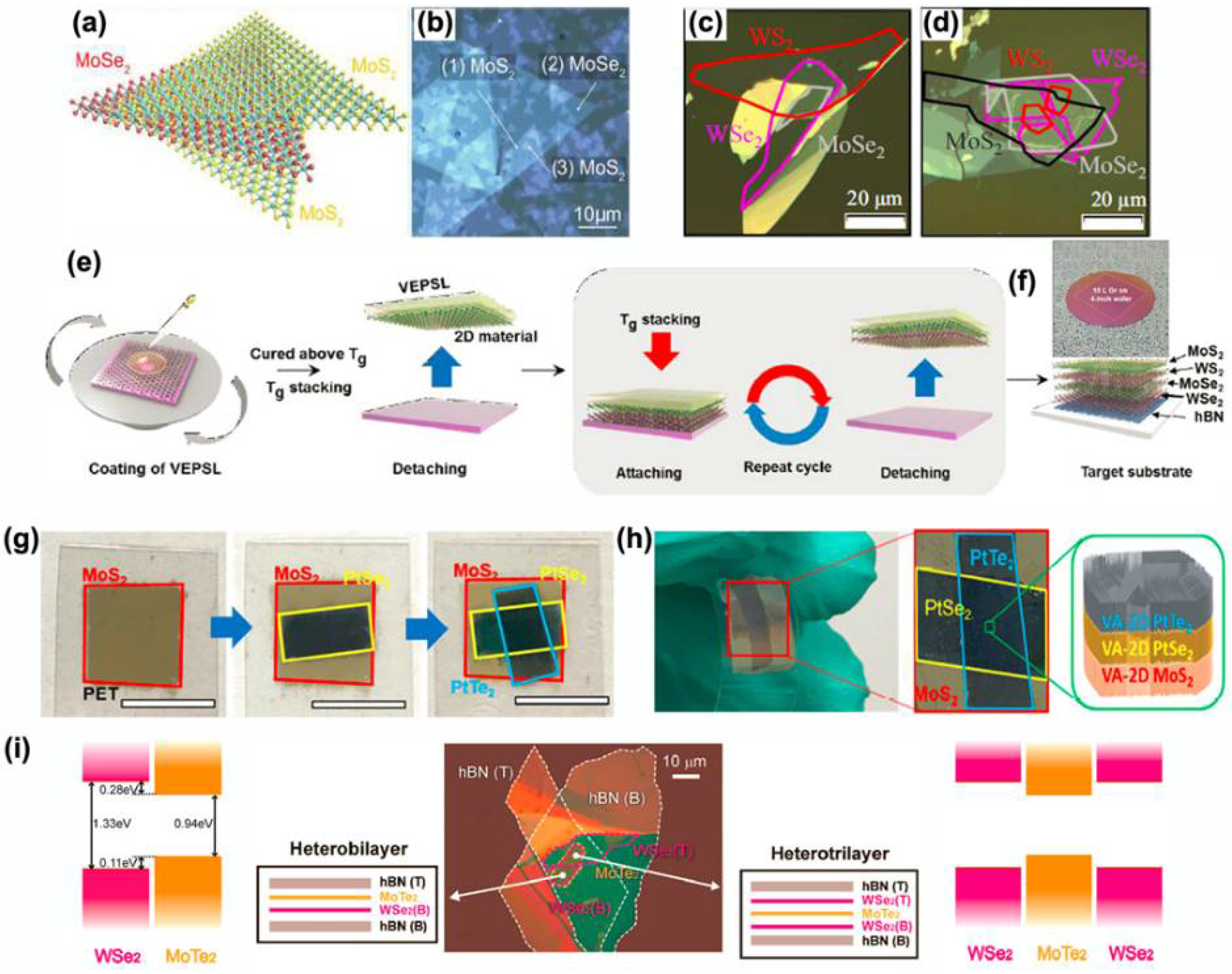

2.1. Exfoliation Method

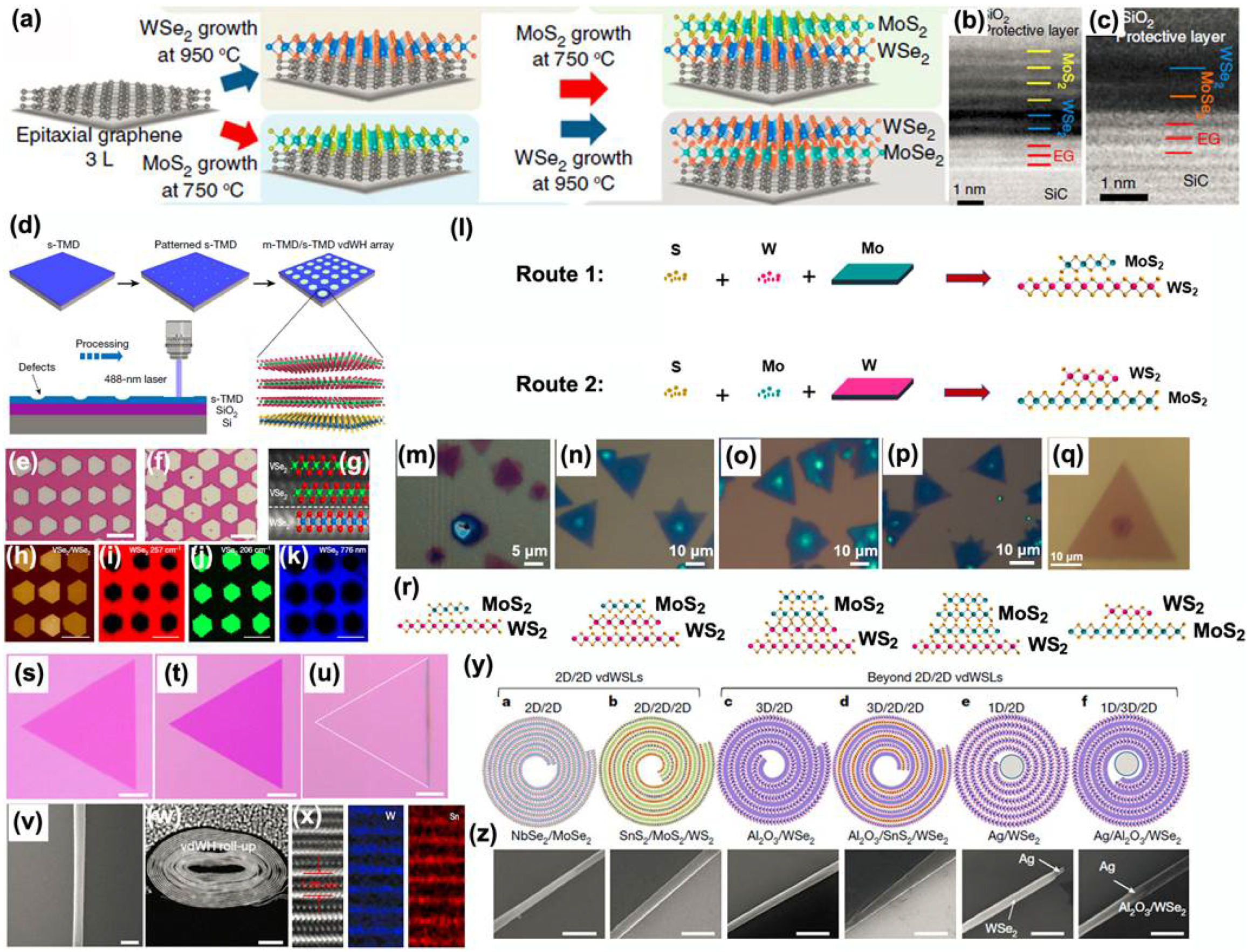

2.2. Chemical Vapor Deposition (CVD)

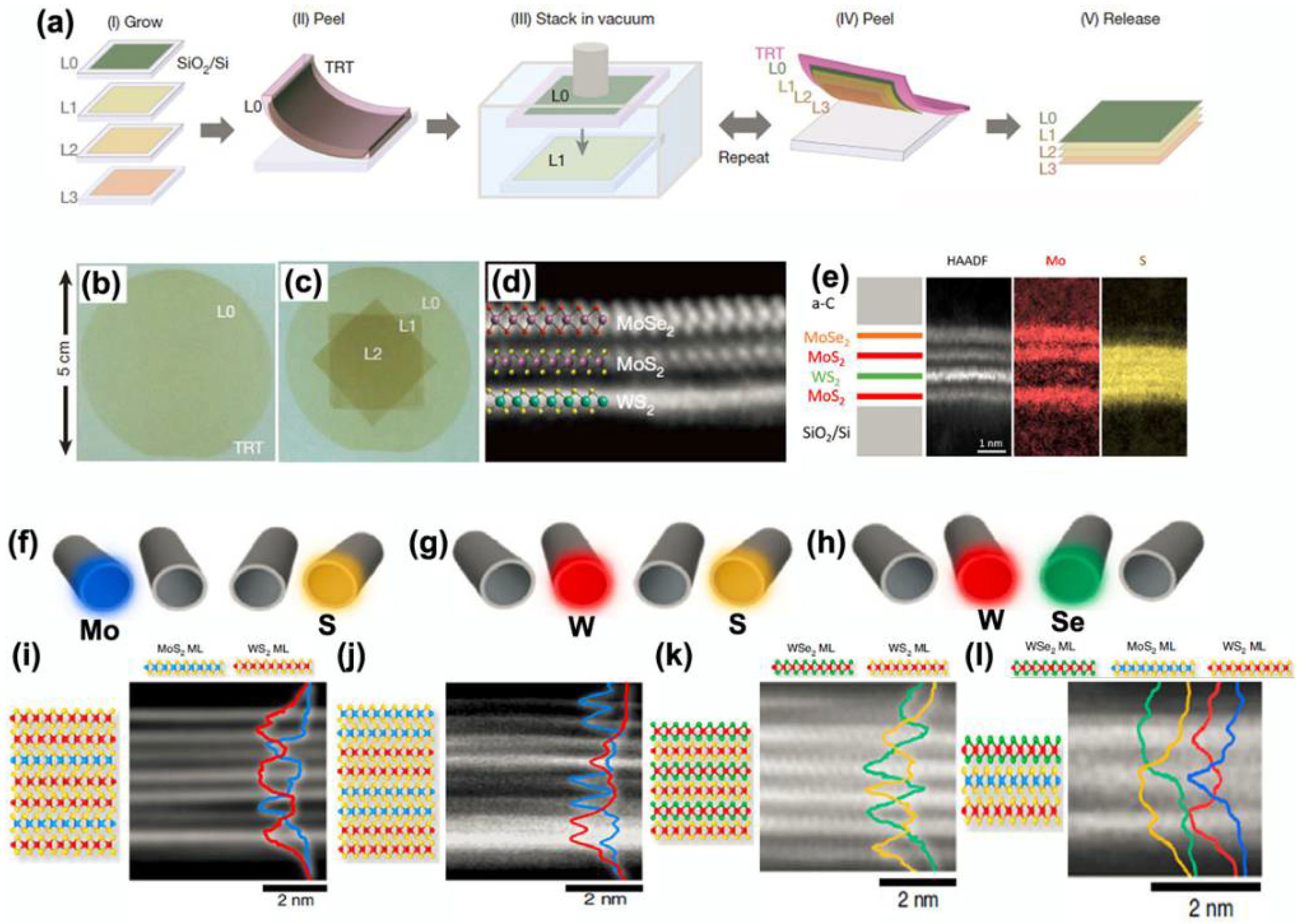

2.3. Metal-Organic Chemical Vapor Deposition (MOCVD)

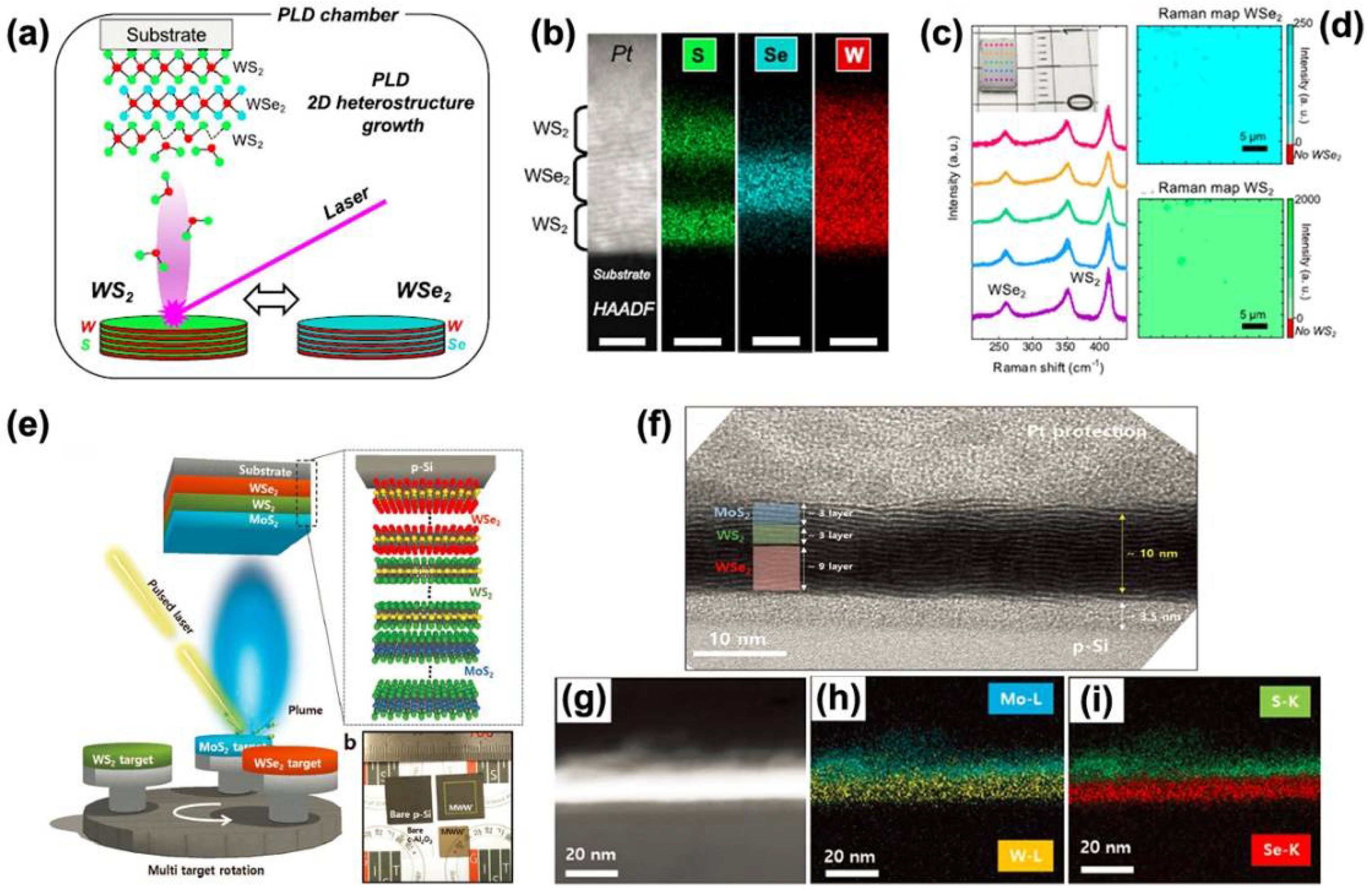

2.4. Pulsed-Laser Deposition (PLD)

3. Typical Property Features of 2D TMDC-Based Multilayered vdWs HSs

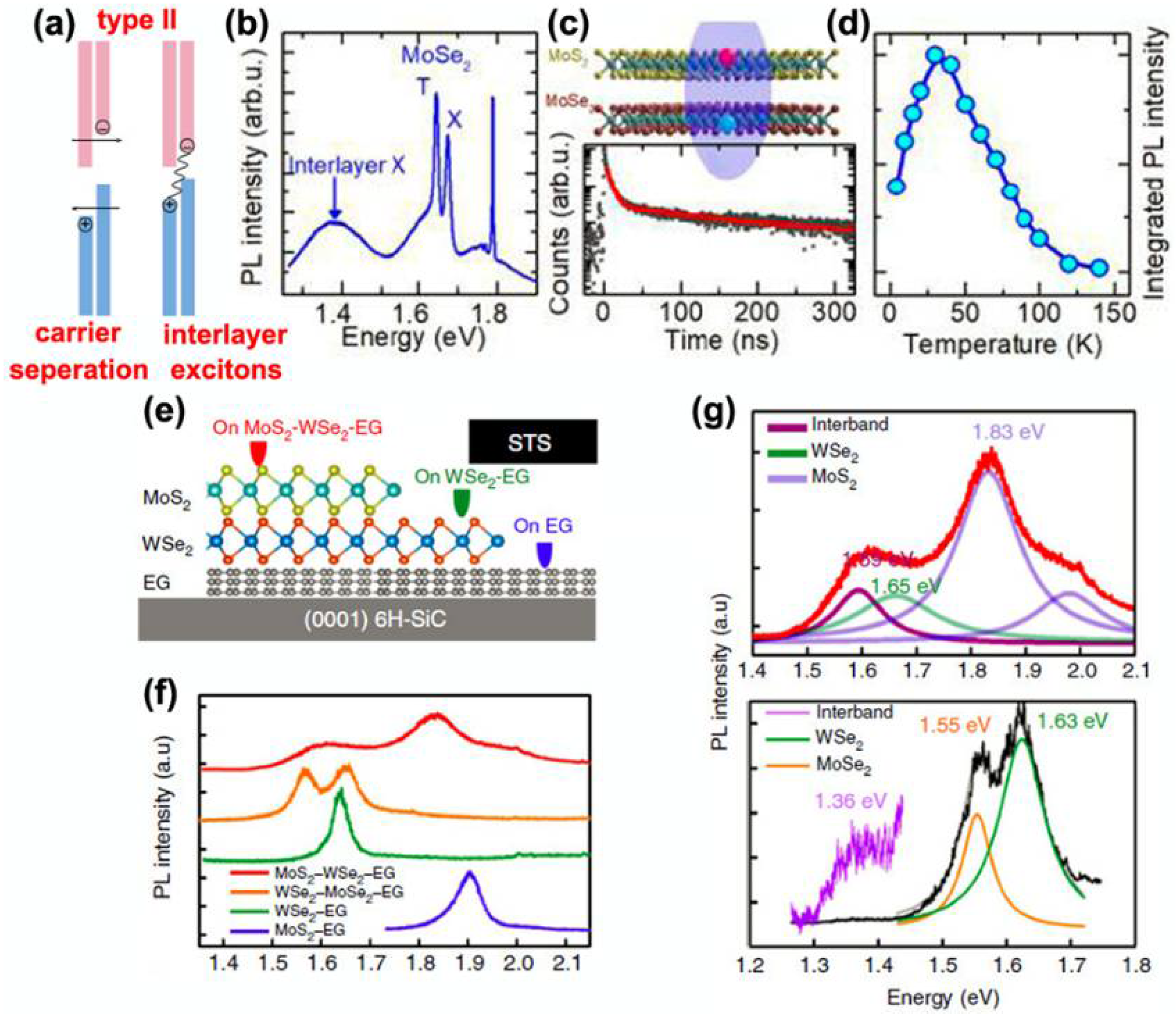

3.1. The Generation of Interlayer Excitons

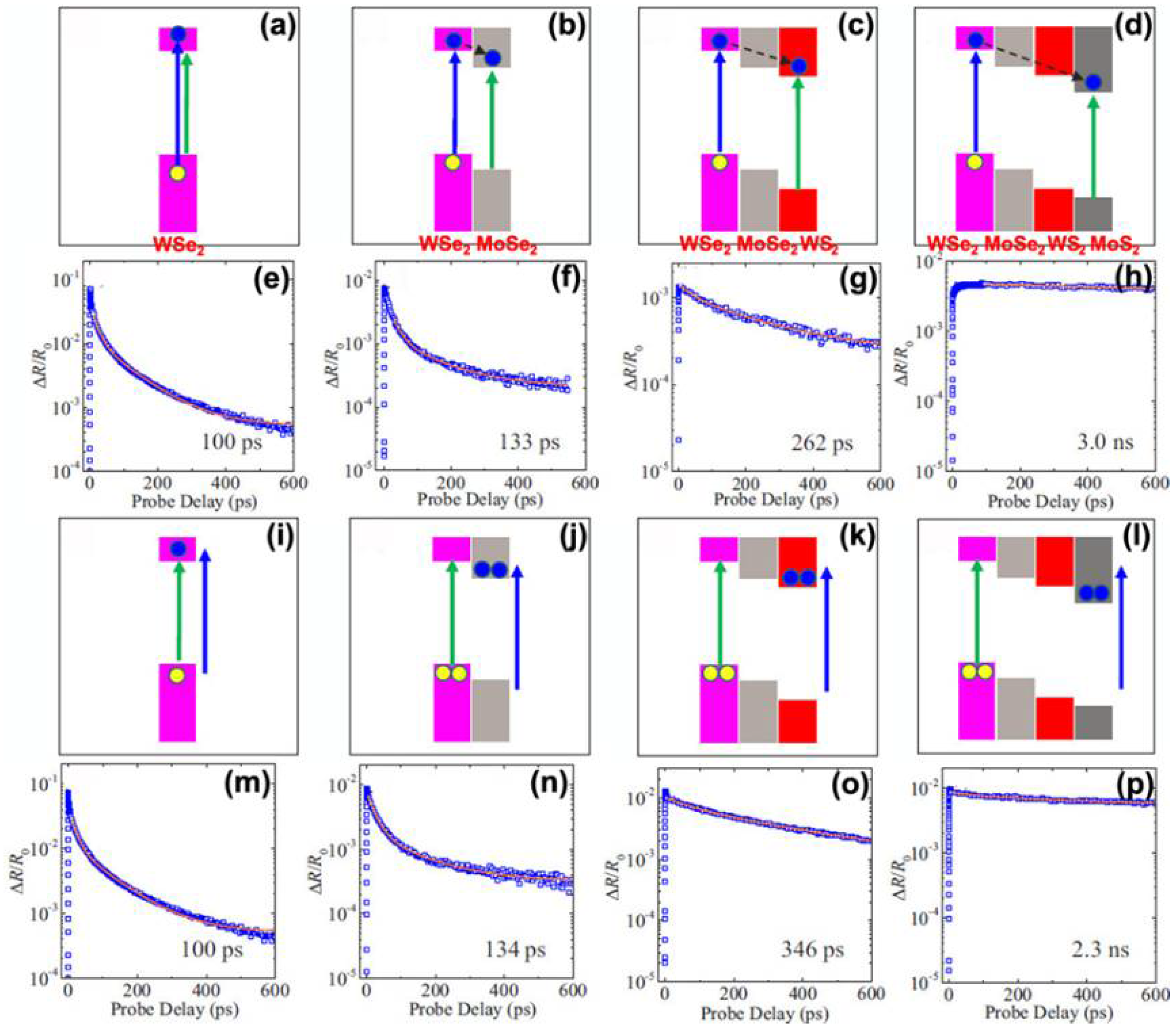

3.2. Long Photocarrier Lifetimes

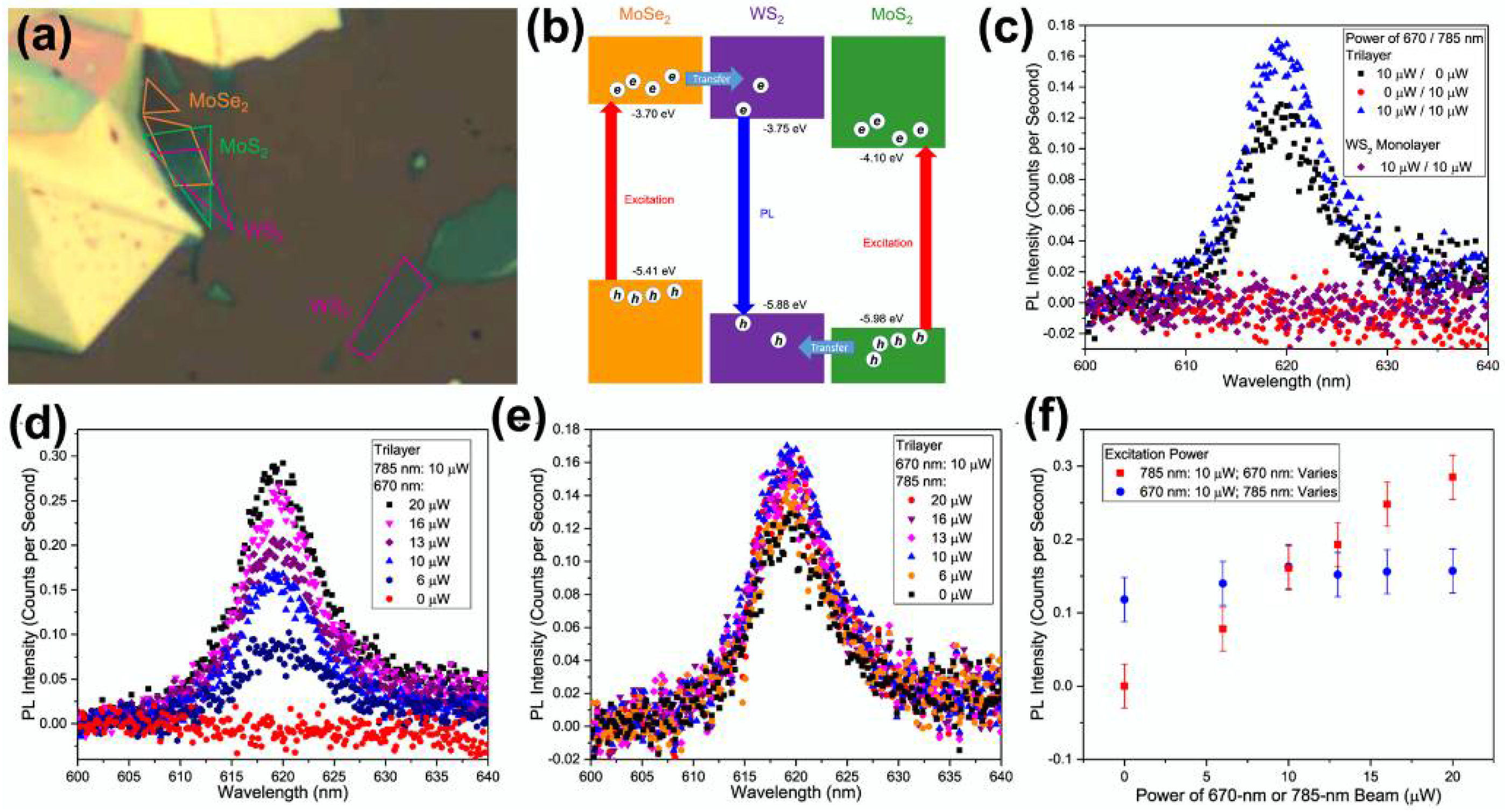

3.3. Upconversion Photoluminescence

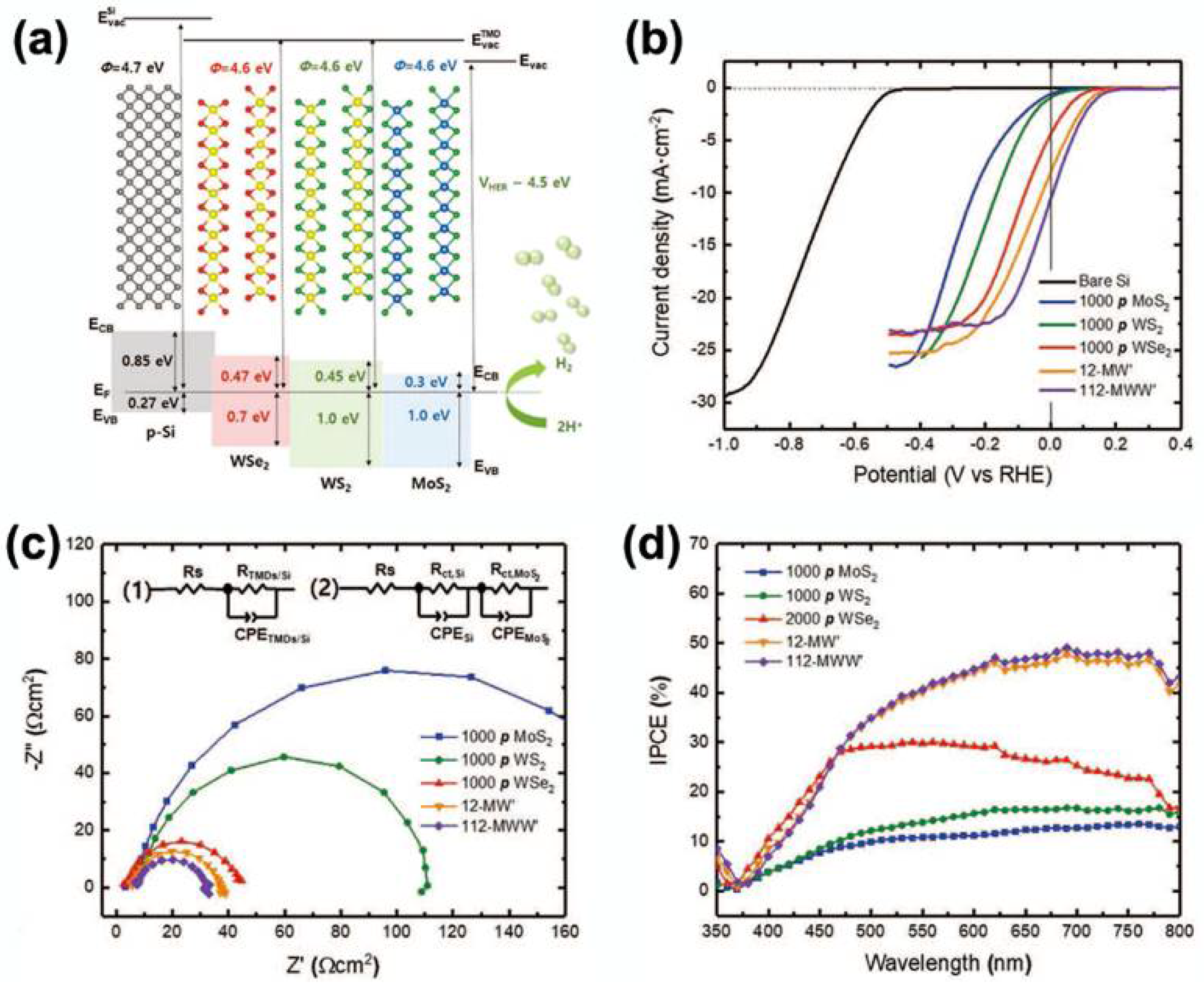

3.4. Improved Photoelectrochemical (PEC) Catalysis

4. Summary and Perspective

- How to control the precise nucleation is a crucial issue that must be addressed during the CVD process and is beneficial for realizing the preparation of TMDC-based multilayered vdWs HSs with sharp interfaces.

- Controllable bottom-up synthesis of large-scale TMDC-based multilayered vdWs HSs with a certain size, stacking order, and twisted angle, is still a challenge.

- Achieving bottom-up synthesis of alloyed TMDC-based multilayered vdWs HSs with desired composition range, which will modulate the emission wavelength of intralayer/interlayer excitons, is still a challenge.

- The stacking angle optical/electrical properties of 2D TMDC-based multilayered vdWs HSs should be intensively studied due to the important effect on the properties of vdWs HSs, including moiré superlattice and interlayer coupling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, J.; Li, N.; Zou, J.; Zhou, X.; Eda, G.; Zhang, Q.; Zhang, H.; Li, L.-J.; Zhai, T.; Wee, A.T. Synergistic additive-mediated CVD growth and chemical modification of 2D materials. Chem. Soc. Rev. 2019, 48, 4639–4654. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Kwak, J.; Ciobanu, C.V.; Kwon, S.Y. Recent Developments in Controlled Vapor-Phase Growth of 2D Group 6 Transition Metal Dichalcogenides. Adv. Mater. 2019, 31, 1804939. [Google Scholar] [CrossRef]

- Zhang, Y.; Yao, Y.; Sendeku, M.G.; Yin, L.; Zhan, X.; Wang, F.; Wang, Z.; He, J. Recent progress in CVD growth of 2D transition metal dichalcogenides and related heterostructures. Adv. Mater. 2019, 31, 1901694. [Google Scholar] [CrossRef] [PubMed]

- You, J.; Hossain, M.; Luo, Z. Synthesis of 2D transition metal dichalcogenides by chemical vapor deposition with controlled layer number and morphology. Nano Converg. 2018, 5, 26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Wang, X.; Wang, P.; Wang, J.; Hu, W.; Zhou, X.; Guo, N.; Huang, H.; Sun, S.; Shen, H.; Lin, T. Ultrasensitive and broadband MoS2 photodetector driven by ferroelectrics. Adv. Mater. 2015, 27, 6575–6581. [Google Scholar] [CrossRef] [Green Version]

- Long, M.; Wang, P.; Fang, H.; Hu, W. Progress, challenges, and opportunities for 2D material based photodetectors. Adv. Funct. Mater. 2019, 29, 1803807. [Google Scholar] [CrossRef]

- Mak, K.F.; He, K.; Shan, J.; Heinz, T.F. Control of valley polarization in monolayer MoS2 by optical helicity. Nat. Nanotechnol. 2012, 7, 494–498. [Google Scholar] [CrossRef]

- Voiry, D.; Fullon, R.; Yang, J.; Kappera, R.; Bozkurt, I.; Kaplan, D.; Lagos, M.J.; Batson, P.E.; Gupta, G. The role of electronic coupling between substrate and 2D MoS2 nanosheets in electrocatalytic production of hydrogen. Nat. Mater. 2018, 15, 1003. [Google Scholar] [CrossRef]

- Chen, F.; Su, W.; Ding, S.; Fu, L. The fabrication and tunable optical properties of 2D transition metal dichalcogenides heterostructures by adjusting the thickness of Mo/W films. Appl. Surf. Sci. 2020, 505, 144192. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, S.; He, J.; Wang, Z.M.; Liu, Z. Recent progress in the fabrication, properties, and devices of heterostructures based on 2D materials. Nano-Micro Lett. 2019, 11, 13. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Hu, S.; Su, L.; Huang, L.; Liu, Y.; Jin, Z.; Purezky, A.A.; Geohegan, D.B.; Kim, K.W.; Zhang, Y. Equally Efficient Interlayer Exciton Relaxation and Improved Absorption in Epitaxial and Non-epitaxial MoS2/WS2 Heterostructures. Nano Lett. 2015, 15, 486–491. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Furchi, M.M.; Pospischil, A.; Libisch, F.; Burgdörfer, J.; Mueller, T. Photovoltaic effect in an electrically tunable van der Waals heterojunction. Nano Lett. 2014, 14, 4785. [Google Scholar] [CrossRef]

- Lee, C.H.; Lee, G.H.; Zande, A.M.V.D.; Chen, W.; Li, Y.; Han, M.; Cui, X.; Arefe, G.; Nuckolls, C.; Heinz, T.F. Atomically thin p-n junctions with van der Waals heterointerfaces. Nat. Nanotechnol. 2014, 9, 676. [Google Scholar] [CrossRef] [Green Version]

- Hong, X.; Kim, J.; Shi, S.-F.; Zhang, Y.; Jin, C.; Sun, Y.; Tongay, S.; Wu, J.; Zhang, Y.; Wang, F. Ultrafast charge transfer in atomically thin MoS2/WS2 heterostructures. Nat. Nanotechnol. 2014, 9, 682. [Google Scholar] [CrossRef] [Green Version]

- Dean, C.R.; Young, A.F.; Meric, I.; Lee, C.; Wang, L.; Sorgenfrei, S.; Watanabe, K.; Taniguchi, T.; Kim, P.; Shepard, K.L. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 2010, 5, 722–726. [Google Scholar] [CrossRef] [PubMed]

- Rivera, P.; Schaibley, J.R.; Jones, A.M.; Ross, J.S.; Wu, S.; Aivazian, G.; Klement, P.; Seyler, K.; Clark, G.; Ghimire, N.J. Observation of long-lived interlayer excitons in monolayer MoSe2-WSe2 heterostructures. Nat. Commun. 2015, 6, 6242. [Google Scholar] [CrossRef] [Green Version]

- Chiu, M.-H.; Zhang, C.; Shiu, H.-W.; Chuu, C.-P.; Chen, C.-H.; Chang, C.-Y.S.; Chen, C.-H.; Chou, M.-Y.; Shih, C.-K.; Li, L.-J. Determination of band alignment in the single-layer MoS2/WSe2 heterojunction. Nat. Commun. 2015, 6, 7666. [Google Scholar] [CrossRef] [Green Version]

- Rigosi, A.F.; Hill, H.M.; Li, Y.; Chernikov, A.; Heinz, T.F. Probing interlayer interactions in transition metal dichalcogenide heterostructures by optical spectroscopy: MoS2/WS2 and MoSe2/WSe2. Nano Lett. 2015, 15, 5033–5038. [Google Scholar] [CrossRef]

- Diaz, H.C.; Ma, Y.; Chaghi, R.; Batzill, M. High density of (pseudo) periodic twin-grain boundaries in molecular beam epitaxy-grown van der Waals heterostructure: MoTe2/MoS2. Appl. Phys. Lett. 2016, 108, 191606. [Google Scholar] [CrossRef]

- Fu, D.; Zhao, X.; Zhang, Y.-Y.; Li, L.; Xu, H.; Jang, A.-R.; Yoon, S.I.; Song, P.; Poh, S.M.; Ren, T. Molecular beam epitaxy of highly crystalline monolayer molybdenum disulfide on hexagonal boron nitride. J. Am. Chem. Soc. 2017, 139, 9392–9400. [Google Scholar] [CrossRef] [PubMed]

- Mortelemans, W.; Nalin Mehta, A.; Balaji, Y.; Sergeant, S.; Meng, R.; Houssa, M.; De Gendt, S.; Heyns, M.; Merckling, C. On the van der Waals Epitaxy of Homo-/Heterostructures of Transition Metal Dichalcogenides. ACS Appl. Mater. Interfaces 2020, 12, 27508–27517. [Google Scholar] [CrossRef] [PubMed]

- Ohtake, A.; Sakuma, Y. Two-Dimensional WSe2/MoSe2 Heterostructures Grown by Molecular-Beam Epitaxy. J. Phys. Chem. C 2021, 125, 11257–11261. [Google Scholar] [CrossRef]

- Zatko, V.; Dubois, S.M.-M.; Godel, F.; Carrétéro, C.; Sander, A.; Collin, S.; Galbiati, M.; Peiro, J.; Panciera, F.; Patriarche, G. Band-Gap Landscape Engineering in Large-Scale 2D Semiconductor van der Waals Heterostructures. ACS Nano 2021, 15, 7279–7289. [Google Scholar] [CrossRef]

- Jie, W.; Yang, Z.; Zhang, F.; Bai, G.; Leung, C.W.; Hao, J. Observation of room-temperature magnetoresistance in monolayer MoS2 by ferromagnetic gating. ACS Nano 2017, 11, 6950–6958. [Google Scholar] [CrossRef]

- Kang, K.; Lee, K.-H.; Han, Y.; Gao, H.; Xie, S.; Muller, D.A.; Park, J. Layer-by-layer assembly of two-dimensional materials into wafer-scale heterostructures. Nature 2017, 550, 229–233. [Google Scholar] [CrossRef] [PubMed]

- Jin, G.; Lee, C.-S.; Okello, O.F.; Lee, S.-H.; Park, M.Y.; Cha, S.; Seo, S.-Y.; Moon, G.; Yang, D.-H.; Han, C. Heteroepitaxial van der Waals semiconductor superlattices. Nat. Nanotechnol. 2021, 16, 1092–1098. [Google Scholar] [CrossRef]

- Chen, F.; Wang, L.; Ji, X. Evolution of Two-Dimensional Mo1−xWxS2 Alloy-Based Vertical Heterostructures with Various Composition Ranges via Manipulating the Mo/W Precursors. J. Phys. Chem. C 2018, 122, 28337–28346. [Google Scholar] [CrossRef]

- Chen, F.; Wang, L.; Ji, X.; Zhang, Q. Temperature-Dependent Two-Dimensional Transition Metal Dichalcogenide Heterostructures: Controlled Synthesis and Their Properties. ACS Appl. Mater. Interfaces 2017, 9, 30821–30831. [Google Scholar] [CrossRef]

- Chen, F.; Wang, Y.; Su, W.; Ding, S.; Fu, L. Position-Selective Growth of 2D WS2-Based Vertical Heterostructures via a One-Step CVD Approach. J. Phys. Chem. C 2019, 123, 30519–30527. [Google Scholar] [CrossRef]

- Chen, F.; Yao, Y.; Su, W.; Ding, S.; Fu, L. Optical performance and growth mechanism of a 2D WS2-MoWS2 hybrid heterostructure fabricated by a one-step CVD strategy. CrystEngComm 2019, 22, 660–665. [Google Scholar] [CrossRef]

- Kim, B.; Kim, J.; Tsai, P.-C.; Choi, H.; Yoon, S.; Lin, S.-Y.; Kim, D.-W. Large Surface Photovoltage of WS2/MoS2 and MoS2/WS2 Vertical Hetero-bilayers. ACS Appl. Electron. Mater. 2021, 3, 2601–2606. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, X.; Zhao, R.; Lv, D.; Xu, G.; Lu, Z.; Sun, L.; Lin, S.; Gao, X.; Zhou, J. Two-Dimensional Layered Heterostructures Synthesized from Core-Shell Nanowires. Angew. Chem. 2015, 127, 9085–9088. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Chen, P.; Sun, Y.; Wu, S.; Jia, Z.; Lu, X.; Yu, H.; Chen, W.; Zhu, J. Observation of Strong Interlayer Coupling in MoS2/WS2 Heterostructures. Adv. Mater. 2016, 28, 1950–1956. [Google Scholar] [CrossRef]

- Kanade, C.K.; Seok, H.; Kanade, V.K.; Aydin, K.; Kim, H.-U.; Mitta, S.B.; Yoo, W.J.; Kim, T. Low-Temperature and Large-Scale Production of a Transition Metal Sulfide Vertical Heterostructure and Its Application for Photodetectors. ACS Appl. Mater. Interfaces 2021, 13, 8710–8717. [Google Scholar] [CrossRef]

- Seok, H.; Megra, Y.T.; Kanade, C.K.; Cho, J.; Kanade, V.K.; Kim, M.; Lee, I.; Yoo, P.J.; Kim, H.-U.; Suk, J.W. Low-Temperature Synthesis of Wafer-Scale MoS2-WS2 Vertical Heterostructures by Single-Step Penetrative Plasma Sulfurization. ACS Nano 2021, 15, 707–718. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, X.; Shao, J.; Zhao, S.; Su, W.; Li, Y. Multilayered Vertical Heterostructures Comprised of MoS2 and WS2 Nanosheets for Optoelectronics. ACS Appl. Nano Mater. 2021, 4, 9293–9302. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Ghosh, R.K.; Addou, R.; Lu, N.; Eichfeld, S.M.; Zhu, H.; Li, M.-Y.; Peng, X.; Kim, M.J.; Li, L.-J. Atomically thin resonant tunnel diodes built from synthetic van der Waals heterostructures. Nat. Commun. 2015, 6, 7311. [Google Scholar] [CrossRef]

- Wan, Y.; Huang, J.-K.; Chuu, C.-P.; Hsu, W.-T.; Lee, C.-J.; Aljarb, A.; Huang, C.-W.; Chiu, M.-H.; Tang, H.-L.; Lin, C.; et al. Strain-Directed Layer-By-Layer Epitaxy Toward van der Waals Homo-and Heterostructures. ACS Mater. Lett. 2021, 3, 442–453. [Google Scholar] [CrossRef]

- Gong, Y.; Lei, S.; Ye, G.; Li, B.; He, Y.; Keyshar, K.; Zhang, X.; Wang, Q.; Lou, J.; Liu, Z. Two-Step Growth of Two-Dimensional WSe2/MoSe2 Heterostructures. Nano Lett. 2015, 15, 6135–6141. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Jiang, B.; Xu, Z.; Mendes, R.G.; Xiao, Y.; Chen, L.; Fang, L.; Gemming, T.; Chen, S.; Rümmeli, M.H. Twinned growth behaviour of two-dimensional materials. Nat. Commun. 2016, 7, 13911. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yang, Y.; Zhang, Z.; Gong, Y.; Zhou, W.; Hu, Z.; Ye, G.; Zhang, X.; Bianco, E.; Lei, S. Strain-Induced Electronic Structure Changes in Stacked van der Waals Heterostructures. Nano Lett. 2016, 16, 3314–3320. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Yan, J.; Wang, Z.; He, Y.; Gong, Y.; Chen, W.; Sum, T.C.; Liu, Z.; Ajayan, P.M.; Shen, Z. Strong coupling and pressure engineering in WSe2-MoSe2 heterobilayers. Nat. Phys. 2021, 17, 92–98. [Google Scholar] [CrossRef]

- Irisawa, T.; Okada, N.; Chang, W.-H.; Okada, M.; Mori, T.; Endo, T.; Miyata, Y. CVD grown bilayer WSe2/MoSe2 heterostructures for high performance tunnel transistors. Jpn. J. Appl. Phys. 2020, 59, SGGH05. [Google Scholar] [CrossRef]

- Nikam, R.D.; Sonawane, P.A.; Sankar, R.; Chen, Y.-T. Epitaxial growth of vertically stacked p-MoS2/n-MoS2 heterostructures by chemical vapor deposition for light emitting devices. Nano Energy 2017, 32, 454–462. [Google Scholar] [CrossRef]

- Zhang, C.; Chuu, C.-P.; Ren, X.; Li, M.-Y.; Li, L.-J.; Jin, C.; Chou, M.-Y.; Shih, C.-K. Interlayer couplings, Moiré patterns, and 2D electronic superlattices in MoS2/WSe2 hetero-bilayers. Sci. Adv. 2017, 3, e1601459. [Google Scholar] [CrossRef] [Green Version]

- Yuan, J.; Sun, T.; Hu, Z.; Yu, W.; Ma, W.; Zhang, K.; Sun, B.; Lau, S.P.; Bao, Q.; Lin, S. Wafer-scale fabrication of two-dimensional PtS2/PtSe2 heterojunctions for efficient and broad band photodetection. ACS Appl. Mater. Interfaces 2018, 10, 40614–40622. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Wang, X.; Zhou, J.; Xia, J.; Zeng, Q.; Lv, D.; Zhu, C.; Wang, X.; Shen, Y.; Li, X. One-step synthesis of metal/semiconductor heterostructure NbS2/MoS2. Chem. Mater. 2018, 30, 4001–4007. [Google Scholar] [CrossRef]

- Zhang, P.; Bian, C.; Ye, J.; Cheng, N.; Wang, X.; Jiang, H.; Wei, Y.; Zhang, Y.; Du, Y.; Bao, L. Epitaxial growth of metal-semiconductor van der Waals heterostructures NbS2/MoS2 with enhanced performance of transistors and photodetectors. Sci. China Mater. 2020, 63, 1548–1559. [Google Scholar] [CrossRef]

- Carozo, V.; Fujisawa, K.; Rao, R.; Kahn, E.; Cunha, J.R.; Zhang, T.; Rubin, D.; Salazar, M.F.; de Luna Bugallo, A.; Kar, S. Excitonic processes in atomically-thin MoSe2/MoS2 vertical heterostructures. 2D Mater. 2018, 5, 031016. [Google Scholar] [CrossRef]

- Ding, Y.; Zhou, N.; Gan, L.; Yan, X.; Wu, R.; Abidi, I.H.; Waleed, A.; Pan, J.; Ou, X.; Zhang, Q. Stacking-mode Confined Growth of 2H-MoTe2/MoS2 Bilayer Heterostructures for UV-vis-IR Photodetectors. Nano Energy 2018, 49, 200–208. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, S.; Nan, H.; Mo, H.; Wan, X.; Gu, X.; Ostrikov, K.K. Controllable one-step growth of bilayer MoS2-WS2/WS2 heterostructures by chemical vapor deposition. Nanotechnology 2018, 29, 455707. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Gong, Y.; Zou, X.; Liu, P.; Yang, P.; Shi, J.; Zhao, L.; Zhang, Q.; Gu, L.; Zhang, Y. Epitaxial growth of two-dimensional metal-semiconductor transition-metal dichalcogenide vertical stacks (VSe2/MX2) and their band alignments. ACS Nano 2018, 13, 885–893. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yang, X.; Liu, Y.; Huang, B.; Wu, R.; Zhang, Z.; Zhao, B.; Ma, H.; Dang, W.; Wei, Z. General synthesis of two-dimensional van der Waals heterostructure arrays. Nature 2020, 579, 368–374. [Google Scholar] [CrossRef]

- Zhou, J.; Kong, X.; Sekhar, M.C.; Lin, J.; Le Goualher, F.; Xu, R.; Wang, X.; Chen, Y.; Zhou, Y.; Zhu, C. Epitaxial synthesis of monolayer PtSe2 single crystal on MoSe2 with strong interlayer coupling. ACS Nano 2019, 13, 10929–10938. [Google Scholar] [CrossRef]

- Wu, R.; Tao, Q.; Dang, W.; Liu, Y.; Li, B.; Li, J.; Zhao, B.; Zhang, Z.; Ma, H.; Sun, G. van der Waals epitaxial growth of atomically thin 2D metals on dangling-bond-free WSe2 and WS2. Adv. Funct. Mater. 2019, 29, 1806611. [Google Scholar] [CrossRef]

- Li, F.; Feng, Y.; Li, Z.; Ma, C.; Qu, J.; Wu, X.; Li, D.; Zhang, X.; Yang, T.; He, Y. Rational kinetics control toward universal growth of 2D vertically stacked heterostructures. Adv. Mater. 2019, 31, 1901351. [Google Scholar] [CrossRef]

- Wu, X.; Wang, X.; Li, H.; Zeng, Z.; Zheng, B.; Zhang, D.; Li, F.; Zhu, X.; Jiang, Y.; Pan, A. Vapor growth of WSe2/WS2 heterostructures with stacking dependent optical properties. Nano Res. 2019, 12, 3123–3128. [Google Scholar] [CrossRef]

- Yuan, L.; Zheng, B.; Kunstmann, J.; Brumme, T.; Kuc, A.B.; Ma, C.; Deng, S.; Blach, D.; Pan, A.; Huang, L. Twist-angle-dependent interlayer exciton diffusion in WS2-WSe2 heterobilayers. Nat. Mater. 2020, 19, 617–623. [Google Scholar] [CrossRef]

- Cao, L.; Zhong, J.; Yu, J.; Zeng, C.; Ding, J.; Cong, C.; Yue, X.; Liu, Z.; Liu, Y. Valley-polarized local excitons in WSe2/WS2 vertical heterostructures. Opt. Express 2020, 28, 22135–22143. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Xu, X.; Peng, J.; Jing, F.; Zhang, Q.; Liu, H.; Hu, Z. Enhanced optoelectronic performance of CVD-grown metal-semiconductor NiTe2/MoS2 heterostructures. ACS Appl. Mater. Interfaces 2020, 12, 24093–24101. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, P.K.; Memaran, S.; Nugera, F.A.; Xin, Y.; Díaz Márquez, T.; Lu, Z.; Zheng, W.; Zhigadlo, N.D.; Smirnov, D.; Balicas, L. Bilayer lateral heterostructures of transition-metal dichalcogenides and their optoelectronic response. ACS Nano 2019, 13, 12372–12384. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Zheng, W.; Ma, C.; Zhao, H.; Jiang, F.; Ouyang, Y.; Zheng, B.; Fu, X.; Fan, P.; Zheng, M. Wavelength-tunable interlayer exciton emission at the near-infrared region in van der Waals semiconductor heterostructures. Nano Lett. 2020, 20, 3361–3368. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Liang, D.; Ping, X.; Xing, L.; Wang, Z.; Wu, L.; Lu, P.; Jiao, L. 1D/2D Heterostructures as Ultrathin Catalysts for Hydrogen Evolution Reaction. Small 2020, 16, 2004296. [Google Scholar] [CrossRef]

- Li, B.; Wan, Z.; Wang, C.; Chen, P.; Huang, B.; Cheng, X.; Qian, Q.; Li, J.; Zhang, Z.; Sun, G. Van der Waals epitaxial growth of air-stable CrSe2 nanosheets with thickness-tunable magnetic order. Nat. Mater. 2021, 20, 818–825. [Google Scholar] [CrossRef]

- Zhao, B.; Wan, Z.; Liu, Y.; Xu, J.; Yang, X.; Shen, D.; Zhang, Z.; Guo, C.; Qian, Q.; Li, J. High-order superlattices by rolling up van der Waals heterostructures. Nature 2021, 591, 385–390. [Google Scholar] [CrossRef]

- Choi, W.; Cho, M.Y.; Konar, A.; Lee, J.H.; Cha, G.-B.; Hong, S.C.; Kim, S.; Kim, J.; Jena, D.; Joo, J.; et al. High-Detectivity Multilayer MoS2 Phototransistors with Spectral Response from Ultraviolet to Infrared. Adv. Mater. 2012, 24, 5832–5836. [Google Scholar] [CrossRef]

- Baranowski, M.; Surrente, A.; Klopotowski, L.; Urban, J.M.; Zhang, N.; Maude, D.K.; Wiwatowski, K.; Mackowski, S.; Kung, Y.C.; Dumcenco, D.; et al. Probing the Interlayer Exciton Physics in a MoS2/MoSe2/MoS2 van der Waals Heterostructure. Nano Lett. 2018, 17, 6360. [Google Scholar] [CrossRef] [Green Version]

- Miller, B.; Steinhoff, A.; Pano, B.; Klein, J.; Jahnke, F.; Holleitner, A.; Wurstbauer, U. Long-Lived Direct and Indirect Interlayer Excitons in van der Waals Heterostructures. Nano Lett. 2017, 17, 5229. [Google Scholar] [CrossRef] [Green Version]

- Surrente, A.; Dumcenco, D.; Yang, Z.; Kuc, A.; Jing, Y.; Heine, T.; Kung, Y.-C.; Maude, D.K.; Kis, A.; Plochocka, P. Defect healing and charge transfer-mediated valley polarization in MoS2/MoSe2/MoS2 trilayer van der Waals heterostructures. Nano Lett. 2017, 17, 4130–4136. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, B.; Zheng, H.; Li, S.; Ding, J.; He, J.; Liu, Z.; Liu, Y. Enhanced interlayer neutral excitons and trions in MoSe2/MoS2/MoSe2 trilayer heterostructure. Nano Res. 2022, 15, 5640–5645. [Google Scholar] [CrossRef]

- Ceballos, F.; Ju, M.G.; Lane, S.D.; Zeng, X.C.; Zhao, H. Highly Efficient and Anomalous Charge Transfer in van der Waals Trilayer Semiconductors. Nano Lett. 2017, 17, 1623–1628. [Google Scholar] [CrossRef] [PubMed]

- Ceballos, F.; Zereshki, P.; Hui, Z. Separating electrons and holes by monolayer increments in van der Waals heterostructures. Phys. Rev. Mater. 2017, 1, 044001. [Google Scholar] [CrossRef]

- Boandoh, S.; Agyapong-Fordjour, F.O.-T.; Choi, S.H.; Lee, J.S.; Park, J.-H.; Ko, H.; Han, G.; Yun, S.J.; Park, S.; Kim, Y.-M. Wafer-scale van der Waals heterostructures with ultraclean interfaces via the aid of viscoelastic polymer. ACS Appl. Mater. Interfaces 2018, 11, 1579–1586. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.; He, D.; Miao, Q.; Han, X.; Liu, S.; Wang, Y.; Zhao, H. Upconversion photoluminescence by charge transfer in a van der Waals trilayer. Appl. Phys. Lett. 2019, 115, 173102. [Google Scholar] [CrossRef]

- Hu, Z.; Hernández-Martínez, P.L.; Liu, X.; Amara, M.-R.; Zhao, W.; Watanabe, K.; Taniguchi, T.; Demir, H.V.; Xiong, Q. Trion-mediated Forster resonance energy transfer and optical gating effect in WS2/hBN/MoSe2 heterojunction. ACS Nano 2020, 14, 13470–13477. [Google Scholar] [CrossRef] [PubMed]

- Han, S.S.; Ko, T.-J.; Yoo, C.; Shawkat, M.S.; Li, H.; Kim, B.K.; Hong, W.-K.; Bae, T.-S.; Chung, H.-S.; Oh, K.H. Automated assembly of wafer-scale 2D TMD heterostructures of arbitrary layer orientation and stacking sequence using water dissoluble salt substrates. Nano Lett. 2020, 20, 3925–3934. [Google Scholar] [CrossRef]

- Bian, A.; He, D.; Hao, S.; Fu, Y.; Zhang, L.; He, J.; Wang, Y.; Zhao, H. Dynamics of charge-transfer excitons in a transition metal dichalcogenide heterostructure. Nanoscale 2020, 12, 8485–8492. [Google Scholar] [CrossRef]

- Wang, P.; He, D.; Wang, Y.; Zhang, X.; He, X.; He, J.; Zhao, H. Ultrafast Interlayer Charge Transfer between Bilayer PtSe2 and Monolayer WS2. ACS Appl. Mater. Interfaces 2021, 13, 57822–57830. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, L.; Chang, J.; Cui, Q.; Zhao, H. Time-Resolved Observation of Hole Tunneling in van der Waals Multilayer Heterostructures. ACS Appl. Mater. Interfaces 2021, 13, 12425–12431. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Wang, R.; Li, X.; Ma, Z.; Li, L.; Su, J.; Yan, Y.; Song, X.; Xia, C. Photovoltaic Field-Effect Photodiodes Based on Double van der Waals Heterojunctions. ACS Nano 2021, 15, 14295–14304. [Google Scholar] [CrossRef] [PubMed]

- Bae, H.; Kim, S.H.; Lee, S.; Noh, M.; Karni, O.; O’Beirne, A.L.; Barré, E.; Sim, S.; Cha, S.; Jo, M.-H. Light Absorption and Emission Dominated by Trions in the Type-I van der Waals Heterostructures. ACS Photonics 2021, 8, 1972–1978. [Google Scholar] [CrossRef]

- Chen, F.; Ji, X.; Lau, S.P. Recent progress in group III-nitride nanostructures: From materials to applications. Mater. Sci. Eng. R Rep. 2020, 142, 100578. [Google Scholar] [CrossRef]

- Ludowise, M. Metalorganic chemical vapor deposition of III-V semiconductors. J. Appl. Phys. 1985, 58, R31–R55. [Google Scholar] [CrossRef]

- Kang, K.; Xie, S.; Huang, L.; Han, Y.; Huang, P.Y.; Mak, K.F.; Kim, C.-J.; Muller, D.; Park, J. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 2015, 520, 656–660. [Google Scholar] [CrossRef]

- Kalanyan, B.; Kimes, W.A.; Beams, R.; Stranick, S.J.; Garratt, E.; Kalish, I.; Davydov, A.V.; Kanjolia, R.K.; Maslar, J.E. Rapid wafer-scale growth of polycrystalline 2H-MoS2 by pulsed metal–organic chemical vapor deposition. Chem. Mater. 2017, 29, 6279–6288. [Google Scholar] [CrossRef]

- Kim, H.; Ovchinnikov, D.; Deiana, D.; Unuchek, D.; Kis, A. Suppressing nucleation in metal-organic chemical vapor deposition of MoS2 monolayers by alkali metal halides. Nano Lett. 2017, 17, 5056–5063. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eichfeld, S.M.; Hossain, L.; Lin, Y.-C.; Piasecki, A.F.; Kupp, B.; Birdwell, A.G.; Burke, R.A.; Lu, N.; Peng, X.; Li, J. Highly scalable, atomically thin WSe2 grown via metal-organic chemical vapor deposition. ACS Nano 2015, 9, 2080–2087. [Google Scholar] [CrossRef]

- Zhang, X.; Choudhury, T.H.; Chubarov, M.; Xiang, Y.; Jariwala, B.; Zhang, F.; Alem, N.; Wang, G.-C.; Robinson, J.A.; Redwing, J.M. Diffusion-controlled epitaxy of large area coalesced WSe2 monolayers on sapphire. Nano Lett. 2018, 18, 1049–1056. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, F.; Wang, Y.; Schulman, D.S.; Zhang, T.; Bansal, A.; Alem, N.; Das, S.; Crespi, V.H.; Terrones, M. Defect-controlled nucleation and orientation of WSe2 on hBN: A route to single-crystal epitaxial monolayers. ACS Nano 2019, 13, 3341–3352. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Tu, L.; Han, Y.; Huang, L.; Kang, K.; Lao, K.U.; Poddar, P.; Park, C.; Muller, D.A.; DiStasio, R.A., Jr. Coherent, atomically thin transition-metal dichalcogenide superlattices with engineered strain. Science 2018, 359, 1131–1136. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, D.H.; Sim, Y.; Wang, J.; Kwon, S.-Y. Metal-organic chemical vapor deposition of 2D van der Waals materials—The challenges and the extensive future opportunities. Appl Mater. 2020, 8, 030901. [Google Scholar] [CrossRef] [Green Version]

- Yao, J.; Zheng, Z.; Yang, G. Production of large-area 2D materials for high-performance photodetectors by pulsed-laser deposition. Prog. Mater. Sci. 2019, 106, 100573. [Google Scholar] [CrossRef]

- Seo, S.; Kim, S.; Choi, H.; Lee, J.; Lee, S. Direct In Situ Growth of Centimeter-scale Multi-heterojunction MoS2/WS2/WSe2 Thin-film Catalyst for Photo-electrochemical Hydrogen Evolution. Adv. Sci. 2019, 6, 1900301. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Liang, J.; Yang, X.; Li, X.; Zhao, B.; Li, B.; Duan, X. Controllable Preparation of 2D Vertical van der Waals Heterostructures and Superlattices for Functional Applications. Small 2022, 18, 2107059. [Google Scholar] [CrossRef]

- Özçelik, V.O.; Azadani, J.G.; Yang, C.; Koester, S.J.; Low, T. Band alignment of two-dimensional semiconductors for designing heterostructures with momentum space matching. Phys. Rev. B 2016, 94, 35125. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Q.; Chen, F.; Xia, Y.; Su, W. Recent Progress in Fabrication and Physical Properties of 2D TMDC-Based Multilayered Vertical Heterostructures. Electronics 2022, 11, 2401. https://doi.org/10.3390/electronics11152401

Lv Q, Chen F, Xia Y, Su W. Recent Progress in Fabrication and Physical Properties of 2D TMDC-Based Multilayered Vertical Heterostructures. Electronics. 2022; 11(15):2401. https://doi.org/10.3390/electronics11152401

Chicago/Turabian StyleLv, Qiuran, Fei Chen, Yuan Xia, and Weitao Su. 2022. "Recent Progress in Fabrication and Physical Properties of 2D TMDC-Based Multilayered Vertical Heterostructures" Electronics 11, no. 15: 2401. https://doi.org/10.3390/electronics11152401

APA StyleLv, Q., Chen, F., Xia, Y., & Su, W. (2022). Recent Progress in Fabrication and Physical Properties of 2D TMDC-Based Multilayered Vertical Heterostructures. Electronics, 11(15), 2401. https://doi.org/10.3390/electronics11152401