Force Tracking Control of Functional Electrical Stimulation via Hybrid Active Disturbance Rejection Control

Abstract

:1. Introduction

- A modified Hammerstein model, including nonlinear mapping function, linear dynamics and EMD, is proposed and used to model the nonlinear dynamics of biceps. The three parts of the proposed model are identified respectively. To speed up the identification process, a fast identification method is presented, in which the linear dynamics and EMD are identified only one time for a participant. In contrast, the nonlinear mapping function will be identified before each experiment.

- A hybrid ADRC method is presented, in which the inverse of the static nonlinear function is cascaded into the control loop to attenuate the nonlinearity of the musculoskeletal system, and a delayed input module is added to reduce the effect of EMD. The controller parameters will be constant once tuned according to the identified model.

- The performance of the proposed methods is verified by experiments and comparisons with the traditional PID method. These results indicate that the proposed methods could be used to improve the FES–induced motion rehabilitation performance of closed–loop controllers that are insensitive to time–varying musculoskeletal characteristics.

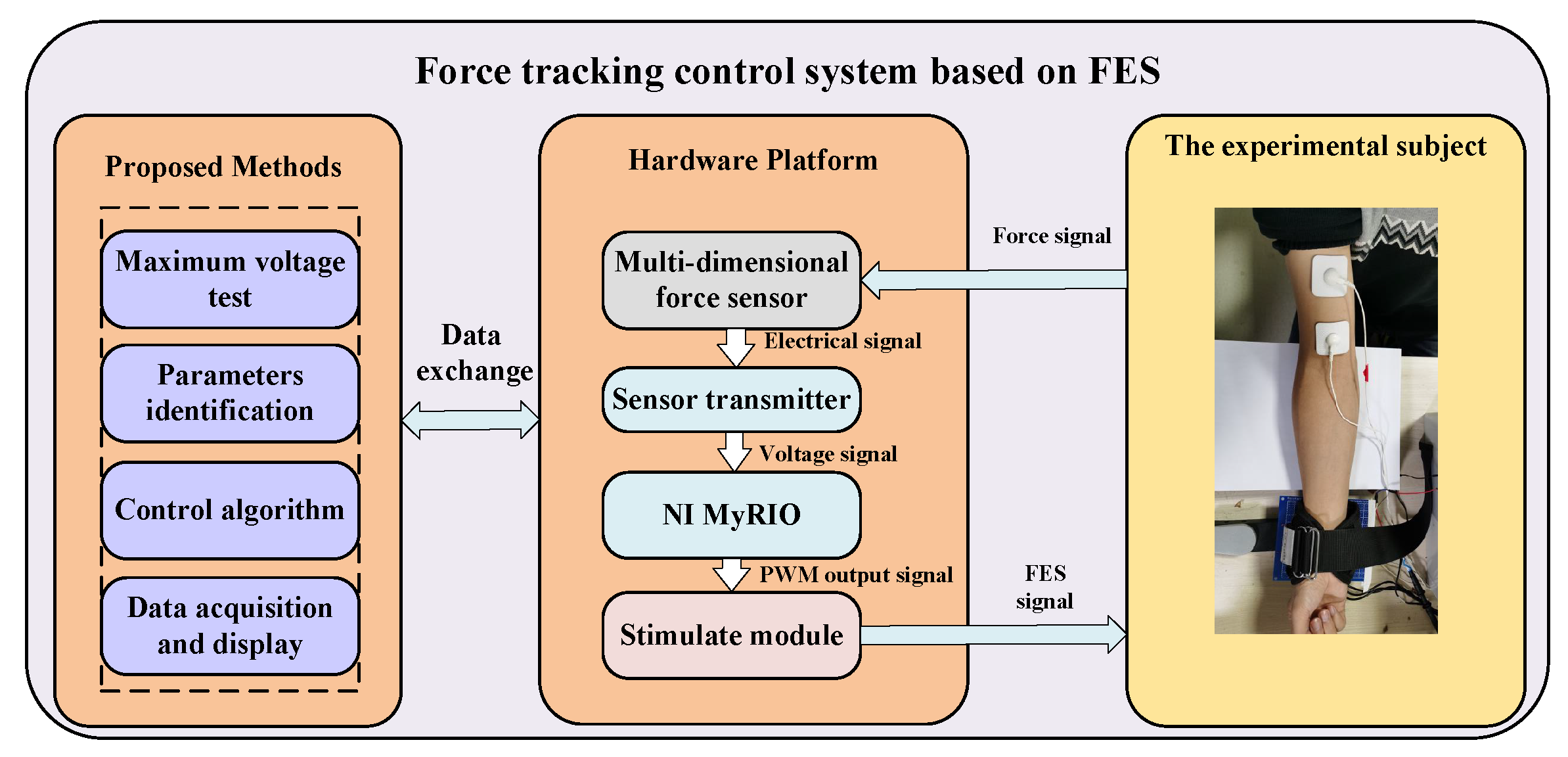

2. System Overview

2.1. Experimental Setup

2.2. Modified Hammerstein Model and Parameter Identification

2.2.1. Modified Hammerstein Model

2.2.2. Model Parameter Identification Methods

2.3. FES Controller Architecture

2.3.1. Traditional ADRC Method

2.3.2. Hybrid ADRC Controller Design for Modified Hammerstein Model

3. Experiments and Results

3.1. Model Parameters Identification

3.2. ADRC Tuning and Simulations

3.3. Experiments Result

3.3.1. Force Tracking Control for Different Reference

3.3.2. Force Tracking Control for Different Participants

3.3.3. Comparison with PID Controller

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barrreca, S.; Wolf, S.L.; Fasoli, S.; Bohannon, R. Treatment interventions for the paretic upper limb of stroke survivors: A critical review. Neurorehabilit. Neural Repair 2003, 17, 220–226. [Google Scholar] [CrossRef]

- Wu, S.; Wu, B.; Liu, M. Stroke in China: Advances and challenges in epidemiology, prevention, and management. Lancet Neurol. 2019, 18, 394–405. [Google Scholar] [CrossRef]

- Chang, K.V.; Wu, W.T.; Huang, K.C.; Han, D.S. Segmental body composition transitions in stroke patients: Trunks are different from extremities and strokes are as important as hemiparesis. Clin. Nutr. 2020, 39, 1968–1973. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zeng, J.; Li, K.; Fang, Y.; Liu, H. Voluntary and FES-Induced Finger Movement Estimation Using Muscle Deformation Features. IEEE Trans. Ind. Electron. 2020, 67, 4002–4012. [Google Scholar] [CrossRef]

- Rushton, D. Functional electrical stimulation and rehabilitation—An hypothesis. Med. Eng. Phys. 2003, 25, 75–78. [Google Scholar] [CrossRef]

- Wolf, D.; Schearer, E. Evaluating an open-loop functional electrical stimulation controller for holding the shoulder and elbow configuration of a paralyzed arm. In Proceedings of the International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 789–794. [Google Scholar]

- Jagodnik, K.; Thomas, P.; Bogert, A.; Branicky, M.; Kirsch, R. Training an actor-critic reinforcement learning controller for arm movement using human-generated rewards. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 1892–1905. [Google Scholar] [CrossRef]

- Sampson, P.; Freeman, C.; Coote, S.; Demain, S.; Feys, P.; Meadmore, K.; Hughes, A. Using functional electrical stimulation mediated by iterative learning control and robotics to improve arm movement for people with multiple sclerosis. IEEE Trans. Neural Syst. Rehabil. Eng. 2016, 24, 235–248. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Zheng, M.; Li, Y.; Wang, X.; Li, L.; Song, R. Iterative Adjustment of Stimulation Timing and Intensity During FES-Assisted Treadmill Walking for Patients After Stroke. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1292–1298. [Google Scholar] [CrossRef]

- Bellman, M.J.; Downey, R.J.; Parikh, A.; Dixon, W.E. Automatic Control of Cycling Induced by Functional Electrical Stimulation With Electric Motor Assistance. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1225–1234. [Google Scholar] [CrossRef]

- Veldema, J.; Jansen, P. Ergometer Training in Stroke Rehabilitation: Systematic Review and Meta-analysis. Arch. Phys. Med. Rehabil. 2020, 101, 674–689. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, T.A. Musculoskeletal Models of Tremor; Springer: New York, NY, USA, 2013; pp. 79–107. [Google Scholar]

- Miller, R.H. Hill-Based Muscle Modeling. In Handbook of Human Motion; Springer: Berlin, Germany, 2018; pp. 373–394. [Google Scholar]

- Carriou, V.; Boudaoud, S.; Laforet, J.; Mendes, A.; Canon, F.; Guiraud, D. Multiscale Hill-type modeling of the mechanical muscle behavior driven by the neural drive in isometric conditions. Comput. Biol. Med. 2019, 115, 14. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Gregory, C.M.; Johnson, M.; Dixon, W.E. Closed-Loop Neural Network-Based NMES Control for Human Limb Tracking. IEEE Trans. Control. Syst. Technol. 2012, 20, 712–725. [Google Scholar] [CrossRef] [Green Version]

- Brend, O.; Freeman, C.; French, M. Multiple-Model Adaptive Control of Functional Electrical Stimulation. IEEE Trans. Control. Syst. Technol. 2015, 23, 1901–1913. [Google Scholar] [CrossRef] [Green Version]

- Sun, L.X.; Sun, Y.F.; Huang, Z.P.; Hou, J.T.; Wu, J.K. Improved Hill-type musculotendon models with activation-force-length coupling. Technol. Health Care 2018, 26, 909–920. [Google Scholar] [CrossRef]

- Hu, H.; Peng, R.; Tai, Y.W.; Tang, C.K. Network trimming: A data-driven neuron pruning approach towards efficient deep architectures. arXiv 2016, arXiv:1607.03250. [Google Scholar]

- Jalaleddini, K.; Kearney, R.E. Subspace Identification of SISO Hammerstein Systems: Application to Stretch Reflex Identification. IEEE Trans. Biomed. Eng. 2013, 60, 2725–2734. [Google Scholar] [CrossRef]

- Copur, E.; Freeman, C.; Chu, B.; Laila, D. System identification for FES-based tremor suppression. Eur. J. Control 2016, 27, 45–59. [Google Scholar] [CrossRef]

- Allen, B.C.; Stubbs, K.J.; Dixon, W.E. Characterization of the Time-Varying Nature of Electromechanical Delay During FES-Cycling. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 2236–2245. [Google Scholar] [CrossRef]

- Downey, R.J.; Merad, M.; Gonzalez, E.J.; Dixon, W.E. The Time-Varying Nature of Electromechanical Delay and Muscle Control Effectiveness in Response to Stimulation-Induced Fatigue. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 1397–1408. [Google Scholar] [CrossRef]

- Paz, P.; Oliveira, T.R.; Pino, A.V.; Fontana, A.P. Model-Free Neuromuscular Electrical Stimulation by Stochastic Extremum Seeking. IEEE Trans. Control. Syst. Technol. 2020, 28, 238–253. [Google Scholar] [CrossRef]

- Rouhani, E.; Erfanian, A. A Finite-time Adaptive Fuzzy Terminal Sliding Mode Control for Uncertain Nonlinear Systems. Int. J. Control. Autom. Syst. 2018, 16, 1938–1950. [Google Scholar] [CrossRef]

- Li, Y.R.; Chen, W.X.; Chen, J.; Chen, X.; Liang, J.; Du, M. Neural network based modeling and control of elbow joint motion under functional electrical stimulation. Neurocomputing 2019, 340, 171–179. [Google Scholar] [CrossRef]

- Huo, B.; Freeman, C.T.; Liu, Y. Data-driven gradient-based point-to-point iterative learning control for nonlinear systems. Nonlinear Dyn. 2020, 102, 269–283. [Google Scholar] [CrossRef]

- Alibeji, N.; Kirsch, N.; Farrokhi, S.; Sharma, N. Further results on predictor-based control of neuromuscular electrical stimulation. IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 1095–1105. [Google Scholar] [CrossRef] [PubMed]

- Obuz, S.; Duenas, V.H.; Downey, R.J.; Klotz, J.R.; Dixon, W.E. Closed-Loop Neuromuscular Electrical Stimulation Method Provides Robustness to Unknown Time-Varying Input Delay in Muscle Dynamics. IEEE Trans. Control. Syst. Technol. 2020, 28, 2482–2489. [Google Scholar] [CrossRef]

- Roux-Oliveira, T.; Costa, L.R.; Pino, A.V.; Paz, P. Extremum Seeking-based Adaptive PID Control applied to Neuromuscular Electrical Stimulation. An. Acad. Bras. Cienc. 2019, 91, 20. [Google Scholar] [CrossRef]

- Freeman, C. Robust ILC design with application to stroke rehabilitation. Automatica 2017, 81, 270–278. [Google Scholar] [CrossRef]

- Teodoro, R.G.; Nunes, W.R.B.M.; de Araujo, R.A.; Sanches, M.A.A.; Teixeira, M.C.M.; de Carvalho, A.A. Robust switched control design for electrically stimulated lower limbs: A linear model analysis in healthy and spinal cord injured subjects. Control Eng. Pract. 2020, 102, 104530. [Google Scholar] [CrossRef]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Jin, H.; Song, J.; Lan, W.; Gao, Z. On the characteristics of ADRC: A PID interpretation. Sci. China Inf. Sci 2019, 63, 209201. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Guo, B.Z. On active disturbance rejection control for nonlinear systems using time-varying gain. Eur. J. Control 2015, 23, 62–70. [Google Scholar] [CrossRef]

- Huang, Y.; Xue, W. Active disturbance rejection control: Methodology and theoretical analysis. ISA Trans. 2014, 53, 963–976. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Li, D.; Xue, Y.; Chen, Y. Gain scheduling design based on active disturbance rejection control for thermal power plant under full operating conditions. Energy 2019, 185, 744–762. [Google Scholar] [CrossRef]

- Wu, Z.; Li, D.; Chen, Y. Active Disturbance Rejection Control Design Based on Probabilistic Robustness for Uncertain Systems. Ind. Eng. Chem. Res. 2020, 59, 18070–18087. [Google Scholar] [CrossRef]

- Wang, J.; He, L.; Sun, M. Application of active disturbance rejection control to integrated flight-propulsion control. In Proceedings of the Chinese Control and Decision Conference, Xuzhou, China, 26–28 May 2010; pp. 2565–2569. [Google Scholar]

- Xia, Y.; Shi, P.; Liu, G.P.; Rees, D.; Han, J. Active disturbance rejection control for uncertain multivariable systems with time-delay. IET Control. Theory Appl. 2007, 1, 75–81. [Google Scholar] [CrossRef]

- Zheng, Q.; Gao, Z. Predictive active disturbance rejection control for processes with time delay. ISA Trans. 2014, 53, 873–881. [Google Scholar] [CrossRef]

- Wang, L.; Tong, C.; Li, Q.; Yin, Z.; Gao, Z. A practical decoupling control solution for hot strip width and gauge regulation based on active disturbance rejection. Control Theory Appl. 2012, 29, 1471–1478. [Google Scholar]

- Goforth, F.J.; Gao, Z. An active disturbance rejection control solution for hysteresis compensation. In Proceedings of the 2008 American Control Conference, Seattle, WA, USA, 11–13 June 2008; pp. 2202–2208. [Google Scholar]

| Fitetype | R–Square | Adj R–sq | RMSE |

|---|---|---|---|

| poly 1 | 0.874 | 0.873 | 3.444 |

| poly 2 | 0.942 | 0.942 | 2.332 |

| poly 3 | 0.954 | 0.954 | 2.073 |

| poly 4 | 0.963 | 0.963 | 1.851 |

| poly 5 | 0.963 | 0.963 | 1.852 |

| Maximum | Mean | Mode | Standard | |

|---|---|---|---|---|

| Value | Value | Number | Deviation | |

| Participant 1 | 1.123 | 0.443 | 0.659 | 0.330 |

| Participant 2 | 0.859 | 0.150 | 0.017 | 0.139 |

| Participant 3 | 0.995 | 0.418 | 0.068 | 0.237 |

| Participant 4 | 0.989 | 0.243 | 0.293 | 0.197 |

| Participant 5 | 0.627 | 0.175 | 0.225 | 0.113 |

| Participant 6 | 1.053 | 0.322 | 0.266 | 0.208 |

| Maximum | Mean | Mode | Standard | |

|---|---|---|---|---|

| Value | Value | Number | Deviation | |

| Participant 1 | 3.839 | 1.180 | 0.159 | 0.812 |

| Participant 2 | 2.676 | 1.113 | 0.190 | 0.720 |

| Participant 3 | 4.551 | 1.171 | 0.059 | 0.910 |

| Participant 4 | 2.490 | 0.957 | 0.521 | 0.577 |

| Participant 5 | 2.455 | 1.101 | 0.137 | 0.676 |

| Participant 6 | 2.636 | 1.422 | 0.050 | 0.838 |

| Type | Maximum | Mean | Mode | Standard |

|---|---|---|---|---|

| Value | Value | Number | Deviation | |

| PID | 3.057 | 0.767 | 0.064 | 0.704 |

| Hybrid ADRC | 0.859 | 0.150 | 0.017 | 0.139 |

| Type | Maximum | Mean | Mode | Standard |

|---|---|---|---|---|

| Value | Value | Number | Deviation | |

| PID | 4.55 | 1.706 | 0.654 | 1.27 |

| Hybrid ADRC | 2.490 | 0.957 | 0.529 | 0.577 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, B.; Wang, R.; Qin, Y.; Wu, Z.; Bian, G.; Liu, Y. Force Tracking Control of Functional Electrical Stimulation via Hybrid Active Disturbance Rejection Control. Electronics 2022, 11, 1727. https://doi.org/10.3390/electronics11111727

Huo B, Wang R, Qin Y, Wu Z, Bian G, Liu Y. Force Tracking Control of Functional Electrical Stimulation via Hybrid Active Disturbance Rejection Control. Electronics. 2022; 11(11):1727. https://doi.org/10.3390/electronics11111727

Chicago/Turabian StyleHuo, Benyan, Ruishun Wang, Yunhui Qin, Zhenlong Wu, Guibin Bian, and Yanhong Liu. 2022. "Force Tracking Control of Functional Electrical Stimulation via Hybrid Active Disturbance Rejection Control" Electronics 11, no. 11: 1727. https://doi.org/10.3390/electronics11111727

APA StyleHuo, B., Wang, R., Qin, Y., Wu, Z., Bian, G., & Liu, Y. (2022). Force Tracking Control of Functional Electrical Stimulation via Hybrid Active Disturbance Rejection Control. Electronics, 11(11), 1727. https://doi.org/10.3390/electronics11111727