Validation of a Platform for the Electrostatic Characterization of Textile

Abstract

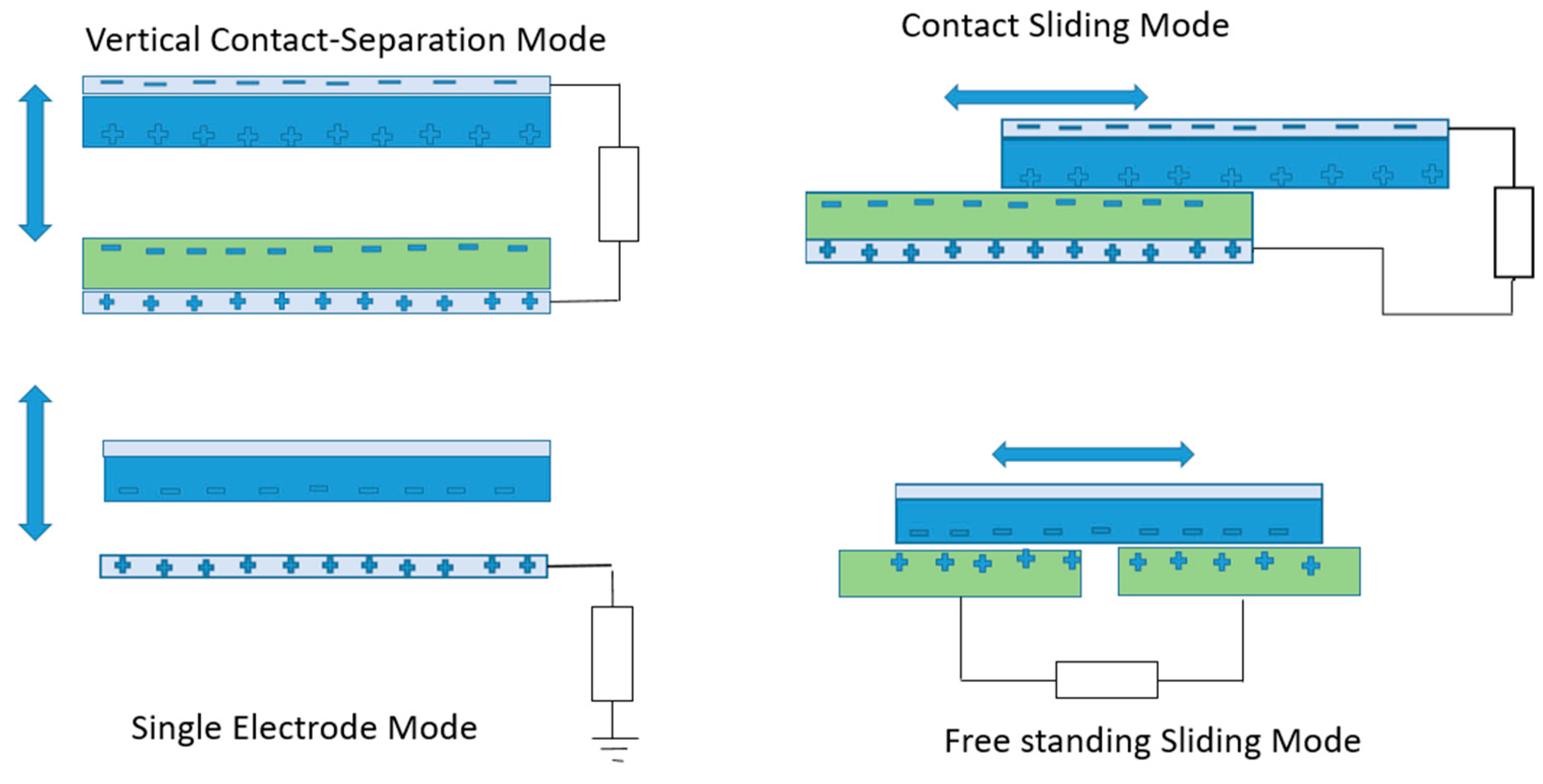

:1. Introduction

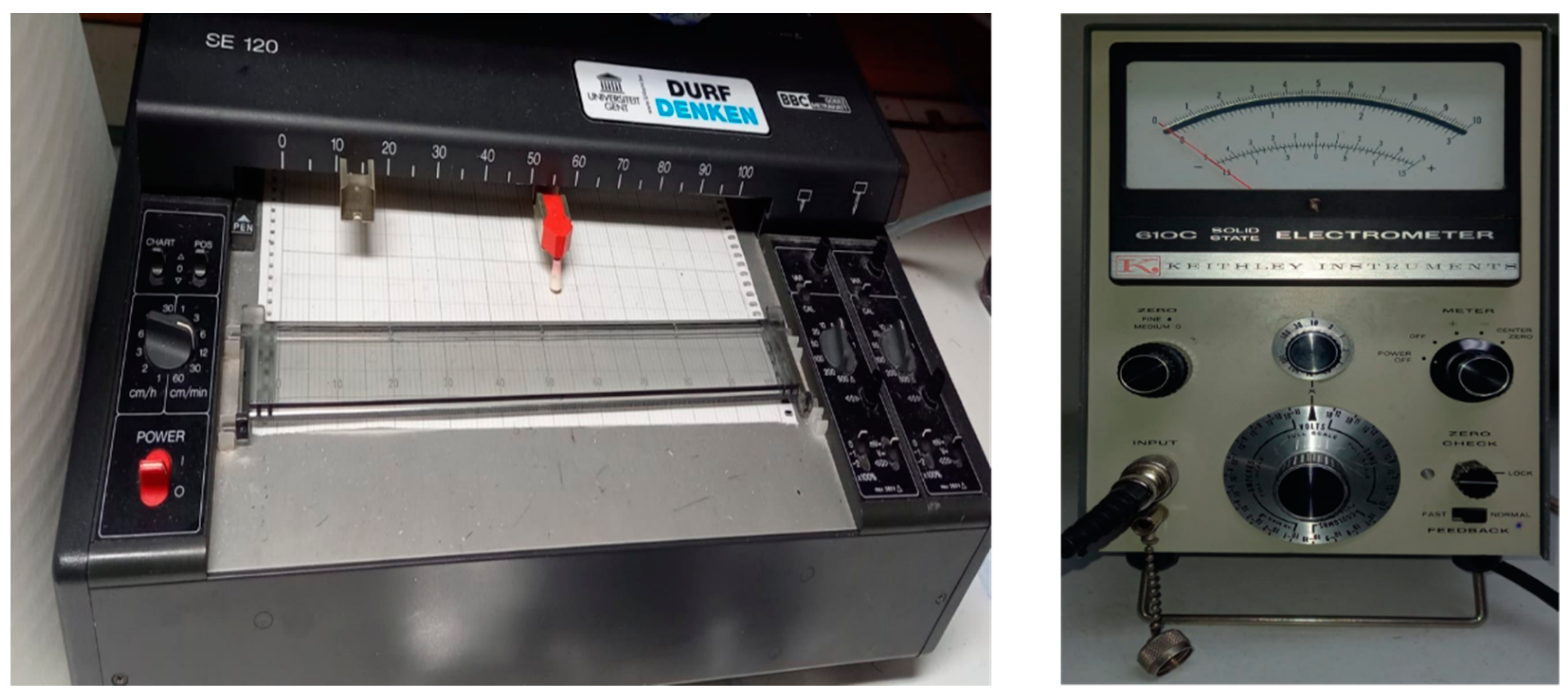

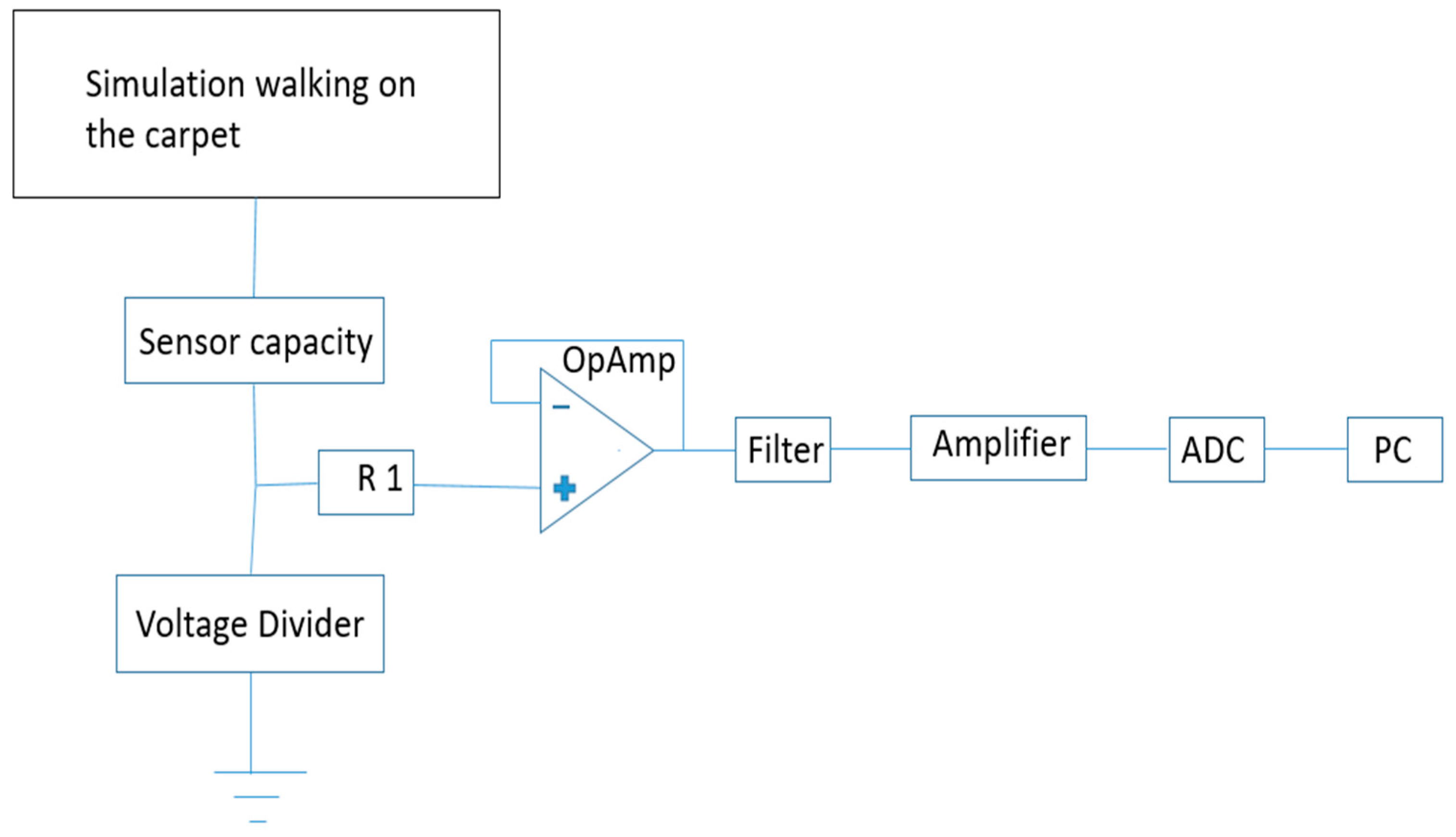

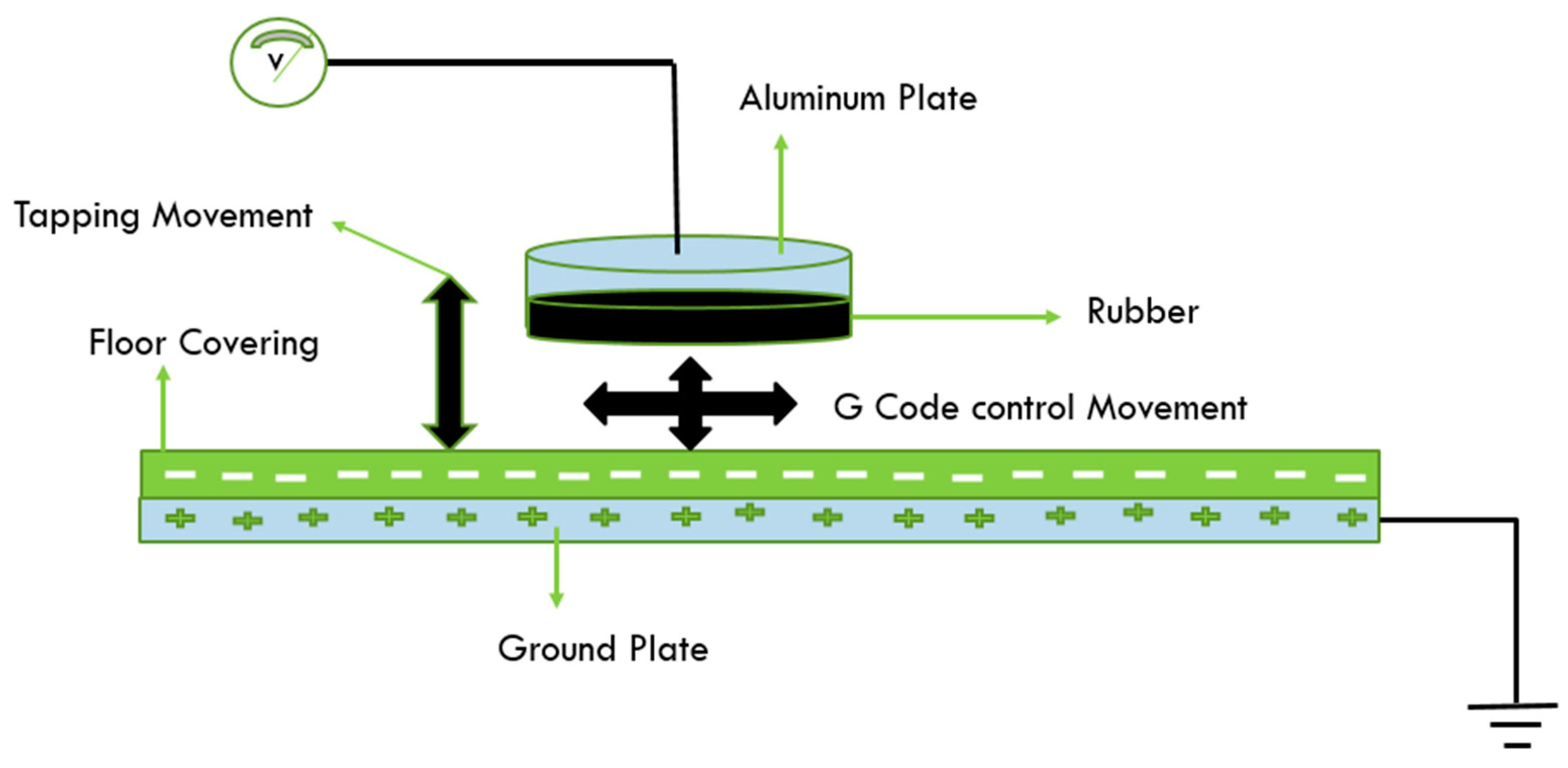

2. Materials and Methods

- Test Sandals BAM

- Ethanol (95% conc.) to clean the soles

- Humidity and Temperature sensor to record the environment

- Sample cutting scissor

- Scoured cotton (free of finish or detergent) for cleaning of sole

- Sandpaper (P280 to P360) to clean sandal

- Ionizing Gun to discharge the floorcoverings

2.1. Method

2.2. Statitical Analysis

2.3. Effective Graphical Display of Data

3. Results and Discussion

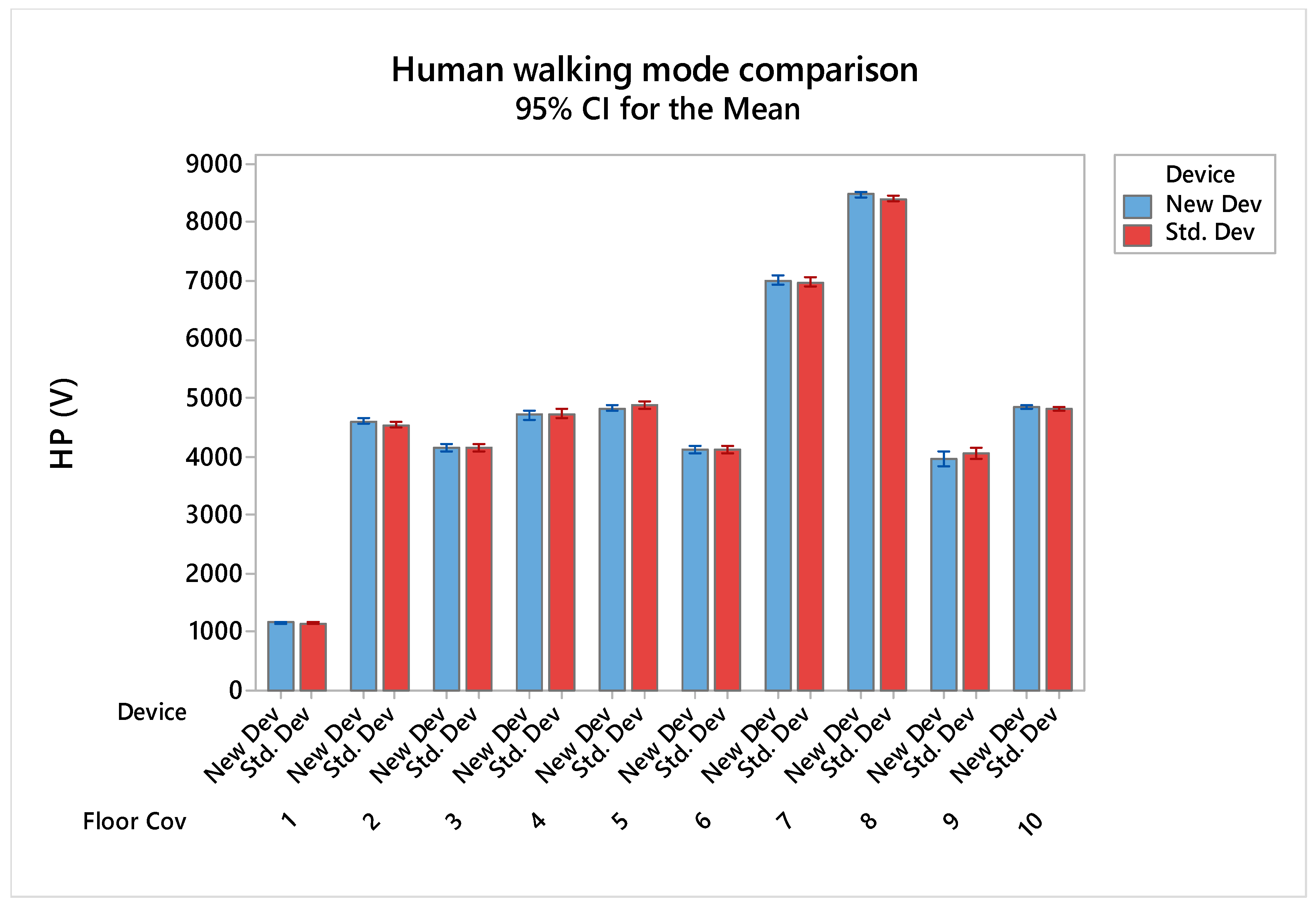

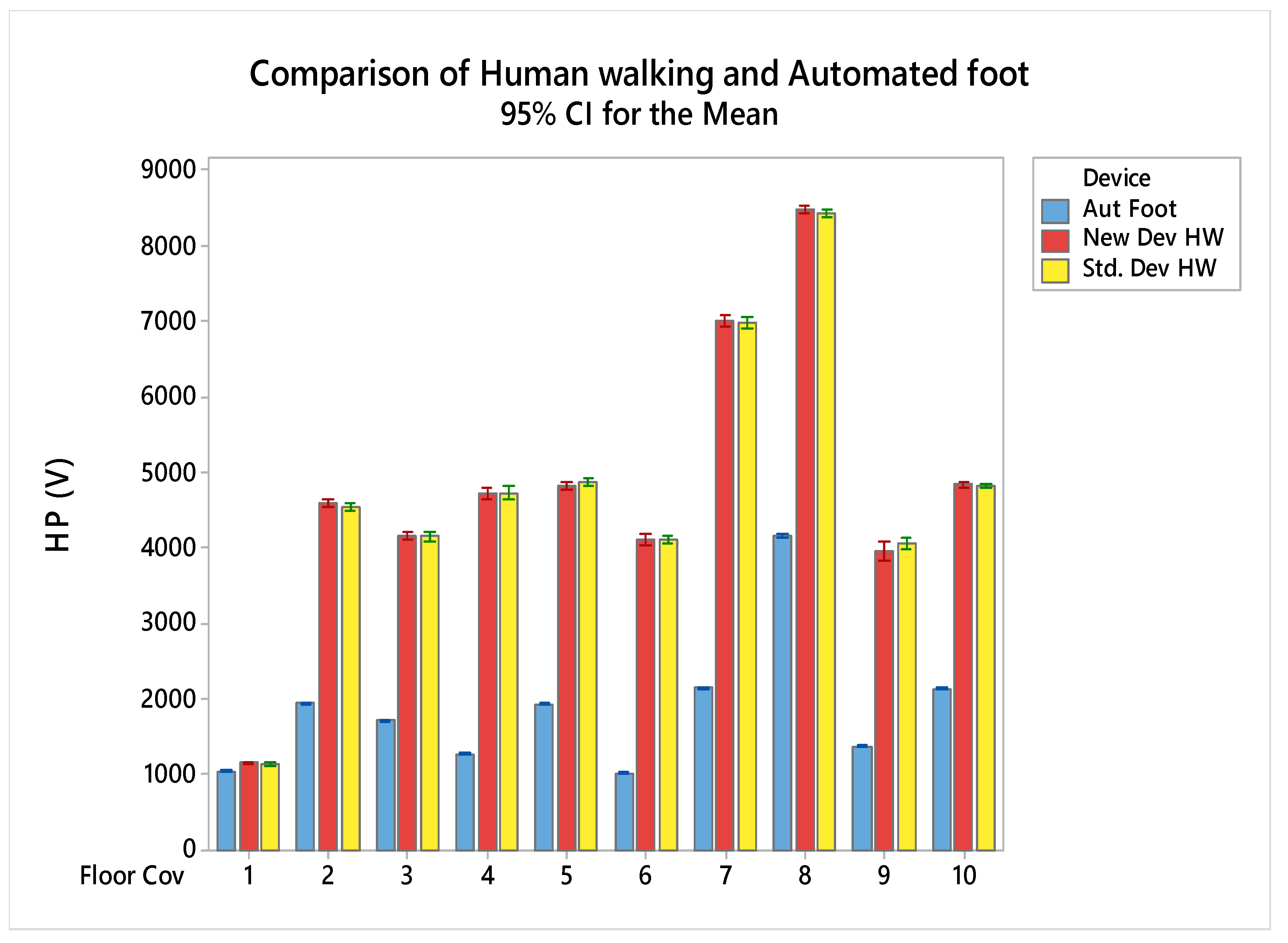

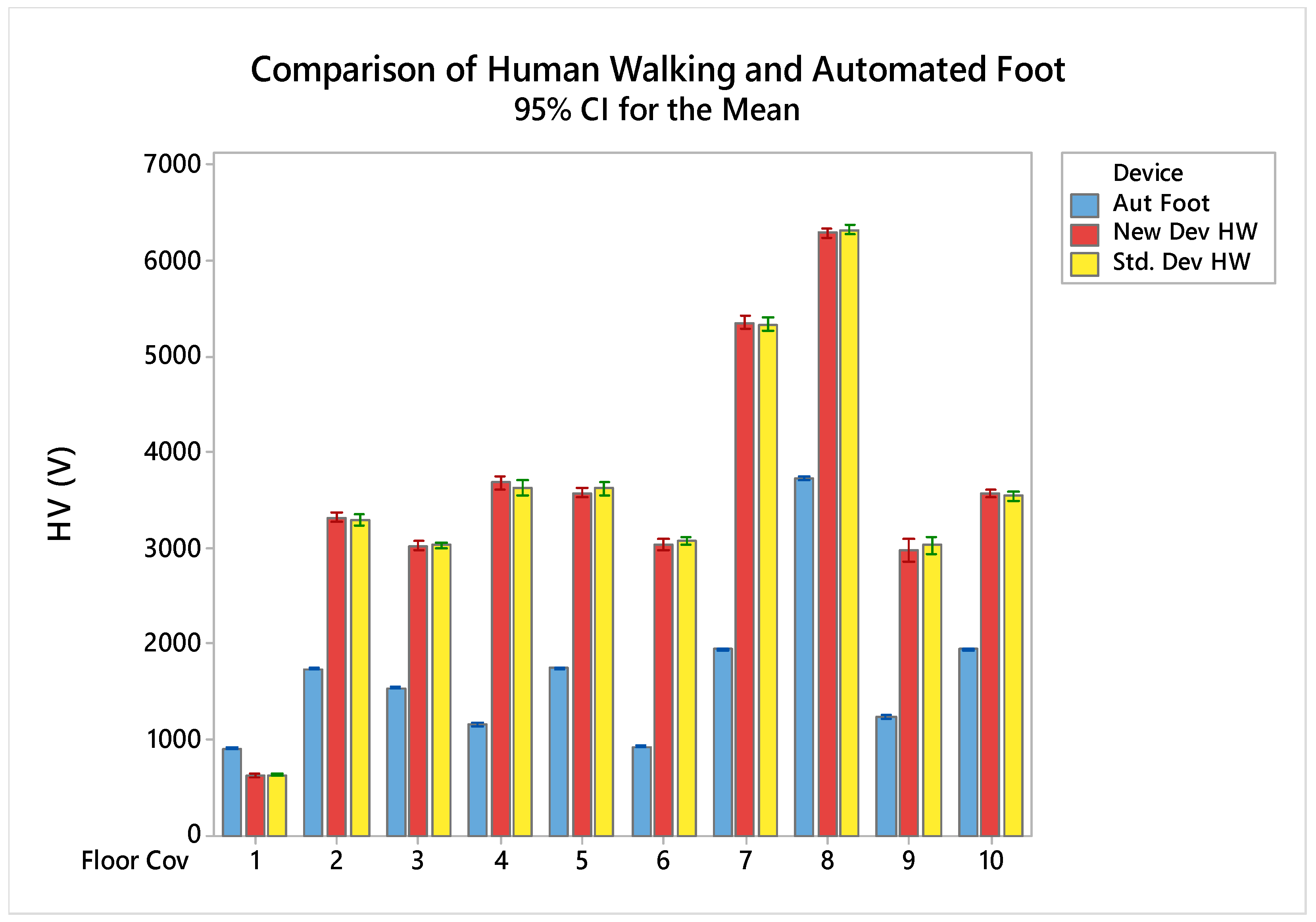

3.1. Validation of Human Walking Mode of New Device

3.2. Automated Foot for the Charecterization of Floorcoverings

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, M.; Liao, L.; Xiao, W.; Yu, X.; Wang, H.; Wang, Q.; Lin, Y.L.; Kilinc-Balci, F.S.; Price, A.; Chu, L.; et al. Household materials selection for homemade cloth face coverings and their filtration efficiency enhancement with triboelectric charging. Nano Lett. 2020, 20, 5544–5552. [Google Scholar] [CrossRef] [PubMed]

- Smallwood, J. Advances in Carpet Manufacture; Electrostatic Solutions Ltd.: Southampton, UK, 2017; p. 135. Available online: http://reessanj.ir/book/Advances%20in%20carpet%20manufactures.pdf (accessed on 7 December 2021).

- Lüttgens, G.; Lüttgens, S.; Schubert, W. Static Electricity: Understanding, Controlling, Applying; John Wiley & Sons.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Smallwood, J. Reducing static electricity in carpets. In Advances in Carpet Manufacture; Elsevier: Amsterdam, The Netherlands, 2018; pp. 135–162. [Google Scholar]

- Ebadat, V. Flash Fire and Explosions Caused by Electrostatic Discharges: Analysis, Prevention and Control. In ASSE Professional Development Conference and Exposition; American Society of Safety Engineers: Des Plaines, IL, USA, 2017; Available online: https://onepetro.org/ASSPPDCE/proceedings-abstract/ASSE17/All-ASSE17/ASSE-17-655/77359 (accessed on 7 December 2021).

- Textile Floor Coverings—Assessment of Static Electrical Propensity—Walking Test, ISO/TC 219 Floor Coverings: 2000. p. 14. Available online: https://www.amazon.com/ISO-6356-Assessment-electrical-propensity/dp/B000XYSTWY (accessed on 7 December 2021).

- Wang, Z.L. From Contact-Electrification to Triboelectric Nanogenerators. Rep. Prog. Phys. 2021, 84, 9. [Google Scholar] [CrossRef] [PubMed]

- Bauch, H.; Emmler, R.; Kleber, D. Improved test methodology regarding the electrostatic properties of laminate floor coverings. Holztechnologie 2008, 49, 46–48. [Google Scholar]

- Liu, S.; Zheng, W.; Yang, B.; Tao, X. Triboelectric charge density of porous and deformable fabrics made from polymer fibers. Nano Energy 2018, 53, 383–390. [Google Scholar] [CrossRef]

- Kleber, D. Electrostatic behaviour of wood and laminate floor coverings and current situation in standardisation. J. Electrost. 2017, 88, 218–224. [Google Scholar] [CrossRef]

- Hilkersberger, M.; Gärtner, R.; Stadler, W.; Niemesheim, J.; Speicher, J. Measuring the Body Voltage While Performing the Walking Test. In Proceedings of the 2020 42nd Annual EOS/ESD Symposium (EOS/ESD), Reno, NV, USA, 13–18 September 2020. [Google Scholar]

- Nowikow, W. The electrostatic behaviour of carpets. J. Electrost. 1982, 13, 249–256. [Google Scholar] [CrossRef]

- Jokelainen, A.; Uusi-Rauva, A. Soil binding in the ground texture and pile of textile floorcoverings after cleaning. Melliand Text. 1979, 60, 394–398. [Google Scholar]

- Von Pidoll, U. An overview of standards concerning unwanted electrostatic discharges. J. Electrost. 2009, 67, 445–452. [Google Scholar] [CrossRef]

- Choi, Y.S.; Kim, S.W.; Kar-Narayan, S. Materials-Related Strategies for Highly Efficient Triboelectric Energy Generators. Adv. Energy Mater. 2021, 11, 2003802. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Xie, Y.; Jing, Q.; Niu, S.; Wang, Z.L. Sliding-triboelectric nanogenerators based on in-plane charge-separation mechanism. Nano Lett. 2013, 13, 2226–2233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niu, S.; Liu, Y.; Wang, S.; Lin, L.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical investigation and structural optimization of single-electrode triboelectric nanogenerators. Adv. Funct. Mater. 2014, 24, 3332–3340. [Google Scholar] [CrossRef]

- Niu, S.; Liu, Y.; Chen, X.; Wang, S.; Zhou, Y.S.; Lin, L.; Xie, Y.; Wang, Z.L. Theory of freestanding triboelectric-layer-based nanogenerators. Nano Energy 2015, 12, 760–774. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Mahmoud, M.; Ibrahim, A. Friction coefficient and triboelectrification of textiles. Surfaces 2016, 3, 1–7. [Google Scholar]

- Liu, L. Electrostatic Generation and Control on Textiles; North Carolina State University, ProQuest Dissertations Publishing: Ann Arbor, MI, USA, 2010. [Google Scholar]

| Sample No. | Area Density (GSM) [g/m2] | Surface Structure | Thickness [mm] | Pile Thickness [mm] | Primary Backing | Secondary Backing |

|---|---|---|---|---|---|---|

| FC-1 | 2339 | Cut Pile | 8.68 | 6.08 | Woven Fabric | PES-Feltback |

| FC-2 | 2583 | Cut Pile | 10.23 | 8.08 | Woven Fabric | |

| FC-3 | 2040 | Cut Pile | 10.17 | 8.19 | Woven Fabric | |

| FC-4 | 2462 | Loop Pile | 9.54 | 5.20 | Non-Woven | PES-Feltback |

| FC-5 | 2651 | Cut Pile | 10.19 | 7.03 | Woven Fabric | |

| FC-6 | 2195 | Cut Pile | 7.68 | 5.41 | Woven Fabric | |

| FC-7 | 1743 | Loop Pile | 8.83 | 6.51 | Woven Fabric | |

| FC-8 | 1862 | Cut Pile | 7.86 | 5.75 | Woven Fabric | |

| FC-9 | 2735 | Cut Pile | 11.04 | 8.53 | Woven Fabric | PES-Feltback |

| FC-10 | 2077 | Cut Pile | 9.60 | 7.20 | Woven Fabric | PES-Feltback |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 1.6549 × 109 a | 19 | 8.7098 × 107 | 3499 | 0.000 |

| Intercept | 1.1473 × 1010 | 1 | 1.1473 × 1010 | 4.609 × 105 | 0.000 |

| Floor. Cov | 1.6546 × 109 | 9 | 1.8384 × 108 | 7386 | 0.000 |

| Device | 2040 | 1 | 2040 | 0.082 | 0.775 |

| Floor. Cov * Device | 2.581 × 105 | 9 | 2.868 × 104 | 1.152 | 0.324 |

| Error | 1.1948 × 107 | 480 | 2.489 × 104 | ||

| Total | 1.314 × 1010 | 500 | |||

| Corrected Total | 1.667 × 109 | 499 |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 1.0109 × 109 a | 19 | 5.320 × 107 | 2441 | 0.000 |

| Intercept | 6.311 × 109 | 1 | 6.311 × 109 | 2.896 × 105 | 0.000 |

| Floor. Cov | 1.011 × 109 | 9 | 1.123 × 108 | 5154 | 0.000 |

| Device | 3553 | 1 | 3553 | 0.163 | 0.687 |

| Floor. Cov * Device | 1.282 × 105 | 9 | 1.424 × 104 | 0.654 | 0.751 |

| Error | 1.046 × 107 | 480 | 2.179 × 104 | ||

| Total | 7.332 × 107 | 500 | |||

| Corrected Total | 1.0214 × 109 | 499 |

| F. Cov | Device | Count | Mean | SE Mean | St. Dev | CV% | IQR | TR Mean | Min | Max | Range |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Auto | 25 | 1047 | 5.2 | 26.1 | 2.5 | 35 | 1046 | 1016 | 1104 | 88 |

| New | 25 | 1158 | 7.146 | 35.729 | 3.1 | 58 | 1157 | 1107 | 1238 | 131 | |

| Old. | 25 | 1148 | 9.928 | 49.641 | 4.3 | 75 | 1147 | 1062 | 1250 | 188 | |

| 2 | Auto Foot | 25 | 1951 | 3.819 | 19.093 | 1.0 | 28 | 1951 | 1915 | 1980 | 65 |

| New | 25 | 4606 | 23.736 | 118.679 | 2.6 | 129 | 4603 | 4456 | 4846 | 390 | |

| Std. | 25 | 4552 | 25.403 | 127.017 | 2.8 | 200 | 4548 | 4380 | 4820 | 440 | |

| 3 | Auto Foot | 25 | 1722 | 7.393 | 36.965 | 2.1 | 63 | 1721 | 1657 | 1794 | 137 |

| New | 25 | 4157 | 25.656 | 128.280 | 3.1 | 194 | 4156 | 3938 | 4399 | 461 | |

| Std. | 25 | 4155 | 27.792 | 138.958 | 3.3 | 220 | 4152 | 3960 | 4420 | 460 | |

| 4 | Auto Foot | 25 | 1272 | 5.595 | 27.973 | 2.2 | 39 | 1271 | 1230 | 1329 | 99 |

| New | 25 | 4727 | 38.723 | 193.617 | 4.1 | 309 | 4727 | 4400 | 5047 | 647 | |

| Std. | 25 | 4733 | 40.396 | 201.980 | 4.3 | 210 | 4725 | 4380 | 5260 | 880 | |

| 5 | Auto Foot | 25 | 1933 | 6.093 | 30.465 | 1.6 | 45 | 1934 | 1872 | 1987 | 115 |

| New | 25 | 4829 | 24.966 | 124.832 | 2.6 | 225 | 4824 | 4694 | 5076 | 382 | |

| Std. | 25 | 4879 | 27.288 | 136.440 | 2.8 | 250 | 4881 | 4640 | 5080 | 440 | |

| 6 | Auto Foot | 25 | 1027 | 6.252 | 31.258 | 3.0 | 52 | 1026 | 978 | 1085 | 107 |

| New | 25 | 4120 | 33.855 | 169.273 | 4.1 | 265 | 4115 | 3914 | 4459 | 545 | |

| Std. | 25 | 4117 | 29.770 | 148.849 | 3.6 | 240 | 4113 | 3920 | 4400 | 480 | |

| 7 | Auto Foot | 25 | 2150 | 9.146 | 45.731 | 2.1 | 65 | 2151 | 2054 | 2230 | 176 |

| New | 25 | 7021 | 38.494 | 192.472 | 2.7 | 394 | 7022 | 6740 | 7260 | 520 | |

| Std. | 25 | 6987 | 39.684 | 198.421 | 2.8 | 410 | 6986 | 6700 | 7300 | 600 | |

| 8 | Auto Foot | 25 | 4165 | 10.145 | 50.725 | 1.2 | 72 | 4165 | 4065 | 4273 | 208 |

| New | 25 | 8493 | 23.992 | 119.961 | 1.4 | 156 | 8496 | 8234 | 8685 | 451 | |

| Std. | 25 | 8424 | 25.994 | 129.971 | 1.5 | 160 | 8430 | 8100 | 8620 | 520 | |

| 9 | Auto Foot | 25 | 1377 | 8.382 | 41.909 | 3.0 | 42 | 1375 | 1324 | 1489 | 165 |

| New | 25 | 3969 | 64.246 | 321.231 | 8.1 | 585 | 3966 | 3460 | 4548 | 1088 | |

| Std. | 25 | 4064 | 40.678 | 203.388 | 5.0 | 240 | 4071 | 3560 | 4400 | 840 | |

| 10 | Auto Foot | 25 | 2141 | 6.021 | 30.106 | 1.4 | 38 | 2142 | 2074 | 2189 | 115 |

| New | 25 | 4843 | 15.643 | 78.214 | 1.6 | 112 | 4839 | 4729 | 5029 | 300 | |

| Std. | 25 | 4824 | 16.052 | 80.260 | 1.7 | 120 | 4820 | 4710 | 5020 | 310 |

| F. Cov | Device | Count | Mean | SE Mean | St. Dev | CV% | IQR | TR Mean | Min | Max | Range |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Auto Foot | 25 | 918 | 5.466 | 27.328 | 3.0 | 34 | 917 | 886 | 973 | 87 |

| New | 25 | 632 | 6.860 | 34.300 | 5.4 | 64 | 631 | 584 | 697 | 113 | |

| Std. | 25 | 640 | 5.205 | 26.026 | 4.1 | 31 | 640 | 587.5 | 687.5 | 100 | |

| 2 | Auto Foot | 25 | 1743 | 3.373 | 16.863 | 1.0 | 22 | 1743 | 1714 | 1774 | 60 |

| New | 25 | 3324 | 26.636 | 133.180 | 4.0 | 130 | 3316 | 3196 | 3628 | 432 | |

| Std. | 25 | 3298 | 26.405 | 132.024 | 4.0 | 75 | 3290 | 3186 | 3600 | 414 | |

| 3 | Auto Foot | 25 | 1548 | 6.621 | 33.103 | 2.1 | 61 | 1549 | 1481 | 1601 | 120 |

| New | 25 | 3023 | 24.305 | 121.524 | 4.0 | 220 | 3021 | 2843 | 3265 | 422 | |

| Std. | 25 | 3036 | 14.283 | 71.414 | 2.4 | 110 | 3037 | 2900 | 3160 | 260 | |

| 4 | Auto Foot | 25 | 1161 | 9.995 | 49.974 | 4.3 | 96 | 1161 | 1083 | 1243 | 160 |

| New | 25 | 3683 | 36.725 | 183.625 | 5.0 | 272 | 3680 | 3419 | 4014 | 595 | |

| Std. | 25 | 3630 | 38.125 | 190.624 | 5.3 | 290 | 3621 | 3400 | 4080 | 680 | |

| 5 | Auto Foot | 25 | 1755 | 4.807 | 24.034 | 1.4 | 37 | 1756 | 1698 | 1795 | 97 |

| New | 25 | 3583 | 24.339 | 121.694 | 3.4 | 190 | 3580 | 3420 | 3818 | 398 | |

| Std. | 25 | 3624 | 32.228 | 161.142 | 4.4 | 290 | 3619 | 3400 | 3960 | 560 | |

| 6 | Auto Foot | 25 | 930 | 5.225 | 26.126 | 2.8 | 36 | 930 | 885 | 984 | 99 |

| New | 25 | 3044 | 29.310 | 146.550 | 4.8 | 232 | 3039 | 2829 | 3369 | 540 | |

| Std. | 25 | 3078 | 21.270 | 106.352 | 3.5 | 170 | 3076 | 2900 | 3300 | 400 | |

| 7 | Auto Foot | 25 | 1948 | 7.260 | 36.299 | 1.9 | 50 | 1948 | 1869 | 2020 | 151 |

| New | 25 | 5354 | 34.790 | 173.952 | 3.2 | 345 | 5352 | 5082 | 5675 | 593 | |

| Std. | 25 | 5340 | 34.293 | 171.464 | 3.2 | 290 | 5341 | 5060 | 5600 | 540 | |

| 8 | Auto Foot | 25 | 3726 | 11.100 | 55.499 | 1.5 | 86 | 3725 | 3633 | 3840 | 207 |

| New | 25 | 6295 | 24.870 | 124.350 | 2.0 | 216 | 6296 | 6078 | 6491 | 413 | |

| Std. | 25 | 6327 | 23.622 | 118.110 | 1.9 | 155 | 6330 | 6092 | 6500 | 408 | |

| 9 | Auto Foot | 25 | 1247 | 7.540 | 37.699 | 3.0 | 35 | 1246 | 1193 | 1330 | 137 |

| New | 25 | 2988 | 56.052 | 280.261 | 9.4 | 585 | 2987 | 2612 | 3384 | 772 | |

| Std. | 25 | 3034 | 39.979 | 199.893 | 6.6 | 360 | 3038 | 2600 | 3360 | 760 | |

| 10 | Auto Foot | 25 | 1951 | 6.011 | 30.053 | 1.5 | 49 | 1952 | 1887 | 2001 | 114 |

| New | 25 | 3574 | 23.054 | 115.271 | 3.2 | 180 | 3567 | 3459 | 3835 | 376 | |

| Std. | 25 | 3546 | 24.041 | 120.205 | 3.4 | 189 | 3542 | 3400 | 3790 | 390 |

| Ranking | Old | New | AFM |

|---|---|---|---|

| 1 | F.Cov. 8 | F.Cov. 8 | F.Cov. 8 |

| 2 | F.Cov. 7 | F.Cov. 7 | F.Cov. 7 |

| 3 | F.Cov. 5 | F.Cov. 5 | F.Cov. 10 |

| 4 | F.Cov. 10 | F.Cov. 10 | F.Cov. 2 |

| 5 | F.Cov. 4 | F.Cov. 4 | F.Cov. 5 |

| 6 | F.Cov. 2 | F.Cov. 2 | F.Cov. 3 |

| 7 | F.Cov. 6 | F.Cov. 6 | F.Cov. 9 |

| 8 | F.Cov. 3 | F.Cov. 3 | F.Cov. 4 |

| 9 | F.Cov. 9 | F.Cov. 9 | F.Cov. 1 |

| 10 | F.Cov. 1 | F.Cov. 1 | F.Cov. 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahir, H.R.; Malengier, B.; Daele, D.V.; Langenhove, L.V. Validation of a Platform for the Electrostatic Characterization of Textile. Electronics 2022, 11, 115. https://doi.org/10.3390/electronics11010115

Tahir HR, Malengier B, Daele DV, Langenhove LV. Validation of a Platform for the Electrostatic Characterization of Textile. Electronics. 2022; 11(1):115. https://doi.org/10.3390/electronics11010115

Chicago/Turabian StyleTahir, Hasan Riaz, Benny Malengier, Didier Van Daele, and Lieva Van Langenhove. 2022. "Validation of a Platform for the Electrostatic Characterization of Textile" Electronics 11, no. 1: 115. https://doi.org/10.3390/electronics11010115

APA StyleTahir, H. R., Malengier, B., Daele, D. V., & Langenhove, L. V. (2022). Validation of a Platform for the Electrostatic Characterization of Textile. Electronics, 11(1), 115. https://doi.org/10.3390/electronics11010115