The Characteristics of Aluminum-Gallium-Zinc-Oxide Ultraviolet Phototransistors by Co-Sputtering Method

Abstract

1. Introduction

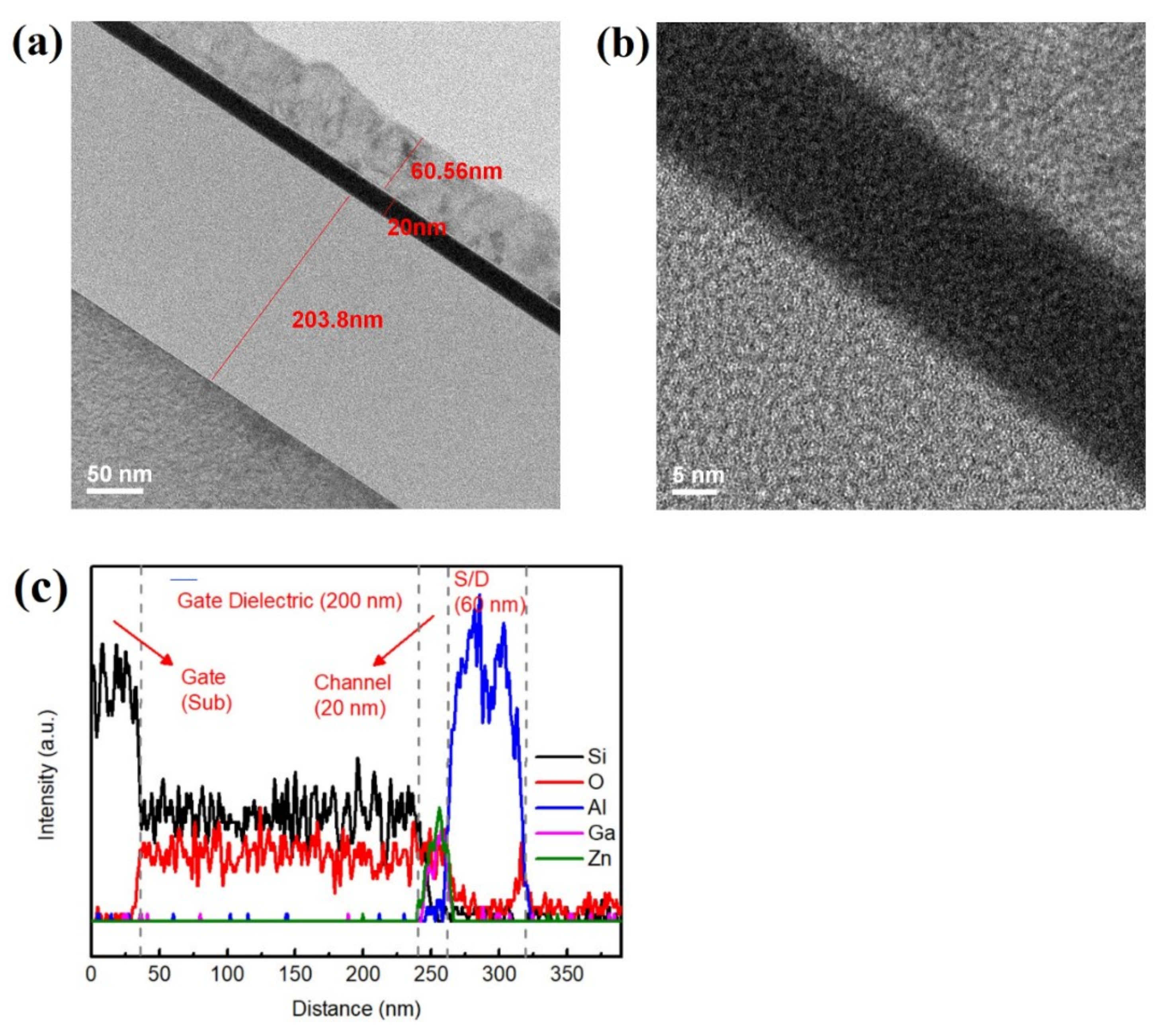

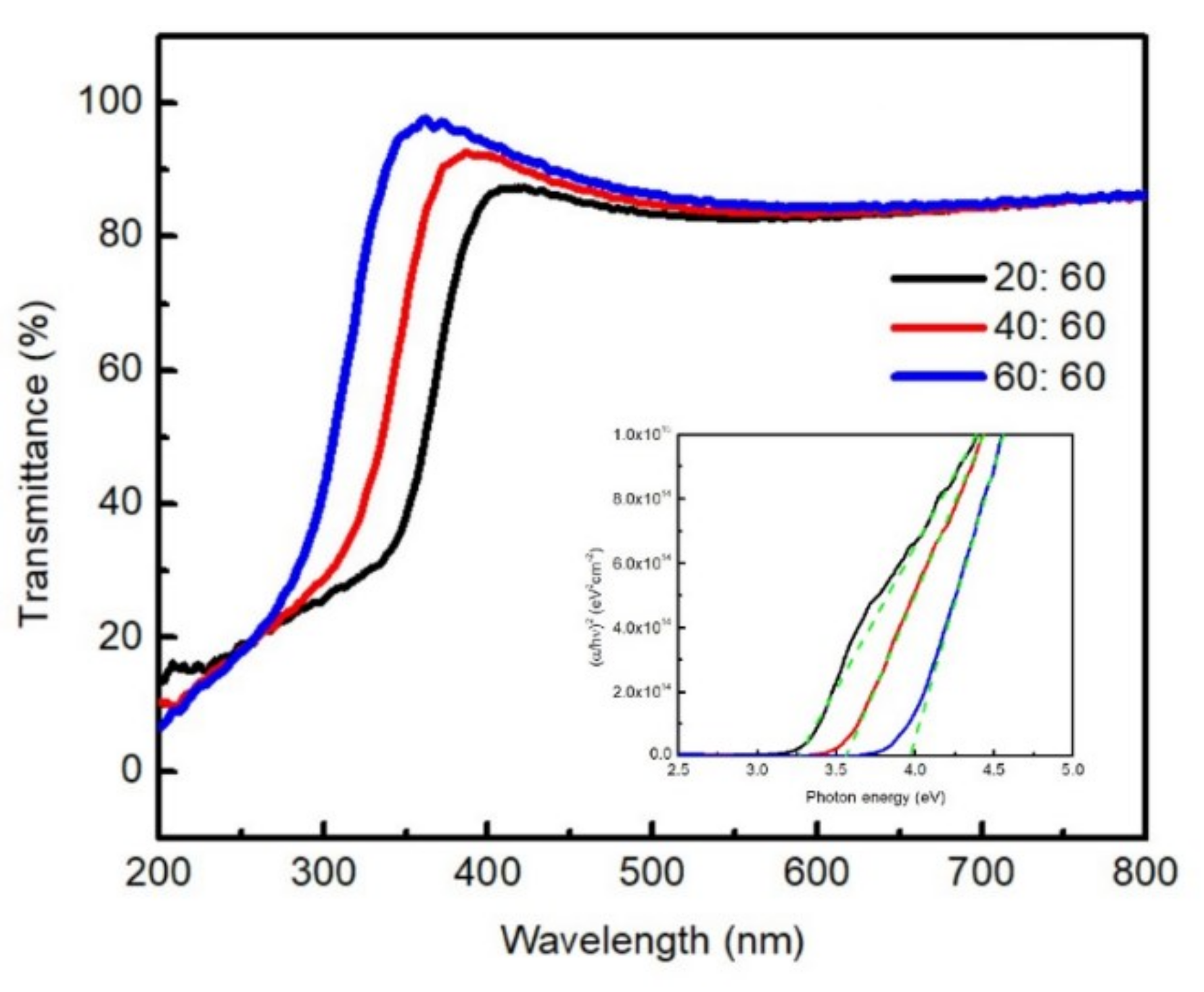

2. Materials and Methods

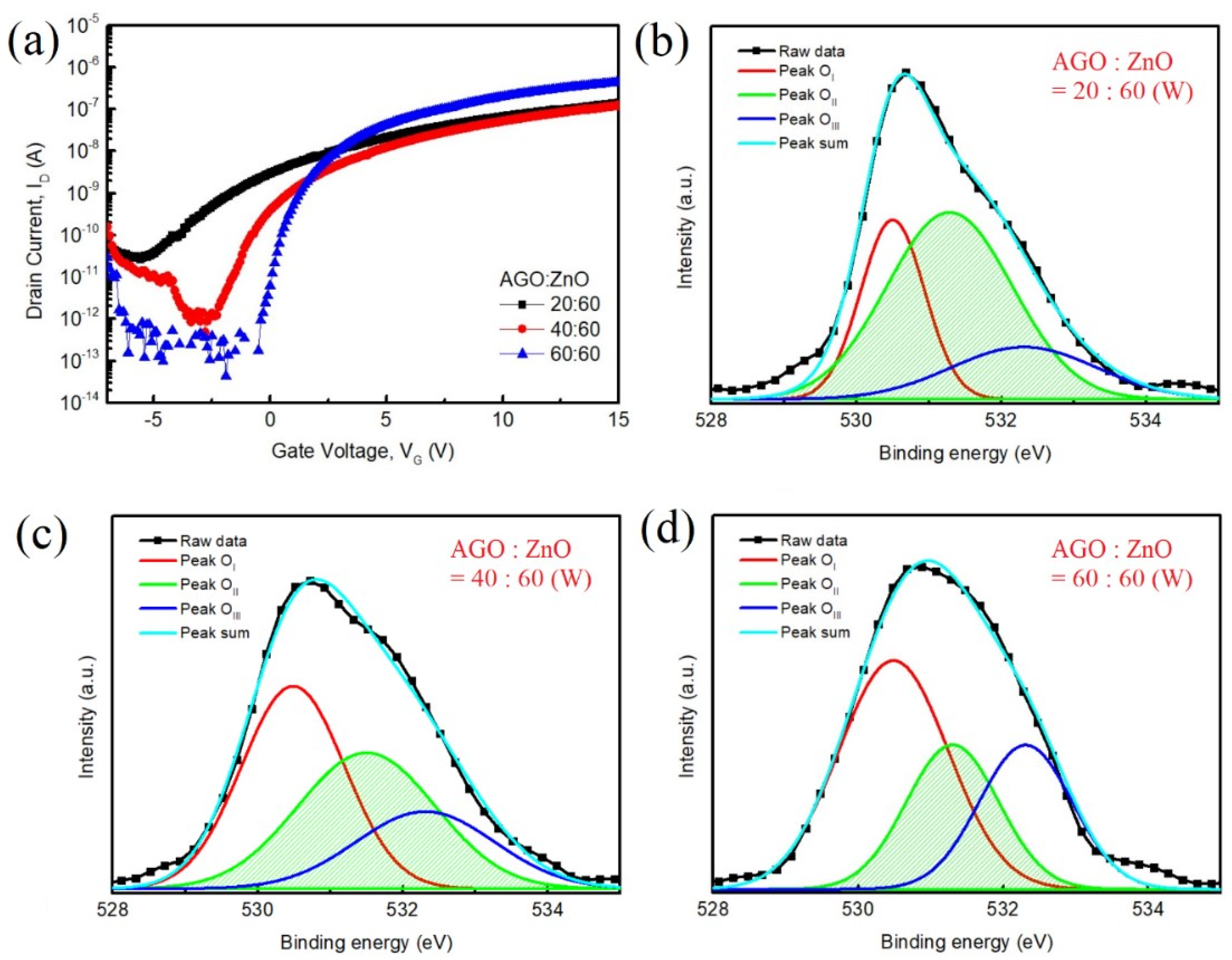

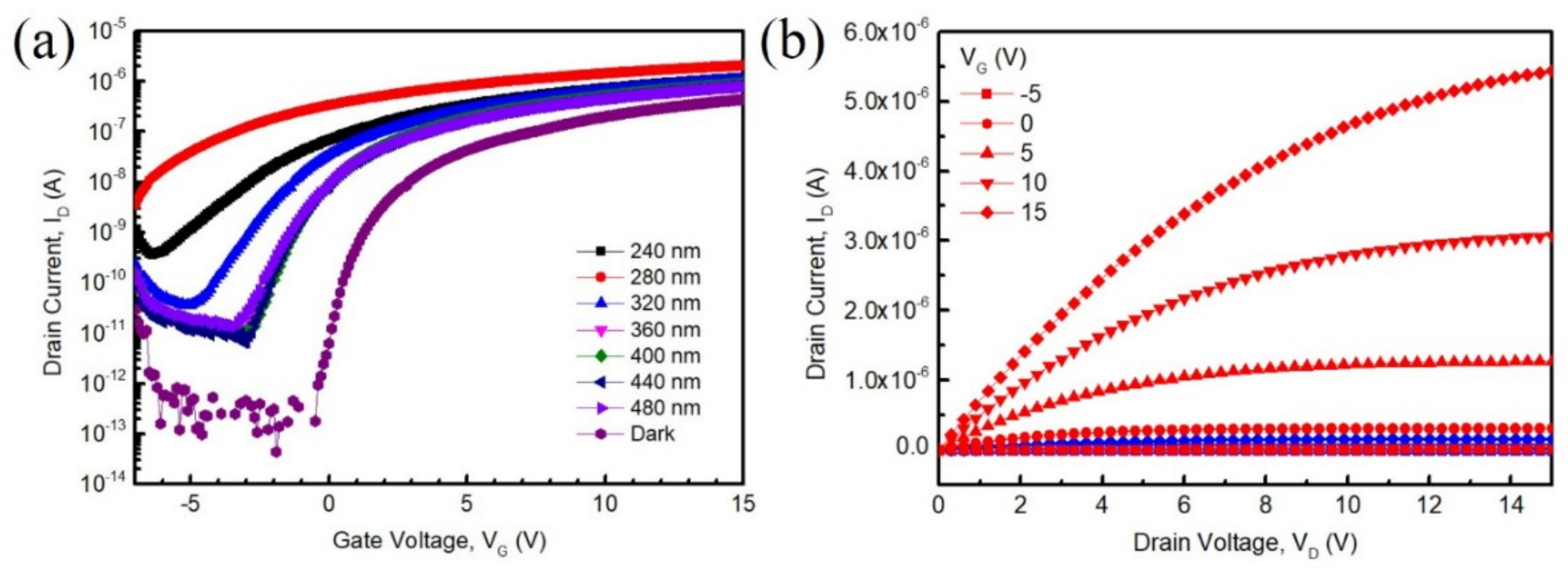

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Ueda, K.; Kamiya, T.; Hirano, M.; Hosono, H. Thin-film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 2003, 300, 1269–1272. [Google Scholar] [CrossRef]

- Fortunato, E.M.; Barquinha, P.M.; Pimentel, A.; Gonçalves, A.M.; Marques, A.J.; Pereira, L.M.; Martins, R.F. Fully transparent ZnO thin-film transistor produced at room temperature. Adv. Mater. 2005, 17, 590–594. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Sheraw, C.; Zhou, L.; Huang, J.; Gundlach, D.; Jackson, T.N.; Kane, M.; Hill, I.; Hammond, M.; Campi, J.; Greening, B. Organic thin-film transistor-driven polymer-dispersed liquid crystal displays on flexible polymeric substrates. Appl. Phys. Lett. 2002, 80, 1088–1090. [Google Scholar] [CrossRef]

- Lee, J.S.; Chang, S.; Koo, S.M.; Lee, S.Y. High-Performance a-IGZO TFT With ZrO2 Gate Dielectric Fabricated at Room Temperature. IEEE Electron Device Lett. 2010, 31, 225–227. [Google Scholar]

- Sun, B.Q.; Peterson, R.L.; Sirringhaus, H.; Mori, K. Low-temperature sintering of in-plane self-assembled ZnO nanorods for solution-processed high-performance thin film transistors. J. Phys. Chem. C 2007, 111, 18831–18835. [Google Scholar] [CrossRef]

- Janotti, A.; Van de Walle, C.G. Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 2009, 72, 29. [Google Scholar] [CrossRef]

- Sung, Y.C.; Kwon, O.K. Low-cost TFT-LCDs with pre-emphasis driving method for large-size and high-definition TVs. IEEE Trans. Consum. Electron. 2007, 53, 1674–1681. [Google Scholar] [CrossRef]

- Li, J.Y.; Chang, S.P.; Hsu, M.H.; Chang, S.J. High responsivity MgZnO ultraviolet thin-film phototransistor developed using radio frequency sputtering. Materials 2017, 10, 126. [Google Scholar] [CrossRef] [PubMed]

- Gruzintsev, A.; Volkov, V.; Yakimov, E. Photoelectric properties of ZnO films doped with Cu and Ag acceptor impurities. Semiconductors 2003, 37, 259–262. [Google Scholar] [CrossRef]

- Martins, R.; Barquinha, P.; Ferreira, I.; Pereira, L.; Goncalves, G.; Fortunato, E. Role of order and disorder on the electronic performances of oxide semiconductor thin film transistors. J. Appl. Phys. 2007, 101, 044505. [Google Scholar] [CrossRef]

- Huang, W.L.; Yang, C.C.; Chang, S.P.; Chang, S.J. Photoresponses of Zinc Tin Oxide Thin-Film Transistor. J. Nanosci. Nanotechnol. 2020, 20, 1704–1708. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In-Ga-Zn-O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 23. [Google Scholar] [CrossRef] [PubMed]

- Tomai, S.; Nishimura, M.; Itose, M.; Matuura, M.; Kasami, M.; Matsuzaki, S.; Kawashima, H.; Utsuno, F.; Yano, K. High-Performance Thin Film Transistor with Amorphous In2O3-SnO2-ZnO Channel Layer. Jpn. J. Appl. Phys. 2012, 51, 5. [Google Scholar] [CrossRef]

- Lee, D.Y.; Lee, J.R.; Lee, G.H.; Song, P.K. Study on In-Zn-Sn-O and In-Sn-Zn-O films deposited on PET substrate by magnetron co-sputtering system. Surf. Coat. Technol. 2008, 202, 5718–5723. [Google Scholar] [CrossRef]

- Cai, J.; Han, D.; Geng, Y.; Wang, W.; Wang, L.; Zhang, S.; Wang, Y. High-performance transparent AZO TFTs fabricated on glass substrate. IEEE Trans. Electron Devices 2013, 60, 2432–2435. [Google Scholar] [CrossRef]

- Ahn, C.H.; Kong, B.H.; Kim, H.; Cho, H.K. Improved electrical stability in the Al doped ZnO thin-film-transistors grown by atomic layer deposition. J. Electrochem. Soc. 2010, 158, H170. [Google Scholar] [CrossRef]

- Park, W.J.; Shin, H.S.; Ahn, B.D.; Kim, G.H.; Lee, S.M.; Kim, K.H.; Kim, H.J. Investigation on doping dependency of solution-processed Ga-doped ZnO thin film transistor. Appl. Phys. Lett. 2008, 93, 083508. [Google Scholar] [CrossRef]

- Nam, T.; Lee, C.W.; Kim, H.J.; Kim, H. Growth characteristics and properties of Ga-doped ZnO (GZO) thin films grown by thermal and plasma-enhanced atomic layer deposition. Appl. Surf. Sci. 2014, 295, 260–265. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Zhu, H.; Li, H.; Jiang, L.; Shu, C.; Hu, W.; Wang, C. High performance ultraviolet photodetectors based on an individual Zn 2 SnO 4 single crystalline nanowire. J. Mater. Chem. 2010, 20, 9858–9860. [Google Scholar] [CrossRef]

- Yadav, H.K.; Sreenivas, K.; Gupta, V. Enhanced response from metal/ZnO bilayer ultraviolet photodetector. Appl. Phys. Lett. 2007, 90, 172113. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, C.; Feng, L.; Gong, L.; Ye, Z.; Lu, J. High-response of amorphous ZnSnO sensors for ultraviolet and ethanol detections. Appl. Surf. Sci. 2015, 357, 1536–1540. [Google Scholar] [CrossRef]

- Shan, C.; Zhang, J.; Yao, B.; Shen, D.; Fan, X.; Choy, K. Ultraviolet photodetector fabricated from atomic-layer-deposited ZnO films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2009, 27, 1765–1768. [Google Scholar] [CrossRef]

- Wang, W.; Pan, X.; Dai, W.; Zeng, Y.; Ye, Z. Ultrahigh sensitivity in the amorphous ZnSnO UV photodetector. RSC Adv. 2016, 6, 32715–32720. [Google Scholar] [CrossRef]

- Tian, W.; Zhai, T.; Zhang, C.; Li, S.L.; Wang, X.; Liu, F.; Liu, D.; Cai, X.; Tsukagoshi, K.; Golberg, D. Low-cost fully transparent ultraviolet photodetectors based on electrospun ZnO-SnO2 heterojunction nanofibers. Adv. Mater. 2013, 25, 4625–4630. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Xu, C.; Xu, X.; Guo, J.; Li, J.; Zhu, G.; Lin, Y. Single ZnO microrod ultraviolet photodetector with high photocurrent gain. ACS Appl. Mater. Interfaces 2013, 5, 9344–9348. [Google Scholar] [CrossRef] [PubMed]

- Higashiwaki, M.; Sasaki, K.; Kuramata, A.; Masui, T.; Yamakoshi, S. Gallium oxide (Ga2O3) metal-semiconductor field-effect transistors on single-crystal beta-Ga2O3 (010) substrates. Appl. Phys. Lett. 2012, 100, 3. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.C.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 56. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Sasaki, K.; Murakami, H.; Kumagai, Y.; Koukitu, A.; Kuramata, A.; Masui, T.; Yamakoshi, S. Recent progress in Ga2O3 power devices. Semicond. Sci. Technol. 2016, 31, 11. [Google Scholar] [CrossRef]

- Green, A.J.; Chabak, K.D.; Heller, E.R.; Fitch, R.C.; Baldini, M.; Fiedler, A.; Irmscher, K.; Wagner, G.; Galazka, Z.; Tetlak, S.E.; et al. 3.8-MV/cm Breakdown Strength of MOVPE-Grown Sn-Doped beta-Ga2O3 MOSFETs. IEEE Electron Device Lett. 2016, 37, 902–905. [Google Scholar] [CrossRef]

- Huang, W.L.; Li, C.H.; Chang, S.P.; Chang, S.J. The Effect of Oxygen Partial Pressure and Annealing Process on the Characteristics of ZnGa2O4 MSM UV Photodetector. ECS J. Solid State Sci. Technol. 2019, 8, Q3213. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi B 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Kamarulzaman, N.; Kasim, M.F.; Rusdi, R. Band gap narrowing and widening of ZnO nanostructures and doped materials. Nanoscale Res. Lett. 2015, 10, 1–12. [Google Scholar] [CrossRef]

- Lee, H.Y.; Liu, J.T.; Lee, C.T. Modulated Al2O3-alloyed Ga2O3 materials and deep ultraviolet photodetectors. IEEE Photonics Technol. Lett. 2018, 30, 549–552. [Google Scholar] [CrossRef]

- Li, J.Y.; Chang, S.P.; Hsu, M.H.; Chang, S.J. Photo-Electrical Properties of MgZnO Thin-Film Transistors With High-Dielectrics. IEEE Photonics Technol. Lett. 2017, 30, 59–62. [Google Scholar] [CrossRef]

- Ko, T.; Chang, S.J.; Sheu, J.K.; Shei, S.C.; Chiou, Y.Z.; Lee, M.; Shen, C.; Chang, S.; Lin, K. AlGaN/GaN Schottky-barrier UV-B bandpass photodetectors with ITO contacts and LT-GaN cap layers. Semicond. Sci. Technol. 2006, 21, 1064. [Google Scholar] [CrossRef]

- Lee, M.; Sheu, J.K.; Shu, Y.R. Ultraviolet bandpass Al0.17Ga0.83N/GaN heterojunction phototransitors with high optical gain and high rejection ratio. Appl. Phys. Lett. 2008, 92, 053506. [Google Scholar] [CrossRef]

- Matsuda, T.; Umeda, K.; Kato, Y.; Nishimoto, D.; Furuta, M.; Kimura, M. Rare-metal-free high-performance Ga-Sn-O thin film transistor. Sci. Rep. 2017, 7, 44326. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.S.; Jeon, J.H.; Hwang, Y.H.; Park, H.; Ryu, M.; Park, S.H.K.; Bae, B.S. Solution-processed flexible fluorine-doped indium zinc oxide thin-film transistors fabricated on plastic film at low temperature. Sci. Rep. 2013, 3, 2085. [Google Scholar] [CrossRef]

- Kim, U.K.; Rha, S.H.; Kim, J.H.; Chung, Y.J.; Jung, J.; Hwang, E.S.; Lee, J.; Park, T.J.; Choi, J.H.; Hwang, C.S. Study on the defects in metal–organic chemical vapor deposited zinc tin oxide thin films using negative bias illumination stability analysis. J. Mater. Chem. C 2013, 1, 6695–6702. [Google Scholar] [CrossRef]

| AGO:ZnO Power Ratio (W) | Al | Ga | Zn | O |

|---|---|---|---|---|

| 20:60 | <0.1 | 1.6 | 55.1 | 43.3 |

| 40:60 | <0.1 | 14.7 | 42.0 | 43.3 |

| 60:60 | 0.7 | 20.8 | 32.2 | 46.3 |

| AGO:ZnO Power Ratio (W) | gm (F/s) | Vt (V) | Mobility (cm2/Vs) | On/Of fRatio | SS (V/dec) | Nt (cm−2) |

|---|---|---|---|---|---|---|

| 20:60 | 3.05 10−9 | −0.15 | 0.029 | 5.19 103 | 1.90 | 3.33 1012 |

| 40:60 | 1.67 10−9 | −0.11 | 0.023 | 2.60 105 | 0.74 | 1.23 1012 |

| 60:60 | 1.39 10−8 | 0.96 | 0.04 | 1.01 107 | 0.33 | 4.85 1012 |

| AGO:ZnO Power Ratio (W) | VG of the Highest RR | Responsivity (270 nm) (A/W) | RR (270 nm/440 nm) |

|---|---|---|---|

| 20:60 | −7 V | 0.26 | 6.12 × 103 |

| 40:60 | −5 V | 0.080 | 2.94 × 104 |

| 60:60 | −3 V | 0.014 | 4.31 × 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.-L.; Chang, S.-P.; Li, C.-H.; Chang, S.-J. The Characteristics of Aluminum-Gallium-Zinc-Oxide Ultraviolet Phototransistors by Co-Sputtering Method. Electronics 2021, 10, 631. https://doi.org/10.3390/electronics10050631

Huang W-L, Chang S-P, Li C-H, Chang S-J. The Characteristics of Aluminum-Gallium-Zinc-Oxide Ultraviolet Phototransistors by Co-Sputtering Method. Electronics. 2021; 10(5):631. https://doi.org/10.3390/electronics10050631

Chicago/Turabian StyleHuang, Wei-Lun, Sheng-Po Chang, Cheng-Hao Li, and Shoou-Jinn Chang. 2021. "The Characteristics of Aluminum-Gallium-Zinc-Oxide Ultraviolet Phototransistors by Co-Sputtering Method" Electronics 10, no. 5: 631. https://doi.org/10.3390/electronics10050631

APA StyleHuang, W.-L., Chang, S.-P., Li, C.-H., & Chang, S.-J. (2021). The Characteristics of Aluminum-Gallium-Zinc-Oxide Ultraviolet Phototransistors by Co-Sputtering Method. Electronics, 10(5), 631. https://doi.org/10.3390/electronics10050631