Implementation of PI and MPC-Based Speed Controllers for a Drive with Elastic Coupling on a PLC Controller

Abstract

:1. Introduction

2. Mathematical Model of the Drive and Control Methods

2.1. Model of the Drive

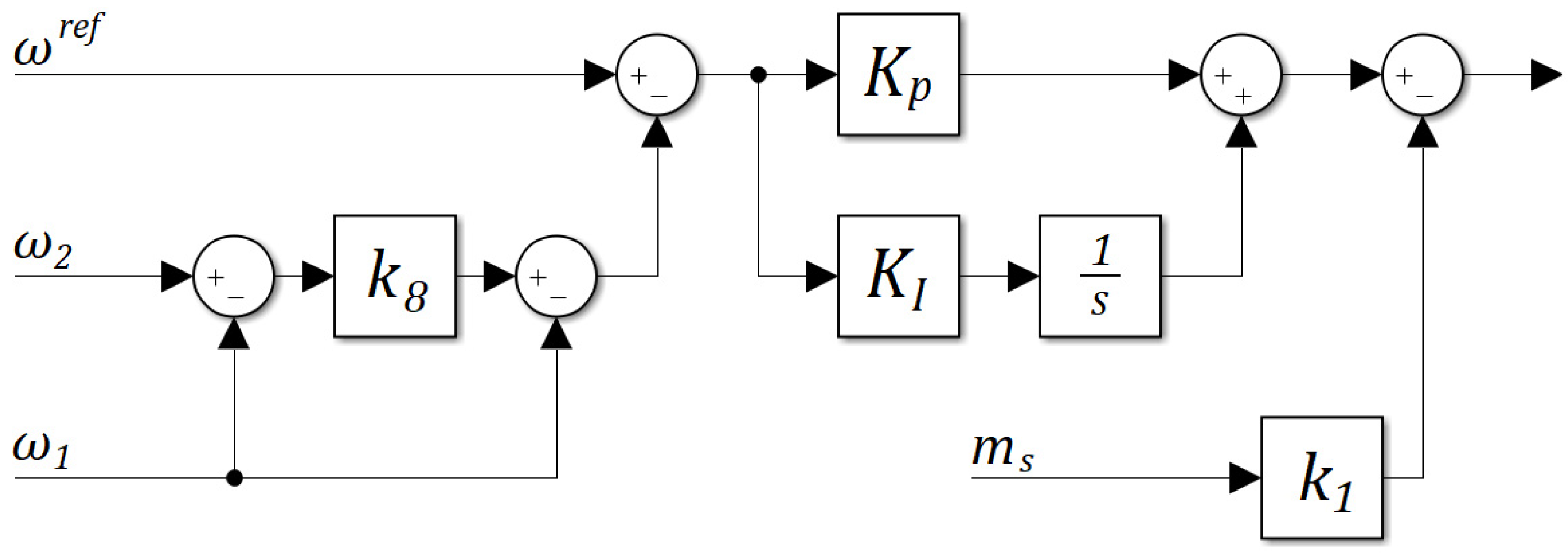

2.2. PI Controller with Additional Feedback Loops

2.3. Predictive Control

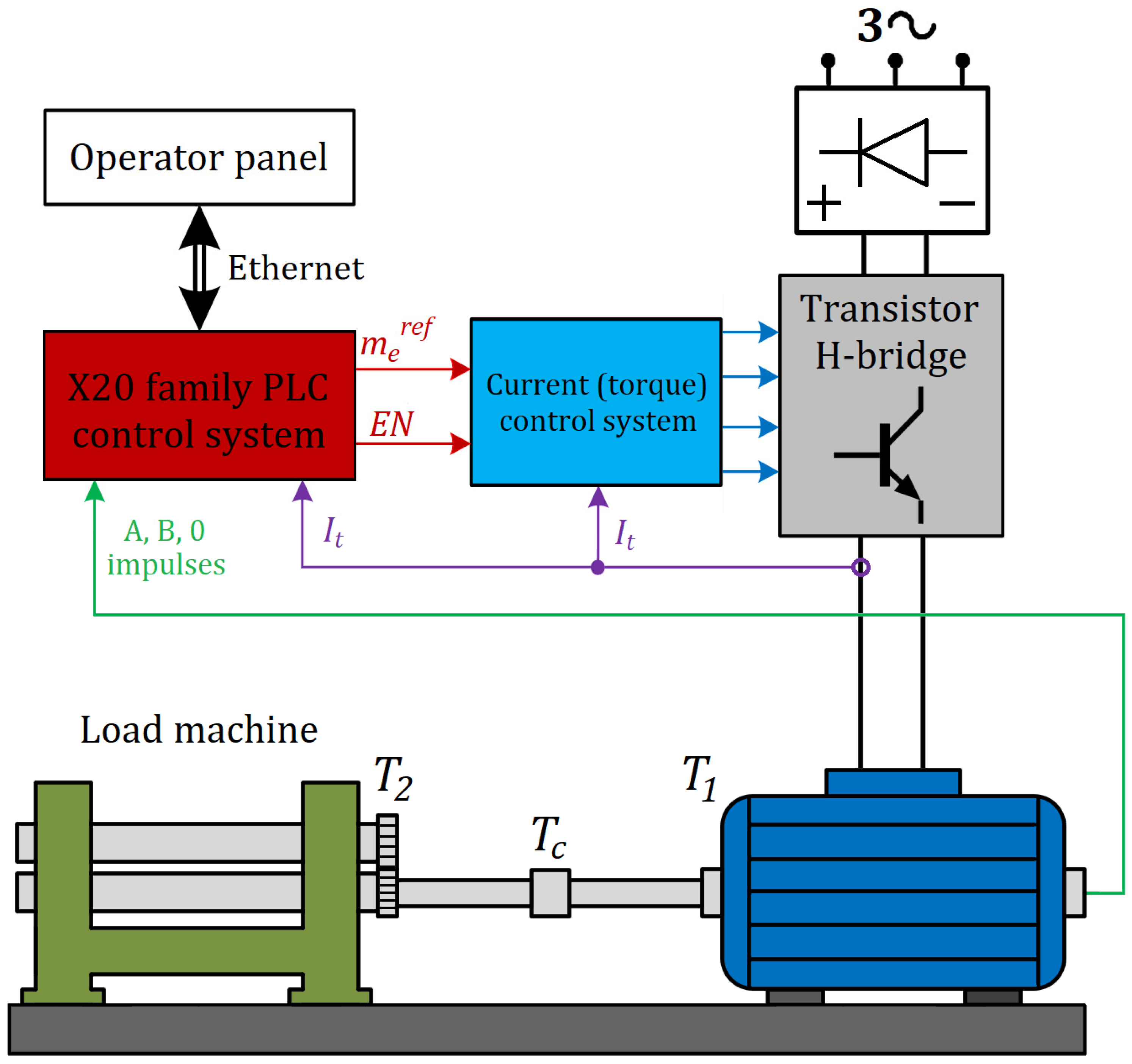

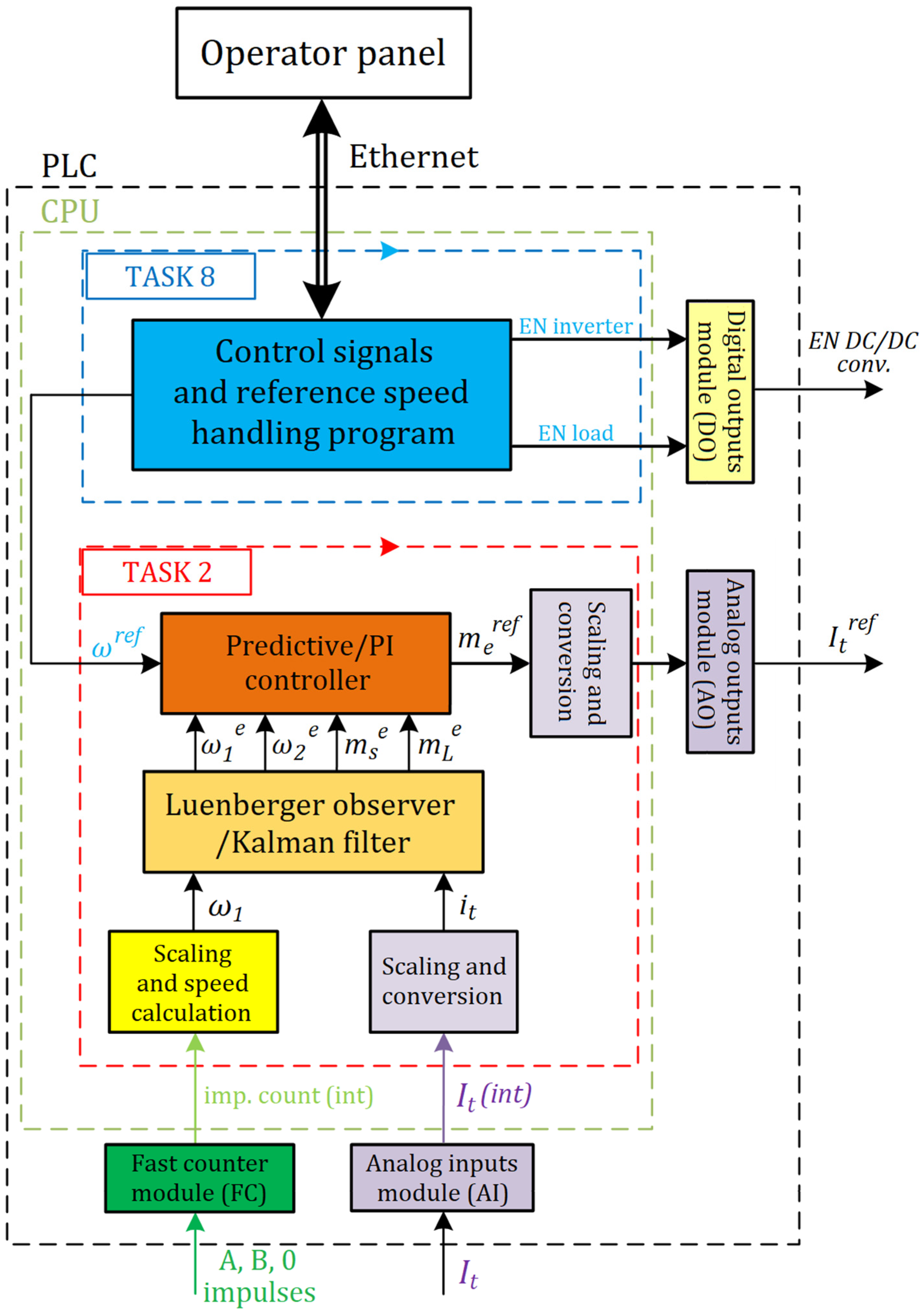

3. Implementation of the Control Structure

4. Results

5. Conclusions

- It is possible to successfully implement an advanced control structure, such as a predictive controller with a Kalman filter, for drives with an elastic connections using a PLC controller;

- Even with a long prediction horizon of the outputs, which greatly increases the computational complexity of the controller, the computation time and CPU load of the PLC controller are sufficiently low;

- For the considered control system, the application of the linear Kalman filter provides a significant improvement in the estimation of state variables compared to a Luenberger observer;

- The presented solution allows for creation of a control function block, which can then be used in other projects as a component of control programs, saving time in the design process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameter | Symbol | Value |

|---|---|---|

| base pulsation | 151.84 rad/s | |

| nominal speed | 1450 rev/min | |

| rated current | 3 A | |

| rated (base) torque | 3.15 Nm | |

| nominal flux | 1.05 Wb | |

| shaft spring constant | 17.38 Nm/rad |

References

- Zawirski, K.; Deskur, J.; Kaczmarek, T. Automatyka Napędu Elektrycznego; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 2012. (In Polish) [Google Scholar]

- Zhang, R.; Tong, C. Torsional vibration control of the main drive system of a rolling mill based on an extended state observer and linear quadratic control. J. Vib. Control 2006, 12, 313–327. [Google Scholar] [CrossRef]

- Valenzuela, M.A.; Bentley, J.M.; Lorenz, R.D. Computer-aided controller setting procedure for paper machine drive systems. IEEE Trans. Ind. Electron. 2009, 45, 638–650. [Google Scholar] [CrossRef]

- Luca, A.D.; Book, W. Robots with flexible elements. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2008; pp. 287–319. [Google Scholar] [CrossRef]

- Štimac, G.; Braut, S.; Bulić, N.; Žigulić, R. Modeling and experimental verification of a flexible rotor/AMB system. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2013, 32, 1244–1254. [Google Scholar] [CrossRef]

- Montague, R.; Bingham, C.; Atallah, K. Servo control of magnetic gears. IEEE/ASME Trans. Mechatron. 2012, 17, 269–278. [Google Scholar] [CrossRef]

- Łuczak, D. The Use of Digital Filters in Control Systems of Electric Drives with Complex Mechanical Structure; Poznań University of Technology: Poznań, Poland, 2014. [Google Scholar]

- Muszyński, R.; Deskur, J. Damping of torsional vibrations in high-dynamic industrial drives. IEEE Trans. Ind. Electron. 2009, 57, 544–552. [Google Scholar] [CrossRef]

- Szabat, K.; Orłowska-Kowalska, T. Vibration suppression in a two-mass drive system using PI speed controller and additional feedbacks—Comparative study. IEEE Trans. Ind. Electron. 2007, 54, 1193–1206. [Google Scholar] [CrossRef]

- Kabziński, J.; Mosiołek, P. Integrated, multi-approach, adaptive control of two-mass drive with nonlinear damping and stiffness. Energies 2021, 14, 5475. [Google Scholar] [CrossRef]

- Petit, F.; Daasch, A.; Albu-Schäffer, A. Backstepping control of variable stiffness robots. IEEE Trans. Control Syst. Technol. 2015, 23, 2195–2202. [Google Scholar] [CrossRef]

- Kamiński, M.; Szabat, K. Adaptive control structure with neural data processing applied for electrical drive with elastic shaft. Energies 2021, 14, 3389. [Google Scholar] [CrossRef]

- Wróbel, K.; Serkies, P.; Szabat, K. Model predictive base direct speed control of induction motor drive—Continuous and finite set approaches. Energies 2020, 13, 1193. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Yang, M.; Zheng, W.; Long, J.; Xu, D. Vibration suppression with shaft torque limitation using explicit MPC-PI switching control in elastic drive systems. IEEE Trans. Ind. Electron. 2015, 62, 6855–6867. [Google Scholar] [CrossRef]

- Cychowski, M.; Szabat, K.; Orłowska-Kowalska, T. Constrained model predictive control of the drive system with mechanical elasticity. IEEE Trans. Ind. Electron. 2009, 56, 1963–1973. [Google Scholar] [CrossRef]

- Serkies, P.; Szabat, K. Application of the MPC controller to the position control of the two-mass drive system. IEEE Trans. Ind. Electron. 2013, 60, 3679–3688. [Google Scholar] [CrossRef]

- Vittek, J.; Ryvkin, S. Decomposed sliding mode control of the drive with interior permanent magnet synchronous motor and flexible coupling. Math. Probl. Eng. 2013, 2013, 680376. [Google Scholar] [CrossRef] [Green Version]

- Serkies, P.; Szabat, K. Effective damping of the torsional vibrations of the drive system with an elastic joint based on the forced dynamic control algorithms. J. Vib. Control 2019, 25, 2225–2236. [Google Scholar] [CrossRef]

- Ilchmann, A.; Schuster, H. PI-funnel control for two mass systems. IEEE Trans. Autom. Control 2009, 54, 918–923. [Google Scholar] [CrossRef] [Green Version]

- Vouzis, P.D.; Bleris, L.G.; Arnold, M.G.; Kothare, M.V. A system-on-a-chip implementation for embedded real-time model predictive control. IEEE Trans. Control Syst. Technol. 2009, 17, 1006–1017. [Google Scholar] [CrossRef]

- Jerez, J.L.; Goulart, P.J.; Richter, S.; Constantinides, G.A.; Kerrigan, E.C.; Morari, M. Embedded predictive control of an FPGA using the fast gradient method. In Proceedings of the European Control Conference (EEC), Zürich, Switzerland, 17–19 July 2013. [Google Scholar] [CrossRef]

- Dominic, S.; Löhr, Y.; Schwung, A.; Ding, S.X. PLC-based real-time realization of flatness-based feedforward control for industrial compression systems. IEEE Trans. Ind. Electron. 2017, 64, 1323–1331. [Google Scholar] [CrossRef]

- Aboelhassan, A.; Abdelgeliel, M.; Zakzouk, E.E.; Galea, M. Design and implementation of model predictive control based PID controller for industrial applications. Energies 2020, 13, 6594. [Google Scholar] [CrossRef]

- Valencia-Palomo, G.; Rossiter, J.A. Efficient suboptimal parametric solutions to predictive control for PLC applications. Control Eng. Pract. 2011, 19, 732–743. [Google Scholar] [CrossRef] [Green Version]

- Lozynskyy, A.; Chaban, A.; Perzyński, T.; Szafraniec, A.; Kasha, L. Application of fractional-order calculus to improve the mathematical model of a two-mass system with a long shaft. Energies 2021, 14, 1854. [Google Scholar] [CrossRef]

- MathWorks. Model Predictive Control Toolbox™. Available online: https://www.mathworks.com/products/model-predictive-control.html (accessed on 1 December 2021).

- B&R Automation. Available online: https://www.br-automation.com/en-gb/products/plc-systems/x20-system/x20-cpus/x20cp3586/ (accessed on 26 November 2021).

| Description | Parameters |

|---|---|

| Central unit X20CP3586 | INTEL ATOM 1.6 GHz processor, 512 MB DDR2 RAM, 1 MB SRAM, calculation speed up to 0.1 ms |

| Digital outputs X20DO9322 | 12 outputs, 24 VDC, 0.5 A |

| Analogue inputs X20AI4632 | 4 inputs ± 10 V/0 to 20 mA, 16 bit resolution, configurable input filter |

| Analogue outputs X20AO4632 | 4 outputs ± 10 V/0 to 20 mA, 16 bit resolution |

| High–speed counter X20DC1196 | One ABR channel, 5 V, max frequency 600 kHz, 4 edges counted |

| Parameter | Value |

|---|---|

| 1.2 ms | |

| 12 | |

| 2 | |

| 0.001 | |

| 3 p.u. | |

| 1.5 p.u. |

| Parameter | CPU Usage (%) | Calculation Time (µs) | ||

|---|---|---|---|---|

| Min | Average | Max | ||

| PI | 3.5 | 36 | 42 | 93 |

| 4.8 | 165 | 188 | 197 | |

| 6.5 | 177 | 192 | 199 | |

| 5.2 | 178 | 192 | 198 | |

| 8.5 | 230 | 251 | 263 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serkies, P.; Gorla, A. Implementation of PI and MPC-Based Speed Controllers for a Drive with Elastic Coupling on a PLC Controller. Electronics 2021, 10, 3139. https://doi.org/10.3390/electronics10243139

Serkies P, Gorla A. Implementation of PI and MPC-Based Speed Controllers for a Drive with Elastic Coupling on a PLC Controller. Electronics. 2021; 10(24):3139. https://doi.org/10.3390/electronics10243139

Chicago/Turabian StyleSerkies, Piotr, and Adam Gorla. 2021. "Implementation of PI and MPC-Based Speed Controllers for a Drive with Elastic Coupling on a PLC Controller" Electronics 10, no. 24: 3139. https://doi.org/10.3390/electronics10243139

APA StyleSerkies, P., & Gorla, A. (2021). Implementation of PI and MPC-Based Speed Controllers for a Drive with Elastic Coupling on a PLC Controller. Electronics, 10(24), 3139. https://doi.org/10.3390/electronics10243139