Wearable Textile Antenna with a Graphene Sheet or Conductive Fabric Patch for the 2.45 GHz Band

Abstract

:1. Introduction

2. Materials and Methods

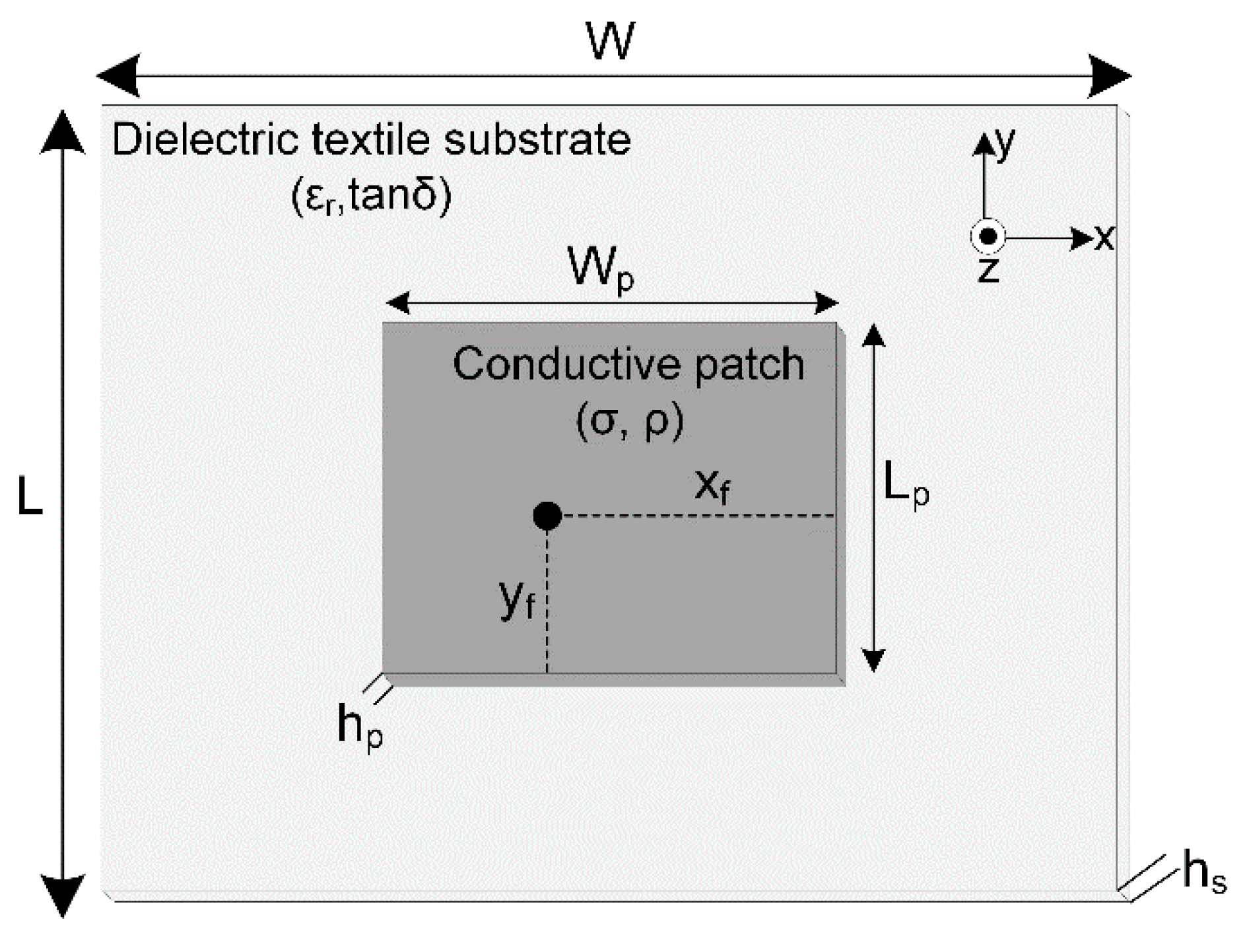

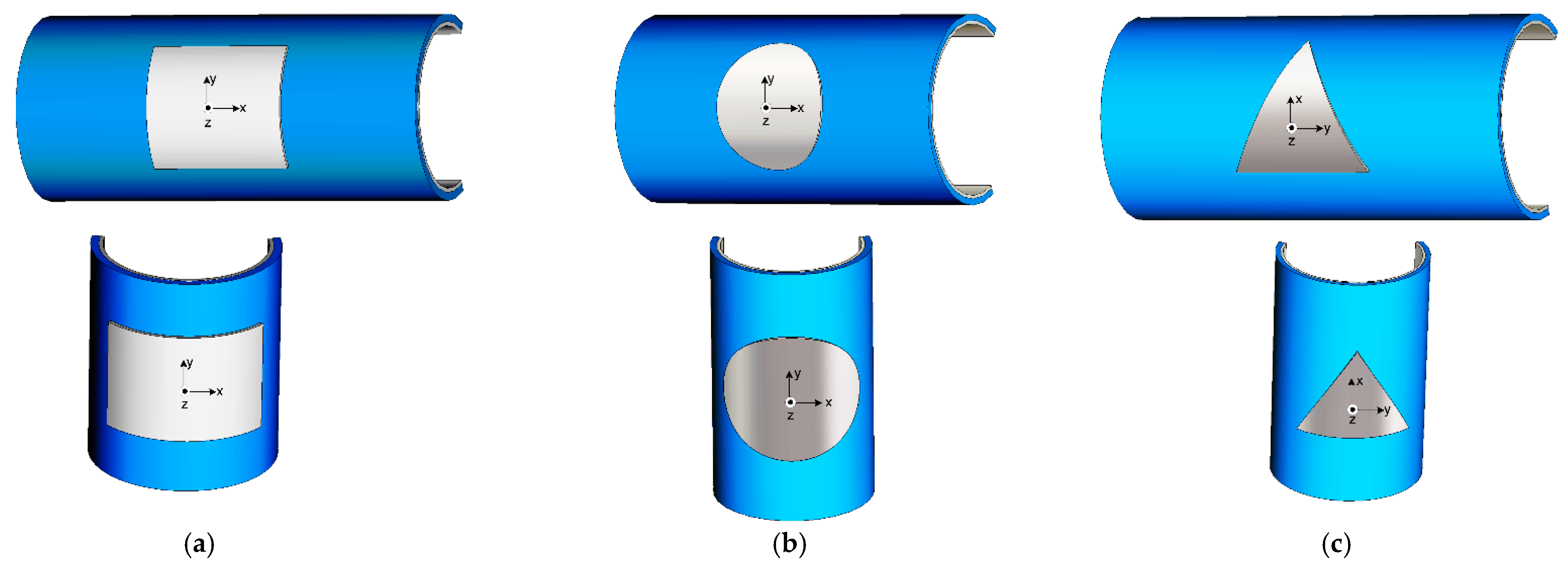

2.1. Rectangular Patch Antenna Design

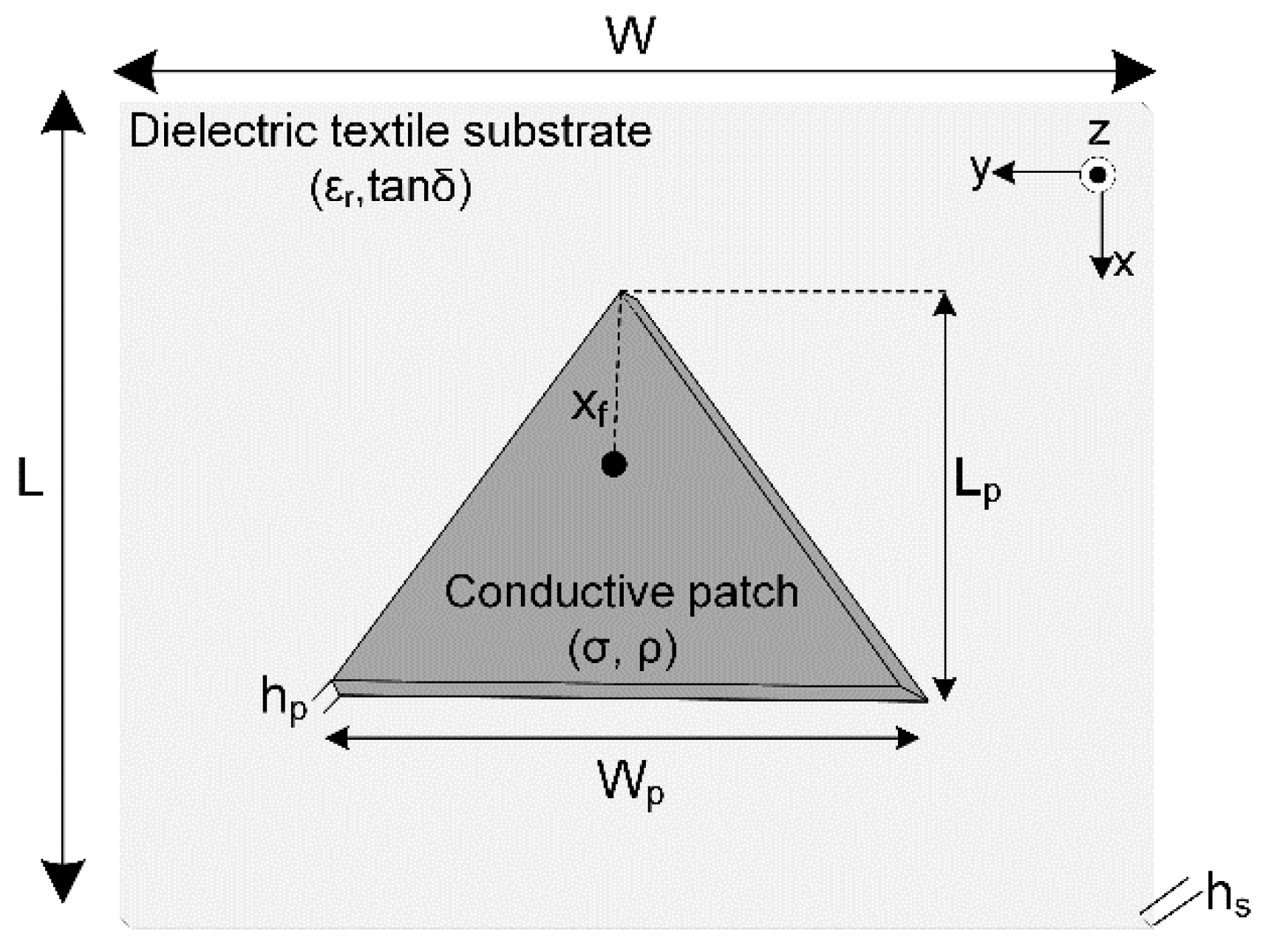

2.2. Triangular Patch Antenna Design

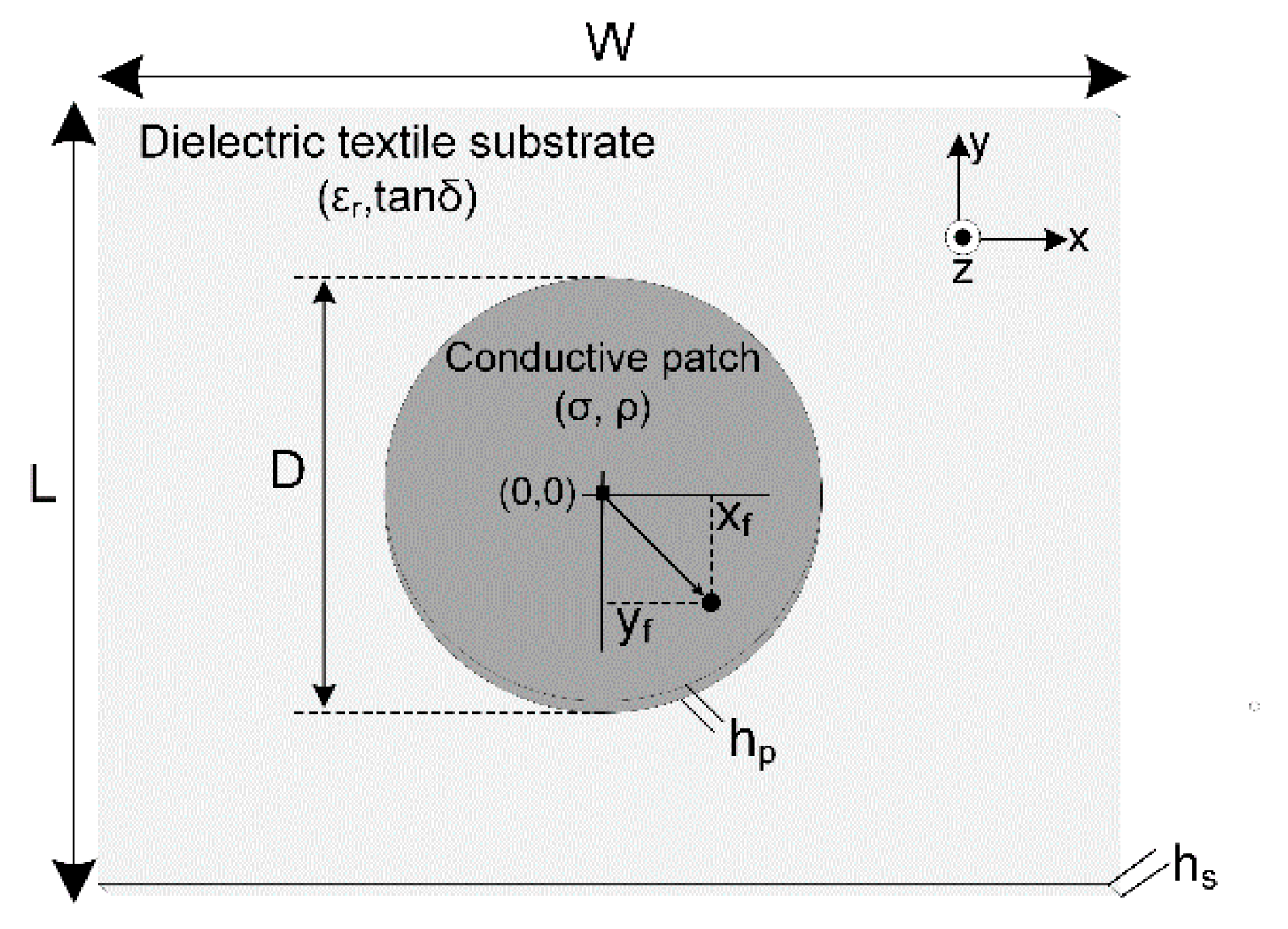

2.3. Circular Patch Antenna Design

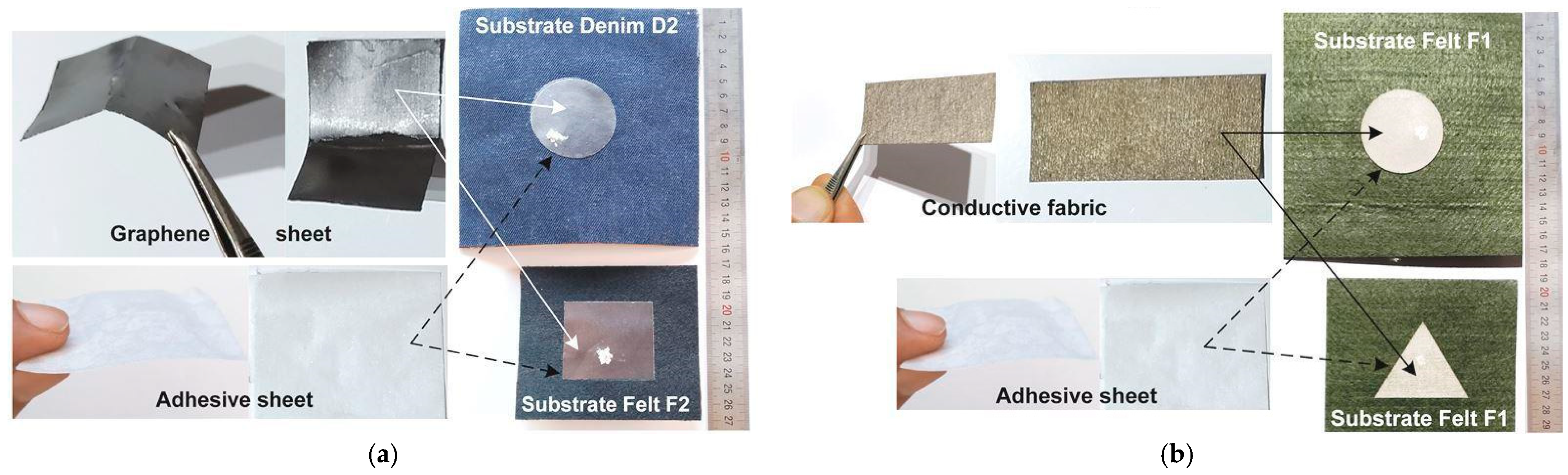

2.4. Optimized for the 2.45 GHz Patch Antenna Design and Fabrication

3. Results

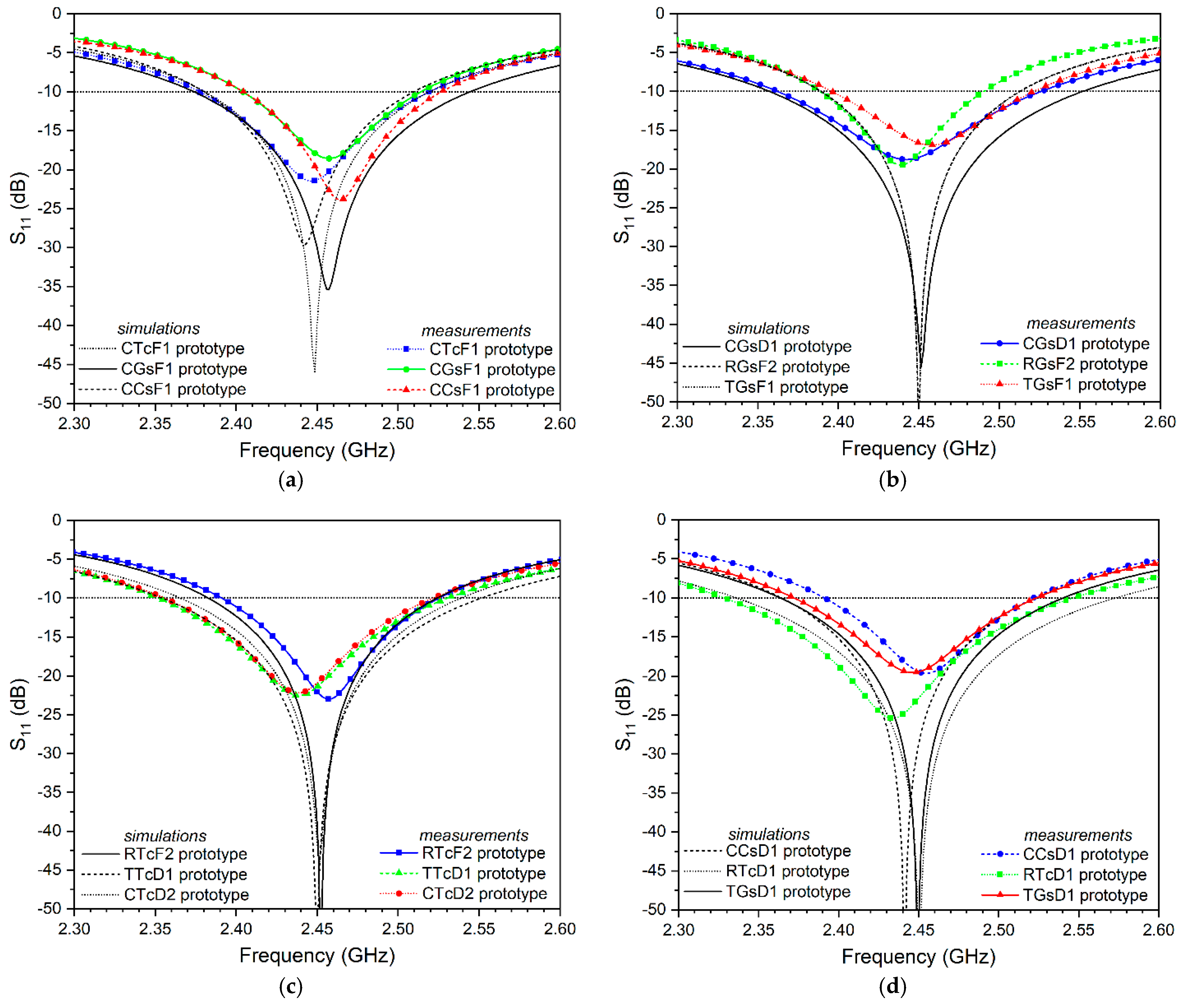

3.1. Simulation and Experimental Results for the Antennas in Free Space

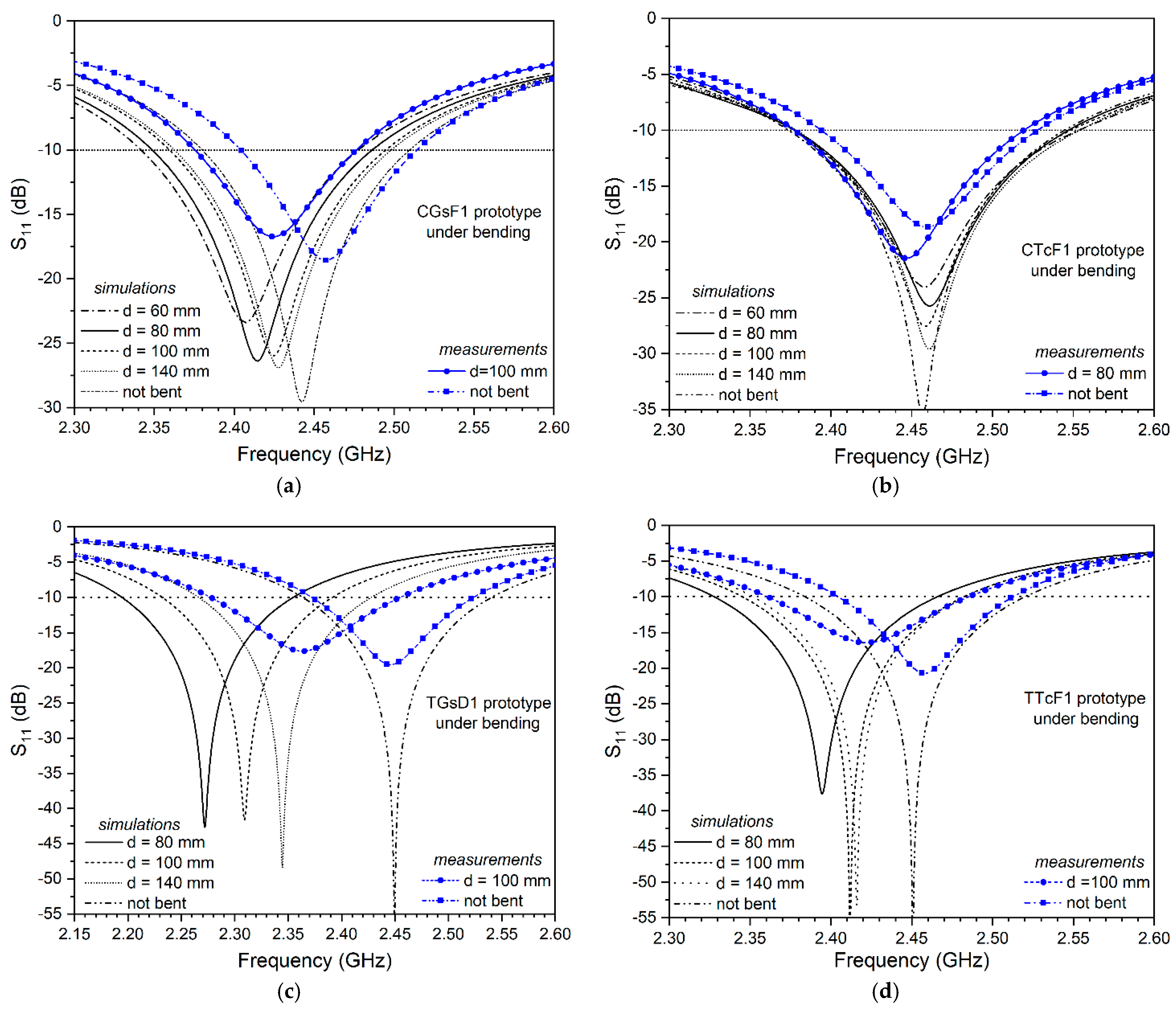

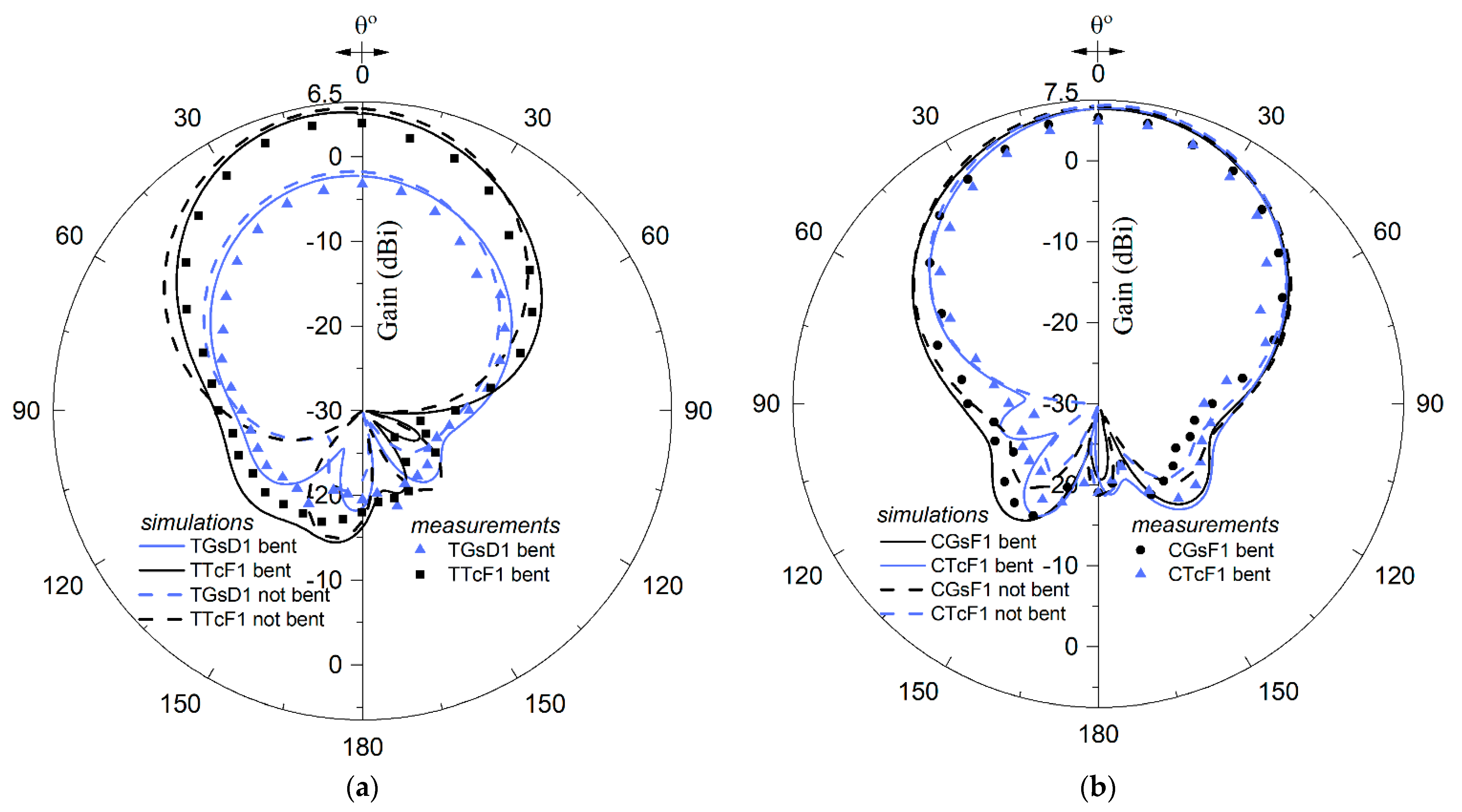

3.2. Results for the Antennas under Bending

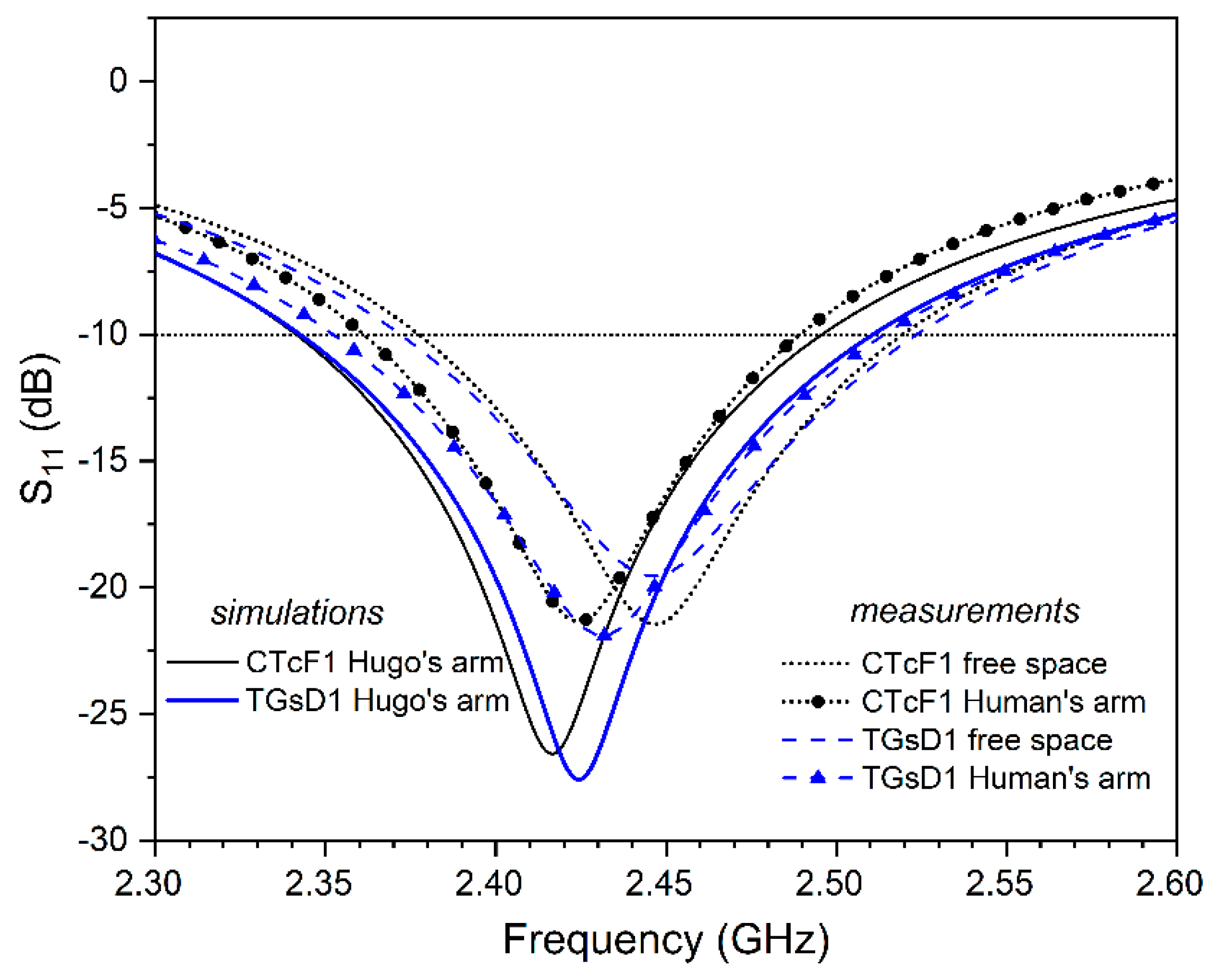

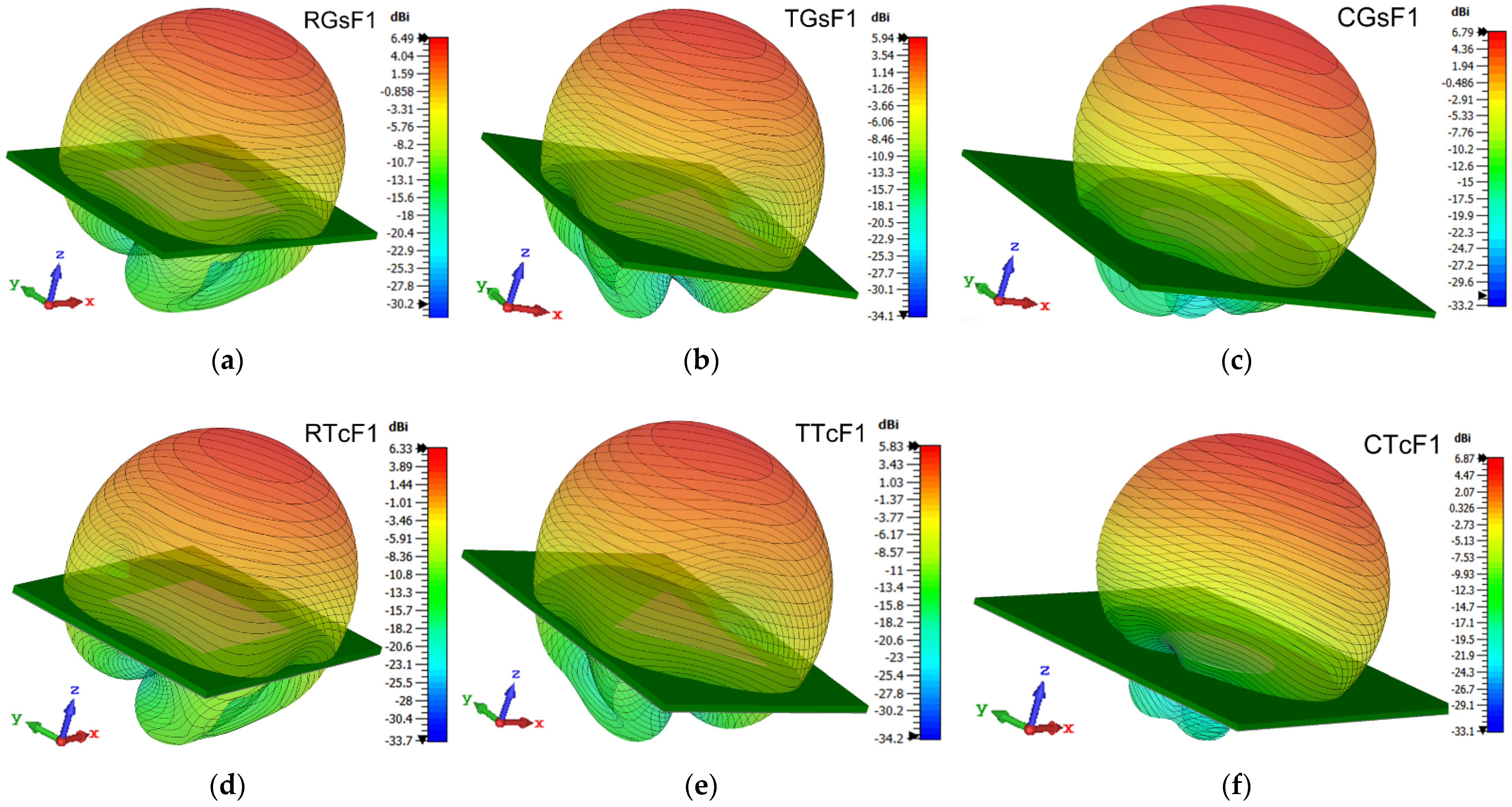

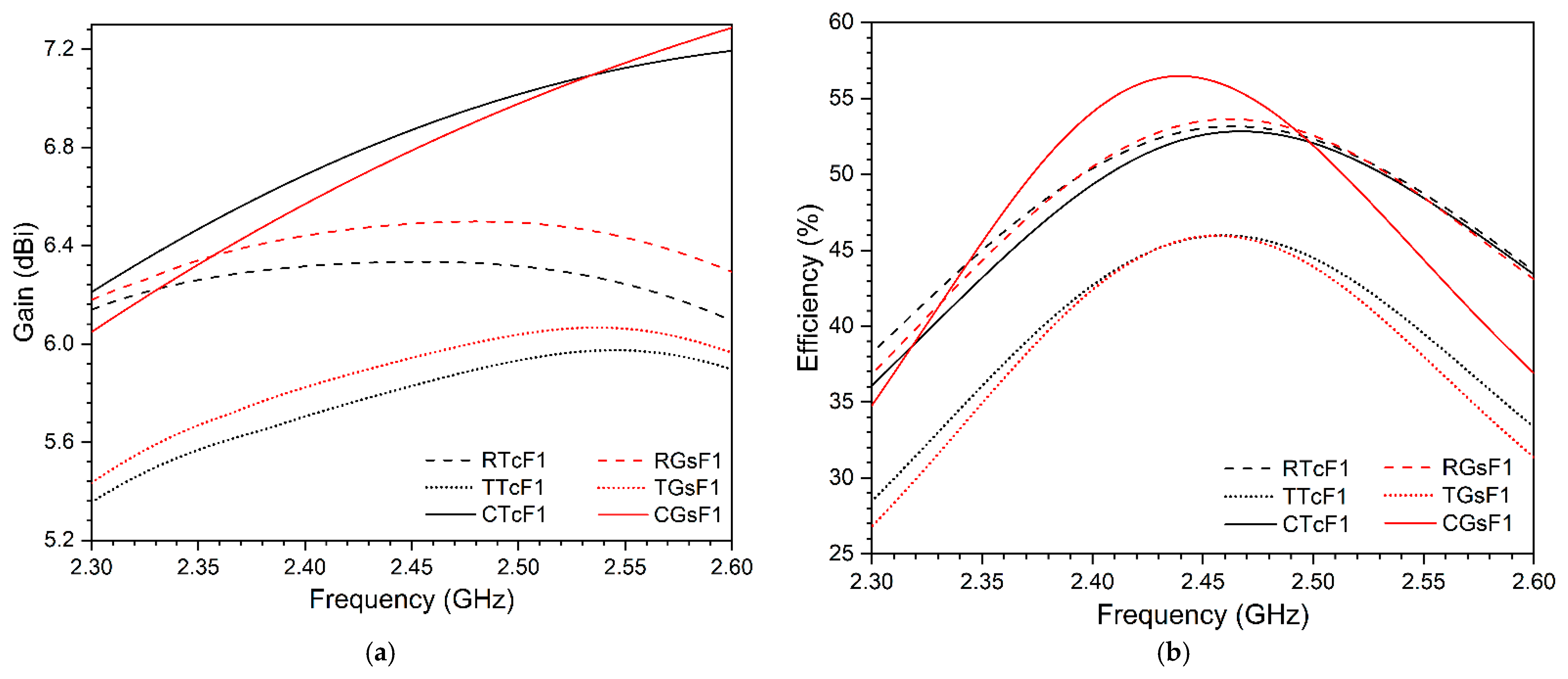

3.3. Radiation Characteristics

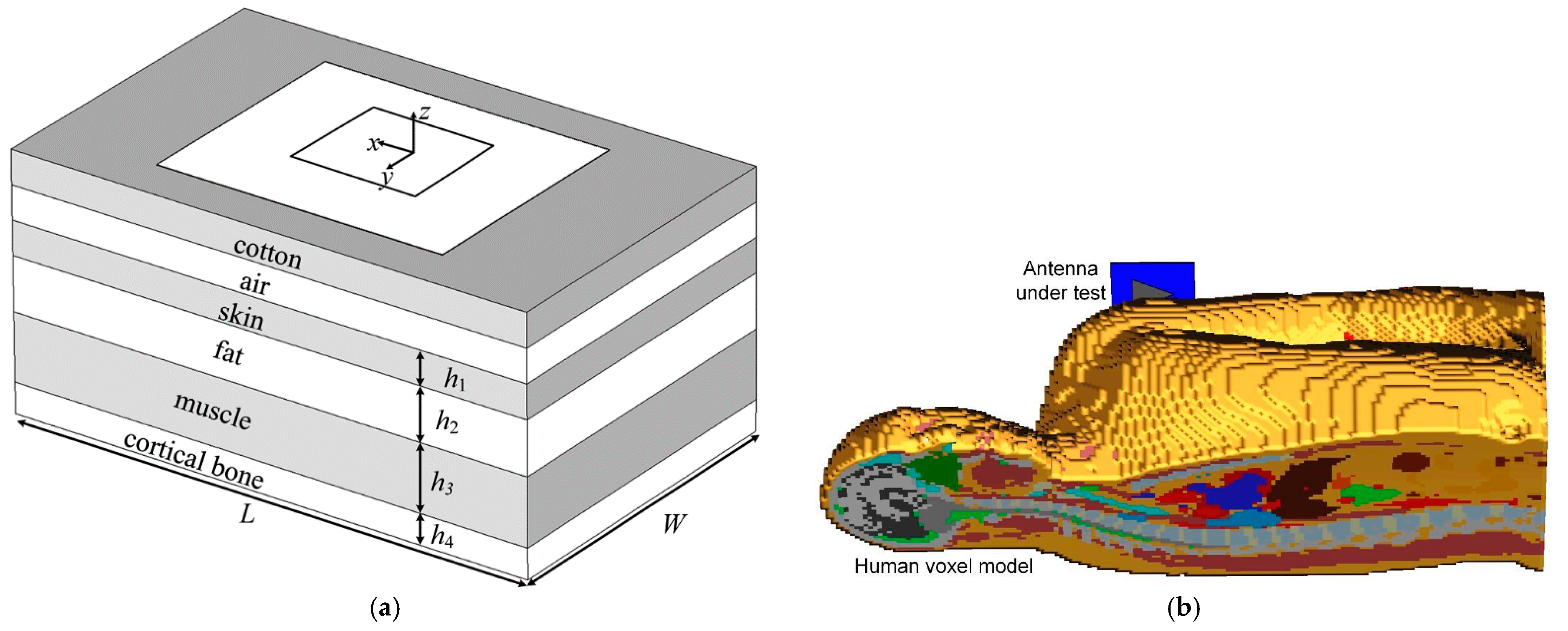

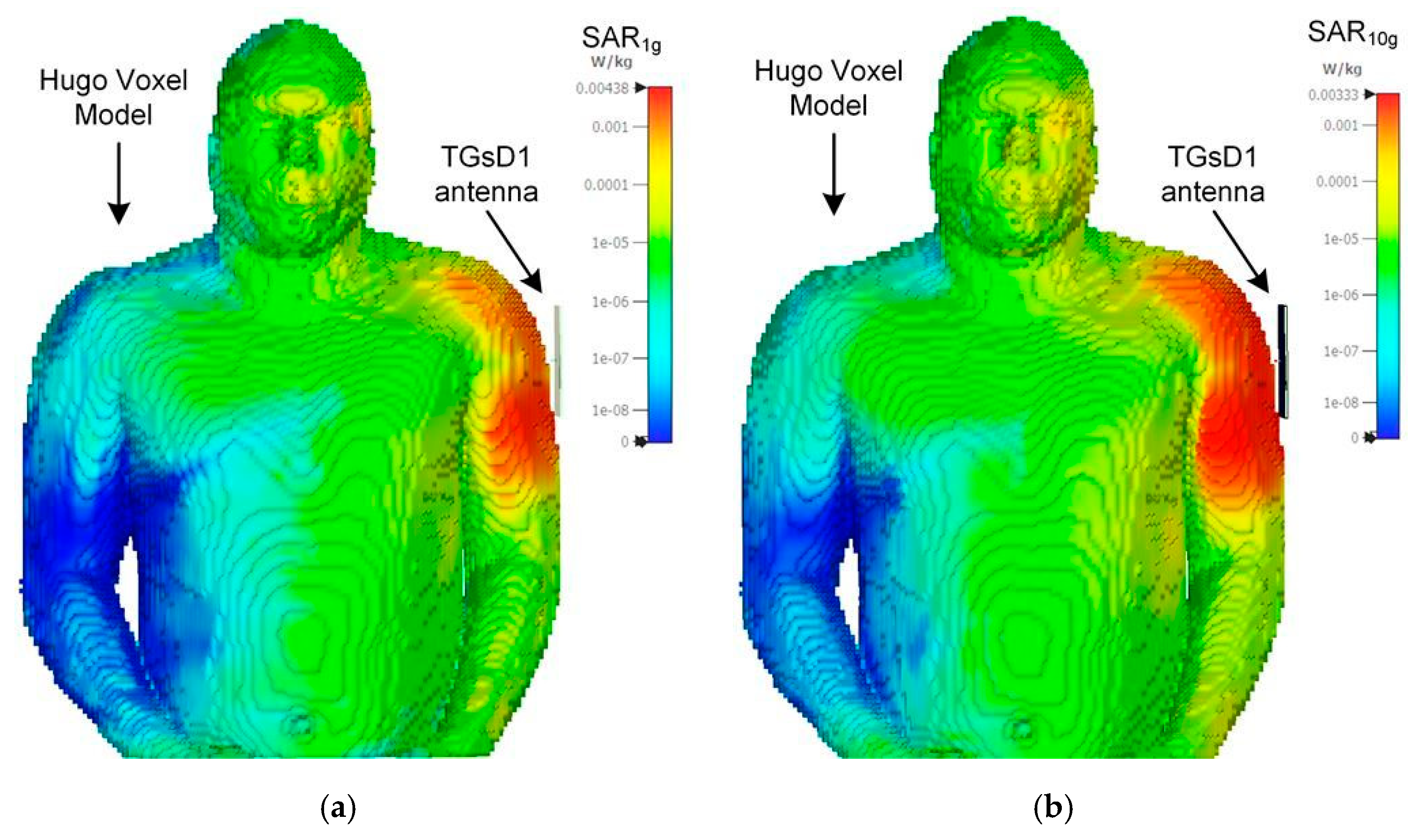

3.4. SAR Εvaluation

3.5. Comparisons

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hall, P.; Hao, Y. Antennas and Radio Propagation for Body-Centric Wireless Communications; Artech House: London, UK, 2006. [Google Scholar]

- Moradi, E.; Koski, K.; Bjorninen, T.; Sydanheimo, L.; Rabaey, J.M.; Carmena, J.M.; Rahmat-Samii, Y.; Ukkonen, L. Miniature implantable and wearable on-body antennas: Towards the new era of wireless body-centric systems. IEEE Antennas Propag. Mag. 2014, 56, 271–291. [Google Scholar]

- Sun, H.; Hu, Y.; Ren, R.; Zhao, L.; Li, F. Design of pattern-reconfigurable wearable antennas for body-centric communications. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 1385–1389. [Google Scholar] [CrossRef]

- Kirtania, S.G.; Elger, A.W.; Hasan, R.; Wisniewska, A.; Sekhar, K.; Karacolak, T.; Sekhar, P.K. Flexible antennas: A review. Micromachines 2020, 11, 847. [Google Scholar] [CrossRef] [PubMed]

- Loss, C.; Goncalves, R.; Lopes, C.; Pinho, P.; Salvado, R. Smart coat with a fully-embedded textile antenna for IoT applications. Sensors 2016, 16, 938. [Google Scholar] [CrossRef] [PubMed]

- Almohammed, B.; Ismail, A.; Sali, A. Electro-textile wearable antennas in wireless body area networks: Materials, antenna design, manufacturing techniques, and human body consideration-A review. Text. Res. J. 2021, 91, 646–663. [Google Scholar] [CrossRef]

- Khaleel, H. Innovation in Wearable and Flexible Antennas; WIT Press: Hampshire, UK, 2015. [Google Scholar]

- Lilja, J.; Salonen, P.; Kaija, T.; de Maagt, P. Design and manufacturing of robust textile antennas for harsh environments. IEEE Trans. Antennas Propagat. 2012, 60, 4130–4140. [Google Scholar] [CrossRef]

- Salvado, R.; Loss, C.; Concalves, R.; Pinho, P. Textile materials for the design of wearable antennas: A survey. Sensors 2012, 12, 15841–15857. [Google Scholar] [CrossRef] [PubMed]

- Pavec, M.; Kapetanakis, T.N.; Ioannidou, M.P.; Nikolopoulos, C.D.; Baklezos, A.T.; Soukup, R.; Blecha, T.; Hamacek, A.; Vardiambasis, I.O. Implementation of an all-textile bow-tie antenna for the 868 MHz ISM band. In Proceedings of the 2020 International Symposium on Electromagnetic Compatibility (EMC Europe 2020), Rome, Italy, 23–25 September 2020. [Google Scholar]

- Kapetanakis, T.N.; Pavec, M.; Ioannidou, M.P.; Nikolopoulos, C.D.; Baklezos, A.T.; Soukup, R.; Vardiambasis, I.O. Embroidered bow-tie wearable antenna for the 868 and 915 MHz ISM bands. Electronics 2021, 10, 1983. [Google Scholar] [CrossRef]

- Kiourti, A.; Lee, C.; Volakis, J.L. Fabrication of textile antennas and circuits with 0.1mm precision. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 151–153. [Google Scholar] [CrossRef]

- Tsolis, A.; Whittow, W.G.; Alexandridis, A.A.; Vardaxoglou, J.C. Embroidery and related manufacturing techniques for wearable antennas: Challenges and opportunities. Electronics 2014, 3, 314–338. [Google Scholar] [CrossRef] [Green Version]

- Zhong, J.; Lee, C.W.; Papantonis, D.; Kiourti, A.; Volakis, J.L. Body-worn 30:1 bandwidth tightly coupled dipole array on conductive textiles. IEEE Antennas Wirel. Propag Lett. 2018, 7, 723–726. [Google Scholar] [CrossRef]

- Kiourti, A.; Volakis, J.L. Colorful textile antennas integrated into embroidered logos. J. Sens. Actuator Netw. 2015, 4, 371–377. [Google Scholar] [CrossRef]

- Tak, J.; Choi, J. An all-textile Louis Vuitton logo antenna. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1211–1214. [Google Scholar] [CrossRef]

- Yadav, A.; Kumar Singh, V.; Kumar Bhoi, A.; Marques, G.; Garcia-Zapirain, B.; de la Torre Díez, I. Wireless body area networks: UWB wearable textile antenna for telemedicine and mobile health systems. Micromachines 2020, 11, 558. [Google Scholar] [CrossRef]

- Ahmed, M.I.; Ahmed, M.F.; Shaalan, A.-E.H. SAR calculations of novel textile dual-layer UWB lotus antenna for astronauts spacesuit. Prog. Electromagn. Res. C 2018, 82, 135–144. [Google Scholar] [CrossRef] [Green Version]

- Bharadwaj, R.; Swaisaenyakorn, S.; Parini, C.G.; Batchelor, J.C.; Alomainy, A. Impulse radio ultra-wideband communications for localization and tracking of human body and limbs movement for healthcare applications. IEEE Trans. Antennas Propagat. 2017, 65, 7298–7309. [Google Scholar] [CrossRef]

- Singh, V.K.; Dhupkariya, S.; Bangari, N. Wearable ultra wide dual band flexible textile antenna for WiMax/WLAN application. Wirel. Pers. Commun. 2017, 95, 1075–1086. [Google Scholar] [CrossRef]

- Gao, Y.; Zheng, Y.; Diao, S.; Toh, W.-D.; Ang, C.-W.; Je, M.; Heng, C.-H. Low-power ultrawideband wireless telemetry transceiver for medical sensor applications. IEEE Trans. Biomed. Eng. 2011, 58, 768–772. [Google Scholar] [CrossRef]

- Ziai, M.A.; Batchelor, J.C. Temporary on-skin passive UHF RFID transfer tag. IEEE Trans. Antennas Propagat. 2011, 59, 3565–3571. [Google Scholar] [CrossRef]

- Liu, F.X.; Xu, Z.; Ranasinghe, D.C.; Fumeaux, C. Textile folded half-mode substrate-integrated cavity antenna. IEEE Antennas Wirel. Propagat. Lett. 2016, 15, 1693–1697. [Google Scholar] [CrossRef]

- Hong, Y.; Tak, J.; Choi, J. An all-textile SIW cavity-backed circular ring-slot antenna for WBAN applications. IEEE Antennas Wirel. Propagat. Lett. 2016, 15, 1995–1999. [Google Scholar] [CrossRef]

- Amendola, S.; Bovesecchi, G.; Palombi, A.; Coppa, P.; Marrocco, G. Design, calibration and experimentation of an epidermal RFID sensor for remote temperature monitoring. IEEE Sens. J. 2016, 16, 7250–7257. [Google Scholar] [CrossRef]

- Islam, M.; Alam, T.; Yahya, I.; Cho, M. Flexible radio-frequency identification (RFID) tag antenna for sensor applications. Sensors 2018, 18, 4212. [Google Scholar] [CrossRef] [Green Version]

- Maleky, O.E.; Abdelouahab, F.B.; Essaaidi, M.; Ali Ennasar, M. Design of simple printed dipole antenna on flexible substrate for UHF band. Procedia Manuf. 2018, 22, 428–435. [Google Scholar] [CrossRef]

- Moradi, B.; Fernandez-Garcia, R.; Gil, I. Wearable high-performance meander ring dipole antenna for electronic-textile applications. J. Text. Instit. 2020, 111, 178–182. [Google Scholar] [CrossRef]

- Sreemathy, R.; Hake, S.; Sulakhe, S.; Behera, S. Slit loaded textile microstrip antennas. IETE J. Res. 2020, 1–9. [Google Scholar] [CrossRef]

- Ansari, J.A.; Singh, P.; Yadav, N.P. Analysis of wideband multilayer patch antenna with two parasitic elements. Microw. Opt. Technol. Lett. 2009, 51, 1397–1401. [Google Scholar] [CrossRef]

- Abdelgwad, A.H. Microstrip patch antenna enhancement techniques. Int. J. Electron. Commun. Eng. 2018, 12, 703–710. [Google Scholar]

- Mohamadzade, B.; Lalbakhsh, A.; Simorangkir, R.B.V.B.; Rezaee, A.; Hashmi, R.M. Mutual coupling reduction in microstrip array antenna by employing cut side patches and EBG structures. Prog. Electromagn. Res. M 2020, 89, 179–187. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, M.; Kashani, F.H.; Ghalibafan, J. A compact planar monopulse combining network at W-band. In Proceedings of the 5th IEEE GCC Conference & Exhibition, Kuwait City, Kuwait, 17–19 March 2009; pp. 1–5. [Google Scholar]

- Lalbakhsh, A.; Afzal, M.U.; Esselle, K.P.; Smith, S.L.; Zeb, B.A. Single-dielectric wideband partially reflecting surface with variable reflection components for realization of a compact high-gain resonant cavity antenna. IEEE Trans. Antennas Propag. 2019, 67, 1916–1921. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Virdee, B.S.; Azpilicueta, L.; Naser-Moghadasi, M.; Akinsolu, M.O.; See, C.H.; Abd-Alhameed, R.A.; Falcone, F.; Huynen, I.; Denidni, T.A.; et al. A comprehensive survey of “Metamaterial transmission-line based antennas: Design, challenges, and applications”. IEEE Access 2020, 8, 144778–144808. [Google Scholar] [CrossRef]

- Shirkolaei, M.M.; Jafari, M. A new class of wideband microstrip falcate patch antennas with reconfigurable capability at circular-polarization. Microw. Opt. Technol. Lett. 2020, 62, 3922–3927. [Google Scholar] [CrossRef]

- Gooran, P.R.; Lalbakhsh, A.; Moradi, H.; Jamshidi, M. Compact and wideband printed log-periodic dipole array antenna using multi-sigma and multi-Tau techniques. J. Electromagn. Waves Appl. 2019, 33, 697–706. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Babaeian, F.; Virdee, B.S.; Aissa, S.; Azpilicueta, L.; See, C.H.; Althuwayb, A.A.; Huynen, I.; Abd-Alhameed, R.A.; Falcone, F.; et al. A comprehensive survey on “Various decoupling mechanisms with focus on metamaterial and metasurface principles applicable to SAR and MIMO antenna systems”. IEEE Access 2020, 8, 192965–193004. [Google Scholar] [CrossRef]

- Shirkolaei, M.M.; Ghalibafan, J. Scannable leaky-wave antenna based on ferrite-blade waveguide operated below the cutoff frequency. IEEE Trans. Magn. 2021, 57, 1–10. [Google Scholar] [CrossRef]

- Kenari, M.A. Printed planar patch antennas based on metamaterial. Int. J. Electron. Lett. 2014, 2, 37–42. [Google Scholar] [CrossRef]

- Zhang, J.; Song, R.; Zhao, X.; Fang, R.; Zhang, B.; Qian, W.; Zhang, J.; Liu, C.; He, D. Flexible graphene-assembled film-based antenna for wireless wearable sensor with miniaturized size and high sensitivity. ACS Omega 2020, 5, 12937–12943. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Leng, T.; Chang, K.H.; Chen, J.C.; Novoselov, K.S.; Hu, Z. Graphene radio frequency and microwave passive components for low cost wearable electronics. 2D Mater. 2016, 3, 25021. [Google Scholar] [CrossRef]

- Song, R.; Wang, Q.; Mao, B.; Wang, Z.; Tang, D.; Zhang, B.; Zhang, J.; Liu, C.; He, D.; Wu, Z.; et al. Flexible graphite films with high conductivity for radio-frequency antennas. Carbon 2018, 130, 164–169. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Z.; Song, R.; Fu, H.; Zhao, X.; Zhang, C.; He, D.; Wu, Z.P. Passive UHF RFID tags made with graphene assembly film-based antennas. Carbon 2021, 178, 803–809. [Google Scholar] [CrossRef]

- Kumar, J.; Basu, B.; Talukdar, F.; Nandi, A. Graphene-based multimode inspired frequency reconfigurable user terminal antenna for satellite communication. IET Commun. 2018, 12, 67–74. [Google Scholar] [CrossRef]

- Lamminen, A.; Arapov, K.; de With, G.; Haque, S.; Sandberg, H.G.O.; Friedrich, H.; Ermolov, V. Graphene-flakes printed wideband elliptical dipole antenna for low-cost wireless communications applications. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1883–1886. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Ma, C.; Zhang, X.; Shen, J.; Hanagata, N.; Huangfu, J.; Xu, M. High-performance printable 2.4 GHz graphene-based antenna using water-transferring technology. Sci. Technol. Adv. Mater. 2019, 20, 870–875. [Google Scholar] [CrossRef] [Green Version]

- Paul, D.L.; Giddens, H.; Paterson, M.G.; Hilton, G.S.; McGeehan, J.P. Impact of body and clothing on a wearable textile dual band antenna at digital television and wireless communications bands. IEEE Trans. Antennas Propagat. 2013, 61, 2188–2194. [Google Scholar] [CrossRef]

- Wang, Z.; Lee, L.Z.; Psychoudakis, D.; Volakis, J.L. Embroidered multiband body-worn antenna for GSM/PCS/WLAN communications. IEEE Trans. Antennas Propagat. 2014, 62, 3321–3329. [Google Scholar] [CrossRef]

- Zhang, S.; Paraskevopoulos, A.; Luxey, C.; Pinto, J.; Whittow, W. Broad-band embroidered spiral antenna for off-body communications. IET Microw. Antennas Propag. 2016, 10, 1395–1401. [Google Scholar] [CrossRef] [Green Version]

- Paraskevopoulos, A.; de Sousa Fonseca, D.; Seager, R.D.; Whittow, W.; Alexandridis, A.A. Higher-mode textile patch antenna with embroidered vias for on-body communication. IET Microw. Antennas Propag. 2016, 10, 802–807. [Google Scholar] [CrossRef] [Green Version]

- Gil, I.; Fernadez-Garcia, R. Wearable PIFA antenna implemented on jean substrate for wireless body area network. J. Electromagn. Waves Appl. 2017, 31, 1194–1204. [Google Scholar] [CrossRef]

- Anbalagan, A.; Sundarsingh, E.F.; Ramalingam, V.S. Design and experimental evaluation of a novel on-body textile antenna for unicat applications. Microw. Opt. Technol. Lett. 2020, 62, 789–799. [Google Scholar] [CrossRef]

- Mao, C.X.; Vital, D.; Werner, D.H.; Wu, Y.; Bhardwai, S. Dual-polarized embroidered textile armband antenna array with omnidirectional radiation for on-/off-body wearable applications. IEEE Trans. Antennas Propagat. 2020, 68, 2575–2584. [Google Scholar] [CrossRef]

- Balanis, C.A. Antenna Theory: Analysis and Design, 4th ed.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Dassault Systemes Simulia. CST Studio Suite Electromagnetic Field Simulation Software, Version 2021. Available online: https://www.3ds.com/products-services/simulia/products/cst-studio-suite/ (accessed on 9 October 2021).

- Milligan, T.A. Modern Antenna Design, 2nd ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Sankaralingam, S.; Gupta, B. Determination of dielectric constant of fabric materials and their use as substrates for design and development of antennas for wearable applications. IEEE Trans. Instrum. Meas. 2010, 59, 3122–3130. [Google Scholar] [CrossRef]

- Memon, A.W.; de Paula, I.L.; Malengier, B.; Vasile, S.; Van Torre, P.; Van Langenhove, L. Breathable textile rectangular ring microstrip patch antenna at 2.45 GHz for wearable applications. Sensors 2021, 21, 1635. [Google Scholar] [CrossRef] [PubMed]

- Aaronia, A.G. Shielding Material Aaronia X-Dream. Available online: https://aaronia.com/shielding-materials/aaronia-x-dream/ (accessed on 9 October 2021).

- Sigma-Aldrich. Graphene Paper XG Leaf. Available online: https://www.sigmaaldrich.com (accessed on 9 October 2021).

- 3M Venture Tape Copper Foil Sheet with Electrically Conductive Acrylic Adhesive. Available online: https://www.3m.com/3M/en_US/p/c/tapes/foil/copper/ (accessed on 9 October 2021).

- IEC/IEEE International Standard. Determining the Peak Spatial-Average Specific Absorption Rate (SAR) in the Human Body from Wireless Communications Devices, 30 MHz to 6 GHz-Part 1: General Requirements for Using the Finite-Difference Time-Domain (FDTD) Method for SAR Calculations; IEC/IEEE 62704-1:2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–86. [Google Scholar]

- IEEE-SA Standards Board. IEEE Recommended Practice for Measurements and Computations of Radio Frequency Electromagnetic Fields with Respect to Human Exposure to Such Fields, 100 kHz 300 GHz; IEEE Std C95.3-2002 (Revision of IEEE Std C95.3-1991); no. 4; IEEE: Piscataway, NJ, USA, 2002; pp. 1–126. [Google Scholar]

- Gabriel, S.; Lau, R.W.; Gabriel, C. The dielectric properties of biological tissues: II. Measurements in the frequency range 10 Hz to 20 GHz. Phys. Med. Biol. 1996, 41, 2251–2269. [Google Scholar] [CrossRef] [Green Version]

- Andreuccetti, D.; Fossi, R.; Petrucci, C. An Internet Resource for the Calculation of the Dielectric Properties of Body Tissues in the Frequency Range 10Hz–100GHz; IFAC-CNR: Florence, Italy, 1997. [Google Scholar]

- Akbari, M.; Khan, M.W.A.; Hasani, M.; Bjorninen, T.; Sydanheimo, L.; Ukkonen, L. Fabrication and characterization of graphene antenna for low-cost and environmentally friendly RFID tags. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1569–1572. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, C.; Wang, Y.; Wang, Z.; Liu, C.; He, D.; Wu, Z.P. Flexible anti-metal RFID tag antenna based on high-conductivity graphene assembly film. Sensors 2021, 21, 1513. [Google Scholar] [CrossRef]

- Ibanez Labiano, I.; Alomainy, A. Flexible inkjet-printed graphene antenna on Kapton. Flex. Print. Electron. 2021, 6, 25010. [Google Scholar] [CrossRef]

- Elmobarak, H.A.; Rahim, S.K.A.; Abedian, M.; Soh, P.J.; Vandenbosch, G.A.E.; Yew Chiong, L. Assessment of multilayered graphene technology for flexible antennas at microwave frequencies. Microw. Opt. Technol. Lett. 2017, 59, 2604–2610. [Google Scholar] [CrossRef]

- Potey, P.M.; Tuckley, K. Design of wearable textile antenna for low back radiation. J. Electromagn. Waves Appl. 2020, 34, 235–245. [Google Scholar] [CrossRef]

| Rectangular Antenna Prototype | RTcD1 | RTcD2 | RTcF1 | RTcF2 | RGsD1 | RGsD2 | RGsF1 | RGsF2 | RCsD1 | RCsD2 | RCsF1 | RCsF2 |

| Patch Material | Tc | Tc | Tc | Tc | Gs | Gs | Gs | Gs | Cs | Cs | Cs | Cs |

| Substate Material | D1 | D2 | F1 | F2 | D1 | D2 | F1 | F2 | D1 | D2 | F1 | F2 |

| Patch Length Lp (mm) | 40.6 | 35.1 | 50.5 | 45.2 | 44.0 | 41.6 | 51.5 | 48.5 | 45.6 | 43.8 | 52.8 | 49.6 |

| Patch Width Wp (mm) | 53.0 | 51.7 | 59.3 | 56.6 | 53.0 | 51.7 | 59.3 | 56.6 | 53.0 | 51.7 | 59.3 | 56.6 |

| Feeding point (xf, yf) (mm) | (1.9, 3.1) | (9.7, 2.0) | (3.4, 13.7) | (0.0, 6.2) | (3.8, 4.5) | (15.5, 4.2) | (6.7, 15.8) | (2.0, 13.2) | (19.8, 6.9) | (5.7, 2.0) | (4.3, 16.2) | (7.9, 15.1) |

| Substrate Length L (mm) | 81.3 | 70.2 | 101.0 | 90.4 | 88.0 | 83.1 | 103.1 | 96.9 | 91.2 | 87.7 | 105.6 | 99.1 |

| Substrate Width W (mm) | 106.0 | 103.4 | 118.6 | 113.2 | 106.0 | 103.4 | 118.6 | 113.2 | 106.0 | 103.4 | 118.6 | 113.2 |

| Triangular Antenna Prototype | TTcD1 | TTcD2 | TTcF1 | TTcF2 | TGsD1 | TGsD2 | TGsF1 | TGsF2 | TCsD1 | TCsD2 | TCsF1 | TCsF2 |

| Patch Material | Tc | Tc | Tc | Tc | Gs | Gs | Gs | Gs | Cs | Cs | Cs | Cs |

| Substate Material | D1 | D2 | F1 | F2 | D1 | D2 | F1 | F2 | D1 | D2 | F1 | F2 |

| Patch Length Lp (mm) | 45.5 | 39.7 | 56.2 | 51.4 | 48.8 | 44.4 | 58.5 | 56.5 | 52.4 | 50.4 | 59.2 | 56.7 |

| Patch Width Wp (mm) | 62.3 | 59.8 | 69.5 | 67.3 | 62.3 | 59.8 | 69.5 | 67.3 | 62.3 | 59.8 | 69.5 | 67.3 |

| Feeding point xf (mm) | 17.0 | 10.3 | 27.3 | 24.2 | 18.5 | 12.1 | 28.7 | 27.6 | 20.4 | 15.0 | 29.4 | 27.7 |

| Substrate Length L (mm) | 91.0 | 79.4 | 112.4 | 102.8 | 97.5 | 88.8 | 117.0 | 113.0 | 104.9 | 100.7 | 118.4 | 113.3 |

| Substrate Width W (mm) | 124.6 | 119.5 | 139.0 | 134.6 | 124.6 | 119.5 | 139.0 | 134.6 | 124.6 | 119.5 | 139.0 | 134.6 |

| Circular Antenna Prototype | CTcD1 | CTTcD2 | CTcF1 | CTcF2 | CGsD1 | CGsD2 | CGsF1 | CGsF2 | CCsD1 | CCsD2 | CCsF1 | CCsF2 |

| Patch Material | Tc | Tc | Tc | Tc | Gs | Gs | Gs | Gs | Cs | Cs | Cs | Cs |

| Substate Material | D1 | D2 | F1 | F2 | D1 | D2 | F1 | F2 | D1 | D2 | F1 | F2 |

| Patch Diameter D (mm) | 48.0 | 42.7 | 59.1 | 53.8 | 52.8 | 50.1 | 55.3 | 48.6 | 54.7 | 52.2 | 61.7 | 58.9 |

| Feeding Point (xf, yf) (mm) | (14.5, 13.2) | (12.4, 8.8) | (12.8, 0.1) | (9.5, 10.3) | (15.5, 10.8) | (21.3, 1.2) | (20.5, 7.0) | (21.6, 2.6) | (15.7, 13.4) | (12.6, 8.1) | (9.9, 19.6) | (10.4, 16.5) |

| Substrate Length L and Width W (mm) | 144.1 | 128.0 | 177.2 | 161.4 | 158.3 | 150.4 | 165.9 | 145.7 | 164.1 | 156.5 | 185.2 | 176.6 |

| Antenna Prototype | RTcF1 | RGsF1 | TTcD1 | TTcF1 | TGsD1 | TCsD2 | CTcF1 | CTcF2 | CGsD1 | CGsF1 | CCsD1 | CCsF1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| fc (MHz) Simulated | 2450 | 2450 | 2450 | 2450 | 2450 | 2447 | 2457 | 2450 | 2451 | 2433 | 2441 | 2448 |

| fc (MHz) Measured | 2454 | 2464 | 2439 | 2461 | 2446 | 2459 | 2447 | 2428 | 2443 | 2457 | 2454 | 2464 |

| S11 (dB) @ fc Simulated | −53.8 | −55.4 | −56.7 | −58.8 | −53.0 | −53.0 | −35.4 | −49.0 | −45.5 | −29.6 | −61.1 | −45.9 |

| S11 (dB) @ fc Measured | −22.36 | −19.47 | −22.50 | −20.59 | −19.54 | −18.06 | −21.45 | −21.78 | −18.79 | −18.57 | −19.65 | −23.85 |

| VSWR @ fc Simulated | 1.004 | 1.003 | 1.003 | 1.002 | 1.004 | 1.004 | 1.035 | 1.007 | 1.011 | 1.068 | 1.002 | 1.010 |

| VSWR @ fc Measured | 1.2373 | 1.2376 | 1.1618 | 1.2059 | 1.2355 | 1.2856 | 1.1847 | 1.1772 | 1.2598 | 1.2672 | 1.2325 | 1.1371 |

| f1 (MHz) Simulated | 2364 | 2373 | 2353 | 2384 | 2364 | 2374 | 2374 | 2379 | 2357 | 2380 | 2364 | 2380 |

| f1 (MHz) Measured | 2371 | 2389 | 2352 | 2400 | 2373 | 2412 | 2378 | 2355 | 2363 | 2404 | 2391 | 2405 |

| f2 (MHz) Simulated | 2541 | 2532 | 2550 | 2520 | 2542 | 2524 | 2545 | 2524 | 2552 | 2511 | 2523 | 2519 |

| f2 (MHz) Measured | 2543 | 2530 | 2521 | 2523 | 2539 | 2518 | 2482 | 2525 | 2513 | 2521 | 2526 | 2543 |

| −10 dB BW (MHz) Simulated | 177 | 159 | 197 | 136 | 178 | 150 | 171 | 145 | 195 | 131 | 159 | 139 |

| −10 dB BW (MHz) Measured | 167 | 154 | 178 | 121 | 150 | 127 | 140 | 127 | 162 | 109 | 130 | 121 |

| −10 dB BW (%) Simulated | 7.2 | 6.5 | 8.0 | 5.6 | 7.3 | 6.1 | 7.0 | 5.9 | 8.0 | 5.4 | 6.5 | 5.7 |

| −10 dB BW (%) Measured | 6.8 | 6.3 | 7.3 | 4.9 | 6.1 | 5.2 | 5.7 | 5.2 | 6.6 | 4.4 | 5.3 | 4.9 |

| Rectangular Antenna Prototype | RTcD1 | RTcD2 | RTcF1 | RTcF2 | RGsD1 | RGsD2 | RGsF1 | RGsF2 | RCsD1 | RCsD2 | RCsF1 | RCsF2 |

| Directivity (dB) | 8.36 | 8.15 | 9.09 | 8.79 | 8.52 | 8.37 | 9.2 | 8.92 | 8.64 | 8.45 | 9.26 | 9.01 |

| Efficiency | 14.0% | 8.5% | 53.0% | 32.2% | 13.1% | 6.7% | 53.5% | 32.3% | 14.5% | 8.0% | 56.7% | 37.6% |

| Gain (dBi) Simulated | −0.20 | −2.55 | 6.33 | 3.86 | −0.31 | −0.37 | 6.49 | 4.00 | 0.24 | −2.50 | 6.80 | 4.74 |

| Gain (dBi) Measured | −1.10 | −4.23 | 5.22 | 2.67 | −1.24 | −4.79 | 5.98 | 3.35 | −0.39 | −3.46 | 5.67 | 3.29 |

| Triangular Antenna Prototype | TTcD1 | TTcD2 | TTcF1 | TTcF2 | TGsD1 | TGsD2 | TGsF1 | TGsF2 | TCsD1 | TCsD2 | TCsF1 | TCsF2 |

| Directivity (dB) | 8.13 | 7.78 | 9.21 | 8.75 | 8.34 | 7.99 | 9.32 | 9.06 | 8.57 | 8.32 | 9.36 | 9.04 |

| Efficiency | 10.3% | 5.2% | 45.9% | 25.9% | 9.9% | 5.0% | 45.9% | 30.5% | 10.7% | 5.5% | 49.5% | 30.3% |

| Gain (dBi) Simulated | −1.73 | −5.03 | 5.83 | 2.89 | −1.69 | −5.00 | 5.94 | 3.89 | −1.16 | −4.27 | 6.30 | 3.86 |

| Gain (dBi) Measured | −2.36 | −6.35 | 4.93 | 1.98 | −2.00 | −5.89 | 4.89 | 2.77 | −2.34 | −5.23 | 5.89 | 2.47 |

| Circular Antenna Prototype | CTcD1 | CTcD2 | CTcF1 | CTcF2 | CGsD1 | CGsD2 | CGsF1 | CGsF2 | CCsD1 | CCsD2 | CCsF1 | CCsF2 |

| Directivity (dB) | 8.48 | 8.10 | 9.68 | 8.85 | 8.55 | 8.45 | 9.20 | 8.44 | 8.64 | 8.45 | 9.90 | 9.16 |

| Efficiency | 13.6% | 11.3% | 52.6% | 31.8% | 13.0% | 25.3% | 56.0% | 35.4% | 14.7% | 16.1% | 57.1% | 37.7% |

| Gain (dBi) Simulated | −0.182 | −1.38 | 6.89 | 3.88 | −0.323 | 2.48 | 6.69 | 3.94 | 0.267 | 0.525 | 7.47 | 4.92 |

| Gain (dBi) Measured | −1.03 | −2.01 | 5.48 | 2.63 | −1.07 | 1.93 | 5.45 | 2.49 | 0.14 | 0.25 | 6.22 | 3.86 |

| Tissue Type | σ (S/m) | εr | tanδ | Density (kg/m3) | Thickness (mm) |

|---|---|---|---|---|---|

| Dry skin | 1.46 | 38.0 | 0.283 | 1100 | 1.5 |

| Fat | 0.11 | 5.3 | 0.145 | 900 | 13 |

| Muscle | 1.74 | 52.7 | 0.242 | 1080 | 20 |

| Cortical bone | 0.39 | 11.4 | 0.254 | 2000 | 3.5 |

| SAR Model | Antenna Prototype | CGsD2 | CCsF2 | CTcF2 | CGsF1 | TTcD1 | TGsF2 | TGsF1 | TCsF1 | RTcD1 | RGsF1 | RTcF1 | RCsF2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Simplified Layered Model | Peak SAR 10 g tissue (W/Kg) | 0.001 | 0.001 | 0.002 | 0.002 | 0.005 | 0.010 | 0.017 | 0.017 | 0.017 | 0.024 | 0.031 | 0.034 |

| Peak SAR 1 g tissue(W/Kg) | 0.002 | 0.001 | 0.004 | 0.002 | 0.010 | 0.019 | 0.031 | 0.031 | 0.025 | 0.037 | 0.060 | 0.049 | |

| CST’s Hugo Voxel Model | Peak SAR 10 g tissue (W/Kg) | 0.002 | 0.002 | 0.016 | 0.003 | 0.017 | 0.002 | 0.003 | 0.002 | 0.012 | 0.011 | 0.033 | 0.023 |

| Peak SAR 1 g tissue (W/Kg) | 0.003 | 0.004 | 0.026 | 0.004 | 0.034 | 0.003 | 0.004 | 0.003 | 0.021 | 0.016 | 0.056 | 0.031 |

| Reference | Antenna | Active Element’s Material | Substrate’s Material | Fabrication Method | Fabrication Complexity | fc (GHz) | −10 dB BW (MHz) | VSWR | Gain (dBi) | Efficiency (%) | SAR10 g (W/kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [67] | Planar dipole | Graphene ink | Flexible | Doctor blading | Medium | 0.876 | 165 | 1.404 | −2.18 | 40 | - |

| [43] | Flexible graphite sheet (FGF) | FR4 | - | - | 0.865 | 160 | 1.061 | 1.45 | - | - | |

| [68] | L-Shaped | Graphene assembly film (GAF) | Foam | Laser cutting | Medium | 0.915 | 30 | 1.135 | −7.3 | 90 | - |

| [45] | Multilayer patches | Graphene ink | Polyimide foam -Polyimide | Print and paste | High | 3.003 5.170 6.130 | 190 160 300 | - | 2.09 | 74 | - |

| [69] | quasi-Yagi–Uda | Graphene ink | Kapton | Inkjet printing | High | 5.65 | 3000 | - | -0.95 | 42 | 1.99 |

| [70] | Rectangular patch | Graphene Based Sheet (GBS) | Flexible | Molding | High | 6 | - | 1.025 | 5.87 | 64.9 | - |

| [47] | Planar dipole with balun | Graphene ink | Flexible | Blade printing | High | 2.4 | 213 | 1.499 | 0.7 | - | - |

| [51] | Higher-mode microstrip patch antenna | Copper sheet | Felt | Embroidering | Medium | 2.4 | 151 | 1.151 | 1.0 | 55 | - |

| [52] | PIFA | Conductive yarn | Jean | Embroidering | Medium | 2.42 | 150 | 1.785 | 2.49 | 29.1 | 0.97 |

| [23] | Folded half-mode cavity | Conductive fabric | Microwave foam | Embroidering | High | 2.42 | 100 | 1.083 | 7.1 | 85 | - |

| [71] | Modified rectangular patch | Conductive fabric | Denim | Conductive adhesive | Low | 2.43 | 42 | 1.01 | 7.1 | 78 | 0.11 |

| [59] | Rectangular ring patch | Conductive fabric | 3D perforated | - | - | 2.45 | 180 | - | 5.9 | ||

| This work | Rectangular, triangular, circular patches | Conductive fabric | Denim or Felt | Heat transfer method | Low | 2.428–2.454 | 121–178 | 1.162–1.237 | −6.35–5.48 | 5.2–53.0 | 0.012–0.033 |

| Graphene sheet | 2.443–2.464 | 109–162 | 1.235–1.267 | −5.89–5.98 | 5.0–56.0 | 0.002–0.011 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapetanakis, T.N.; Nikolopoulos, C.D.; Petridis, K.; Vardiambasis, I.O. Wearable Textile Antenna with a Graphene Sheet or Conductive Fabric Patch for the 2.45 GHz Band. Electronics 2021, 10, 2571. https://doi.org/10.3390/electronics10212571

Kapetanakis TN, Nikolopoulos CD, Petridis K, Vardiambasis IO. Wearable Textile Antenna with a Graphene Sheet or Conductive Fabric Patch for the 2.45 GHz Band. Electronics. 2021; 10(21):2571. https://doi.org/10.3390/electronics10212571

Chicago/Turabian StyleKapetanakis, Theodoros N., Christos D. Nikolopoulos, Konstantinos Petridis, and Ioannis O. Vardiambasis. 2021. "Wearable Textile Antenna with a Graphene Sheet or Conductive Fabric Patch for the 2.45 GHz Band" Electronics 10, no. 21: 2571. https://doi.org/10.3390/electronics10212571

APA StyleKapetanakis, T. N., Nikolopoulos, C. D., Petridis, K., & Vardiambasis, I. O. (2021). Wearable Textile Antenna with a Graphene Sheet or Conductive Fabric Patch for the 2.45 GHz Band. Electronics, 10(21), 2571. https://doi.org/10.3390/electronics10212571