Adaptive On-Time Control Buck Converter with a Novel Virtual Inductor Current Circuit

Abstract

:1. Introduction

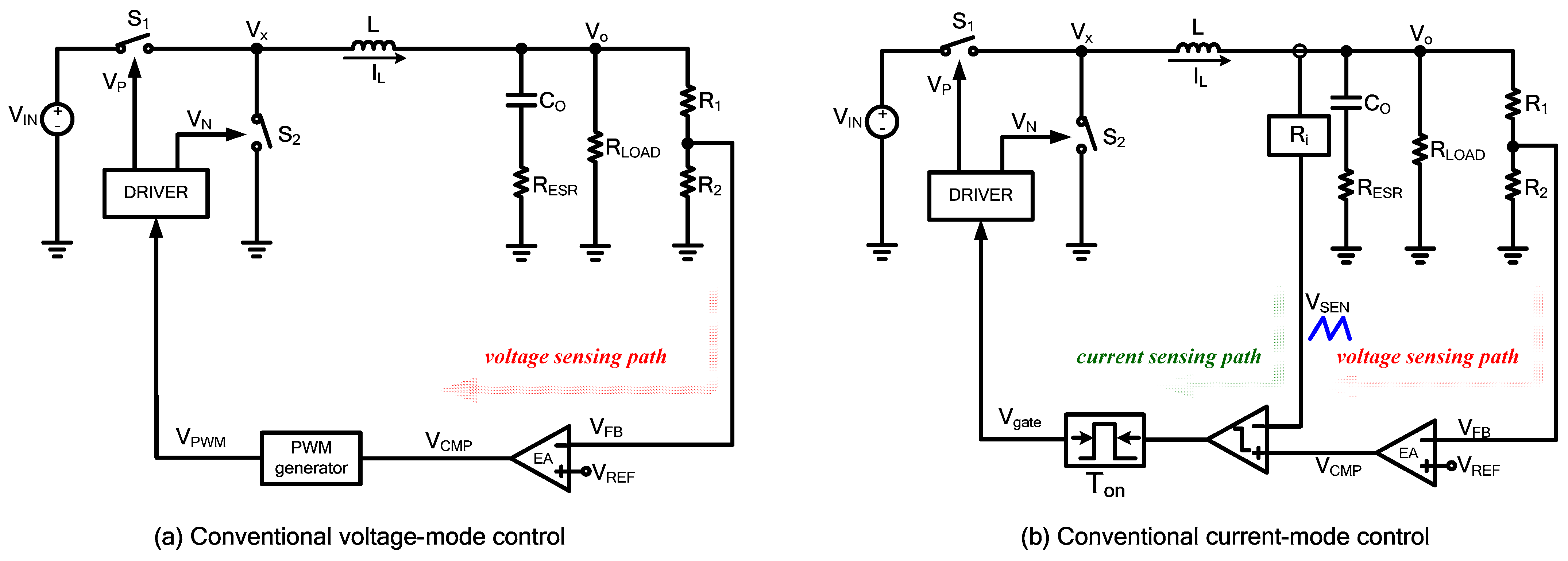

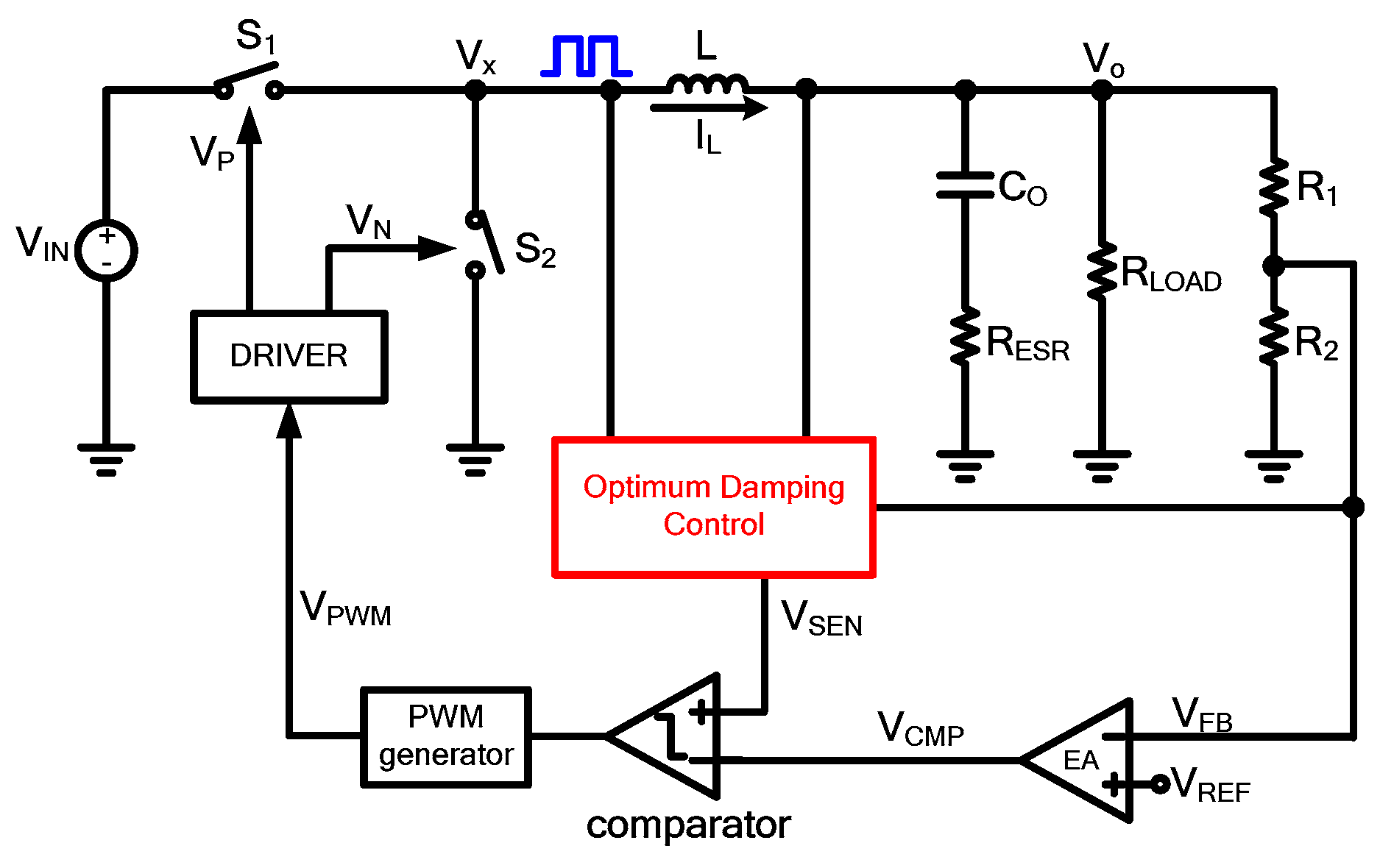

2. Conventional Control Scheme Descriptions

2.1. Current Mode COT (CM-COT) Operating Principle

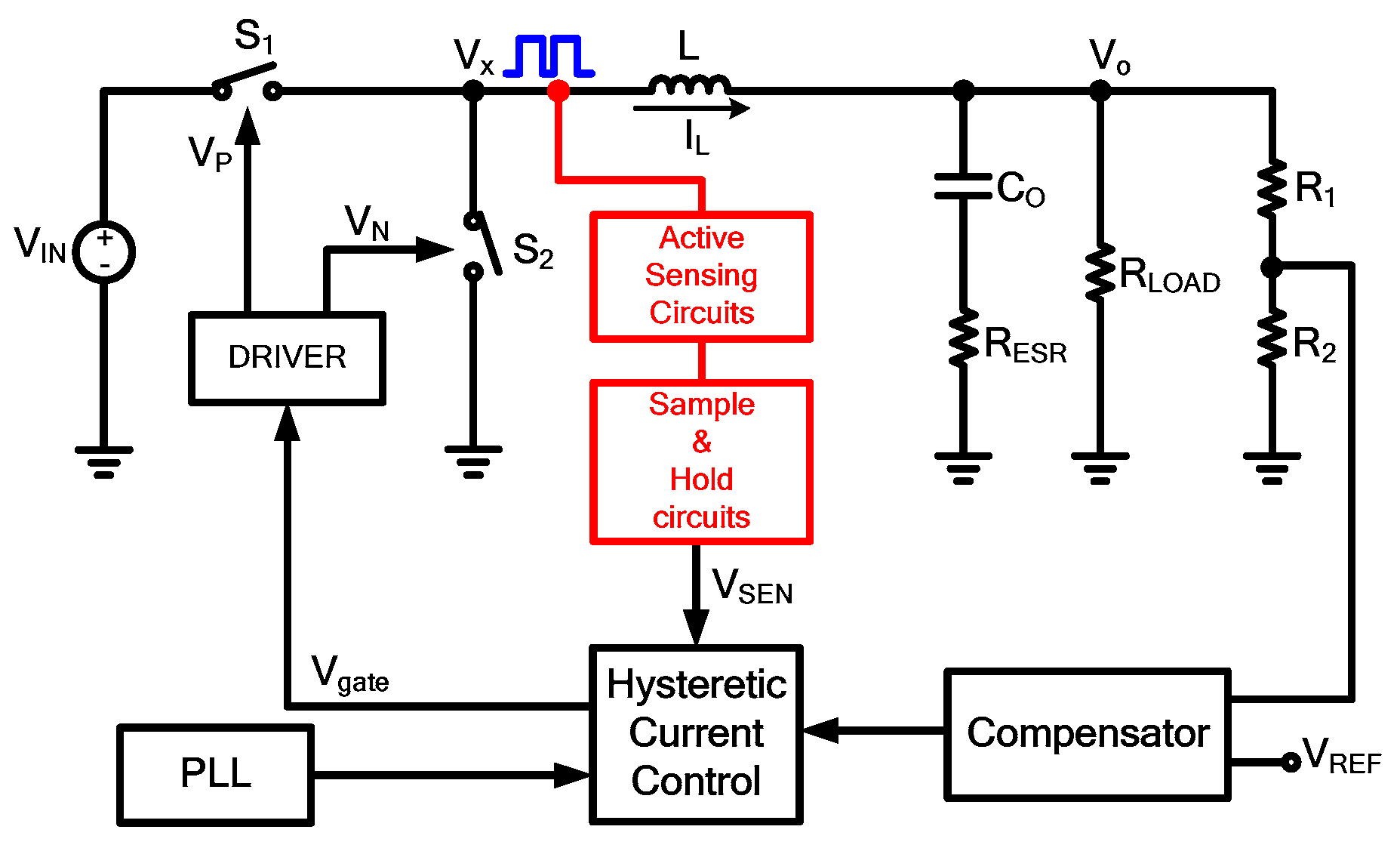

2.2. Current Mode AOT (CM-AOT) Operating Principle

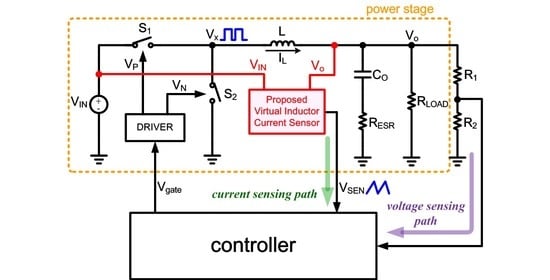

3. Proposed Control Scheme and Implementation

3.1. Operating Principle

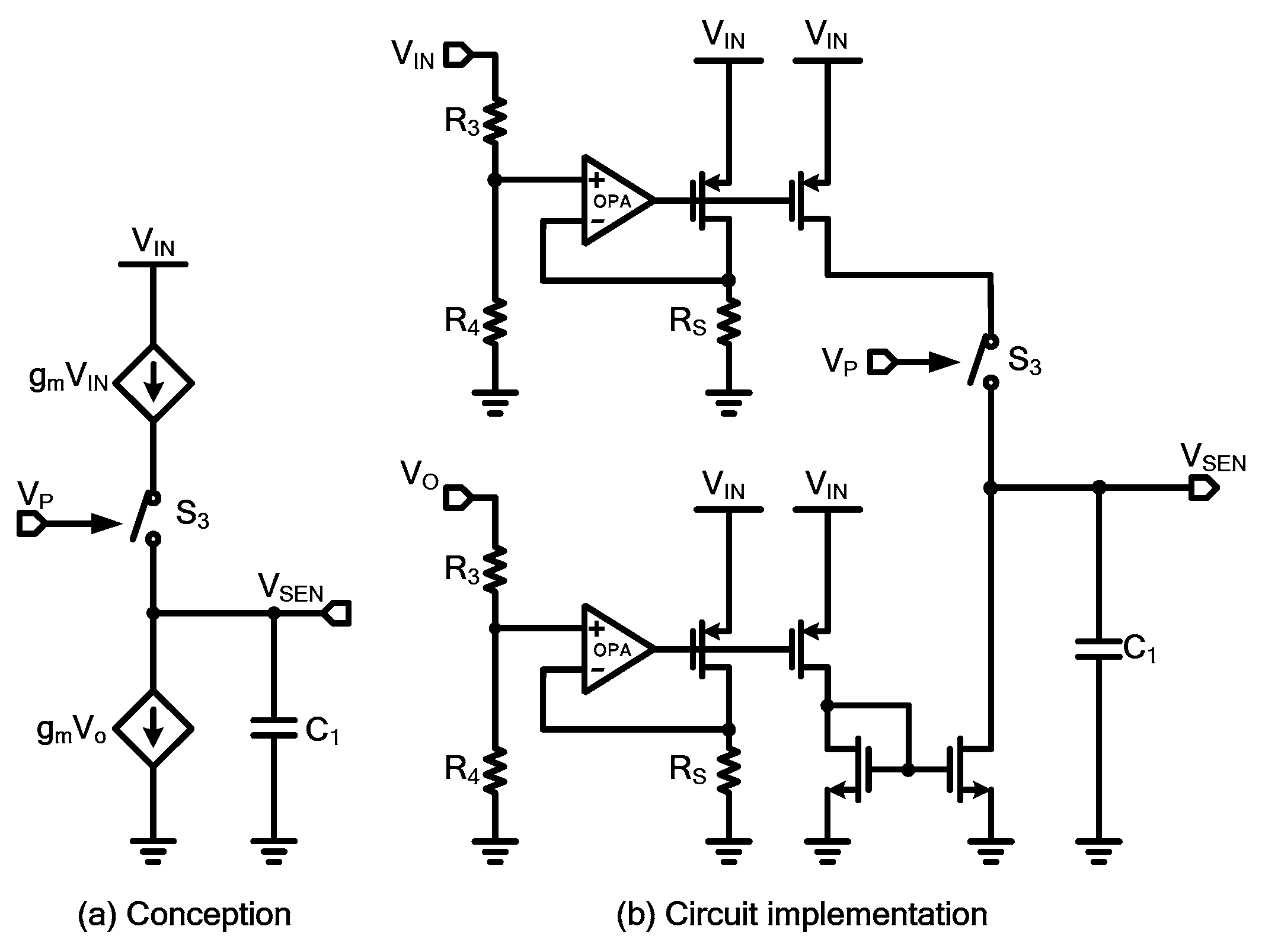

3.2. Proposed Virtual Inductor Current Sensor

4. Design Procedure

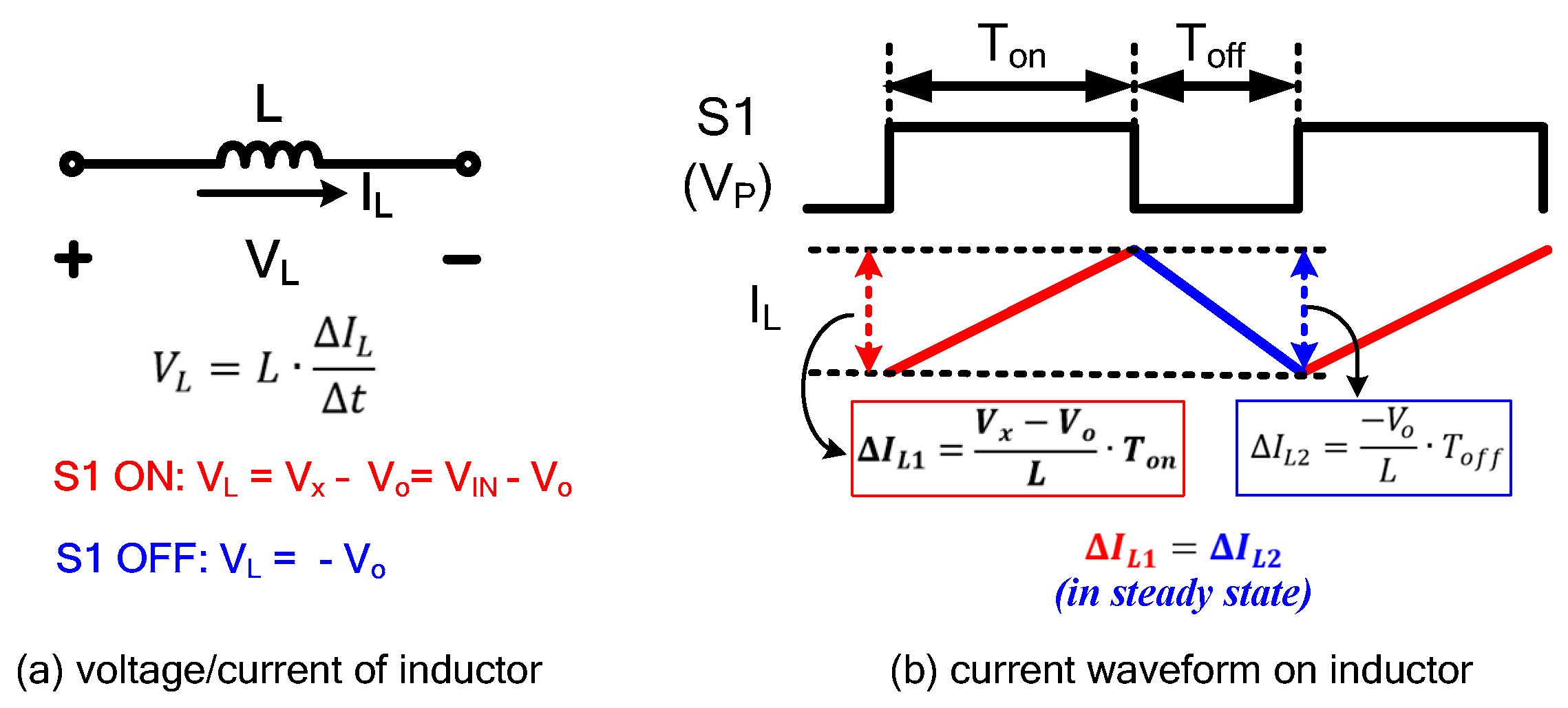

4.1. Buck Converter Modeling

4.2. Crossover Frequency fC Determination

4.3. Compensator Design

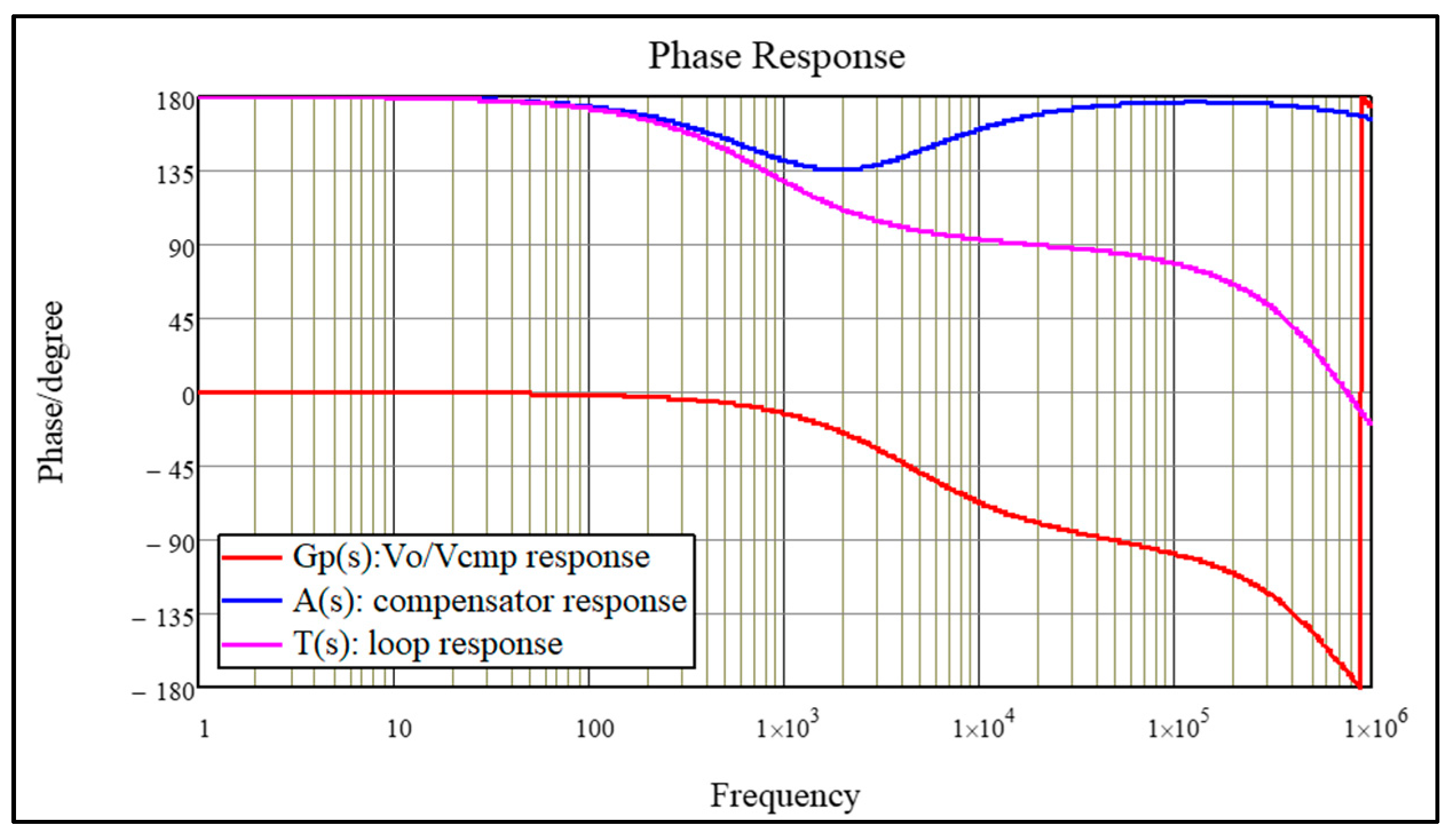

4.4. Stability Analysis

5. Simulation Results

5.1. CM-AOT SIMPLIS Schematic Building

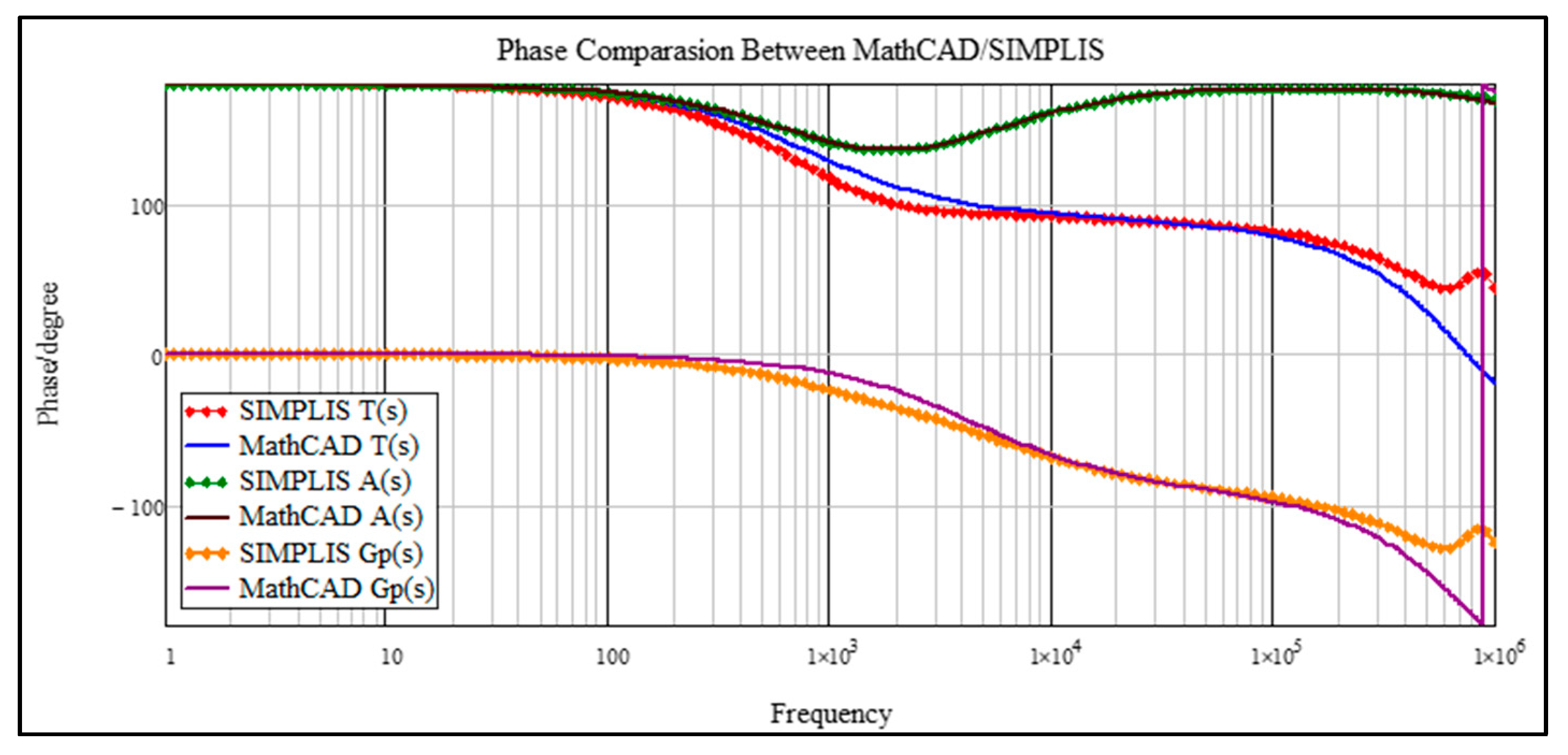

5.2. Schematic Stability Analysis

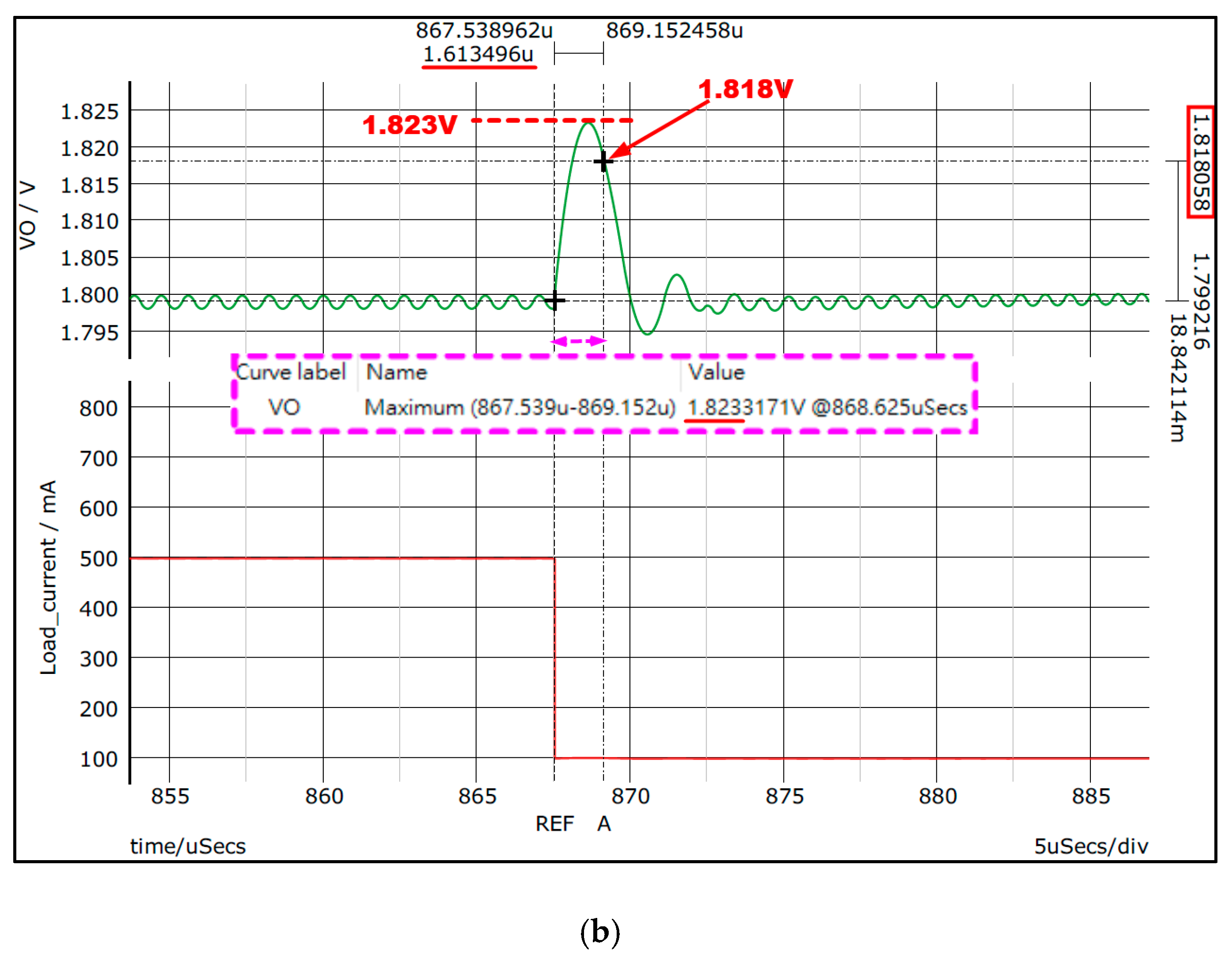

5.3. Transient Performance

5.4. Load Regulation/Line Regulation

5.5. Performance List

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, J.J.; Yang, F.C.; Chen, C.C. A new monolithic fast-response buck converter using spike-reduction current-sensing circuits. IEEE Trans. Ind. Electron. 2008, 55, 1101–1111. [Google Scholar] [CrossRef]

- Chen, J.J.; Hwang, Y.S.; Hwang, B.H.; Jhang, Y.C.; Ku, Y.T. A dual-mode fast-transient average-current-mode buck converter without slope-compensation. In Proceedings of the 2018 7th International Symposium on Next Generation Electronics(ISNE) Conference, Taipei, Taiwan, 7–9 May 2018. [Google Scholar]

- Huang, Q.; Zhan, C.; Burm, J. A 30-MHz Voltage-Mode Buck Converter Using Delay-Line-Based PWM Control. IEEE Trans. Circuits Syst. II 2018, 65, 1659–1663. [Google Scholar] [CrossRef]

- Chen, J.J.; Hwang, Y.S.; Chen, J.H.; Ku, Y.T.; Yu, C.C. A New Fast-Response Current-Mode Buck Converter with Improved I2-Controlled Techniques. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2018, 26, 903–911. [Google Scholar] [CrossRef]

- Chen, J.J.; Hwang, Y.S.; Lin, J.Y.; Ku, Y.T. A Dead-Beat-Controlled Fast-Transient-Response Buck Converter with Active Pseudo-Current-Sensing Techniques. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2019, 27, 1751–1759. [Google Scholar] [CrossRef]

- Hwang, Y.S.; Chen, J.J.; Ku, Y.T.; Yang, J.Y. An Improved Optimum-Damping Current-Mode Buck Converter with Fast-Transient Response and Small-Transient Voltage Using New Current Sensing Circuits. IEEE Trans. Ind. Electron. 2021, 68, 9505–9514. [Google Scholar] [CrossRef]

- Chen, W.W.; Chen, J.F.; Liang, T.J.; Wei, L.C.; Ting, Y.W. Designing a Dynamic Ramp with an Invariant Inductor in Current-Mode Control for an On-Chip Buck Converter. IEEE Trans. Power Electron. 2014, 29, 750–758. [Google Scholar] [CrossRef]

- Saini, D.K.; Reatti, A.; Kazimierczuk, M.K. Average Current-Mode Control of Buck DC-DC Converter with Reduced Control Voltage Ripple. In Proceedings of the IECON 2016 42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016. [Google Scholar]

- Zhong, S.; Shen, Z. A Hybrid Constant On-Time Mode for Buck Circuits. Electronics 2021, 10, 930. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chen, C.-J.; Chen, D.; Wang, B. A Ripple- Based Constant On-Time Control with Virtual Inductor Current and Offset Cancellation for DC Power Converters. IEEE Trans. Power Electron. 2012, 27, 4301–4310. [Google Scholar] [CrossRef]

- Nien, C.-F.; Chen, D.; Hsiao, S.-F. A Novel Adaptive Quasi-Constant On-Time Current-Mode Buck Converter. IEEE Trans. Power Electron. 2017, 32, 8124–8133. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Huynh, H.A.; Kim, S.Y.; Song, H. Active EMI Reduction Using Chaotic Modulation in a Buck Converter with Relaxed Output LC Filter. Electronics 2018, 7, 254. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.C.; Chen, H.C.; Chien, M.W.; Chou, Y.W.; Chen, K.H.; Lin, Y.H.; Lee, C.C. Pseudo-constant switching frequency in on-time controlled buck converter with predicting correction techniques. IEEE Trans. Power Electron. 2016, 31, 3650–3662. [Google Scholar] [CrossRef]

- Chen, W.C.; Lin, K.L.; Chen, K.H.; Lin, Y.H.; Tsai, T.Y.; Huang, C.C.; Yang, C.C. A pseudo fixed switching frequency 2 kHz/A in optimum on-time control buck converter with predicting correction technique for EMI solution. In Proceedings of the 2014 IEEE International Symposium on Circuits and Systems (ISCAS), Melbourne, Australia, 1–5 June 2014; pp. 946–949. [Google Scholar]

- Zhen, S.; Zeng, P.; Chen, J.; Zhou, W.; Wang, J.; Luo, P.; Zhang, B. Transient Response Improvement of DC-DC Converter by Current Mode Variable on Time Control. In Proceedings of the 2018 IEEE 61st International Midwest Symposium on Circuits and Systems (MWSCAS), Windsor, ON, Canada, 5–8 August 2018. [Google Scholar]

- Lin, H.-C.; Fung, B.-C.; Chang, T.-Y. A current mode adaptive on-time control scheme for fast transient DC-DC converters. In Proceedings of the 2008 IEEE International Symposium on Circuits and Systems, Seattle, WA, USA, 18–21 May 2008. [Google Scholar]

- Zhen, S.; Zhou, S.; Zeng, L.; Yang, M.; Ming, X.; Luo, P.; Zhang, B. Variable on time controlled buck converter for DVS applications. In Proceedings of the IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar]

- Bari, S.; Li, Q.; Lee, F.C. Fast Adaptive On Time Control for Transient Performance Improvement. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015. [Google Scholar]

- Liu, P.-J.; Kuo, M.-H. Adaptive On-Time Buck Converter with Wave Tracking Reference Control for Output Regulation Accuracy. Energies 2021, 14, 3809. [Google Scholar] [CrossRef]

- Tsai, C.H.; Chen, B.M.; Li, H.L. Switching Frequency Stabilization Techniques for Adaptive On-Time Controlled Buck Converter with Adaptive Voltage Positioning Mechanism. IEEE Trans. Power Electron. 2016, 31, 443–451. [Google Scholar] [CrossRef]

- Bari, S.; Li, Q.; Lee, F.C. A New Fast Adaptive On-Time Control for Transient Response Improvement in Constant On-Time Control. IEEE Trans. Power Electron. 2018, 33, 2680–2689. [Google Scholar] [CrossRef]

- Aiello, O.; Fiori, F. A new mirroring circuit for power MOS current sensing highly immune to EMI. Sensor 2013, 13, 1856–1871. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Min, R.; Chen, C.; Zhang, X.; Zou, X.; Tong, Q.; Zhang, Q. An Optimal Current Observer for Predictive Current Controlled Buck DC-DC Converters. Sensors 2014, 14, 8851–8868. [Google Scholar] [CrossRef] [Green Version]

- Tong, Q.; Chen, C.; Zhang, Q.; Zou, X. A Sensorless Predictive Current Controlled Boost Converter by Using an EKF with Load Variation Effect Elimination Function. Sensors 2015, 15, 9986–10003. [Google Scholar] [CrossRef] [Green Version]

- Aiello, O.; Fiori, F. Current sensing circuit for DC-DC converters based on the miller effect. In Proceedings of the 2013 International Conference on Applied Electronics (AE), Pilsen, Czech Republic, 10–11 September 2013; pp. 1–4. [Google Scholar]

- Sheehan, R. Understanding and Applying Current-Mode Control Theory. Texas Instruments Technical Document Application Reports. Literature Number: SNVA555. 2007. Available online: https://www.ti.com/lit/pdf/snva555 (accessed on 31 August 2021).

- Chen, J.J.; Hwang, Y.S.; Ku, Y.T.; Li, Y.H.; Chen, J.A. A Current-Mode-Hysteretic Buck Converter with Constant-Frequency-Controlled and New Active-Current-Sensing Techniques. IEEE Trans. Power Electron. 2021, 36, 3126–3134. [Google Scholar] [CrossRef]

- Chen, J.-J. An Active Current-Sensing Constant-Frequency HCC Buck Converter using Phase-Frequency-Locked Techniques. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 761–769. [Google Scholar] [CrossRef]

- Aiello, O. Hall-Effect Current Sensors Susceptibility to EMI: Experimental Study. Electronics 2019, 8, 1310. [Google Scholar] [CrossRef] [Green Version]

- Aiello, O.; Fiori, F. A New MagFET-Based Integrated Current Sensor Highly Immune to EMI. Elsevier Microelectron. Reliab. 2013, 53, 573–581. [Google Scholar] [CrossRef]

- Ouyang, Y.; He, J.; Hu, J.; Wang, S.X. A current sensor based on the giant magnetoresistance effect: Design and potential smart grid applications. Sensors 2012, 12, 15520–15541. [Google Scholar] [CrossRef]

- Jantaratana, P.; Sirisathitkul, C. Low-cost sensors based on the GMI effect in recycled transformer cores. Sensors 2008, 8, 1575–1584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dalessandro, L.; Karrer, N.; Kolar, J.W. High-Performance Planar Isolated Current Sensor for Power Electronics Applications. IEEE Trans. Power Electron. 2007, 22, 1682–1692. [Google Scholar] [CrossRef]

- Song, C. Accuracy Analysis of Constant-On Current-Mode DC-DC Converters for Powering Microprocessors. In Proceedings of the 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 21 March 2009. [Google Scholar]

- Zhang, H.J. Modeling and Loop Compensation Design of Switching Mode Power Supplies. LINEAR Technology Application Note 149, January 2015. Available online: https://www.analog.com/media/en/technical-documentation/application-notes/an149fa.pdf (accessed on 31 August 2021).

- Li, J.; Lee, F.C. New modeling approach and equivalent circuit representation for current-mode control. IEEE Trans Power Electron. 2010, 25, 1218–1230. [Google Scholar]

- Enrique, J.-M.; Barragán, A.-J.; Durán, E.; Andújar, J.-M. Theoretical Assessment of DC/DC Power Converters’ Basic Topologies. A Common Static Model. Appl. Sci. 2018, 8, 19. [Google Scholar] [CrossRef] [Green Version]

- Suntio, T. Dynamic Modeling and Analysis of PCM-Controlled DCM-Operating Buck Converters—A Reexamination. Energies 2018, 11, 1267. [Google Scholar] [CrossRef] [Green Version]

- Ridley, R.B. An Accurate and Practical Small-Signal Model for Current-Mode Control. Available online: www.ridleyengineering.com (accessed on 1 September 2021).

- Li, J. Current-Mode Control: Modeling and Its Digital Application. Ph.D. Dissertation, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2009. [Google Scholar]

- Jiang, C.R.; Chai, C.C.; Han, C.X.; Yang, Y.T. A high performance adaptive on-time controlled valley-current-mode DCDC buck converter. J. Semicond. 2020, 41, 062406. [Google Scholar] [CrossRef]

| Component | Value | Unit |

|---|---|---|

| RLOAD | 3.6 | Ω |

| Co | 10 | μF |

| L | 4.7 | μH |

| RESR | 5 | mΩ |

| Input voltage | 3.0–3.6 V | |

| Output voltage | 1.0–2.5 V | |

| Max. output ripple (@Vin = 3.6 V, Vo = 2.5 V) | 2.51 mV | |

| Max. load current | 0.5 A | |

| Inductor/DCR * | 4.7 μH/30 mΩ | |

| Output capacitor/ESR | 10 μF/5 mΩ | |

| Transient response @ Vo = 1.8 V | 100 mA to 500 mA | 1.98 μs |

| 500 mA to 100 mA | 1.6 μs | |

| Transient voltage @ Vo = 1.8 V | Overshoot | 23 mV |

| Undershoot | 26 mV | |

| References | 2018 [15] | 2020 [41] | 2021 [27] | This work |

|---|---|---|---|---|

| Results | simulation | simulation | measurement | simulation |

| Control scheme | AOT | AOT | Hysteretic PLL | AOT |

| Process (μm) | 0.35 | 0.18 | 0.35 | 0.35 ** |

| Input voltage (V) | 12 | 3.3–5.0 | 3.3–3.6 | 3.0–3.6 |

| Output voltage (V) | 1.2 | 1.8 | 0.9–2.5 | 1.0–2.5 |

| Inductor (μH) | 1 | 1.5 | 4.7 | 4.7 |

| Output capacitor (μF) | 47 | 20 | 10 | 10 |

| Max. load current (mA) | 5000 | 2000 | 600 | 500 |

| Load current step (mA) | 4000 | 800 | 400 | 400 |

| Undershoot/overshoot (mV) | 20/26 | 13/14 | 30/60 | 23/26 |

| Recovery time (μs) (rise/fall) | <3 | 6/2 | 2.6/2.2 | 1.98/1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chou, H.-H.; Chen, H.-L.; Fan, Y.-H.; Wang, S.-F. Adaptive On-Time Control Buck Converter with a Novel Virtual Inductor Current Circuit. Electronics 2021, 10, 2143. https://doi.org/10.3390/electronics10172143

Chou H-H, Chen H-L, Fan Y-H, Wang S-F. Adaptive On-Time Control Buck Converter with a Novel Virtual Inductor Current Circuit. Electronics. 2021; 10(17):2143. https://doi.org/10.3390/electronics10172143

Chicago/Turabian StyleChou, Hsiao-Hsing, Hsin-Liang Chen, Yang-Hsin Fan, and San-Fu Wang. 2021. "Adaptive On-Time Control Buck Converter with a Novel Virtual Inductor Current Circuit" Electronics 10, no. 17: 2143. https://doi.org/10.3390/electronics10172143

APA StyleChou, H.-H., Chen, H.-L., Fan, Y.-H., & Wang, S.-F. (2021). Adaptive On-Time Control Buck Converter with a Novel Virtual Inductor Current Circuit. Electronics, 10(17), 2143. https://doi.org/10.3390/electronics10172143