A Novel Energy-Efficiency Optimization Approach Based on Driving Patterns Styles and Experimental Tests for Electric Vehicles

Abstract

1. Introduction

1.1. Literature Review

1.2. Motivation

1.3. Contributions of the Study

- We formulate a model for commercial EV that aims to include a realistic efficiency analysis for the whole system of the vehicle using a mathematical model, experimental tests in a dynamometric bank and the On-Board Diagnostics (OBD) that provides access to data from the Electronic Control Unit (ECU), allowing the inclusion of realistic nonlinear effects of EV in lookup tables.

- A strategy is proposed to improve consumption and energy efficiency in an EV through an optimization algorithm that adapts to the user’s driving pattern in real conditions, generating corrections in vehicle speed according to defined ranges. This formulation guarantees the improvement of the EV’s energy efficiency without the need to generate previous training for the identification or classification of driving styles.

1.4. Outline

2. Electric Vehicle System and Dynamic Modeling

2.1. Dynamic Modeling

2.2. Battery Model

2.3. Inverter and Electric Motor

3. Energy Efficiency Optimizer

- Step 1 Parameter settings: the maximum number of iterations N, particle size X, the inertial weight factor , acceleration coefficients and , random numbers for and , and constraint conditions (, and );

- Step 2 Fitness calculations and evaluation: compute the best value and position of the particle that maximizes the objective function in Equation (14) determined for driven pattern sample;

- Step 4 If the maximum iteration is met, terminate the algorithm. Otherwise, go to step 2.

- Step 5 Repeat the process for sample .

4. Results and Analysis

5. Conclusions

- The optimal rotational speed is calculated online corresponding to the driving requirements of DC using a metaheuristic algorithm and vehicle constraints (maximum torque and maximum power), ensuring minimal energy consumption between the battery pack and wheel over the road during driving.

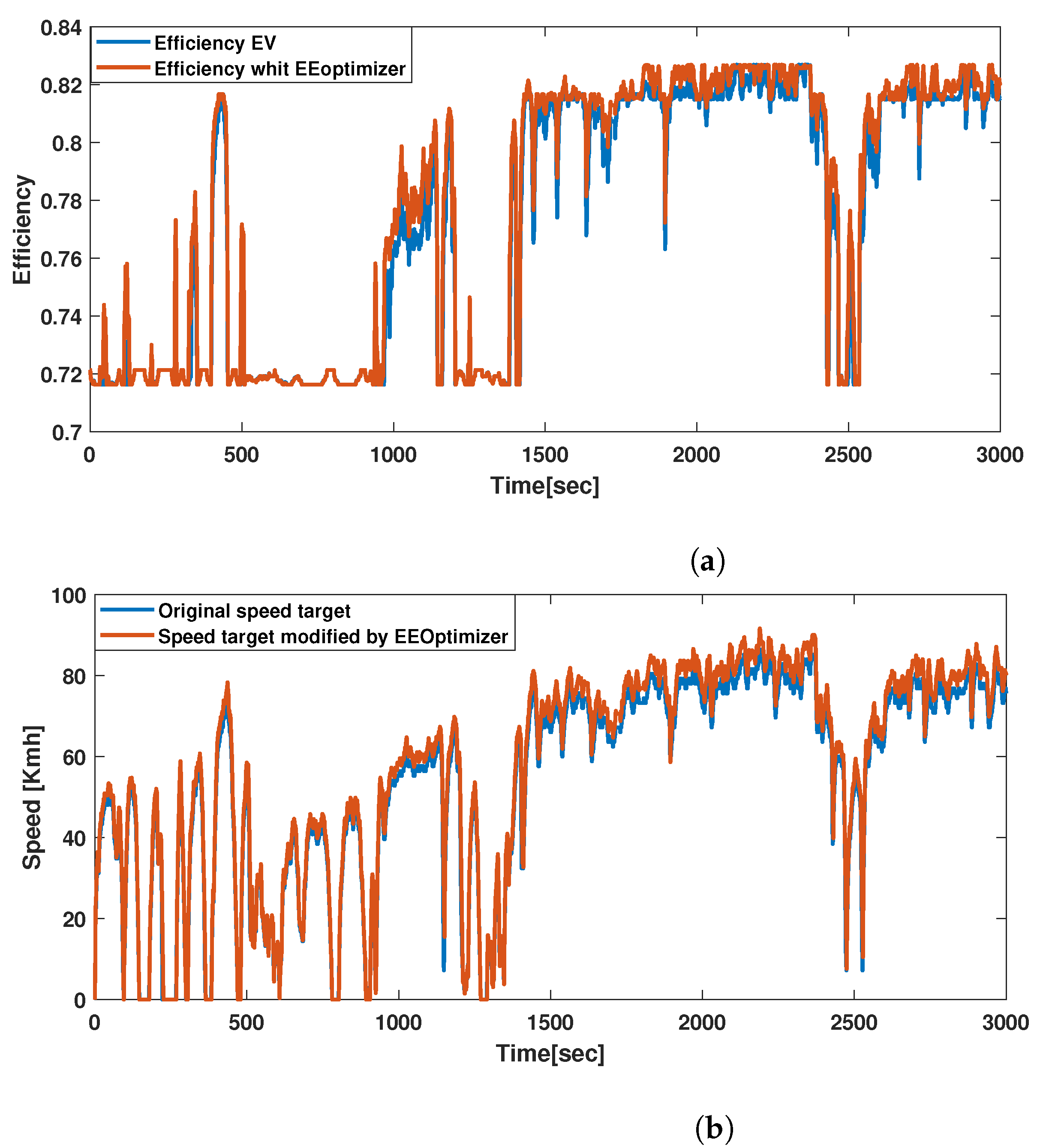

- The mathematical model of the EV and the optimization algorithm proposed were designed for a commercial test vehicle. Its performance was verified using simulation on driving profiles described in Figure 9, Figure 10 and Figure 11. This methodology could be applied to other electric propulsion vehicles with different architectures in the power train and even HEVs. For each variation in the speed reference, the proposal is improving efficiency. The results presented in Table 3 and Figure 15 are evaluated with 3000 s (50 min). On a daily route, the average driving time for a common citizen is approximately 7200 s (120 min), which means that EV’s energy efficiency can increase.

- According to the simulation results and considering improving the energy efficiency performance, the strategy showed that the best results are obtained when is 10%. However, according to Figure 15 is possible to determine that the major efficiency increment is when is between 5% and 6%. Therefore, this scenario can be considered to obtain the greatest increase in efficiency with low speed variation. The use of lookup tables and PSO for solving the optimization problem generates an alternative for implementation.

- The simulations have shown that the optimizer finds the best solution for each sample of DC in a 55-millisecond average, considering that samples of DC have a rate of 0.5 s; thus, the optimizer has enough time to complete the whole process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DC | Driving Cycles |

| DCR | Driving Condition Recognition |

| DP | Dynamic Programming |

| EV | Electric Vehicle |

| ECU | Electronic Control Unit |

| ECMS | Equivalent Consumption Minimization Strategy |

| EMS | Engine Management System |

| DSR | Driving Styles Recognition |

| FL | Fuzzy Logic |

| GA | Genetic Algorithm |

| HEV | Hybrid Electric Vehicle |

| iDP | iterative Dynamic Programming |

| OBD | On-Board Diagnostics |

| OCV | Open-Circuit Voltage |

| Opt-CPPT | Optimal Constant Pedal Position Technique |

| PMSM | Permanentmagnet Synchronous Motor |

| PnG | Pulse and Glide |

| PSO | Particle Swarm Optimization |

| SDP | Stochastic dynamic programming |

| SA | Simulated annealing |

| SOC | State of Charge |

Appendix A

| NOMENCLATURE | ||

| Notation | Definition | Units |

| the inclination angle of vehicle | deg | |

| variation between set point | rpm | |

| the efficiency factor of the PMSM | – | |

| the efficiency factor of the transmission system | – | |

| the rotational speed of the PMSM | rad/s | |

| the air density | m3 | |

| A | the front area of the vehicle | m2 |

| the Aerodynamic Drag Coefficient | – | |

| d | the front and rear track width | m |

| the aerodynamic drag force | N | |

| g | the acceleration of gravity | m/s2 |

| i | particle number of PSO algorithm | – |

| the battery current | A | |

| j | the value obtained during the driven cycle | – |

| the objective function | – | |

| and optimizer proposal | ||

| k | the iteration index during simulation | – |

| the distance from the gravity center | m | |

| m | the vehicle mass | kg |

| the rotational speed of the PMSM | rpm | |

| the electrical power in the battery | W | |

| the mechanical power | W | |

| the state of charge | % | |

| the rolling resistance coefficient | – | |

| to the front axle and rear axle | ||

| T | the battery temperature | °C |

| the torque in the transmission system | Nm | |

| , | the velocity and position of particle for PSO | – |

| the longitudinal speed | m/s | |

| the lateral speed | m/s | |

| the battery voltage | V | |

| the velocity of particles at time k + 1 for PSO | – | |

| the open circuit voltage of battery | V |

References

- Skouras, T.A.; Gkonis, P.K.; Ilias, C.N.; Trakadas, P.T.; Tsampasis, E.G.; Zahariadis, T.V. Electrical Vehicles: Current State of the Art, Future Challenges, and Perspectives. Clean Technol. 2020, 2, 1–16. [Google Scholar] [CrossRef]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A Comprehensive Study of Key Electric Vehicle (EV) Components, Technologies, Challenges, Impacts, and Future Direction of Development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Sthel, M.; Tostes, J.G.R.; Tavares, J.R. Current energy crisis and its economic and environmental consequences: Intense human cooperation. Nat. Sci. 2013, 5, 244–252. [Google Scholar] [CrossRef]

- Rajamani, R. Longitudinal vehicle dynamics. In Vehicle Dynamics and Control; Springer: Berlin, Germany, 2012; pp. 87–111. [Google Scholar]

- Lv, C.; Hu, X.; Sangiovanni-Vincentelli, A.; Li, Y.; Martinez, C.M.; Cao, D. Driving-Style-Based Codesign Optimization of an Automated Electric Vehicle: A Cyber-Physical System Approach. IEEE Trans. Ind. Electron. 2019, 66, 2965–2975. [Google Scholar] [CrossRef]

- Jafari, M.; Gauchia, A.; Zhang, K.; Gauchia, L. Simulation and Analysis of the Effect of Real-World Driving Styles in an EV Battery Performance and Aging. IEEE Trans. Transp. Electrif. 2015, 1, 391–401. [Google Scholar] [CrossRef]

- Yang, S.; Wang, W.; Zhang, F.; Hu, Y.; Xi, J. Driving-Style-Oriented Adaptive Equivalent Consumption Minimization Strategies for HEVs. IEEE Trans. Veh. Technol. 2018, 67, 9249–9261. [Google Scholar] [CrossRef]

- Neubauer, J.; Wood, E. Accounting for the Variation of Driver Aggression in the Simulation of Conventional and Advanced Vehicles. In Proceedings of the SAE World Congress and Exhibition, Detroit, MI, USA, 16–18 April 2013; Volume 1. [Google Scholar]

- Guo, Q.; Zhao, Z.; Shen, P.; Zhan, X.; Li, J. Adaptive optimal control based on driving style recognition for plug-in hybrid electric vehicle. Energy 2019, 186, 115824. [Google Scholar] [CrossRef]

- Sciarretta, A.; De Nunzio, G.; Ojeda, L.L. Optimal Ecodriving Control: Energy-Efficient Driving of Road Vehicles as an Optimal Control Problem. IEEE Control Syst. Mag. 2015, 35, 71–90. [Google Scholar]

- Sarabi, S.; Kefsi, L. Electric vehicle charging strategy based on a dynamic programming algorithm. In Proceedings of the 2014 IEEE International Conference on Intelligent Energy and Power Systems (IEPS), Kyiv, Ukraine, 2–6 June 2014; pp. 1–5. [Google Scholar]

- Yang, Y.; Pei, H.; Hu, X.; Liu, Y.; Hou, C.; Cao, D. Fuel economy optimization of power split hybrid vehicles: A rapid dynamic programming approach. Energy 2019, 166, 929–938. [Google Scholar] [CrossRef]

- Duc, D.; Fujimoto, H.; Koseki, T.; Yasuda, T.; Kishi, H.; Fujita, T. Iterative Dynamic Programming for Optimal Control Problem with Isoperimetric Constraint and Its Application to Optimal Eco-driving Control of Electric Vehicle. IEEJ J. Ind. Appl. 2018, 7, 80–92. [Google Scholar] [CrossRef]

- Schwarzer, V.; Ghorbani, R. Drive Cycle Generation for Design Optimization of Electric Vehicles. IEEE Trans. Veh. Technol. 2013, 62, 89–97. [Google Scholar] [CrossRef]

- Liaw, B.Y.; Dubarry, M. From driving cycle analysis to understanding battery performance in real-life electric hybrid vehicle operation. J. Power Sources 2007, 174, 76–88. [Google Scholar] [CrossRef]

- Salameh, M.; Brown, I.P.; Krishnamurthy, M. Driving Cycle Analysis Methods Using Data Clustering for Machine Design Optimization. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar]

- Ye, K.; Li, P.; Li, H. Optimization of Hybrid Energy Storage System Control Strategy for Pure Electric Vehicle Based on Typical Driving Cycle. Math. Probl. Eng. 2020, 2020, 1365195. [Google Scholar] [CrossRef]

- Lei, Z.; Qin, D.; Liu, Y.; Peng, Z.; Lu, L. Dynamic energy management for a novel hybrid electric system based on driving pattern recognition. Appl. Math. Model. 2017, 45, 940–954. [Google Scholar] [CrossRef]

- So, K.M.; Gruber, P.; Tavernini, D.; Karci, A.E.H.; Sorniotti, A.; Motaln, T. On the Optimal Speed Profile for Electric Vehicles. IEEE Access 2020, 8, 78504–78518. [Google Scholar] [CrossRef]

- Zeng, X.; Cui, C.; Wang, Y.; Li, G.; Song, D. Segemented Driving Cycle Based Optimization of Control Parameters for Power-Split Hybrid Electric Vehicle With Ultracapacitors. IEEE Access 2019, 7, 90666–90677. [Google Scholar] [CrossRef]

- Moura, S.J.; Fathy, H.K.; Callaway, D.S.; Stein, J.L. A Stochastic Optimal Control Approach for Power Management in Plug-In Hybrid Electric Vehicles. IEEE Trans. Control Syst. Technol. 2011, 19, 545–555. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Wang, K.; Jiao, B. Optimal Energy Management Strategy of a Plug-in Hybrid Electric Vehicle Based on a Particle Swarm Optimization Algorithm. Energies 2015, 8, 3661–3678. [Google Scholar] [CrossRef]

- Zhang, P.; Wu, X.; Du, C.; Xu, H.; Wang, H. Adaptive Equivalent Consumption Minimization Strategy for Hybrid Heavy-Duty Truck Based on Driving Condition Recognition and Parameter Optimization. Energies 2020, 13, 5407. [Google Scholar] [CrossRef]

- Valladolid, J.D.; Montesdeoca, H.D.; Ortiz, M.B.; Ortiz, J.P. Optimal Adjustment of Parameters for the Powertrain Model of an Electric Vehicle Using Experimental Data. In Proceedings of the 2020 IEEE International Conference on Industrial Technology (ICIT), Buenos Aires, Argentina, 26–28 February 2020; pp. 939–944. [Google Scholar]

- Aguilar, Y.; Caldas, I.; Rivera, A.; Tapia, E. Estudio de la influencia de la apertura de las ventanas y la Velocidad de circulacilaón en la aerodinámica de un vehículo de turismo. Ingenius. Rev. Cienc. Tecnol. 2017, 7–13. [Google Scholar] [CrossRef]

- Grunditz, E.A.; Thiringer, T. Performance Analysis of Current BEVs Based on a Comprehensive Review of Specifications. IEEE Trans. Transp. Electrif. 2016, 2, 270–289. [Google Scholar] [CrossRef]

- Iyama, H.; Namerikawa, T. Fuel consumption optimization for a power-split HEV via gain-scheduled model predictive control. In Proceedings of the 2014 SICE Annual Conference (SICE), Sapporo, Japan, 9–12 September 2014; pp. 468–473. [Google Scholar] [CrossRef]

- Ahssan, M.R.; Ektesabi, M.M.; Gorji, S.A. Electric Vehicle with Multi-Speed Transmission: A Review on Performances and Complexities. SAE Int. J. Altern. Powertrains 2018, 7, 169–182. [Google Scholar] [CrossRef]

- Valladolid, J.D.; Patiño, D.; Ortiz, J.P.; Minchala, I.; Gruosso, G. Proposal for Modeling Electric Vehicle Battery Using Experimental Data and Considering Temperature Effects. In Proceedings of the 2019 IEEE Milan PowerTech, Milan, Italy, 23–27 June 2019; pp. 1–6. [Google Scholar]

- Gao, L.; Liu, S.; Dougal, R.A. Dynamic lithium-ion battery model for system simulation. IEEE Trans. Compon. Packag. Technol. 2002, 25, 495–505. [Google Scholar]

- Cao, Y.; Kroeze, R.C.; Krein, P.T. Multi-timescale parametric electrical battery model for use in dynamic electric vehicle simulations. IEEE Trans. Transp. Electrif. 2016, 2, 432–442. [Google Scholar] [CrossRef]

- Gruosso, G.; Gajani, G.S.; Valladolid, J.D.; Patino, D.; Ruiz, F. State of Charge Estimation of LiFePO4 Battery Used in Electric Vehicles Using Support Vector Regression, PCA and DP Battery Model. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; pp. 1–5. [Google Scholar]

- Gruosso, G.; Storti Gajani, G.; Ruiz, F.; Valladolid, J.D.; Patino, D. A Virtual Sensor for Electric Vehicles’ State of Charge Estimation. Electronics 2020, 9, 278. [Google Scholar] [CrossRef]

- Ma, X.; Qiu, D.; Tao, Q.; Zhu, D. State of Charge Estimation of a Lithium Ion Battery Based on Adaptive Kalman Filter Method for an Equivalent Circuit Model. Appl. Sci. 2019, 9, 2765. [Google Scholar] [CrossRef]

- Chakraborty, S.; Vu, H.N.; Hasan, M.M.; Tran, D.D.; Baghdadi, M.E.; Hegazy, O. DC-DC Converter Topologies for Electric Vehicles, Plug-in Hybrid Electric Vehicles and Fast Charging Stations: State of the Art and Future Trends. Energies 2019, 12, 1569. [Google Scholar] [CrossRef]

- Urkizu, J.; Mazuela, M.; Alacano, A.; Aizpuru, I.; Chakraborty, S.; Hegazy, O.; Vetten, M.; Klink, R. Electric Vehicle Inverter Electro-Thermal Models Oriented to Simulation Speed and Accuracy Multi-Objective Targets. Energies 2019, 12, 3608. [Google Scholar] [CrossRef]

- Kolli, A.; Gaillard, A.; De Bernardinis, A.; Bethoux, O.; Hissel, D. A review on DC/DC converter architectures for power fuel cell applications. Energy Convers. Manag. 2015, 105, 716–730. [Google Scholar] [CrossRef]

- Valladolid, J.D.; Albarado, R.; Mallahuari, D.; Patiño, D. Experimental Performance Evaluation of Electric Vehicles (EV) Based on Analysis of Power and Torque Losses. In Proceedings of the 2020 IEEE International Conference on Industrial Technology (ICIT), Buenos Aires, Argentina, 26–28 February 2020; pp. 933–938. [Google Scholar]

- Irimescu, A.; Mihon, L.; Pãdure, G. Automotive transmission efficiency measurement using a chassis dynamometer. Int. J. Automot. Technol. 2011, 12, 555–559. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Gan, C.; Sun, Q.; Kong, W. Efficiency Optimization of PMSM Drives Using Field-Circuit Coupled FEM for EV/HEV Applications. IEEE Access 2018, 6, 15192–15201. [Google Scholar] [CrossRef]

- Lai, C.; Feng, G.; Tian, J.; Li, Z.; Zuo, Y.; Balamurali, A.; Kar, N.C. PMSM Drive System Efficiency Optimization Using a Modified Gradient Descent Algorithm with Discretized Search Space. IEEE Trans. Transp. Electrif. 2020, 6, 1104–1114. [Google Scholar] [CrossRef]

- Estima, J.O.; Marques Cardoso, A.J. Efficiency Analysis of Drive Train Topologies Applied to Electric/Hybrid Vehicles. IEEE Trans. Veh. Technol. 2012, 61, 1021–1031. [Google Scholar] [CrossRef]

- Jang, I.G.; Lee, C.S.; Hwang, S.H. Energy Optimization of Electric Vehicles by Distributing Driving Power Considering System State Changes. Energies 2021, 14, 594. [Google Scholar] [CrossRef]

- Mohammadi, F.; Nazri, G.A.; Saif, M. A Bidirectional Power Charging Control Strategy for Plug-in Hybrid Electric Vehicles. Sustainability 2019, 11, 4317. [Google Scholar] [CrossRef]

- Sengupta, S.; Basak, S.; Peters, R.A. Particle Swarm Optimization: A Survey of Historical and Recent Developments with Hybridization Perspectives. Mach. Learn. Knowl. Extr. 2019, 1, 157–191. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Jiang, L.; Huang, Y.; Cao, Y. PSO-based optimization for constant-current charging pattern for li-ion battery. Chin. J. Electr. Eng. 2019, 5, 72–78. [Google Scholar] [CrossRef]

- Cheng, S.; Lu, H.; Xiujuan, L.; Shi, Y. A quarter century of particle swarm optimization. Complex Intell. Syst. 2018, 4. [Google Scholar] [CrossRef]

- Rahman, I.; Vasant, P.M.; Mahinder, B.; Abdullah, M. On the performance of accelerated particle swarm optimization for charging plug in hybrid electric vehicles. Alex. Eng. J. 2016, 55, 419–426. [Google Scholar] [CrossRef]

| Ref. | Methods and Algorithms | Computational Cost | Experimental Data for EV Modeling | Database Required |

|---|---|---|---|---|

| [8,9] | FL, GA, PSO and DSR | medium | ✓ | large |

| [10,11] | DP | high | small | |

| [12] | Rapid-DP | medium | small | |

| [13] | iDP | medium | small | |

| [16] | Cluster Analysis | medium | large | |

| [17] | GA and PSO | medium | ✓ | large |

| [18] | PSO and DSR | low | medium | |

| [19] | DP, PnG and Opt-CPPT | medium | ✓ | small |

| [20] | PSO and IPSO | low | smal | |

| [21] | SDP | medium | small | |

| [22] | PSO | medium | medium | |

| [23] | ECMS and PSO | medium | large | |

| This Paper | PSO | low | ✓ | small |

| Parameter | Value | Unit |

|---|---|---|

| Total mass of the vehicle | 1670 | kg |

| Aerodynamic Drag Coefficient | 0.35 | – |

| Frontal area vehicle | 2.3 | m2 |

| Air density | 0.96 | kg/m3 |

| Tire radius | 0.325 | m |

| Rolling resistance coefficient | 0.017 | – |

| Distance from gravity center to front axle | 1.2 | m |

| Distance from gravity center to rear axle | 1.4 | m |

| Track width | 1.576 | m |

| Max. torque of Electric Motor | 285 | Nm |

| Ratio in the transmission system | 8.2 | – |

| Algorithm | The Best Efficiency Value Found (%) | Mean Time Execution (ms) |

|---|---|---|

| GA | 79.15 | 0.79 |

| SA | 78.76 | 0.84 |

| PSO | 79.86 | 0.55 |

| Variation | Wheel Power (kW) | Battery Energy Consumption (kWh) | Power Efficiency (%) | SOC (%) | |

|---|---|---|---|---|---|

| DC 1 | - | 5.00 | 5.33 | 78.12 | 82.49 |

| 1% | 5.09 | 5.32 | 78.53 | 82.32 | |

| 2% | 5.18 | 5.31 | 78.80 | 82.30 | |

| 3% | 5.25 | 5.30 | 78.88 | 82.21 | |

| 4% | 5.33 | 5.30 | 78.84 | 82.21 | |

| 5% | 5.42 | 5.29 | 79.22 | 81.99 | |

| 6% | 5.47 | 5.26 | 79.41 | 81.81 | |

| 7% | 5.55 | 5.25 | 79.55 | 81.42 | |

| 8% | 5.62 | 5.24 | 79.51 | 81.12 | |

| 9% | 5.71 | 5.23 | 79.62 | 81.11 | |

| 10% | 5.79 | 5.22 | 79.86 | 80.90 | |

| DC 2 | - | 3.20 | 3.62 | 73.76 | 86.51 |

| 1% | 3.24 | 3.61 | 73.96 | 86.44 | |

| 2% | 3.26 | 3.56 | 74.19 | 86.42 | |

| 3% | 3.28 | 3.51 | 74.14 | 86.43 | |

| 4% | 3.17 | 3.49 | 74.48 | 86.35 | |

| 5% | 3.37 | 3.50 | 74.90 | 86.35 | |

| 6% | 3.38 | 3.47 | 74.97 | 86.28 | |

| 7% | 3.39 | 3.43 | 75.27 | 86.31 | |

| 8% | 3.41 | 3.41 | 75.34 | 86.21 | |

| 9% | 3.45 | 3.41 | 75.34 | 86.01 | |

| 10% | 3.50 | 3.40 | 75.42 | 86.00 | |

| DC 3 | - | 3.20 | 3.63 | 73.59 | 86.50 |

| 1% | 3.24 | 3.62 | 73.96 | 86.43 | |

| 2% | 3.26 | 3.56 | 74.19 | 82.42 | |

| 3% | 3.28 | 3.51 | 74.24 | 86.43 | |

| 4% | 3.31 | 3.49 | 74.48 | 86.35 | |

| 5% | 3.37 | 3.50 | 74.90 | 86.36 | |

| 6% | 3.27 | 3.47 | 75.35 | 86.28 | |

| 7% | 3.40 | 3.43 | 75.37 | 86.31 | |

| 8% | 3.41 | 3.41 | 75.39 | 86.21 | |

| 9% | 3.45 | 3.40 | 75.48 | 86.08 | |

| 10% | 3.51 | 3.39 | 75.55 | 86.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valladolid, J.D.; Patino, D.; Gruosso, G.; Correa-Flórez, C.A.; Vuelvas, J.; Espinoza, F. A Novel Energy-Efficiency Optimization Approach Based on Driving Patterns Styles and Experimental Tests for Electric Vehicles. Electronics 2021, 10, 1199. https://doi.org/10.3390/electronics10101199

Valladolid JD, Patino D, Gruosso G, Correa-Flórez CA, Vuelvas J, Espinoza F. A Novel Energy-Efficiency Optimization Approach Based on Driving Patterns Styles and Experimental Tests for Electric Vehicles. Electronics. 2021; 10(10):1199. https://doi.org/10.3390/electronics10101199

Chicago/Turabian StyleValladolid, Juan Diego, Diego Patino, Giambattista Gruosso, Carlos Adrián Correa-Flórez, José Vuelvas, and Fabricio Espinoza. 2021. "A Novel Energy-Efficiency Optimization Approach Based on Driving Patterns Styles and Experimental Tests for Electric Vehicles" Electronics 10, no. 10: 1199. https://doi.org/10.3390/electronics10101199

APA StyleValladolid, J. D., Patino, D., Gruosso, G., Correa-Flórez, C. A., Vuelvas, J., & Espinoza, F. (2021). A Novel Energy-Efficiency Optimization Approach Based on Driving Patterns Styles and Experimental Tests for Electric Vehicles. Electronics, 10(10), 1199. https://doi.org/10.3390/electronics10101199