Social License to Operate in Mining: Present Views and Future Trends

Abstract

1. Introduction

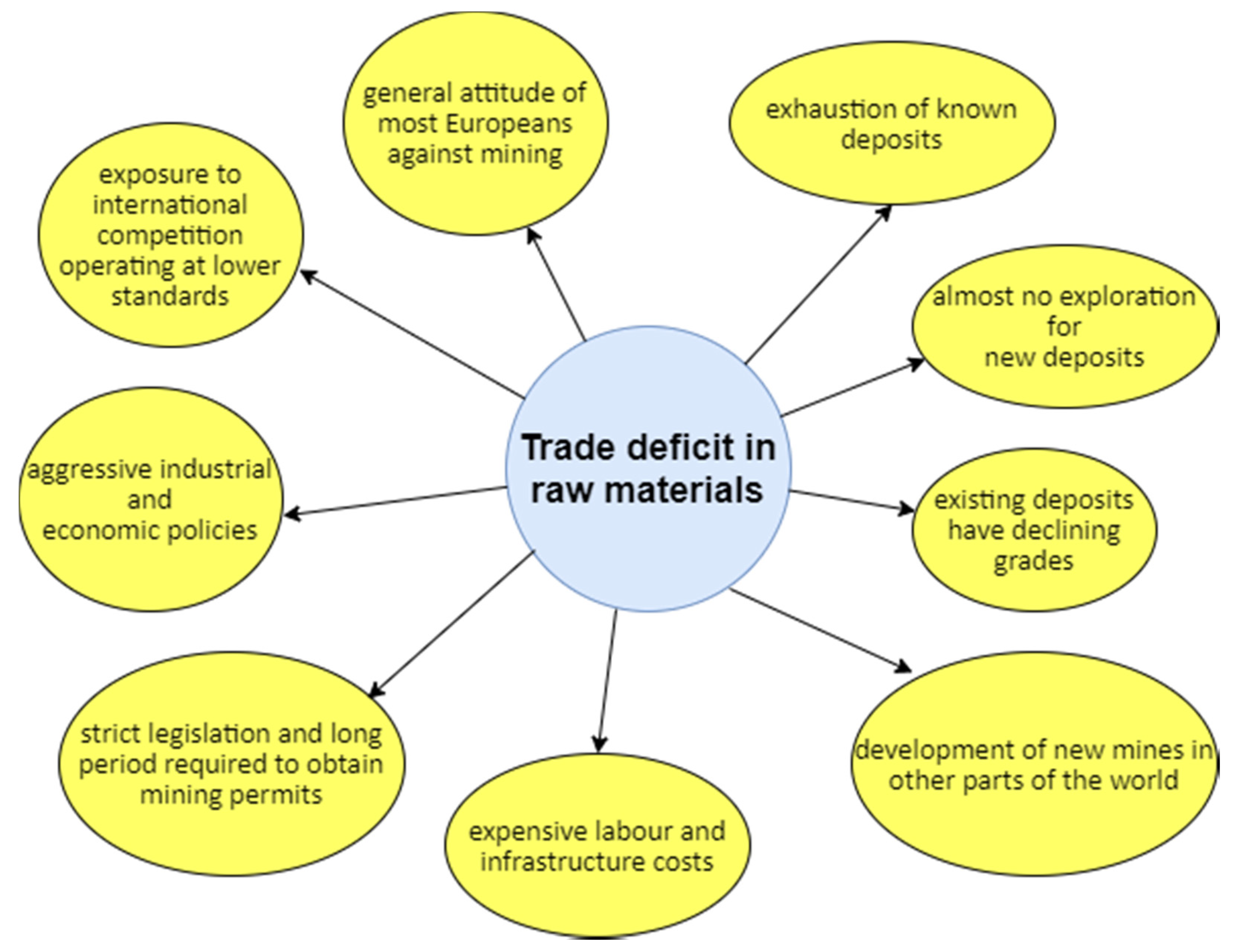

2. Criticality of Raw Materials at the EU Level

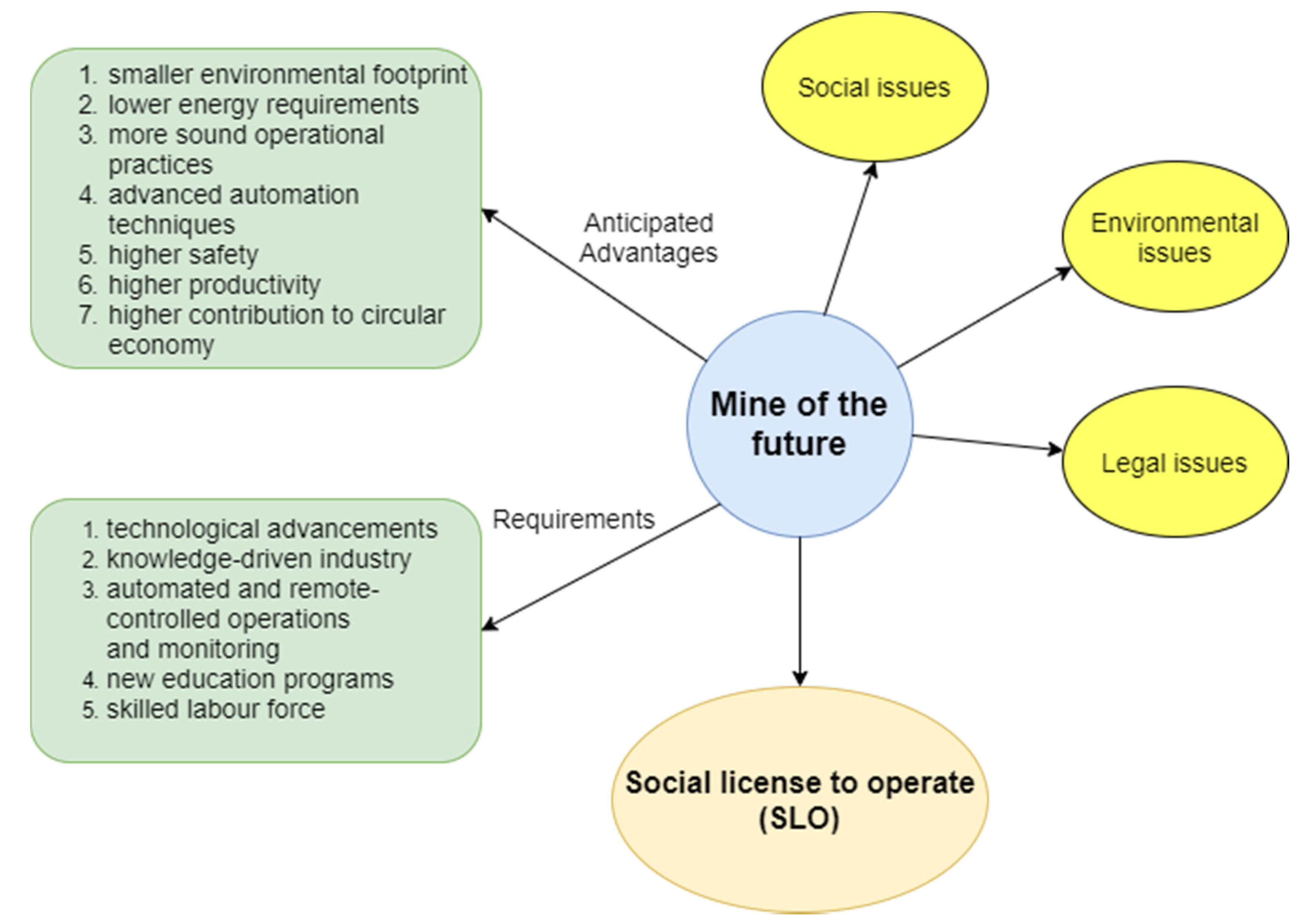

3. Mine of the Future

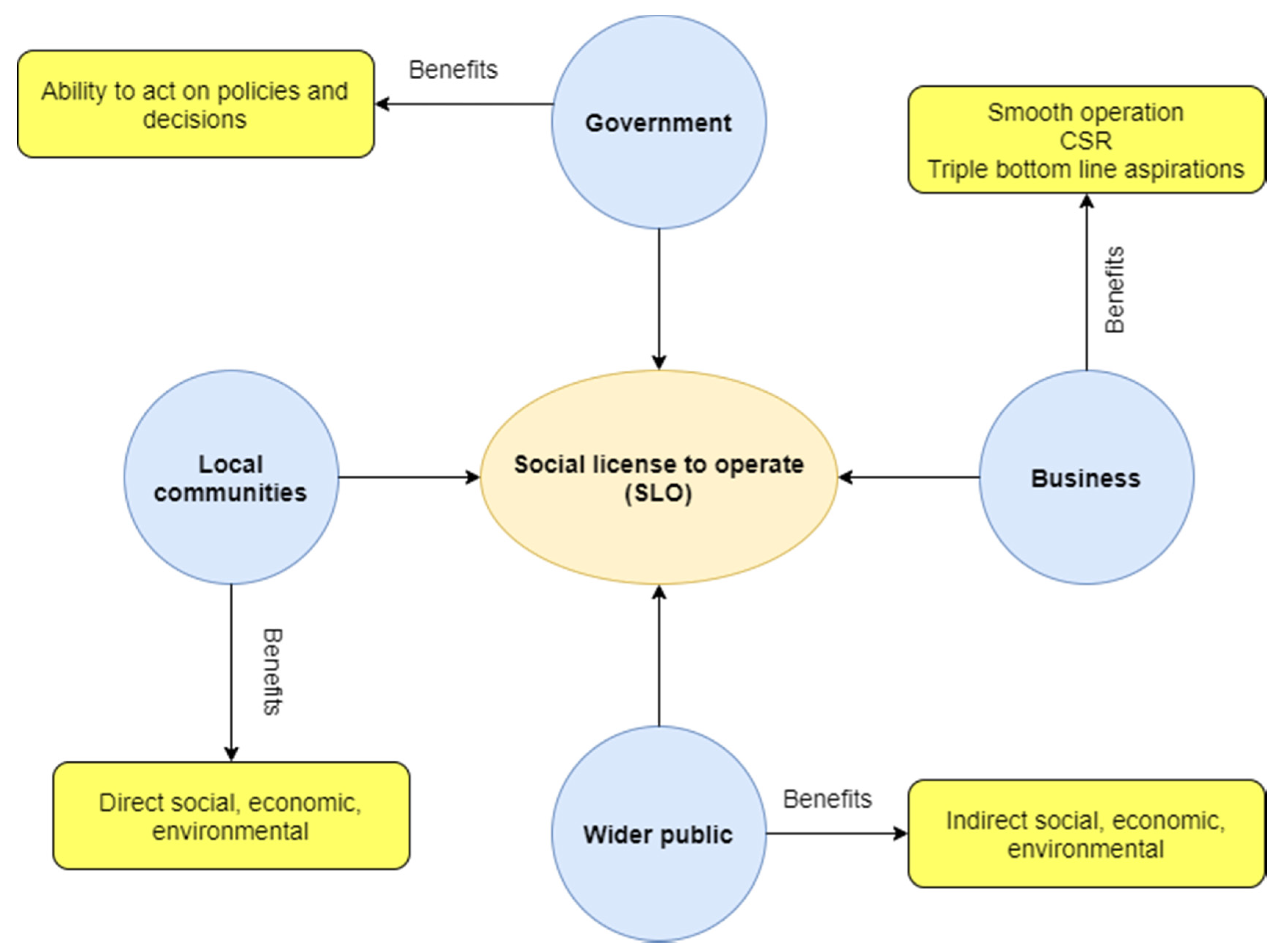

4. European Dimension of Social License to Operate in Mining

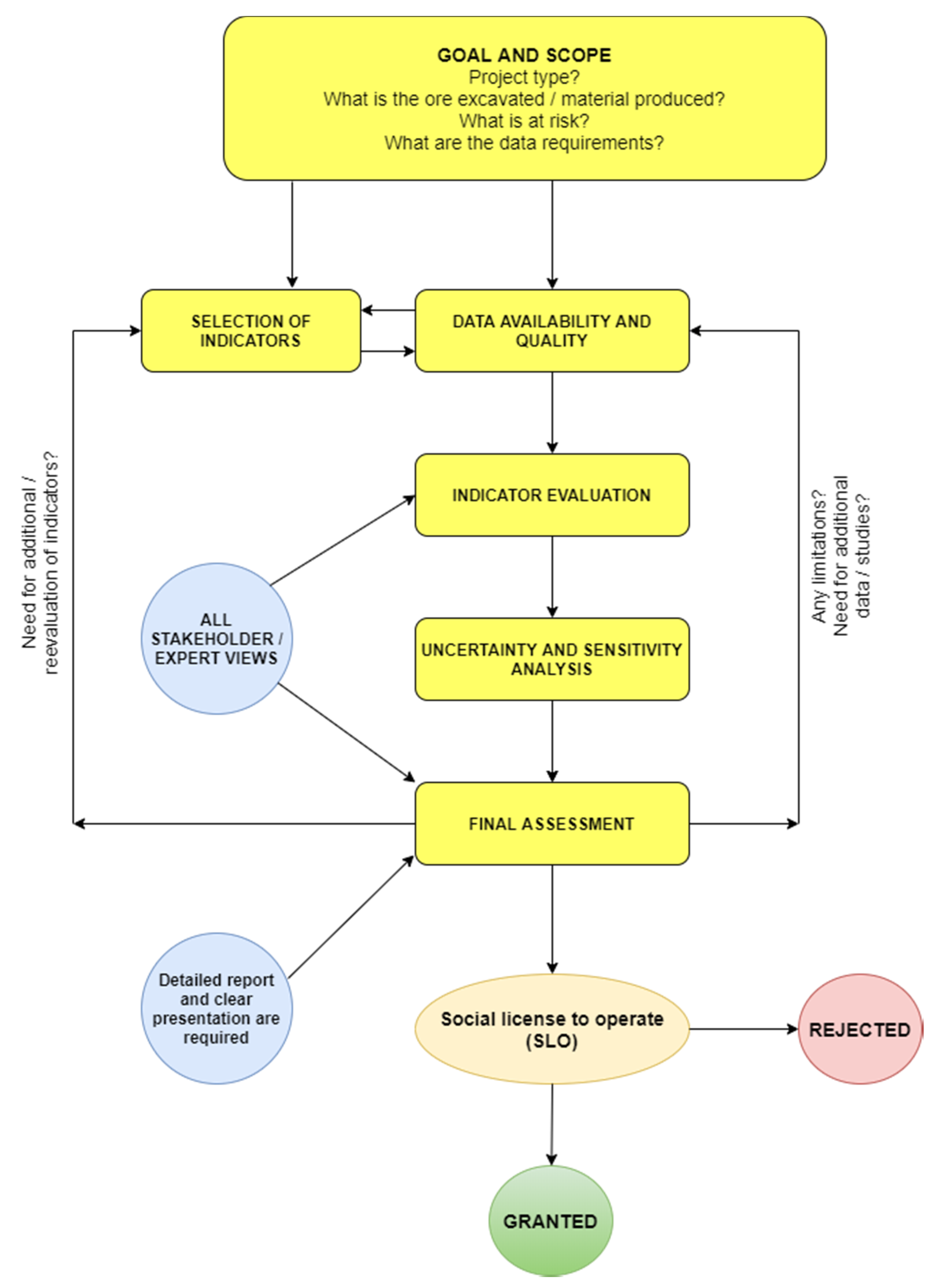

5. Proposed Methodological Approach for the Future

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Beck, K.K.; Mariani, M.; Fletcher, M.-S.; Schneider, L.; Aquino-López, M.A.; Gadd, P.S.; Heijnis, H.; Saunders, K.K.; Zawadzki, A. The impacts of intensive mining on terrestrial and aquatic ecosystems: A case of sediment pollution and calcium decline in cool temperate Tasmania, Australia. Environ. Pollut. 2020, 114695. [Google Scholar] [CrossRef]

- Bisquert, D.S.; Castejón, J.M.P.; Fernández, G.G. The impact of atmospheric dust deposition and trace elements levels on the villages surrounding the former mining areas in a semi-arid environment (SE Spain). Atmos. Environ. 2017, 152, 256–269. [Google Scholar] [CrossRef]

- Komnitsas, K.; Xenidis, A.; Adam, K. Oxidation of pyrite and arsenopyrite in sulphidic spoils in Lavrion. Miner. Eng. 1995, 8, 1443–1454. [Google Scholar] [CrossRef]

- Komnitsas, K.; Kontopoulos, A.; Lazar, I.; Cambridge, M. Risk assessment and proposed remedial actions in coastal tailings disposal sites in Romania. Miner. Eng. 1998, 11, 1179–1190. [Google Scholar] [CrossRef]

- Xenidis, A.; Papassiopi, N.; Komnitsas, K. Carbonate rich mine tailings in Lavrion: Risk assessment and proposed rehabilitation schemes. Adv. Environ. Res. 2003, 7, 207–222. [Google Scholar] [CrossRef]

- Di Noi, C.; Ciroth, A. Environmental and Social Pressures in Mining. Results from a Sustainability Hotspots Screening. Resources 2018, 7, 80. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Life cycle assessment of FeNi production in Greece: A case study. Resour. Conserv. Recycl. 2015, 105, 113–122. [Google Scholar] [CrossRef]

- Ekman Nilsson, A.; Macias Aragones, M.; Royo, F.; Dunon, V.; Oorts, K.; Angel, H.; Komnitsas, K.; Willquist, K. A Review of the Carbon footprint of Cu and Zn production from primary and secondary sources. Minerals 2017, 7, 168. [Google Scholar] [CrossRef]

- Kamenopoulos, S.; Agioutantis, Z.; Komnitsas, K. A new Hybrid Decision Support Tool for evaluating the sustainability of mining projects. Int. J. Min. Sci. Technol. 2018, 28, 259–265. [Google Scholar] [CrossRef]

- Tuusjärvi, M.; Mäenpää, I.; Vuori, S.; Eilu, P.; Kihlman, S.; Koskela, S. Metal mining industry in Finland—Development scenarios to 2030. J. Clean. Prod. 2014, 84, 271–280. [Google Scholar] [CrossRef]

- Woźniak, J.; Jurczyk, W. Social and environmental activities in the Polish mining region in the context of CSR. Resour. Policy 2020, 65, 101554. [Google Scholar] [CrossRef]

- International Institute for Environment and Development (IIED). Breaking New Ground: Mining, Minerals, and Sustainable Development; Earthscan: London, UK, 2002; Available online: https://www.iied.org/mmsd-final-report (accessed on 5 June 2020).

- Joyce, S.; Thomson, I. Earning a social license to operate: Social acceptability and resource development in Latin America. CIM Bull. 2000, 93, 49–53. [Google Scholar]

- Hilson, G.; Murck, B. Sustainable development in the mining industry: Clarifying the corporate perspective. Resour. Policy 2000, 26, 227–238. [Google Scholar] [CrossRef]

- Gunningham, N.; Kagan, R.A.; Thornton, D. Social license and environmental protection: Why businesses go beyond compliance. Law Soc. Inq. 2004, 29, 307–341. [Google Scholar] [CrossRef]

- Ruokonen, E. Preconditions for successful implementation of the Finnish standard for sustainable mining. Extr. Ind. Soc. 2020, 7, 611–620. [Google Scholar] [CrossRef]

- International Council on Mining and Metals (ICMM). Role of Mining in National Economies, 3rd ed.; International Council on Mining and Metals (ICMM): London, UK, 2016; Available online: https://www.icmm.com/website/publications/pdfs/social-and-economic-development/161026_icmm_romine_3rd-edition.pdf (accessed on 2 June 2020).

- Lacey, J.; Lamont, J. Using social contract to inform social licence to operate: An application in the Australian coal seam gas industry. J. Clean. Prod. 2014, 84, 831–839. [Google Scholar] [CrossRef]

- Bice, S.; Brueckner, M.; Pforr, C. Putting social licence to operate on the map: A social, actuarial and political risk and licensing model (SAP Model). Resour. Policy 2017, 53, 46–55. [Google Scholar] [CrossRef]

- Badera, J.; Kocoń, P. Moral panic related to mineral development projects –examples from Poland. Resour. Policy 2015, 45, 29–36. [Google Scholar] [CrossRef]

- Jartti, T.; Litmanen, T.; Lacey, J.; Moffat, K. National level paths to the mining industry’s Social Licence to Operate (SLO) in Northern Europe: The case of Finland. Extr. Ind. Soc. 2020, 7, 97–109. [Google Scholar] [CrossRef]

- Litmanen, T.; Jartti, T.; Rantala, E. Refining the preconditions of a social licence to operate (SLO): Reflections on citizens’ attitudes toward mining in two Finnish regions. Extr. Ind. Soc. 2016, 3, 782–792. [Google Scholar] [CrossRef]

- Zhang, A.; Moffat, K.; Lacey, J.; Wang, J.; González, R.; Uribe, K.; Cui, L.; Dai, Y. Understanding the social licence to operate of mining at the national scale: A comparative study of Australia, China and Chile. J. Clean. Prod. 2015, 108, 1063–1072. [Google Scholar] [CrossRef]

- Owen, J.R.; Kemp, D. Social licence and mining: A critical perspective. Resour. Policy 2013, 38, 29–35. [Google Scholar] [CrossRef]

- Bice, S. What gives you a social licence? An exploration of the social licence to operate in the Australian mining industry. Resources 2014, 3, 62–80. [Google Scholar] [CrossRef]

- Prno, J.; Slocombe, S. Exploring the origins of ‘social license to operate’ in the mining sector: Perspectives from governance and sustainability theories. Resour. Policy 2012, 37, 346–357. [Google Scholar] [CrossRef]

- Matebesi, S.; Marais, L. Social licensing and mining in South Africa: Reflections from community protests at a mining site. Resour. Policy 2018, 59, 371–378. [Google Scholar] [CrossRef]

- Measham, T.G.; Zhang, A. Social licence, gender and mining: Moral conviction and perceived economic importance. Resour. Policy 2019, 61, 363–368. [Google Scholar] [CrossRef]

- Prno, J. An analysis of factors leading to the establishment of a social licence to operate in the mining industry. Resour. Policy 2013, 38, 577–590. [Google Scholar] [CrossRef]

- Robinson, L.M.; Fardin, J.; Boschetti, F. Clarifying the current role of a social licence in its legal and political context: An examination of mining in Western Australia. Resour. Policy 2020, 67, 101649. [Google Scholar] [CrossRef]

- Gulley, A.L. Valuing environmental impacts of mercury emissions from gold mining: Dollar per troy ounce estimates for twelve open-pit, small-scale, and artisanal mining sites. Resour. Policy 2017, 52, 266–272. [Google Scholar] [CrossRef]

- Aryee, B.N.A.; Ntibery, B.K.; Atorkui, E. Trends in the small-scale mining of precious minerals in Ghana: A perspective on its environmental impact. J. Clean. Prod. 2003, 11, 131–140. [Google Scholar] [CrossRef]

- Owusu, O.; Bansah, K.J.; Mensah, A.K. “Small in size, but big in impact”: Socio-environmental reforms for sustainable artisanal and small-scale mining. J. Sustain. Min. 2019, 18, 38–44. [Google Scholar] [CrossRef]

- Watari, T.; Nansai, K.; Kenichi Nakajima, K. Review of critical metal dynamics to 2050 for 48 elements. Resour. Conserv. Recyl. 2020, 155, 104669. [Google Scholar] [CrossRef]

- Godoy León, M.F.; Blengini, G.A.; Dewulf, J. Cobalt in end-of-life products in the EU, where does it end up?—The MaTrace approach. Resour. Conserv. Recyl. 2020, 158, 104842. [Google Scholar] [CrossRef]

- Hammond, G.P.; Howard, H.R.; Rana, H.S. Environmental and resource burdens associated with low carbon, more electric transition pathways to 2050: Footprint components from carbon emissions and land use to waste arisings and water consumption. Global Transit. 2019, 1, 28–43. [Google Scholar] [CrossRef]

- Sen, B.; Onat, N.C.; Kucukvar, M.; Tatari, O. Material footprint of electric vehicles: A multiregional life cycle assessment. J. Clean. Prod. 2019, 209, 1033–1043. [Google Scholar] [CrossRef]

- Habib, K.; Hansdóttir, S.T.; Habib, H. Critical metals for electromobility: Global demand scenarios for passenger vehicles, 2015–2050. Resour. Conserv. Recyl. 2020, 154, 104603. [Google Scholar] [CrossRef]

- Zafrilla, J.E.; Arce, G.; Cadarso, M.A.; Córcoles, C.; Gómez, N.; López, L.A.; Monsalve, F.; Tobarra, M.A. Triple bottom line analysis of the Spanish solar photovoltaic sector: A footprint assessment. Renew. Sustain. Energy Rev. 2019, 114, 109311. [Google Scholar] [CrossRef]

- Besseau, R.; Sacchi, R.; Blanc, I.; Pérez-López, P. Past, present and future environmental footprint of the Danish wind turbine fleet with LCA_WIND_DK, an online interactive platform. Renew. Sustain. Energy Rev. 2019, 108, 274–288. [Google Scholar] [CrossRef]

- Vikström, H. Risk or opportunity? The extractive industries’ response to critical metals in renewable energy technologies, 1980–2014. Extr. Ind. Soc. 2020, 7, 20–28. [Google Scholar] [CrossRef]

- European Commission. Methodology for Establishing the EU List of Critical Raw Materials: Guidelines; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-68051-9. [Google Scholar] [CrossRef]

- Eurostat. NACE Rev. 2, Statistical Classification of Economic Activities in the European Community. 2008. ISBN 978-92-79-04741-1. Available online: https://ec.europa.eu/eurostat/documents/3859598/5902521/KS-RA-07-015-EN.PDF (accessed on 21 May 2020).

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.-Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A review of methods and data to determine raw material criticality. Resour. Conserv. Recyl. 2020, 155, 104617. [Google Scholar] [CrossRef]

- Terlouw, T.; Zhang, X.; Bauer, C.; Alskaif, T. Towards the determination of metal criticality in home-based battery systems using a Life Cycle Assessment approach. J. Clean. Prod. 2019, 221, 667–677. [Google Scholar] [CrossRef]

- Dewulf, J.; Blengini, G.A.; Pennington, D.; Nuss, P.; Nassar, N.T. Criticality on the international scene: Quo vadis? Resour. Policy 2016, 50, 169–176. [Google Scholar] [CrossRef]

- Werner, T.T.; Bebbington, A.; Gregory, G. Assessing impacts of mining: Recent contributions from GIS and remote sensing. Extr. Ind. Soc. 2019, 6, 993–1012. [Google Scholar] [CrossRef]

- Sparenberg, O. A historical perspective on deep-sea mining for manganese nodules, 1965–2019. Extr. Ind. Soc. 2019, 6, 842–854. [Google Scholar] [CrossRef]

- Savvilotidou, V.; Kritikaki, A.; Stratakis, A.; Komnitsas, K.; Gidarakos, E. Energy efficient production of glass-ceramics using photovoltaic (P/V) glass and lignite fly ash. Waste Manag. 2019, 90, 46–58. [Google Scholar] [CrossRef] [PubMed]

- European Union. Raw Materials Week; European Union: Brussels, Belgium, 18–22 November 2019; Available online: https://circulareconomy.europa.eu/platform/en/news-and-events/all-events/raw-materials-week-2019 (accessed on 1 June 2020).

- European Commission. EU Circular Economy Action Plan; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Hartley, K.; van Santen, R.; Kirchherr, J. Policies for transitioning towards a circular economy: Expectations from the European Union (EU). Resour. Conserv. Recyl. 2020, 155, 104634. [Google Scholar] [CrossRef]

- Urban Mining Platform. 2018. Available online: http://www.urbanmineplatform.eu/homepage (accessed on 19 May 2020).

- Barakos, G.; Gutzmer, J.; Mischo, H. Strategic evaluations and mining process optimization towards a strong global REE supply chain. J. Sustain. Min. 2016, 15, 26–35. [Google Scholar] [CrossRef]

- Dushyantha, N.; Batapola, N.; Ilankoon, I.M.S.K.; Rohitha, S.; Abeysinghe, B.; Ratnayake, N.; Dissanayake, K. The story of rare earth elements (REEs): Occurrences, global distribution, genesis, geology, mineralogy and global production. Ore Geol. Rev. 2020, 122, 103521. [Google Scholar] [CrossRef]

- Proelss, J.; Schweizer, D.; Volker Seiler, V. The economic importanceof rare earth elements volatility forecasts. Int. Rev. Financ. Anal. 2019. [Google Scholar] [CrossRef]

- Tunsu, C.; Petranikova, M.; Gergorić, M.; Ekberg, C.; Retegan, T. Reclaiming rare earth elements from end-of-life products: A review of the perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy 2015, 156, 239–258. [Google Scholar] [CrossRef]

- Zuo, L.; Wang, C.; Corder, G.D.; Sun, Q. Future trends and strategies of recycling high-tech metals from urban mines in China: 2015–2050. Resour. Conserv. Recyl. 2019, 149, 261–274. [Google Scholar] [CrossRef]

- Xavier, L.H.; Giese, H.C.; Ribeiro-Duthie, A.C.; Lins, F.A.F. Sustainability and the circular economy: A theoretical approach focused on e-waste urban mining. Resour. Policy 2019, 101467. [Google Scholar] [CrossRef]

- UN. United Nations Convention on the Law of the Sea. 1982. Available online: https://www.un.org/depts/los/convention_agreements/texts/unclos/unclos_e.pdf (accessed on 21 May 2020).

- Wakefield, J.R.; Myers, K. Social cost benefit analysis for deep sea minerals mining. Mar. Policy 2018, 95, 346–355. [Google Scholar] [CrossRef]

- Kakee, T. Deep-sea mining legislation in Pacific Island countries: From the perspective of public participation in approval procedures. Mar. Policy 2020. [Google Scholar] [CrossRef]

- Kirkham, N.R.; Gjerde, K.M.; Wilson, A.M.W. DEEP-SEA mining: Policy options to preserve the last frontier—Lessons from Antarctica’s mineral resource convention. Mar. Policy 2020, 115, 103859. [Google Scholar] [CrossRef]

- Childs, J. Greening the blue? Corporate strategies for legitimising deep sea mining. Polit. Geogr. 2019, 74, 102060. [Google Scholar] [CrossRef]

- Washburn, T.W.; Turner, P.J.; Durden, J.M.; Jones, D.O.B.; Weaver, P.; Van Dover, C.L. Ecological risk assessment for deep-sea mining. Ocean Coast. Manag. 2019, 176, 24–39. [Google Scholar] [CrossRef]

- Clark, M.R.; Durden, J.M.; Christiansen, S. Environmental Impact Assessments for deep-sea mining: Can we improve their future effectiveness? Mar. Policy 2020, 114, 103363. [Google Scholar] [CrossRef]

- Durden, J.M.; Murphy, K.; Jaeckel, A.; Van Dover, C.L.; Christiansen, S.; Gjerde, K.; Ortega, A.; Jones, D.O.B. A procedural framework for robust environmental management of deep-sea mining projects using a conceptual model. Mar. Policy 2017, 84, 193–201. [Google Scholar] [CrossRef]

- Jones, D.O.B.; Durden, J.M.; Murphy, K.; Gjerde, K.M.; Gebicka, A.; Colaco, A.; Morato, T.; Cuvelier, D.; Billett, D.S.M. Existing environmental management approaches relevant to deep-sea mining. Mar. Policy 2019, 103, 172–181. [Google Scholar] [CrossRef]

- Ribeiro, M.C.; Ferreira, R.; Pereira, E.; Soares, J. Scientific, technical and legal challenges of deep sea mining. A vision for Portugal—Conference report. Mar. Policy 2020, 114, 103338. [Google Scholar] [CrossRef]

- Batterham, R.J. The mine of the future—Even more sustainable. Miner. Eng. 2017, 107, 2–7. [Google Scholar] [CrossRef]

- Nyembo, N.; Lees, Z. Barriers to implementing a social license to operate in mining communities: A case study of peri-urban South Africa. Extr. Ind. Soc. 2020, 7, 153–160. [Google Scholar] [CrossRef]

- Ofori, J.J.Y.; Ofori, D.R. Earning a social license to operate: Perspectives of mining communities in Ghana. Extr. Ind. Soc. 2019, 6, 531–541. [Google Scholar] [CrossRef]

- Belle, B.; Biffi, M. Cooling pathways for deep Australian longwall coal mines of the future. Int. J. Min. Sci. Technol. 2018, 28, 865–875. [Google Scholar] [CrossRef]

- Oshokoya, P.O.; Tetteh, M.N.M. Mine-of-the-future: How is Africa prepared from a mineral and mining engineering education perspective? Resour. Policy 2018, 56, 125–133. [Google Scholar] [CrossRef]

- Spooren, J.; Breemersch, K.; Dams, Y.; Mäkinen, J.; Lopez, M.; González-Moya, M.; Tripiana, M.; Pontikes, Y.; Kurylak, W.; Pietek, G.; et al. Near-zero-waste processing of low-grade, complex primary and secondary ores: Challenges and opportunities. Resour. Conserv. Recyl. 2020, 160, 104919. [Google Scholar] [CrossRef]

- Bertrand, G.; Cassard, D.; Arvanitidis, N.; Stanley, G.; the EuroGeoSurvey Mineral Resources Expert Group. Map of Critical Raw Material Deposits in Europe. Energy Procedia 2016, 97, 44–50. [Google Scholar] [CrossRef]

- Domenech, T.; Bahn-Walkowiak, B. Transition Towards a Resource Efficient Circular Economy in Europe: Policy Lessons From the EU and the Member States. Ecol. Econ. 2019, 155, 7–19. [Google Scholar] [CrossRef]

- Løvik, A.N.; Hagelüken, C.; Wäger, P. Improving supply security of critical metals: Current developments and research in the EU. Sustain. Mater. Techn. 2018, 15, 9–18. [Google Scholar] [CrossRef]

- Eurostat. Extra-EU Trade in raw Materials. 2019. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=International_trade_in_raw_materials&oldid=381170 (accessed on 19 May 2020).

- European Parliament. Workers’ Conditions in the Textile and Clothing Sector: Just an Asian Affair? Issues at Stake after the Rana Plaza Tragedy. Briefing. August 2014. Available online: https://www.europarl.europa.eu/EPRS/140841REV1-Workers-conditions-in-the-textile-and-clothing-sector-just-an-Asian-affair-FINAL.pdf (accessed on 2 June 2020).

- European Commission. 2011/753/EU: Commission Decision of 18 November 2011 establishing rules and calculation methods for verifying compliance with the targets set in Article 11(2) of Directive 2008/98/EC of the European Parliament and of the Council (notified under document C(2011) 8165. 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011D0753 (accessed on 2 June 2020).

- Aznar-Sánchez, J.A.; García-Gómez, J.J.; Velasco-Muñoz, J.F.; Carretero-Gómez, A. Mining Waste and Its Sustainable Management: Advances in Worldwide Research. Minerals 2018, 8, 284. [Google Scholar] [CrossRef]

- Horta Arduin, R.; Mathieux, F.; Huisman, J.; Blengini, G.A.; Charbuillet, C.; Wagner, M.; Baldé, C.P.; Perry, N. Novel indicators to better monitor the collection and recovery of (critical) raw materials in WEEE: Focus on screens. Resour. Conserv. Recyl. 2020, 157, 104772. [Google Scholar] [CrossRef] [PubMed]

- Poelzer, G.; Segerstedt, E.; Beland Lindahl, K.; Abrahamsson, L.; Karlsson, M. Licensing acceptance in a mineral-rich welfare state: Critical reflections on the social license to operate in Sweden. Extr. Ind. Soc. 2020, in press. [Google Scholar] [CrossRef]

- Basson, M.; Erdiaw-Kwasie, M.O. Entrepreneurship under siege in regional communities: Evidence from Moranbah in Queensland, Australia. J. Rural Stud. 2019, 66, 77–86. [Google Scholar] [CrossRef]

- Devenin, V.; Bianchi, C. Characterizing a mining space: Analysis from case studies in Chile and Australia. Resour. Policy 2019, 63, 101402. [Google Scholar] [CrossRef]

- Entrepreneurship in the Minerals Industry, Conference 31 July–1 August 2019, The Canvas Riversands, Fourways, Johannesburg, South Africa. Available online: https://www.saimm.co.za/saimm-events/upcoming-events/entrepreneurship-in-mining-conference-2019 (accessed on 21 June 2020).

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Komnitsas, K. Social License to Operate in Mining: Present Views and Future Trends. Resources 2020, 9, 79. https://doi.org/10.3390/resources9060079

Komnitsas K. Social License to Operate in Mining: Present Views and Future Trends. Resources. 2020; 9(6):79. https://doi.org/10.3390/resources9060079

Chicago/Turabian StyleKomnitsas, Konstantinos. 2020. "Social License to Operate in Mining: Present Views and Future Trends" Resources 9, no. 6: 79. https://doi.org/10.3390/resources9060079

APA StyleKomnitsas, K. (2020). Social License to Operate in Mining: Present Views and Future Trends. Resources, 9(6), 79. https://doi.org/10.3390/resources9060079