Lean Management Approach to Reduce Waste in HoReCa Food Services

Abstract

1. Introduction

- prevention, minimization of food surplus and avoidable food waste

- distribution of food surplus to groups afflicted by food poverty

- conversion of food waste to animal feed

2. Background

- Value—all activities of the company should focus on delivering value for the customers, external and internal, and needs of other stakeholders.

- Value stream—all activities should be considered as a unitary process, and changes in any part of the process should consider the potential influence of the change on the whole process.

- Flow—all processes should act without any backflows, delays or stoppages, and should operate in predictable manner.

- Pull—all processes should be activated only if there is demand of process product or even activity product (result). Under this principle no products are generated as stock.

- Perfection—all activities should be executed right the first time. Any repetitions or fixes violate this principle. If any problem does occur, immediate corrective action should be focused on the source of the problem for resolution.

- Measure. Generating a “food waste inventory” enabled sites to identify how much and where food was wasted, so managers could prioritize hotspots and monitor progress over time.

- Engage staff. Kitchen and service staff often want to help prevent food waste but need more definition and guidance from managers and owners.

- Reduce over-production. Certain production techniques contribute to a culture of over-production. For example, batch cooking, casserole trays, and buffets tend to overproduce food relative to cook-to-order preparation.

- Rethink inventory and purchasing practices. Restaurants that want to prevent food waste need to critically examine their current inventory management and purchasing practices.

- Repurpose excess food. Because forecasting customer demand is not a perfect science, restaurant kitchens will find themselves with extra ingredients and potentially wasted food. In these cases, planning alternatives to safely repurpose these ingredients can allow the kitchen to generate revenue from this potential waste, or alternatively contribute to a charitable cause.

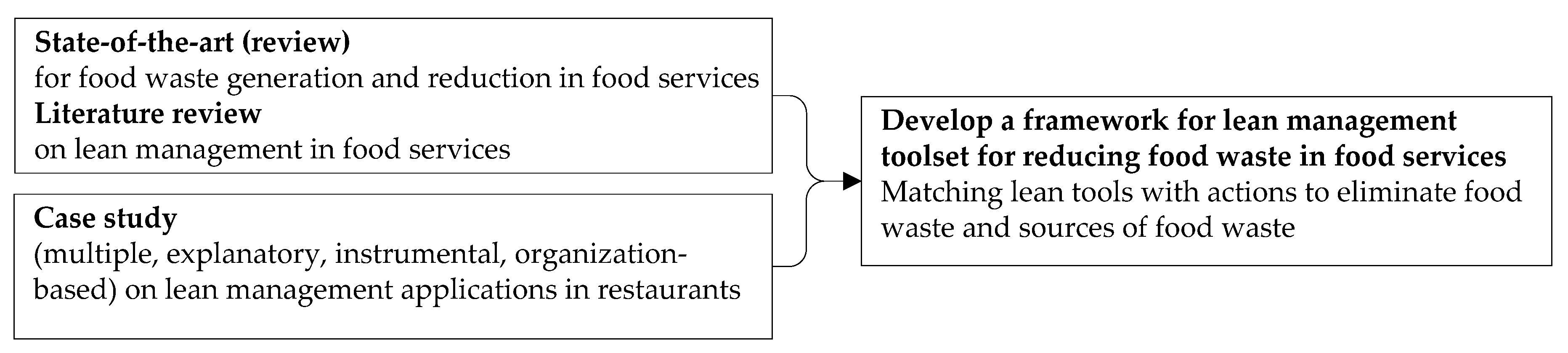

3. Methodology

4. Results

4.1. Lean Management Applications in Food Services

4.2. Multiple Case Study

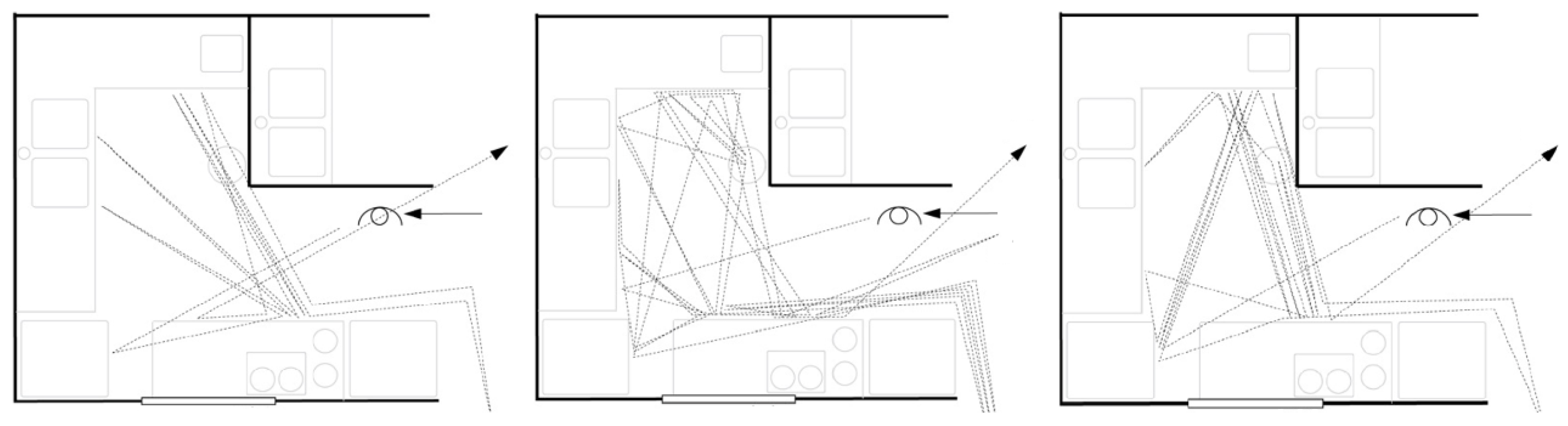

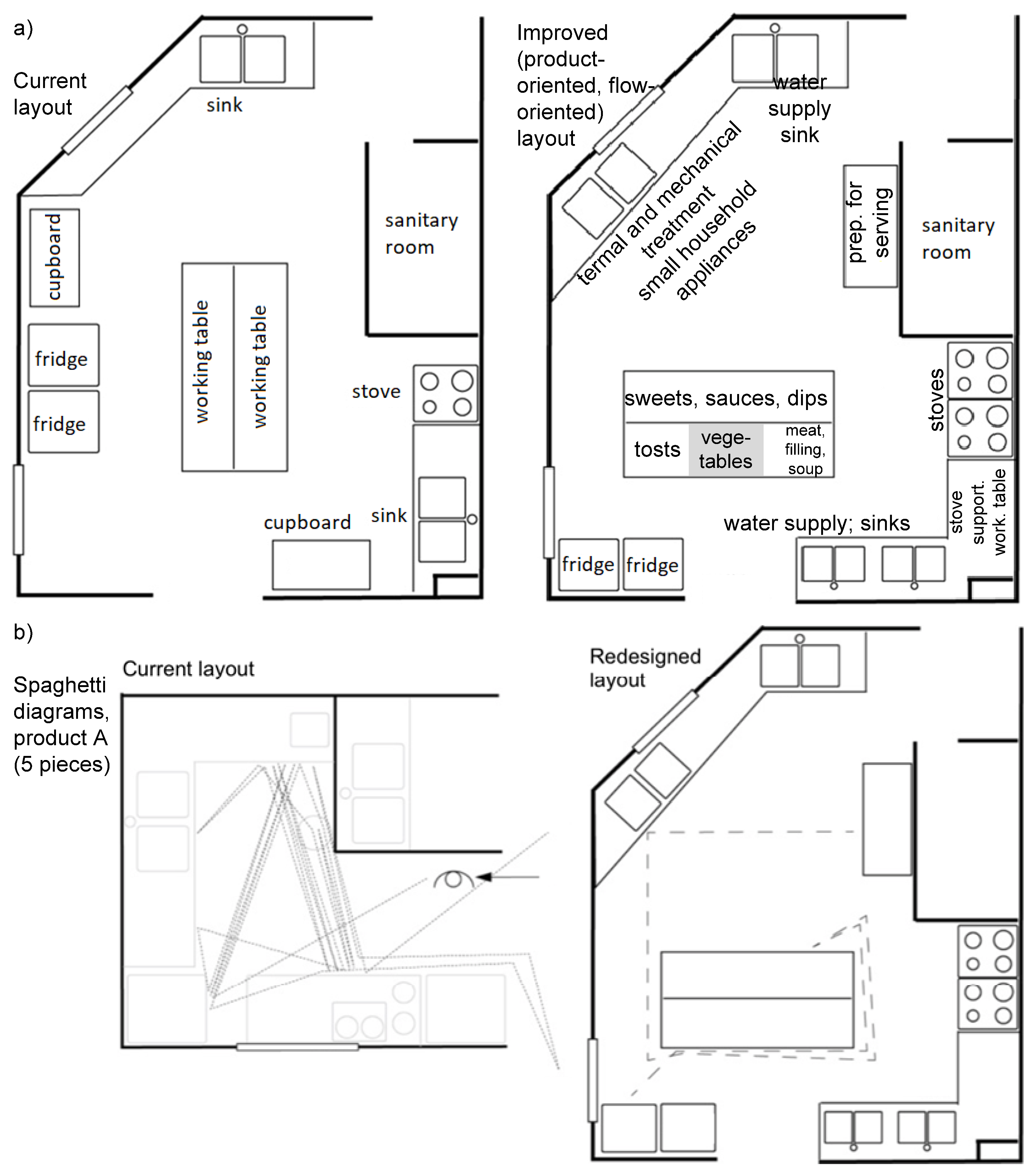

4.2.1. Cafeteria and Board Games Club

- Layout redesign using a product-oriented line approach and flow principles for food preparation, which resulted in shortened lead times and food served in a timely manner (warm), which translated into reduced food waste.

- Implementation of visual management and standardization to strengthen layout redesign; clear marking of inventory and replenishment labels) enabled execution of a first-expired first-out priority rule and maintaining stock levels adequate to demand, which resulted in a decrease of food waste due to expiration dates and spoilage.

- Establishing a training and career program for employees that considered both implementation of lean management tools and their impact on food waste reduction. These programs were addressed for all restaurant personnel, including management, kitchen staff and waiters.

- Sort (jap. seiri): recovery of ca. 30% of space, which was reallocated for additional kitchen tasks; achieved by removing four unnecessary pieces of furniture and ca. 40 utensils, transforming unused cupboard into additional working table, installation of 3 additional running meters of the working table

- Set in order (jap. seiton): allocation of necessary utensils to workstations, visual marking of utensils, hanging utensils in front of a workstation meant more space on the working tables

- Shine (jap. seiso): establish daily schedules for cleaning the working areas and storage furniture, and allocate a separate area for cleaning equipment

- Standardize (jap. seiketsu): introduction of a standardized internal audit form and the procedure for analyzing it; training staff on the procedures

- Sustain/self-discipline (jap. shitsuke): institute safety and health training, cleaning training

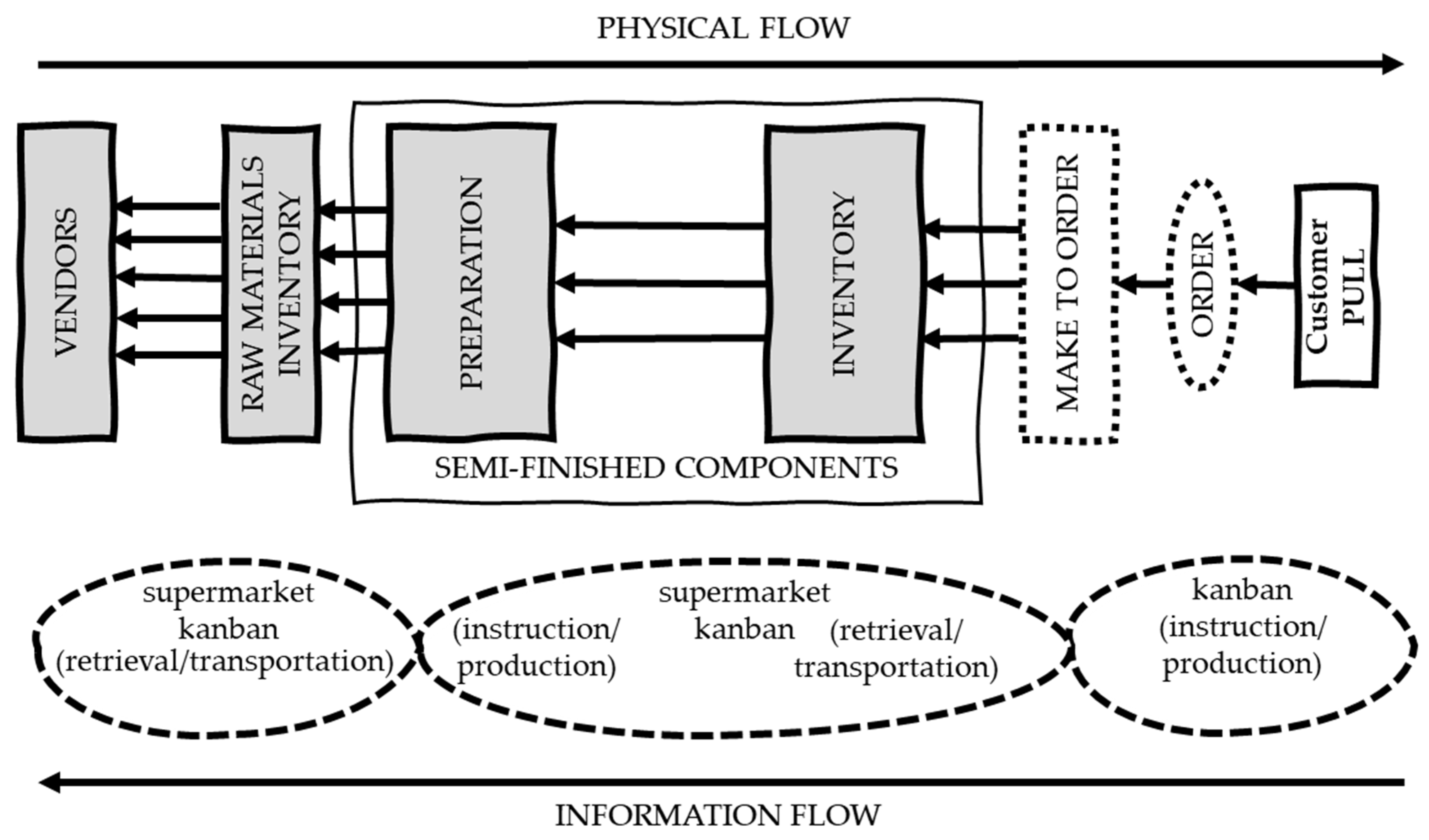

4.2.2. Railway Food Services Facility

- Preparation of raw materials (washing, peeling, cutting)

- Composition of the dish by compilation of selected raw materials

- Vacuum packing

- Cooking combined with pasteurization

- Quick cooling

- Refrigerated storage

- The technological lines were redesigned so that the flow of raw materials, semi-finished and finished products takes place in one direction. The process redesign also considered internal storages (cold rooms) reallocation as well as creation of smaller cold rooms co-located in the various places of “production processes”.

- The production processes were developed so that their execution could take place in the shortest possible time. This combined with the previous bullet enabled lead times to decrease, an increase in the timely service of meals (warm), and efficient flow of smaller batches, which resulted in reduced inventory levels of ingredients and led to decrease of food waste.

- Crossing “clean” with “dirty” routes was eliminated; this eliminated cases of spoiling clean food and, therefore, decreased food waste.

4.2.3. Small Inn

- Preparing and serving food to travelers

- Organizing special events such as weddings, birthdays, baptisms

- Appointment of the lean change team; the team leader (kaizen coordinator) became co-owner of the company

- 5S implementation both in kitchen and dining room

- Establishment of the metric system for the operational activities of the company

- Improvement of order fulfillment process flow, in particular accounting for inventory management based on visual management and Kanban implementation

- Personnel involvement throughout using mini-kaizen sessions focused on problem identification with immediate implementation of small improvements and defining and implementing a suggestion system; during mini-kaizen sessions, personnel learned the 5 whys and other problem identification tools, methods and techniques.

4.2.4. Summary of the Polish Case Studies

- Spaghetti diagrams and gemba walk—for identification of waste

- 5S and standardization—for improvement implementation

- Visual management—for process monitoring and physical layout

4.3. Lean Management Framework for Reducing Food Waste in Food Services

5. Discussion

- accurate demand forecasting

- designing food preparation processes resistant to fluctuations in demand

- designing recipes of dishes with ingredients that have longer shelf life

- change in the perception of the standard of high service by customers

- the introduction of appropriate legal and tax regulations encouraging restaurateurs not to generate food waste

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Case Study 1—Cafeteria and Board Games Club, Facts and Figures

| Product | Lead Time in Minutes | Number of Operations | Distance in Meters | Cost in EUR | Price in EUR | |

|---|---|---|---|---|---|---|

| Materials | Labor | |||||

| A | 22 | 79 | 62 | 2.6 | 1.0 | 5.9 |

| B | 18 | 38 | 22 | 1.4 | 0.8 | 4.7 |

| C | 27 | 93 | 91 | 5.1 | 1.2 | 15.8 |

| Product | Lead Time in Minutes | Number of Operations | Distance in Meters | Cost of Labor in EUR | ||||

|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | Before | After | |

| A (5 pcs) | 22 | 8.5 | 79 | 27 | 61.5 | 13.5 | 1.00 | 0.39 |

| C (1 pc) | 27 | 11 | 93 | 55 | 90.5 | 24.5 | 1.20 | 0.44 |

| Dry Ingredients | Wet Ingredients | ||

| 2¼ cup of flour 1½ cup of sugar 2/3 cup cocoa ½ teaspoon of soda | 1 teaspoon of salt 1 teaspoon of baking powder 1 pack of vanilla sugar | ¾ cup oil 2 large eggs 1½ cup of sparkling water | |

| Old instruction: Pour dry ingredients into the bowl, mix thoroughly and then add wet ingredients and mix with the mixer. Spread a margarine on a baking tray and pour out some cocoa. Pour the dough and bake about 45 min at 180 °C | |||

| New instruction: | |||

| Prepare the workstation | Prepare the bowl type 4. | ||

| Prepare the mixer. | |||

| Prepare stirrers type 3 for the mixer. | |||

| Prepare the baking tray type 2. Round, diameter 30 cm. | |||

| Prepare little butter and cocoa. Needed to spread over the baking tray and pour it before applying the finished cake mass. | |||

| Prepare small utensils. Teaspoon, wooden spoon, kitchen knife. | |||

| Prepare all the ingredients given in the recipe. | |||

| Set the oven type 2 to 180 °C and thermoregulation. If needed, use the oven manual. Be careful to not burn yourself. | |||

| Prepare the meal | Collect the bowl type 4 and our all the dry ingredients into the bowl. The sequence is irrelevant. Pour carefully—ingredients light and may dust. | ||

| Install type 3 stirrers into to the kitchen robot. Set the robot to “slow”. | |||

| Gently mix all the dry ingredients using the mixer. Mix until the homogeneous, light brown, dry mass is obtained. | |||

| Switch the robot off. | |||

| Pour the oil and break eggs. All the egg should be used—the yolk and the egg white. Take care that the shells do not get into the mass. If necessary, remove them with a spoon. | |||

| Set the mixer to “slow”. Mix until the homogeneous, light brown mass is obtained. | |||

| Pour mineral water without switching the mixer off. Pour the water slowly to not spoil the table and utensils. When the mass is homogenous, switch the robot off. | |||

| Collect the baking tray. | |||

| Lubricate the inner surface of the tray with a little butter. Use a piece of butter paper or a silicone brush to do this. | |||

| Pour a little cocoa (¾ kitchen spoon) on a baking tray and spread it evenly by shaking. The baking tray must be evenly lubricated and sprinkled with cocoa. If there is any lightening in the topping, the dough will stick there. | |||

| Pour the finished mass onto a baking tray. The mass level must be equal over the entire surface. If necessary, use a wooden spoon to distribute it evenly. | |||

| Put the baking tray in the middle level of the oven. Be careful not to burn yourself, use protective gloves. | |||

| Set the timer to 45 min. | |||

| After 20 min, check that everything is OK. Do not open the oven door. Look through the glass and use the light inside the oven. | |||

| After 45 min, pull out the dough and let it cool. Be careful not to burn yourself, use protective gloves. | |||

References

- Gladysz, B.; Buczacki, A. Wireless Technologies for Lean Manufacturing—A Literature Review. Manag. Prod. Eng. Rev. 2018, 9, 20–34. [Google Scholar] [CrossRef]

- Frank, A. Über Verwertung der Küchenabfälle für Gewinnung von Trockenfutter und von Fett durch Ausnutzung der abgehenden Hitze der Gasanstalten, sowie anderer industrieller Betriebe. J. Für Prakt. Chem. 1915, 92, 419–424. [Google Scholar] [CrossRef]

- Brown, L.P. Food wastes—some causes and remedies. J. Frankl. Inst. 1918, 185, 585–610. [Google Scholar] [CrossRef]

- JAMA. The prevention of food waste. J. Am. Med. Assoc. 1920, 74, 892. [Google Scholar] [CrossRef]

- Gruber, T.K.; Hammond, C.A. Food waste as an administrative problem. Am. J. Psychiatry 1943, 99, 886–889. [Google Scholar] [CrossRef]

- Daniel, C.E.H. Food-Waste Control. J. High. Educ. 1945, 16, 24–28. [Google Scholar] [CrossRef]

- Arneil, G.C.; Badham, D.R. The Losses of Edible Food Due to Plate Waste, in Army Dining Halls. Br. J. Nutr. 1949, 2, 310–313. [Google Scholar] [CrossRef]

- Sanborn, N.H. Waste Disposal in Food Plants. Food Technol. 1947, 1, 214–221. [Google Scholar]

- Lau, W.; Cipani, E. Reducing student food waste in a cafeteria-style dining setting through contingency management. Child Care Q. 1983, 12, 301–310. [Google Scholar] [CrossRef]

- Youngs, A.J.; Nobis, G.; Town, P. Food waste from hotels and restaurants in the U.K. Waste Manag. Res. 1983, 1, 295–308. [Google Scholar] [CrossRef]

- Dreyer, H.C.; Dukovska-Popovska, I.; Yu, Q.; Hedenstierna, C.P. A ranking method for prioritising retail store food waste based on monetary and environmental impacts. J. Clean. Prod. 2019, 210, 505–517. [Google Scholar] [CrossRef]

- Chabada, L.; Damgaard, C.M.; Dreyer, H.C.; Hvolby, H.H.; Dukovska-Popovska, I. Logistical Causes of Food Waste: A Case Study of a Norwegian Distribution Chain of Chilled Food Products. In Proceedings of the Advances in Production Management Systems. Innovative and Knowledge-Based Production Management in a Global-Local World. IFIP WG 5.7 International Conference, Ajaccio, France, 20–24 September 2014; Grabot, B., Vallespir, B., Gomes, S., Bouras, A., Kiritsis, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 273–280. [Google Scholar]

- Gunders, D.; Bloom, J. Wasted: How America is Losing up to 40 Percent of Its Food from Farm to Fork to Landfill; Natural Resources Defense Council: New York, NY, USA, 2017. [Google Scholar]

- Stenmarck, Â.; Jensen, C.; Quested, T.; Moates, G.; Buksti, M.; Cseh, B.; Juul, S.; Parry, A.; Politano, A.; Redlingshofer, B. Estimates of European Food Waste Levels; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2016. [Google Scholar]

- Benton, D. Portion size: What we know and what we need to know. Crit. Rev. Food Sci. Nutr. 2015, 55, 988–1004. [Google Scholar] [CrossRef] [PubMed]

- Bloom, J. American Wasteland: How America Throws Away Nearly Half of Its Food; Da Capo Books: Cambridge, MA, USA, 2010. [Google Scholar]

- Malefors, C.; Callewaert, P.; Hansson, P.-A.; Hartikainen, H.; Pietiläinen, O.; Strid, I.; Strotmann, C.; Eriksson, M. Towards a Baseline for Food-Waste Quantification in the Hospitality Sector—Quantities and Data Processing Criteria. Sustainability 2019, 11, 3541. [Google Scholar] [CrossRef]

- Sirieix, L.; Lála, J.; Kocmanová, K. Understanding the antecedents of consumers’ attitudes towards doggy bags in restaurants: Concern about food waste, culture, norms and emotions. J. Retail. Consum. Serv. 2017, 34, 153–158. [Google Scholar] [CrossRef]

- Stöckli, S.; Dorn, M.; Liechti, S. Normative prompts reduce consumer food waste in restaurants. Waste Manag. 2018, 77, 532–536. [Google Scholar] [CrossRef]

- Dhir, A.; Talwar, S.; Kaur, P.; Malibari, A. Food waste in hospitality and food services: A systematic literature review and framework development approach. J. Clean. Prod. 2020, 270, 122861. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Lozano, R.; Steinberger, J.K.; Wright, N.; Ujang, Z. The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; CRC Press: Portland, OR, USA, 1988; ISBN 978-0-915299-14-0. [Google Scholar]

- Blum, D. Ways to Reduce Restaurant Industry Food Waste Costs. Int. J. Appl. 2020, 19, 1–12. [Google Scholar] [CrossRef]

- Bicheno, J.; Holweg, M. The Lean Toolbox: A Handbook for Lean Transformation; PICSIE Books: Buckingham, UK, 2016. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking—Banish Waste and Create Wealth in your Corporation. J. Oper. Res. Soc. 1997, 48, 1148. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Wright, N.; Lozano, R.; Steinberger, J.; Padfield, R.; Ujang, Z. Conceptual framework for the study of food waste generation and prevention in the hospitality sector. Waste Manag. 2016, 49, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Papargyropoulou, E.; Steinberger, J.K.; Wright, N.; Lozano, R.; Padfield, R.; Ujang, Z. Patterns and Causes of Food Waste in the Hospitality and Food Service Sector: Food Waste Prevention Insights from Malaysia. Sustainability 2019, 11, 6016. [Google Scholar] [CrossRef]

- Clowes, A.; Hanson, C.; Swanell, R. The Business Case for Reducing Food Loss and Waste: Restaurants. 2019. Champions 12.3. Available online: www.champions123.org (accessed on 4 December 2020).

- Pirani, S.I.; Arafat, H.A. Reduction of food waste generation in the hospitality industry. J. Clean. Prod. 2016, 132, 129–145. [Google Scholar] [CrossRef]

- Vizzoto, F.; Tessitore, S.; Iraldo, F.; Testa, F. Passively concerned: Horeca managers’ recognition of the importance of food waste hardly leads to the adoption of more strategies to reduce it. Waste Manag. 2020, 107, 266–275. [Google Scholar] [CrossRef]

- Lasek, A.; Cercone, N.; Saunders, J. Restaurant Sales and Customer Demand Forecasting: Literature Survey and Categorization of Methods. In Proceedings of the First EAI International Summit, Smart City 360°, Bratislava, Slovakia and Toronto, ON, Canada, 13–16 October 2015; Leon-Garcia, A., Lenort, R., Holman, D., Staš, D., Krutilova, V., Wicher, P., Cagáňová, D., Špirková, D., Golej, J., Nguyen, K., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 479–491. [Google Scholar]

- Heikkilä, L.; Reinikainen, A.; Katajajuuri, J.-M.; Silvennoinen, K.; Hartikainen, H. Elements affecting food waste in the food service sector. Waste Manag. 2016, 56, 446–453. [Google Scholar] [CrossRef]

- Tsai, W.-T. Turning Food Waste into Value-Added Resources: Current Status and Regulatory Promotion in Taiwan. Resources 2020, 9, 53. [Google Scholar] [CrossRef]

- Laakso, S. Creating New Food Practices: A Case Study on Leftover Lunch Service. Food Cult. Soc. 2017, 20, 631–650. [Google Scholar] [CrossRef]

- Luciano, A.; Tretola, M.; Ottoboni, M.; Baldi, A.; Cattaneo, D.; Pinotti, L. Potentials and Challenges of Former Food Products (Food Leftover) as Alternative Feed Ingredients. Animals 2020, 10, 125. [Google Scholar] [CrossRef]

- Castrica, M.; Tedesco, D.E.A.; Panseri, S.; Ferrazzi, G.; Ventura, V.; Frisio, D.G.; Balzaretti, C.M. Pet Food as the Most Concrete Strategy for Using Food Waste as Feedstuff within the European Context: A Feasibility Study. Sustainability 2018, 10, 2035. [Google Scholar] [CrossRef]

- Jiménez-Antillón, J.; Calleja-Amador, C.; Romero-Esquivel, L.G. Food Waste Recovery with Takakura Portable Compost Boxes in Offices and Working Places. Resources 2018, 7, 84. [Google Scholar] [CrossRef]

- Franchetti, M. Development of a Novel Food Waste Collection Kiosk and Waste-to-Energy Business Model. Resources 2016, 5, 26. [Google Scholar] [CrossRef]

- Sakaguchi, L.; Pak, N.; Potts, M.D. Tackling the issue of food waste in restaurants: Options for measurement method, reduction and behavioral change. J. Clean. Prod. 2018, 180, 430–436. [Google Scholar] [CrossRef]

- Bergström, P.; Malefors, C.; Strid, I.; Hanssen, O.J.; Eriksson, M. Sustainability Assessment of Food Redistribution Initiatives in Sweden. Resources 2020, 9, 27. [Google Scholar] [CrossRef]

- Suárez-Barraza, M.F.; Smith, T.; Dahlgaard-Park, S.M. Lean Service: A literature analysis and classification. Total Qual. Manag. Bus. Excell. 2012, 23, 359–380. [Google Scholar] [CrossRef]

- Abdelhadi, A. Using lean manufacturing as service quality benchmark evaluation measure. Int. J. Lean Six Sigma 2016, 7, 25–34. [Google Scholar] [CrossRef]

- Abdi, F.; Shavarini, S.K.; Seyed Hoseini, S.M. Glean lean: How to use lean approach in service industries? J. Serv. Res. 2006, 6, 191–206. [Google Scholar]

- Alva, I.; Rojas, J.; Raymundo, C. Improving Processes Through the Use of the 5S Methodology and Menu Engineering to Reduce Production Costs of a MSE in the Hospitality Sector in the Department of Ancash. In Proceedings of the Human Interaction and Emerging Technologies, Nice, France, 22–24 August 2019; Ahram, T., Taiar, R., Colson, S., Choplin, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 818–824. [Google Scholar]

- Bowen, D.E.; Youngdahl, W.E. “Lean” service: In defense of a production-line approach. Int. J. Serv. Ind. Manag. 1998, 9, 207–225. [Google Scholar] [CrossRef]

- Indrawati, S.M.; Azzam, A.; Adrianto, E.; Miranda, S.; Prabaswari, A.D. Lean Concept Development in Fast Food Industry Using Integration of Six Sigma and TRIZ Method. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 3rd International Conference on Engineering Technology for Sustainable Development (ICET4SD), Yogakarta, Indonesia, 23–24 October 2019; IOP Publishing: Bristol, UK, 2020; Volume 722, pp. 012044:1–012044:7. [Google Scholar]

- Keyser, R.S.; Clay, K.; Marella, V.K. Lean Restaurants: Improving the Dining Experience. J. High. Educ. Theory Pract. 2017, 17, 67–79. [Google Scholar]

- LeGrand, C.; Pawar, N.; Digraskar, S.; Mahajan, S.; Mishra, S.; Polson, S. Lean restaurant. In Lean Systems: Applications and Case Studies in Manufacturing, Service, and Healthcare; Cudney, E.A., Furterer, S., Dietrich, D., Eds.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 978-1-4665-5681-2. [Google Scholar]

- Pan, W.-T.; Leu, Y.; Zhu, W.; Lin, W.-Y. A Data Mining Approach to the Analysis of a Catering Lean Service Project. Intell. Autom. Soft Comput. 2017, 23, 243–250. [Google Scholar] [CrossRef]

- Rahimnia, F.; Moghadasian, M.; Castka, P. Benchmarking leagility in mass services: The case of a fast food restaurant chains in Iran. Benchmarking Int. J. 2009, 16, 799–816. [Google Scholar] [CrossRef]

- Tucki, K.; Bączyk, A.; Prystasz, M. Options for Implementing Lean Management Elements (Case Study of a Restaurant at the Warsaw Chopin Airport). In Proceedings of the International Scientific Days 2018. Towards Productive, Sustainable and Resilient Global Agriculture and Food Systems, Nitra, Slovak Republic, 16–17 May 2018; Wolters Kluwer: Prague, Czech Republic, 2018; pp. 510–518. [Google Scholar]

- Application of Lean Management to the Tourism, Hotel and/or Restaurant Sector. Master’s Thesis, Universitat Politecnica de Catalunya, Barcelona, Spain, 2018.

- Dyrina, E.; Gavrikova, N. Experience in applying lean production concepts in the service sector. SHS Web Conf. 2016, 28, 01030. [Google Scholar] [CrossRef]

- Szymanska-Bralkowska, M.; Malinowska, E. The use of selected green lean instruments to improve catering services. Sci. Pap. Silesian Univ. Technol. Organ. Manag. Ser. 2019, 136, 601–608. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manage. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Shah, S.R.; Naghi Ganji, E. Lean production and supply chain innovation in baked foods supplier to improve performance. Br. Food J. 2017, 119, 2421–2447. [Google Scholar] [CrossRef]

- Francis, M.; Simons, D.; Bourlakis, M. Value chain analysis in the UK beef foodservice sector. Supply Chain Manag. Int. J. 2008, 13, 83–91. [Google Scholar] [CrossRef]

- Ma, J.; Ghiselli, R. Measuring, monitoring, and managing the green practices in mid-sized restaurants in China. J. Foodserv. Bus. Res. 2016, 19, 64–76. [Google Scholar] [CrossRef]

- Morales-Contreras, M.F.; Suárez-Barraza, M.F.; Leporati, M. Identifying Muda in a fast food service process in Spain. Int. J. Qual. Serv. Sci. 2020, 12, 201–226. [Google Scholar] [CrossRef]

- Muller, C. The Restaurant as Hybrid: Lean Manufacturer and Service Provider. Boston Hosp. Rev. 2012, Fall, 39–47. [Google Scholar]

- Orynycz, O.; Tucki, K.; Prystasz, M. Implementation of Lean Management as a Tool for Decrease of Energy Consumption and CO2 Emissions in the Fast Food Restaurant. Energies 2020, 13, 1184. [Google Scholar] [CrossRef]

- Nowicki, J. Reorganization of the Cafeteria Considering the Change of Its Internal Culture; Postgraduate; Warsaw University of Technology—Kaizen Academy: Warsaw, Poland, 2018. [Google Scholar]

- Dinero, D. Training Within Industry; Productivity Press: Portlan, OR, USA, 2005. [Google Scholar]

- Kniberg, H. Lean from the Trenches: Managing Large-Scale Projects with Kanban; Pragmatic Bookshelf: Stockholm, Sweden, 2011. [Google Scholar]

- Kim, W.C.; Mauborgne, R.A. Blue Ocean Leadership, 2nd ed.; Harvard Business School Publishing: Boston, MA, USA, 2017. [Google Scholar]

- Dalton, J. Great Big Agile: An OS for Agile Leaders; Apress: Berkeley, NY, USA, 2019. [Google Scholar]

- Nadler, D.A.; Lawler III, E.E. Motivation: A diagnostic approach. Read. Manag. Psychol. 1989, 3, 3–19. [Google Scholar]

- Szewczyk, P. A Project of Modernization of Central Kitchen in a Production and Service Company Based on Selected Kaizen Tools; Postgraduate; Warsaw University of Technology—Kaizen Academy: Warsaw, Poland, 2019. [Google Scholar]

- Karbowniczak, B. Analysis of the Possibility of Using Selected Kaizen Tools to Improve the Efficiency of a Gastronomic Facility; Postgraduate; Warsaw University of Technology—Kaizen Academy: Warsaw, Poland, 2014. [Google Scholar]

| Reference | Summary | Full-Scale Lean | Specific Tool | Environmental Issues | Lean Principles and Food Waste |

|---|---|---|---|---|---|

| [42] | Literature review categorizing lean services; One of categories dedicated to lean hotels and restaurant | X | X | ||

| [43] | Comparison of three restaurants; limited to takt time and lead time | X | |||

| [44] | Examples of lean approach in services; Taco Bell example (line approach in restaurant, push/pull interface) | X | |||

| [45] | 5S, forecasts, linear programming, long-term orders, and inventory management | X | |||

| [46] | Justification of line approach in services; Taco Bell example | X | |||

| [47] | Lean combined with 6 sigma and TRIZ * in fast food chain; VSM **, 5S | X | X | ||

| [48] | Three case studies of restaurants in Knoxville (Tennessee) | X | X | ||

| [49] | Explanatory case study of lean management in a restaurant; Discussion of applied methods, tools, techniques and achieved results | X | X | ||

| [59] | Measuring green practices of restaurants in China; Proposed a waste framework adopted from lean management | X | X | X | |

| [60] | Identifying waste in a fast food service process | X | X | ||

| [61] | Applications of cellular layout, kanban, just-in-time, TQM *** in McDonald’s and Burger King | X | |||

| [62] | Value stream mapping, 5S, work balancing in airport fast food restaurant; Impact on energy consumption and CO2 emissions | X | X | X | |

| [50] | Data mining for evaluation of lean service on example of catering | X | |||

| [51] | Benchmarking lean and agile advancements in Iranian restaurants | X | X | ||

| [53] | Ishikawa diagram, spaghetti diagram, VSM, 5S, cycle time, supermarket | X | X | ||

| [54] | Framework of lean implementation in Russian restaurant | X | |||

| [52] | Preliminary study for [63] | X | X | ||

| [55] | Kaizen, 5S, standardization, visual management, kanban, 5 whys, benchmarking, just-in-time, spaghetti diagram used in improving catering services by identifying and eliminating green waste | X | X | X |

| Step | Techniques |

|---|---|

| Identification of waste | Interviews (structured, with list of searched data) with all employees; Gemba walk; Random observation; TWI (Training Within Industry); Job instructions; Spaghetti diagram |

| Program launch | Mentoring; Training; Literature/readings distribution |

| Strategic goals setting | SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis; Brainstorming; ERRC (Eliminate-Reduce-Raise-Create) diagram |

| Program management | Brainstorming; Prioritization; Planning poker; KPIs (Key Performance Indicators); Kanban for project management |

| Elimination of waste | 5S; New layout design, Kanban; TWI job instructions; Standardization; Visual management; Motivational system; Matrix of competences; Suggestion system |

| Continuous improvement | Interviews with all stakeholders; Strategic planning; Brainstorming; Suggestion system; Gemba walk |

| Case 1 | Case 2 | Case 3 | |

|---|---|---|---|

| Tools used for identification and analysis of waste | Spaghetti diagram Gemba walk SWOT/TOWS Brainstorming | Spaghetti diagram Gemba walk SWOT | 5Why Gemba walk SWOT Mini-kaizen |

| Tools used for improvements implementation | 5S Standardization Process balancing | 5S Standardization Daily meetings | 5S Standardization |

| Tools used for process monitoring | Visual management Kanban | Visual management | Visual management Kanban |

| Scope of implementation | Layout redesign Process redesign Suggestion system Motivation system Matrix of competencies | Layout redesign Process redesign Designation of area leaders | Layout redesign Suggestion system Staff involvement |

| Expected/ achieved operational results | (Achieved) Lead time reduction ca. 60% Number of operations reduction ca. 53% Cost of labor reduction ca. 62% Inventory reduction ca. 65% Space reallocation | (Expected) Process path reduction (Achieved 12% process efficiency) Space reduction | (Expected) Inventory reduction Lead time reduction |

| Action as Defined by [20] | Lean Management Tools/Techniques/Methods | Contributing Factors/Indicators |

|---|---|---|

| Measure | Visual Management | ingredients stock, outdated food, serving lead time |

| Engage staff | 5S Kaizen TWI *, Suggestion System | incorrect or delayed meals, personnel engagement, staff meals, career progression |

| Reduce over-production | Forecasting, leveling, Heijunka Kanban (production) Portfolio management (short menu) TWI Visual management | size of meals, ingredients stock, cooking batches, edible leftovers, nonedible leftovers, plate leftovers, serving lead time |

| Rethink inventory and purchasing practices | Just-in-time (JIT) Kanban (inventory) Standardization Portfolio management (short menu) Visual management | level of stocks, number of ingredients, amount of outdated food, sales, serving lead time, donations to charity, leftovers taken/not taken by consumer, size of meals |

| Repurpose excess food | Kaizen Menu planning | edible leftovers, reprocessed leftovers, number of ingredients, number of meals, plate leftovers |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gładysz, B.; Buczacki, A.; Haskins, C. Lean Management Approach to Reduce Waste in HoReCa Food Services. Resources 2020, 9, 144. https://doi.org/10.3390/resources9120144

Gładysz B, Buczacki A, Haskins C. Lean Management Approach to Reduce Waste in HoReCa Food Services. Resources. 2020; 9(12):144. https://doi.org/10.3390/resources9120144

Chicago/Turabian StyleGładysz, Bartłomiej, Aleksander Buczacki, and Cecilia Haskins. 2020. "Lean Management Approach to Reduce Waste in HoReCa Food Services" Resources 9, no. 12: 144. https://doi.org/10.3390/resources9120144

APA StyleGładysz, B., Buczacki, A., & Haskins, C. (2020). Lean Management Approach to Reduce Waste in HoReCa Food Services. Resources, 9(12), 144. https://doi.org/10.3390/resources9120144