Powering Multiple Gas Condensate Wells in Russia’s Arctic: Power Supply Systems Based on Renewable Energy Sources

Abstract

1. Introduction

2. Materials and Methods

- Choke manifold (for lowering the pressure and performing flow control),

- Christmas tree (for regulating gas condensate flow from the wellhead),

- Wellhead manifold (for lowering wellhead pressure),

- Flowline and methanol pipeline connector (for hydrate prevention),

- Ground flare piping (a combustion system for utilizing extra gas),

- Test separator (a moveable unit that is used once a year to measure and separate gas),

- Gas condensate testing equipment (a moveable unit that is used once a year to measure and separate condensate),

- Storage tank (for gas, water, and condensate separation after the wellhead and before transportation to the gas processing unit),

- Radio communications (for sending measurement results to the gas processing unit).

- There is no electric heating (equipment that can withstand low temperatures is used).

- There is no cathodic protection system to protect well casings and flowlines as the well casings operate in a medium that is not corrosive and the flowlines do not touch the ground.

- There is no lighting system for multiwell pads (the service interval for the off-grid power supply system is one year; the staff is off-site when the system is not being serviced).

3. Results and Discussion

- A wind turbine with a steel tower,

- Ground-mounted solar panels,

- Backup batteries.

- Two twenty-meter-deep wells for electrical equipment (batteries, an inverter, and a controller) with a bottom hole temperature of +5 °C,

- A road from the multiwell pad (100 m long),

- A power cable along the road (100 m long),

- A two-meter-high embankment as a measure against the swampy ground,

- A wind turbine foundation,

- Piles and well foundations.

4. Conclusions

- An energy budget was compiled to ensure that gas condensate wells located in Russia’s Arctic (multiple gas condensate wells in Novy Urengoy, Western Siberia in the Arctic Circle) are provided with smooth power supply. As a result of the study, critical temperature indicators were determined at the gas production facility. The authors identified the need to implement measures to adapt the wind generator to Arctic conditions in order to prevent soil subsidence in permafrost conditions and equipment failure due to low temperatures or icing. A list of measures for adaptation to Arctic weather conditions of individual elements of the power plant design was proposed.

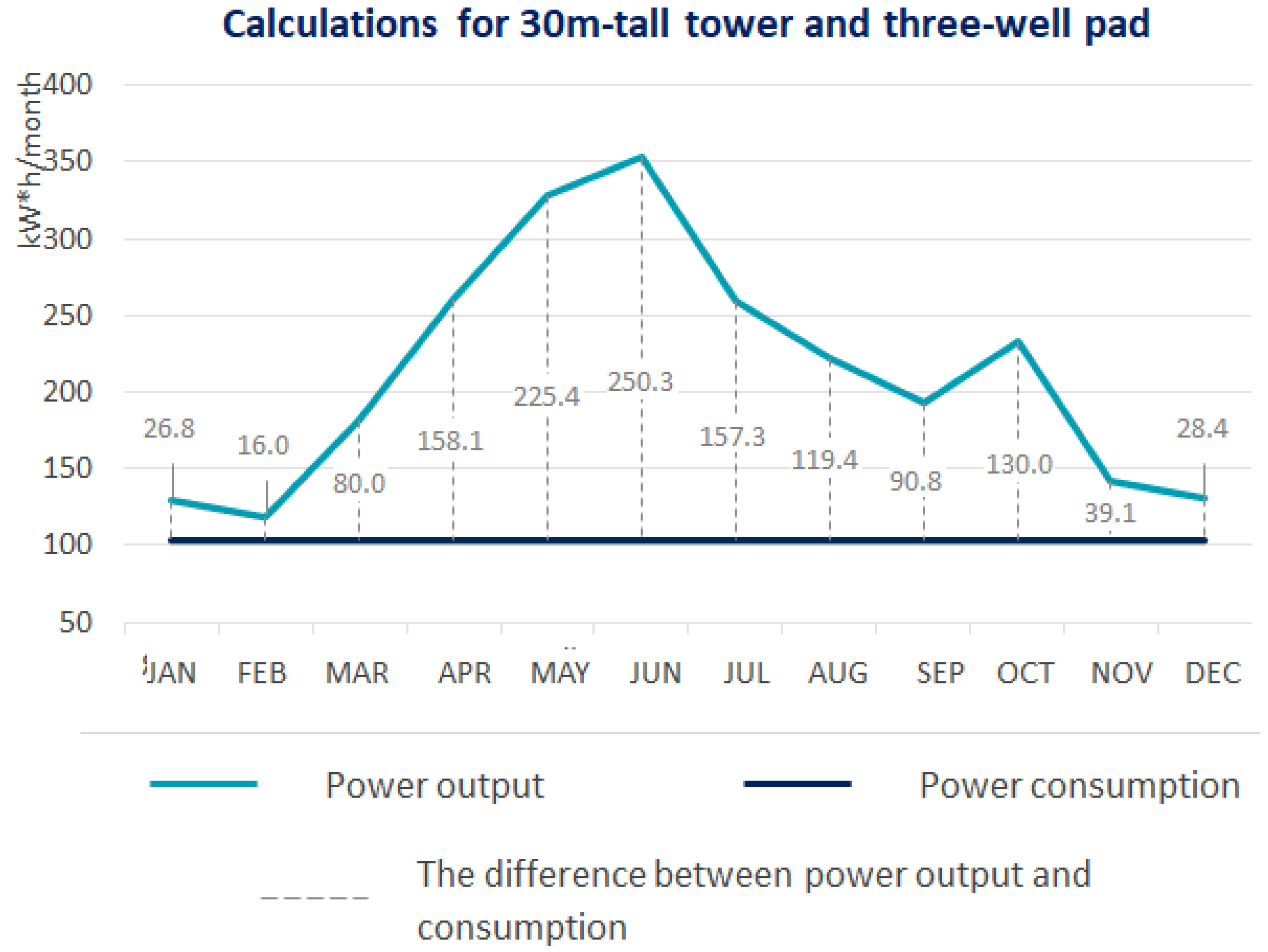

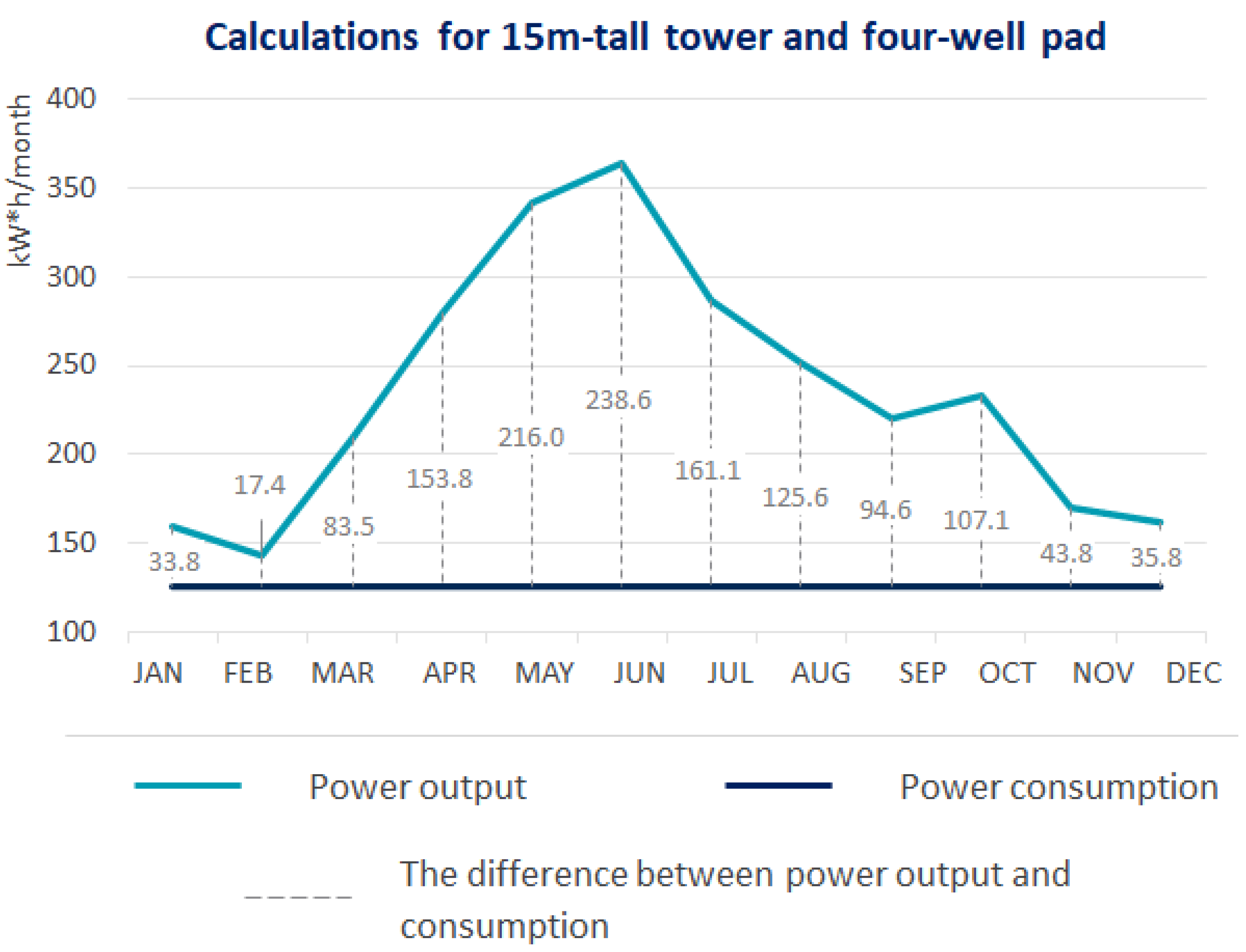

- Equipment was selected for a power supply system based on renewable energy sources and the design parameters of this system were calculated taking into account the necessity to adapt the equipment for the Arctic climate. In the process of selecting equipment for each type of multiwell pads, the parameters of the wind turbine (the rotor radius and the tower height) and backup battery. All the components of the system ensure a smooth power supply, which prevents possible interruptions in hydrocarbon production.

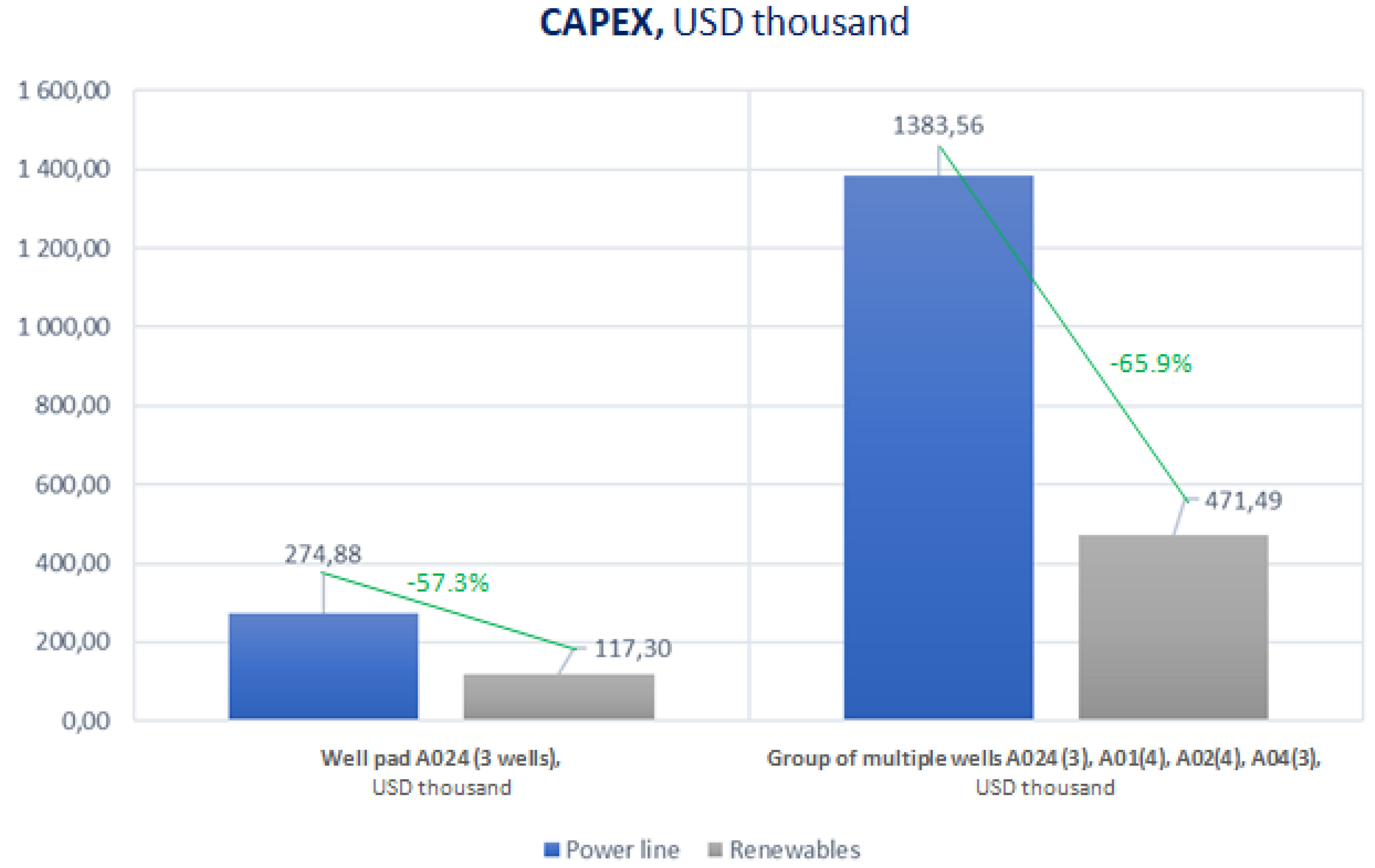

- Capital and operating costs were analyzed for using the proposed system to power a three-well pad, a four-well pad, and a group of multiwell pads (two three-well pads and two four-well pads). They were compared with costs for the construction of a power transmission line. The total capital costs of the proposed power supply system based on renewable energy sources amount to approximately 123 thousand US dollars. Equipping the whole group of multiple wells with this technology will cost 492.11 thousand US dollars, it can be said that capital costs for powering a three-well pad by using renewable energy are 57% lower than if a power transmission line is used. If this option is used for the whole group of wells, capital costs will be 65.9% lower.

- Risks were analyzed and measures were proposed to mitigate them to ensure the reliability of the proposed power supply system. As a result of expert assessment of the identified risks and proposed measures to mitigate them, it was found that after taking measures, a number of risks are reduced to a minimum (the probability of occurrence is less than 10%), and most of the risks are reduced by 12.5–25%. However, the most possible risk remains the icing of the power plant design elements. Despite proposed measures such as hydrophobic coating, ice detection system (from Emercon), and low-temperature lubrication for Arctic conditions, the probability of risk is at least 35%.

Author Contributions

Funding

Conflicts of Interest

References

- Zharan, K.; Bongaerts, J.C. Decision-making on the integration of renewable energy in the mining industry: A case studies analysis, a cost analysis and a SWOT analysis. J. Sustain. Min. 2017, 16, 162–170. [Google Scholar] [CrossRef]

- Fattahi, M.; Mosadegh, H.; Hasani, A. Sustainable planning in mining supply chains with renewable energy integration: A real-life case study. Resour. Policy 2018. [Google Scholar] [CrossRef]

- Soberanis, M.E.; Alnaggar, A.; Merida, W. The economic feasibility of renewable energy for off-grid mining deployment. Extr. Ind. Soc. 2015, 2, 509–518. [Google Scholar] [CrossRef]

- Soberanis, M.E.; Mithrush, T.; Ali, B.; Mérida, W. A sensitivity analysis to determine technical and economic feasibility of energy storage systems implementation: A flow battery case study. Renew. Energy 2018, 115, 547–557. [Google Scholar] [CrossRef]

- Habibzadeh, M.; Hassanalieragh, M.; Ishikawa, A.; Soyata, T.; Sharma, G. Hybrid solar-wind energy harvesting for embedded applications: Supercapacitor-based system architectures and design tradeoffs. IEEE Circuits Syst. Mag. 2017, 17, 29–63. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, L.; Zhong, S.; Elshkaki, A. Economic structure transformation and low-carbon development in energy-rich cities: The case of the contiguous area of shanxi and shaanxi provinces, and inner Mongolia Autonomous Region of China. Sustainability 2020, 12, 1875. [Google Scholar] [CrossRef]

- Heidari, A.A.; Abbassi, R.; Heidari, A.A.; Oliva, D.; Chen, H.; Habib, A.; Jemli, M.; Wang, M. Parameters identification of photovoltaic cell models using enhanced exploratory salp chains-based approach. Energy 2020, 198, 117333. [Google Scholar] [CrossRef]

- Prabatha, T.; Hager, J.; Carneiro, B.; Hewage, K.; Sadiq, R.; Prabatha, T. Analyzing energy options for small-scale off-grid communities: A Canadian case study. J. Clean. Prod. 2020, 249, 119320. [Google Scholar] [CrossRef]

- Nam, K.; Hwangbo, S.; Yoo, C. A deep learning-based forecasting model for renewable energy scenarios to guide sustainable energy policy: A case study of Korea. Renew. Sustain. Energy Rev. 2020, 122, 109725. [Google Scholar] [CrossRef]

- Kirsanova, N.Y.; Lenkovets, O.M.; Nikulina, A.Y. The role and future outlook for renewable energy in the Arctic zone of Russian Federation. Eur. Res. Stud. J. 2018, 21, 356–368. [Google Scholar]

- Elistratov, V.; Denisov, R. Justification of wind turbine operation and management modes for russian arctic conditions. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Saint-Petersburg, Russia, 16–19 May 2017; Available online: https://www.researchgate.net/publication/320653381_Justification_of_wind_turbine_operation_and_management_modes_for_russian_arctic_conditions (accessed on 5 June 2020).

- Bessel, V.; Llc, R.N.S.; Kutcherov, V.; Lopatin, A.; Martynov, V.; Mingaleeva, R. Energy efficiency and reliability increase for remote and autonomous objects energy supply of Russian oil and gas complex. Neft. Khozyaystvo Oil Ind. 2018, 9, 144–147. [Google Scholar] [CrossRef]

- Belsky, A.A.; Morenov, V.; Kupavykh, K.; Sandyga, M.S. Wind turbine electrical energy supply system for oil well heating. ENERGETIKA. Proc. CIS High. Educ. Inst. Power Eng. Assoc. 2019, 62, 146–154. [Google Scholar] [CrossRef]

- Gulkov, Y.V.; Ustinov, D.A. Electric power quality distortions influencing oil processing plant parameters and characteristics. Int. J. Appl. Eng. Res. 2017, 12, 2027–2030. [Google Scholar]

- Pankov, I.A.; Frolov, V.Y. Increase of electric power quality in autonomous electric power systems. J. Min. Inst. 2017, 227, 563–568. [Google Scholar] [CrossRef]

- Elistratov, V.; Kudryasheva, I. Regimes, management and economics of energy complexes on the basis of renewable energy sources for autonomous power supply. E3S Web Conf. 2019, 124, 04023. [Google Scholar] [CrossRef]

- Abramovskiy, A.L.; Shalin, V.V.; Shestakov, S.A. Wind energy development policy as a type of alternative renewable energy sources. J. Environ. Manag. Tour. 2019, 10, 947–955. [Google Scholar] [CrossRef]

- Akhmetshin, E.; Zhiltsov, S.; Dmitrieva, A.; Plotnikov, A.; Kolomeytseva, A. The formation of the contemporary renewable energy sector and its role in the industry development. Int. J. Energy Econ. Policy 2019, 9, 373–378. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.E.; Tcvetkov, P. Overview of the prospects for developing a renewable energy in Russia. In Proceedings of the 2017 International Conference on Green Energy and Applications (ICGEA), Singapore, 25–27 March 2017; pp. 113–117. [Google Scholar] [CrossRef]

- Kozhevnikov, M.; Gitelman, L.; Magaril, E.; Magaril, R.; Aristova, A. Risk reduction methods for managing the development of regional electric power industry. Sustainability 2017, 9, 2201. [Google Scholar] [CrossRef]

- Shabalov, M.; I Filatova, I.; Kuskova, Y.V. Prospects of binary energy generation systems based on the joint use of traditional sources of energy and wave motion energy. IOP Conf. Series: Mater. Sci. Eng. 2019, 643, 012143. [Google Scholar] [CrossRef]

- Belsky, A.; Dobush, V.S. Simulation of a wind power generator operation as a part of an electrotechnical complex. J. Phys. Conf. Ser. 2018, 1111, 012051. [Google Scholar] [CrossRef]

- Belsky, A.; Dobush, V.S.; Kuksov, N.; Gluhanich, D.Y. Autonomous power supply complex for oil leakage detection system in pipelines. IOP Conf. Ser. Mater. Sci. Eng. 2019, 643, 012029. [Google Scholar] [CrossRef]

- Bolshev, A.S.; Elistratov, V.V.; Panfilov, A.A.; Kharseev, A.E. Conceptual analysis of the power of offshore wind plants designed to operate in arctic conditions. In Proceedings of the International Offshore and Polar Engineering Conference, Shanghai, China, 14–19 June 2020; pp. 508–514. [Google Scholar]

- Nikulina, A.Y.; Kruk, M.N. Organizational and economic mechanism of oil and gas projects in the Russian arctic shelf. J. Internet Bank. Commer. 2016, 21, 12. [Google Scholar]

- Carayannis, E.G.; Cherepovitsyn, A.E.; Ilinova, A. Development of the Russian Arctic zone: The role of innovation infrastructure and legal regulation. Int. J. Appl. Eng. Res. 2017, 12, 8179–8187. [Google Scholar]

- Ilinova, A.; Chanysheva, A. Algorithm for assessing the prospects of offshore oil and gas projects in the Arctic. Energy Rep. 2020, 6, 504–509. [Google Scholar] [CrossRef]

- Kruk, M.; Semenov, A.; Cherepovitsyn, A.; Nikulina, A. Environmental and economic damage from the development of oil and gas fields in the Arctic shelf of the Russian Federation. Eur. Res. Stud. J. 2018, 21, 423–433. [Google Scholar]

- Viacheslav, Z.; Alina, I. Problems of unconventional gas resources production in arctic zone - Russia- [Article@Problemas de producción de recursos gasíferos no convencionales en la zona ártica rusa]. Espacios 2018, 39, 8. [Google Scholar]

- Savard, C.; Nikulina, A.; Mécemmène, C.; Mokhova, E. The electrification of ships using the Northern Sea Route: An approach. J. Open Innov. Technol. Mark. Complex. 2020, 6, 13. [Google Scholar] [CrossRef]

- Kirsanova, N.Y.; Lenkovets, O.M.; Nikulina, A.Y. Renewable energy sources (RES) as a factor determining the social and economic development of the arctic zone of the Russian Federation. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, Albena, Bulgaria, 30 June–9 July 2018; Volume 18, pp. 679–686. [Google Scholar] [CrossRef]

- Marinina, O.A.; Nevskaya, M.A. Specific nature of labour management in the oil and gas sector in the Russian Far North. Int. J. Appl. Bus. Econ. Res. 2017, 15, 177–185. [Google Scholar]

- Edenhofer, O.; Madruga, R.P.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schlömer, S.; et al. Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2011; pp. 1–1075. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 2019, 14, 043004. [Google Scholar] [CrossRef]

- Vasilev, Y.; Vasileva, P.; Tsvetkova, A. International review of public perception of ccs technologies. In Proceedings of the 19th International Multidisciplinary Scientific GeoConference SGEM, Vienna, Austria, 9–12 December 2019; Volume 19, pp. 415–422. [Google Scholar] [CrossRef]

- Romasheva, N.; Ilinova, A. CCS projects: How regulatory framework influences their deployment. Resources 2019, 8, 181. [Google Scholar] [CrossRef]

- He, G.; Lin, J.; Sifuentes, F.; Liu, X.; Abhyankar, N.; Phadke, A. Rapid cost decrease of renewables and storage accelerates the decarbonization of China’s power system. Nat. Commun. 2020, 11, 1–9. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2019; International Renewable Energy Agency: Abu Dhabi, UAE, 2020; Available online: https://www.irena.org/publications/2020/Jun/Renewable-Power-Costs-in-2019 (accessed on 27 August 2020).

- IRENA. The Power to Change: Solar and Wind Cost Reduction Potential to 2025. 2016. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_Power_to_Change_2016.pdf (accessed on 27 August 2020).

- Darrell Proctor Reduced Cost for Renewables Supports Sector Growth. POWER Magazine. 2020. Available online: https://www.powermag.com/reduced-cost-for-renewables-supports-sector-growth/ (accessed on 28 August 2020).

- Sustainable Development Report Schneider Electric. 2018. Available online: https://sdreport.se.com/en/climate-overview (accessed on 22 July 2020).

- Archive of Actual Weather Hydrometeorological Center of Russia. Available online: https://meteoinfo.ru/archive-pogoda (accessed on 28 June 2020).

- VYMPEL. Telemechanics Complex for Gas Well Clusters. 2019. Available online: http://en.vympel.group/products/telemechanics/kompleks-telemekhaniki-kustov-gazovykh-skvazhin/ (accessed on 18 May 2020).

| Parameter/Month | January | February | March | April | May | June | July | August | September | October | November | December | Avg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wind speed (at 10 m height), m/s | 3.3 | 2.9 | 3.5 | 3.9 | 4.2 | 4.4 | 3.5 | 3.4 | 3.5 | 4.1 | 3.3 | 3.3 | 3.6 |

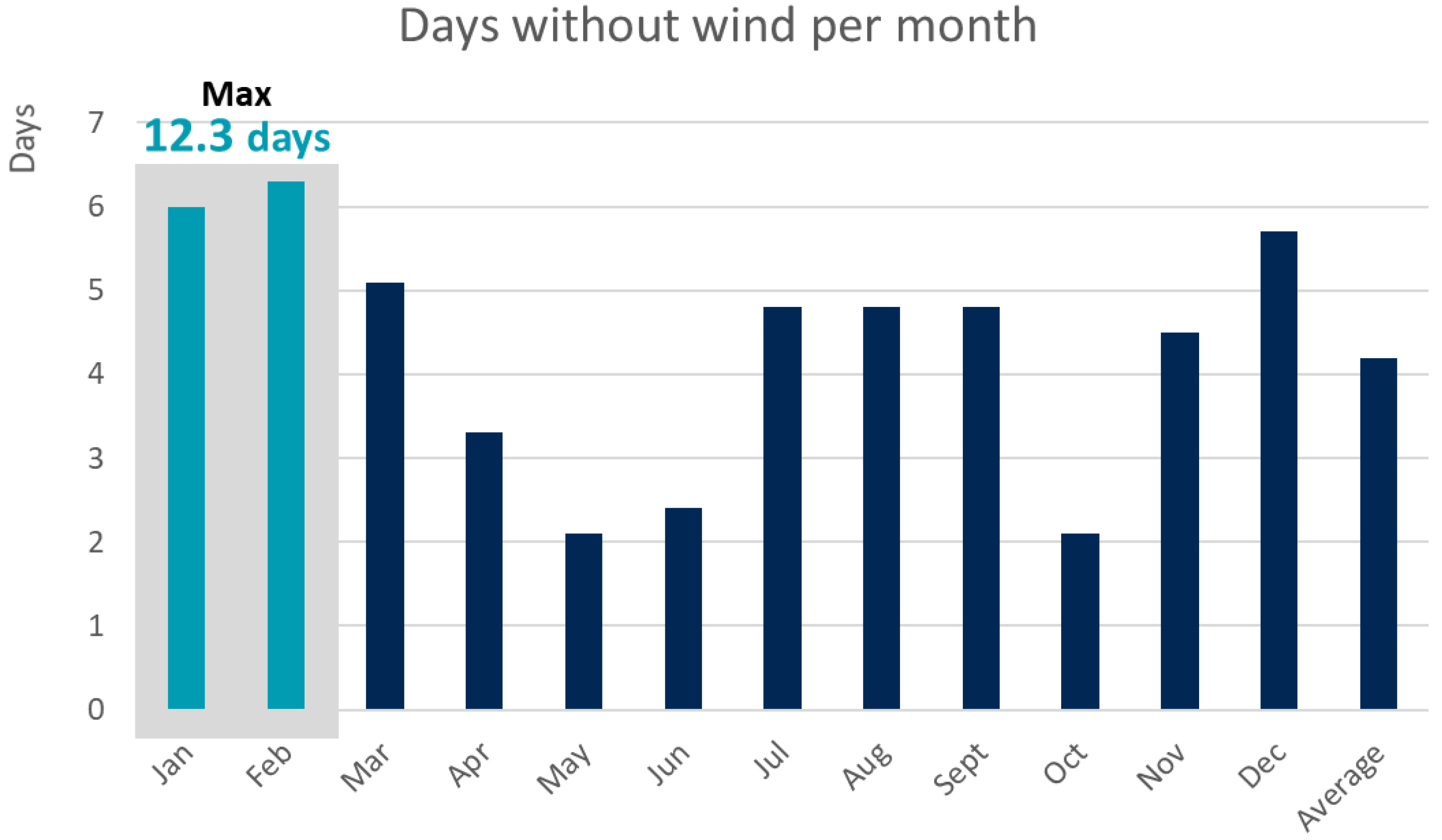

| Calm periods, % | 20 | 21 | 17 | 11 | 7 | 8 | 16 | 16 | 16 | 7 | 15 | 19 | 14.4 |

| Solar irradiance, kWh/m2 | 0.0 | 31.1 | 78.3 | 157.5 | 224.7 | 240.3 | 246.9 | 177.5 | 98.6 | 33.9 | 9.4 | 0.0 | 108.2 |

| Temperature, °C | −26.4 | −26.4 | −19.2 | −10.3 | −2.6 | 8.4 | 15.4 | 11.3 | 5.2 | 6.3 | −18.2 | −24.0 | −7.8 |

| Structural Component | Measure | Aspect |

|---|---|---|

| Rotor | Using blades made of steel for low-temperature applications | Conventional steel becomes brittle and less wear-resistant at low temperatures, which can result in a breakdown or power cut |

| Hydrophobic coating | An increase in surface tension at the water-metal interface prevents ice from accumulating | |

| Ice detection system (produced by Enercon) | Sensors show information on power output and wind speed | |

| Nacelle | Additional insulation | A decrease in heat loss in the generator; the grease will not freeze |

| Low-temperature grease | The generator will not stall at low temperatures (lower than −15 °C) | |

| Generator shutdown system | Storm damage prevention | |

| Tower | Using steel for low-temperature applications | Conventional steel becomes brittle and less wear-resistant at low temperatures, which can result in collapse under heavy loads due to poor weather conditions |

| Designing the foundation taking into account such factors as permafrost and thawing | Structural stability |

| Renewables | Well Pad A024 (3 Wells), USD Thousand | Well Pad A01 (4 Wells), USD Thousand | Group of Multiple Wells A024(3), A01(4), A02(4), A04(3), USD Thousand |

|---|---|---|---|

| CAPEX (2019) | 122.46 | 123.60 | 492.11 |

| Unit design calculations | 7.42 | 7.42 | 29.67 |

| Equipment with logistics | 33.58 | 34.72 | 136.6 |

| Construction and installation works | 81.46 | 81.46 | 325.84 |

| Annual OPEX | 1.31 | 1.31 | 5.22 |

| Operation and Maintenance | 1.31 | 1.31 | 5.22 |

| PV@7,5% (20 years) | 127.22 | 128.28 | 510.99 |

| Power Transmission Line | Well Pad A024 (3 Wells), USD Thousand | Group of Multiple Wells A024(3), A01(4), A02(4), A04(3), USD Thousand |

|---|---|---|

| CAPEX (2019) | 274.88 | 1383.56 |

| Construction of a power transmission line (Achim Development Project documentation) | 274.88 | 1383.56 |

| Annual OPEX | 2.14 | 10.58 |

| Operation and Maintenance | 2.02 | 10.02 |

| Electricity (payments to Gazprom Energosbyt Tyumen JSC) | 0.13 | 0.56 |

| PV@7,5% (20 years) | 277.52 | 1394.89 |

| Risk | Mitigation Tools |

|---|---|

| 1. Low wind speed |

|

| 2. Hurricane |

|

| 3.Emergency shutdown |

|

| 4. Faulty insulation |

|

| 5. Lightning and thunderstorms |

|

| 6. Icing |

|

| Risk | Before Mitigation | After Mitigation | ||

|---|---|---|---|---|

| Probability (Weighted Average Indicators) | Impact (Weighted Average Indicators) | Probability (Weighted Average Indicators) | Impact (Weighted Average Indicators) | |

| 1. Low wind velocity | 65.0% | 90.0% | 35.0% | 37.5% |

| 2. Hurricane wind | 35.0% | 77.5% | 10.0% | 50.0% |

| 3. Emergency shutdown | 10.0% | 77.5% | 10.0% | 35.0% |

| 4. Insulation breakdown | 22.5% | 65.0% | 10.0% | 35.0% |

| 5. Thunderstorms | 22.5% | 22.5% | 22.5% | 10.0% |

| 6. Icing | 77.5% | 90.0% | 35.0% | 77.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stroykov, G.; Cherepovitsyn, A.Y.; Iamshchikova, E.A. Powering Multiple Gas Condensate Wells in Russia’s Arctic: Power Supply Systems Based on Renewable Energy Sources. Resources 2020, 9, 130. https://doi.org/10.3390/resources9110130

Stroykov G, Cherepovitsyn AY, Iamshchikova EA. Powering Multiple Gas Condensate Wells in Russia’s Arctic: Power Supply Systems Based on Renewable Energy Sources. Resources. 2020; 9(11):130. https://doi.org/10.3390/resources9110130

Chicago/Turabian StyleStroykov, Gennadiy, Alexey Y. Cherepovitsyn, and Elizaveta A. Iamshchikova. 2020. "Powering Multiple Gas Condensate Wells in Russia’s Arctic: Power Supply Systems Based on Renewable Energy Sources" Resources 9, no. 11: 130. https://doi.org/10.3390/resources9110130

APA StyleStroykov, G., Cherepovitsyn, A. Y., & Iamshchikova, E. A. (2020). Powering Multiple Gas Condensate Wells in Russia’s Arctic: Power Supply Systems Based on Renewable Energy Sources. Resources, 9(11), 130. https://doi.org/10.3390/resources9110130