WEEE Resource Management System in Costa Rica

Abstract

:1. Introduction

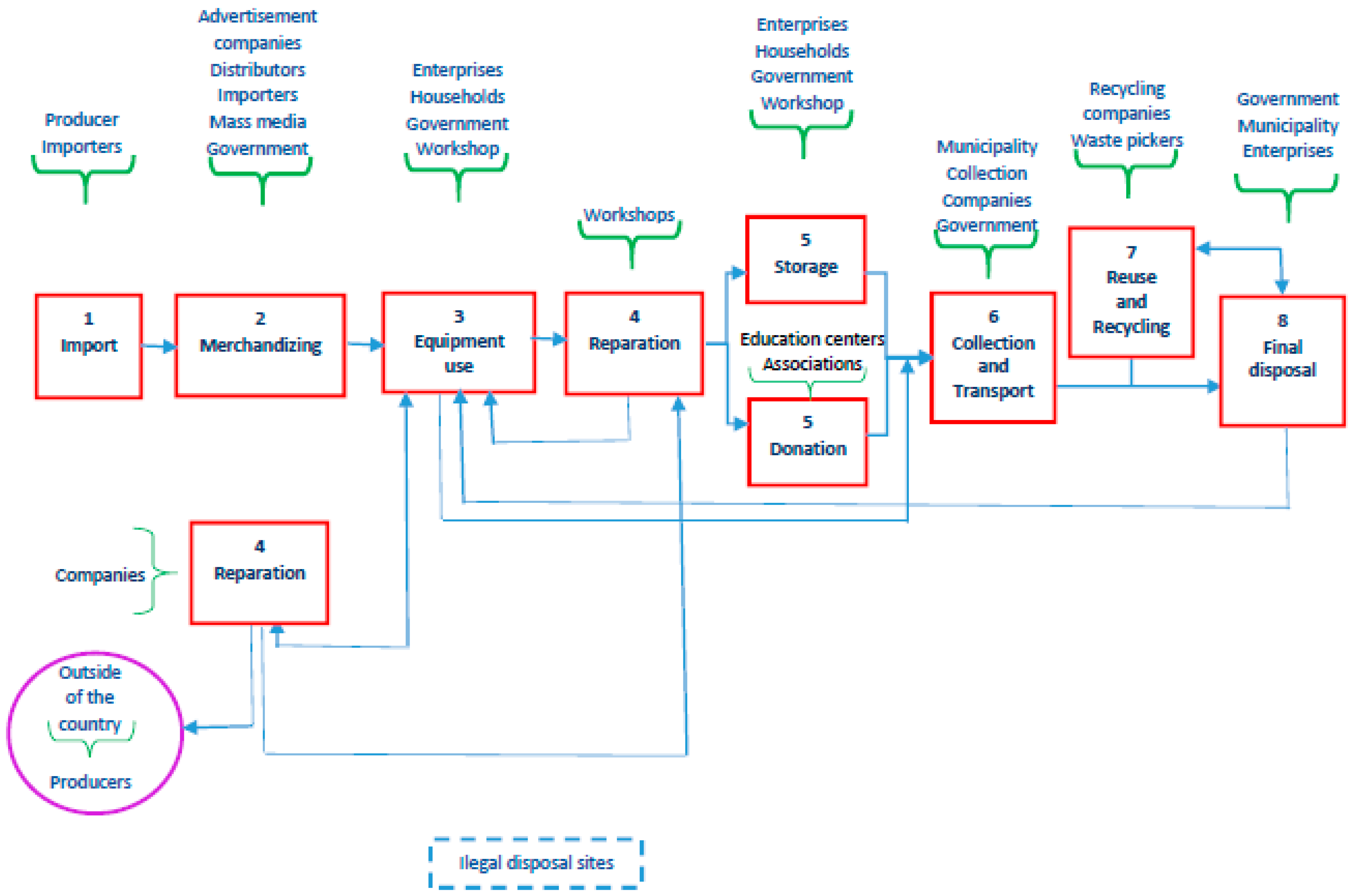

Waste of Electrical and Electronic Equipment in Costa Rica

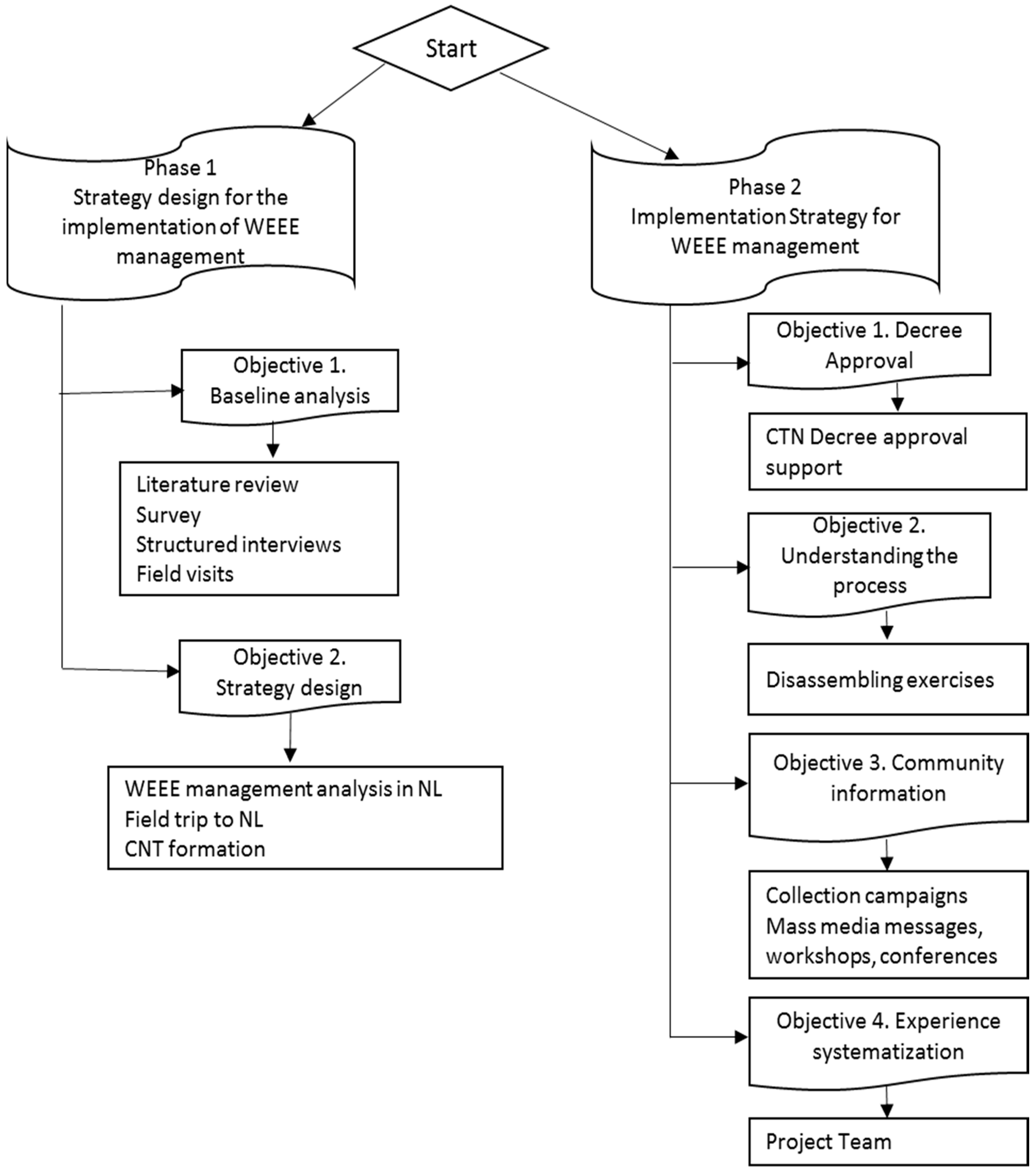

2. Methodology

2.1. First Phase

- (1)

- Equipment importers and distributors. Importers and distributors existing in the Great Metropolitan Area (GMA) providing services since 2003 independently of its size;

- (2)

- Electric and electronic refurbishing workshops. Workshops in the GMA with services since 2003;

- (3)

- Governmental and private clients. Public and private banks in the GMA, public and private universities with Informatics or Electronic careers, ministries and autonomous institutions, and enterprises that are members of the Industry and Commerce Chambers;

- (4)

- Municipalities. Municipalities from GMA that have that have the responsibility of managing the disposal sites; and

- (5)

- Households. Owners of a desk telephone line in the capital city in 2003.

2.2. Second Phase

3. Results and Discussion

- Prohibits discarding WEEE together with household waste

- Officially creates the National Executive Committee with representatives of importers, consumers, and government which will establish the quotes, treatment fees, etc.

- New electronics will be covered by the management system once implemented, while historical (EEE generated before the Decree approval) and orphan waste (EEE from a producer or importer that is not in the market anymore) must pay a treatment fee

- The compliance entities (individual or collective) must present their plans for WEEE treatment, which must be approved by the Controller (Ministries of Health and Environment)

- The processors must show compliance to the national regulation such as operation, permit, environmental impact assessment, ad labour safety, in addition to transparency concerning local and international materials trade according to the regulations, including the Basel Convention

- International materials trade may vary according to the development of technologies in the national territory

- Enterprises in Free Trade Zones can also contemplate the use of the system

- In the case of equipment donations, the donor can transfer the hardware but not the responsibility of the waste (treatment fee should be covered by the donor organisation)

4. Limitations of the Process

- The change of the political party ruling the country and the roles and responsibilities of the state institutions responsible for leading the Decree approval produced a delay of several years, affecting key issues in the strategy implementation.

- It was not possible to motivate municipalities and other related institutions to participate in the two phases in spite of the efforts made.

- There was a lack of knowledge on how to recover, reuse, or recycle materials e.g., Cathode Ray Tubes of monitors.

5. Conclusions

- When installing a recovery and recycling system for WEEE, existing collecting, transporting, and recycling enterprises should be incorporated.

- Regulation on WEEE should be based on existing national legislation to reduce approval times.

- The national strategy must be the result of a consensus among the different stakeholders that are participating in the process through private public partnerships.

- The identification of the possible institutions and organisations related to the EEE and their capacity and accountability were fundamental in setting up the National Technical Committee.

- The participation of institutions and individuals of different backgrounds enriched the National Technical Committee with different points of view. Nevertheless, this also implied having to invest major efforts in negotiation processes to be able to reach agreements through consensus. The leading organisation for the constitution of such a committee should be an independent organisation that is neutral to enable interdisciplinary and inter-institutional exchange.

- When WEEE as a subject was placed on the national agenda, it began to generate a demand for the environmentally safe treatment of EEE.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Examples of Instrument for Data Collection

| Date:________________________ |

| Questionnaire for importers and distributors of electric and electronic equipment (Computers, printers, scanners, digital cameras, copying machines, and all the components) |

- Company name_____________________________________

- Address_______________________________________________

- Telephone number_______________________Fax______________________

- E-mail ________________________________________

- Interviewed name___________________________________

- Gender

- ( ) Male

- ( ) Female

- Position in the company: ______________________

- Years of work in the company: _______

- Education level:

- ( ) Primary

- ( ) High School

- ( ) University

- ( ) Other

- Company´s activity:

- ( ) Importer

- ( ) Distributer

- ( ) Both

- Company status:

- ( ) National

- ( ) International

- Does the company have other shops in the country?

- ( ) No

- ( ) Yes Where?: _______________________

- Does the company have policies, procedures, norms or regulations related to WEEE Management?

- ( ) No (Go to question 15)

- ( ) Yes Which one(s) (Please attach them)

- Who designs them?

- Is the company aware of WEEE management companies?

- ( ) No (Go to question 17)

- ( ) Yes which one(s)_________________________

- Does the company have any kind of share with the WEEE management company?

- No ( )

- Yes ( ) Type of share__________________

- 17.

- Products imported

Product Supplier/City/Country - 18.

- Who are your most important clients?

- ( ) Workshops

- ( ) Commerce

- ( ) Government

- ( ) Enterprises

- ( ) Households

- ( ) Others Who? __________________

- 19.

- Which mass media does the company use for promotions of its products?

- ( ) TV

- ( ) Radio

- ( ) Newspaper

- ( ) Internet

- ( ) Others. Which ones?

- 20.

- Does the company receive defective equipment for refurbishing?

- ( ) No (Go to question 23)

- ( ) Yes

- 21.

- Does the company have refurbishing services?

- ( ) No (Go to question 23)

- ( ) Yes

- 22.

- Does the company reuse spare parts?

- ( ) No Why?

- ( ) Yes Which ones?

- 23.

- What does the company do with the obsolete equipment?

- 24.

- Does the company generate WEEE?

- ( ) No (Go to question 28)

- ( ) Yes. Approximately how much a month?

- 25.

- Where does the company send them?

- ( ) Own warehouse

- ( ) Disposal site. Which one? Who takes the waste there?

- ( ) Material refuse facility. Which?

- ( ) Recycling company. Which one?

- ( ) Others. Which?

- 26.

- Who makes the decisions where the waste goes?

- 27.

- Does the company pay for the WEEE transfer to any of those places?

- ( ) No

- ( ) Yes How much (monthly)

- 28.

- Do you know any reason why WEEE should be disposed in a different matter than it is done now?

- ( ) No

- ( ) Yes Which?

- 29.

- Which measures do you suggest to improve WEEE Management in the company and in the country?

- 30.

- Who do you think is responsible for WEEE management?

- ( ) EEE importers and distributors

- ( ) EEE assembling companies

- ( ) Commercial enterprises selling the equipment

- ( ) Refurbishing workshops

- ( ) Government

- ( ) Municipalities

- ( ) Clients

- ( ) Others Specify:

- 31.

- Do you know which substances are present in EEE?

- ( ) No

- ( ) Yes Which?

- 32.

- Do you know the health challenges related to the manipulation of EEE?

- ( ) No

- ( ) Yes Which?

- 33.

- Is the company interested in participating in a National Strategy Design for WEEE and its implementation?

- ( ) No Why?

- ( ) Yes

| Household | No.___ |

| PRESENTATION: ACEPESA is performing a research with the objective to determine the type of WEEE management at a national level | |

- Did /do you have a computer, printer, or scanner not in use?

- ( ) No (Go to question 3)

- ( ) Yes

- What did you (do you) do with the equipment?

- ( ) You keep it in your house.

- ( ) You disposed it with the ordinary waste

- ( ) You gave/will give it to a person/recycling company Who/which?_________

- ( ) You disposed/will dispose it in empty lot, or river basin

- ( ) You gave it/will give it to store that sells the equipment Which?______________

- ( ) Gave it/will give it as donation

- ( ) Sold/will sell it

- ( ) Others. Which?

- Are you willing to pay for a person/enterprise that receives the equipment and manages it in an environmental way?

- ( ) No (Go to question 5)

- ( ) Yes

- How much are you willing to pay to dispose your equipment?

- ( ) Less than ¢1.000

- ( ) Between ¢1.000 to less than ¢2.000

- ( ) Between ¢2.000 to less than ¢3.000

- ( ) More than ¢3.000

- Do you have any suggestion for a better WEEE management system?

Appendix B. Tool for Interviews with Waste Pickers at Disposal Sites

- Do you recuperate computers, printers, or photocopying machines or spare parts of that equipment?

- From where does that equipment come?

- Is the equipment or spare parts mixed with regular waste or does it come separated?

- Which materials are you recuperating and how do you do it?

- To whom do you sell it?

- What price do they pay for it?

- How did you get information about those buyers?

- Which conditions do they request for that equipment?

- Do you know the health impacts caused by contact with that equipment?

- Which advantages do you find in recuperating the equipment?

- What do you think is a problem in relation to the recuperation of those materials?

References

- Tanskanen, P. Management and recycling of electronic waste. Acta Mater. 2013, 61, 1001–1011. [Google Scholar] [CrossRef]

- Ongondo, F.O.; Williams, I.D.; Cherrett, T.J. How are WEEE doing? A global review of the management of electrical and electronic wastes. Waste Manag. J. 2011, 31, 714–730. [Google Scholar] [CrossRef] [PubMed]

- Silva, U.; Ott, D.; Boeni, H. E-waste recycling in Latin America: Overview, challenges and potential. In Proceedings of the Global Symposium on Recycling Waste Treatment and Clean Technology, Cancun, Mexico, 12–15 October 2008. [Google Scholar]

- Borthakur, A. Generation and management of electronic waste in India. An assessment from stakeholders’ perpective. J. Dev. Soc. 2015, 31, 220–248. [Google Scholar] [CrossRef]

- Pathaka, P.; Srivastava, R.R. Assessment of legislation and practices for the sustainable management of waste electrical and electronic equipment in India. Renew. Sustain. Energy Rev. 2017, 78, 220–232. [Google Scholar] [CrossRef]

- Arroyo-Araya, H.; Marín-Araya, M.; Rudin-Vega, V. Electronic Waste Management in Costa Rica: Systematization of the Methodology; Bilateral Project—Costa Rica/The Netherlands; Phases I and II, 2003–2007; San Jose, Costa Rica, 2007. [Google Scholar]

- Herrera-Murillo, J.; Rojas-Marín, J.F.; Anchía-Leitón, D. Generation rates and characterization of ordinary solid waste in four municipalities of the metropolitan area Costa Rica. Rev. Geogr. Am. Cent. 2016, 57, 235–260. [Google Scholar]

- Programa de Competitividad y Medio Ambiente (CYMA). Reporte Nacional de Manejo de Materiales, Costa Rica. 2006, pp. 66–69. Available online: https://www.ministeriodesalud.go.cr/index.php/investigacion-y-tecnologia-en-salud/inventarios/inventario-de-tecnologias-en-girs/documentacion-tecnica/1387-reporte-materiales-2006/file (accessed on 20 August 2017).

- WASTE. Integrated Sustainable Waste Management. Click on ISWM “Approaches”. Available online: http://waste.nl/en/our-approach (accessed on 21 December 2017).

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. J. 2013, 33, 220–232. [Google Scholar] [CrossRef] [PubMed]

- ISSOWAMA (Integrated Sustainable Solid Waste Management in Asia) Consortium. Seventh Framework Programme; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Rudin-Vega, V. Gestión de residuos electrónicos en Costa Rica 2003–2013. Presented at Meeting Platform RELAC, Brasilia, Brasil, 25–27 November 2013. [Google Scholar]

- Roa-Gutierrez, F.; Rudin-Vega, V. Costa Rica’s first EPR Model towards a sustainable management of e-waste. In Proceedings of the R’07 World Congress Recovery of Materials and Energy for Resource Efficiency, Davos, Switzerland, 1–9 September 2007. [Google Scholar]

- Roa-Gutierrez, F.; Salas-Jiménez, J.C. Closing the technological gap on e-waste processing in developing countries: A Costa Rica case study. In Proceedings of the Electronics and Battery Recycling Conference, Canadian Association of Recycling Industries (CARI), Toronto, ON, Canada, 24–26 June 2009. [Google Scholar]

- Roa-Gutiérrez, F. Sistema de manejo sostenible para residuos electrónicos. Tecnología Marcha 2009, 22, 3–9. [Google Scholar]

| Population | Total | Sample Framework | Sample Size |

|---|---|---|---|

| Equipment importers and distributors | 704 | Telephone book, 2003 Commercial Directory, 2003 Industrial Directory, 2003 Database of Ministry of Economic, Industrial, and Commercial Affairs, December 2002 | 85 |

| Electric and electronic refurbishing workshops | 23 | Telephone book, 2003 | 17 |

| Governmental and private clients | 1.429 | Commercial Directory, 2003 Industrial Directory, 2003 Telephone book, 2003 Internet | 131 |

| Municipalities | 9 | San José, Atenas, Alajuela, Santo Domingo, Curridabat, Tres Ríos, San Pablo de Heredia, San Isidro de Heredia, and Goicoechea. | 100 |

| Households | - | Telephone book 2003 | 9 |

| Total | 2.165 | 342 |

| Operator | Time (min) | |||

|---|---|---|---|---|

| CPU | CRT * Monitor | Keyboard | Total | |

| 1 | 15.0 | 14.5 | 3.5 | 33.0 |

| 2 | 14.0 | 16.9 | 2.5 | 33.4 |

| 3 | 13.0 | 14.8 | 2.5 | 30.3 |

| Average | 14.0 | 15.4 | 2.8 | 32.2 |

| Title | Descriptor | 1st Pilot Exercise Costs ($) | 2nd Pilot Exercise Costs ($) |

|---|---|---|---|

| Warehouse area | Warehouse renting cost for the processing facility, including a 30% benefit | −6.37 | −4.0 |

| Dismantling process | Labour including local transportation and forklift moving of the materials inside the facility | −4.30 | −4.30 |

| Packaging | Sacks, shipping boxes | −0.13 | 0.13 |

| Local market | Sales of copper, aluminium, ferrous metals, and plastics | +0.46 | +0.46 |

| Exportation | Shipping logistics services, Basel Convention declaration and permits, shipping and final processing of CRTs and PVC *-covered wiring at certified international processing facilities | −7.91 | −3.95 |

| International market | Sales return for precious metal recovery in circuits | +1.23 | +1.23 |

| TOTAL | −17.02 | −10.69 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abarca-Guerrero, L.; Roa-Gutiérrez, F.; Rudín-Vega, V. WEEE Resource Management System in Costa Rica. Resources 2018, 7, 2. https://doi.org/10.3390/resources7010002

Abarca-Guerrero L, Roa-Gutiérrez F, Rudín-Vega V. WEEE Resource Management System in Costa Rica. Resources. 2018; 7(1):2. https://doi.org/10.3390/resources7010002

Chicago/Turabian StyleAbarca-Guerrero, Lilliana, Floria Roa-Gutiérrez, and Victoria Rudín-Vega. 2018. "WEEE Resource Management System in Costa Rica" Resources 7, no. 1: 2. https://doi.org/10.3390/resources7010002

APA StyleAbarca-Guerrero, L., Roa-Gutiérrez, F., & Rudín-Vega, V. (2018). WEEE Resource Management System in Costa Rica. Resources, 7(1), 2. https://doi.org/10.3390/resources7010002