Abstract

Dematerialization is a paradigm in resource conservation strategies. Material use should be reduced so that resource consumption as a whole can be lowered. The benefit for humankind should be completely decoupled from the natural expenditure by a definite factor X. Instinctively, this approach is convincing, because our entire value-added chain is based on material transformation. Targets for mass-based indicators are found within the context of justification for ecological carrying capacity and intergenerational fairness, taking into account the economic and socio-political expectation of raw material scarcity. However, in light of further development of material flow indicators and the related dematerialization targets, the question arises as to what they actually stand for and what significance they have for resource conservation. Can it be assumed that pressure on the environment will decline steadily if the use of materials is reduced, whether for an economy or at the level of individual products or processes? The present narrative review paper has discussed this issue and takes into account the authors’ experience of the extended political and scientific discourse on dematerialization in Germany and Europe. As a result, a high “resource relevance” cannot be inferred from high physical material inputs at any of the levels considered. It has been shown that establishing mass-based indicators as control and target variables is questionable and that dematerialization exclusively based on such indicators without mapping other resources should be critically examined.

1. Introduction

Biophysical methods and models suggest that a global safe operating space can be identified where safe and sustainable life is granted to humankind without exceeding certain ecological limits [1]. However, a degradation of ecosystems and ecosystem services shows that those ecological limits have already been reached [2]. Moreover, humankind has most probably already exceeded the stress limits for climate change, phosphate and nitrogen nutrient fluxes, land-use changes, and biosphere integrity—four out of nine specified planetary limits [3]. If this situation is not resolved effectively, it must be assumed that not only will the Earth’s state gradually worsen but also change irreversibly with devastating consequences for life on this planet.

Making express references to the planetary boundaries as well as resource scarcity and availability, national and international political agendas are increasingly migrating towards acceptance of resource conservation with a prime focus on increasing the efficiency of its use. European activities—starting from the milestone of the “Thematic Strategy on the Sustainable Use of Natural Resources” in 2005—have provided an implementation roadmap for the “resource-efficient Europe” flagship initiative [4,5,6]. This initiative is aimed at simultaneously enhancing economic performance and reducing the associated resource consumption. The European Environment Agency (EEA) has published a comprehensive report to show how 32 European states want to increase their resource efficiency [7]. The Federal Government of Germany stipulated its own resource efficiency programme ProgRess in 2012 [8]. An evaluation of performance was published on the basis of a progress report in 2016, and a second resource efficiency programme was adopted at the same time [9]. Countries such as Japan developed national strategies [10] many years ago, or—as in the case of India [11]—have recently developed one.

At an international level, in founding the Resource Efficiency Alliance, the G7 countries have committed to ambitious measures to protect natural resources and improve resource efficiency, building essentially on the reduce–reuse–recycle framework of the Kobe 3R Action Plan and existing national initiatives [12]. Even more importantly, the G20 launched a Resource Efficiency Dialogue, which will exchange good practices and national experiences to improve the efficiency and sustainability of natural resource use across the entire life cycle and to promote sustainable consumption and production patterns [13]. Resource efficiency is most prominently represented by the UN Sustainable Development Goals (SDGs). The 2030 Agenda for Sustainable Development envisages a world in which consumption and production patterns and use of all natural resources are sustainable [14].

In recent years, the concept of a circular economy has received increasing attention worldwide due to the recognition that the security of supply of resources and resource efficiency are crucial for the prosperity of economies [15]. In the meantime, existing strategies for resource efficiency have already been supplemented or even replaced by those for a circular economy, although there is a very large congruence in terms of contents. The EU Commission has presented a new circular economy strategy in line with the existing 2020 Europe Strategy flagship initiatives [16]. The Strategy consists of an EU Action Plan for the Circular Economy, including revised legislative proposals on waste that establishes a concrete and ambitious programme of action, with measures covering the whole cycle: from production and consumption to waste management and the market for secondary raw materials. A declared goal is to implement the paradigm shift from the resource-intensive, linear, “take, make, consume, and dispose” economic model to a resource-efficient circular economy. Initiatives, strategies, programmes, and roadmaps are being pursued to help further the development of a circular economy by organizations, and in many countries such as Finland [17] and the Netherlands [18], with the aim of strengthening a resource-efficient economy [19]. Even if the distinction between resource efficiency and circular economy is not clear, circular economy can be described as a desirable target state of a resource-conserving economy.

In the programmes and strategies mentioned, there is as yet no generally accepted definition of the central object, the natural resources. Depending on their definition and interpretation, they include materials, raw materials, natural energy flows, land, wildlife, agricultural goods, environmental media, ecosystems, the services they provide, and biodiversity. This results in more or less major overlaps between the natural environment, natural resources, natural capital, and, as a consequence, resource use and environmental impact. The strategies often use the terms of resource use and resource consumption synonymously or arbitrarily. This unclear terminology is not solely linguistic but raises fundamental conceptual questions about the relationship between environmental protection and resource conservation and the target parameters of resource conservation.

It is striking that, although a “broad understanding” of natural resources is often considered, an implicit or partly explicit focus is placed on raw materials or materials. For example, those indicators concerned with the frugal use of fresh water, land areas, or the protection of genetic diversity are also included in the final list of coordinated SDG indicators. However, the material footprint or its productivity was chosen as the only indicator to represent natural resources under the central SDG 12 meant to achieve sustainable management and efficient use of natural resources by 2030 [20]. Similar material flow indicators and their productivities have also been described in national programmes and sustainability strategies, or even prominently set as leading indicators for the programmes to measure the success of resource conservation or resource efficiency [21,22,23,24].

The widespread focus on material in strategies for natural resource use goes back to a 1990s school of thought that considers dematerialization, i.e., a reduction of material use by a “factor X”, as a guiding principle for a sustainable economy. Such an economy avoids negative environmental impacts and faces scarcities in a precautionary way, in responsibility as well, for future generations. The declared objective is to decouple benefits from resource demand, which is equated to material demand in this school of thought. This dematerialization approach is propagated not only at the overall economic level but also at the micro level for products and processes [25]. The discussion of approaches to dematerialization has given a great boost to the development of material flow calculations and accounting [26,27]. However, the significance of the concept and its material-based indicators is considered controversial [28,29,30,31,32]. The objectives are the subject of political, societal, and scientific discussions. Although, to the authors’ knowledge, there are so far no binding resource policies that explicitly aim at dematerialization, the above-mentioned focus on material efficiency and the common synonymous use of the terms resources and material makes an implicit reference to this school of thought.

Research Questions and Goals

In light of further developments of the macroeconomic material flow indicators for resource efficiency assessment and of the analysis of material flows at process and product levels, questions arise as to what mass-based indicators stand for and what they reveal about the conservation or the efficient use of natural resources. Instinctively and emotionally, they are highly relevant. Our entire value-added chain is based on material and substance transformation: we extract material from the environment, transform it, and permanently discharge emissions and waste into the natural environment, which influences its state. Even services and non-material goods in the strict sense such as education are dependent on these material transformation processes: they require infrastructure such as roads, railways, heated buildings, computer centers, and much more. In turn, these can be used to fulfil their purpose only with auxiliary materials and fuels, mostly fossil fuels.

If so much depends on our material flows, does reduction of material use by a factor X suit as a guiding principle for a sustainable economy? Is it safe to assume that environmental pressure will drop steadily and resource scarcity be addressed if material use is reduced across the board by a certain factor X, as the dematerialization school of thought is assuming? How reliable is the measurement of the success of resource conservation using dematerialization indicators in kilograms, tonnes, and megatonnes and can any connection be made to the relevant areas of protection? Regarding the breadth of all natural resources, how “resource-relevant” are mass-based indicators? Do they qualify as control variables for policies that aim at conservation or the efficient use of resources?

Against this background, this paper presents a narrative review of relevant methodologies and assessments for raw materials. It discusses the current application of material flow indicators and juxtaposes concepts for raw materials and safeguard subjects from a micro level. It reflects the shortcomings, advantages and main criticism with regard to methodology and transported messages. Thereof, conclusions are drawn about the use and interpretation of mass-based indicators for resource policy.

The structure of this paper is as follows: Section 2 discusses the technical background. The authors present their classification of resource conservation terminology. The application of economy-wide material flow accounting (EW-MFA) indicators in political programmes is described using Germany as an example. This is followed by an outline of the factor X approach and its fundamentals for dematerialization as a strategy. In Section 3, the relevance of material flow indicators for the use of natural resources is discussed on the basis of the author’s experience. Areas of protection and impact paths of raw material consumption are described. The authors discuss the relevance of material flow indicators for environmental impacts and raw material scarcities, which are at the core of the justification for dematerialization and resource efficiency strategies. The extent to which it is legitimate to use the precautionary principle to justify dematerialization strategies and to derive dematerialization targets is additionally discussed. In Section 4, the key findings are summarized, followed by a concluding discussion to put the results into perspective in the resource policy debate in Section 5.

2. Resource Conservation Conceptualization for Materials and the Factor X Approach

2.1. Terminology

The resource conservation policy field has so far been strongly anthropocentric and utilitarian, which is already laid out in the semantics of the resource term and is reflected in different definitions of the term natural resources [33,34,35,36,37] and in explanations on the subject [6,8,38,39,40]. This means that this policy field does not focus on nature’s intrinsic value and its living beings or the needs of other sentient creatures, but rather on the needs of humans or benefit or value for humans. Natural resources create the material, energy and spatial basis for human life and are indispensable for our economy and welfare. We satisfy our needs by using them as sources of energy, production means, living and recreational areas, a pool of pharmaceutical active agents, and so on [40]. All these natural resources contribute to our natural capital, which must be conserved and enlarged over the long term.

Other definitions do not make this explicit reference to human needs or benefit but define them as “all components of nature” [9] or are confined to the final and non-exhaustive list of their components [4,9,41,42]. Depending on the definition, natural resources include at least the geological stocks of primary raw materials, defined as unprocessed materials or material mixtures which are extracted from nature to be input into production processes [43]. In addition, physical space including area, environmental media such as water, soil, and air, flow resources such as solar radiation, wind and water flows, ecosystems, and ecosystem services for humans are also counted as natural resources [6].

One of the few recent definitions that are not exhausted in an enumeration of its components defines natural resources as “means found in nature that can be beneficial for humans” [43]. This paper uses this definition. This conception of natural resources includes environmental media and ecosystems, not only in their function as source of material and energy, but also as a sink for emissions (sink function) and other functions. They bring us services on a daily basis, often invisibly—be it the soil’s water filter function, the rivers’ self-cleaning capacity, the atmosphere’s emission absorption capability, flood control by floodplain forests, the regeneration capability of fish stocks, or the pollination by wind, water, and animals—and must therefore be considered natural resources in the sense that they are “means found in nature that can be beneficial for humans”.

From this broad understanding of natural resources, however, delineation questions arise about the natural environment and, subsequently, conceptual issues about the relationship between environmental protection and resource conservation. Emissions into environmental media and ecosystems are, in this sense, not only environmental impacts but also a resource use. According to this understanding, resource conservation is merely another, strictly utilitarian–anthropocentric perspective of environmental protection. This is followed by a further terminological blurring of resource conservation, which is of decisive relevance for the conceptual development of this field of science and policy: Is resource conservation aiming at reducing resource use or resource consumption? Resource use means any human access to natural resources, while resource consumption is a form of resource use that converts resources in such a way that they are not available for any other uses [43].

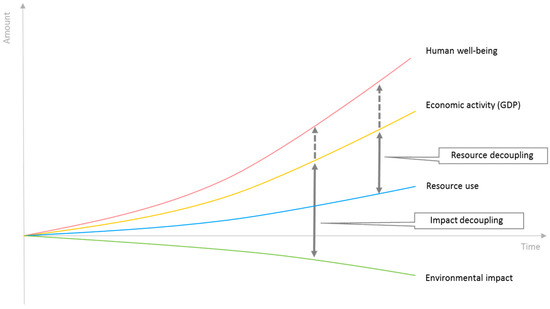

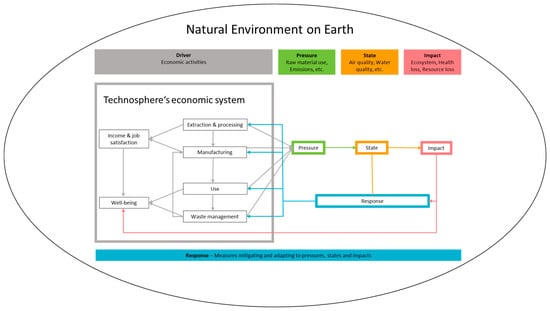

While resource conservation designates the careful handling of natural resources in order to avoid their depletion or consumption, resource efficiency or resource productivity is the ratio between a given benefit or result and the natural resource use required to achieve it [43,44,45]. Resource efficiency is conceptually based on the decoupling concept shown in Figure 1. However, the arguments in the last paragraph raise the question whether or not a double decoupling concept is reasonable and necessary, aiming at decoupling both prosperity and human well-being from resource use as well as resource use from environmental impacts (see Figure 1). In contrast to the resources, the benefit is a rather subjective or judgemental category. “The benefit of products and services is given by functions that are frequently described by technical parameters. In economy, the benefit is frequently expressed in monetary terms and given as turnover or product price numbers. Both the technical and monetary assessments of benefit do not fully cover all forms of all benefit aspects” [43]. Since the political resource efficiency debate aims to address economic performance in relation to natural resource use (see Section 1), this article uses the term benefit, which includes technical function but allows monetary valuation.

Figure 1.

Absolute and realtive decoupling pathways for well-being, economic activity, resource use, and environmental impacts [46]. In the most desirable case, benefits, i.e., GDP, increase while cost, i.e., environmental impact or resource use, decreases. This constellation is called absolute decoupling. Even if cost in terms of resource use increases, productivity can still increase if benefits increase more strongly. This constellation is also called relative decoupling. A third case is also conceivable: if both cost and benefit decrease, but cost decreases more than benefit, productivity increases.

2.2. Productivity Indicators and Decoupling by Germany’s Example

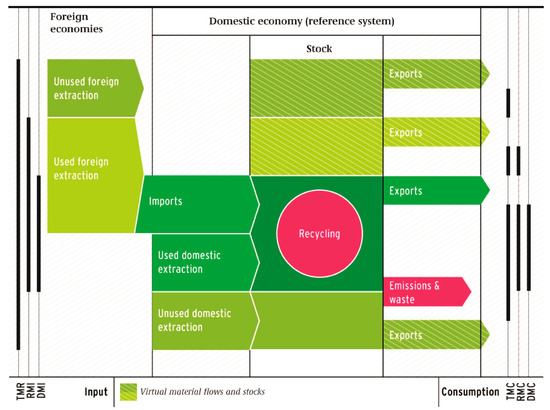

Raw material productivity, a key indicator of the German sustainability strategy from 2002, is a basic element of the German resource efficiency programme [8,9]. Raw material productivity sets the gross domestic product in relation to the abiotic part of direct material input (DMIabiot) from domestic raw material extraction and imports. DMI is an input indicator in the system of economy-wide material flow indicators (Figure 2). Input indicators map the (raw) material inputs used to provide all services of an economy. If imports are recorded not only in their own weight as in the case of the DMI but also together with the used or even unused foreign extraction, the indicators Raw Material Input (RMI) or Total Material Requirement (TMR) are used for this purpose. The same metabolic system also specifies indicators that map domestic consumption using the DMC, RMC, or TMC indicators, and physical trade balance or stock growth by balancing inputs and outputs in different ways [47].

Figure 2.

Illustration of economy-wide material flow indicators. The lateral lines indicate the respective system boundaries and balancing items [40].

The indicator for raw material productivity provides information on the efficient handling of abiotic materials. Through its relationship to GDP the indicator is chiefly considered to be an economic parameter for the production factor of abiotic materials. Raw material productivity is thus analogous to labor and capital productivity.

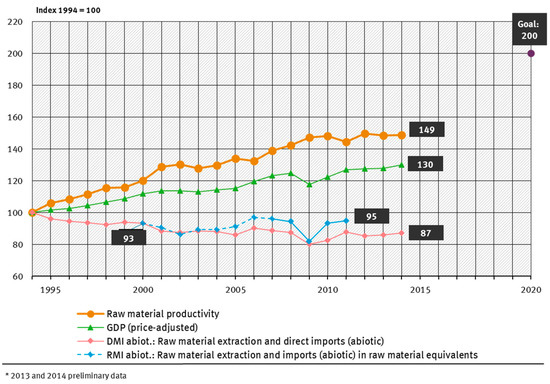

GDP and DMIabiot show an absolute decoupling over time (Figure 3). However, DMIabiot takes into account imports at their actual processing level, the so-called direct material flows [47]. Those raw materials that were used for the production of imported goods in other countries beyond the dead weight of imports are not accounted for. If resource-intensive processes are relocated abroad and highly processed goods are imported instead, raw material productivity increases [48]. Since the tendency is that semi-finished and finished products are increasingly imported, the observed absolute decoupling is mainly due to the indicator’s methodological weakness [49].

Figure 3.

Raw material productivity in Germany from 1994 to 2014 and the underlying trends of GDP, DMIabiot, and RMIabiot. Data based on [50].

Since 2007, a methodology has been developed to cover raw materials used for imports [49,51,52]. This methodology uses input–output analyses and process chain approaches to identify goods together with their raw material equivalents (RMEs). On average, the RME is 2.7 tonnes per 1 tonne of directly imported material into Germany, which means that 2.7 tonnes of raw material are needed abroad to produce 1 tonne of physically imported goods [48]. As a comparison, the corresponding imports in RME for the EU-28 on average are estimated as being 2.4 times higher than actual physical imports, thus in the same order of magnitude as in Germany [53]. The primary raw material input (RMI) indicator maps the sum of domestic raw material extraction and direct and indirect imports beyond the dead weight of the physical imports (Figure 2). RMIabiot is only relatively decoupled from GDP over time [21]—in contrast to DMIabiot (Figure 3). If consumption indicators are taken into account, physical material flow indicators such as domestic material consumption (DMC) may even exhibit diametrically opposed trends to their analogous indicators in RME (raw material consumption, RMC), i.e., a decrease versus a rise [22].

2.3. “Factor X”

In the context of resource conservation policy, firm objectives for dematerialization are being discussed. These are linked to different material flow indicators (Figure 2) and have very different ambition levels. Bringezu and Mancini et al. provide an overview of more recent proposals [30,54]. The dematerialization objectives are rooted in the tradition of a so-called factor X concept. X stands for a reduction factor in the use of a resource for providing a service. Both should be decoupled from each other. This corresponds to the concepts and logic of eco- and resource efficiency or respective productivity [31]. The factor X approach is applied not only to national economies but also to products, services, sectors, industries, and needs [55]. Precursors of the factor X approach can be found in Daly [56] and Ayres [57] whose environmental models also emphasized the necessity of dematerialization, but above all a significant increase in productivity of natural resources. The actual pioneering work of the factor X approach includes a report to the Club of Rome by von Weizsäcker et al.: “Doubling wealth—halving resource use” [58] and Schmidt-Bleek’s book: “How much environment does man need?” [59]. While the two Wuppertal Institute scientists estimated necessary enhancement factors “X” to 4, 5 [60], and 10, other factors of up to 50 have been postulated [31]. The factor targets can hardly be compared since they have different base years depending on the publication date and they extend to very different time periods, from a few decades up to 100 years. Moreover, the authors do not often believe that target horizons and sizes can be made more precise but rather aim at target corridors and orders of magnitude.

Very different perceptions are behind the factor approaches as to which kind of resource use should be reduced. Schmidt-Bleek linked a factor 10 to the concept of material intensity per service unit (MIPS) that he developed, i.e., the reciprocal of productivity. Here, abiotic and biotic materials, including air, and water, are balanced over the service life cycle of products and services. This concept explicitly includes the so called “unused extraction” such as overburden in mining, soil movements in agriculture and forestry, erosion as well as soil excavation for construction [61,62,63]. The categories mentioned minus air and water are also called primary materials and are mapped by the material flow indicator total material requirement (TMR) at the national economic level (see Figure 2). The Factor 10 concept has also been promoted by the identically named Factor 10 club—starting with a Carnoules Declaration in 1994 [64]. However, the references are too general and ambiguous in a terminological sense. This leads to an interpretation mismatch as to which resource use or input is being addressed (see Section 2.1).

Schmidt-Bleek’s MIPS-concept is at the core of dematerialization as a strategy for resource conservation [25,59,61,65]. It is based on the assumptions that the planetary ecological carrying limits have been exceeded, each man-made material flow causes changes in the ecosphere, and the volume of man-made material flows (extraction of material from the ecosphere) exceeds the extent of natural material flows at the earth’s crust (volcanism, erosion, etc.). Furthermore, Schmidt-Bleek bases the necessity for dematerialization on the realization that man is a long way from fully understanding the cause–effect relationships in the interaction between man and nature, our knowledge about specific environmental pressures is extremely limited, and environmental problems are only recognized as such after their occurrence.

Therefore, Schmidt-Bleek proposed that, in addition to emissions and wastes, the focus of environmental policy must be directed towards material inputs into the industrial metabolism since the laws of conservation of mass and energy imply that any input (material extraction) would inevitably become an output (waste, emission, etc.) and thus would address the total environmental impact potential of human activities, including the still unknown environmental problems. This hypothesis has been questioned by various authors [29,66,67,68]. Schmidt-Bleek deduces from the precautionary principle the premise that natural systems should be changed by human activities as little and as slowly as possible and justifies this with the above-mentioned assumptions about the connection between material input and environmental impacts and the wide ignorance of cause–effect relationships. He states that, by lowering the industrial metabolism to “an ecologically compatible degree”, not only known and unknown environmental pressures due to raw material extraction and processing but also environmental impacts during production, use, and disposal of the products produced therefrom should be reduced or avoided, and an “evolutionary balance”, “ecological balance”, or “ecological stability” reached [59].

Other factor approaches such as those of von Weizsäcker do not make an explicit reference to material flow indicators and are not restricted to rigid dematerialization as his approach focuses on eco-efficiency [58]. The action proposals are backed by great technological optimism. Energy demand and greenhouse gas emissions have been chosen as the design basis. However, it may be considered a problem that a factor target for certain resources can be achieved, while it may clearly be missed or even opposing effects may arise for other natural resources within the same system.

Factor approaches must be scrutinized in certain cases because contrasting ambition levels with different societal, economic, and political implications may result from numerically identical factors depending on the consideration’s system boundaries, resources addressed, indicators applied including their specified balance limits, the periods considered, the stipulation of absolute targets or productivities, which may also be substantially driven by autonomous GDP developments (see Section 2.2).

The discussion on dematerialization initiated by Schmidt-Bleek and others in the 1990s has given a great boost to the development of material flow calculations and accounting [26,27]. Mass-based indicators and their productivities are at the heart of most resource-efficiency policies (see Section 1) and make an implicit reference to Schmidt-Bleek’s hypothesis that aggregated mass would constitute a reasonable proxy for potential environmental impact. According to the perception of the authors, this bold interpretation of the significance of mass-based indicators still endures in debates on resource efficiency and conservation and is an obstacle for successful resource policies.

3. Assessment

3.1. Areas of Protection

The area of protection (AoP) that is addressed by primary raw materials is ambiguous. What exactly must be prevented by using less primary raw materials [69]? Can this also be best represented by means of mass-based indicators? An insight into the widely developed method discussion of life cycle assessment since the beginning of the 1990s helps answer these questions [70]. The logic of life cycle assessment is about the relative reduction of environmental pressures by individual products or processes. However, in order to cover the impact on the environment as a whole, it is described using AoP. These AoPs are damaged by relevant environmental pressures [71]. However, life cycle assessment does not specify which AoP must be respected or why [72]. This issue is addressed by a school of thought that logically argues that the environment is worthy of protection and must first be defined top-down according to the value system in society before its influence and damage can be assessed.

In the early phases of life cycle assessment, the Society of Environmental Toxicology and Chemistry (SETAC) recognized that raw materials are part of the environment worthy of protection [73]. Recently however, different AoP concepts have still led to very diverse approaches for interpretation and definition. The evaluation and preferred selection of certain methods is the subject of on-going discussions [74]. The fundamental anthropocentric context of justification for the raw materials consumption as part of the AoP natural resources can be seen less in the ecological impacts—represented by the ecosystem quality—or human health—which is an AoP on its own—but more in the actual consumption, availability, and possible shortages of raw materials [75,76]. The interest in AoPs can go beyond the purely ecological sector [77]. Societal and social welfare or the fundamental adherence to the precautionary principle is also mentioned in this context [75,78]. Both the definition and the logical connection between AoPs contain normative stipulations that stem from anthropocentric, pathocentric, and biocentric positions [79]. Such issues of value judgement can also be supported by ethical, theological, legal, and economic arguments [71]. Many established ecological assessment methods allocate environmental impacts to the three AoPs: human health, ecosystem quality, and resource consumption [80]. Some authors argue that the man-made—anthropogenic—environment should also be addressed as an independent AoP that inherently goes beyond the ecological sphere [81]. In that sense, Dewulf proposes five different perspectives of natural resources, which comprise not only the natural resources’ asset, their provisioning capacity, and their role as constituents in global ecosystem functions but also their provisioning function for human welfare and human welfare as an inclusive category itself [78].

The AoPs are intrinsically linked to one another. Thus, the extraction and processing of raw materials inevitably leads to reactions with the state of the ecosystem and to a threat to health, for example, through soil changes and mobilized heavy metals. An acidifying emission can cause damage to buildings and thus damage the physical capital of the anthropogenic environment and impair human welfare (see Section 3.2.1). These relationships lead to the fact that resource use and the associated material changes and shifts can subsequently affect different safeguard subjects within the AoP.

There are four basic notions for the assessment of raw materials use and their interpretation as safeguard subjects in the AoP natural resources that are of particular interest [71].

- Intrinsic values: Infringing the supply of raw materials as such is understood as an inadmissible intervention. Each raw material extraction is therefore to be regarded as detrimental to the protection objective.

- Reduction: Reducing the raw materials’ availability is regarded as a restriction on the freedom of future generations. In this case, the decision-making freedom of future generations and intergenerational fairness are the overriding protection objective.

- Devaluation: It is assumed that raw material deposits of lower quality must be exploited in future. This will cause increased mining costs for future generations.

- Substitution: From this perspective, the demands of future generations will be equated with today’s consumption interests and the substitution options of non-renewable raw materials will be regarded based on the technical and economic costs for developing alternative technologies.

Although denoted differently, these are congruent to the categories of impact pathways for resource depletion for raw material use, indicator approaches and addressed safeguard subjects in the AoP natural resources [82]. Accordingly, the scope of ideas ranges from primary raw materials as safeguard subjects over the purely physical availability for future generations and the anticipated impairment by the decreasing quality of deposits and resources, to the functional, intergenerational fulfilment of purpose as an actual safeguard subject from an anthropocentric consumer perspective.

Indicators in the first category are comparatively easy to determine at the life cycle inventory level. However, these indicators do not reveal the scarcity of raw materials, their thermodynamic properties, the time-related changes to deposit qualities, or the functional and monetary utility value of the extracted raw materials. This considerably limits their relevance to the safeguard subject of raw material consumption [82]. In contrast, the depreciation of raw material supply and the substitution of raw materials are of particular interest since they both try to measure actual damage as end points. The rationales clearly go beyond environmental considerations [78] into life cycle sustainability assessment (LCSA) [74,75].

Economy-wide material flow indicators such as RMI or RMC (see Section 2.2, Figure 2) and the methodically equivalent cumulative raw material demand (CRD) that collect the sum of the primary raw materials used to produce and transport a product along the value chain at the level of products and processes can clearly be assigned to a natural resource: primary raw materials. These indicators enable all material systems to be traced back to the basic extraction and exploitation of primary raw materials from the natural environment. The indicators explicitly address the AoP natural resources in terms of raw material consumption for biotic and abiotic raw materials minus water and air in units of mass without further characterization. Since no impact characterization or weighting that may project a scarcity information has been carried out, they can be arranged unequivocally into the context of justification: an intrinsic value is attributed to raw materials, expressed by its mass, and any form of raw material extraction and removal ex aequo impairs the AoP. Resources and deposits of all raw materials are thus regarded equally worthy to protect, irrespective of raw material availability. The indicators map this issue reliably and contradiction free and are appropriate to cover the mass of primary raw materials used. The change of state over several periods indicates whether reserves and resources (biotic extractions and crops) are actually more or less used. This is based on a rather egalitarian assessment approach, which assumes that it makes no difference at which time the raw material is extracted and that each removal can trigger the same potential environmental impacts in a damage model [83,84].

3.2. Relevance and Representativeness of Mass-Based Indicators

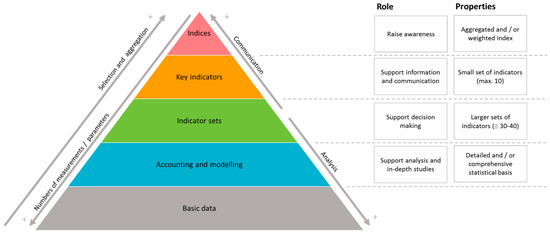

As mentioned in Section 1, mass-based material flow indicators are assigned a strong communication function in an information hierarchy as indices or key indicators to draw attention and possibly represent other natural resources [24]. The more these indicators are aggregated, the more they are subject to a target conflict between their information content and their effectiveness in communication [85]. This is illustrated by the information pyramid in Figure 4. By choosing and limiting the analysis to one or a few indicators, other key figures of a system that may also be important are disregarded. In the lower part of the pyramid, material flow indicators are analytically far more interesting for the analysis of the socio-economic metabolism. In contrast to the use of highly aggregated mass-based indicators the concept of the socio-economic metabolism also established as anthropogenic [86] or industrial metabolism [87,88] incorporates MFA-indicators in a systemic way and puts emphasis on the actual transformation of materials [26,27]. For complex systems such as national economies, material flow indicators, in their functional aggregation and classification according to different materials and uses, enable considerable insights into the system conditions, changes, and driving forces [89]. They provide basic structural information about the economy’s material basis. Thus, input indicators linked to output indicators provide important systemic information and control variables for exports and inputs into the environment, stock accounting balances and domestic use, which can also be interpreted by the comparison of different economies and their development. The analytical instruments are essentially based on material flow analyses, accounting and modeling for comprehensive analysis.

Figure 4.

Information pyramid where indicators exercise multiple roles according to their position. Based on [45].

However, when highly aggregated mass-based indicators are used at process and product levels purely solitarily or at a macro-economic level as headline indicators for natural resources, they are in the context of justification of economic necessities, ecological requirements, and intergenerational fairness and thus scarcity expectation is significant for economic and societal policy [90]. Beyond the intended signal effect and communication function, two crucial questions arise: How good are those mass-based indicators at representing environmental impacts and scarcities?

3.2.1. Representation Function for Environmental Impacts

In the environmental policy relevant DPSIR model (Driver-Pressure-State-Impact-Response), mass-based material flow indicators represent environmental pressures that can cause undesirable effects and condition changes (Figure 5). The DPSIR model is suitable for locating material flows in the human–environment set of interactions [91]. This creates an interdependency between socioeconomic drivers, environmental pressures and impacts, the state of the natural environment and the ecological effects or actual damage. Furthermore, it enables an integrated view of the societal, political, and economic measures that have an impact on the overall set of interactions.

Figure 5.

DPSIR-Framework that shows the interplay between the environment and socio-economic activities, based on [91,92].

Translated into the model logic of DPSIR, a dematerialization strategy now suggests that fewer raw materials are used when modified technologies or changed demand profiles in the economic system are employed; consequently, not only adverse, degrading changes in the environmental status but above all negative environmental impacts are avoided. As a result, fewer responses and adaptive measures would be required. The approach of dematerializing at all can also be interpreted as a response to an already experienced or expected over-use of natural resources, as suggested by Factor X approaches (see Section 2.3). If this is supposed to be promising, mass-based indicators would have to correlate with the actual environmental effects, in spite of the lack of effectivity characterization, i.e., they must be ecologically significant. The ecological significance of raw materials extends to the assessment of further use of natural resources through pressures on the environment (land use and conversion, energy demand, fresh water use, and consumption) and, in particular, environmental impacts (use of the environmental media sink function provided as an ecosystem service and impairments of biodiversity).

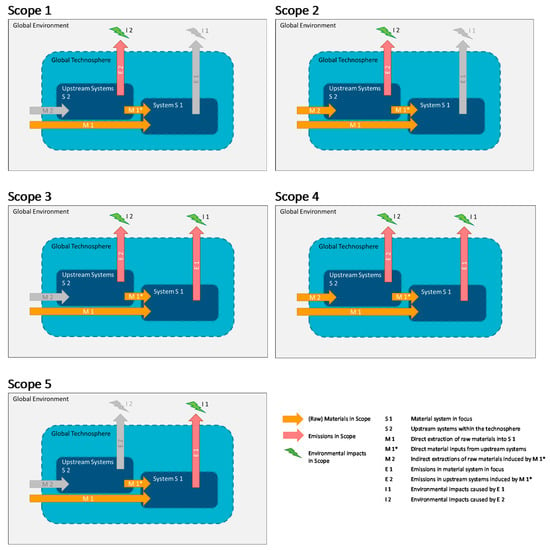

In the following, five scopes are to be systematically differentiated in order to correlate the raw material use of System S 1 with environmental impacts (Figure 6). Opposed to Scopes 1, 3, and 5, Scopes 2 and 4 are based on a consideration of the RME; i.e., cumulative raw material requirements up to the actual extraction and thus the physical pre-chains are taken into account. On the other hand, a kilogram of gold and a kilogram of steel would be included in equal measure in a correlation analysis in approaches 1, 3, and 5. However, the actual specific raw material requirement per ton of material (primary raw material intensity) as defined by the indicator CRD (see Section 3.1) of basic materials and homogeneous semi-finished and finished products increases in the following order, as an initial approximation: construction minerals < fuels < biomass < industrial minerals < basic chemicals and plastics < ferrous and non-ferrous metals < special metals < precious metals [93]. In detail, however, there is a special rank sequence for each environmental pressure or impact category (e.g., land use, energy use, and greenhouse gas emissions) at the impact level of the respective materials [94,95]. With regard to environmental pressures and impacts, Figure 6 shows Scopes 1 and 2 as well as Scopes 3 and 4 forming pairs. The crux is whether material or primary raw material use in System S 1 is only correlated to the impacts in the upstream chains (for example, by the extraction, refining, and casting of a semi-finished metal product outside System S 1, under consideration) or additionally with the effects which are described in the following material use in System S 2 (for example, by a car in which said semi-finished metal product has been installed). The dematerialization logic of the factor X concept, “any input would become an output”, suggests the latter (see Section 2.3).

Figure 6.

Two-tier raw material system to schematically show the different levels of impacts caused by a material input into System S 1 and its use. Scope 1: Direct material input (M 1 as direct extraction and M 1* as processed material from any upstream systems S 2) with environmental impacts I 2 in the upstream systems S 2; Scope 2: The sum of direct material input and the related indirect raw material inputs M 2 in the upstream systems S 2 with the environmental impacts I 2 caused there; Scope 3: Direct material input with the sum of the environmental impacts I 2 in the upstream systems and the environmental impacts I 1 caused in System S 1; Scope 4: The sum of direct material input and indirect raw material inputs M 2 in the upstream System S 2 with the sum of environmental impacts I 2 in the upstream systems S 2 and environmental impacts I 1 caused in System S 1; Scope 5: Direct material input with environmental impacts I 1 in System S 1.

The narrow Scope 5 according to Figure 6 was pursued in a study for the EU 27 that was aimed at identifying threshold indicators in seven environmental action fields [96]. The extent to which direct abiotic domestic materials consumption (DMCabiot) can serve as a proxy indicator for national emission limiting values for different air pollutants was investigated, and it was compared with the emissions reported according to the territorial principle of the NEC Directive. However, no linearity could be found which would indicate that DMCabiot could represent achieving the national emission limiting values. Neither DMCabiot nor emission data take account of processes abroad. Therefore, they methodically correspond to each other, although they allow only a limited perspective of the overall resource consumption.

Numerous studies have performed regression analyses according to Scopes 1 and 2 in Figure 6 to systematically check the representation function of mass-based and further resource indicators for other natural resources (e.g., representativeness of (raw) material input for land-take or the emission of greenhouse gases). In their study, based on 130 materials and products, Giegrich et al. [97] concluded that pure mass-based material flow indicators (RMI and TMR) are not suitable as representative resource indicators. A general representation function of individual indicators for the other resource indicators has not been established. This applies neither to other input resources (especially energy, land, and water) nor to the use of the sink function. Other studies that performed similar correlation analyses on up to 100 materials based on their life cycle inventories have arrived at comparable results [98,99]. In addition to raw materials, the physical input resources such as land, water, and energy must be dealt with separately in order to map the use of physical resources with sufficient reliability [97]. If a single environmental impact indicator is supposed to represent environmental impacts, the most appropriate indicator is the primary energy demand according to the results. The latter is also the result of a very complex regression analyses on up to 1200 products and materials. Huijbregts et al. [100,101] found that non-renewable energy demand represents many environmental impacts fairly well. Use of non-renewable fossil and nuclear fuels with unambiguous qualitative interactions can be regarded as a key driver for many well-known negative environmental impacts. Conclusions about an inadequate representation function of mass-based indicators apply at a virtual economic system level that contains all materials investigated. A great mix of materials already results in a certain leveling of various environmental characteristics since outliers lose their relevance [99]. This is valid far less at a micro level of product or process systems, e.g., in the case of paired material substitutions in processes or products, since the heterogeneity of environmental profiles of more similar materials is even more pronounced. An excellent example is the similarity in masses between copper and aluminum: copper meets multiple raw material requirements (in terms of CRD) and acidification potential, while aluminum has high energy demand and global warming potential (GWP)—which can be retraced to both mineralogical and technological factors. When substituting copper with aluminum, a decrease in raw material input and acidification potential comes at the expense of energy demand and greenhouse gas emissions.

In addition, mass-based input indicators do not reflect the environmental burdens or benefit of abatement technologies used within the economy. For example, very specifically mass-intensive materials in terms of raw material intensity may be accompanied by chemico-physical functionalities which can lead to significant resource efficiency gains and additional benefits in their material life cycle compared to technologies lacking these materials. Examples to be mentioned include platinum, palladium, and rhodium catalysts, which can significantly reduce the emission of nitric oxides and volatile hydrocarbons in combustion engines, although they themselves are among the most resource-intensive materials. A selective catalytic reduction system in diesel cars also represents an additional expense during the entire life cycle, but this leads to significant reductions in nitrogen oxides in exhaust gases. Scopes 3 and 4 should be selected according to Figure 6 as the most elaborate approaches in order to take account of the effects in the use phase. However, apart from the availability of data for such analyses, there is a great allocation problem as to which materials of a good we can attribute to the environmental impacts occurring in its further use. A UNEP study for the EU 27 and Turkey took Scope 3 according to Figure 6 using the actual annual material flows in terms of domestic material consumption [102]. In this case, the consumption phase was taken into account, which generally includes a consuming use of fossil fuels and leads to more intensive environmental pollution profiles. Very different characteristic environmental pollution profiles are obtained for various material categories such as fossil fuels or agricultural products. The respective material flows over different resource consumptions and impact categories do not follow a uniform pattern, which explains the barely existing correlations. This is one explanation that no linearity between material input into the economy and emissions out of the economy could be observed in these studies.

Only if the raw material use were lowered in equal measure for all raw materials, in other words, if a constant distribution of raw material use were assumed, would the overall environmental impact also be consistently reduced. However, this becomes generally invalid as soon as production and consumption patterns lead to deviating raw material input vectors (for example, by a material substitution from bricks to wood materials or simply technology changes regardless of the actual material input of a good). The actual variability of the macroeconomic material use and the cyclical dynamics in individual sectors over time, which can be traced back using environmental-economic accounting data [53,103], render this simplistic assumption seem unjustifiable.

Mass-based indicators are not good proxy indicators for relevant environmental impacts according to the studies presented. This makes establishing dematerialization problematic. If mass-based indicators alone are not very representative, the question arises whether they are important in a dashboard of indicators. A set of a small number of indicators can be determined to best describe environmental impacts through a system. This procedure can help reduce effort compared to a comprehensive assessment of all relevant impact categories by eliminating redundancy and thus increase relevance for decisions [104].

An equally complex correlation analysis, a so-called principal component analysis of approximately 1000 raw materials, semi-finished, and finished products, plus 135 impact, midpoint, and end point indicators showed that the number of indicators can be reduced substantially while almost never losing significance [104]. A 92.3% variance between all 135 indicators could be explained by combining only six indicators—GWP, land use, stratospheric ozone depletion, marine ecotoxicity, terrestrial ecotoxicity, acidification, and eutrophication—in a highly representative set. In the case of environmental pressure indicators, 82% of the variance of all indicators can be explained by a combination of four variables: fossil CED, land use, water consumption, and raw material input. Thus, such a set of physical input indicators is not as reliable for use as a set as is a verifiable midpoint (impact) indicator set, but can nonetheless be a notable alternative. The fossil CED already represents 73%, which confirms the above-mentioned study results [97] as of equal importance to the best possible proxy indicator. As a comparison, the raw material input represents only 54% of the characteristics of all 135 indicators, which underlines its rather poor suitability and the availability of other, more appropriate alternatives. Using one of the proposed indicator sets will be the most robust option at a macroeconomic level. RMI or RMC as the only material flow indicator is of little significance.

3.2.2. Representation Function for Scarcities

The scarcity of raw materials is a keynote for resource conservation. Combined with the perception of large price fluctuations for raw materials, concerns are being raised that existing production patterns cannot be sustained on a permanent basis due to a critical scarcity of raw material-bound production factors that will occur on the input side. In the case of abiotic raw materials, the terminological distinction between actual raw material consumption (“depletion”) and raw material availability is very important. From a geological point of view, the consumption concept refers to the depletion of a deposit or, at a global scale, to raw material resources combined in the lithosphere. However, availability is defined with regard to technical and economic conditions and is closely linked to market price trends and possible opportunity cost [105]. (Another availability term was introduced by Georgescu Roegen (The entropy law and the economic process. Harvard University Press: 1971). He applied the thermodynamic concepts of available and unavailable energy (entropy) to materials and argues that any kind of material is irrevocably degraded into unavailable states, e.g., by dissipation. For this reason, he concludes that the materials that are vital for current technologies in available states will become unavailable eventually. However, the reasoning considers the material transformation and losses within the economy and not just the use of the primary raw materials). Availability and consumption—expressed in terms of ranges—also refer to very different timelines, from a few years or decades up to many centuries in the case of the consumption of finite geogenic resources. Against this background, raw material scarcity discussions can be performed at three levels:

- physical depletion;

- structural supply risks;

- raw material criticality.

Physical Depletion

Measuring physical depletion is closely linked to the paradigm of geological fixed stock. The lithosphere provides a finite geopotential of raw materials. Neoclassical approaches to natural resource economics and the growth-critical positions taken by representatives of ecological economics—e.g., the influential “Limits to growth”—emphasize that raw material consumption exhausts the fixed stock that is assumed to be known [106,107].

A first rough orientation can be provided by the proportion of elements in the lithosphere (and the atmosphere for gaseous elements). Detached from short-term technological trends and demand situations, this enables a categorization of the elements that are available to the extent that they cannot be exhausted in human time periods. Accordingly, the elements that occur in typical rock formations—silicon, aluminum, iron, calcium, sodium, potassium, and magnesium—all of which are present in the single-digit percentage range and together with oxygen and hydrogen form 98% of the lithosphere [108] are also referred to as Elements of Hope [109]. In addition to this categorization, elements are also grouped as scarce and critical elements. When considering these Elements of Hope together with carbon, which constitutes approximately 80% of fossil fuels and 50% of biomass, it can be estimated by the example of Germany and the EU-28 that more than 99% of RMI is characterized by these 10 elements [52,103]. Approximately 30% of this is carbon. Accordingly, macroeconomic material flow indicators also significantly represent the elements that are physically most common on Earth.

The geological content of elements does not in itself indicate any economic or technical extractability. If the top-down approach of the fixed stock is to be adhered to, the geochemical postulate of the mineralogical barrier stipulates an average threshold for all elements (particularly relevant for scarce and critical elements), which represents the stoichiometric limit concentration in ores. Below this threshold, most of these elements are dispersed thinly in rock, such that extraction could only be achieved through wet-chemical separation of the rock rather than by separating accumulated fractions [110,111]. Even if the postulate of the mineralogical barrier is not scientifically proven and is indirectly questioned by reference to the exploration cycles and technological advances in the mining industry, it still prompts a fruitful discussion about the increase in extraction costs [112,113,114]. This looks into the topic of resource intensity of extraction, particularly with regard to energy demand and the resulting emissions. However, this “environmental scarcity of raw materials” is revealed by other tangible AoPs, not the physical scarcity of extractable raw material amounts per se. Material flow indicators do not have any direct or indirect links in this context.

Only a few exceptions present any empirical evidence for absolute, static, and physical scarcities—in resource economics, the complete exhaustion of a resource or a raw material. Peak oil is one of these exceptions. The peak oil phenomenon predicted in the 1950s by Hubbert [115] for US oil production and in later projections for global production as a whole—described in light of an analysis of new discoveries of conventional oil deposits—is widely regarded as being substantiated [116]. However, a transfer of Hubbert’s peak analysis concept with the assumption of a fixed-stock of mineral raw materials, as occasionally propagated [112,117,118], is regarded by many authors as critical [119,120]. This is because the concept does not take into account the actual causes of supply and demand development for mineral, non-fossil raw materials, nor does it consider the variability of the reserves and resources parameters [121]. Criticism is directed particularly at the static lifetimes that are misinterpreted as lifetime up to the exhaustion of a material [122]. Retrospectively, it appears that the static lifetimes have remained almost constant or even increased for both fossil energy resources and ores in spite of a conspicuously increased consumption development [123] in the second half of the 20th century [124]. The fact that the reserve range of rare earth metals is around 1048 years, that for copper is around 40 years, and that for lead is only 20 years is not indicative of an alleged earlier exhaustion of global lead deposits [125]. Regardless of this limited significance of static lifetimes for physical scarcities, they cannot be derived from aggregated mass-based flow indicators.

Structural Supply Risks

In addition to physical depletion, technical-structural aspects that can limit global availability of raw materials are also discussed. Some of them can be objectified and are assessed independently from the players and their use. This method takes into account spatial disparities of distribution, and the resulting geographical concentrations of the deposits, and of raw material production [126,127]. Due to geological and geochemical conditions, the most significant known deposits of some metals, such as tin (soap deposits in Indonesia), niobium (Brazil), platinum (South Africa and Zimbabwe), palladium (Ni-Cu deposits around Norilsk/Russia), and cobalt (Central African copper belt, especially in DRC), accumulate in a few districts worldwide. Others—such as rare earths—do not occur in such a high geological concentration, but in a sizeable concentration in the current mining production (China). Country and enterprise concentrations in an oligopolistic market environment have in the past repeatedly led to sensitive supply disruptions with high price fluctuations [128].

A further basal structural supply risk affects metals that are present but associated with other materials in their ores. Many metals can only be extracted as by-products or co-products. Exploration, production volumes, and related ranges are thus also bound to the carrier metal [122,129]. By-products are present in comparatively lower concentrations and their availability is strongly or exclusively coupled to the production capacity of one or more carrier elements, for example, gallium in bauxite ores for aluminum production as well as indium and germanium from zinc and lead production. On the other hand, co-products have no clear carrier element. The metals concerned such as platinum group metals (PGMs) and rare earths exist in defined mineralogical ratios, which require joint processing and refining in order to purify the individual elements. Due to their large ionic radii, rare earths are not finely dispersed in typical rock formations, but form their own minerals in which they are jointly integrated in characteristic ratios [108]. Regardless of the element-specific demand, actual production is determined by the characteristics of the deposits. As a result, there are production-driving elements—formerly europium and cerium, currently neodymium and dysprosium—that determine the production volume and others whose production volume exceeds demand, which means that a low market price is highly likely due to the overproduction of such elements, for example, cerium and lanthanum [130].

The outlined structural risks are to be regarded as element-specific and require a geoscientific statistical model. Conclusions cannot be drawn about the rise of structural supply risks using material flow indicators, even in disaggregation, without this complementary model knowledge.

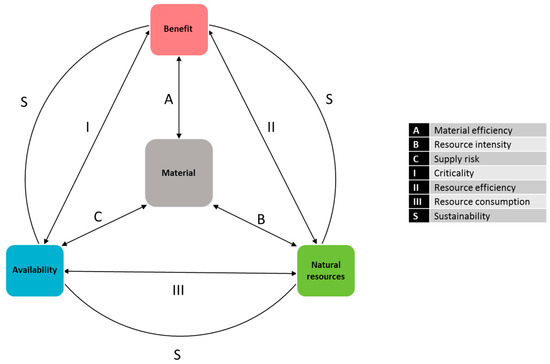

Raw Material Criticality

The assessment of raw material criticality goes beyond the two previous scarcity scales in two respects. On one hand, supply risks are more complex. In addition to the geological, technical, and structural criteria, geopolitical, socio-economic, and ecological risks are also integrated [93,131]. On the other hand, the importance of raw materials (and their uses) for a specific system and the impacts in the event of a manifested supply risk are taken into account.

Against this background, criticality analysis aims to identify the raw materials of a system that uses them (for example, national economy, industry, and enterprises) to fulfill essential functions for this system but whose supply is at risk. This enables a vulnerability assessment of that system in the face of supply disturbances of specific raw materials [93]. The criticality assessment does not correspond to the characterization of total, but relative scarcities, which occur when raw material demand of the reference system cannot be satisfied by the raw material supply in terms of time, space, and organization. Linked to this, the impact horizon can also have global, continental, and national impacts, or may only be (supra-) regionally limited.

Such scarcities can occur due to a dynamic supply or demand development as well as a combination of both. The more a raw material suffers from a supply risk and the more inelastic its demand will be, the more critical will it become to the reference system [93]. Relative scarcities must therefore also be assessed depending on the parties involved; for example, diversification of raw material suppliers or internal recycling can reduce the relative scarcity risk of a single market participant.

The first studies that correspond to today’s logic of criticality analysis were motivated by a raw material security policy and date back to the 1970s [132,133,134] and the basics even to the 1950s. Numerous new criticality metrics have been developed since 2008 [135]. Different raw materials are now classified as critical depending on the criteria used within these metrics, the reference systems, and the up-to-dateness of the analyses. Discrete lists of critical and uncritical raw materials—e.g., 20 out of 54 raw materials of an ad hoc working group of the EU COM [136]—can create a strong impact signal in communication. However, it also counteracts the relative nature of the concept [121].

To allow for a universal and flexible application of the concept on different levels from macro- to micro-scales, i.e., countries, economies, regions, industries, branches, sectors, technologies, companies, product lines, products, and building blocks, an expert group at the Association of German Engineers (VDI) has elaborated a harmonized criticality methodology as part of an industrial guideline on resource efficiency (VDI 4800-2) [93]. The two-dimensional approach clearly distinguishes between exogenous geological, technical, structural, geo-political, regulatory, and economic criteria to characterize the overall supply risks and subjective endogenous vulnerability criteria for the object in focus. Current work focuses pragmatically on the future. Thus, the expected demand impulses due to dynamically emerging technologies are systematically estimated [123,137,138] or the impacts of climate change on the future supply of raw materials are analyzed in risk assessments [139,140]. The results can be integrated in prospective criticality analyses. Other research initiatives do not end with the assessment of criticality but develop approaches to mitigate it by efficiency, recycling, or planned substitution measures [141,142]. These strategy initiatives are aimed at both the supply and the demand side and are not generic, but they are explicitly aligned to the respective technological functional materials. Moreover, the assessment of ecological and social impacts of raw material supply is further developed in criticality analyses [143,144,145,146,147]. This has not been systematically taken into account in existing criticality assessment methods and forms a link to sustainability assessment [148]. The example of coltan mining in the Democratic Republic of Congo showed in the past that strategic importance of raw materials, in this case tantalum, can also aggravate and catalyze armed conflicts in producer countries [149,150]. In addition, overuse of ecosystems and degradation of further natural resources by the extraction of raw materials can lead to violent conflicts [124,147,151,152].

In the trend of current studies, raw materials for environmental and emerging technologies are classified as particularly critical. These include, for example, essential raw materials for thin-film photovoltaic technologies such as indium, tellurium, gallium, and germanium. In addition to these specialty metals, precious metals such as platinum, rhodium, and gold, or refractory metals required in significantly larger amounts such as tungsten, molybdenum, tantalum, niobium, and chromium, are also classified as critical or, from a national perspective, as “economically strategic” [141].

At a global scale, total use of raw materials rose from about 40 billion tonnes to 75 billion tonnes between 1993 and 2013 [153]. With its growth factor of approximately 1.9, it has grown slightly stronger than the global economic performance (an increase factor of 1.75 with an average annual growth of 2.8%). Thus, there is a minor relative decoupling of the raw material input from the GDP at the aggregated raw material level over the long term. Although significant demand increases are still expected for many materials considered as critical, their production—including germanium, indium, tantalum, and cobalt—has multiplied between 2 to 5 times in the same 20-year period [123]. Consequently, their use is clearly decoupled from the use of the total primary raw materials, which indicates that broad-brush approaches for dematerialization do not solve criticality issues at all.

Criticality analysis has established itself as a multi-layered and complex, action-oriented socio-economic raw materials assessment method to deal with scarcities. Thus, it is a highly relevant method to address the safeguard subject raw material availability. In principle, intra- and intergenerational availability and distribution fairness can be derived as socio-economic AoPs within the criticality concept (see Section 3.1). It could be argued, taking an egalitarian value scale, that critical functional materials should be available to the same extent as a resource for the fulfilment of a benefit both intra- and intergenerationally. However, conclusions cannot be derived in general—only discreetly linked to the elements and materials investigated. This action field cannot be addressed using a static development of material flow indicators simply because most critical raw materials link to technological and specialty metals plus industrial minerals that have relatively small mass flows and can barely be dealt with in aggregated mass flow calculations at this depth. A general dematerialization does not lead to the reduction of criticality of raw materials. Instead, more focused complementary material flow analyses are required that also take into account the inventory dynamics of product groups and functional materials bound in them [154].

3.3. Exegese of the Precautionary Principle

Mass-based indicators failed to provide a strict representation for either environmental impacts or scarcity. One reason may be that qualitative and quantitative relationships and cause–effect relationships are not sufficiently known or are not mapped by the methods discussed in this article. Some authors, who propagate dematerialization as the central and dominant maxim of action for resource conservation [59], borrow the precautionary principle as a context of justification from environmental policy. It serves both the derivation for the basic necessity of a reduction of primary material extraction and a determination of different quantitative targets of dematerialization [30]. Since the precautionary principle is at the core of justification for dematerialization strategies (see Section 2.3), we take a closer look at this central principle of environmental policy in this section.

The European Union’s environmental policy is based on the precautionary principle (Article 191 of the Treaty on the Functioning of the European Union). Internationally, the precautionary principle was enshrined in the 1992 Rio Declaration on Environment and Development [155] as a principle for the protection of the environment and human beings. The precautionary principle guides environmental policy towards acting early and with foresight to avoid future environmental pressures or preserve natural resources for future generations, even if the knowledge of type, extent, likelihood, and cause–effect relationships is incomplete or uncertain.

Despite its importance in the political decision-making process, there is always confusion as to what the principle actually means and in what cases it can be applied as a principle of action. In the case of dematerialization as a strategy for resource conservation three main conditions and one assumption can be initially identified (see Section 2.3): The knowledge about exceeding the planetary boundaries is incomplete and uncertain [1]. There is an extensive lack of knowledge about cause–effect relationships in the environment. Estimations suggest that man-made material flows exceed the extent of natural material flows. With reference to the laws of conservation of mass and energy, it can be hypothesized that the material input into the socio-economic-system could be a proxy for the total environmental impact potential of this system (see Figure 6) [156]. However, do these arguments suffice to legitimize a dematerialization agenda and formulate dematerialization targets making reference to the precautionary principle?

The European Commission has issued a communication on the applicability of the precautionary principle (COM (2000) 1) [157]. According to the European Commission, the precautionary principle can legitimize or even impose political acts in such cases where scientific uncertainty is high, but there is concern due to a scientific risk assessment that dangerous consequences for humans and the environment are inconsistent with the EU’s high protection standards. However, the precautionary principle can under no circumstances be used to justify the adoption of arbitrary decisions. In order to apply the precautionary principle, the following prerequisites must be met, unless there is a concrete perception of risk, according to the EU Commission: Before the precautionary principle is invoked, potentially negative effects of a phenomenon, must be identified based on the relevant scientific data and should be scientifically examined. When considering whether measures are necessary to protect the environment, every effort should be made to scientifically evaluate the available information. Reliable scientific data and logical reasoning are required to come to a conclusion, which expresses the possibility of occurrence and the severity of a hazard’s impact. If the available data is sufficient, scientific uncertainties must be determined and assessed at each stage of the procedure. Do these prerequisites apply in the case of dematerialization?

The dematerialization logic of the factor X concept postulates that the material input measured in mass units is causally related not only to the environmental impacts of the upstream chains of material production but also to the total environmental impacts of the system in which the material is used (see Scopes 3 and 4 in Figure 6). The postulated connection between mass and environmental impact potential is based solely on plausibility arguments [156]. There is still no scientific evidence (see Section 3.2.1 and [30]). Regression analyses failed to show either a link between direct and indirect material demand and environmental impacts caused in upstream systems, or for the direct material consumption of a system and the environmental impacts generated by this system. An explanation for the first case is the heterogeneity of the environmental profiles of the materials used, which is not taken into account by the mere addition of the masses. For the second case, an explanation approach is that the material input into a system does not map the functions of the materials within the system and the way the materials contribute to environmental impacts or benefits (see Section 3.2.1).

However, the empirical evidence that has not been provided does not yet preclude the application of the precautionary principle. On the contrary, it is precisely in this case that legitimation of environmental protection measures can be considered if the presumed cause–effect relationships are plausible and can be described based on reliable scientific data and logical reasoning. However, such a description that allows a conclusion on the occurrence and severity of a hazard’s impact is not available. In contrast to the application of the precautionary principle in other environmental policy areas, e.g., in the field of potentially dangerous substances, the cause–effect relationships cannot be systematically described biophysiochemically in the case of dematerialization logic. Although it is plausible that overall mass input must eventually equal overall mass output, the entire material input into a system cannot be brought into a logical cause–effect relationship with the environmental impacts exerted by this system. For small systems such as products, the large allocation problem mentioned in Section 3.2.1 should be solved, that is, the impacts of the product along its life cycle ought to be attributed to the materials entering the product system. Although, for example, the reference to greenhouse gas emissions can be produced in the case of fuels, nitric oxide emissions cannot be attributed solely to the fuel, but are a function of combustion technology and exhaust gas purification technology, which require other raw materials. This reference can hardly be established by logical reasoning for constructive or functional materials used, for example, in electronics. In larger, dynamic systems such as economies, a modeling of the cause–effect relationships is an almost impossible undertaking due to the multiplicity of factor combinations in the use and further processing of materials into products and the environmental benefits and environmental impacts of the same products along their entire life cycle, user behavior, and product design decisions. An assessment of the scientific uncertainty is only possible if these fundamental allocation and modeling problems are solved.

Therefore, most of the EU Commission requirements on the applicability of the precautionary principle are not met. According to these criteria, resource conservation or efficiency policies focusing on mass-based indicators and having the objective of reducing environmental pressure cannot be legitimized by the precautionary principle. Setting global dematerialization as well as material efficiency targets is, therefore, arbitrary within the meaning of the communication [157], and the precautionary principle cannot be relied upon. Bringezu also argues that dematerialization targets should be set “rather arbitrarily” due to the lack of scientific evidence “void of better alternatives” and should be based on Schmidt-Bleek’s proposals [30,59]. However, there is an alternative to general dematerialization by an arbitrary factor as a strategy for the urgently needed response to the threat of exceeding planetary carrying capacity. The complexity of socio-economic systems and the planetary ecosystem that oppose the scientific check of the “Schmidt-Bleek conjecture” can be reduced by focusing on the impacts of socioeconomic systems and breaking the planetary ecosystem down into a few large compartments. This has been shown by the work of Rockström et al. on the planetary boundaries [1,3,158]. Although his derivation of the planetary boundaries is also scientifically controversial, it is based on scientific and at least partly empirically provable cause–impact relationships, which, according to EU-COM (2000) 1, qualifies it for the legitimation by the precautionary principle and thus as a measure of action for environmental policy. Even though, the disaggregation of planetary boundaries seems to be more promising for justifying the precautionary principle, whether all relevant environmental impacts and social conflicts in the nexus of land use and raw material extraction are reflected has to be checked.

4. Findings

This paper critically assessed the relevance and representativeness of mass-based indicators’ multiple layers as a basis for resource policy. The current application of material flow indicators and targets was discussed, and concepts for raw materials and safeguard subjects were juxtaposed from a micro-level such as LCA. Thereof, conclusions are drawn about the robustness of dematerialization as a strategy for resource conservation.