Data Systematization and Preliminary Analysis of Accidental Oil and Petroleum Product Spills in the Russian Arctic and Far North

Abstract

1. Introduction

- To establish criteria for the systematization of accidental oil and petroleum product spills.

- To identify the primary causes of such spills in the Russian Arctic and Far North.

2. Materials and Methods

- Processing and systematizing secondary information on oil and petroleum product spills.

- Data formalization.

- Data structuring.

- Comprehensive data analysis.

3. Results

- Table 1 presents the results of the classification of oil and petroleum product spills across Russia, as well as specifically within the Russian Arctic (RA), the Russian Far North (RFN), and their combined territories.

- 2.

- 3.

- 1.

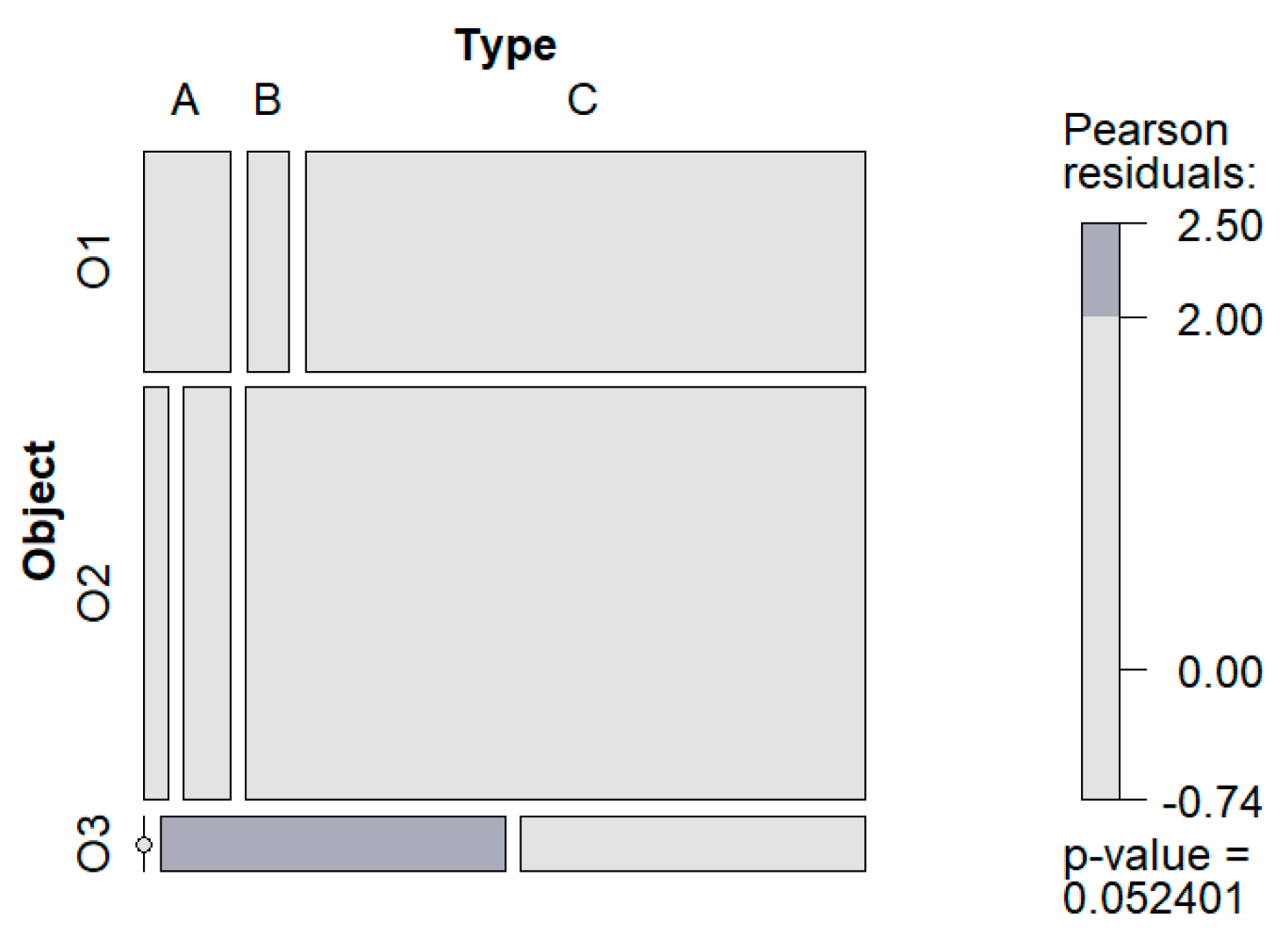

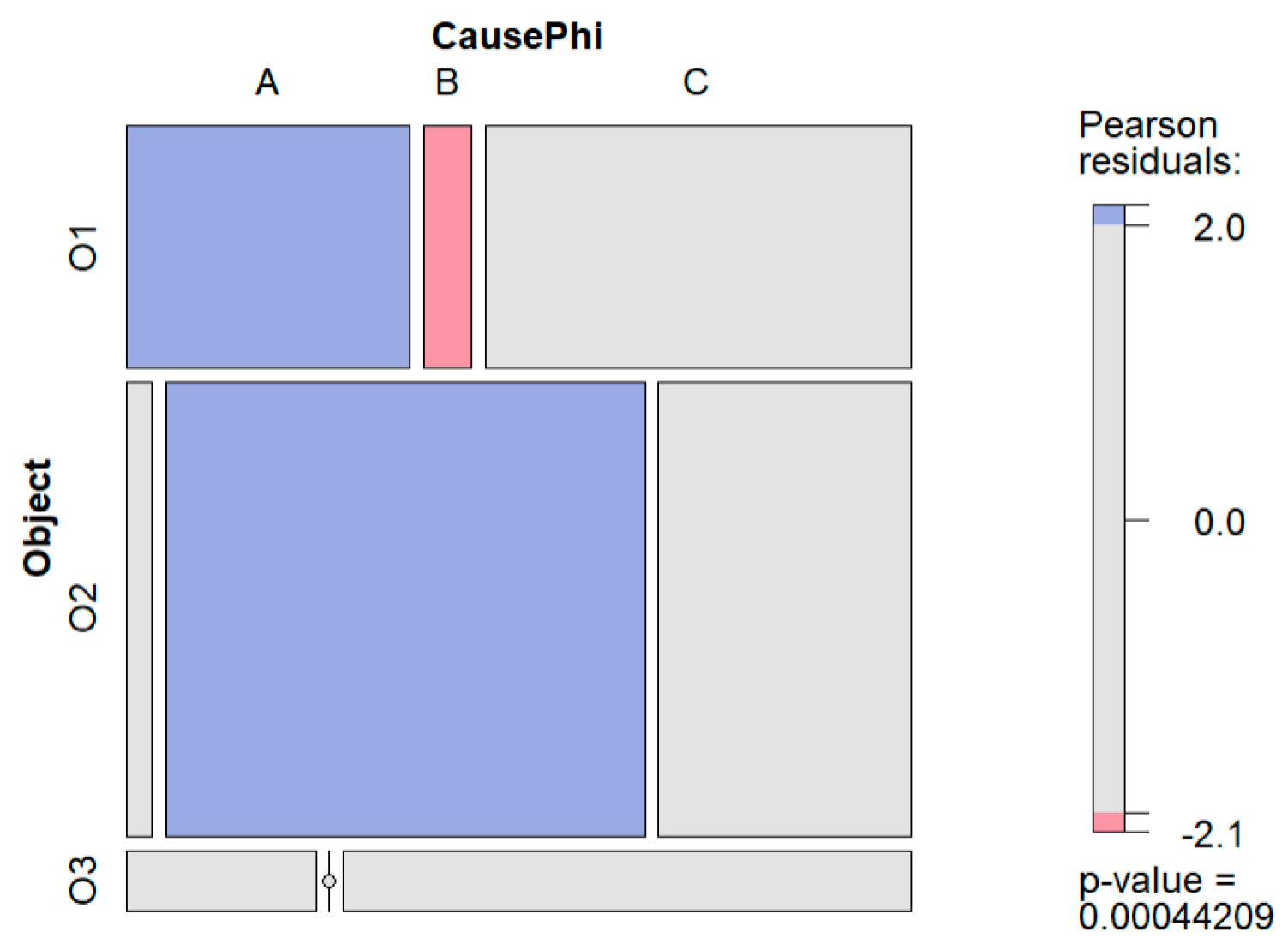

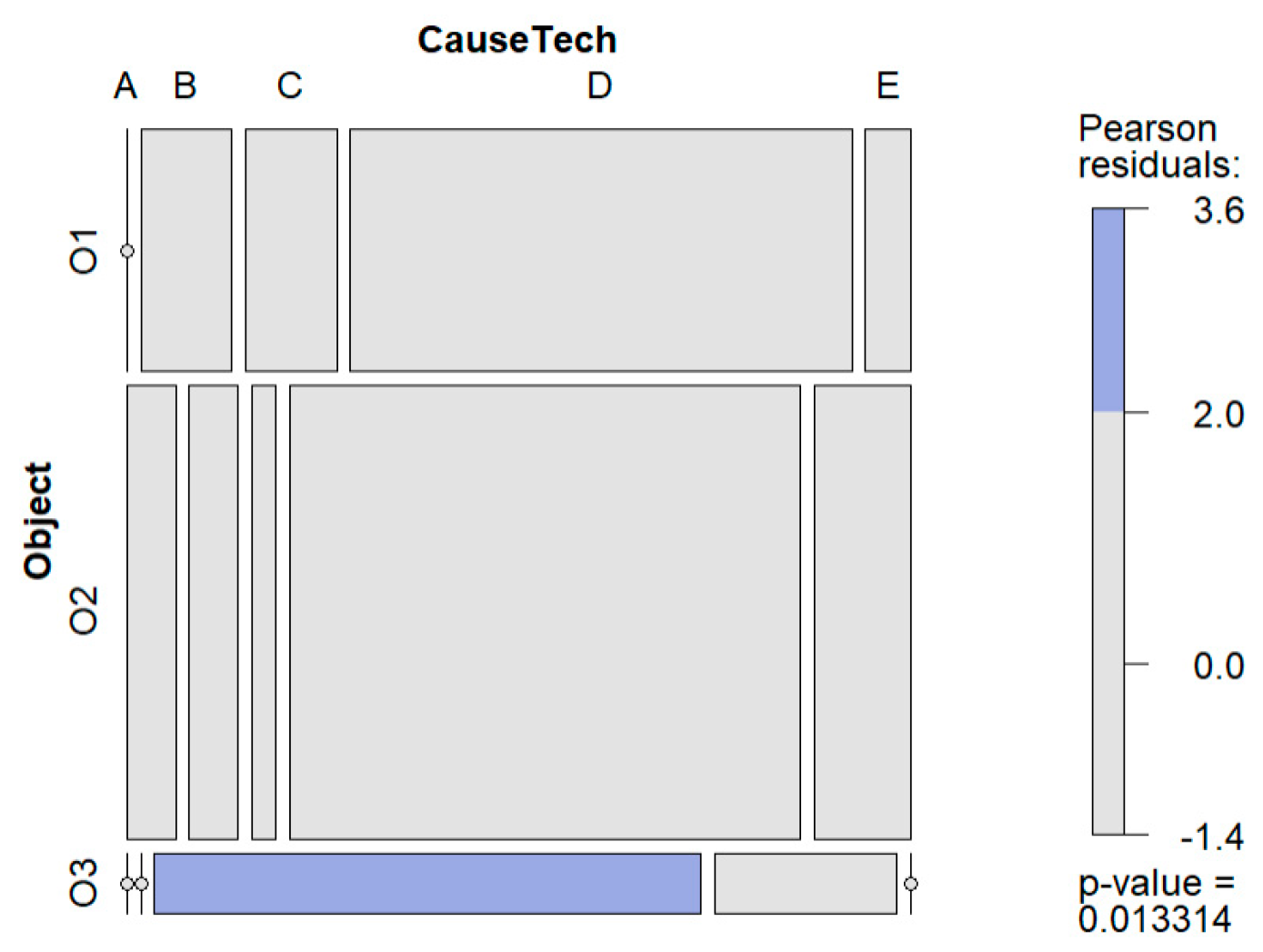

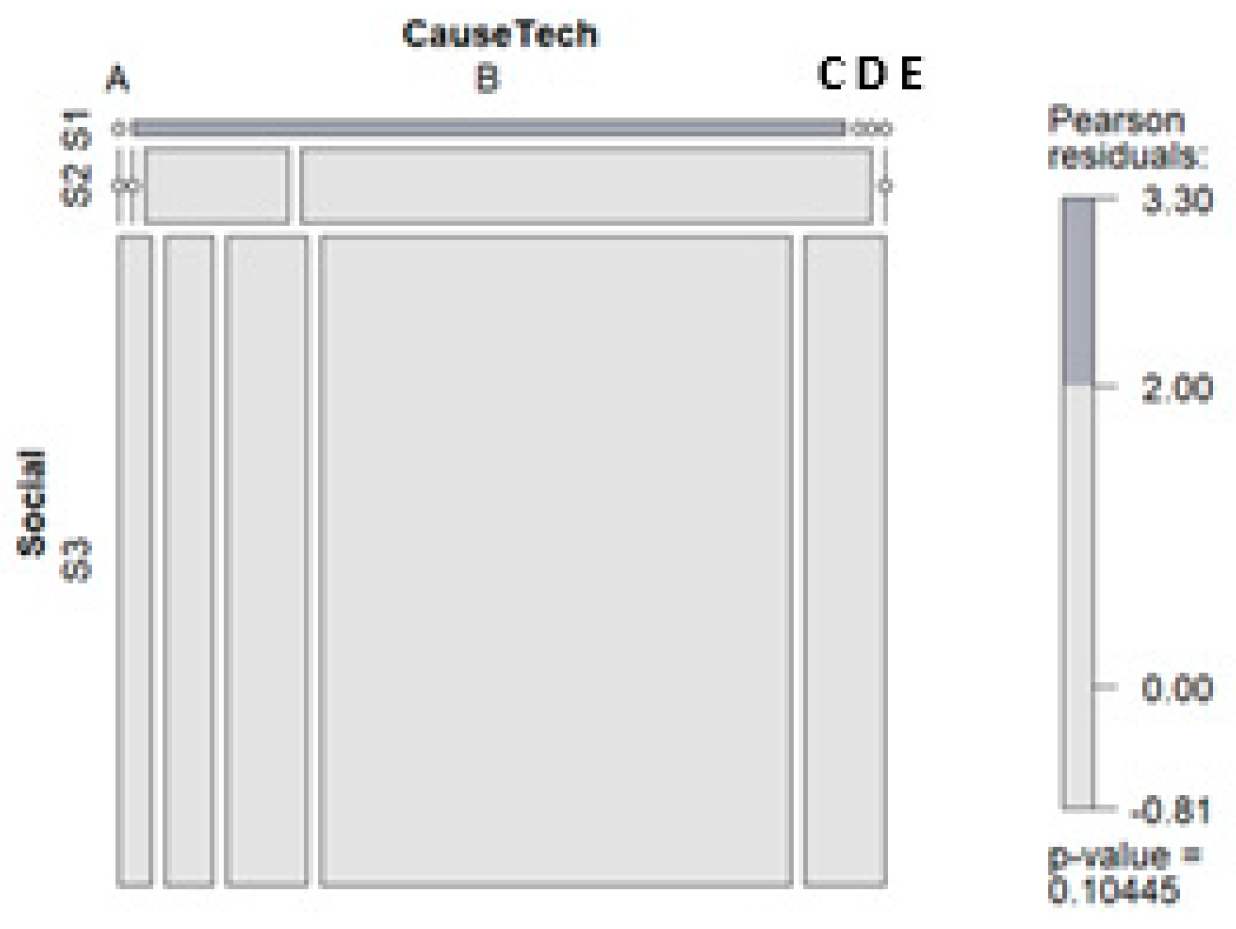

- Small in absolute terms, when , with the corresponding cell shown in gray.

- 2.

- Significantly positive, , with the cell shown in blue.

- 3.

- Significantly negative, with the cell shown in red.

4. Discussion

- -

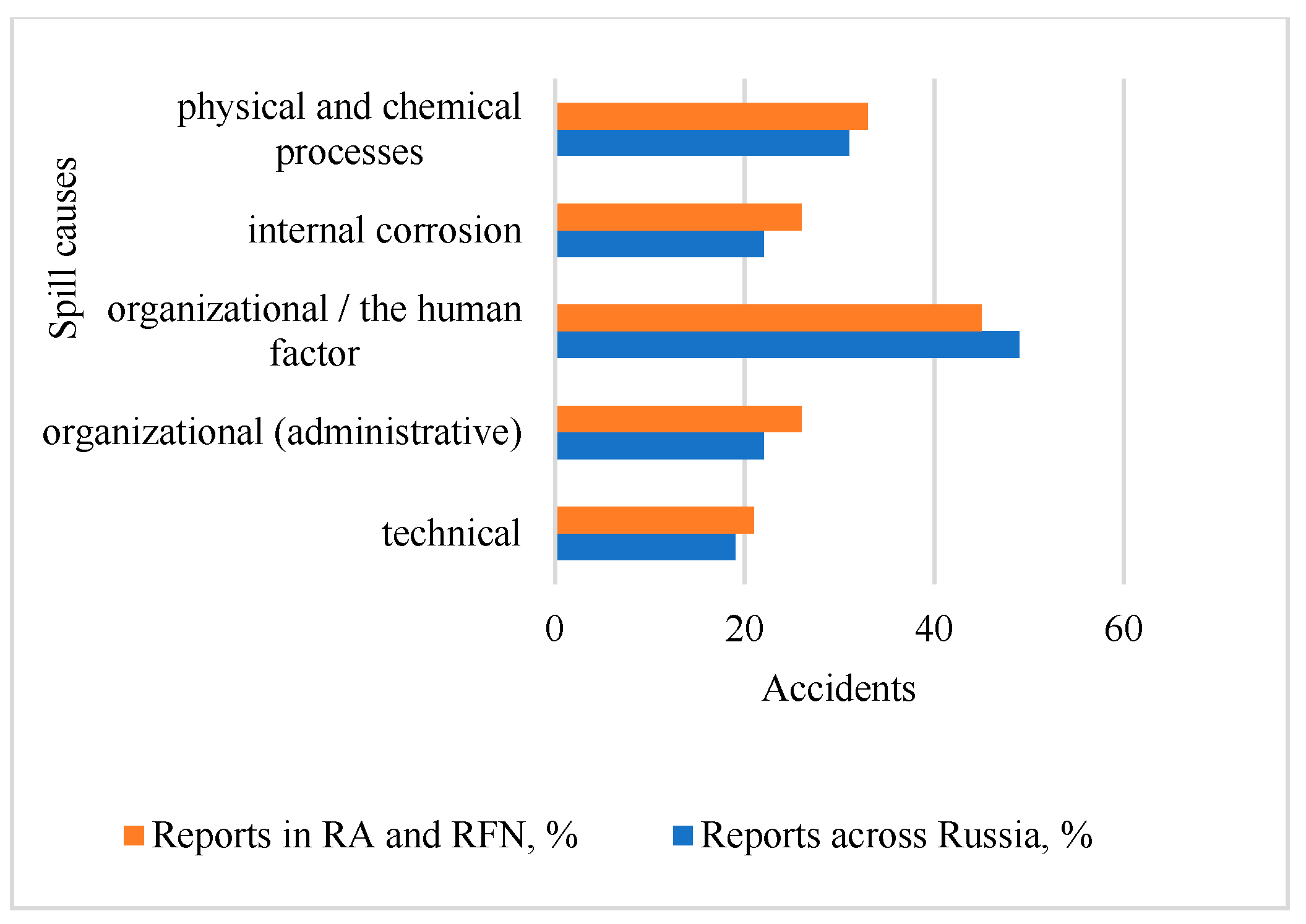

- at gathering stations, the main causes included external corrosion, pressure/temperature parameter fluctuations, electrostatic charge formation, and vibration-related failures, grouped collectively as “Other causes”.

- -

- for field pipelines, internal corrosion was the leading cause of accidents, aligning with findings from previous studies.

- -

- at well sites, the dominant cause was identified as equipment defects.

5. Conclusions

- -

- Modernizing infrastructure with corrosion-resistant materials and real-time monitoring systems (with a potential 30% risk reduction, according to the Ministry of Emergencies, 2025);

- -

- Developing adaptive technologies for Arctic conditions, particularly to address paraffin-related challenges (based on studies by TatNIPIneft, 2020);

- -

- Strengthening regulatory enforcement through stricter operational standards (as recommended by PHMSA, 2025) [11];

- -

- Implementing rapid response strategies informed by best practices, such as those developed in response to the Deepwater Horizon incident.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PHMSA | Pipeline and Hazardous Materials Safety Administration |

| ESPO | Eastern Siberia–Pacific Ocean |

| TatNPIneft | Tatar Research and Design Institute of Oil |

| CDU TEK | Central Dispatch Office of the Fuel and Energy Complex |

| AMAP | Arctic Monitoring and Assessment Programme |

| Rostekhnadzor | Federal Service for Ecological, Technological and Nuclear Supervision |

References

- Michel, J.; Owens, E.H.; Zengel, S.; Graham, A.; Nixon, Z.; Allard, T.; Holton, W.; Reimer, P.D.; Lamarche, A.; White, M.; et al. Extent and Degree of Shoreline Oiling: Deepwater Horizon Oil Spill, Gulf of Mexico, USA. PLoS ONE 2013, 8, e65087. [Google Scholar] [CrossRef] [PubMed]

- Pashkevich, M.A.; Bykova, M.V. Methodology for thermal desorption treatment of local soil pollution by oil products at the facilities of the mineral resource industry. J. Min. Inst. 2022, 253, 49–60. [Google Scholar] [CrossRef]

- Vasileva, Z.V.; Vasekha, M.V.; Tyulyaev, V.S. Evaluation of the efficiency of sorbents for accidental oil spill response in the Arctic waters. J. Min. Inst. 2023, 264, 856–864. [Google Scholar] [CrossRef]

- Sarapulova, G.I. Environmental Geochemical Assessment of Technogenic Soils. J. Min. Inst. 2018, 234, 658–662. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2023—Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 14 July 2025).

- Sozina, I.D.; Danilov, A.S. Microbiological remediation of oil-contaminated soils. J. Min. Inst. 2023, 260, 297–312. [Google Scholar] [CrossRef]

- UNEP—UN Environment Programme. Annual Report 2022. Available online: https://www.unep.org/resources/annual-report-2022 (accessed on 14 July 2025).

- Reiersen, L.-O.; Guardans, R.; Sydnes, L.K. The Arctic Monitoring and Assessment Programme. Chem. Int. 2020, 42, 8–14. [Google Scholar] [CrossRef]

- Massanés, B.; Pera, L.S.; Semenova, T.; Sokolov, I. Theoretical Substantiation of Risk Assessment Directions in the Development of Fields with Hard-to-Recover Hydrocarbon Reserves. Resources 2025, 14, 64. [Google Scholar] [CrossRef]

- Massel, L.; Komendantova, N.; Massel, A.; Tsvetkova, A.; Zaikov, K.; Marinina, O. Resilience of socio-ecological and energy systems: Intelligent information technologies for risk assessment of natural and technogenic threats. J. Infrastruct. Policy Dev. 2024, 8, 4700. [Google Scholar] [CrossRef]

- PHMSA. HL IM Performance Measures. Available online: https://www.phmsa.dot.gov/pipeline/hazardous-liquid-integrity-management/hl-im-performance-measures (accessed on 17 July 2025).

- US EPA. Restoring the Gulf of America After the Deepwater Horizon Oil Spill. Available online: https://www.epa.gov/deepwaterhorizon (accessed on 14 July 2025).

- International Crisis Group. Iraq. Available online: https://www.crisisgroup.org/middle-east-north-africa/gulf-and-arabian-peninsula/iraq (accessed on 17 July 2025).

- Amnesty International Nigeria. Nigeria: Shell Must Clean Up Devastating Oil Spills in the Niger Delta. Available online: https://www.amnesty.org.ng/2023/02/02/nigeria-shell-must-clean-up-devastating-oil-spills-in-the-niger-delta/ (accessed on 17 July 2025).

- Zanoli, S.M.; Pepe, C.; Semenova, T.; Churrana, N. Assessment of the Projects’ Prospects in the Economic and Technological Development of the Oil and Gas Complex in the Republic of Mozambique. Resources 2025, 14, 106. [Google Scholar] [CrossRef]

- International Crisis Group. Iraq: Stabilising the Contested District of Sinjar. Available online: https://www.crisisgroup.org/middle-east-north-africa/gulf-and-arabian-peninsula/iraq/iraq-stabilising-contested-district-sinjar (accessed on 17 July 2025).

- UPI.com. Husky: ‘Anomalies’ Found Night Before Saskatchewan Oil Spill. Available online: https://www.upi.com/Energy-News/2016/07/27/Issues-reported-before-Saskatchewan-oil-spill/4241469619189/ (accessed on 17 July 2025).

- Soto, L.; Botello, A.; Licea, S.; Lizarra-Partida, M.; Yáñez-Arancibia, A. The environmental legacy of the Ixtoc 1 oil spill in Campeche Sound, southwestern Gulf of Mexico. Front. Mar. Sci. 2014, 1, 57. [Google Scholar] [CrossRef]

- US Department of Transportation. Pipeline Safety: Reviewing Implementation of the PIPES Act of 2020 and Examining Future Safety Needs. Available online: https://www.transportation.gov/pipeline-safety-reviewing-implementation-pipes-act-2020-and-examining-future-safety-needs (accessed on 18 July 2025).

- Congress.gov. Library of Congress. Pipeline Safety: Reviewing Implementation of the PIPES Act of 2020 and Examining Future Safety Needs. Available online: https://www.congress.gov/event/118th-congress/house-event/115415/text (accessed on 18 July 2025).

- FracTracker Alliance. 2022 Pipeline Incidents Update: Is Pipeline Safety Achievable? Available online: https://www.fractracker.org/2023/02/2022-pipeline-incidents-update-is-pipeline-safety-achievable/ (accessed on 18 July 2025).

- AK Dept. of Environmental Conservation. 2024 Point Thomson Export Pipeline Leak. Available online: https://dec.alaska.gov/spar/ppr/spill-information/response/2024/01-point-thomson-export-pipeline-leak/ (accessed on 19 July 2025).

- The Ussinskaya Disaster of 1994. Causes and Consequences. Available online: https://nashural.ru/dostoprimechatelnosti-urala/respublika-komi/usinskaya-katastrofa-1944-goda-prichiny-i-posledstviya/?ysclid=md7f93lvql101698981 (accessed on 19 July 2025).

- RIA Novosti. Major Oil and Oil Product Spills in Russia in 1994–2021. 11 August 2021. Available online: https://ria.ru/20210811/razliv-1745316414.html (accessed on 14 July 2025).

- Decree of the President of the Russian Federation Dated 05/02/2014 No. 296 ‘On the Land Territories of the Arctic Zone of the Russian Federation’. Available online: http://www.kremlin.ru/acts/bank/38377 (accessed on 18 July 2025).

- Decree of the Government of the Russian Federation No. 1946 Dated 11/16/2021 ‘On Approval of the List of Regions of the Far North and Localities Equated to the Regions of the Far North in Order to Provide State Guarantees and Compensations’. Available online: https://base.garant.ru/403069486/ (accessed on 18 July 2025).

- State Report on the State of Protection of the Population and Territories of the Russian Federation from Natural and Man-Made Emergencies in 2024. Available online: https://mchs.gov.ru/dokumenty/7807 (accessed on 18 July 2025).

- Khasanov, I.I.; Kashirina, D.A. Effect of the composition of asphaltene deposits on the process of waxing of main oil pipelines. Transp. Storage Oil Prod. Hydrocarb. 2022, 3–4, 26–31. [Google Scholar] [CrossRef]

- Delo—Truba. Fuel and Energy Complex of Russia. Available online: https://www.cdu.ru/tek_russia/issue/2021/4/890/?ysclid=md7kphiku8990243626 (accessed on 19 July 2025).

- Kuprikov, M.; Kuprikov, N.; Zaikov, K.; Zadorin, M.; Tsvetkova, A. Regional climate change adaptation plans in Russia: Legal political overview. J. Infrastruct. Policy Dev. 2024, 8, 5303. [Google Scholar] [CrossRef]

- Marinina, O.; Tsvetkova, A.; Vasilev, Y.; Komendantova, N.; Parfenova, A. Evaluating the Downstream Development Strategy of Oil Companies: The Case of Rosneft. Resources 2022, 11, 4. [Google Scholar] [CrossRef]

- AMAP. Socio-Economic Drivers of Change in the Arctic. Available online: https://www.amap.no/documents/doc/socio-economic-drivers-of-change-in-the-arctic/1115 (accessed on 19 July 2025).

- Kvasov, I.N.; Shendaleva, E.V.; Shtengauer, O.V.; Aleksandrov, M.A. Environmental risk analysis of accident on main and technological oil pipelines. Oil Gas Stud. 2020, 2, 107–119. [Google Scholar] [CrossRef]

- Gritsenko, A.I.; Akopova, G.S.; Maximov, V.M. Ecology. In Oil and Gas; Nauka: Moscow, Russia, 2020. [Google Scholar]

- Lessons Learned from Accidents. Available online: https://www.gosnadzor.ru/industrial/oil/lessons/ (accessed on 19 July 2025).

- Nevskaya, M.A.; Belyaev, V.V.; Pasternak, S.N.; Vinogradova, V.V.; Shagidulina, D.I. Accidental oil spills in the Arctic: An assessment of potential soil damage. Sev. I Rynok Form. Ekon. Porad. 2024, 27, 107–122. [Google Scholar] [CrossRef]

- Federal Service for Environmental, Technological and Nuclear Supervision Rostechnadzor. Available online: https://www.gosnadzor.ru/ (accessed on 19 July 2025).

- Vladimirov, V.A. Oil spills: Causes, scale, consequences. Civ. Prot. Strategy Probl. Res. 2014, 4, 217–229. [Google Scholar]

- Decree of the Government of the Russian Federation, No. 2451 Dated December 31, 2020 ‘On Approval of the Rules for Organizing Measures to Prevent and Eliminate Oil and Petroleum Product Spills in the Territory of the Russian Federation’. Available online: https://base.garant.ru/400170332/ (accessed on 19 July 2025).

- R Core Team. R A Language and Environment for Statistical Computing. R Foundation for Statistical Computing. 2024. Available online: https://www.scirp.org/reference/referencespapers?referenceid=3887298 (accessed on 14 July 2025).

- Mangiafico, S. Summary and Analysis of Extension Program Evaluation in R; Rutgers Cooperative Extension: New Brunswick, NJ, USA, 2016. [Google Scholar]

- Meyer, B.; Zeileis, A.; Hornik, K. Visualizing Independence Using Extended Association and Mosaic Plots. DSC 2003 Working Papers. 2003. Available online: https://www.researchgate.net/publication/2556711 (accessed on 2 September 2025).

- Shishlyannikov, D.I.; Zverev, V.Y.; Zvonareva, A.G.; Frolov, S.A.; Ivanchenko, A.A. Evaluation of the energy efficiency of functioning and increase in the operating time of hydraulic drives of sucker-rod pump units in difficult operating conditions. J. Min. Inst. 2023, 261, 349–362. Available online: https://pmi.spmi.ru/pmi/article/view/16187 (accessed on 2 September 2025).

- Tsiglianu, P.; Romasheva, N.; Nenko, A. Conceptual Management Framework for Oil and Gas Engineering Project Implementation. Resources 2023, 12, 64. [Google Scholar] [CrossRef]

- Litvinenko, V.S.; Dvoynikov, M.V.; Trushko, V.L. Elaboration of a conceptual solution for the development of the Arctic shelf from seasonally flooded coastal areas. Int. J. Min. Sci. Technol. 2022, 32, 113–119. [Google Scholar] [CrossRef]

| № | Variable | Level/Category | Reports (2014–2024) | |||

|---|---|---|---|---|---|---|

| Russia | RA | RFN | RA and RFN | |||

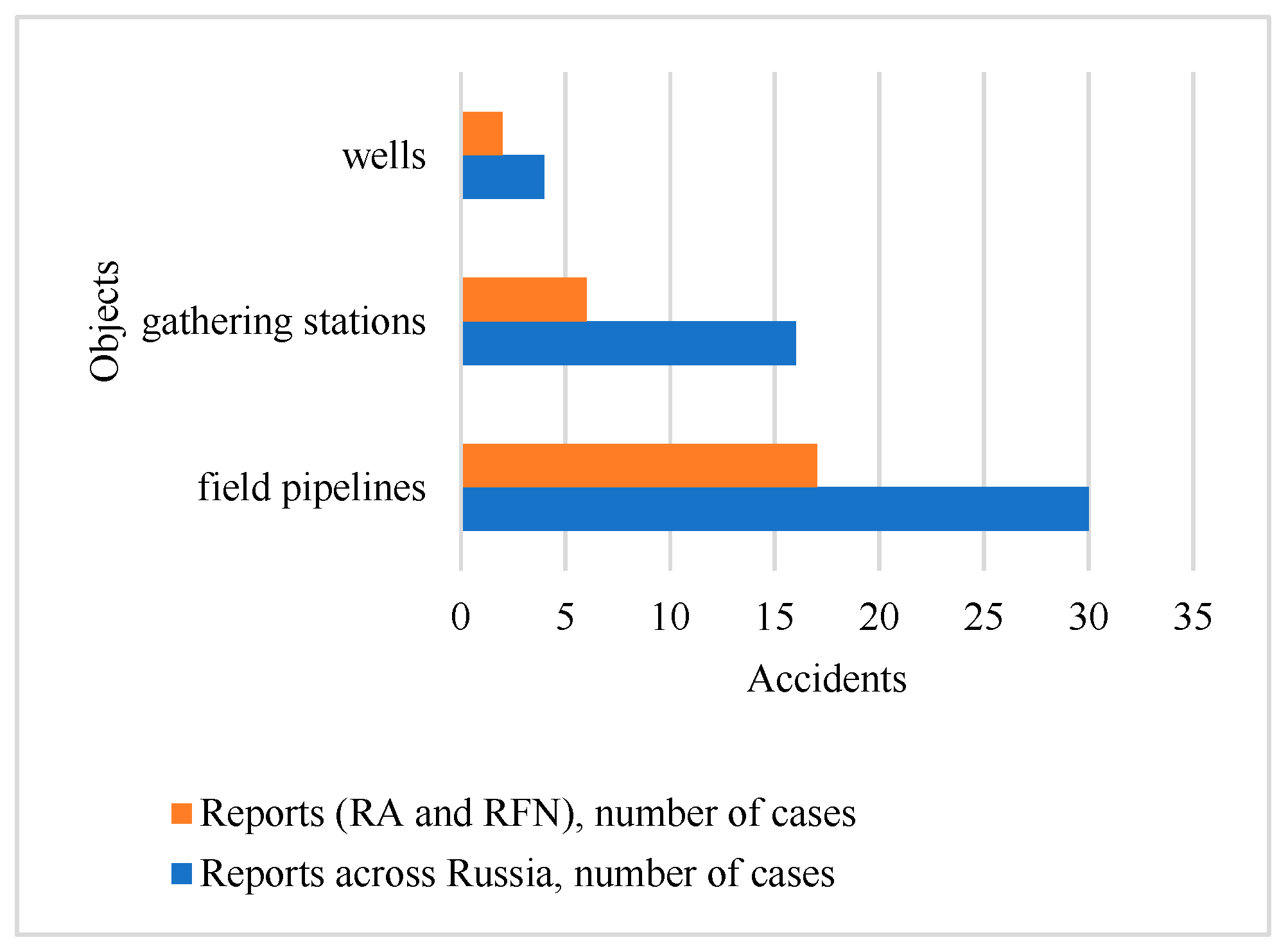

| 1 | Object | Field pipelines | 30 | 11 | 6 | 17 |

| Gathering stations | 16 | 3 | 3 | 6 | ||

| Wells | 4 | 1 | 1 | 2 | ||

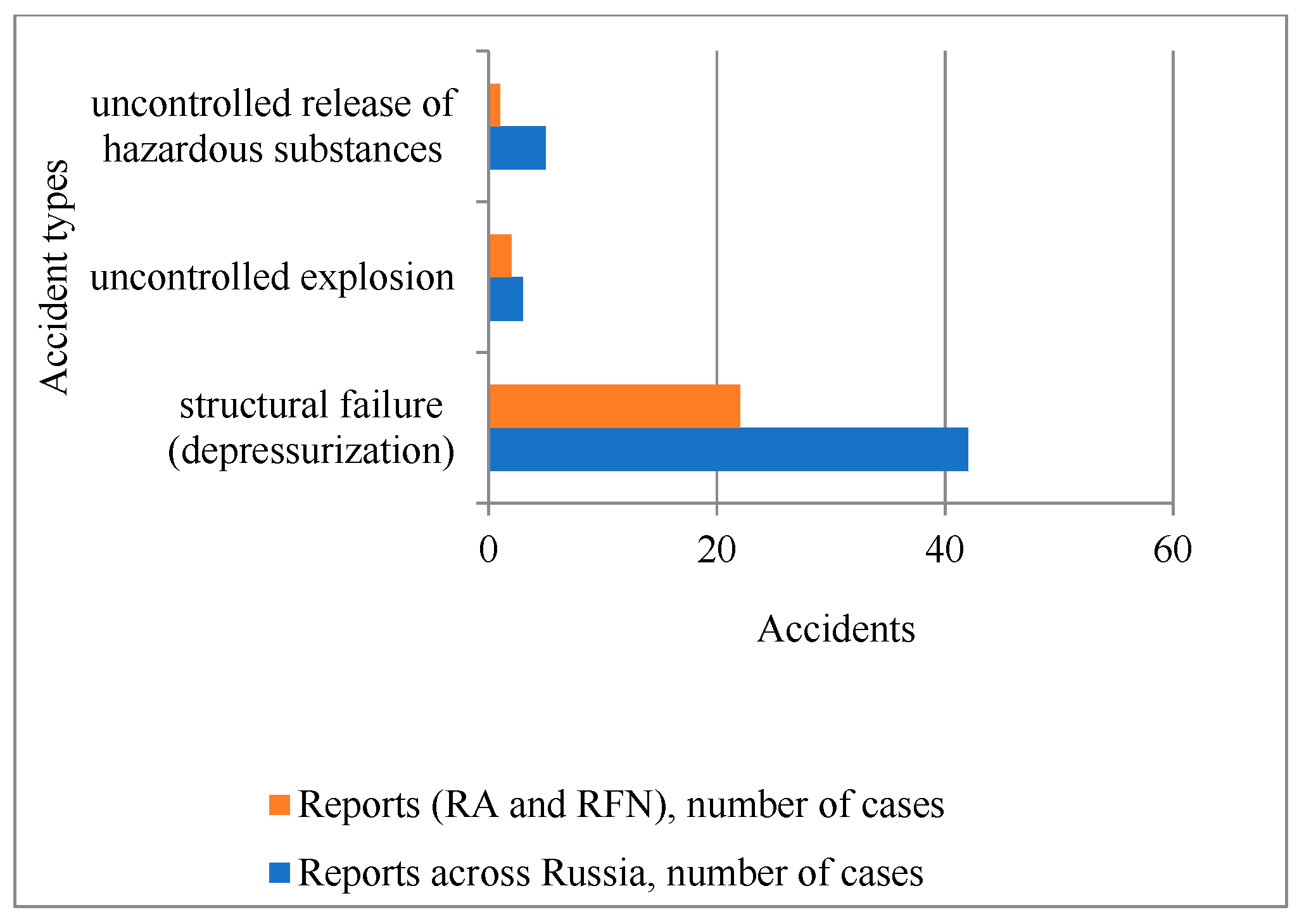

| 2 | Accident type | Structural failure (depressurization) | 42 | 14 | 8 | 22 |

| Uncontrolled explosion | 3 | - | 2 | 2 | ||

| Uncontrolled release of hazardous substances | 5 | 1 | - | 1 | ||

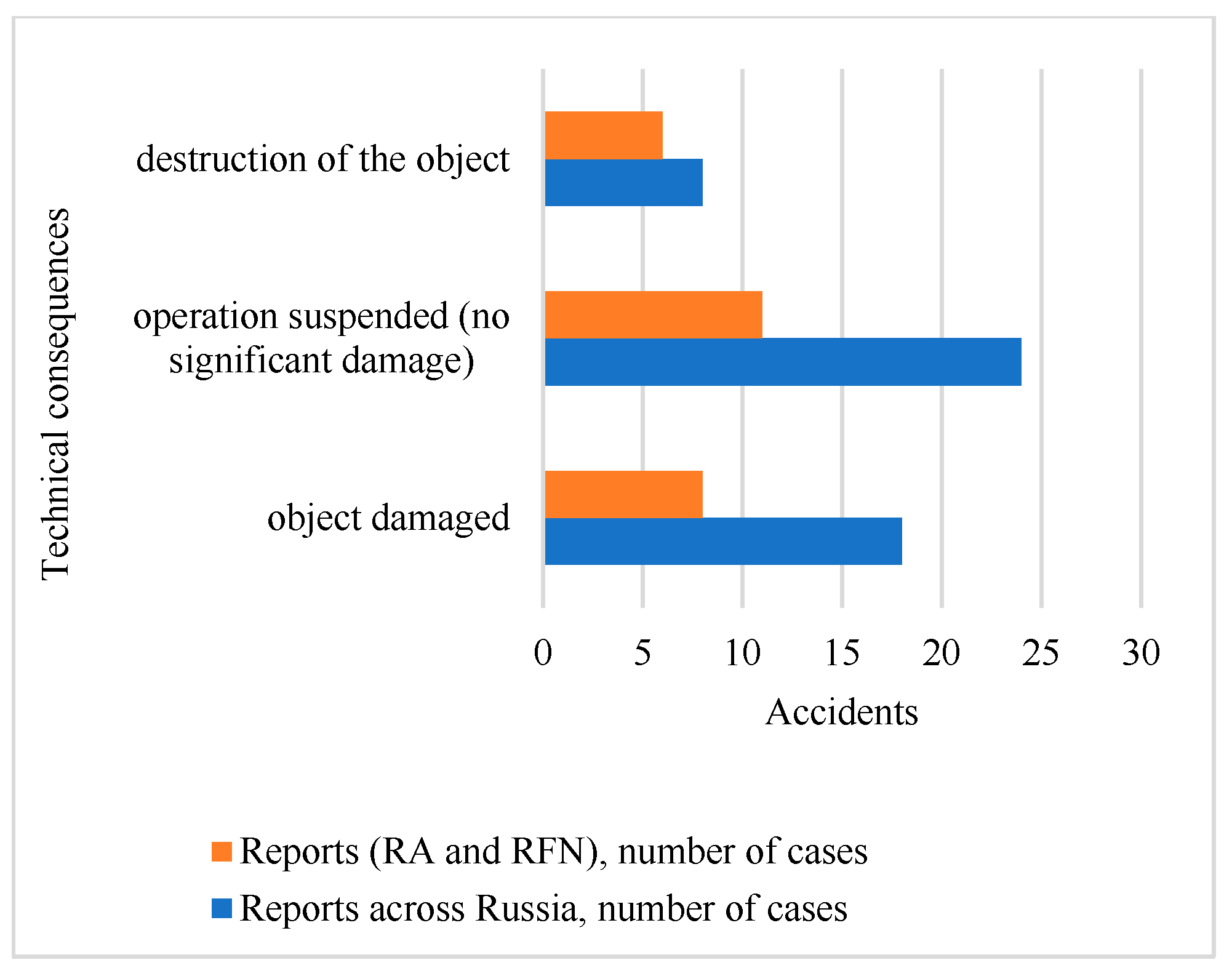

| 3 | Consequences (technical) | Object damaged | 18 | 5 | 3 | 8 |

| Operation suspended (no significant damage) | 24 | 7 | 4 | 11 | ||

| Destruction of the object | 8 | 3 | 3 | 6 | ||

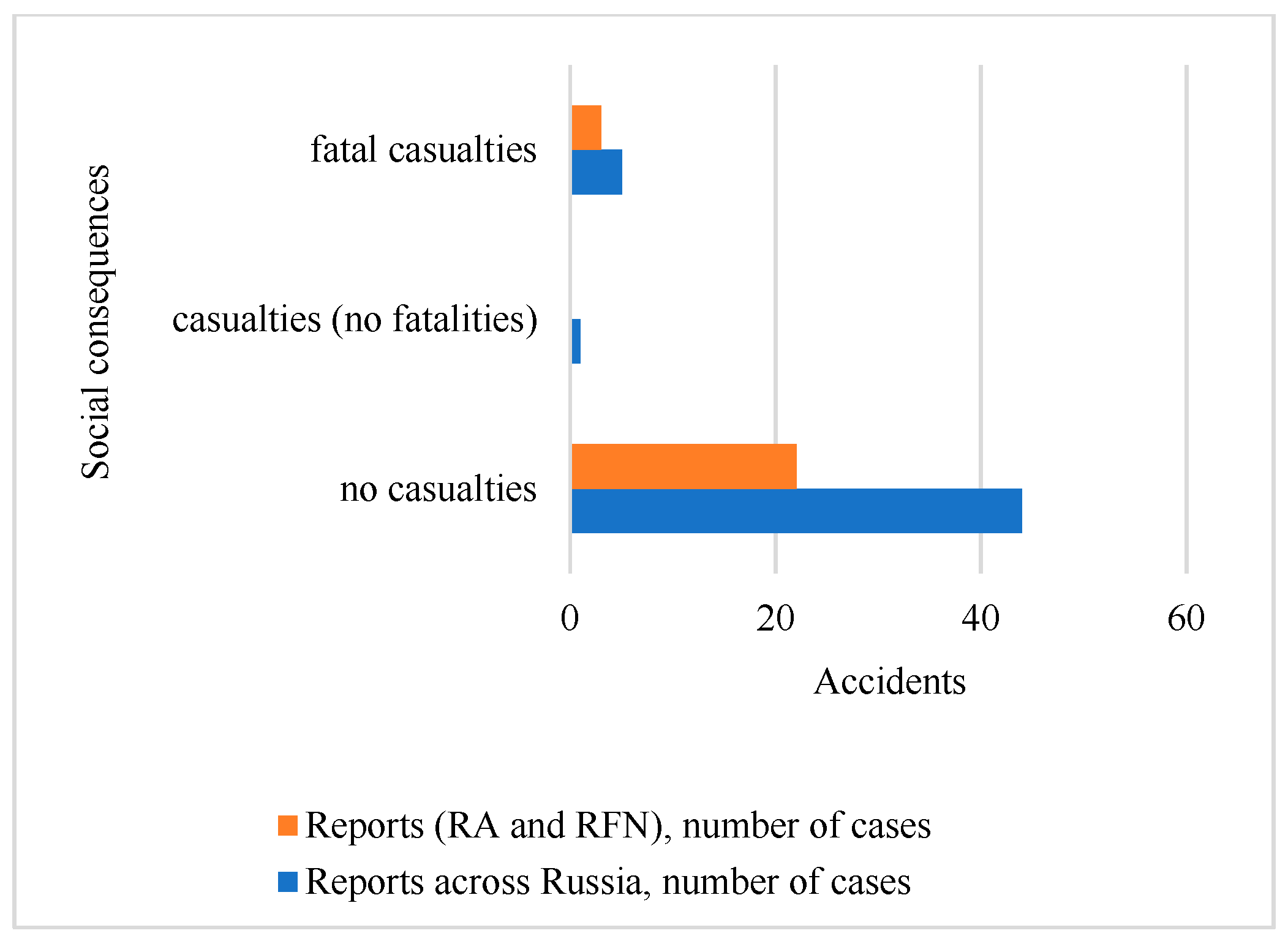

| 4 | Consequences (social) | No casualties | 44 | 15 | 7 | 22 |

| Casualties (no fatalities) | 1 | - | - | - | ||

| Fatal casualties | 5 | - | 3 | 3 | ||

| 5 | Spill type | Local | 27 | 4 | 7 | 11 |

| Regional | 1 | - | - | - | ||

| Interregional | 11 | 4 | 1 | 5 | ||

| Federal | 2 | 1 | - | 1 | ||

| No data | 9 | 2 | 2 | 4 | ||

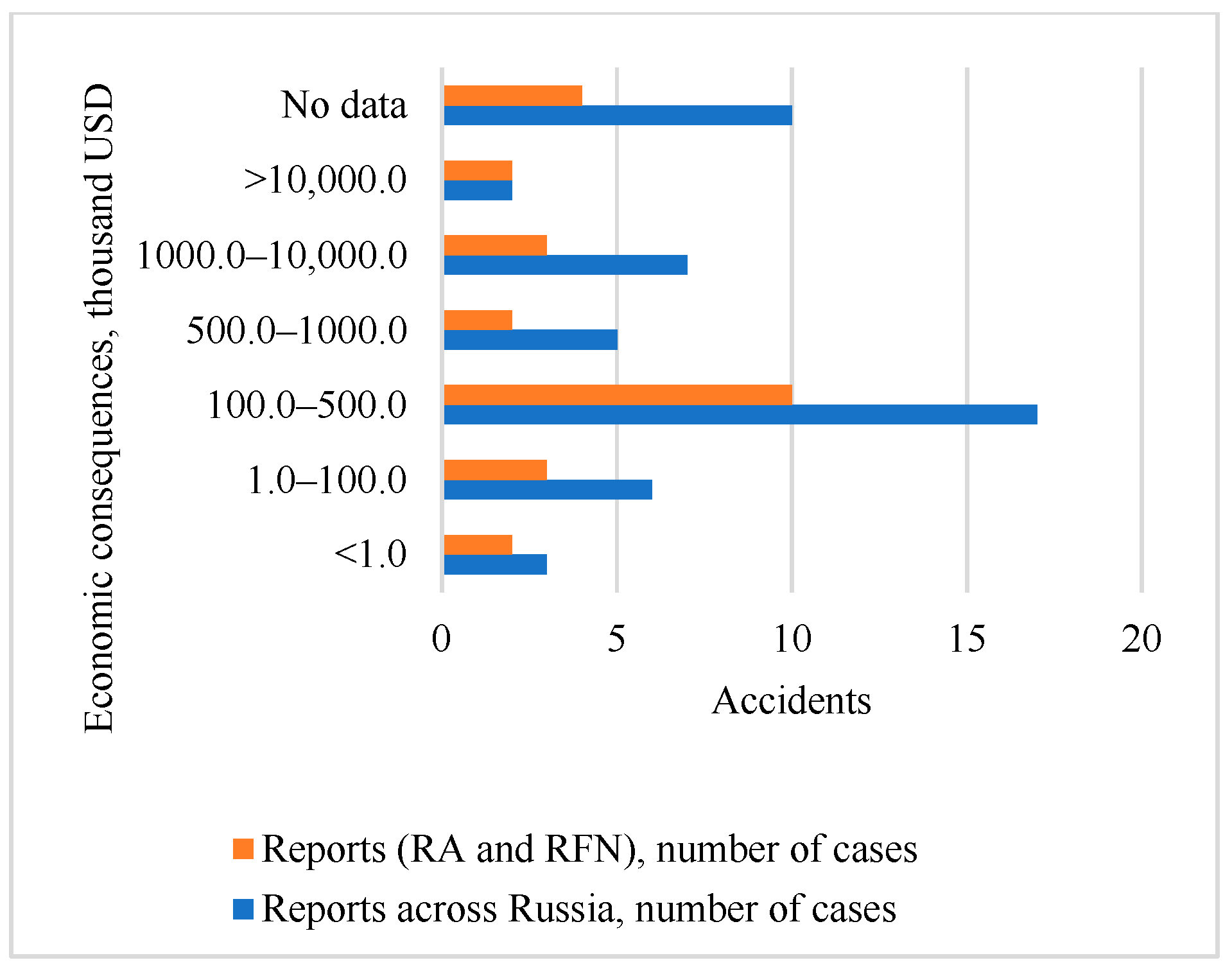

| 6 | Consequences (economic; total damage in thousand USD) | <1.0 | 3 | 1 | 1 | 2 |

| 1.0–100.0 | 6 | - | 3 | 3 | ||

| 100.0–500.0 | 17 | 7 | 3 | 10 | ||

| 500.0–1000.0 | 5 | 1 | 1 | 2 | ||

| 1000.0–10,000.0 | 7 | 3 | - | 3 | ||

| >10,000.0 | 2 | 1 | - | 2 | ||

| No data | 10 | 2 | 2 | 4 | ||

| 7 | Cause (technical) | External mechanical damage | 2 | 1 | - | 1 |

| Material defects | 4 | 2 | - | 2 | ||

| Equipment defects | 6 | 1 | 1 | 2 | ||

| Weld seam rupture | 5 | 2 | 2 | 4 | ||

| Not identified | 33 | 9 | 7 | 16 | ||

| 8 | Cause (organizational) | Operational | 22 | 4 | 6 | 9 |

| Administrative | 22 | 7 | 3 | 10 | ||

| Not identified | 4 | 4 | 1 | 4 | ||

| 9 | Cause (physical and chemical processes) | Internal corrosion | 20 | 6 | 5 | 11 |

| Other causes (external corrosion, vibration, electrostatics) | 8 | 3 | - | 3 | ||

| Not identified | 22 | 6 | 5 | 11 | ||

| 10 | Region | Russian Arctic (RA) | 15 | 15 | - | 15 |

| Russian Far North (RFN) | 10 | - | 10 | 10 | ||

| Other regions | 25 | - | - | - | ||

| № | Variable | Label | Levels | Type |

|---|---|---|---|---|

| 1 | Object | Object | 3 | nominal |

| 2 | Type of accident | Type | 3 | nominal |

| 3 | Consequences (technical) | Tech | 3 | nominal |

| 4 | Consequences (social) | Social | 3 | nominal |

| 5 | Type of spill | SpillType | 4 | ordered |

| 6 | Total damage in thousand USD | TotalDamage | 7 | ordered |

| 7 | Cause (technical) | CauseTech | 5 | nominal |

| 8 | Cause (organizational) | CauseOrg | 3 | nominal |

| 9 | Cause (physical and chemical processes) | CausePhi | 3 | nominal |

| 10 | Region | Region | 3 | nominal |

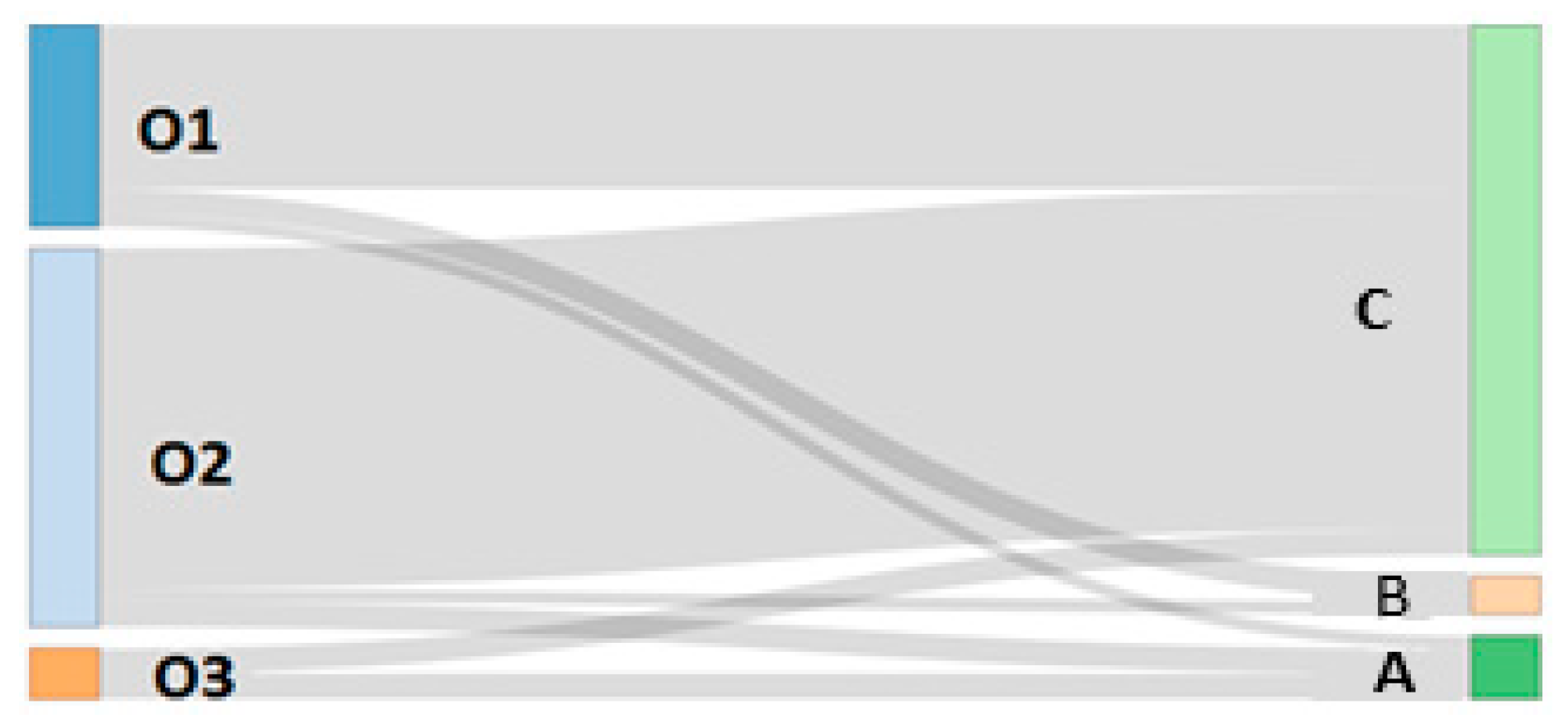

| Object | Type | Totals | ||

|---|---|---|---|---|

| A | B | C | ||

| O1 | 2 | 1 | 13 | 16 |

| O2 | 1 | 2 | 27 | 30 |

| O3 | 0 | 2 | 2 | 4 |

| Totals | 3 | 5 | 42 | 50 |

| Object | Type | Tech | Social | CauseTech | CauseOrg | CausePhi | Region | |

|---|---|---|---|---|---|---|---|---|

| Object | 1.0000 | 0.3062 | 0.2251 | 0.2093 | 0.3695 | 0.2508 | 0.4502 | 0.1408 |

| Type | 0.3062 | 1.0000 | 0.2934 | 0.1603 | 0.2198 | 0.1424 | 0.1300 | 0.2573 |

| Tech | 0.2251 | 0.2934 | 1.0000 | 0.1978 | 0.2636 | 0.2901 | 0.1991 | 0.1685 |

| Social | 0.2093 | 0.1603 | 0.1978 | 1.0000 | 0.3058 | 0.2127 | 0.1523 | 0.2686 |

| CauseTech | 0.3695 | 0.2198 | 0.2636 | 0.3058 | 1.0000 | 0.2629 | 0.4815 | 0.1863 |

| CauseOrg | 0.2508 | 0.1424 | 0.2901 | 0.2127 | 0.2629 | 1.0000 | 0.2433 | 0.2513 |

| CausePhi | 0.4502 | 0.1300 | 0.1991 | 0.1523 | 0.4815 | 0.2433 | 1.0000 | 0.1577 |

| Region | 0.1408 | 0.2573 | 0.1685 | 0.2686 | 0.1863 | 0.2513 | 0.1577 | 1.0000 |

| Object | Type | Tech | Social | CauseTech | CauseOrg | CausePhi | Region | |

|---|---|---|---|---|---|---|---|---|

| TotalDamage | 0.5727 | 0.8891 | 0.1376 | 0.2645 | 0.7100 | 0.2017 | 0.8217 | 0.3818 |

| SpillType | 0.8645 | 0.4196 | 0.4271 | 0.4118 | 0.8898 | 0.6993 | 0.6082 | 0.428 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nevskaya, M.; Belyaev, V.; Aleshichev, S.; Vinogradova, V.; Shagidulina, D. Data Systematization and Preliminary Analysis of Accidental Oil and Petroleum Product Spills in the Russian Arctic and Far North. Resources 2025, 14, 147. https://doi.org/10.3390/resources14090147

Nevskaya M, Belyaev V, Aleshichev S, Vinogradova V, Shagidulina D. Data Systematization and Preliminary Analysis of Accidental Oil and Petroleum Product Spills in the Russian Arctic and Far North. Resources. 2025; 14(9):147. https://doi.org/10.3390/resources14090147

Chicago/Turabian StyleNevskaya, Marina, Victor Belyaev, Sergey Aleshichev, Victoriya Vinogradova, and Dinara Shagidulina. 2025. "Data Systematization and Preliminary Analysis of Accidental Oil and Petroleum Product Spills in the Russian Arctic and Far North" Resources 14, no. 9: 147. https://doi.org/10.3390/resources14090147

APA StyleNevskaya, M., Belyaev, V., Aleshichev, S., Vinogradova, V., & Shagidulina, D. (2025). Data Systematization and Preliminary Analysis of Accidental Oil and Petroleum Product Spills in the Russian Arctic and Far North. Resources, 14(9), 147. https://doi.org/10.3390/resources14090147