Research Progress of Coal Stacks Reducing Dust Emissions: Ecological Technology in the Example of the Karaganda Region

Abstract

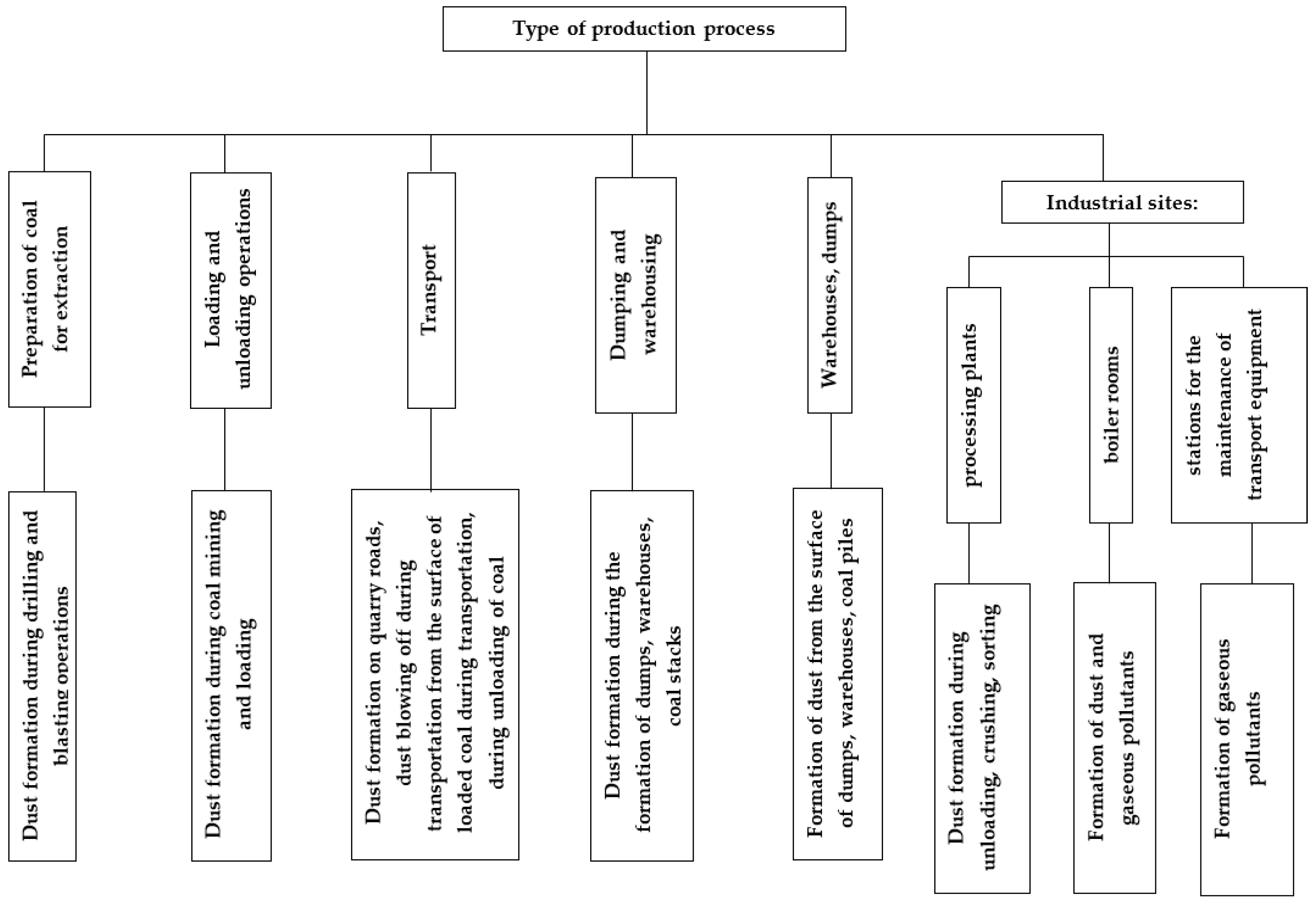

1. Introduction

2. Materials and Methods

- Analysis of initial data and materials from previous studies of coal storage time, depending on the technology used.

- Analysis of methods and technological solutions to prevent weathering of ordinary coal and to increase its shelf life.

- Assessment of the volume and shelf life of coal mass in stacks, the dynamics of its receipt and shipment to consumers. Estimation of the size of the extracted coal.

- Conducting experimental measurements of the temperature of stacks with thermal sensors (or a portable temperature probe with a scale up to 150 °C or lowering a thermometer in a stack into vertical control metal pipes with a diameter of 0.025 to 0.050 m) in operational coal stacks in a coal mine, depending on the shelf life, conditions, and size of the coal mass. Metal tubes for thermal probes are placed inside during the formation of coal stacks.

- Investigation of the weathering process over time and depending on the chemical composition of the stored coals; creation of a regular grid of diagnostic sensors across the space of technological stacks, and monitoring of the temperature of coals.

- Conducting experimental tests and applied research in the following areas, considering the influence of ash content in the range of 5–13%, humidity—14.5%, volatile matter yield—43.5%, non-volatile (bound carbon)—76%, sulfur content—0.5%.

- Conducting experimental studies to determine the impact of coal on the environment.

- Development of proposals to reduce environmental impact.

- -

- exposure for 20 min after immersion in the medium to achieve thermal equilibrium;

- -

- the use of a metal protective case when removing the thermometer from the tubes to prevent mechanical damage;

- -

- placement of the mercury tank in a copper capsule filled with technical oil or iron filings to maintain constant thermal contact;

- -

- using a rubber stopper to fix a constant distance (3–4 mm) between the mercury tank and the capsule wall.

- -

- the pipes should be placed on the top of the stack, following a checkerboard pattern, with a maximum distance between the pipes of 25 m;

- -

- the lower ends of the pipes must be at least one-quarter of the height of the stack from its base;

- -

- each control pipe must have a clearly visible serial number placed on the protruding end of the pipe at a height of at least 0.2 m above the stack surface;

- -

- the area around the installed pipes must be carefully sealed to ensure the accuracy of temperature measurements.

- -

- measurements are made on the upper base of the stack in three sections: in the central part and at a distance of 0.25 of the stack length from its ends;

- -

- in stacks with a width of more than 50 m, three measurements are performed: in the center of the upper base and on the ridge of the stack, at a distance of 10 m from the ends;

- -

- in stacks with a width of less than 50 m, the temperature is measured in the center of the upper base;

- -

- on the slopes of the stack, measurements are carried out at a distance of 2 m from the bottom edge;

- -

- the distance between the temperature measuring points on the slopes corresponds to the same distance as on the upper base of the stack (in the central part and at a distance of 0.25 of the stack length from the ends, measured at the lower base);

- -

- when measuring the temperature on the playground or ridge, the thermal probes are installed vertically, while on the slopes, they are perpendicular to the surface;

- -

- after taking measurements, the holes formed by the thermal probe, as well as footprints, are filled in with coal;

- -

- if a solid frozen layer of coal is found at the control points, the temperature in these places is not measured;

- -

- the depth of immersion of the thermal probe in the stack when measuring the temperature of coal is 1.25–1.5 m.

- -

- maximum wetting and penetrating power;

- -

- technologically advanced in preparation and use;

- -

- have a low cost;

- -

- non-toxic;

- -

- must have a long shelf life.

3. Results

- -

- when loading coal, depending on its volume (Table 5);

- -

- when blowing coal dust particles from the surface of the stack, depending on its area.

- -

- areas of the equal size (150 m2, on one side of the stack) were treated;

- -

- application of AEC is a single application;

- -

- simultaneous method of application of AEC subjects (date, time, climatic conditions during the application period).

- -

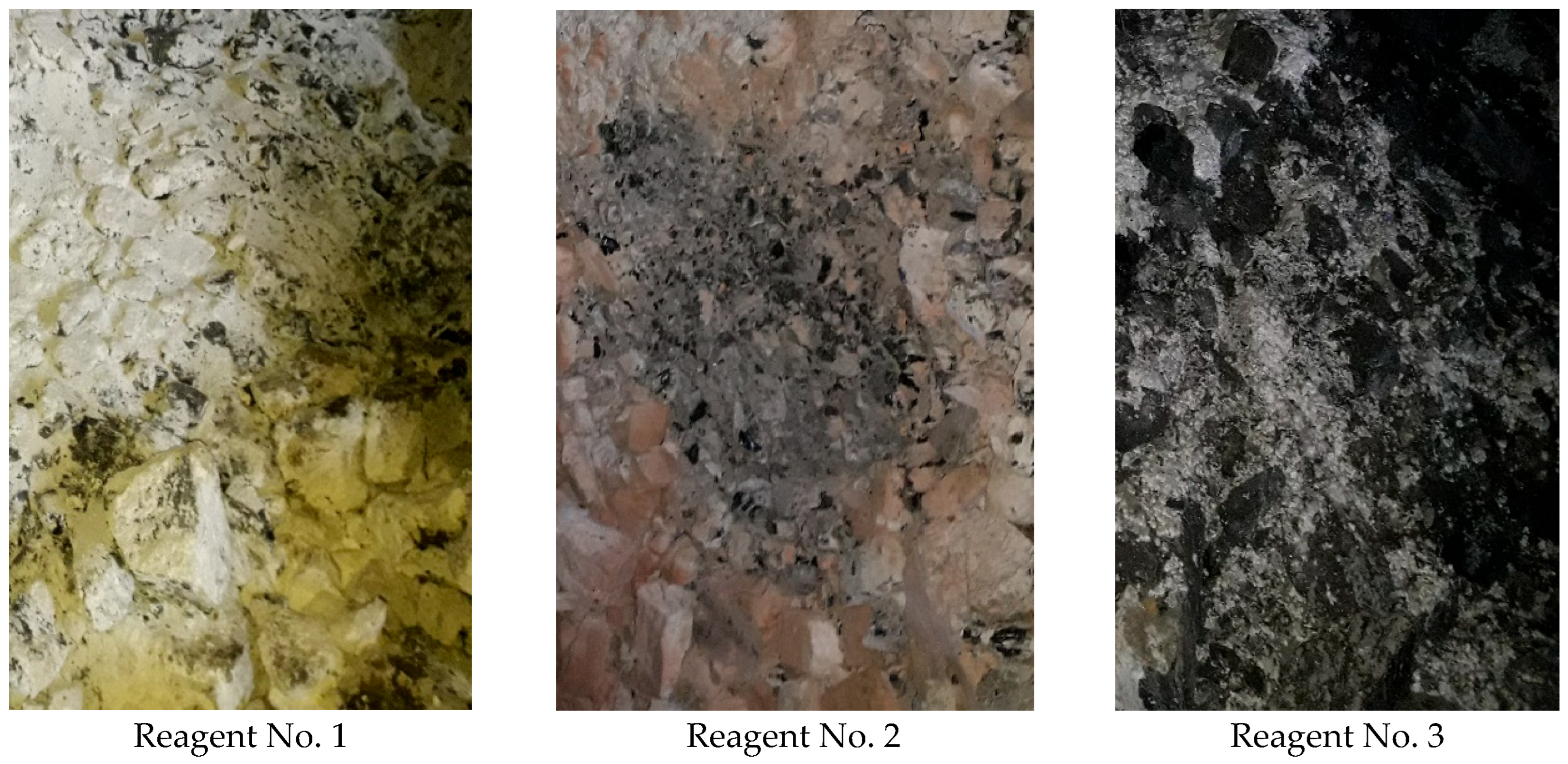

- the condition of the experimental sites was assessed after 24 h. Treatment of the site with chemical reagent No. 1 resulted in the formation of an elastic, flexible covering with a thickness from 1.1 mm to 1.9 mm. The covering formed at site No. 2 had the following properties: elasticity, bending flexibility, rubber-like stretchability, and thickness in the range of 1–1.9 mm. A covering similar to a crust formed on the area treated with chemical reagent No. 3. The thickness of the crust was 1.6–2.8 mm.

- -

- the inspection was carried out 45 days after the sites were processed. There was no precipitation during this period. The safety of the film coating in the areas treated with reagents No. 1 and No. 2 was preserved by 90–95%. The properties of these films remained at the level of the first inspection. Uniform surface cracking was observed in the area treated with reagent No. 3. The site was no longer examined.

- -

- the next inspection was carried out in autumn, 90 days after the processing of the plots. During this period, there were both precipitation and the first frosts. The preservation of the covering in the areas treated with reagents No. 1 and No. 2 was preserved by 90%. The coating is visually different in the area treated with reagent No. 1. In some places, the covering is layered. In places where the covering is delaminated, the thickness reaches 12 mm, the coating is hard, not elastic, and brittle. In the places of the single-layer coating, the covering remained elastic, flexible, and 1.1–1.9 mm thick. In the area covered with reagent No. 2, the visual coating is almost the same and uniform. The coating is single-layer, elastic, flexible, stretchable, and 1–1.9 mm thick.

- -

- the final inspection was carried out in April 2023. The film-forming coatings have been lying all winter, covered with snow. The air temperature for the entire period of the experiment ranged from +36 °C to −37 °C. A visual inspection of the sites showed that the film was preserved on 40 % of the area of the studied sites. In the area coated with reagent No. 1, the cover is thick, reaching a thickness of 9 mm. In the area treated with reagent No. 2, the cover is plastic, thin, and 3 mm thick. The key characteristic of the tested AEC coatings is their strength and resistance to mechanical stress and loads caused by human walking on their surface.

4. Discussion

- -

- Assessment of the territory (landscape, groundwater level, soil type, possible flooding areas, as well as climatic conditions) and design of the drainage system (grooves and drainage wells);

- -

- Development and laying of grooves (dimensions should consider the volume of water flow for the period of heavy rains and snowmelt, as well as the slope of the direction of water from the stacks towards drainage wells and drainage systems);

- -

- Installation of drainage wells with filters (to prevent clogging) in places with large concentrations of wastewater.

- -

- Install a heat-conducting coating in the form of compacted crushed stone, clay, cobblestone, and paving stones under the stack;

- -

- Construction of sites with a mandatory slope from the center to the edges for the forced outflow of meltwater and rainwater;

- -

- Provide for the availability of spare sites (at least 5% of the total area) that will effectively cope with force majeure situations (cooling of superheated coal and expansion of storage area in case of increased storage volumes).

- -

- one is formed;

- -

- the second, fully formed, is shipped.

- -

- AEC solution treatment of the surface of the stacks in the summer;

- -

- Temperature monitoring in stacks using mercury thermometers;

- -

- Coal is shipped from the stack when the temperature reaches 30–35 °C;

- -

- When the temperature reaches 60 °C in any of the sensors, treat the spontaneous combustion site locally with AEC solutions or ship heated coal from this site.

5. Conclusions

- -

- when forming stacks, it is necessary to consider the brand of coal (it is not permissible to form a stack of coal of various grades);

- -

- minimization of coal unloading and stacking time (no more than 2 days);

- -

- consideration of parameters: area no more than 350 m2; length no more than 30 m; capacity no more than 1000 t;

- -

- placing an information plate near each stack with data on the brand of coal and the date of its arrival at the storage;

- -

- systematic visual monitoring and monitoring of the temperature regime of stacks (different stack depths). The temperature regime of the stacks is monitored through special tubes arranged in a checkerboard pattern inside the stack. At the upper end of the pipe, which has a pointed lower end to facilitate hammering, a plug is installed that locks the cord to which a metal case with a technical thermometer is attached. In this case, the pipe rises 0.3 m above the stack surface. This type of regular monitoring will help prevent coal weathering (oxidation);

- -

- to monitor atmospheric air pollution and measure the levels of physical impact on atmospheric air at the border of the sanitary protection zone (SPZ) and the residential area;

- -

- to plant green spaces around the perimeter of the SPZ.

- -

- ease of preparation and use of AEC;

- -

- low cost on the market;

- -

- coatings retain their properties for a 90% long period of time;

- -

- rapid hardening of the coating;

- -

- withstand the aggressiveness of the environment (temperature fluctuations, constant and strong wind load, various types of precipitation (rain, snow, hail));

- -

- they have shown strength and resistance to mechanical influences and loads, such as human walking on them.

- -

- if there are no dusting or fire hazards, enterprises will not be subject to penalties under the Environmental Code of the Republic of Kazakhstan [9];

- -

- elimination of payments for excessive and unauthorized emissions;

- -

- starting from 2025, enterprises that implement the best available technologies (BAT) will be exempt from emission fees for 10 years; otherwise, the emission fee rates will be increased by 2–8 times;

- -

- the enterprise will be issued a comprehensive environmental permit to operate in accordance with environmental requirements (Article 112 [9]).

- Application time: The optimal time for applying reagents to dust-prone surfaces is the beginning of the second quarter of this year. A necessary condition is a favorable meteorological situation: no precipitation (rain, snow), low wind speed, lack of snow cover, and surface moisture in the cultivated areas.

- Frequency of treatment: The recommended frequency of coating is once a year during the warmer months.

- Parameters of the working solution: The working solution for the application must have a concentration of 5 %. The specific consumption of the reagent should be at least 50 g/m2.

- Application technology: The coating should be applied evenly using air spray equipment (nozzle type).

- Post-application conditions: After coating, it is necessary to ensure that there is no mechanical impact on the treated area for 2–3 h, necessary for the coating to harden.

- Application quality requirements: The coating must be applied evenly, without gaps. If necessary, it is allowed to increase the specific consumption of the reagent and apply a multilayer coating, which does not reduce the anti-emission properties of the material.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AEC | Anti-emission cover |

| SPZ | Sanitary protection zone |

References

- Tseshkovskaya Ye, A.; Golubeva Ye, I.; Tsoy, N.K.; Oralova, A.T.; Matonin, V.V. Geoecological Aspects of Recultivation of Disturbed Lands in the Karaganda Region (Republic of Kazakhstan). Bull. Mosc. Univ. 2019, 73–80. [Google Scholar]

- The Zhalyn Coal Deposit. Available online: https://zhalyncoal.kz/field/ (accessed on 7 February 2025).

- Citizens and Ecology. Available online: https://ecocitizens.kz/polluters/korporatsiya-kazakhmys-filial-borly-ugolnyj-razrez-molodezhnyj (accessed on 7 February 2025).

- Kuznetsky Section. Available online: https://kuznetskiy.kz/en/ (accessed on 7 February 2025).

- Pernebek, B.P.; Rassolova, M.A.; Selyanina, A.V. On the issue of dedusting air during loading and transportation of coal. Coal 2024, 107–110. Available online: https://www.researchgate.net/publication/380640945_ON_THE_ISSUE_OF_DUST_CLEARING_AIR_DURING_LOADING_AND_TRANSPORTATION_OF_COAL (accessed on 7 February 2025).

- Chaiyo, R.; Wongwiwat, J.; Sukjai, Y. Numerical and Experimental Investigation on Combustion Characteristics and Pollutant Emissions of Pulverized Coal and Biomass Co-Firing in a 500 kW Burner. Fuels 2025, 6, 9. [Google Scholar] [CrossRef]

- Gao, J.; Zeng, Q. Study on the Eco-Environmental Index and Its Application: A Case Study of the Surablak Coal Fire Area, Xinjiang, China. Fire 2025, 8, 53. [Google Scholar] [CrossRef]

- Guo, J.; Wang, L.; Liu, Y.; Chen, C.; Cai, G.; Du, W. Experimental Study on the Influence of Staged Oxygen Consumption on the Oxidation Characteristics of Coal Spontaneous Combustion. Fire 2024, 7, 359. [Google Scholar] [CrossRef]

- Environmental Code of the Republic of Kazakhstan Dated 02.01.2021 № 400—VI 3RK. Available online: https://adilet.zan.kz/rus/docs/K2100000400 (accessed on 7 February 2025).

- On the Approval of Fire Safety Regulations. Order of the Minister of Emergency Situations of the Republic of Kazakhstan Dated February 21, 2022 No. 55. Available online: https://adilet.zan.kz/rus/docs/V2200026867 (accessed on 7 February 2025).

- Gendler, S.G.; Stepanova, A.Y.; Kuznetsov, V.S. Problems of Industrial and Environmental Safety When Using Open and Closed Storages for Temporary Storage of Coal. News of TulSU. Earth Sciences 2022, No. 4. рр. 134–143. Available online: https://cyberleninka.ru/article/n/problemy-promyshlennoy-i-ekologicheskoy-bezopasnosti-pri-ispolzovanii-dlya-vremennogo-hraneniya-uglya-otkrytyh-i-zakrytyh-skladov/viewer (accessed on 7 February 2025).

- Jha, P.K.; Das, T.K.; Soni, A.B. Effect of Weathering on Coal Quality. Energy 2014, 75, 155–160. [Google Scholar]

- John, L.; Doyoung, L.; Thomas, S.; Grint, A. Multiple mechanisms for the loss of coking properties caused by mild air oxidation. Fuel 1986, 65, 595–596. [Google Scholar] [CrossRef]

- Bao, R.; Lei, C.; Wang, C.; Zhou, F. Thermal Reaction Process and Thermokinetic Characteristics of Coking Coal Oxidation. Fire 2024, 7, 448. [Google Scholar] [CrossRef]

- Shesternev, D.M. Physical and chemical weathering of rock massifs in the cryolithozone. Min. Inf. Anal. Bull. 2017, 3, 350–360. [Google Scholar]

- Kuznetsov, V.G. Evolution of weathering processes in the history of the Earth. Moscow City Office the island of nature testers. Ed. Geol. 2021, 96, 52–61. [Google Scholar]

- Jolanta, K.; Magdalena, M.-K. Coal weathering and laboratory (artificial) coal oxidation. Int. J. Coal Geol. 2016, 171, 12–36. [Google Scholar]

- Voroshilov, S.P.; Voroshilov, Y.S.; Voroshilov, A.S.; Uvarova, V.A. The Effect of Moisture on the Oxidation of Coal. Bull. Sci. Cent. Saf. Work. Coal Ind. 2008, 68–82. Available online: https://cyberleninka.ru/article/n/vliyanie-vlagi-na-okislenie-kamennyh-ugley/viewer (accessed on 7 February 2025).

- Portola, V.A.; Zhdanov, A.N.; Bobrovnikova, A.A. The prospect of using flame retardants to prevent spontaneous combustion of coal storages. Coal 2019, 14–19. [Google Scholar]

- Zbigniew, S.T.; Krzysztof, S.T.; Anna, M.-S. Fire hazards of coal storage sites—Monitoring and protection. Civ. Environ. Eng. Rep. CEER 2022, 32, 242–258. [Google Scholar]

- Tseshkovskaya, Y.A.; Oralova, A.T.; Golubeva, E.I.; Tsoy, N.K.; Zakharov, A.M. Dust Suppression on the Surfaces of Storage Device of Technogenic Mineral Formations. Izv. NAN RK Seriya Geol. Tekhnicheskikh Nauk 2022, 230–241. [Google Scholar] [CrossRef]

- Tseshkovskaya, Y.; Tsoy, N.; Oralova, A.; Obukhov, Y.; Zakharov, A. Dust suppression on industrial waste storage (on example of the waste storage of the Ulytau region). E3S Web Conf. 2023, 407, 03011. [Google Scholar] [CrossRef]

- Fedorov, V.I.; Gavrilov, V.L. Evaluation of changes in the granulometric composition of low-metamorphosed coals during long-term storage. Min. Inf. Anal. Bull. 2021, 12-1, 223–232. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, W.; Cheng, X.; Yan, K.; Zhao, W.; Yang, F. Air and oxy-fuel combustion characteristics of coal gangue and weathered coal blends. Energy 2023, 284, 128660. [Google Scholar] [CrossRef]

- Sharov, N.A.; Dudayev, R.R.; Krishchuk, D.I.; Liskova, M.Y. Dust suppression methods in coal mines of the Far North. Perm J. Pet. Min. Eng. 2019, 19, 184–200. [Google Scholar]

- Bulbashev, A.P.; Shuvalov, Y.V. Dust Control in Quarries for the Extraction of Building Materials; MANEB: Saint Petersburg, Russia, 2006; p. 87. [Google Scholar]

- Dalbaeva, E.P. Development of a method to reduce the risk of occupational diseases in cryolithozone quarries. In Notes of the Mining Institute; The Mining Institute: Belgrade, Serbia, 2014; Volume Т.207, pp. 110–111. [Google Scholar]

- Molotilov, S.G.; Kortelev, O.B.; Norrie, V.K. Intensification of loading and transport operations at coal depots. Min. Inf. Anal. Bull. 2005, 197–200. [Google Scholar]

- Fomin, A.I.; Voroshilov, Y.S.; Paleev, D.Y. Investigation of the Effect of Coal Dust on the Safety of Mining Operations. Mining Industry, 2019, No. 1 (143), pp. 33–36. Available online: https://cyberleninka.ru/article/n/issledovanie-vliyaniya-ugolnoy-pyli-na-bezopasnost-vedeniya-gornyh-rabot (accessed on 7 February 2025).

- Sikarev, S.; Adamov, E.; Smirnov, S.; Lipatov, I.; Lyudmilin, M. Development of a mathematical model of behavior of air flows in the therritory of open port coal storages. Russ. J. Water Transp. 2020, 20–26. [Google Scholar] [CrossRef]

- Biliaiev, M.M.; Karpo, A.A.; Yakubovska, Z.M. Reducing the intensity of takeaway pulverized coal by using special solution. Sci. Transp. Progress. 2017, 8–15. [Google Scholar] [CrossRef]

- Gendler, S.G.; Stepanova, A.Y.; Popov, M.M. Justification of the safe operation of a closed coal storage by the gas factor. J. Min. Inst. 2024, 272, 72–82. Available online: https://cyberleninka.ru/article/n/obosnovanie-bezopasnoy-ekspluatatsii-zakrytogo-ugolnogo-sklada-po-gazovomu-faktoru/viewer (accessed on 7 February 2025).

- Cheng, J.; Wang, Y.; Lei, Y.; Zheng, X.; Luo, W.; Song, W.; Wang, Z.; Han, F. Study on coal dust crusting for coal pile based on a compound binder. Powder Technol. 2020, 376, 149–166. [Google Scholar] [CrossRef]

- Pakchotanon, P.T.; Tontiwachwuthikul, P. Coal dust dispersion from a coal storage stack. Songklanakarin J. Sci. Technol. 2020, 42, 557–563. Available online: https://www.researchgate.net/publication/350398500_Coal_dust_dispersion_from_a_coal_storage_pile (accessed on 7 February 2025).

- Mueller, S.F.; Mallard, J.W.; Mao, Q.; Shaw, S.L. Variability of Natural Dust Erosion from a Coal Stack. J. Appl. Meteor. Climatol. 2015, 54, 3–14. [Google Scholar] [CrossRef]

- Rongting, H.; Yichun, T.; Jianglin, C.; Shihang, L.; Shiyuan, W. Review on Dust Control Technologies in Coal Mines of China. Sustainability 2024, 16, 4038. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Q.; Tai, C.; Li, J.; Yang, Z.; Shen, K.; Guo, C.; Guo, H. Design of PM2.5 monitoring and forecasting system for opencast coal mine road based on internet of things and ARIMA Mode. PLoS ONE 2022, 17, e0267440. [Google Scholar] [CrossRef] [PubMed]

- Xia, N.; Hai, W.; Song, G.; Tang, M. Identification and monitoring of coal dust pollution in Wucaiwan mining area, Xinjiang (China) using Landsat derived enhanced coal dust index. PLoS ONE 2022, 17, e0266517. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Han, W.; Xu, Y.; Wang, Z. Analysis on the Development Status of Coal Mine Dust Disaster Prevention Technology in China. J. Healthc. Eng. 2021, 2021, 5574579. [Google Scholar] [CrossRef]

- Panicker, S.; Shankar, S.; Jithin, S.; Sandeep, S.; Irshad, M.; Daniel, J.; Sajjad, T. Online coal dust suppression system for opencast coal mines. Int. J. Coal Sci. Technol. 2023, 10, 60. [Google Scholar] [CrossRef]

- Ghose, M.; Majee, S. Assessment of Dust Generation Due to Opencast Coal Mining—An Indian Case Study. Environ. Monit. Assess. 2020, 61, 257–265. [Google Scholar] [CrossRef]

- Lal, B.; Tripathy, S.S. Prediction of dust concentration in open cast coal mine using artificial neural network. Atmos. Pollut. Res. 2012, 3, 211–218. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Wang, R. Characteristics of dust pollution and its influencing factors during cold period of open-pit coal mines in northern China. Front. Earth Sci. 2025, 13, 1458847. [Google Scholar] [CrossRef]

- Trechera, P.; Moreno, T.; Córdoba, P.; Moreno, N.; Zhuang, X.; Li, B.; Li, J.; Shangguan, Y.; Dominguez, A.O.; Kelly, F.; et al. Comprehensive evaluation of potential coal mine dust emissions in an open-pit coal mine in Northwest China. Int. J. Coal Geol. 2021, 235, 103677. [Google Scholar] [CrossRef]

- Oei, P.Y.; Brauers, H.; Herpich, P. Lessons from Germany’s hard coal mining phase-out: Policies and transition from 1950 to 2018. Clim. Policy 2019, 20, 963–979. [Google Scholar] [CrossRef]

- Krüger, T.; Kraus, T.; Kaifie, A. A Changing Home: A Cross-Sectional Study on Environmental Degradation, Resettlement and Psychological Distress in a Western German Coal-Mining Region. Int. J. Environ. Res. Public Health 2022, 19, 7143. [Google Scholar] [CrossRef]

- Aubourg, M.A.; Livi, K.J.T.; Sawtell, G.G.; Sanchez-Gonzalez, C.C.; Spada, N.J.; Dickerson, R.R.; Chiou, W.A.; Kamanzi, C.; Ramachandran, G.; Rule, A.M.; et al. Use of electron microscopy to determine presence of coal dust in a neighborhood bordering an open-air coal terminal in Curtis Bay, Baltimore, Maryland, USA. Sci. Total Environ. 2024, 957, 176842. [Google Scholar] [CrossRef] [PubMed]

- Kirichenko, K.Y.; Kholodov, A.S.; Vakhniuk, I.A.; Tretyakova, M.O.; Chernyshev, V.V.; Moskovaya, I.V.; Artemenko, A.F.; Ilyashchenko, D.P.; Petukhov, V.I.; Agoshkov, A.I. The Study of Air Pollution with Coal Dust in Nakhodka City and Posyet Settlement (Primorsky Krai, Russian Federation). Bulletin of KamchatGTU. In Proceedings of the International Science and Technology Conference “Earth Science”, Vladivostok, Russia, 8–10 December 2020; pp. 6–13. [Google Scholar]

- Zinovieva, O.M.; Kolesnikova, L.A.; Merkulova, A.M.; Smirnova, N.A. Analysis of environmental problems in coal-mining regions. Coal 2020, 10, 62–67. [Google Scholar]

- Hong, N.; Peng, S.; Zhao, H.; Su, N. Wind tunnel investigation on the dust emission characteristics of high moisture coal stacks. E3S Web Conf. In Proceedings of the 2019 International Academic Exchange Conference on Science and Technology Innovation (IAECST 2019), Guangzhou, China, 20–22 December 2019; Volume 145, p. 02019. [Google Scholar]

- Fedorovich, A.P.; Igishev, V.G.; Vershinin, S.N.; Panchishin, V.Y. On the effectiveness of the use of antipyrogens. Bull. Sci. Cent. Saf. Work Coal Ind. 2010, 1, 81–88. [Google Scholar]

- Shlapakov, P.A.; Lebedev, K.S.; Gracheva, T.M. Effectiveness of Water-Based Antipyrogens. Bulletin. 2015, No. 3, pp. 45–51. Available online: https://cyberleninka.ru/article/n/effektivnost-antipirogenov-na-vodnoy-osnove (accessed on 7 February 2025).

- Tang, Y.; Li, Z.-H.; Yang, Y.I.; Ma, D.-J.; Ji, H. Effect of inorganic chloride on spontaneous combustion of coal. J. S. Afr. Inst. Min. Metall. 2015, 115, 87–92. [Google Scholar] [CrossRef]

- Dariusz, O.; Tung, T.; Marek, K.; Kazimierz, P. Effect of calcium chloride solution on the spontaneous combustion of coal using Olpiński method. Fuel 2022, 339, 126903. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Z.; Wang, Z.; Nie, S.; Han, C. Inhibition Effect of Coal Spontaneous Combustion by Composite Inhibitory Foam Based on CaCl2-Melatonin Inhibitor. ACS Omega 2024, 9, 13323–13331. [Google Scholar] [CrossRef]

- Sun, L.; Zhan, M.; Zhang, C.; Shi, Q.; Huang, Q.; Wang, W. Experimental study on prevention of spontaneous combustion of coal by ionic surfactant solution injection in coal seam. Energy 2022, 260, 125079. [Google Scholar] [CrossRef]

- Wang, D.; Dou, G.; Zhong, X.; Xin, H.; Qin, B. An experimental approach to selecting chemical inhibitors to retard the spontaneous combustion of coal. Fuel 2014, 117, 218–223. [Google Scholar] [CrossRef]

- Rodionov, V.; Tursenev, S.; Skripnik, I.; Ksenofontov, Y. Results of the study of kinetic parameters of spontaneous combustion of coal dust. J. Min. Inst. 2021, 246, 617–622. [Google Scholar] [CrossRef]

- Ozdogan, M.V.; Turan, G.; Karakus, D.; Onur, A.H.; Konak, G.; Yalcin, E. Prevention of spontaneous combustion in coal drifts using a lining material: A case study of the Tuncbilek Omerler underground mine, Turkey. J. S. Afr. Inst. Min. Metall. 2018, 118, 149–156. [Google Scholar] [CrossRef]

- National Report on the State of the Environment and the Use of Natural Resources (National Report), 2020–2023. Available online: https://www.gov.kz/memleket/entities/ecogeo/documents/1?lang=ru&title=%D0%BD%D0%B0%D1%86%D0%B8%D0%BE%D0%BD%D0%B0%D0%BB%D1%8C%D0%BD%D1%8B%D0%B9%20%D0%B4%D0%BE%D0%BA%D0%BB%D0%B0%D0%B4 (accessed on 7 February 2025).

- Mayorova, L.P.; Lukyanov, A.I.; Dakhova, E.V. Modeling the Distribution of Suspended Coal Dust During Storage and Loading and Unloading Operations in Ports (Using the Example of the Port of Vanino). Innov. Investig. 2021, 89–94. Available online: https://cyberleninka.ru/article/n/modelirovanie-rasprostraneniya-vzvesi-ugolnoy-pyli-pri-hranenii-i-pogruzochno-razgruzochnyh-rabotah-v-portah-na-primere-porta (accessed on 7 February 2025).

- On Approval of the Methodology for Determining Emission Standards into the Environment, Order No. 63 of the Minister of Ecology, Geology and Natural Resources of the Republic of Kazakhstan Dated March 10, 2021. Available online: https://adilet.zan.kz/rus/docs/V2100022317 (accessed on 7 February 2025).

- On Approval of the Instructions on the Organization and Conduct of an Environmental Assessment, Order No. 280 of the Minister of Ecology, Geology and Natural Resources of the Republic of Kazakhstan Dated July 30, 2021. Available online: https://adilet.zan.kz/rus/docs/V2100023809 (accessed on 7 February 2025).

- Malyshev, V.P. Mathematical Planning of A Metallurgical and Chemical Experiment. Available online: https://libcats.org/book/489440 (accessed on 7 February 2025).

- On the approval of certain methodological documents in the field of environmental protection. Order of the Minister of Environment and Water Resources of the Republic of Kazakhstan Dated June 12, 2014 No. 221-O. Available online: https://adilet.zan.kz/rus/docs/V14M0009585 (accessed on 7 February 2025).

- On Approval of Hygienic Standards for Atmospheric Air in Urban and Rural Settlements, on the Territories of Industrial Organizations, Order of the Minister of Health of the Republic of Kazakhstan Dated 2 August 2022 No. KR DSM-70.It was registered with the Ministry of Justice of the Republic of Kazakhstan on August 3, 2022. Available online: https://adilet.zan.kz/rus/docs/V2200029011#z10 (accessed on 7 February 2025).

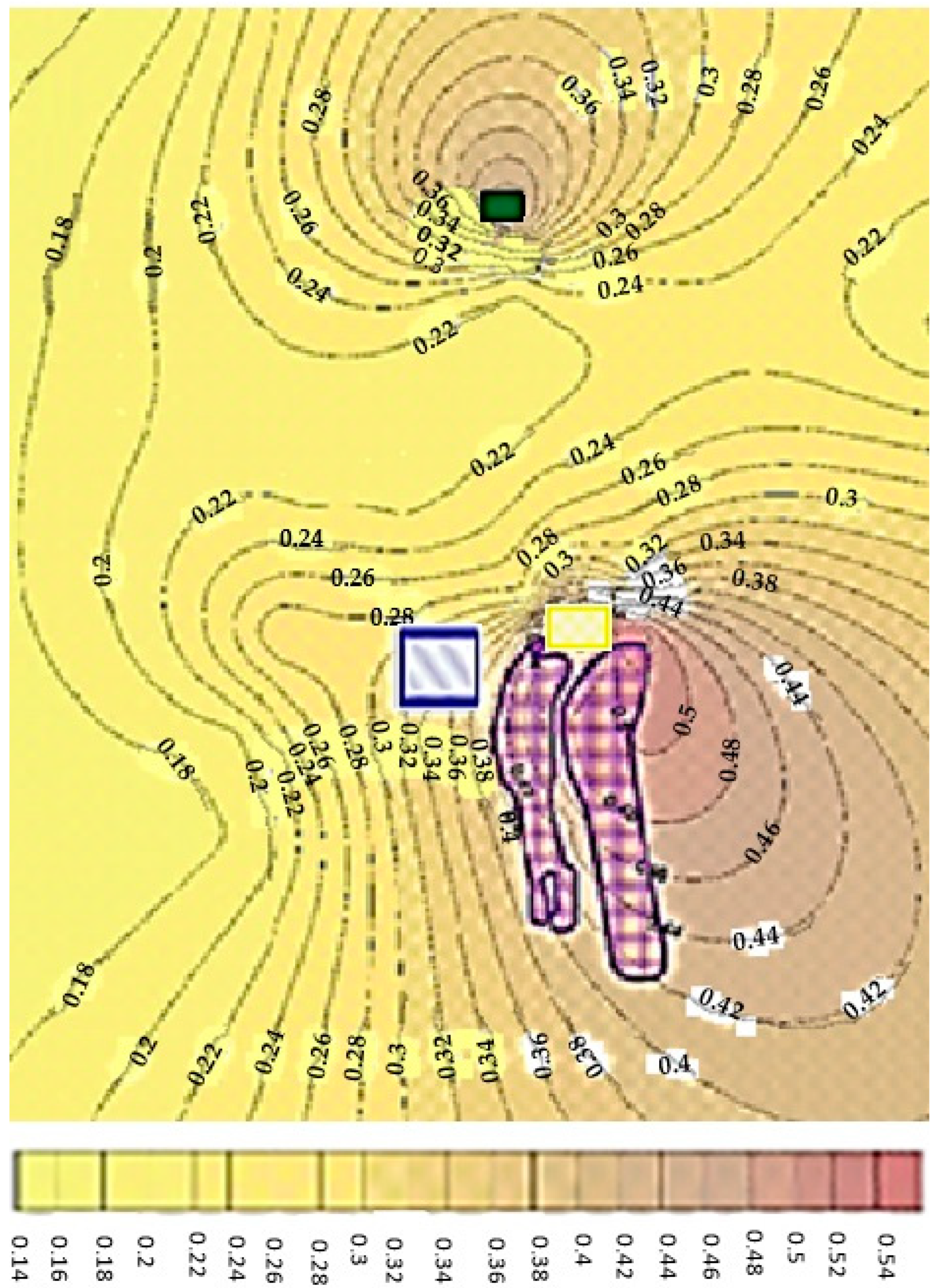

—quarry;

—quarry;  —mine water reservoir;

—mine water reservoir;  —work area;

—work area;  —shift houses.

—shift houses.

—quarry;

—quarry;  —mine water reservoir;

—mine water reservoir;  —work area;

—work area;  —shift houses.

—shift houses.

| Types of Process | Description | Reason | Result |

|---|---|---|---|

| Physical weathering | Grinding of coals without changing their chemical structure and composition. It begins on the surface of coal, in places of contact with the external environment, and its effect manifests itself in physical destruction under the influence of solar energy, atmosphere, and water. | It is caused by various factors (sun, wind, precipitation, and ambient temperature). Depending on the nature of the influencing factor, the nature of the destruction of coal during physical weathering varies. In some cases, the destruction process occurs inside the coal without the participation of an external acting agent. | With prolonged exposure to temperature fluctuations and different expansion coefficients, the mutual adhesion of individual mineral grains in coal is disrupted, and it cracks and breaks up into separate fragments. |

| Mechanical weathering | Occurs under the mechanical influence of extraneous agents | Freezing of water has a particularly destructive effect. When water gets into the cracks and pores of coal and then freezes, it increases in volume by 9–10%, while producing enormous pressure. | The coal splits into separate fragments |

| Chemical weathering | A set of different chemical processes that result in further destruction of coal | The destruction of coal under the influence of physical weathering is always accompanied to one degree or another by chemical weathering. The main factors of chemical weathering are water, oxygen, carbon dioxide, and organic acids. | The structure and composition of minerals change significantly, and new minerals are formed that correspond to certain physicochemical conditions. |

| Coal Stack | Average Monthly Temperature, °C; | ||||

|---|---|---|---|---|---|

| April | May | June | July | August | |

| Without AEC | 27 | 32.5 | 36.4 | 40.2 | 40.2 |

| With AEC | - | 25.8 | 25 | 24.3 | 22.1 |

| With AEC | - | 26.1 | 25.1 | 24.8 | 22.5 |

| With AEC | - | 25.1 | 23.4 | 22.5 | 21.9 |

| Indicator | Ash Content, % | Total Moisture, % | Release of Volatile Substances, % | Non-Volatile (Bound) Carbon, % | Specific Heat of Combustion, MJ/kg |

|---|---|---|---|---|---|

| Parameter | 5…13 | 14.5 | 43.5 | 76.0 | 30.14 |

| Group | Description | Result |

|---|---|---|

| The first group | Chemical inhibitors of the oxidation reaction, i.e., reducing the rate of these reactions | Molecules of reacting substances are rendered inactive |

| The second group | Various substances by applying them to the surface | Blocking of combustible materials |

| The third group | Pore blockers in charcoal by filling them with the appropriate liquid | It makes it difficult for oxygen to diffuse into a piece of coal, while also dissipating heat by evaporating water |

| The fourth group |

|

|

|

|

| Region | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|---|---|---|---|

| Atyrau | 110.7 | 167.1 | 177.0 | 172.3 | 164.5 | 154 | 160.3 | 132.1 | 140.1 |

| East Kazakhstan | 127.1 | 128.7 | 129.3 | 130.7 | 128.8 | 127.2 | 128.1 | 83.3 | 80.9 |

| Karagandinskaya | 596.4 | 593.0 | 598.7 | 587.5 | 641.3 | 627.7 | 569.7 | 469.0 | 455.0 |

| Kostanay | 91.6 | 98.7 | 114.8 | 124 | 130.5 | 123.4 | 137.9 | 121.4 | 118.3 |

| Pavlodarskaya | 552.9 | 542.7 | 609.8 | 709.3 | 721.5 | 723 | 736.2 | 724.2 | 694.2 |

| Republic of Kazakhstan | 2180.0 | 2271.6 | 2357.8 | 2446.7 | 2483.1 | 2441.0 | 2407.5 | 2314.8 | 2257.5 |

| Indicators for Calculation | Units of Measurement | Parameter | ||

|---|---|---|---|---|

| A coefficient that considers the moisture content of the material | 1.2 | |||

| Wind speed (average) | m/s | 5 | ||

| The amount of coal entering the storage | t/year | 413,160 | 1,000,000 | 2,000,000 |

| Gross dust emission | t/year | 0.72 | 1.764 | 3.528 |

| Indicators for Calculation | Units of Measurement | Parameter | ||

|---|---|---|---|---|

| A coefficient that considers the moisture content of the material | 1.2 | |||

| Wind speed (average) | m/s | 5 | ||

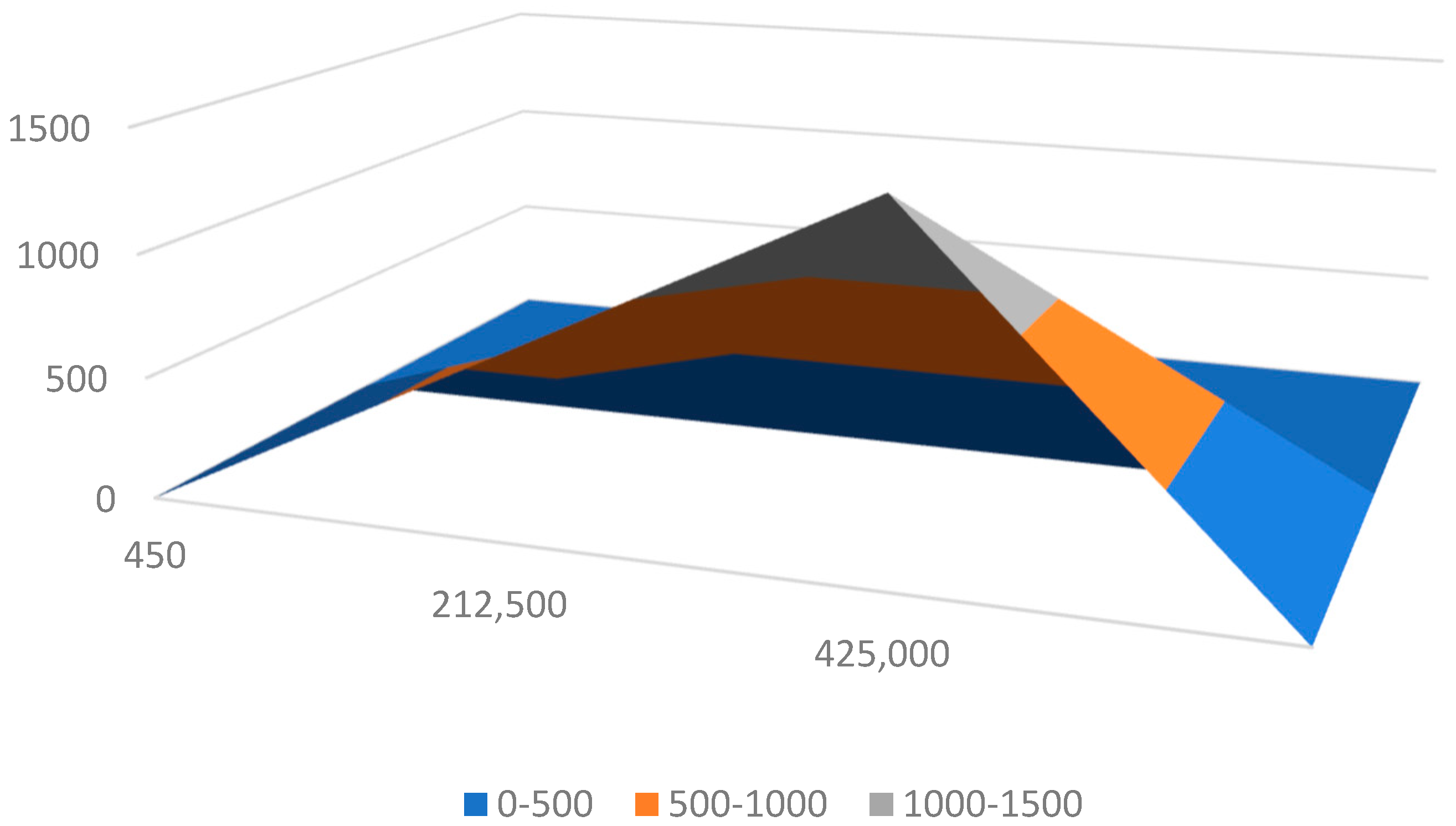

| The base area of the stacks | m2 | 450 | 212,500 | 425,000 |

| Gross dust emission | t/year | 1.54791 | 730.9575 | 1461.8 |

| Indicators | Description of the Reagent | ||

|---|---|---|---|

| № 1 | № 2 | № 3 | |

| Chemical type | Anionic polyacrylamide | Anionic polyacrylamide | Anionic polyacrylamide |

| Appearance | Opaque liquid with a light-yellow tint | White milky liquid | White liquid |

| Degree of charge | High | High | High |

| Molecular weight | High | High | High |

| Specific gravity at 25 °C | 1.0–1.1 | 1.05–1.2 | 1.04–1.1 |

| Freezing point, °C | −18 | 0 | 0 |

| The content of the active component, % | 65 | 60–70 | At least 55 |

| Specific consumption, g/m2 | 50 | 50 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseshkovskaya, Y.; Tsoy, N.; Oralova, A.; Tseshkovskiy, V.; Ibrayev, M.K.; Zakharov, A. Research Progress of Coal Stacks Reducing Dust Emissions: Ecological Technology in the Example of the Karaganda Region. Resources 2025, 14, 142. https://doi.org/10.3390/resources14090142

Tseshkovskaya Y, Tsoy N, Oralova A, Tseshkovskiy V, Ibrayev MK, Zakharov A. Research Progress of Coal Stacks Reducing Dust Emissions: Ecological Technology in the Example of the Karaganda Region. Resources. 2025; 14(9):142. https://doi.org/10.3390/resources14090142

Chicago/Turabian StyleTseshkovskaya, Yelena, Natalya Tsoy, Aigul Oralova, Vadim Tseshkovskiy, Marat K. Ibrayev, and Alexandr Zakharov. 2025. "Research Progress of Coal Stacks Reducing Dust Emissions: Ecological Technology in the Example of the Karaganda Region" Resources 14, no. 9: 142. https://doi.org/10.3390/resources14090142

APA StyleTseshkovskaya, Y., Tsoy, N., Oralova, A., Tseshkovskiy, V., Ibrayev, M. K., & Zakharov, A. (2025). Research Progress of Coal Stacks Reducing Dust Emissions: Ecological Technology in the Example of the Karaganda Region. Resources, 14(9), 142. https://doi.org/10.3390/resources14090142