1. Introduction

The decarbonization of air transport represents one of the main challenges of the global energy transition, particularly in a context where the electrification of medium- and long-haul flights is not feasible in the short term [

1]. Sustainable aviation fuel (SAF) has emerged as one of the most promising technological alternatives to reduce net CO

2 emissions from the aviation sector without requiring modifications to airport infrastructure or aircraft engines [

2,

3]. In addition to SAF, the same synthesis technology enables the production of renewable diesel as a secondary product, expanding industrial applications and improving the model’s economic viability [

4,

5].

Biomass gasification followed by FT synthesis using lignocellulosic biomass residues as feedstock is one of the thermochemical routes officially recognized by European regulations for SAF production [

2,

6]. This route is versatile, scalable, and compatible with current agricultural and forestry residue management practices, making it suitable for integration into localized production models.

Several studies cited in this work have explored the individual components of the biomass-to-SAF pathway. The gasification of lignocellulosic residues has been widely [

7] documented, including techno-economic assessments and experimental results for downdraft gasifiers operating with agricultural biomass, such as olive prunings and cereal straw [

7,

8,

9]. Regarding SAF production, the Fischer–Tropsch route has been studied extensively as a viable pathway for converting biomass-derived syngas into synthetic fuels that meet ASTM specifications [

4,

10]. Syngas cleaning systems, such as cyclones, ceramic filters, and acid gas removal, have also been analyzed for their compatibility with catalytic upgrading, including cost estimates for advanced configurations [

7]. While these studies contribute valuable knowledge, most focus on centralized systems or broader supply chains. Our work builds on these foundations by proposing a regionally adapted, decentralized model tailored to Spain’s biomass availability, integrating not only gasification and synthesis but also the logistics of biomass collection, syngas transport, and SAF distribution.

Spain has significant volumes of residual lignocellulosic biomass, including cereal straw, vine pruning, and olive tree pruning. Although some of these residues are already partially used for energy or agricultural purposes, their conversion into advanced fuels such as SAF can increase their profitability, enhance their value, and support national decarbonization goals [

11,

12].

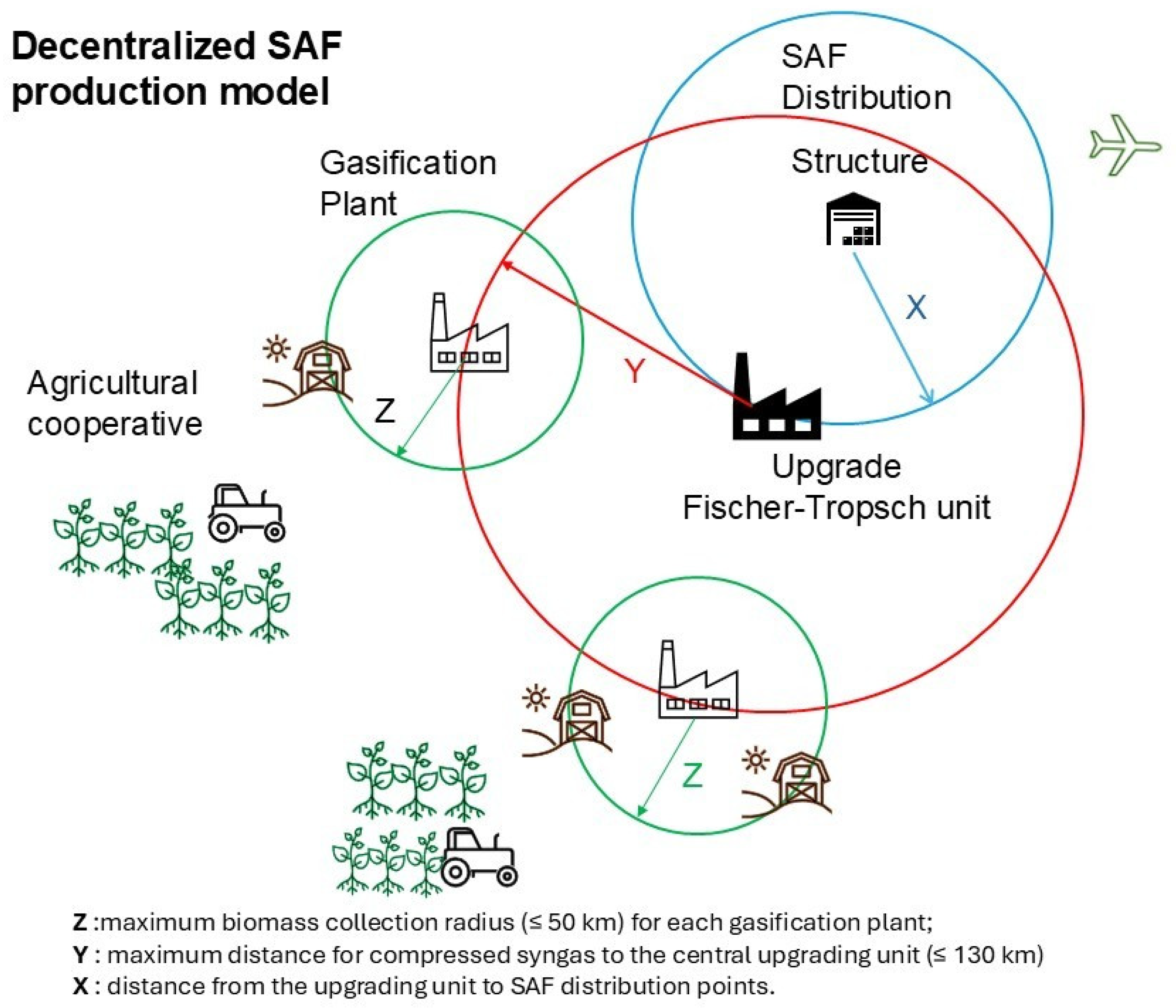

This study proposes a decentralized model for producing SAF and renewable diesel through residual biomass gasification and FT synthesis. The model is based on the deployment of medium-scale gasification plants strategically located in rural or peri-urban areas near biomass generation hotspots. The compressed syngas is then transported to a central upgrading facility. This configuration substantially reduces biomass logistics costs, maximizes the efficient utilization of local resources, and upholds stringent technical oversight throughout the synthesis phase to ensure process integrity and reproducibility [

13,

14].

Figure 1 shows the scheme of the proposed model.

In addition to energy and operational efficiency, the decentralized model offers several strategic benefits related to the Sustainable Development Goals (SDGs) contained in the 2030 Agenda. First, it enhances the energy independence of the Spanish aviation sector by reducing reliance on imported fossil fuels [

15,

16]. Second, it promotes a circular economy by valorizing currently underutilized residues. Third, it drives green reindustrialization in low-density industrial regions, promoting rural employment and reducing territorial disparities [

17,

18]. The model’s applicability across various agricultural regions of Spain is supported by studies such as Polonio et al. (2024) [

8], who concluded that gasification plants based on olive by-products can be economically viable, environmentally sustainable, and socially accepted in rural settings.

This article presents the technical, logistical, and economic foundations of the proposed model, based on scientific articles and technical regulations, as well as its technical and environmental viability within the Spanish context. The available biomass types were characterized, the operational parameters of the gasification plants were defined, investment and operational costs were evaluated, and two territorial deployment scenarios were analyzed. Finally, the potential impact of the model in terms of SAF production, emissions reduction, and alignment with the energy and climate policy objectives of the European Union is discussed.

2. Materials and Methods

This section provides a detailed description of the methodology followed for the development of the decentralized model for SAF and renewable diesel production through biomass gasification and FT synthesis. This assessment begins with the selection of biomass types available in the Spanish context and their technical characterization, followed by the definition of operational parameters for the gasification plants and the required pretreatment of the resulting syngas, based on data extracted from the relevant literature.

Subsequently, a central upgrading unit is proposed, including the basic operating conditions of the FT process, as it is a mature and well-established industrial technology, along with the economic assumptions applied in the cost calculations. The criteria used for selecting potential plant locations are also explained, and two simulated deployment scenarios are presented to assess the feasibility of the model. All data used in this study were derived from comparable sources in the literature, covering both the physicochemical properties of lignocellulosic feedstock and the operational parameters of gasification units and upgrading facilities.

2.1. Selection and Characterization of Lignocellulosic Biomass Residues in Spain

The decentralized model proposed for SAF production is based on the exclusive use of residual lignocellulosic biomass from agricultural and forestry sources. This feedstock type meets the sustainability requirements established by European regulations for the production of advanced biofuels, avoiding conflicts with food uses and indirect land use change [

6].

In this study, three types of lignocellulosic residues were selected, which were cereal straw, olive tree prunings, and vine prunings, due to their high availability, geographic distribution, and favorable techno-economic characteristics. According to the Spanish Ministry of Agriculture, Spain produces over 17 million tonnes of cereal straw annually, along with 1.74 million tonnes of olive prunings (mainly in Andalusia), and up to 250,000 tonnes of vine prunings across key wine-producing regions such as Castilla-La Mancha and Castilla y León [

19]. Detailed data regarding biomass availability can be found in

Table 1.

From a technical perspective, these biomasses exhibit a high fixed carbon content (45–50%), low moisture content after drying (<15%), and a lower heating value (LHV) ranging from 14 to 18 MJ/kg, making them suitable for use in downdraft gasifiers [

13,

20]. Drying can be performed naturally in the field under favorable climatic conditions or through forced methods using low-temperature systems when required. The need for external thermal energy can be minimized through appropriate site selection and seasonal scheduling and partially offset by recovering residual heat from the gasification process itself. Moisture content is particularly critical, as values above 15% reduce the thermal efficiency and increase tar formation [

21]. Elemental (C, H, O, N, and S) and proximate analyses of these biomasses were used to assess their behavior during gasification and to confirm their compatibility with the operational conditions considered (850–1000 °C and equivalence ratio (ER) for the gasification agent between 0.25 and 0.35).

Table 1 summarizes the key properties of the selected biomasses.

An additional advantage of biomass valorization to produce SAF is that it also produces other renewable co-products, such as renewable diesel, biochar, and ash, which have potential agronomic value owing to their nutritional properties [

22]. Biochar, which contains phosphorus and potassium, can be used as an organic soil input in agriculture, contributing to nutrient dynamics and reinforcing the circular and sustainable approach of the proposed model [

9,

23,

24].

2.2. Biomass Pretreatment and Logistics

Before undergoing thermochemical conversion, the selected residual biomass requires basic physical pretreatment to ensure compatibility with gasifier operational parameters and to facilitate transport and handling. This pretreatment consists primarily of three stages, which are drying, size reduction, and screening (chipping and milling). Its purposes are to ensure a homogeneous feedstock supply with a moisture content below 15%, a uniform particle size, and a minimization of inert materials [

20]. Drying can be performed naturally in the field under favorable climatic conditions or through forced methods using low-temperature systems when required. The need for external thermal energy can be minimized through appropriate site selection and seasonal scheduling and partially offset by recovering residual heat from the gasification process itself. The size reduction step adjusts the size of the particles to meet downdraft gasifier specifications. A particle size between 2 and 3 mm is required to ensure proper feeding into the gasifier, minimizing the channeling risk and supporting stable combustion. Sieving removes impurities such as stones, metals, and coarse vegetal matter that are unsuitable for gasification [

23].

Figure 2 illustrates the biomass pretreatment and logistics process.

The type of mechanical treatment depends on the specific nature of the biomass. For cereal residues, the standard practice involves baling them into rectangular bales using agricultural machinery in the field. In situ chipping is employed to convert olive tree pruning residues into a more compact and homogeneous material. In the case of vine pruning, either chipping or briquetting is applied, which requires specialized equipment.

From a logistical standpoint, the model is based on a distributed collection and transport scheme. It proposes the establishment of intermediate storage points near production areas (farms, cooperatives, and municipal pruning centers), where pretreated biomass is temporarily aggregated before being transported to the nearest gasification facility. This strategy reduces the transport distance per tonne of biomass, optimizes vehicle utilization, and improves the overall efficiency of the system [

17,

25]. Since the collection of these residues is highly seasonal and occurs in large volumes, the implementation of intermediate storage facilities located 30–50 km from the gasification plant is recommended, where the biomass can be compacted and temporarily stored prior to final processing [

25].

2.3. Design and Technical Parameters of Gasification System

The proposed decentralized production model involves the thermochemical conversion of lignocellulosic biomass into syngas using downdraft gasification reactors, a technology that is particularly suitable for medium-scale units. This type of gasifier was selected due to its operational reliability, low tar content in syngas, reduced technical complexity, and good thermal efficiency, especially when fed with biomass with low moisture content and uniform particle size [

9,

10]. Among the available gasification technologies, downdraft reactors offer one of the best cost–efficiency ratios for small- and medium-scale plants. According to Lourinho et al. (2023) [

26], this type of gasifier can achieve capital expenditures (CAPEX) 30–50% lower than those of fluidized bed or entrained flow systems for comparable applications.

In addition, downdraft gasifiers have been widely applied in decentralized settings with heterogeneous biomass streams, offering high thermal efficiency and low tar content. This was confirmed in recent studies such as Malik Abbas et al. (2024) [

27], who assessed the economic viability of renewable hydrogen production in rural contexts. A table with main gasification reactions is located in

Appendix A,

Table A1.

To produce syngas with a high proportion of carbon monoxide (CO) and hydrogen (H

2), which is a critical requirement for subsequent FT synthesis, the use of steam and oxygen as gasifying agents is proposed. This combination avoids nitrogen dilution, enhances the H

2/CO ratio, and reduces the formation of contaminants such as tar [

28]. As an alternative, a mixture of air and steam could be used, offering a more economical option [

29]. However, the resulting syngas typically requires an H

2/CO ratio adjustment prior to upgrading, which may lead to additional costs at that stage.

The selected operating parameters fall within the ranges validated by previous experimental studies and simulations, ensuring both process stability and compatibility of the resulting syngas with downstream compression, purification, and upgrading stages. The key technical conditions proposed in the model are listed in

Table 2.

Based on the synthesis of data from the studies consulted, the following assumptions were proposed:

Gasification plant thermal capacity: 5 MW (medium scale);

Annual processing capacity per plant: 10,000–15,000 tonnes of dry biomass (depending on plant size);

Syngas lower heating value (LHV): 10 MJ/Nm3;

Gasifying agents: steam and oxygen;

Syngas production: 1200 Nm3 per tonne of dry biomass (based on syngas LHV).

The syngas yield and its lower heating value, which will be used later in the SAF cost calculations, were deliberately conservative and consistent with the methodological framework of this study. The proposed modular configuration of gasification plants enables the number and location of these plants to be adapted to regional biomass availability. This approach combines decentralized primary conversion with centralized upgrading, with the aim of optimizing costs, logistics, and the overall efficiency of the system.

2.4. Syngas Pretreatment and Logistics

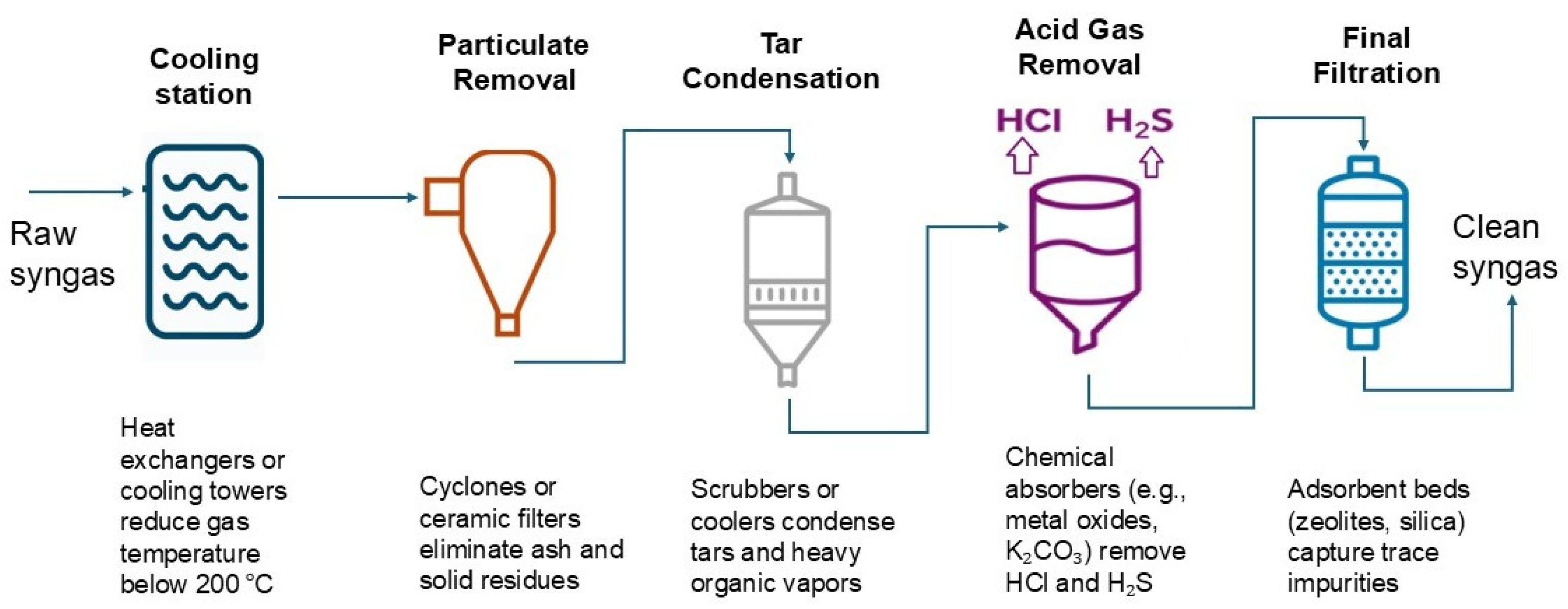

Once generated in gasification plants, syngas must undergo a pretreatment stage to ensure their compatibility with subsequent compression, transport, and conversion to SAF in the upgrading unit. This stage is critical for preserving the overall system efficiency and protecting the FT catalysts from contaminants. The syngas is directed through a multi-stage cleaning system designed to match its composition and ensure its suitability for FT synthesis. The proposed system, as described by Restrepo et al. (2023) [

31], consists of the following steps. Initially, cooling is performed using heat exchangers or cooling towers to reduce the gas temperature below 200 °C to prevent thermal damage to downstream systems. Secondly, the removal of solid particles occurs through high-efficiency cyclones or ceramic filters, where ash, dust, and non-combustible materials are eliminated from the gasifier reactor. Thereafter, the condensation of tars and heavy organic vapors is produced via scrubbing stages or direct coolers to remove compounds that would otherwise compromise FT catalyst performance. This stage may include scrubber towers with absorbing or refrigerating liquids. Following that, acid compounds such as HCl and H

2S are eliminated through chemical absorption systems (e.g., metallic oxide beds or reactors using potassium carbonate), thereby ensuring catalyst protection and compliance with environmental specifications. A final filtration of any trace metals and residual impurities is performed using adsorbent beds (such as zeolites or activated silica) to achieve the purity levels required for subsequent compression and conversion.

This system is incorporated directly into the gasification plant and operates under atmospheric pressure conditions, with flow rates of 1200 Nm

3 per tonne of biomass. The proposed system is illustrated in

Figure 3.

Once treated, the syngas is compressed to a pressure of 25 bar, which is the operational value required for transport in pressurized tank trailers. This pressure level optimizes the transport volume and minimizes energy losses. The compression and storage of syngas [

14] enable temporal decoupling between gas production and its end use, introducing operational flexibility and improving economic performance, particularly in facilities with intermittent production or variable load conditions [

32] The model considers that the compress syngas can then be transported by road, offering the highest degree of flexibility for decentralized systems, particularly in regions where pipeline or rail infrastructure is not available. This flexibility is a key factor in site selection and system integration and is the reason that this transport option was used to calculate logistical costs in the model, allowing freedom in the placement of refining units.

For syngas transportation from gasification plants to the central upgrading unit, a maximum distance of 130 km was adopted as a reference, which is compatible with the use of pressurized tank trailers. This distance allows the system to remain both energetically and economically viable, while preserving territorial flexibility in the siting of the plants, considering the costs extracted from the Ministry of Transport and Sustainable Mobility [

33]. The strategy of compressing and transporting syngas, instead of mobilizing biomass in its solid form, significantly reduces the overall logistical burden of the system, minimizes transport-related emissions, and improves global energy efficiency. Moreover, it enables the upgrading stage to be centralized in a large-scale FT plant, where higher industrial standards for quality control, efficiency, and safety can be applied.

2.5. Upgrading and Fischer–Tropsch Synthesis

The final stage of the process involves the synthesis of liquid hydrocarbons from purified syngas using FT technology. This thermochemical route is recognized by European regulations as an approved pathway for SAF production from lignocellulosic feedstocks [

6,

34]. FT technology was selected over other thermochemical options, such as pyrolysis or alcohol reforming, due to its higher level of technological maturity, compatibility with existing infrastructure, and lower carbon footprint at an industrial scale [

34,

35]. While the technology route of Hydroprocessed Esters and Fatty Acids (HEFA) remains the most commercially established pathway for SAF production, this study focuses on the FT route due to its compatibility with lignocellulosic agricultural residue feedstocks that are not suitable for HEFA processing due to their lack of lipid content.

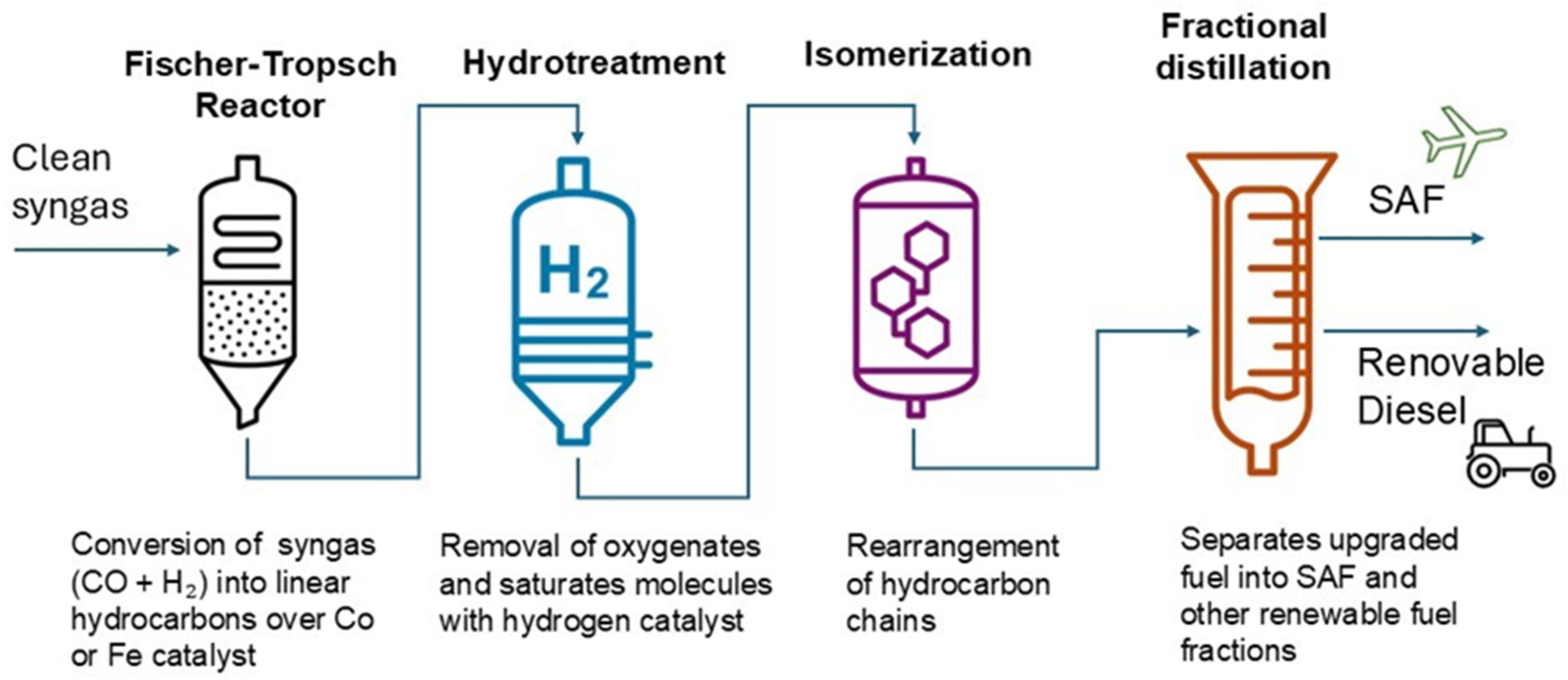

The FT process converts mixtures of CO and H

2 into linear hydrocarbon chains via heterogeneous catalysis. In the proposed model, this stage is centralized in a single upgrading facility that receives compressed syngas from the decentralized gasification plants. The refining unit operates at pressures between 15 and 30 bar and temperatures ranging from 200 to 250 °C, using cobalt or iron-based catalysts depending on the H

2/CO ratio and the desired product distribution. Cobalt catalysts are preferred due to their high selectivity toward medium-chain linear paraffins, which meet the specifications of the aviation sector [

4,

5]. To obtain a fuel that complies with aviation standards, this product mixture undergoes hydrotreatment, isomerization, and fractional distillation, which allows for the adjustment of critical parameters such as density, viscosity, freezing point, and energy content, as required by the ASTM [

36].

Figure 4 summarizes the steps required for syngas to meet ASTM requirements.

In addition to SAF, the FT process also generates renewable diesel as a co-product, which can be used to fuel agricultural machinery or the logistics fleet of biomass-supplying cooperatives. This localized energy return helps to close the system loop, reduce the overall carbon footprint of the process, and enhance both environmental and economic sustainability.

An overall energy efficiency of 40% was assumed for the entire process, from biomass to final SAF, accounting for losses during cleaning, compression, transport, and synthesis stages [

37]. This value is supported by previous studies and remains within the range of technical feasibility reported in the literature [

35].

2.6. Economic Assumptions

The economic viability of the model was analyzed based on a set of assumptions regarding capital investment, operational costs, logistics, and feedstock expenses. The model is structured as a modular configuration of decentralized gasification plants connected to a central FT upgrading facility, as are the economic assumptions.

2.6.1. Biomass

The base price of biomass has been estimated according to its type; it is lower for herbaceous residues, such as straw, and higher for woody biomass like olive or vine pruning, owing to differences in density, ash content, and mechanical processing requirements [

12,

13].

Biomass treatment and transport costs (i.e., mechanical processing and delivery to the gasification facility) vary significantly depending on the type of residue, degree of mechanization during collection, and distance to the processing center. For this analysis, an average transport distance of 40 to 50 km was assumed.

Logistics costs for cereal straw harvesting and transport are based on values reported by Suardi et al. (2019) [

36], who presented a techno-economic analysis of biomass collection in a Spanish region. For typical distances of 30–50 km, the total logistics cost is estimated between 12 and 20 EUR/t, depending on the harvesting system and transport configuration. For cereal straw, logistical costs are estimated in the range of 50–60 EUR/t, based on the study by Bosona et al. (2019), which considered a more conservative cost [

25].

Regarding olive pruning transport, the cost was consistent with the range reported in studies focusing on similar rural contexts. For instance, Spinelli and Picchi (2010) [

18] reported harvesting and pretreatment costs between 17 and 52 EUR/t (excluding transport), while total logistics costs have been estimated between 40 and 90 EUR/t in other studies [

17,

25]. Owing to the variability in these estimates, a conservative range of 90–100 EUR/t was adopted in this study.

Vine pruning was assumed to be pelletized, using the logistics and transport costs estimated by Bosona et al. (2019) [

25] for densified biomass, given the similar physical and operational characteristics of the vine-derived pellets. Transport costs range between 65 and 85 EUR/t, depending on the origin and type. For this study, the logistics cost for vine pruning was conservatively estimated at approximately 95 EUR/t.

Table 3 summarizes the estimated logistics costs for the three biomass types selected in this study, including harvesting, collection, mechanical processing, and transport to the gasification facility.

2.6.2. CAPEX for Gasification Plants and FT Upgrading Unit

Gasification Plant

Each medium-scale gasification plant (designed to process between 10,000 and 15,000 t/year of biomass) was sized with a thermal capacity of up to 5 MW. Polonio et al. (2024) [

8] reported that a 5 MW plant has a CAPEX of approximately 3.5 million euros. To estimate the cost of the cleaning system, using Kreutz et al. (2020) [

7] as a reference, the capital cost of a complete syngas treatment system, including Rectisol acid gas removal, sulfur recovery (WSA), and thermal conditioning, scaled to 5 MWh and updated to 2025 levels, reaches approximately EUR 1.5 million.

The proposed model assumes an investment cost of EUR 12 million per plant, a conservative estimate that remains consistent with recent studies on decentralized facilities within this power range [

11]. This value is notably higher than the literature. Additionally, when mechanical drying is needed, additional energy demand must be included in the gasification plant’s operational costs under energy consumption.

This difference is attributed to the inclusion of advanced cleaning systems, gas compression, thermal control, and a higher degree of integration with synthesis processes, which are required to achieve the gas quality necessary for SAF production. These include feed systems, gas treatment, compression, and automation. Advanced cleaning systems (cyclones, ceramic filters, and adsorption units) may account for 15–30% of the total CAPEX of a gasification plant, especially when the gas is intended for liquid fuel synthesis, where extremely low impurity levels are required [

26]. This higher capital cost reflects the inclusion of advanced syngas cleaning systems required to meet SAF-grade specifications, such as extremely low levels of sulfur (<0.1 ppm), tars, particulates, and nitrogen compounds, which are critical to protect Fischer–Tropsch catalysts and ensure synthesis efficiency. Additionally, this will help prevent issues during syngas compression and transport to upgrading facilities.

Fisher-Tropsch Unit

For the central upgrading plant using FT synthesis, an investment range from EUR 23 to 28 million was adopted. This corresponds to a medium-scale facility (50 MW thermal) designed to process pre-purified syngas from decentralized gasification plants. This value is based on the techno-economic breakdown provided by Hamelinck et al. (2004) [

30], who estimated a total capital investment (TCI) of approximately EUR 286 million for a 400 MWth facility. In this case, due to the calculations only considering the FT and the upgrading unit, from the same source, the estimated cost is EUR 93M. When applying a scaling law with an exponent of 0.7–0.75, the estimated cost for a plant ten times smaller falls in the range of EUR 28–32 million, which supports the reference value used in this model.

The scaled cost (C

1) of a plant with a known cost

C0 and scale

S0 is calculated using the following Equation (1) [

31]:

where

R is the scaling exponent, which typically ranges between 0.6 and 0.8 for chemical processes.

For a scale-down from 400 MWth to 50 MWth, using

R = 0.7, the result is shown as follows in Equation (2):

An investment reference of EUR 30 million was adopted for a 50 MW thermal-scale upgrading unit. This figure excludes the costs of gasification, syngas cleaning, and compression, which are addressed separately in the proposed decentralized model. The final estimate of EUR 30 million used in this study represents the upper bound of the projected range, serving as a conservative assumption that accounts for contingencies and potential future capacity expansion. The investment figure is also supported by the cost breakdowns provided in studies by Markowitsch et al. (2023) [

35], Wange et al. (2022) [

5], and Peters et al. (2022) [

37], where the FT reactor and separation system account for approximately 15–20% of the total CAPEX (EUR 3.5–5.6 million); the hydrotreatment and isomerization system, 60–70% (EUR 14–20 million); and auxiliary systems such as distillation, PSA, and storage, an additional 10–20% (EUR 2.3–5.6 million). The CAPEX values adopted in this study are summarized in

Table 4:

To estimate the capital cost of a Fischer–Tropsch (FT) synthesis and refining unit scaled to a 50 MWth thermal input, the standard power law cost-scaling formula was applied using data from Kreutz et al. (2020) [

7]. The base cost for the FT block, including reactors, hydrocracking, and distillation, was reported to be USD 15.1 million for a plant producing 989 barrels per day (bbl/day). A target capacity of 200 bbl/day was derived from the assumed FT liquid efficiency of 30.5% and a net product yield of 80%, resulting in 15.25 MW of liquid energy output, or 366 MWh/day.

Given an average energy content of 1.464 MWh per barrel of synthetic fuel (Ebbl = 42.5 LHV (MJ/kg) [

7] × 0.78 Density (kg/L) [

30] × Volume 159 (L/bbl)), this yields 250 bbl/day gross, and applying an 80% efficiency will result in 200 bbl/day net. Using a scaling exponent of 0.67 and applying Equation (1), the unit cost was calculated at USD 5.23 million. After applying a 1.22 multiplier to account for indirect costs and contingencies, also suggested in the same study, the total plant investment (TPI) is USD 6.38 million. Finally, to account for auxiliary systems (e.g., cooling, storage, and utilities), a 15% uplift was included, resulting in a final capital estimate of approximately USD 7.3 million (around EUR 6.7M) for a standalone FT synthesis and upgrading unit producing SAF at the 50 MWth scale.

This configuration focuses on a modular FT synthesis and upgrading unit designed to produce SAF and light naphtha. It includes FT reactors, hydrocracking, hydrotreatment, and fractional distillation, which are supported by a simplified set of auxiliary systems. In contrast, the system modeled by Hamelinck et al. (2004) [

30] represents a more comprehensive synthetic fuel refinery designed for the co-production of FT diesel, gasoline, and kerosene. This configuration incorporates additional units such as naphtha reforming, alkylation, isomerization, and pressure swing adsorption (PSA) for hydrogen recovery, along with full off-gas utilization and a more detailed off-site infrastructure. As a result, Hamelinck’s designs have higher capital investment and flexibility, while the Thomas-based approach adopted here prioritizes cost efficiency and SAF-specific performance at a small-to-medium scale.

To compare the investment requirements for the FT synthesis and refining units, both reference studies were updated to 2025 using the Chemical Engineering Cost Index (CEPCI). The SAF-focused configuration from Kreutz et al. (2020) [

7] scales to approximately EUR 8.4 million, while the broader refining setup in Hamelinck et al. (2004) [

30], which includes reforming, alkylation, and PSA, reaches EUR 44 million. The adopted capital cost of EUR 30 million in this study provides a conservative and technical midpoint. It captures the likely auxiliary system requirements, infrastructure needs, and future design flexibility while avoiding the overestimation that would result from assuming a full synthetic fuel refinery configuration for an SAF-focused system.

2.6.3. OPEX for Gasification Plants and FT Upgrading Unit

Gasification Plant

The OPEX for the gasification plants was set in the range of 20–25% of the annualized CAPEX. Although Gruber et al. (2021) [

4] and W.C. Wang et al. (2022) [

5] do not provide a single definitive figure, their detailed cost breakdowns support using this 20–25% range as a reference for the annual OPEX of a gasification plant. The components and values adopted in this study are summarized in the

Table 5, based on data from the referenced literature.

Fisher-Tropsch Unit

The total OPEX for the FT unit is estimated to range between 20% and 25% of the annualized CAPEX. This estimate follows the same methodological criteria used for gasification plants, based on the cost assessments provided by Gruber et al. (2021) [

4], Hamelinck et al. (2004) [

31], and W. C. Wang et al. (2022) [

5]. For the decentralized model proposed in this study, the OPEX for the FT upgrading unit was estimated to be 7–10% of the annualized CAPEX, in accordance with the same references used previously [

4,

5,

30]. This estimate specifically covers the hydrotreatment, isomerization, and separation stages and excludes syngas production and other upstream costs, since the syngas is delivered in suitable conditions from the gasification plants. For the amortization of industrial facilities, a service life of 20 years was assumed, consistent with the values cited in Hamelinck et al. (2004) [

30] and Markowitsch et al. (2023) [

35].

LCOF, expressed in EUR/L of SAF produced, is used as the primary profitability metric. This metric enables the evaluation of the model’s competitiveness relative to other technologies and renewable fuel sources [

11].

2.6.4. Logistics

Regarding syngas transport costs, the gas is compressed to 25 bar and transported to the upgrading unit using pressurized-tube trailers. A maximum distance of 130 km was assumed. The logistical cost is estimated to be between 0.11 and 0.13 EUR/Nm

3 based on data from Gruber et al. (2021) [

4] and Hamelinck et al. (2004) [

30]. This estimate includes loading and unloading operations, mileage, maintenance, and the return of the empty vehicle. For this study, an average cost of 0.12 EUR/Nm

3 per 100 km was adopted. Transport costs are detailed further based on the selected site locations and scenario-specific assumptions.

2.6.5. Calculation of the Break-Even Point

A centralized FT unit is oversized and not economically viable if there are not enough gasification plants in the model; therefore, a techno-economic assessment must be performed to determine the optimal number of plants required to economically operate the FT. The break-even point is calculated by looking for when the break-even price of SAF levels off. This stabilization is achieved once the FT plant reaches its designed operating capacity. Each new plant could cover its own costs through increased production, thereby preventing further fluctuations in the break-even price.

The break-even price is defined as the price necessary to obtain a net present value (NPV) of 0 [

38]. The following Equation (3) shows the calculation used to obtain the break-even price:

CAPEX is the total investment of each gasification plant and FT unit in EUR,

S is the annual revenue produced in SAF sales in EUR/year, and

OPEX is the operational cost of the gasification plant, transport, and FT unit in EUR/year.

t is the year, and

N is the service life (20 years).

R is the discount rate, which has a value of 3.65% [

39]. The break-even price is calculated by dividing the annual revenue by the annual SAF production in MWh.

The maximum number of plants is given by the capacity of the central FT upgrading unit. This plant is estimated to have a thermal capacity of 50 MW. According to Gruber et al. (2021) [

4], a 50 MW FT unit operates 7500 h/year. This means that the maximum production of SAF is 375 GWh/year or 39,705 m

3/year, assuming an energy density of 34 MJ/L [

34]. The conversion efficiency from syngas to SAF has an average value of 45 L SAF/GJ syngas [

11], after accounting for upgrading and separation losses, and syngas, as explained in

Section 2.3, has 10 MJ/m

3; therefore, this plant has a maximum consumption of 88.2 million m

3/year.

2.7. Site Selection Criteria for Gasification and Upgrading Plants

The selection of the most suitable locations for installing gasification and upgrading plants was based on a combination of technical–productive, logistical, and territorial variables. The primary criteria were (1) a high density of agricultural and forestry residue generation, with a focus on regions characterized by extensive and permanent crops; (2) excellent road accessibility, including proximity to national highways and logistical nodes; (3) the presence of active or convertible industrial zones equipped with basic utilities and available industrial land; and (4) proximity to fuel distribution infrastructure, particularly nodes within the Exolum

1 network [

40], as depicted in

Figure 5, taken from the CNMC report from Exolum (Madrid, Spain) [

41].

The Exolum network is Spain’s main system for transporting and storing liquid fuels, with over 4000 km of pipelines and multiple storage hubs connected to refineries, ports, and airports.

Based on these factors and considering the supply constraints identified by Comber et al., (2015) [

42], the model identified the autonomous communities of Andalusia, Castilla-La Mancha, Castilla y León, and Extremadura as priority regions owing to their combination of biomass availability and favorable logistical conditions [

43,

44,

45].

This territorial approach enables the configuration of a distributed network of gasification plants located near biomass generation sources, thereby reducing biomass transport costs, supporting rural development, and increasing the resilience of the energy system against supply chain disruptions.

3. Results

This section presents the results derived from the application of the proposed decentralized model, which combines empirical data on biomass availability with techno-economic calculations and territorial siting criteria. The analysis was structured into the following three parts: first, the total syngas production potential was estimated based on the selected agricultural and forestry residues; next, two operational scenarios were simulated, evaluating in each case the annual SAF output, investment and operational costs, and LCOF; finally, the potential reduction in greenhouse gas emissions was estimated in comparison to the use of conventional fossil fuels to assess the environmental contribution of the system within the national and European context of aviation decarbonization.

3.1. Estimation of Potential SAF Production from Selected Lignocellulosic Biomass

Based on the biomass availability analysis presented in the previous section, the potential volume of residual lignocellulosic biomass from cereal straw, olive pruning, and vine pruning in Spain is estimated to exceed 11 million tonnes annually. A conservative estimate was adopted, based on the assumption that only one-third of the total available biomass was effectively utilized to calculate the SAF production potential. Under this more realistic assumption, the amount of biomass available for gasification processes is as follows:

Assuming an estimated syngas yield of 1200 Nm

3 per tonne of dry biomass, the total annual syngas production is as follows:

This corresponds to a total primary energy content of the following:

By applying a global conversion efficiency of 40% from biomass to final SAF [

46], the useful energy yield is as follows:

Finally, assuming an energy density of 34 MJ/L and an SAF density of 0.8 kg/L according to ASTM D7566 [

34], the energy translates into an annual theoretical SAF production of 517,647,100 L/year or 414,118 tonnes/year of SAF. The total consumption of kerosene in the aviation sector in Spain was 6643 kt in 2023 [

47], which is equivalent to 292,950 TJ/year. This means that, in the case of producing SAF from one-third of the available biomass of cereal straw and olive and vine pruning, it would cover 6% of the total Spanish consumption of aviation kerosene.

This conservative scenario demonstrates that, even by mobilizing only a fraction of the available potential from the three widely available lignocellulosic residues in Spain, the application of the decentralized model to these biomass sources would enable the generation of a substantial volume of sustainable aviation fuel. This can contribute meaningfully to the decarbonization of the aviation sector without requiring immediate structural transformation of the agricultural sector or full mobilization of national biomass resources.

3.2. Case Study

3.2.1. Case 1: One Gasification Plant in Valdepeñas and One FT Upgrading Unit in Puertollano

This scenario represents an initial modular implementation of a decentralized model applicable to agricultural regions with high availability of residual biomass. A specific configuration was analyzed in which a gasification plant was in Valdepeñas (Ciudad Real), using biomass derived from vine production, and an FT upgrading unit was situated in Puertollano, approximately 120 km away. Puertollano was selected due to its proximity to Spain’s kerosene and SAF distribution networks, as shown in

Figure 5. This initial hypothesis enables the assessment of the techno-economic viability of the decentralized system.

Biomass Availability

In Valdepeñas, with over 5400 hectares of vineyards, up to 13,500 tonnes of dry matter (tDM/year) from vine pruning are generated annually [

47]. This amount is sufficient to supply a 5 MW thermal gasification plant, as the estimated annual biomass requirement for such facilities ranges between 13,000 and 15,500 tonnes of dry biomass. The exact demand depends on the LHV of the residue, which is typically between 15 and 17 MJ/k, and the thermal efficiency of the gasifier (70–75%), as explained in

Section 2. This estimation is consistent with the specific consumption figures reported in studies such as that of Chireshe et al. (2025) [

11], García-Maraver et al. (2012) [

13], and D. Wang et al. (2023) [

48], which are applicable to medium-scale plants operating with woody lignocellulosic biomass.

The total biomass consumption can be calculated based on the power capacity of the gasification plant. Assuming a power capacity of 5 MW and 8000 h of operation per year, this translates into an annual energy production of 144,000 GJ. Given a biomass lower heating value (LHV) of 16 MJ/kg and a gasifier efficiency of 75%, the required amount of biomass to meet this energy demand is approximately 12,000 tonnes per year. The annual energy production is shown as follows:

LHV of biomass = 16 MJ/kg and gasifier efficiency η = 75%.

The energy output is shown as follows:

The total cost of biomass supply, including harvesting, collection, chipping, and transport (within a 50 km radius), is estimated at EUR 1,140,000 per year for the assumed annual consumption.

Syngas Production and Transport

The gasification process was carried out using steam and oxygen, generating syngas with a lower heating value (LHV) of 10 MJ/Nm

3; the equation is shown as follows:

The plant produces 14.4 million Nm

3 of syngas annually, which is transported to the FT upgrading plant via high-pressure tube trailers. The estimated logistics cost was EUR 0.12/Nm

3 per 100 km [

33]. Given that Valdepeñas is approximately 120 km from Puertollano (where the FT unit would be located) the total annual transport cost is estimated at EUR 2,073,60.

FT Upgrading Unit

The FT upgrading plant in Puertollano is designed with a thermal capacity of 50 MW and an estimated capital investment of EUR 30 million, as explained in the previous section. Its annual operating cost is calculated at EUR 2.25 million, with 7.5% of the CAPEX. According to the study by Chireshe et al. (2025) [

11], the conversion efficiency from syngas to SAF can reach between 40 and 48 L per gigajoule (L/GJ). Adopting a median value of 45 L/GJ, the resulting annual production is shown as follows:

With an annual SAF output of 6,480,000 L, the unit production cost, according to the results in

Table A2 (

Appendix A), is calculated as follows:

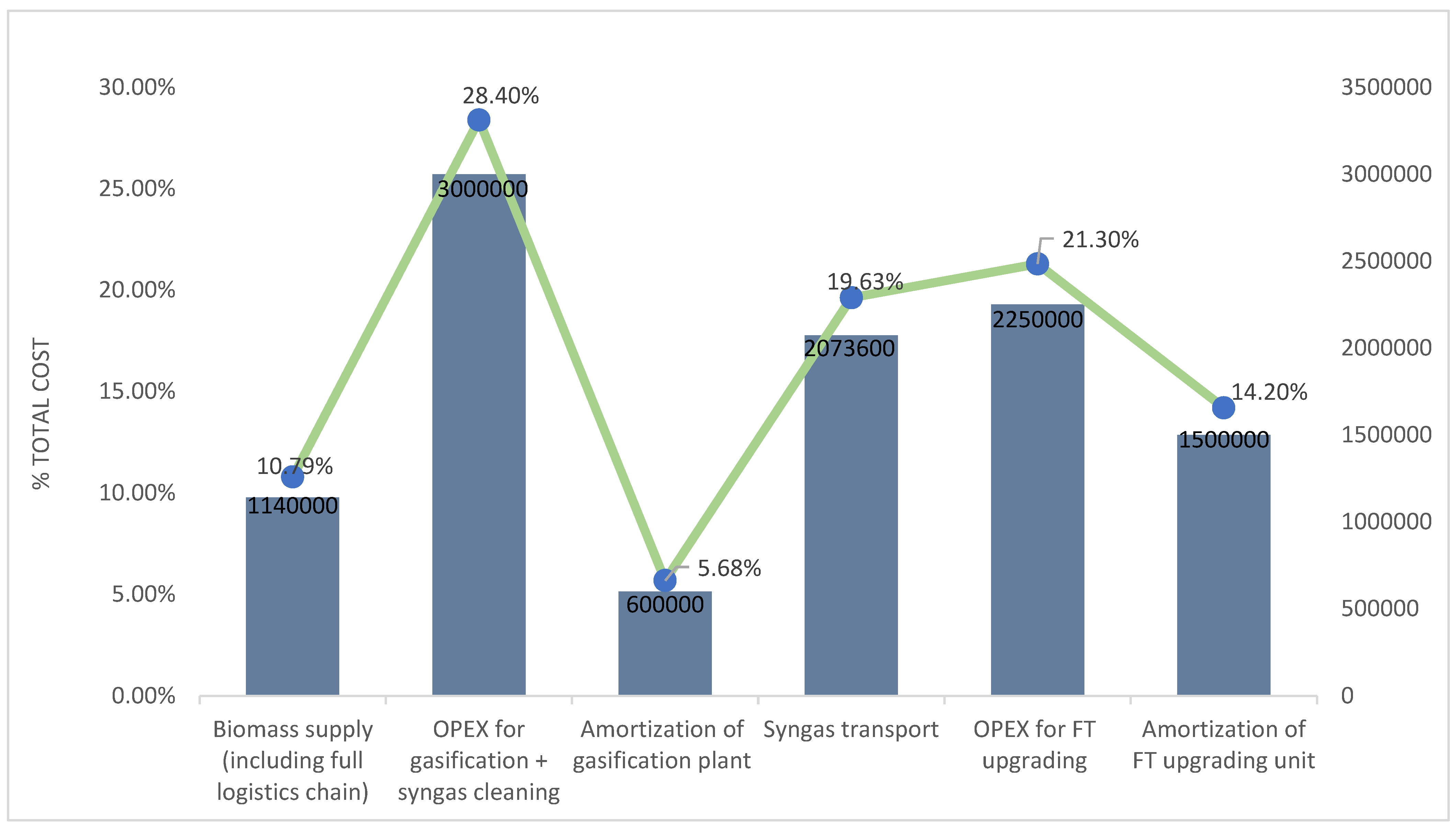

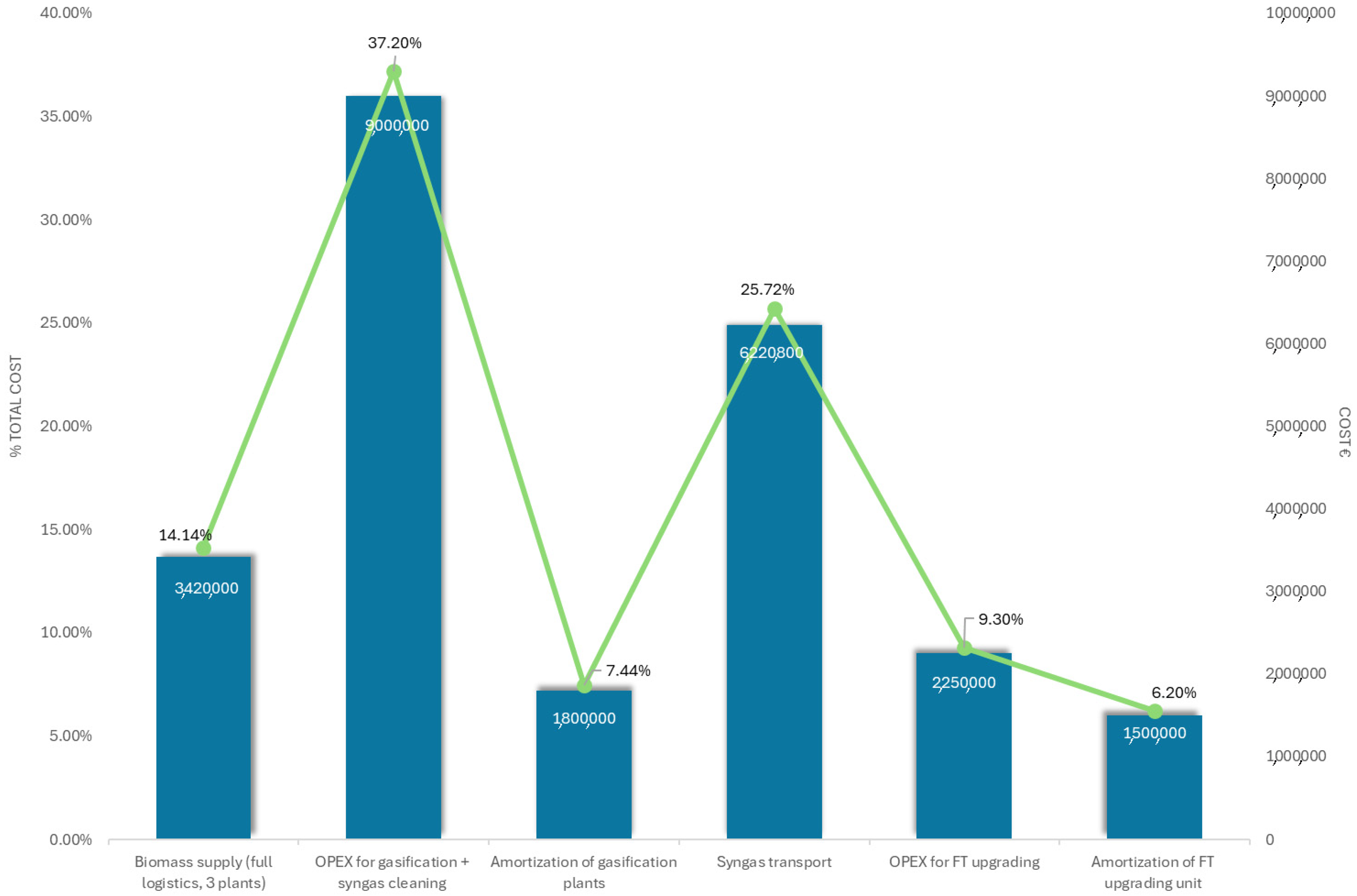

The estimated costs for this scenario are presented in

Figure 6.

This results in an SAF production cost of approximately 1.63 EUR/L, which may be compared to average fossil kerosene prices in the range of 0.55–1.10 EUR/L (depending on market conditions, as discussed in

Section 3.4), providing a basis for assessing competitiveness. The table with the estimated costs for this scenario is included in

Appendix A.

3.2.2. Case 2: Three Gasification Plants, 2 in Castilla La-Mancha, 1 in Andalucía, and 1 FT Upgrading Unit in Puertollano

This second case represents an optimized implementation of the decentralized model, in which three 5 MW gasification plants located in strategic agricultural regions supply a single central FT upgrading unit situated between 100 and 130 km away. The objective is to increase the utilization rate of the upgrading facility, reduce unit production costs, and enhance the overall logistical efficiency of the system.

The three gasification plants are in Valdepeñas (Castilla-La Mancha), Tomelloso (Castilla-La Mancha), and Baena (Andalusia). Each plant processes 12,000 tonnes of biomass annually, as calculated in the previous scenario, for a total combined input of 36,000 t/year.

The total logistics costs, including collection, pretreatment, and transport, were calculated using an average value of EUR 95 per tonne for both vine pruning (Valdepeñas and Tomelloso) and olive pruning (Baena). Based on this estimate, the total annual cost for supplying biomass to the three plants amounts to EUR 3,420,000.

Syngas Production and Transport

Each plant produces approximately 14.4 million Nm3 of syngas per year, with an average lower heating value (LHV) of 10 MJ/Nm3, resulting in a total annual production of 43.2 million Nm3 and an energy yield of 432 TJ/year.

The syngas is transported via pressurized tube trailers to the FT upgrading facility in Puertollano, Spain. The logistics cost, adjusted for the transport distance from each location, is summarized in

Table 6.

The situation of the plants is shown in

Figure 7, with the driving routes between the gasification plants and the FT refinement unit.

The OPEX and amortization values for each gasification plant were assumed to be the same as those in the first case.

The central FT upgrading plant located in Puertollano was designed for a thermal capacity of 50 MW, as in the previous case. Therefore, the same OPEX and amortization costs were assumed. Owing to the increased syngas supply, the utilization rate of the upgrading unit reached 30%, improving economic efficiency compared with Case 1.

Figure 8 illustrates the distribution of estimated annual costs for case 2, showing how the costs assigned to the gasification plants have increased compared with the first case. A table with figures of the estimated costs for this case is included in

Appendix A,

Table A3.

With a conversion efficiency of 45 L per gigajoule (L/GJ), the annual SAF production is estimated at 19,440,000 L/year, resulting in the unit cost of SAF produced under this scenario as follows:

This scenario demonstrates how the decentralized model can achieve both logistical and technical economies of scale, reducing the unit cost per liter by more than 30% compared to the base scenario. This strategy enables greater operational stability of the FT upgrading plant, improves overall profitability, and aligns with the national targets for sustainable fuel production [

11]. Based on the SAF and fossil kerosene price levels, it is possible to estimate the number of decentralized plants required to achieve economic breakeven, considering the effects of scale on production costs.

3.3. CO2 Emission Reduction and Environmental Benefits of the Model

One of the primary objectives of SAF production is to effectively reduce net greenhouse gas (GHG) emissions in the aviation sector. According to emission factors published by the International Energy Agency and European regulations, fossil-derived kerosene emits approximately 89 gCO

2e/MJ, whereas SAF produced from residual biomass can achieve up to 80% reduction in life-cycle emissions, depending on the feedstock type, process efficiency, and energy source used in auxiliary operations [

49]. In 2022, airlines based in Spain emitted approximately 6.89 Mt of CO

2, 64% of which had to be offset through the purchase of emission allowances on the market [

16].

In the simulated cases, the use of lignocellulosic residues and the decentralization of the gasification process helped minimize the impacts associated with biomass collection, transport, and pretreatment. For an annual SAF production of 19.4 million liters (optimized case), it is estimated in more than the following:

Beyond the environmental benefits, SAF production under this model avoids the cost of emission allowances. In the optimized case, the substitution of fossil kerosene with SAF would result in annual savings of approximately EUR 3.07 million on the European carbon market, assuming an average carbon price of EUR 65.28 per tonne of CO

2 [

50].

Moreover, the model promotes the valorization of solid co-products resulting from the gasification stage, such as biochar and ash, which have potential agronomic benefits in terms of soil improvement and carbon sequestration. When applied to agricultural soils, biochar can contribute to the long-term capture of stable carbon, reinforcing the negative emissions balance of the overall system [

23,

24]. In line with studies on circular bioeconomy strategies in the olive sector [

8], the model supports the return of nutrients to agricultural soils through the use of biochar and ash, contributing to nutrient cycling and enhancing the environmental sustainability of the farming system [

51].

From a broader environmental perspective, the model prevents the open burning or abandonment of agricultural residues. In addition, it mitigates the risk of wildfire in areas adjacent to forests. Moreover, it substitutes fossil fuel imports with locally produced renewable energy sources. Finally, it enhances the sustainability of the agricultural cycle through nutrient return via ash-based fertilization.

In summary, the decentralized system not only provides an SAF solution but also constitutes a low-climate-impact, territorially inclusive, and environmentally regenerative approach. It is consistent with the principles of a circular economy and climate neutrality.

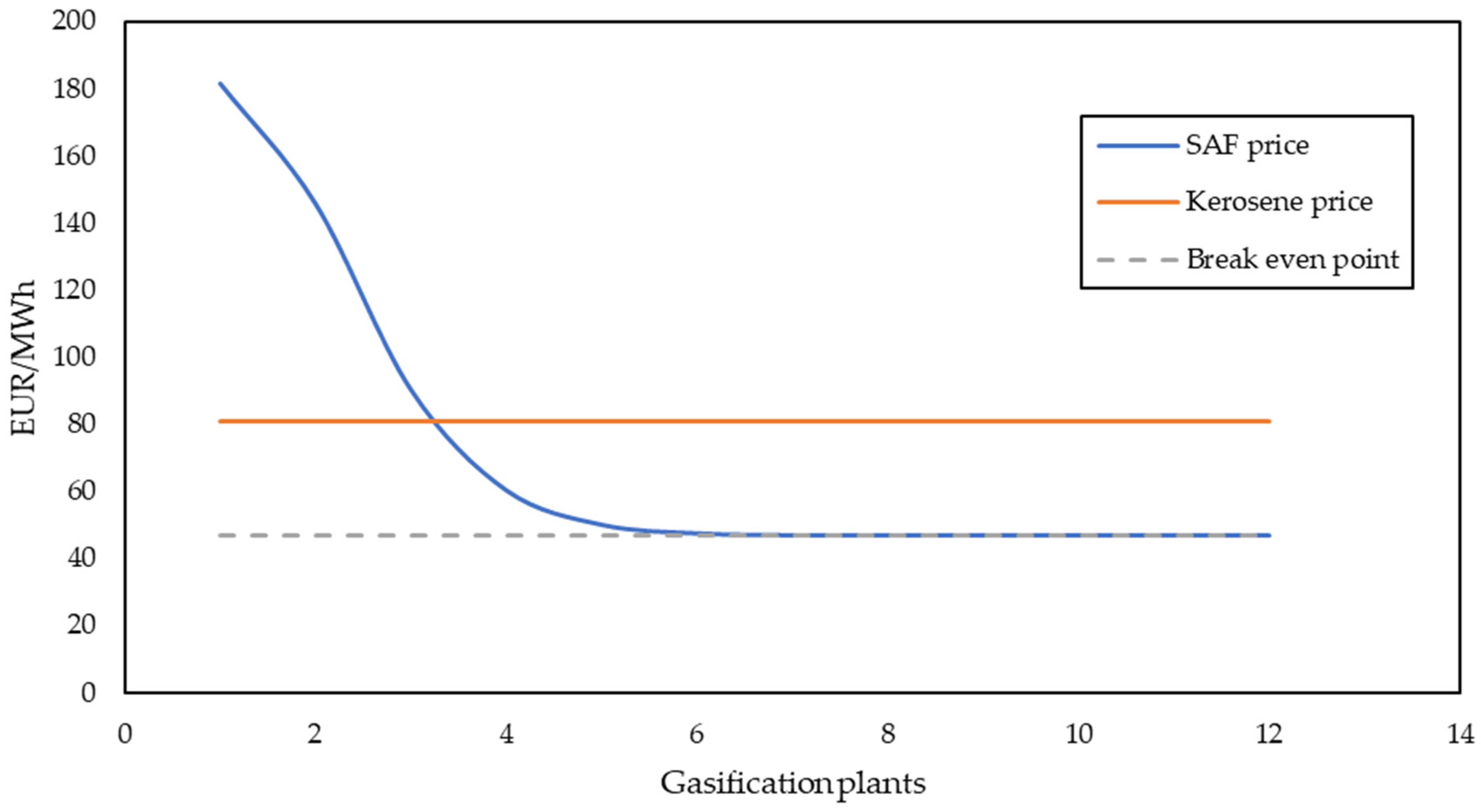

3.4. Break-Even Point

Figure 9 shows the study of the SAF price and break-event point of the centralized system of SAF production in EUR/MWh. The break-even point shows that the minimum number of plants required to have an economic operation of FT is six, where the break-even price levels off at 46.86 EUR/MWh. The maximum number of plants will be given by the capacity of central FT upgrading unit. This plant is estimated to be in Puertollano, with a thermal capacity of 50 MW. According to

Section 2.6.5, the maximum consumption of syngas is 88.2 million m

3, and considering that the results of

Section 3.2.2 show that one gasification plant produces 14.4 million of m

3, the maximum number of gasification plants can be six, which coincides with the value where the break-even price stabilizes. Therefore, the optimum number of plants is six.

Figure 9 shows that the price of SAF in a centralized system and centralized FT unit is more competitive than kerosene, even if the centralized system is not optimal and has more than four plants. The total price of kerosene was obtained from the sales price, 734 EUR/t [

52], without considering the cost of CO

2 emissions. One MJ of kerosene produces 89 g of CO

2, and CO

2 had an average cost in 2024 of 65.29 EUR/t [

50]. The energy density of kerosene is 44.1 GJ/t [

52]; therefore, the total cost is 88.83 EUR/MWh or 0.8 EUR/L.

To ensure a reliable and cost-effective supply of syngas, decentralized gasification plants should be strategically located within a 130 km radius of the central FT upgrading facility in Puertollano. Site selection for each gasification plant must prioritize areas with sufficient annual biomass availability to maintain continuous operation, while also offering access to road infrastructure to support efficient feedstock of syngas to Puertollano. Although this study focused on the Puertollano region because it is a strategic location (where the construction of an FT plant is planned) the proposed model is replicable in other areas of Spain and even internationally, as it does not depend on existing facilities. The developed methodology facilitates the adaptation of location and biomass availability criteria to various territories, provided that the fundamental conditions of raw material access and transportation are satisfied. For example, in the case study, the results focused on pruning waste due to its greater presence in the selected area. However, the use of straw (which has a lower pretreatment cost) would further reduce the cost of PBS production if the model were replicated in other regions where this biomass is more abundant. Thus, its potential should be considered in future applications of this model.

4. Conclusions

This study demonstrates the technical, economic, and environmental feasibility of a decentralized model for SAF production in Spain, based on the gasification of residual lignocellulosic biomass and subsequent conversion through FT synthesis. Using available feedstocks such as cereal straw, olive pruning, and vine pruning, a modular system was developed in which several medium-scale gasification plants, located near biomass generation sites, supply syngas to a central upgrading facility. The model utilizes currently underexploited resources, avoids competition with food use, and minimizes emissions associated with transportation and processing.

The simulated scenarios showed that, even with a conservative utilization of one-third of the available biomass that has been considered in this study, it is possible to achieve SAF production, resulting in 19 million liters per year in the optimized scenario and unit costs ranging from EUR 1.63 to EUR 1.24 per liter. These values are competitive with current technological pathways, despite conservative assumptions regarding plant and logistics costs. In addition, the model is estimated to reduce up to 47,000 tonnes of CO2 emissions annually, representing economic savings of EUR 3.79 million per year in the European carbon market at the current allowance prices.

These results could be significantly optimized by increasing the number of 5 MW thermal gasification units supplying a single 50 MW FT upgrading plant to six gasification plants, reaching a break-even point. Alternatively, a downscaling strategy for the installed upgrading capacity, aligning the FT plant with the actual syngas supply, would allow for investment rationalization, at the expense of economies of scale. However, this approach requires a detailed analysis of the balance between fixed costs, utilization rates, and productivity.

Furthermore, the cost of SAF production could be optimized by improving the logistics of syngas transport, which accounted for approximately 20–25% of the total system cost in the simulated scenarios. Establishing a well-coordinated and efficient syngas distribution network, based on optimized routing, shared infrastructure, and scalable transport technologies, could significantly reduce this cost component and enhance the overall economic performance of the decentralized model.

The decentralized approach also enables green reindustrialization in rural areas, supports local employment, creates synergies with the agricultural sector, and strengthens the country’s energy autonomy. The valorization of co-products such as biochar and ash adds environmental value to the system by closing nutrient cycles and promoting carbon sequestration in agricultural soils. In addition, the model supports circular economy principles by returning surplus renewable diesel from the process to the agricultural production centers.

The validation and refinement of these scenarios should be carried out using process simulation tools that will allow a more accurate modeling of materials and energy balances, as well as the economic flows of the overall system. Additionally, it is essential to conduct specific physicochemical characterizations of the selected biomass feedstocks to refine energy yield and syngas composition estimates under real operating conditions. The definition of appropriate pretreatment steps should be addressed in more detail once the biomass types and the placement of both the gasification units and the refining plant have been selected.

While the model offers a realistic and regionally adapted pathway for SAF production, several limitations should be acknowledged. First, the contributions of co-products such as biochar and renewable diesel have not been quantified in this study. Although their potential environmental and economic value is recognized, further analysis is needed to assess their impact on system performance and overall cost reduction. Second, the assumed global energy efficiency is based on the literature benchmarks and simplified conversion assumptions. Future work should incorporate the detailed simulation of each subsystem, such as the gasifier core, syngas cleaning stages, compression, and upgrading units, to validate these assumptions and refine CAPEX and global efficiency. Third, a comprehensive life cycle assessment (LCA) is needed to quantify the greenhouse gas emissions of the entire system, including off-gas management and carbon balances, in order to assess its alignment with sustainability targets defined under RED III and ReFuelEU Aviation. Addressing these aspects will provide a more complete evaluation of the system’s technical, economic, and environmental performance and support the development of viable decentralized SAF strategies.

In conclusion, the proposed model is both technically and economically viable, while also presenting a scalable and replicable solution that aligns with European policies on sustainability, the circular economy, and a just energy transition. Its progressive implementation could position Spain as a leading producer of SAF from local agricultural resources. However, the proposed model could be replicated in other countries, provided that the basic conditions of access to raw materials and transportation are met.