Abstract

Restaurants and open markets generate considerable quantities of organic waste. Converting these residues into poultry feed ingredients offers a sustainable disposal route. This study aimed to evaluate the nutritional and sensory viability of a novel feed complement formulated from Bonito fish meal (Sarda chiliensis chiliensis) and Única potato peel flour (Solanum tuberosum L. cv. Única). This study was conducted in three phases: (i) production and nutritional characterization of the two by-product flours; (ii) formulation of a 48:52 (w/w) blend, incorporated into broiler diets at 15%, 30%, and 45% replacement levels over a 7-week trial divided into starter (3 weeks), grower (3 weeks), and finisher (1 week) phases; and (iii) assessment of growth performance (weight gain, final weight, and feed conversion ratio), followed by a sensory evaluation of the resulting meat using a Check-All-That-Apply (CATA) analysis. The Bonito fish meal exhibited 50.78% protein, while the Única potato peel flour was rich in carbohydrates (74.08%). The final body weights of broiler chickens ranged from 1872.1 to 1886.4 g across treatments, and the average feed conversion ratio across all groups was 0.65. Replacing up to 45% of commercial feed with the formulated complement did not significantly affect growth performance (p > 0.05). Sensory analysis revealed that meat from chickens receiving 15% and 45% substitution levels was preferred in terms of aroma and taste, whereas the control group was rated higher in appearance. These findings suggest that the formulated feed complement may represent a viable poultry-feed alternative with potential sensory and economic benefits, supporting future circular-economy strategies.

1. Introduction

The utilization of agro-industrial by-products has gained prominence because of its potential to mitigate environmental impact and generate value across various sectors, including animal feed production. Globally, between 2014 and 2018, more than 34 million tons of food were wasted, with 44% corresponding to fruits and vegetables and 4% to meat products [1]. These losses contribute considerably to greenhouse gas emissions and represent an inefficient use of resources such as land and water [2]. Within this context, the food service industry is a significant source of nutrient-rich organic waste, including vegetable peels and meat residues, which could be repurposed into animal feed.

In Peru, approximately 18 tons of solid waste are generated daily, with 58.75% classified as organic waste [3]. Notably, fish and potato by-products are among the most commonly discarded materials, particularly in pollerías (roast chicken restaurants) and cevicherías (ceviche restaurants), two of the most popular food establishments in the country [4]. For instance, cevicherías often discard heads, viscera, and bones after extracting fish fillets, while pollerías routinely dispose of large quantities of potato peels. Although typically regarded as waste, these residues are rich in proteins, carbohydrates, fats, vitamins, and minerals, and therefore hold nutritional potential for animal feeding applications.

In recent decades, chicken meat consumption has risen significantly, becoming the primary source of animal protein in Peru, with a per capita intake of approximately 55 kg per year [5]. Broiler chickens are particularly valued in the poultry market due to their rapid growth and adaptability to various climatic conditions. However, their diets depend heavily on corn, a commodity subject to international price fluctuations due to import dependence, prompting the search for more sustainable and cost-effective alternatives, such as agro-industrial by-products [6].

Broiler chickens require nutritionally balanced diets tailored to their three primary growth phases: starter, grower, and finisher. These diets must provide specific levels of crude protein (18–20%), energy (2845 kcal/kg), lysine (0.85–1.00%), methionine (0.32–0.38%), methionine + cystine (0.60–0.72%), and tryptophan (0.16–0.18%) [7]. Numerous studies have reported favorable effects on growth and performance following the inclusion of by-products such as cereal husk flour [8], vegetable residues [9], fish meal [10], and viscera meal [11], in poultry feed formulations. Within this context, fish and potato by-products could represent a viable alternative in poultry feed formulation, helping to reduce costs and agro-industrial waste [12].

The global interest in valorizing agro-industrial and food service residues as animal feed inputs is growing, as this approach contributes to environmental sustainability, feed cost reduction, and the advancement of circular economy principles. In various regions, waste streams such as dried fruit peels, spent grains, and fish processing residues have been successfully incorporated into livestock diets through drying, fermentation, or silage techniques, yielding nutritionally adequate and productive results in pigs, poultry, and ruminants [7,8,12,13]. These strategies help divert biodegradable waste from landfills, reduce methane emissions, and relieve pressure on conventional feed resources. However, most existing studies focus narrowly on specific residues or animal species, often lacking a comprehensive evaluation of their economic feasibility, environmental impact, or scalability. Investigating such feed alternatives in underexplored contexts can generate broader insights for sustainable animal production systems.

Bonito (Sarda chiliensis chiliensis) is a widely available and low-cost fish species in Peru, known for its high content of protein, vitamins, minerals, and omega-3 fatty acids. A significant proportion of these nutrients is found in commonly discarded parts such as bones, skin, and head, making it an underutilized resource with potential for animal feed use [14]. Similarly, the peel of the Única potato (Solanum tuberosum L.), a variety widely cultivated in Peru, is a rich source of fiber and residual starch, making it a potential energy source in poultry diets [15]. Although no previous studies have investigated its use in animal feed, Única potatoes are recognized for their disease resistance and adaptability to diverse agro-climatic conditions. In 2020, production reached 1.133 million tons, representing a 12.2% increase from the previous year [16].

In this context, this study aimed to formulate and evaluate a feed complement (FC) composed of Bonito fish meal (BFM) and Única potato peel flour (PPF), assessing its impact on growth performance, feed conversion ratio, and sensory quality of broiler chicken meat when partially replacing commercial balanced feed. This strategy not only seeks to add value to discarded by-products but also aims to reduce environmental impact and feeding costs in poultry production, promoting a sustainable alternative for the local economy.

2. Materials and Methods

2.1. Production and Nutritional Characterization of Bonito Fish Meal (BFM) and Potato Peel Flour (PPF)

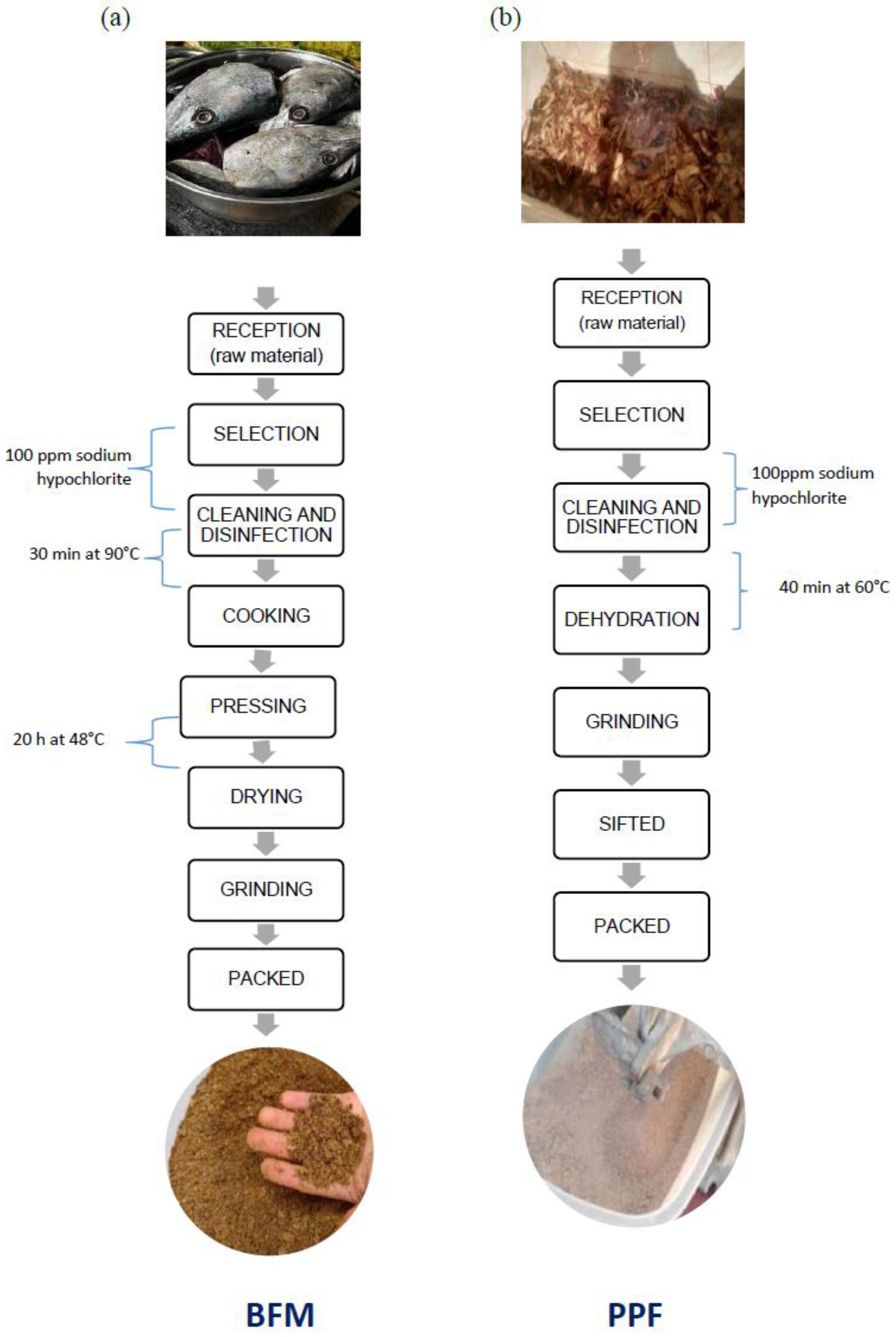

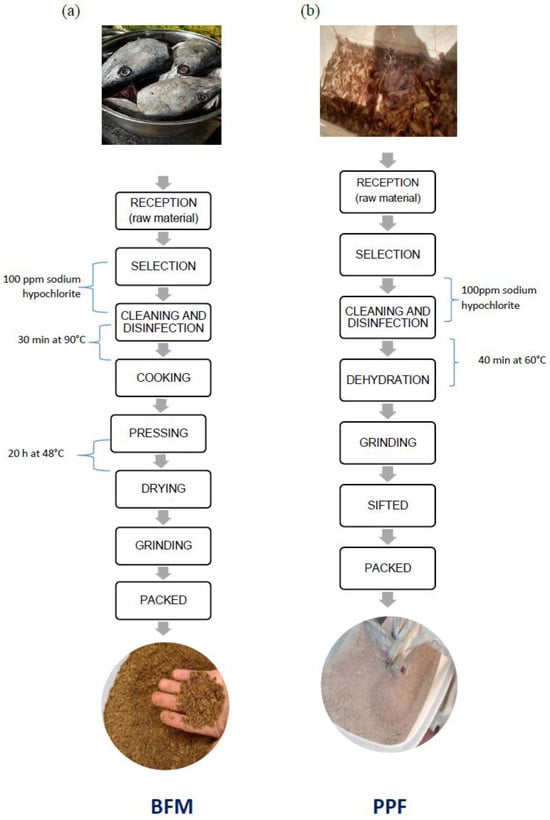

To produce the flours, 50 kg of Bonito fish residues were collected from a fish market, and 58 kg of Única potato peels were obtained from local pollerías in Arequipa, Peru. The processing steps for both by-products are illustrated in Figure 1.

Figure 1.

Flow diagram of the production process for (a) Bonito fish meal (BFM) and (b) Única potato peel flour (PPF).

The production of BFM began with washing and sanitizing the fish residues to eliminate impurities and potential microbial contaminants. The residues were then cooked at 90 °C for 30 min in an industrial pot, a thermal treatment commonly used to denature proteins and reduce microbial load in fish by-products [17]. The cooked material was pressed using a gauze cloth (500 µm pore size) to extract excess moisture. The resulting solid fraction was dried in a forced-air oven at 48 °C for 20 h and subsequently milled using a manual blade grinder until a homogeneous powder was obtained. The powder was then hermetically sealed and stored under refrigeration until use.

The PPF production process followed a similar procedure. The potato peels were manually sorted to remove any spoiled or mold-contaminated material. After washing to eliminate surface residues, the selected peels were dried in a forced-air oven at 60 °C for 40 min, following drying conditions reported in previous studies on potato peel valorization for food and feed applications [18]. The dried material was ground using a blade mill and sieved through a 250 µm mesh to achieve uniform particle size.

Both flours were subjected to proximate composition analysis to determine their nutritional profiles. Analyses were conducted in triplicate using official AOAC methods [19]: moisture (method 934.01), crude protein (method 976.05), ash (method 942.05), fat (method 996.01), and crude fiber (method 962.09). Total carbohydrate content was calculated by difference, subtracting moisture, protein, crude fiber, fat, and ash percentages from 100%.

2.2. Formulation of Balanced Diets

Based on the nutritional composition of BFM and PPF, a feed complement (FC) was formulated by combining the two flours in a fixed 48:52 ratio (w/w), designed to meet the macronutrient requirements of broiler chickens during the starter and finisher phases. According to nutritional recommendations for poultry, standard diets should contain approximately 20–22% crude protein, 2800–3000 kcal/kg of metabolizable energy, 3–5% crude fat, and 3–6% crude fiber, depending on the production stage and genetic line [20,21]. These values were used as reference to ensure that the feed complement provided sufficient protein from fish meal and energy from the carbohydrate-rich potato peel flour, while maintaining acceptable levels of fat and fiber to support growth and feed efficiency.

Four experimental diets were formulated, using the FC as a partial replacement for a commercial balanced feed (CBF) (TOMASINO, Arequipa, Peru). Table 1 presents the proportions of CBF and FC in each diet. A maximum substitution level of 45% was selected, based on previous studies indicating that fish meal can be incorporated at levels up to 25% without affecting sensory characteristics [7], and that potato peel flour has been used at levels up to 30% without negative effects on poultry weight [22].

Table 1.

Formulation of experimental diets using feed complement (FC) as a partial substitute for commercial balanced feed (CBF).

2.3. Nutritional Evaluation of Feed-Complemented Diets for Broiler Chicken Growth

To evaluate the impact of the experimental diets on broiler chicken growth, a total of 40 Cobb 500 broiler chickens (Agriproducts SAC, Arequipa, Peru) were used, all one week old, with an average initial weight of approximately 180 ± 10 g. The chickens were randomly assigned to four experimental groups (10 per group).

The feeding process was divided into three phases: starter (weeks 1–3), grower (weeks 4–6), and finisher (week 7). During the starter and finisher phases, chickens received the corresponding experimental diets according to their group assignment. However, during the grower phase, all groups were fed exclusively with 100% commercial balanced feed (CBF). This decision was based on the fact that the grower phase is a critical period for muscle development and metabolic efficiency in broilers. Nutritional demands during this stage are high, and even small imbalances or the introduction of untested ingredients may impair nutrient absorption and reduce growth performance. Prior studies have reported that the inclusion of alternative ingredients during this phase can negatively affect weight gain and feed efficiency [23]. For instance, Acosta [22] observed that a 6% substitution with potato by-product flour during the grower phase led to reduced final weights compared to chickens fed standard diets. Therefore, maintaining 100% CBF during this period ensured optimal development and allowed the effects of the feed complement to be evaluated under controlled and nutritionally stable conditions during the starter and finisher phases [24].

From the collected data, weekly weight gain (G) was calculated as the difference between final weight (Wf) and initial weight (Wi), divided by the duration of the experiment (t), according to Equation (1) [20,24]:

G = (Wf − Wi)/t

Additionally, the feed conversion ratio (FCR), which represents the efficiency of feed conversion into body mass, was determined as the ratio of total feed intake (A) in grams to total weight gain (ΔW), according to Equation (2) [20,24]:

FCR = A/∆W

2.4. Sensory Analysis

The sensory analysis was approved by the Committee of the Faculty of Industrial Engineering at Universidad Tecnológica del Perú under institutional code N° 20.500.12867/8840 (27 January 2024). This study was conducted in Arequipa, with 20 semi-trained consumers aged 18 to 60 years. All participants signed an informed consent form prior to the evaluation.

The analysis was conducted in two phases. In the first phase, participants were presented with four coded chicken samples (identified with randomly generated three-digit numbers) in randomized order to minimize bias. A nine-point hedonic scale was used to evaluate the attributes of aroma, color, flavor, texture, and overall acceptability, where 1 represented “dislike very much” and 9 “like very much” [25].

In the second phase, the CATA (Check-All-That-Apply) method was applied to identify the sensory characteristics perceived by consumers. Participants were provided with a list of 29 predefined sensory attributes, developed by a focus group of 10 panelists. These attributes were classified into five categories: appearance (greasy, shiny, attractive, opaque), color (pale, intense, yellowish, pink, natural, white, bright), taste (neutral, fishy, acidic, bitter, salty, savory, corn-like), aroma (odorless, natural, fishy, corn-like, acidic), and texture (soft, hard, pasty, sticky, greasy), following the methodology proposed by Ares and Jaeger [26].

2.5. Statistical Analysis

Proximate composition data were analyzed in triplicate to ensure reproducibility. The hedonic scale results were analyzed using a one-way analysis of variance (ANOVA). When significant differences were found (p < 0.05), Tukey’s post hoc test was used to identify differences between treatments (SISVAR software, version 5.6) [27].

For the CATA analysis, Cochran’s Q test was used to identify significant sensory descriptors distinguishing the samples (p ≤ 0.10). The significant terms were then subjected to correspondence analysis using Hellinger distance, followed by principal coordinate analysis (PCA) and penalty-lift analysis, to explore the relationship between CATA attributes and overall acceptance.

All statistical analyses were performed using XLSTAT, version 2018.5 (ADDINSOFT, New York, NY, USA).

3. Results and Discussion

3.1. Nutritional Characteristics of Bonito Fish Meal (BFM) and Potato Peel Flour (PPF)

Table 2 summarizes the proximate composition of BFM and PPF as determined through nutritional analysis.

Table 2.

Nutritional composition of Bonito fish meal (BFM) and potato peel flour (PPF).

The BFM exhibited a high content of protein (50.78%), fat (25.94%), and ash (13.93%), attributes commonly associated with marine by-products [19]. According to [20], the high ash content in BFM is due to the presence of minerals in bones, skin, and other skeletal tissues of Bonito fish, reinforcing its potential as a source of essential minerals for animal feed.

Conversely, PPF exhibited a high carbohydrate content (74.08 g/100 g) and a significant amount of crude fiber (6.23 g/100 g). These findings are consistent with the typical composition of tubers, in which carbohydrates, primarily starch, predominate, and the peel contains higher fiber concentrations [8]. The protein content of PPF (10.76 g/100 g) is relatively moderate, which can be explained by the retention of nitrogenous compounds in the peel, as previously reported [2].

The energy content of PPF (341.97 Kcal/100 g) is comparable to values reported by Espinoza et al. [18] for flours derived from potato by-products (314 Kcal/100 g). The variations may be attributed to differences in the potato varieties used. In contrast, the BFM protein content (50.78 g/100 g) was lower than the 45.46% reported for fish viscera meal [9], likely due to the use of a mixture of six marine species in that study, while the present study used only Bonito fish.

These findings confirm that both flours are nutritionally complementary: BFM provides proteins and lipids, while PPF contributes carbohydrates and dietary fiber, which may contribute to energy metabolism in animals. This synergy supports their combined use in balanced poultry diets aimed at promoting growth and feed efficiency.

3.2. Nutritional Evaluation of the Feed Complement and Experimental Diets

Based on the nutritional characterization of raw materials, it was determined that the combination of BFM and PPF represents a viable alternative for poultry feeding, as each flour contributes essential nutrients for broiler growth.

Considering the nutritional composition of CBF and the analyzed values of by-product flours (Table 2), the optimal BFM:PPF ratio was calculated to formulate FC, ensuring it met the minimum nutritional requirements for broiler growth [16]. The formulation aimed to achieve a minimum protein content of 30%, equivalent to that found in CBF, as protein is critical for muscle synthesis and overall chicken development.

As a result, the optimal formulation was set at 48% BFM and 52% PPF. This ratio ensured a balanced macronutrient profile and practical feasibility for ingredient mixing. The calculated nutritional composition of the resulting FC and its comparison with the CBF are shown in Table 3, confirming its adequacy for broiler nutrition.

Table 3.

Calculated nutritional composition of the feed complement (FC), based on the contribution of Bonito fish meal (BFM) and potato peel flour (PPF), and comparison with commercial balanced feed (CBF) to assess its nutritional adequacy.

Based on this formulation, three experimental diets were established by substituting the CBF with FC at 15% (E15), 30% (E30), and 45% (E45), along with a control group (E0) receiving 100% CBF. These substitution levels were selected to evaluate the effects of gradually increasing the use of by-product-based formulations on broiler performance and meat quality.

3.3. Effect of Feed-Complemented (FC) Inclusion on Broiler Chicken Growth

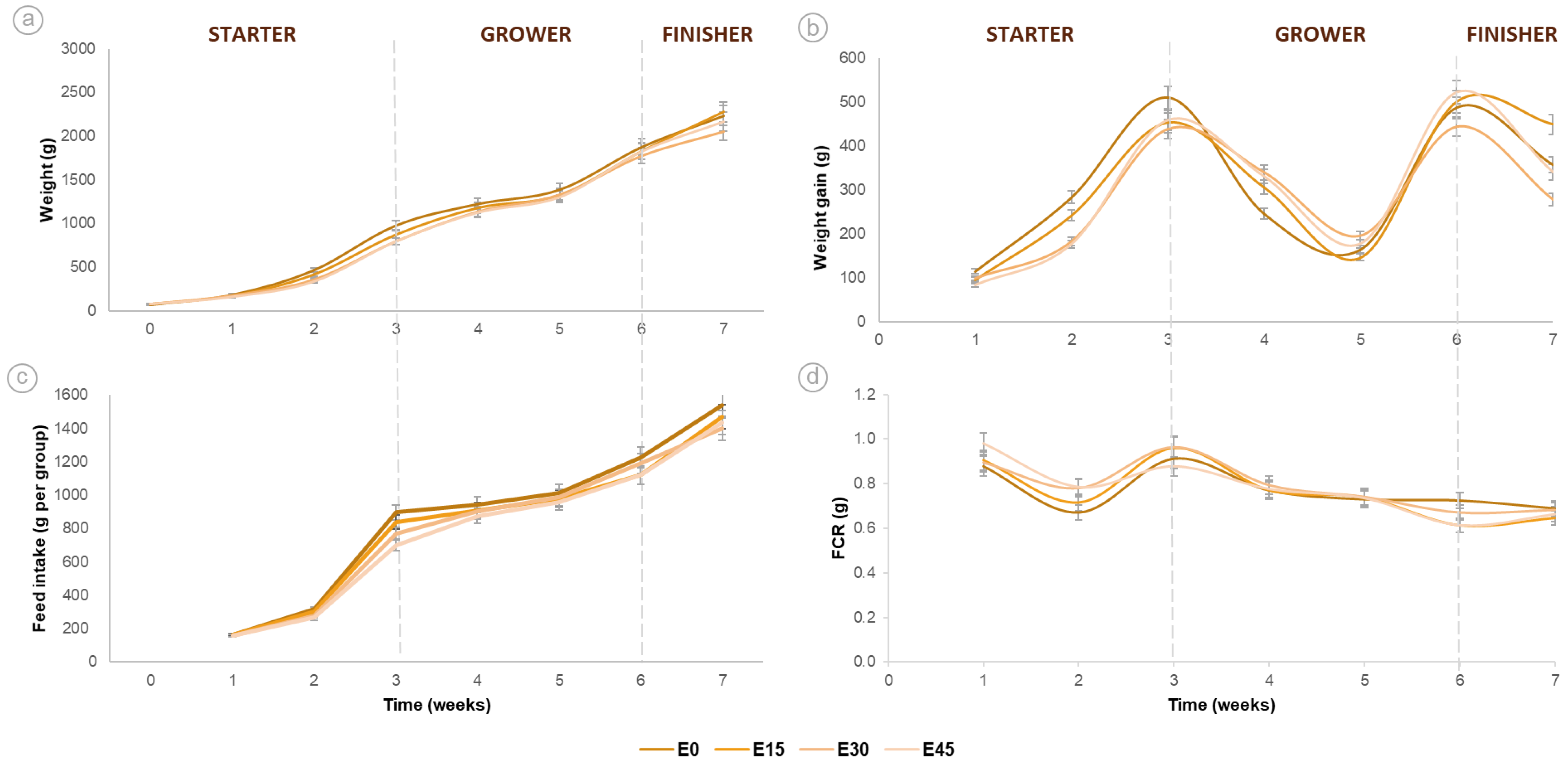

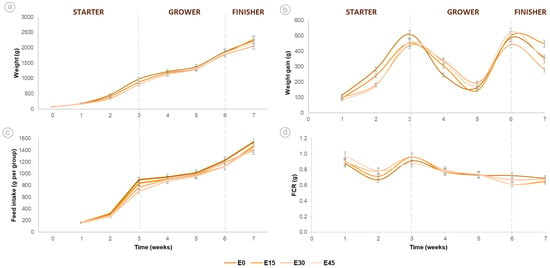

Figure 2 presents the evolution of body weight, weight gain, feed intake, and feed conversion ratio (FCR) of broiler chickens during the 7-week experimental period.

Figure 2.

Growth performance of broiler chickens over 7 weeks under different feeding treatments (n = 10 chickens per group): (a) body weight evolution, (b) weight gain, (c) feed intake, and (d) feed conversion ratio (FCR). E0 = 100% commercial feed; E15, E30, E45 = 15%, 30%, and 45% replacement with feed complement formulated from Bonito fish meal and Única potato peel flour.

Throughout the trial, a progressive increase in body weight was observed across all groups. During the initial phase, the growth followed an exponential trend; however, by weeks 2 and 3, notable differences emerged between treatments (Figure 2a,b). The control group (E0), fed exclusively with commercial balanced feed (CBF), exhibited the highest weight gain, reaching an average of 981 g by the end of week 3, in contrast to the groups receiving partial substitution with FC. As the trial progressed, these differences began to diminish, especially from week 4 onward, when all groups received the same balanced feed. This convergence became more evident in week 5 and remained consistent in week 6, indicating that FC inclusion did not adversely affect broiler development at this stage.

During the finisher phase, where FC was reintroduced, all groups maintained continuous weight gain (Figure 2b). Although slight variations were observed among treatments, statistical analysis confirmed no significant differences in final body weight at week 7 (p > 0.05) (Supplementary Material: Tables S1–S3). These results confirm that incorporating up to 45% of FC does not negatively impact final growth outcomes. While some numerical differences were noted, the lack of statistical significance reinforces the conclusion that FC inclusion does not impair performance, rather than demonstrating superior efficacy.

The weight gain profile revealed two prominent peaks at weeks 3 and 6 (Figure 2b). In the early stages, E0 recorded the highest gains, likely due to the complete provision of CBF, which efficiently supported initial nutritional demands. From week 4 onward, however, the groups receiving FC showed greater weight gain, a trend sustained through week 6. This improvement may reflect both the nutritional adequacy of the FC formulation and behavioral adaptation to the new diet. The initially lower feed intake in the FC groups may be attributed to an adjustment period, after which intake increased, enabling more effective conversion of nutrients into body mass.

This hypothesis is supported by the feed intake data shown in Figure 2c. During the starter phase (weeks 1–3), feed consumption was relatively low in the FC groups (E15–E45), but intake increased substantially in subsequent phases. For instance, E45 showed one of the highest consumption levels by week 7. This progressive rise aligns with the improved weight gain and stabilization of FCR observed after the adaptation period (weeks 3–4). Furthermore, the decoupling between weight gain and FCR during weeks 5 and 6 may indicate a temporary delay in nutrient assimilation following the diet transition, which was later offset by increased intake and adaptation.

By week 7, E15 and E0 achieved the highest weight gains (Supplementary Material, Table S2), suggesting that the nutritional balance in E15 was comparable to the control. The FCR data indicated that E0 had the most favorable conversion efficiency during the early stages (Supplementary Material, Table S3); however, from week 3 onward, higher FC levels, particularly in E45, resulted in similar or even better FCR values. A lower FCR indicates higher production efficiency, meaning that chickens gain more weight with less feed intake, thus enhancing both economic and productive performance. The groups receiving partial substitution with FC (E15, E30, E45) achieved similarly low FCR values (close to 0.65), supporting the hypothesis that, while an initial reluctance toward the new feed may have occurred, chickens adapted over time, ultimately optimizing feed conversion efficiency.

These results align with prior research on by-product-based feed inclusion. Lazo [5] reported differences in the growth performance of Cobb broilers compared to conventional broilers, the latter being recommended for the Peruvian climate due to their higher resistance and fattening efficiency. Regarding fish by-product meal inclusion, Kangle [23] recently conducted research with laying hens, reusing fish bones to transform them into fishmeal. Replacing 3% of conventional feed with this meal resulted in significant improvements in egg quality, as well as in the health and performance of the chickens. These findings demonstrate that including fish bone meal in the diet of laying hens is a viable and cost-effective alternative.

Acosta [22] emphasized that the growth stage is critical, recommending no dietary modifications during this phase to avoid potential developmental setbacks. In his study, a 6% potato meal substitution resulted in a weight gain of 2049.3 g in 42 days. Following this guideline, the present study supplied only CBF during the growth phase, achieving an average weight gain of 2100 g in the same period, reinforcing the viability of this approach.

Regarding fish meal inclusion, Valdivia [24] investigated chemical silage from Perico fish for broiler chicken diets, where 25% substitution led to a gain of 855 g in 23 days. In this study, the E45 group reached 900 g in just 21 days, indicating that FC formulations can serve as a viable alternative in poultry feeding strategies.

In terms of FCR, Valenzuela [13] noted that by-product meal inclusion could negatively impact FCR. However, in this study, no detrimental effects on productive performance were observed. Additionally, the results are consistent with those reported by Pérez [11], who highlighted that fish viscera meal has 80% digestibility in broilers, owing to its high protein content (54%), which enhances nutrient absorption and metabolic efficiency. Finally, the total feed intake in this study reached 30,800 g over 49 days, exceeding the values reported by Lazo [5], thereby confirming that by-product meal inclusion in poultry diets does not negatively impact broiler growth or feed efficiency.

Although no statistically significant improvements were observed, the absence of detrimental effects across performance parameters provides preliminary support for the use of FC in broiler diets. It is important to acknowledge, however, that each treatment group in this trial was composed of a single pen with 10 chickens. Although this design is frequently adopted in preliminary feeding studies due to logistical constraints, the lack of pen-level replication may limit the ability to generalize findings or account for environmental and behavioral variation. Additionally, the amino acid profile of FC was not determined, restricting a more precise assessment of protein quality, especially regarding limiting amino acids such as lysine, methionine, and tryptophan. Despite these limitations, the consistent outcomes observed in growth and feed efficiency indicate that the FC formulation holds promise for future implementation. Subsequent studies should include pen-level replication and amino acid profiling to ensure greater robustness.

3.4. Effect of Feed Complement (FC) Inclusion on the Sensory Characteristics of Broiler Chicken Meat

3.4.1. Acceptance Test

The acceptance test results revealed significant differences in aroma, color, taste, and appearance scores among the evaluated samples, with scores ranging between 6.83 and 8.06 on the hedonic scale, indicating an overall positive acceptance of the product (Table 4). The E15 and E45 samples obtained higher taste, color, and aroma scores, surpassing both the control group (E0) and E30, which had similar ratings.

Table 4.

Mean hedonic scores (±standard deviations) for aroma, color, taste, and appearance of broiler chicken meat samples after feeding with different inclusion levels of the formulated feed complement (n = 20 consumers).

These results suggest that FC inclusion had a positive impact on chicken meat acceptance, as E15 and E45 were rated higher than the control group (E0). This finding is consistent with Valenzuela [13], who reported that feeding broilers with dry salmon silage (ESS) did not affect the perception of fishy odor or taste. However, in his study, the control sample (T0, without ESS) received the highest scores for taste and appearance. Similarly, Cornejo [28] observed that adding fish oil to the traditional diet of laying hens did not cause adverse sensory effects on either meat or eggs, improving the overall acceptability of poultry products. The study found that treatments containing 4% olein and 3% crude fish oil excelled in appearance, while those with 4% olein and 6% alkitol were better rated for taste. These findings align with the present study, where E0 had the highest appearance score, which may be linked to consumer expectations regarding the visual attributes of poultry meat. However, to gain deeper insight into the specific attributes that contributed to acceptance, a CATA analysis was conducted in the second phase of the study.

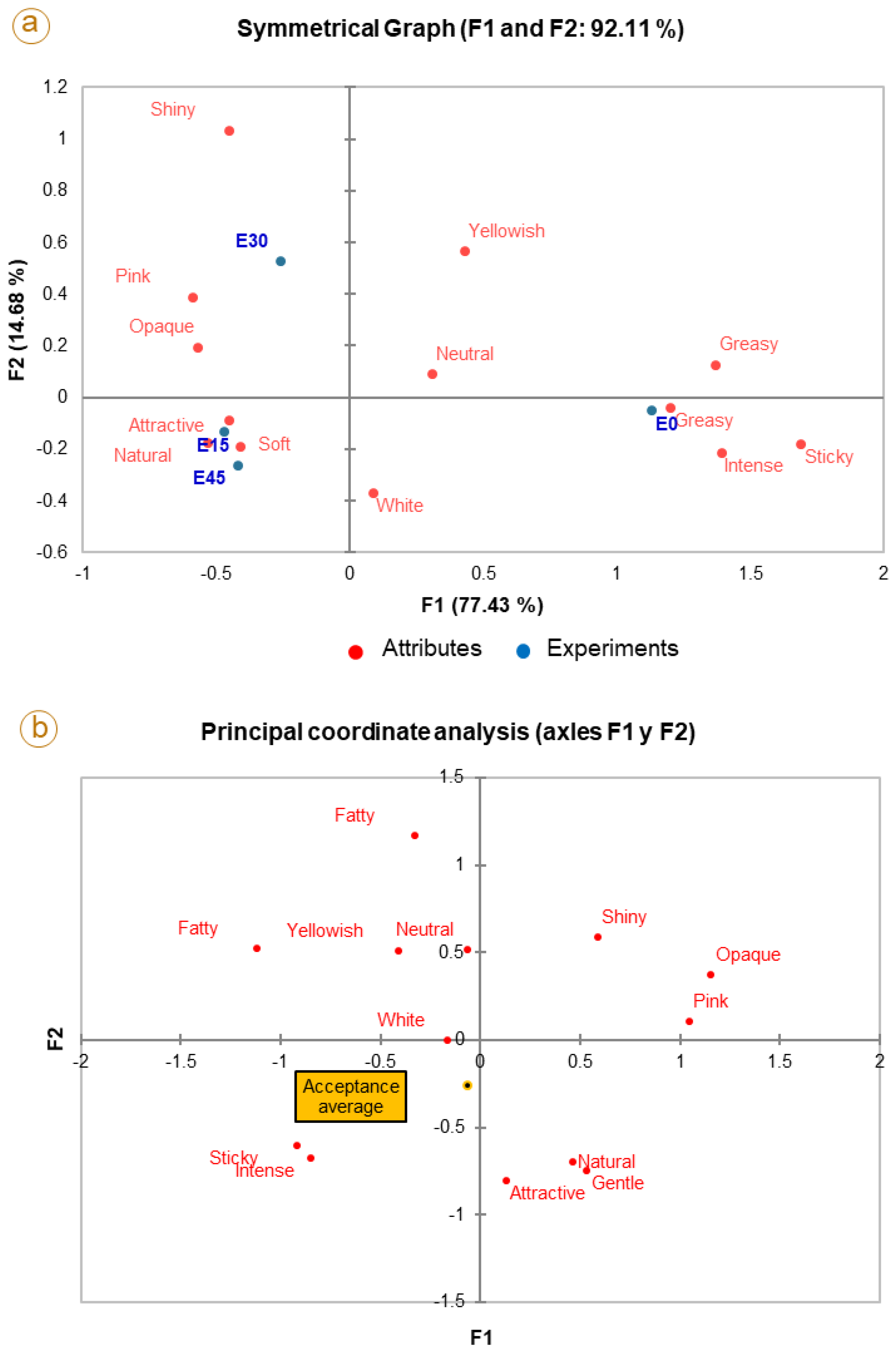

3.4.2. CATA

The CATA analysis identified the key sensory attributes influencing the acceptance of broiler meat fed with FC. According to Cochran’s Q test (Table 5), 13 out of the 30 evaluated attributes were significant in differentiating the samples (p ≤ 0.10). The most frequently mentioned attributes were “greasy,” “attractive,” “natural aroma,” and “soft texture,” all of which exceeded 50% incidence, highlighting their importance in consumer perception.

Table 5.

Significant sensory attributes differentiating broiler meat samples based on the Check-All-That-Apply (CATA) method using Cochran’s Q test (n = 20 consumers).

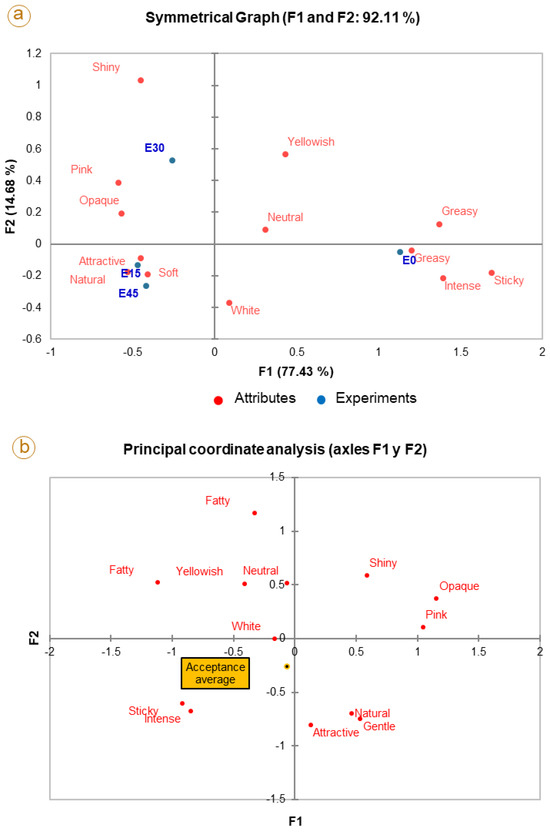

The principal component analysis (PCA, Figure 3b) demonstrated that the attributes identified through Cochran’s Q test effectively distinguished between the samples. The quadrant distribution revealed that the first component (F1) separated samples along the X-axis, while the second component (F2) distinguished them along the Y-axis, collectively explaining 92.11% of the variability in sensory perception. The E0 sample was associated with greasy texture, intense color, and sticky texture, whereas E15 and E45 were linked to an “attractive appearance,” “natural color,” and “soft texture.” Meanwhile, the E30 sample was characterized by a “shiny and opaque appearance” with “rosy color hues.”

Figure 3.

Multivariate analysis of sensory attributes from CATA data (n = 20 consumers): (a) correspondence analysis (CA) based on the Hellinger distance; (b) principal coordinate analysis (PCA) showing distribution of meat samples (E0–E45) and associated sensory descriptors. E0 = 100% commercial feed; E15–E45 = 15–45% substitution with the feed complement.

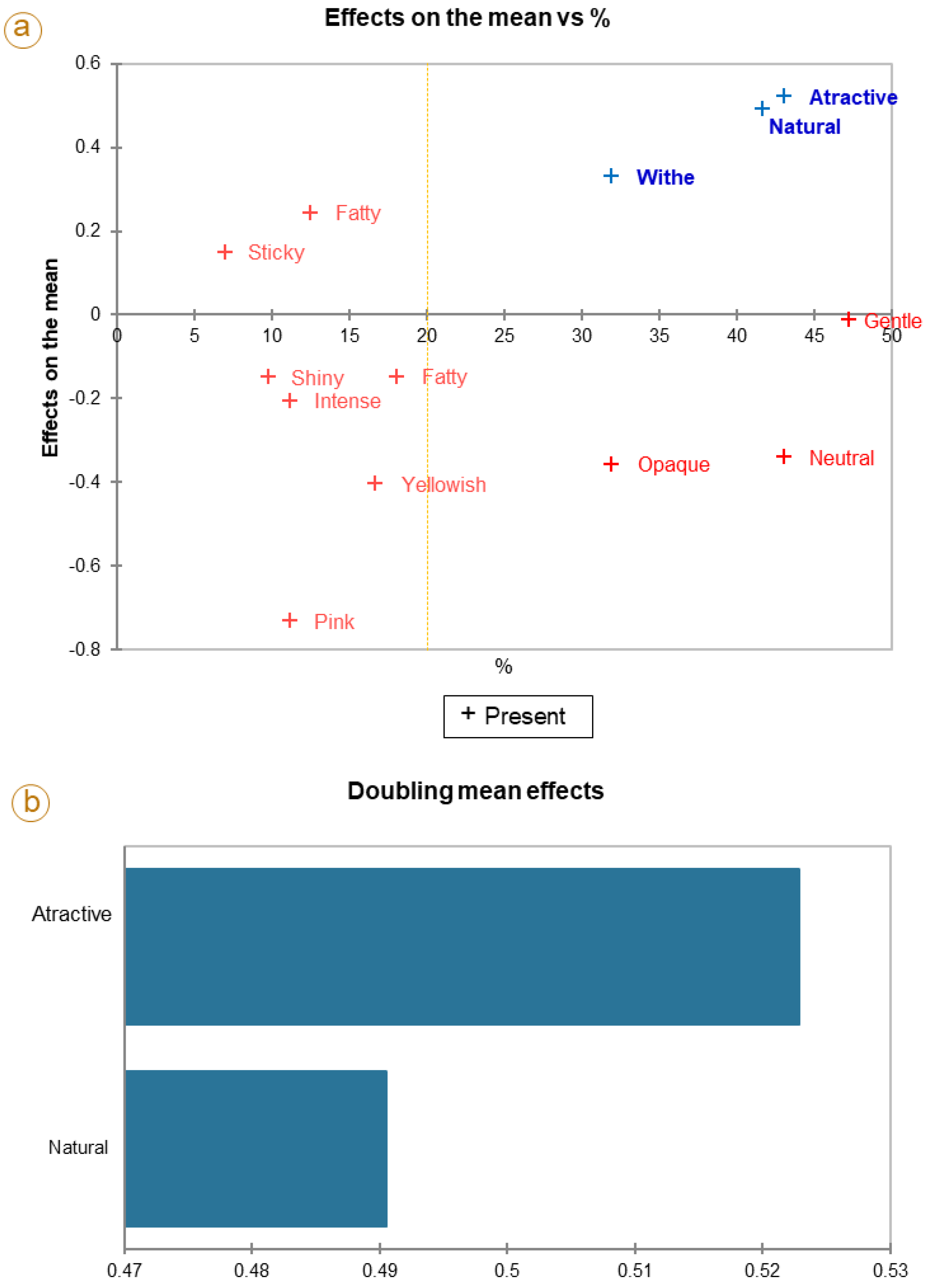

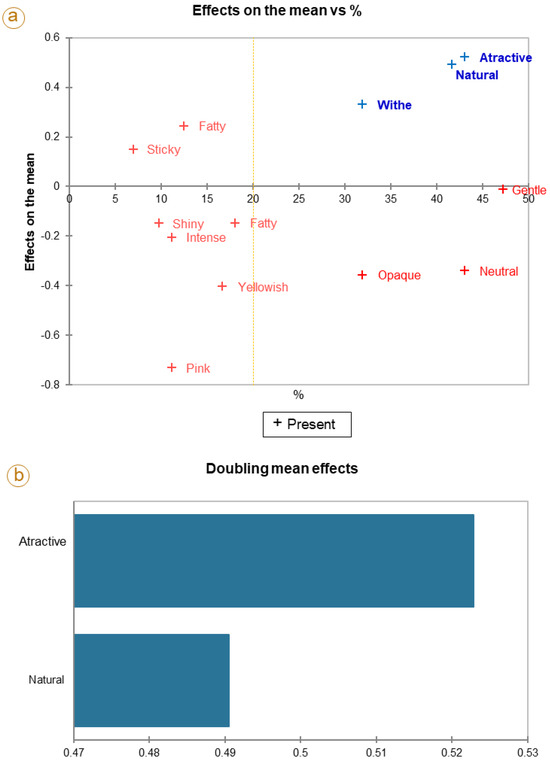

The penalty-lift analysis (Figure 4a,b) revealed that “attractive appearance” and “natural color” were positive attributes that should be enhanced to improve chicken meat acceptance. The E15 and E45 samples exhibited a superior sensory profile compared to the control group (E0), which was perceived as greasier and more opaque. Additionally, no intense fishy aroma was detected, suggesting that high FC incorporation levels do not compromise sensory acceptance.

Figure 4.

Penalty-lift analysis: (a) terms with the highest positive (blue) or negative (red) mean impact, used by more than 20% of consumers; (b) mean impact vs. answers (%). Attributes situated in the lower part of the graphic are negative.

These findings contrast with previous reports on fish silage inclusion in poultry diets. Al-Marzooqi et al. [29] observed that a CATA analysis of broiler meat fed with sardine silage (0–30%) showed significantly lower juiciness and taste scores, with judges describing the 30% silage sample as having an undesirable “suspicious” taste. This effect was attributed to sardine’s high-fat content (9.5%), which negatively impacted sensory perception. However, despite using BFM in this study, which has a high-fat content (25.9%) and omega-3 levels (Table 2), no adverse sensory effects were reported. This could be explained by the balanced FC formulation combined with CBF, which prevented the accumulation of undesirable volatile compounds.

Additionally, Kangle [23] suggested that a withdrawal diet, in which fish bone meal is removed in the last few days of the grow-out period, could help minimize its sensory impact on the meat. In this study, no treatments were applied during the grow-out phase, which could have helped to avoid possible adverse effects on meat perception.

From an industrial application perspective, the results of this study demonstrate that incorporating up to 45% FC in broiler diets is feasible, without negatively affecting meat sensory quality, offering a nutritious, sustainable, and economically viable alternative for poultry production.

3.5. Broader Implications and Resource Context

The integration of fish and potato peel by-products into poultry feed may contribute to a more resource-efficient and sustainable food system. From a market perspective, the inclusion of up to 45% of the feed complement (FC) in poultry diets could offer an opportunity to reduce dependence on imported ingredients such as corn and soy. In countries such as Peru, where over 70% of the maize used for animal feed is imported at fluctuating prices, the use of locally sourced by-products might help mitigate economic pressures on small- and medium-scale poultry producers by lowering feed costs and enhancing local circularity [30].

Although this study did not conduct a formal cost-benefit analysis, previous reports suggest that substituting conventional feed inputs with agro-industrial residues can reduce feed costs by 15–30%, depending on local sourcing and processing logistics [31,32]. In this study, raw materials were collected within a 5 km radius, a distance selected to reflect feasible small-scale collection. However, broader economic viability would depend on processing methods (e.g., drying, ensiling) and the scale of operation.

Environmentally, the diversion of food residues from landfills could help avoid greenhouse gas emissions resulting from anaerobic decomposition. According to Teigiserova et al. [30], valorizing one ton of food waste into animal feed instead of landfilling may prevent up to 0.9 tons of CO2-equivalent emissions. Based on this estimate, the use of 238 kg of organic residues per batch in our study could potentially avoid approximately 210 kg CO2-eq, though this is only a theoretical projection and would require confirmation through life cycle assessment (LCA) methods.

Overall, while further formal assessments are needed, the use of Bonito fish meal and Única potato peel flour appears to align with the principles of a circular economy and could contribute to Sustainable Development Goals (SDGs) 2 (Zero Hunger), 12 (Responsible Consumption and Production), and 13 (Climate Action), particularly in regions with abundant and underutilized food processing residues.

4. Conclusions

This study demonstrated that the feed complement (FC), composed of 48% Bonito fish meal (BFM) and 52% Única potato peel flour (PPF), exhibited a suitable nutritional profile for inclusion in broiler chicken diets. Partial replacement of commercial balanced feed with up to 45% FC did not significantly affect final body weight, weight gain, or feed conversion ratio (p > 0.05), confirming its viability at these levels without compromising broiler performance. Furthermore, FC inclusion positively influenced the sensory attributes of broiler meat. Samples from E15 and E45 groups were rated higher in terms of attractive appearance, natural color, and soft texture, while the control group (E0) was associated with a greasier appearance and more opaque color.

These results suggest that FC maintains broiler growth performance while enhancing the sensory quality of broiler meat, potentially increasing consumer acceptance. Therefore, incorporating up to 45% FC in broiler diets may represent a promising alternative in poultry production by ensuring adequate growth and improved sensory perception. Moreover, the use of co-products derived from restaurants and markets could contribute to reducing food waste and offer potential benefits within circular economy strategies and sustainability efforts in the agri-food sector.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/resources14080125/s1, Table S1. Evolution of broiler chicken weight (g) over seven weeks under different feeding treatments; Table S2. Weekly weight gain (g) of broiler chickens over seven weeks under different feeding treatments; Table S3. Feed Conversion Ratio (FCR) of broiler chickens over seven weeks under different feeding treatments.

Author Contributions

Conceptualization, R.S.-R. and A.M.E.D.; methodology, R.S.-R. and A.M.E.D.; software, R.S.-R. and A.M.E.D.; validation, A.M.E.D.; formal analysis, A.M.E.D.; investigation, R.S.-R. and A.M.E.D.; resources, R.S.-R.; data curation, R.S.-R. and A.M.E.D.; writing—original draft preparation, R.S.-R. and A.M.E.D.; writing—review and editing, R.S.-R. and A.M.E.D.; visualization, R.S.-R.; supervision, R.S.-R.; project administration, R.S.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was approved by the Committee of the Faculty of Industrial Engineering at Universidad Tecnológica del Perú, under institutional code N° 20.500.12867/8840 (Approval Date: 27 January 2024).

Data Availability Statement

The original contributions of this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- World Health Organization. Food Production Grew by 12.2% in April 2020. National Institute of Statistics and Informatics (INEI). 2020. Available online: https://iris.who.int/bitstream/handle/10665/332070/9789240005105-eng.pdf (accessed on 30 July 2025).

- Basso, N.; Brkic, M.; Moreno, C.; Pouiller, P.; Romero, A. Let’s value food, avoid losses and waste. Diaeta 2016, 34, 25–32. [Google Scholar]

- Morales, M.; Gabriela, M. Technical Analysis of Andean Tubers (Chinese Potato, Sweet Potato, White Carrot) to Process Functional Products in Tungurahua Province; Technical University of Ambato: Ambato, Ecuador, 2021; Available online: https://repositorio.uta.edu.ec/handle/123456789/33638 (accessed on 29 April 2025).

- Giuffra, B. The palate industry and the boom of Peruvian gastronomy. Cont. J. 2016, 1, 7. [Google Scholar]

- APA-AVICULTURA PERÚ. Boletín APA Informa; Asociación Peruana de Avicultura (APA): Lima, Peru, 2022. [Google Scholar]

- Abad Bazán, J.C. Rendimiento Productivo y Económico del Engorde Intensivo de Pollos Broiler de las Líneas Ross y Cobb en Huancayo. Tesis de Pregrado, Universidad Nacional del Centro del Perú, Huancayo, Peru, 2008. Available online: https://repositorio.uncp.edu.pe/handle/20.500.12894/2888 (accessed on 10 April 2025).

- El Khattabi, A.; Handa, S.; El Midaoui, M.; Nassiri, M.; Lemkhanter, S.; Ibijbijen, Y.M. Reutilización de desechos alimentarios en la alimentación de pollos orgánicos. E3S Web Conf. 2021, 234, 00090. [Google Scholar]

- Ramírez, V.M.; Peñuela, L.M.; Pérez, M.R. Organic waste as an alternative for swine feeding. Anim. Sci. Dairy Colomb. 2017, 34, 2. [Google Scholar] [CrossRef]

- Calderón Hernández, R.; Cortés Jaramillo, N.C. Utilization of Organic Waste as Input for Animal Feed Industry ABA. Bachelor‘s Thesis, University of La Salle, Bogotá, Colombia, 2004. Available online: https://hdl.handle.net/20.500.14625/33186 (accessed on 12 April 2025).

- Barrera, L.; Pablo, J. Evaluation of Feed Conversion in Broiler Chickens Using Three Levels of Fishmeal; Polytechnic University of Salesian: Quito, Ecuador, 2016; Available online: https://dspace.ups.edu.ec/handle/123456789/12165 (accessed on 12 April 2025).

- Lúquez-Pérez, L.d.R.; Hleap-Zapata, J.I. Feasibility of using fishmeal from Zapatosa Swamp in broiler feeding. Rev. U.D.C.A Actual. Divulg. Cient. 2020, 23, e1202. [Google Scholar] [CrossRef]

- Garnida, Y.; Rudiansyah, M.; Yasin, G.; Mahmudiono, T.; Kadhim, A.J.; Sharma, S.; Hussein, A.; Shichiyakh, R.A.; Abdelbasset, W.K.; Iswanto, A.H. Investigation of parameters in restaurant food waste for use as poultry rations. Food Sci. Technol. 2022, 42, e118621. Available online: https://www.scielo.br/j/cta/a/wpTjxNBS5rJFkKrkqDQNrQM/ (accessed on 12 April 2025). [CrossRef]

- Valenzuela, C.; Carvallo, F.; Morales, M.S.; Reyes, P. Effect of using dry salmon silage in broiler diets on productive parameters and meat sensory quality. Arch. Med. Vet. 2015, 47, 53–59. [Google Scholar] [CrossRef]

- Dávalos Cuno, L.M. Desarrollo de Nuggets de Bonito (Sarda chiliensis chiliensis) Bajos en Calorías y con la Adición de chía (Salvia hispanica) como Antioxidante. Bachelor’s Thesis, Universidad Nacional de San Agustin de Arequipa, Arequipa, Peru, 2016. [Google Scholar]

- Gutierrez Rosales, R.O.; Espinoza-Trelles, J.A.; Bonierbale, M. UNICA: Peruvian variety for fresh market and fries with tolerance and resistance to adverse climatic conditions. Lat. Am. J. Potatoes 2016, 14, 41–50. [Google Scholar] [CrossRef]

- INEI. Producción de Papa Creció 12,2% en Abril del 2020. Instituto Nacional de Estadística e Informática. 2020. Available online: https://m.inei.gob.pe/prensa/noticias/produccion-de-papa-crecio-122-en-abril-del-2020-12263/ (accessed on 14 April 2025).

- Karim, A.A.; Bhat, R. Fish gelatin: Properties, challenges, and prospects as an alternative to mammalian gelatins. Food Hydrocoll. 2009, 23, 563–576. [Google Scholar] [CrossRef]

- Espinoza, D.A.; Torres, B.D.M.; Vargas, R.D.; Torrescano, G.R.; Sánchez, A. Valorization of potato peel waste as natural additive for use in meat products. Resources 2023, 12, 148. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Rockville, MD, USA, 2005; Available online: https://www.researchgate.net/publication/292783651_AOAC_2005 (accessed on 10 January 2025).

- NRC. Nutrient Requirements of Poultry, 9th ed.; National Academies Press: Washington, DC, USA, 1994. [CrossRef]

- Rostagno, H.S.; Albino, L.F.T.; Hannas, M.I.; Donzele, J.L.; Sakomura, N.K.; Perazzo, F.G.; Saraiva, A.; de Abreu, M.L.T.; Paulo Rodrigues, B.; de Oliveira, R.F.; et al. Tablas Brasileñas para Aves y Cerdos: Composición de Alimentos y Requerimientos Nutricionales, 4th ed.; UFV: Viçosa, Brazil, 2017. [Google Scholar]

- Acosta, R.D. Evaluación Productiva y Económica del uso de tres Niveles de Harina de Papa (Solanum tuberosum) en la Alimentación de Pollos Cobb 500 en Huánuco-2021. Bachelor’s Thesis, Universidad Nacional Hermilio Valdizán, Huánuco, Peru, 2022. [Google Scholar]

- Wu, K.; Wang, F.; Yang, S.; Zhang, C.; Xie, M.; Li, J.; Yin, Y.; Yao, K. Effects of fish bone meal supplementation on growth performance, blood immunity, intestinal morphology, and gut microbiota in laying hens. Poult. Sci. 2025, 104, 103878. [Google Scholar] [CrossRef] [PubMed]

- Majo, V.; Alejandra, K.N. Production of Chemical Ensilage from Fish Waste for Balanced Poultry Feeding in Ilo-Moquegua; César Vallejo University: Moquegua, Peru, 2022; Available online: https://repositorio.ucv.edu.pe/handle/20.500.12692/96315 (accessed on 10 January 2025).

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques, 4th ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Ares, G.; Jaeger, S.R. Check-all-that-apply questions: Influence of attribute order on sensory product characterization. Food Qual. Prefer. 2013, 28, 141–153. [Google Scholar] [CrossRef]

- Salvador-Reyes, R.; de Brito, A.D.C.; Sampaio, U.; Moro, T.M.A.; Clerici, M.T.P.S.; Behrens, J. Exploring the perception and sensory acceptance of a Peruvian purple maize breakfast cereal by Brazilian consumers. Sci. Agropecu. 2023, 14, 7–19. [Google Scholar] [CrossRef]

- Cornejo, S.; Hidalgo, H.; Araya, J.; Pokniak, J. Supplementation of commercial laying hen diets with fish oils of different refining levels: Productive effects on the birds and organoleptic quality of the eggs. Arch. Med. Vet. 2008, 40, 45–50. [Google Scholar] [CrossRef]

- Al-Marzooqi, W.; Al-Farsi, M.A.; Kadim, I.T.; Mahgoub, O.; Goddard, J.S. The effect of feeding different levels of sardine fish silage on broiler performance, meat quality and sensory characteristics under closed and open-sided housing systems. Asian-Australas. J. Anim. Sci. 2010, 23, 1614–1625. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards transparent valorization of food surplus, waste and loss: Clarifying definitions, food waste hierarchy, and role in the circular economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef] [PubMed]

- Makkar, H.P.S.; Tran, G.; Heuzé, V.; Ankers, P. State-of-the-art on use of insects as animal feed. Anim. Feed. Sci. Technol. 2014, 197, 1–33. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, L.; Cossu, R. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).