Spatial Optimization of Bioenergy Production by Introducing a Cooperative Manure Management System in Bangladesh

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Management

2.2. Scenario Analysis

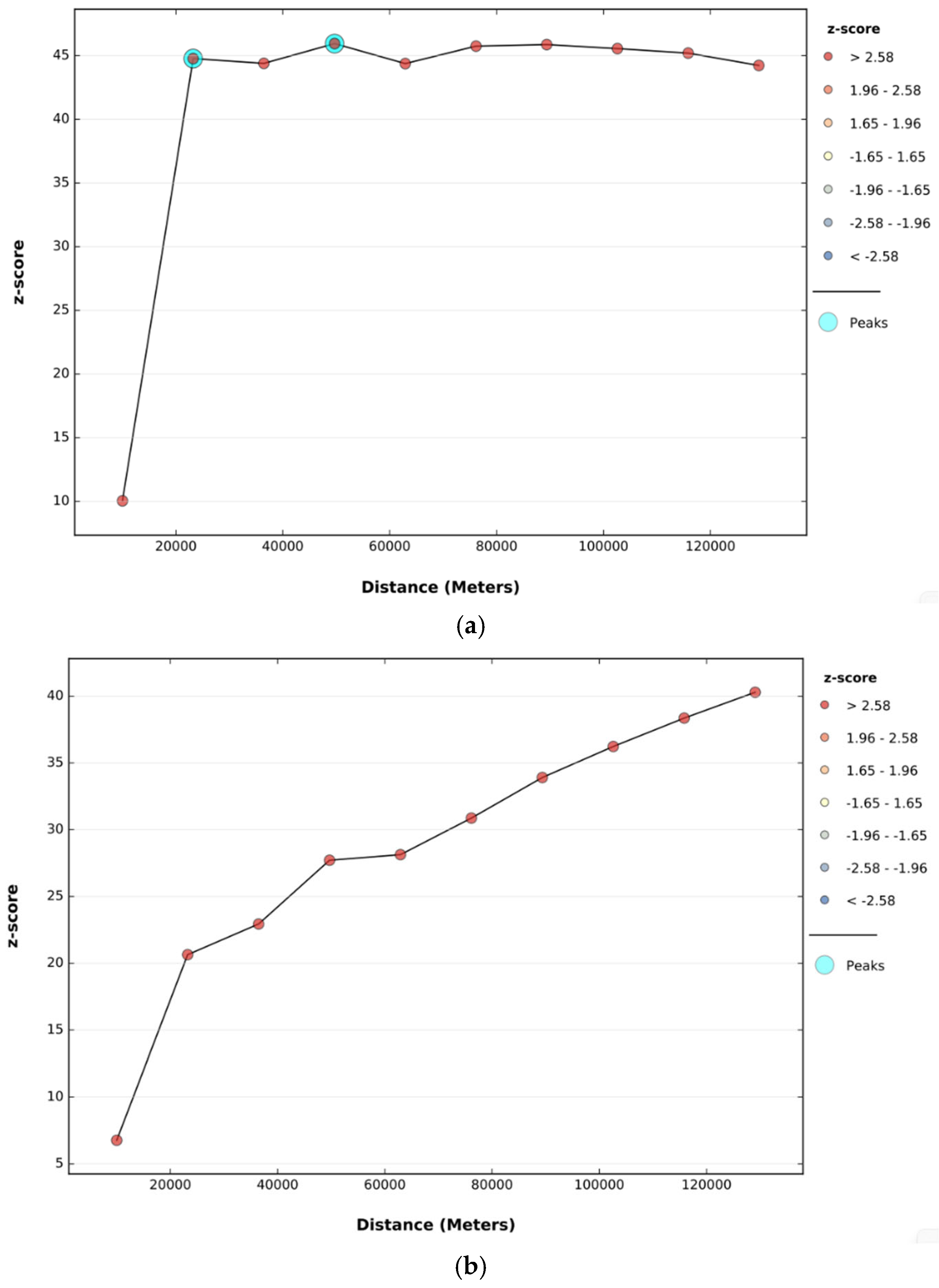

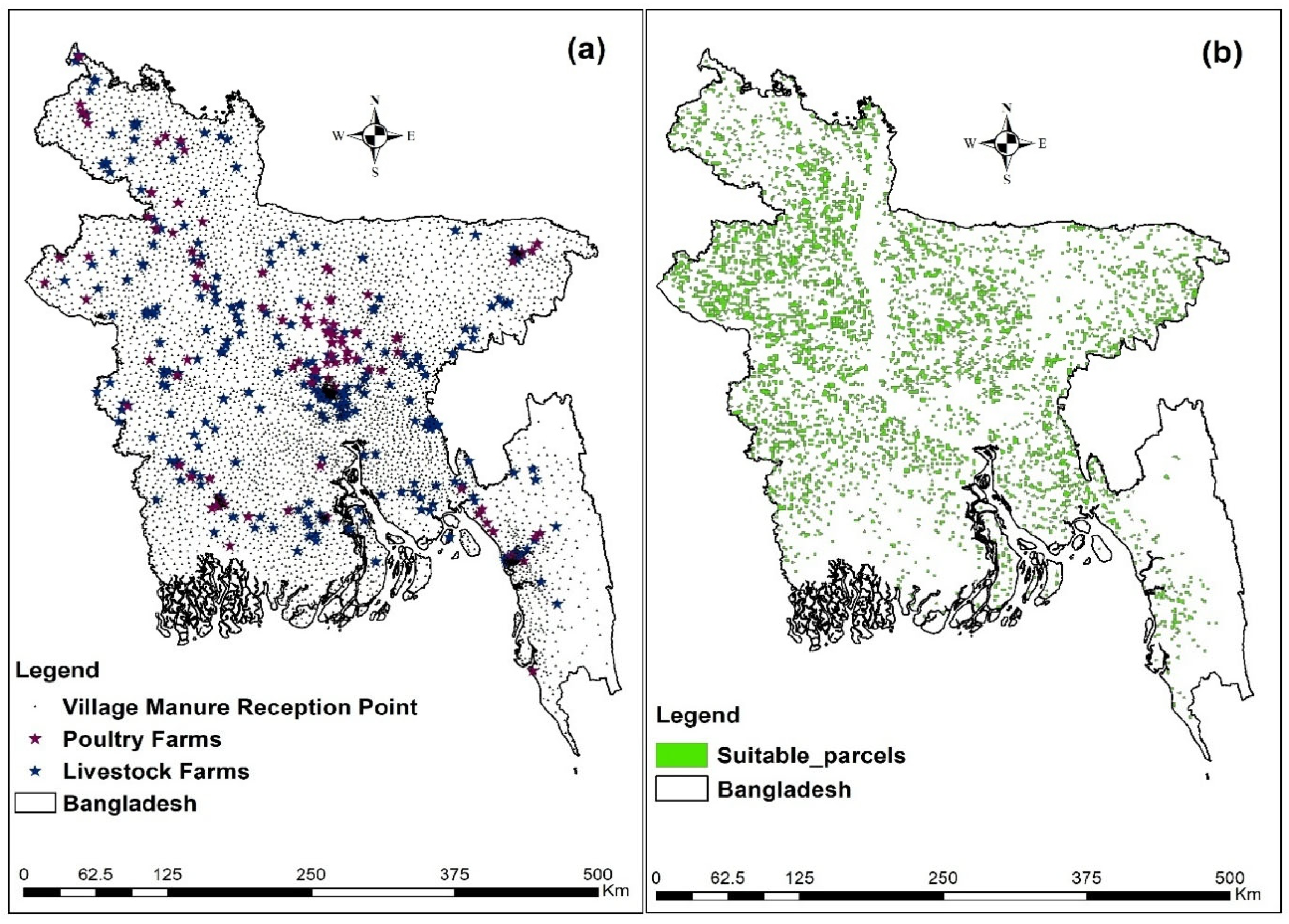

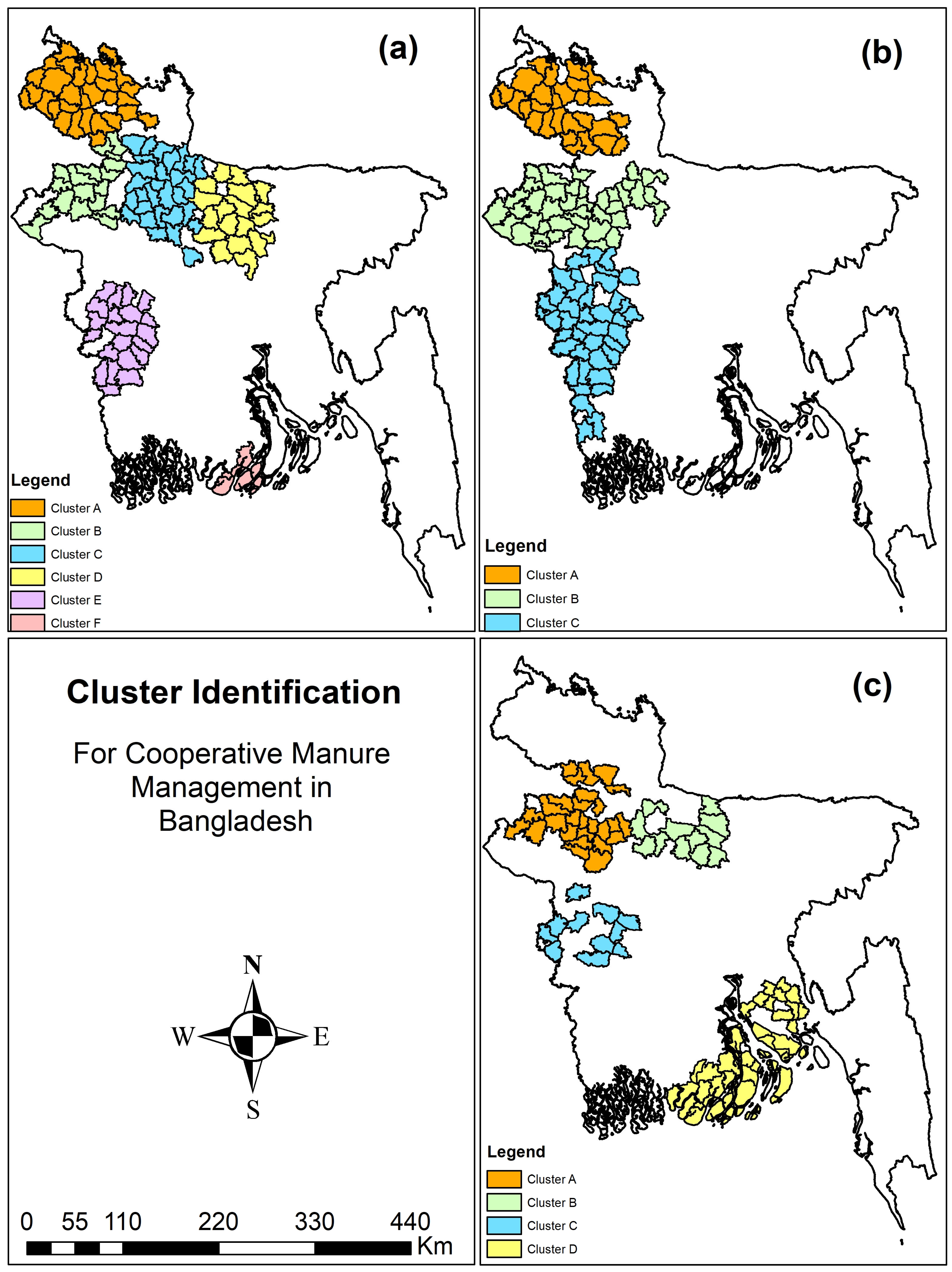

2.2.1. Cluster Analysis

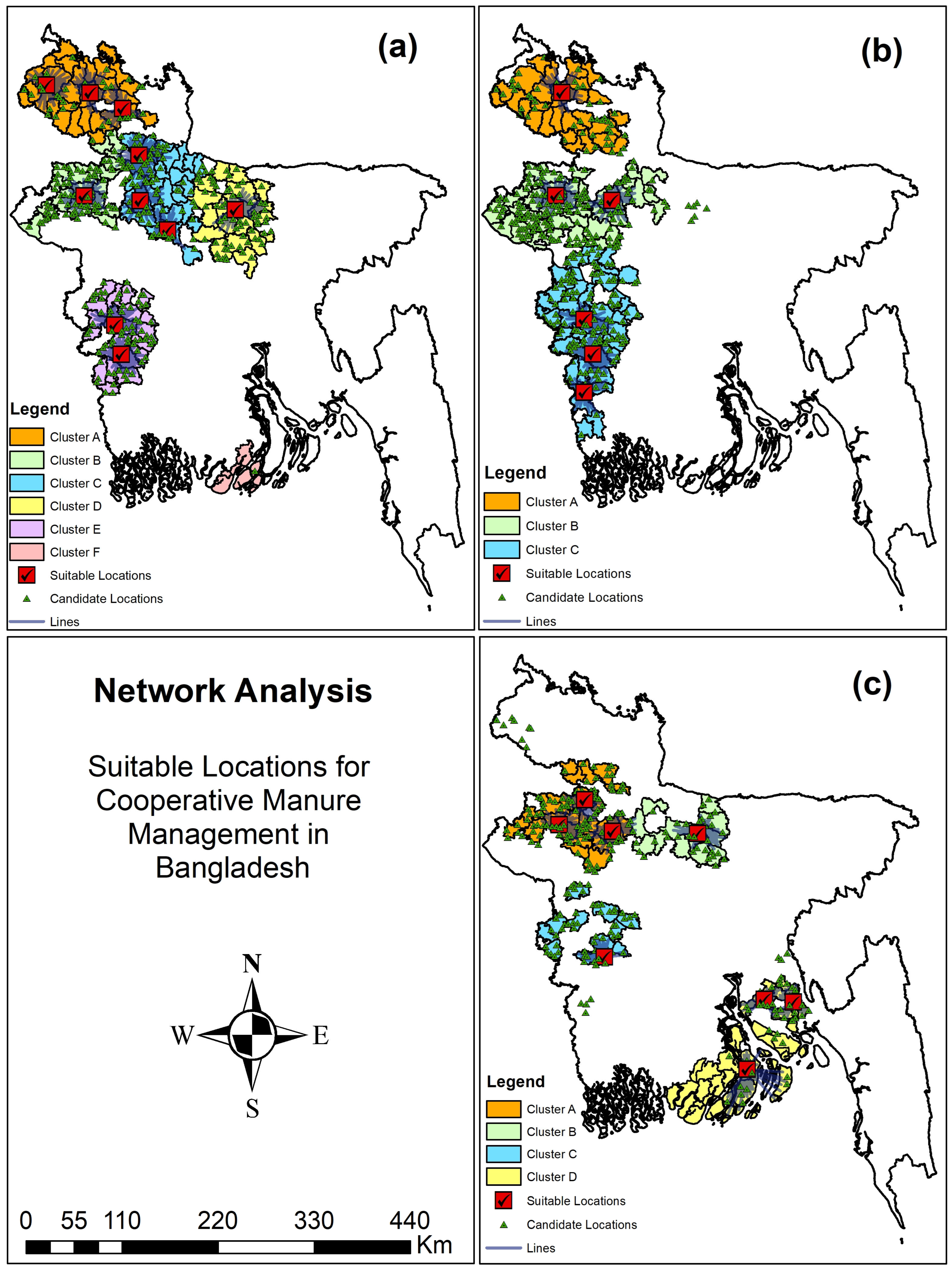

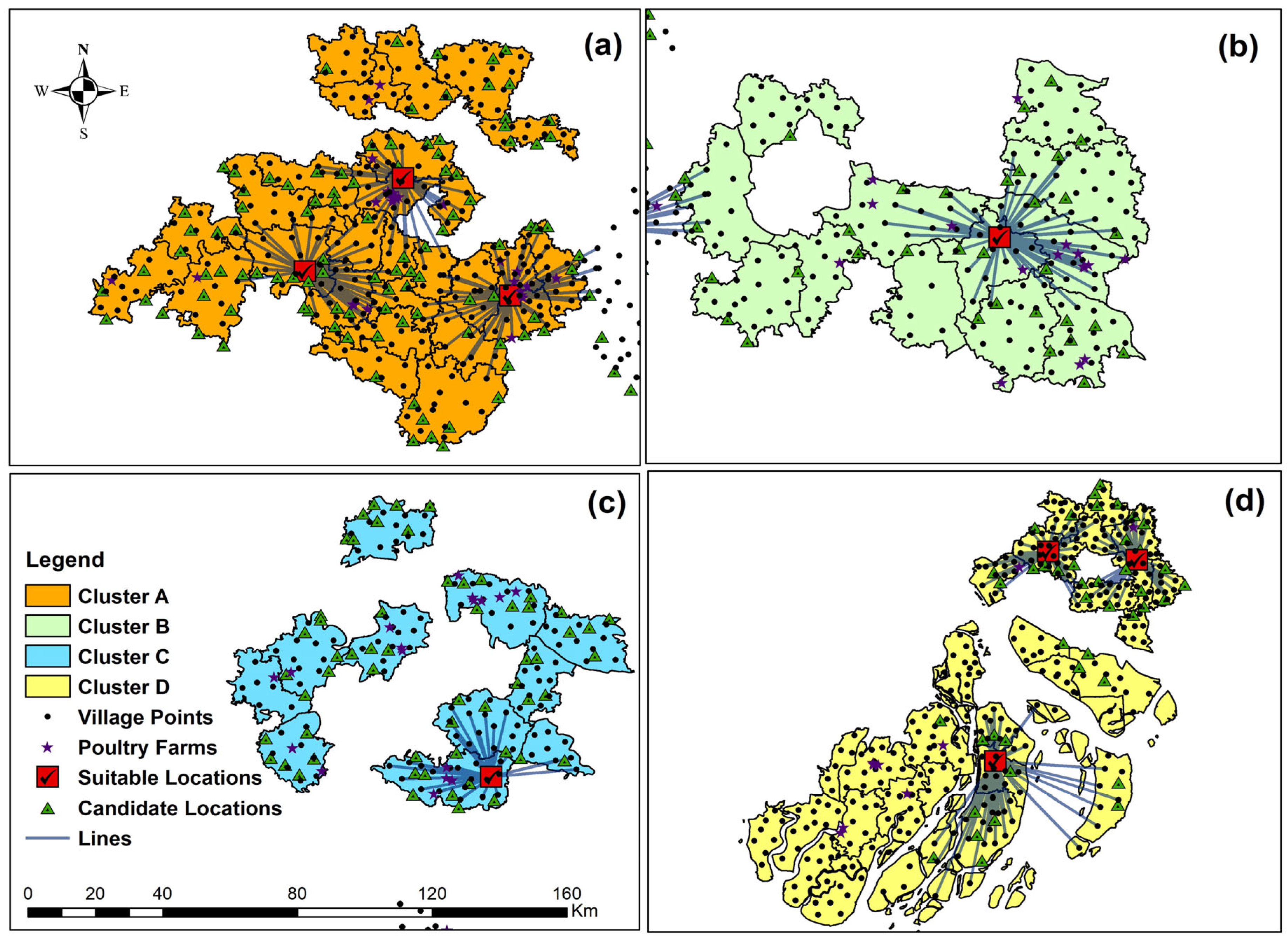

2.2.2. Network Analysis

2.3. Theoretical Assessments

2.3.1. Assessment of Livestock Manure Generation

2.3.2. Biogas Generation

× Collection efficiency × Biogas yield (m3/kg TS)

2.3.3. Electricity Generation from Biogas

2.3.4. Biofertilizer Production from Biogas

2.3.5. GHG Emissions Reduction Potential of Biogas After Replacing Natural Gas

in liter × SEF

3. Results

3.1. Cluster and Outlier Analysis for Livestock Manure Intensity

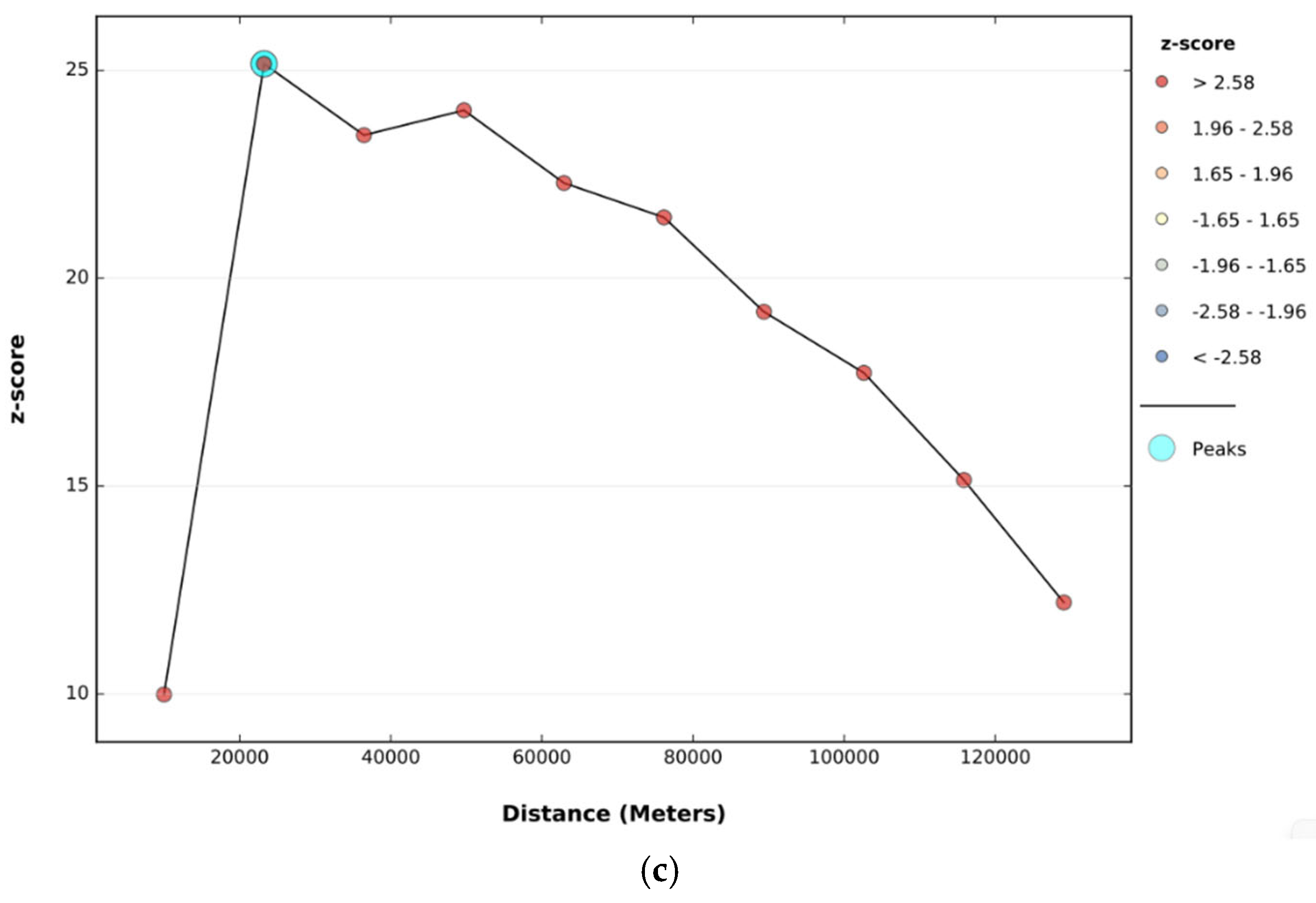

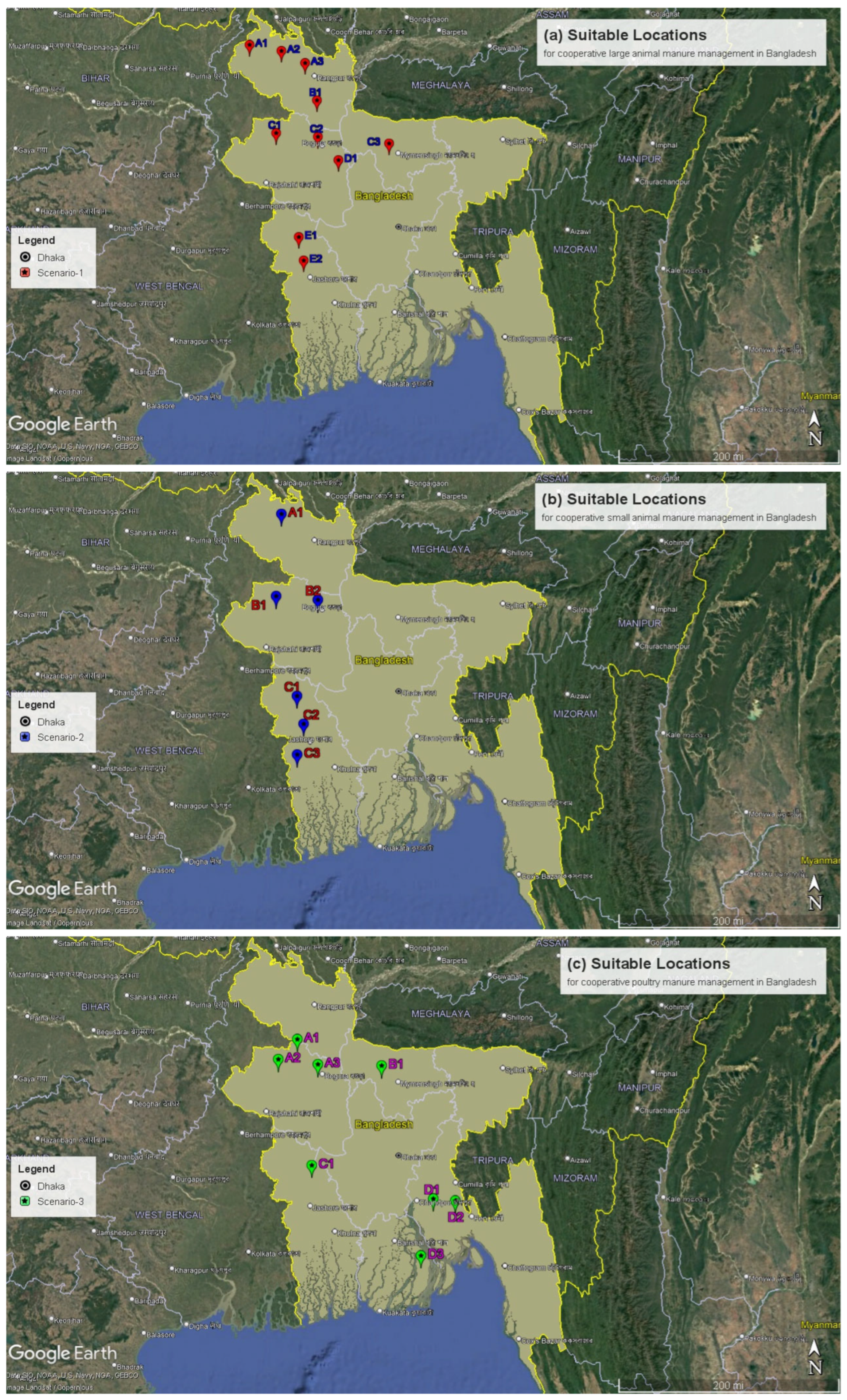

3.2. Suitable Locations Optimization

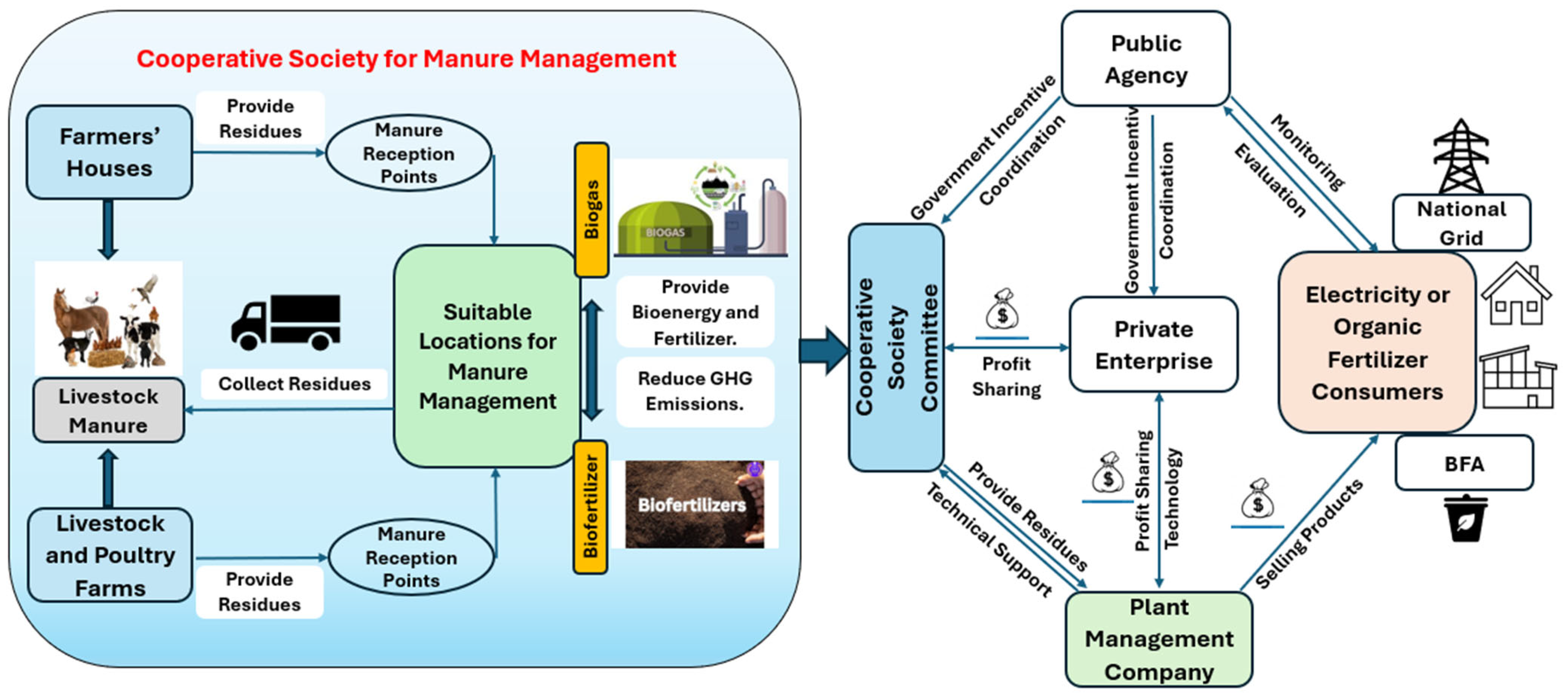

3.3. Cooperative Manure Management Action Plan

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Livestock Types | Livestock Population (in Million Heads) | Waste Generation (Kilotons/Year) | Waste Availability (Kilotons/Year) |

|---|---|---|---|

| Cattle | 24.69 | 188,743.36 | 94,371.68 |

| Buffalo | 1.51 | 11,543.23 | 5771.62 |

| Goat | 2.68 | 862.62 | 112.14 |

| Sheep | 3.75 | 1207.03 | 156.91 |

| Chicken | 311.81 | 5645.46 | 5080.91 |

| Duck | 63.84 | 1155.85 | 1040.27 |

| Total | 408.28 | 209,157.57 | 106,533.54 |

References

- DLS. Department of Livestock Services. Dhaka, Bangladesh. 2024. Available online: https://dls.gov.bd/ (accessed on 24 April 2024).

- ILMM. Draft National Integrated Livestock Manure Management (ILMM) Policy; Ministry of Fisheries and Livestock, Dhaka, The People’s Republic of Bangladesh. 2019. Available online: https://mofl.portal.gov.bd/sites/default/files/files/mofl.portal.gov.bd/page/221b5a19_4052_4486_ae71_18f1ff6863c1/ILMM%20Policy.pdf (accessed on 16 March 2025).

- Brandão, J.B.; Breitenbach, R. What are the main problems in the management of rural cooperatives in Southern Brazil? Land Use Policy 2019, 85, 121–129. [Google Scholar] [CrossRef]

- Sambuo, D. Co-operatology and the science of cooperative societies: A synthetic review of research on cooperative evolution. J. Co-Oper. Organ. Manag. 2023, 11, 100190. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H. Spatial Estimation of Biogas and Compost Potential for Sustainable Livestock Manure Management in Bangladesh. Appl. Sci. 2025, 15, 6753. [Google Scholar] [CrossRef]

- FAO. Livestock and Environment Statistics: Manure and Greenhouse Gas Emissions. Global, Regional and Country Trends, 1990–2018. Report No: FAOSTAT Analytical Brief Series No. 14; Rome. 2020. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/f0cebfdd-725e-4d7a-8e14-3ba8fb1486a7/content (accessed on 26 January 2025).

- Afotey, B.; Sarpong, G.T. Estimation of biogas production potential and greenhouse gas emissions reduction for sustainable energy management using intelligent computing technique. Meas. Sens. 2023, 25, 100650. [Google Scholar] [CrossRef]

- Faaij, A.; Van Doorn, J.; Curvers, T.; Waldheim, L.; Olsson, E.; Van Wijk, A.; Daey-Ouwens, C. Characteristics and availability of biomass waste and residues in The Netherlands for gasification. Biomass Bioenergy 1997, 12, 225–240. [Google Scholar] [CrossRef]

- Kang, Y.O.; Yabar, H.; Mizunoya, T.; Higano, Y. Optimal landfill site selection using ArcGIS Multi-Criteria Decision-Making (MCDM) and Analytic Hierarchy Process (AHP) for Kinshasa City. Environ. Chall. 2024, 14, 100826. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H.; Mizunoya, T. Spatial Assessment of Greenhouse Gas Emissions and Eutrophication Potential from Livestock Manure in Bangladesh. Sustainability 2024, 16, 5479. [Google Scholar] [CrossRef]

- MoEF. The National Environment Policy, 2018; Ministry of Environment and Forest, The Government of Bangladesh. 2024. Available online: https://moef.gov.bd/site/page/1c05e31e-1bb0-46ce-95a3-6ee3c82b439f/%E0%A6%AA%E0%A6%B0%E0%A6%BF%E0%A6%AC%E0%A7%87%E0%A6%B6-%E0%A6%A8%E0%A7%80%E0%A6%A4%E0%A6%BF,%E0%A6%86%E0%A6%87%E0%A6%A8-%E0%A6%93-%E0%A6%AC%E0%A6%BF%E0%A6%A7%E0%A6%BF (accessed on 1 May 2024).

- BPDB. Bangladesh Power Development Board. Available online: http://www.bpdb.gov.bd/site/page/d2d5afd4-9f20-4c05-9102-a7c7de13798e/- (accessed on 12 November 2024).

- Ai, P.; Jin, K.; Alengebawy, A.; Elsayed, M.; Meng, L.; Chen, M.; Ran, Y. Effect of application of different biogas fertilizer on eggplant production: Analysis of fertilizer value and risk assessment. Environ. Technol. Innov. 2020, 19, 101019. [Google Scholar] [CrossRef]

- Li, J.; Wei, L.; Duan, Q.; Hu, G.; Zhang, G. Semi-continuous anaerobic co-digestion of dairy manure with three crop residues for biogas production. Bioresour. Technol. 2014, 156, 307–313. [Google Scholar] [CrossRef]

- Mathew, A.K.; Bhui, I.; Banerjee, S.N.; Goswami, R.; Chakraborty, A.K.; Shome, A.; Balachandran, S.; Chaudhury, S. Biogas production from locally available aquatic weeds of Santiniketan through anaerobic digestion. Clean Technol. Environ. Policy 2015, 17, 1681–1688. [Google Scholar] [CrossRef]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric. Ecosyst. Environ. 2006, 112, 153–162. [Google Scholar] [CrossRef]

- Alengebawy, A.; Mohamed, B.A.; Ghimire, N.; Jin, K.; Liu, T.; Samer, M.; Ai, P. Understanding the environmental impacts of biogas utilization for energy production through life cycle assessment: An action towards reducing emissions. Environ. Res. 2022, 213, 113632. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health Part A 2018, 53, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Aktar, K.; Yabar, H.; Mizunoya, T.; Islam, M.D.M. Application of GIS in Introducing Community-Based Biogas Plants from Dairy Farm Waste: Potential of Renewable Energy for Rural Areas in Bangladesh. Geomatics 2024, 4, 384–411. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H. A Spatial Modeling Approach for Optimizing the Locations of Large-Scale Biogas Plants from Livestock Manure in Bangladesh. Land 2025, 14, 79. [Google Scholar] [CrossRef]

- Venier, F.; Yabar, H. Renewable energy recovery potential towards sustainable cattle manure management in Buenos Aires Province: Site selection based on GIS spatial analysis and statistics. J. Clean. Prod. 2017, 162, 1317–1333. [Google Scholar] [CrossRef]

- Google Earth Pro Earth Versions. Google Earth. 2025. Available online: https://www.google.com/earth/about/versions/ (accessed on 16 January 2025).

- BBS. Bangladesh Bureau of Statistics. Government of the People’s Republic of Bangladesh. Available online: http://bbs.portal.gov.bd/site/page/6b4c2697-452b-4bc6-9ee2-1fb5e0fc66c0/- (accessed on 24 April 2024).

- ArcGIS Online. Available online: https://www.google.com/search?client=firefox-b-d&q=arcgis+online (accessed on 13 November 2024).

- ESRI. Spatial Autocorrelation (Global Moran’s I) (Spatial Statistics)—ArcGIS Pro|Documentation. Available online: https://pro.arcgis.com/en/pro-app/latest/tool-reference/spatial-statistics/spatial-autocorrelation.htm (accessed on 9 January 2025).

- ESRI. Incremental Spatial Autocorrelation (Spatial Statistics)—ArcMap|Documentation. ArcMap. 2025. Available online: https://desktop.arcgis.com/en/arcmap/latest/tools/spatial-statistics-toolbox/incremental-spatial-autocorrelation.htm (accessed on 9 January 2025).

- ESRI Environmental Research Systems Institute. Types of Network Analysis Layers—ArcMap|Documentation. 2024. Available online: https://desktop.arcgis.com/en/arcmap/latest/extensions/network-analyst/types-of-network-analyses.htm (accessed on 12 September 2024).

- Schnorf, V.; Trutnevyte, E.; Bowman, G.; Burg, V. Biomass transport for energy: Cost, energy and CO2 performance of forest wood and manure transport chains in Switzerland. J. Clean. Prod. 2021, 293, 125971. [Google Scholar] [CrossRef]

- Ashik-Ur-Rahman, M.D.; Waheduzzaman, M.D.; Waresul Hassan Nipun, M. Optimized municipal solid waste transportation with landfill requirement in a coastal city of Bangladesh. Environ. Qual. Mgmt. 2022, 31, 197–210. [Google Scholar] [CrossRef]

- Hasan, S. Problems of municipal waste management in Bangladesh: An inquiry into its nature. Habitat Int. 1998, 22, 191–202. [Google Scholar] [CrossRef]

- District Statistics. BBS. Bangladesh Bureau of Statistics. Government of the People’s Republic of Bangladesh. 2019. Available online: https://bbs.gov.bd/site/page/2888a55d-d686-4736-bad0-54b70462afda/District-Statistics (accessed on 12 September 2024).

- Rezapoor, P.; Rahimpour, M.R. Animal Waste to Energy, Technologies, Economics, and Challenges. In Encyclopedia of Renewable Energy, Sustainability and the Environment; Elsevier: Amsterdam, The Netherlands, 2024; pp. 61–70. Available online: https://linkinghub.elsevier.com/retrieve/pii/B9780323939409001481 (accessed on 27 June 2025).

- Dong, H.; Yang, M.; Hu, X.; Cui, C.; Liu, W. Biogas and nutrient recovery potential: A spatially explicit analysis of China’s county-level livestock and poultry manure. Waste Manag. 2025, 204, 114906. [Google Scholar] [CrossRef]

- Economic Review Finance Division, Ministry of Finance. 2024. Available online: https://mof.portal.gov.bd/site/page/28ba57f5-59ff-4426-970a-bf014242179e/Bangladesh-Economic-Review (accessed on 2 May 2024).

- Huque, K.; Khan, M. Socio-geographic distribution of livestock and poultry in Bangladesh-A review. Bang. J. Anim. Sci. 2017, 46, 65–81. [Google Scholar] [CrossRef]

- Islam, K.N.; Sarker, T.; Taghizadeh-Hesary, F.; Atri, A.C.; Alam, M.S. Renewable energy generation from livestock waste for a sustainable circular economy in Bangladesh. Renew. Sustain. Energy Rev. 2021, 139, 110695. [Google Scholar] [CrossRef]

- Siddiki, S.K.Y.A.; Uddin, M.N.; Mofijur, M.; Fattah, I.M.R.; Ong, H.C.; Lam, S.S.; Kumar, P.S.; Ahmed, S.F. Theoretical calculation of biogas production and greenhouse gas emission reduction potential of livestock, poultry and slaughterhouse waste in Bangladesh. J. Environ. Chem. Eng. 2021, 9, 105204. [Google Scholar] [CrossRef]

- Nehra, M.; Jain, S. Estimation of renewable biogas energy potential from livestock manure: A case study of India. Bioresour. Technol. Rep. 2023, 22, 101432. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Hossain, N.; Ahmed, A.; Hossen, M.S.; Chowdhury, P.; Thirugnanasambandam, M.; Saidur, R. Latest advancements on livestock waste management and biogas production: Bangladesh’s perspective. J. Clean. Prod. 2020, 272, 122818. [Google Scholar] [CrossRef]

- DLS. Livestock Economy at a Glance; Department of Livestock Services: Dhaka, Bangladesh, 2024. Available online: http://dls.portal.gov.bd/sites/default/files/files/dls.portal.gov.bd/page/ee5f4621_fa3a_40ac_8bd9_898fb8ee4700/2023-07-23-12-04-afbcccb96f8b27d4bab6501aa8c2c2ff.pdf (accessed on 20 April 2025).

- MoEFCC. Second National Communication of Bangladesh to the United Nations Framework on Convention on Climate Change; Ministry of Environment and Forest: Dhaka, Bangladesh, 2012.

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Afazeli, H.; Jafari, A.; Rafiee, S.; Nosrati, M. An investigation of biogas production potential from livestock and slaughterhouse wastes. Renew. Sustain. Energy Rev. 2014, 34, 380–386. [Google Scholar] [CrossRef]

- Avcioğlu, A.O.; Türker, U. Status and potential of biogas energy from animal wastes in Turkey. Renew. Sustain. Energy Rev. 2012, 16, 1557–1561. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources. In Biogas from Waste and Renewable Resources; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 85–95. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9783527632794.ch8 (accessed on 24 May 2024).

- Benito, M.; Ortiz, I.; Rodríguez, L.; Muñoz, G. Ni–Co bimetallic catalyst for hydrogen production in sewage treatment plants: Biogas reforming and tars removal. Int. J. Hydrogen Energy 2015, 40, 14456–14468. [Google Scholar] [CrossRef]

- Garcia, A.P. Techno-Economic Feasibility Study of a Small-Scale Biogas Plant for Treating Market Waste in the City of El Alto, KTH School of Industrial Engineering and Management Energy Technology EGI-2014-083MSC Division of Energy and Climate SE-100 44 STOCKHOLM, 2014. Available online: http://kth.diva-portal.org/smash/get/diva2:741758/FULLTEXT01.pdf (accessed on 26 December 2024).

- Ioannou-Ttofa, L.; Foteinis, S.; Seifelnasr Moustafa, A.; Abdelsalam, E.; Samer, M.; Fatta-Kassinos, D. Life cycle assessment of household biogas production in Egypt: Influence of digester volume, biogas leakages, and digestate valorization as biofertilizer. J. Clean. Prod. 2021, 286, 125468. [Google Scholar] [CrossRef]

- Alfa, M.I.; Adie, D.B.; Igboro, S.B.; Oranusi, U.S.; Dahunsi, S.O.; Akali, D.M. Assessment of biofertilizer quality and health implications of anaerobic digestion effluent of cow dung and chicken droppings. Renew. Energy 2014, 63, 681–686. [Google Scholar] [CrossRef]

- Slepetiene, A.; Volungevicius, J.; Jurgutis, L.; Liaudanskiene, I.; Amaleviciute-Volunge, K.; Slepetys, J.; Ceseviciene, J. The potential of digestate as a biofertilizer in eroded soils of Lithuania. Waste Manag. 2020, 102, 441–451. [Google Scholar] [CrossRef] [PubMed]

- Ngumah, C.; Ogbulie, J.; Orji, J.; Amadi, E. Potential of Organic Waste for Biogas and Biofertilizer Production in Nigeria. Environ. Res. Eng. Manag. 2013, 63, 60–66. [Google Scholar] [CrossRef]

- Ezemagu, I.G.; Ejimofor, M.I.; Menkiti, M.C.; Diyoke, C. Biofertilizer production via composting of digestate obtained from anaerobic digestion of post biocoagulation sludge blended with saw dust: Physiochemical characterization and kinetic study. Environ. Chall. 2021, 5, 100288. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- Kaygusuz, K. Renewable and sustainable energy use in Turkey: A review. Renew. Sustain. Energy Rev. 2002, 6, 339–366. [Google Scholar] [CrossRef]

- Viswanathan, B. Chapter 3—Natural Gas. In Energy Sources; Viswanathan, B., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–79. Available online: https://www.sciencedirect.com/science/article/pii/B9780444563538000034 (accessed on 30 May 2024).

- Lebel, E.D.; Finnegan, C.J.; Ouyang, Z.; Jackson, R.B. Methane and NOx Emissions from Natural Gas Stoves, Cooktops, and Ovens in Residential Homes. Environ. Sci. Technol. 2022, 56, 2529–2539. [Google Scholar] [CrossRef]

- Nasir, I.M.; Mohd Ghazi, T.I.; Omar, R. Anaerobic digestion technology in livestock manure treatment for biogas production: A review. Eng. Life Sci. 2012, 12, 258–269. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Kheirrouz, M.; Asl, H.F.; Yousefi, H.; Hajinezhad, A. Biogas production potential from livestock manure in Iran. Renew. Sustain. Energy Rev. 2015, 50, 748–754. [Google Scholar] [CrossRef]

- Saha, C.K.; Nandi, R.; Akter, S.; Hossain, S.; Kabir, K.B.; Kirtania, K.; Islam, M.T.; Guidugli, L.; Reza, M.T.; Alam, M.M. Technical prospects and challenges of anaerobic co-digestion in Bangladesh: A review. Renew. Sustain. Energy Rev. 2024, 197, 114412. [Google Scholar] [CrossRef]

- Akash, F.A.; Shovon, S.M.; Rahman, W.; Rahman, M.A.; Chakraborty, P.; Monir, M.U. Greening the grid: A comprehensive review of renewable energy in Bangladesh. Heliyon 2024, 10, e27477. [Google Scholar] [CrossRef] [PubMed]

- Abdullah-Al-Mahbub, M.D.; Islam, A.R.M.T. Current status of running renewable energy in Bangladesh and future prospect: A global comparison. Heliyon 2023, 9, e14308. [Google Scholar] [CrossRef] [PubMed]

- IEA. CO2 Emissions From Fuel Combustion Highlights 2013; International Energy Agency: Paris, France, 2013; p. 112. [Google Scholar]

- Benefits of a Biogas Plant. In Biogas from Waste and Renewable Resources; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 353–356. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9783527632794.ch34 (accessed on 24 May 2024).

- Halder, P.K.; Paul, N.; Joardder, M.U.H.; Khan, M.Z.H.; Sarker, M. Feasibility analysis of implementing anaerobic digestion as a potential energy source in Bangladesh. Renew. Sustain. Energy Rev. 2016, 65, 124–134. [Google Scholar] [CrossRef]

- FAO. FAOSTAT. Food and Agriculture Organization of the United Nations. 2024. Available online: https://www.fao.org/faostat/en/#data/EK (accessed on 23 April 2024).

| Scenarios | Livestock Groups | Livestock Types |

|---|---|---|

| Scenario-1 | Large-animal | Cattle, Buffalo |

| Scenario-2 | Small-animal | Sheep, Goat |

| Scenario-3 | Poultry | Chicken, Duck |

| Livestock Groups | Livestock Types | Average Body Weight (kg/Head) | Manure Generation Based on Body Size (%) | Manure Generation Rate (kg/Head/Day) | Collection Efficiency (%) |

|---|---|---|---|---|---|

| Large Animal | Cattle, Buffalo | 210 | 9 | 19 | 50 |

| Small Animal | Sheep, Goat | 20 | 4 | 0.8 | 13 |

| Poultry | Chicken, Duck | 1.5 | 3 | 0.045 | 90 |

| Scenarios | Clusters (From Cluster Analysis) | Available Manure Kiloton/Year | Biogas Potential: Million m3/Year | Electricity Potential GWh/Year | Biofertilizer Kiloton/Year |

|---|---|---|---|---|---|

| Scenario-1 | Cluster A | 11,189.89 | 1522.69 | 2284.04 | 1403.29 |

| Cluster B | 6244.70 | 849.77 | 1274.64 | 783.13 | |

| Cluster C | 93,73.43 | 1275.52 | 1913.27 | 1175.49 | |

| Cluster D | 7249.91 | 986.55 | 1479.82 | 909.19 | |

| Cluster E | 6656.34 | 905.77 | 1358.66 | 834.75 | |

| Cluster F | 926.43 | 126.06 | 189.09 | 116.18 | |

| Scenario-2 | Cluster A | 150.73 | 13.67 | 20.511 | 18.90 |

| Cluster B | 228.29 | 20.71 | 31.06 | 28.63 | |

| Cluster C | 222.57 | 20.19 | 30.28 | 27.91 | |

| Scenario-3 | Cluster A | 469.01 | 98.71 | 148.06 | 58.82 |

| Cluster B | 234.27 | 49.31 | 73.96 | 29.38 | |

| Cluster C | 173.35 | 36.48 | 54.74 | 21.74 | |

| Cluster D | 666.64 | 140.31 | 210.46 | 83.60 | |

| total | 43,785.57 | 6045.76 | 9068.64 | 5491.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahal, Z.; Yabar, H. Spatial Optimization of Bioenergy Production by Introducing a Cooperative Manure Management System in Bangladesh. Resources 2025, 14, 111. https://doi.org/10.3390/resources14070111

Mahal Z, Yabar H. Spatial Optimization of Bioenergy Production by Introducing a Cooperative Manure Management System in Bangladesh. Resources. 2025; 14(7):111. https://doi.org/10.3390/resources14070111

Chicago/Turabian StyleMahal, Zinat, and Helmut Yabar. 2025. "Spatial Optimization of Bioenergy Production by Introducing a Cooperative Manure Management System in Bangladesh" Resources 14, no. 7: 111. https://doi.org/10.3390/resources14070111

APA StyleMahal, Z., & Yabar, H. (2025). Spatial Optimization of Bioenergy Production by Introducing a Cooperative Manure Management System in Bangladesh. Resources, 14(7), 111. https://doi.org/10.3390/resources14070111