Aquafaba and Cinnamon Essential Oil for the Production of Biodegradable and Compostable Wine Vineyard Waste-Based Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Obtaining Aquafaba (Aq)

2.3. Biomaterial Preparation

2.4. Experimental Design and Formulation

2.5. Physicochemical Characterization of the Material

2.5.1. Chemical Composition

2.5.2. Water Absorption Capacity

2.5.3. Mechanical Properties and Morphology

2.6. Biodegradability

2.7. Microbiological Analysis

2.8. Statistic Analysis

3. Results

3.1. Characterization of Mechanical and Physicochemical Properties of the Biomaterial

3.2. Biomaterial Morphology and Microstructure

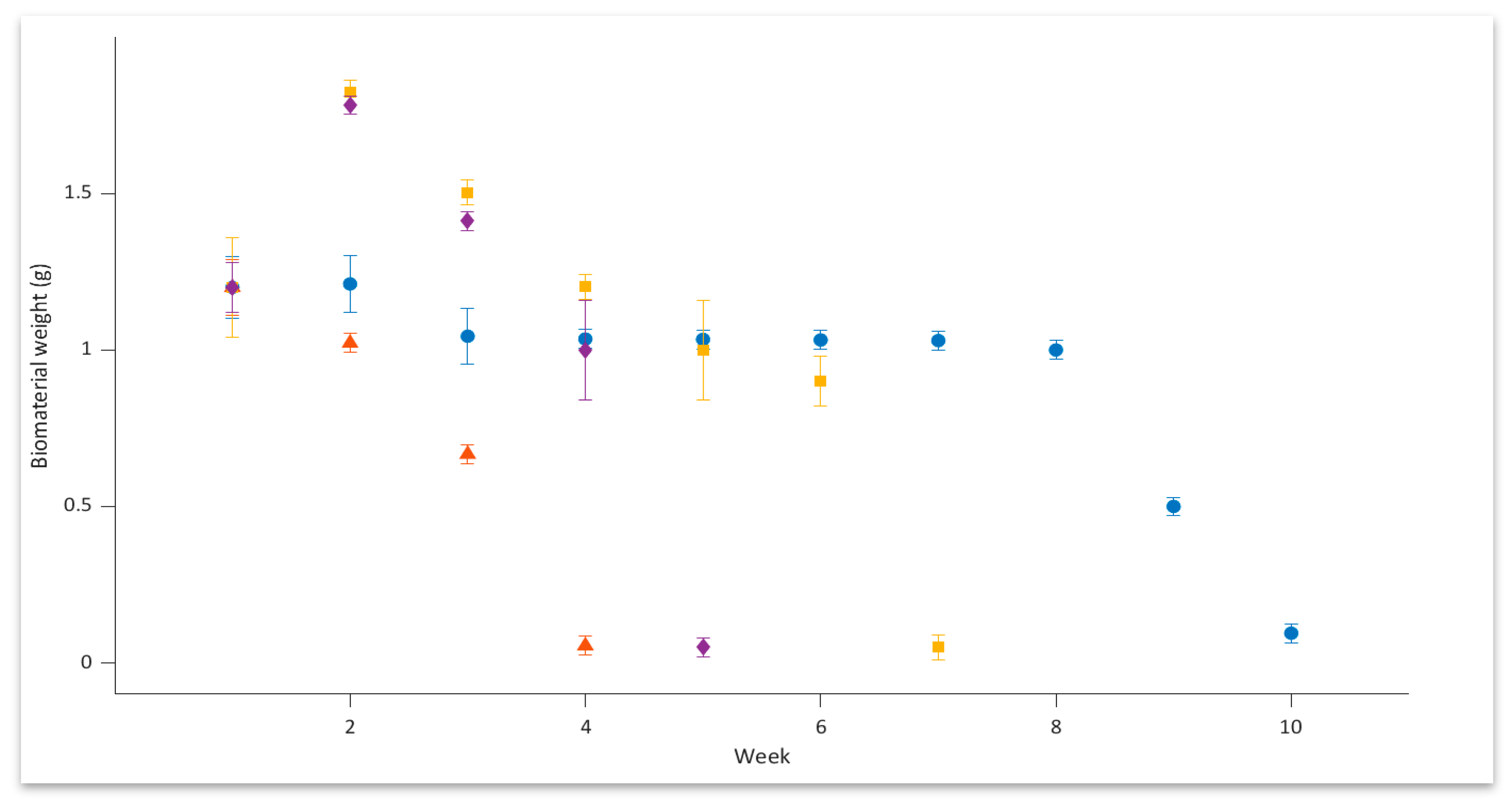

3.3. Biodegradability

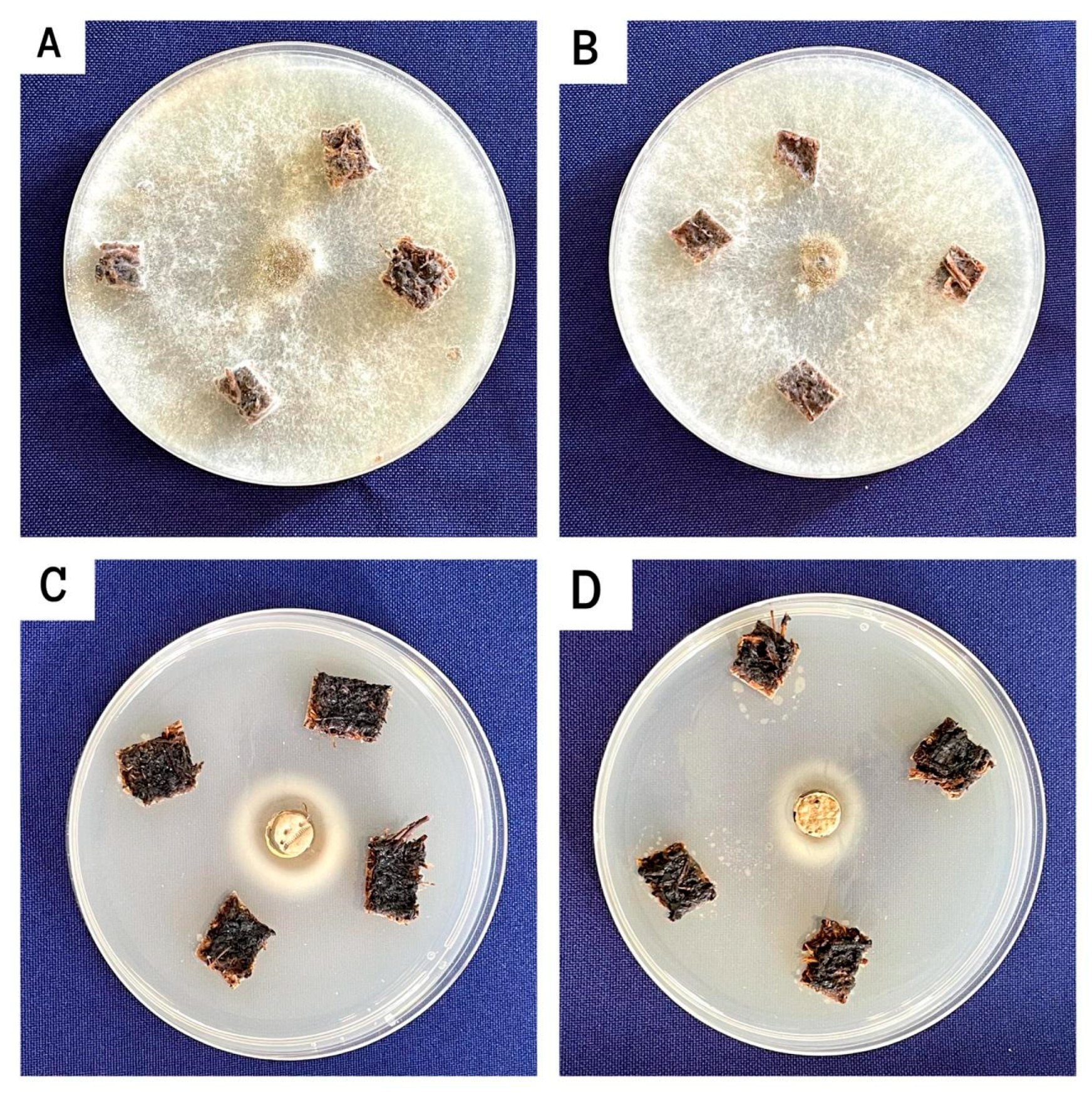

3.4. Microbiological Analysis

4. Discussion

4.1. Characterization of Mechanical and Physicochemical Properties of the Biocomposite Material

4.2. Biomaterial Morphology and Microstructure

4.3. Biodegradability

4.4. Microbiological Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vazquez, A.; Valdemar, R.M.E.; Villavicencio, M.B.; Pérez, M.V. Reciclaje de plásticos; Universidad Autónoma de México: Mexico City, Mexico, 2016. [Google Scholar]

- Bueno, D.; Brienzo, M. Production of Bioplastics with Chemical and Enzymatic Modificated Xylan (Lignin- and Arabinose-Free) from Sugarcane Bagasse. Biotechnol. Sustain. Mater. 2025, 2, 2. [Google Scholar] [CrossRef]

- Soni, P. Comparison between Corn and Potato Starch-Based Bioplastic: Thermal Variation. J. Mater. Sci. Appl. Eng. 2023, 2, 1–4. [Google Scholar]

- Molla, A.; Haque, J.; Moyeen, A.A.; Mahmud, R.M. Plant Fiber-Reinforced Green Composite: A review on surface modification, properties, fabrications and applications. Mater. Open Res. 2024, 3, 6. [Google Scholar] [CrossRef]

- Almeida, V.H.M.; Jesus, R.M.; Santana, G.M.; Pereira, T.B. Polylactic Acid Polymer Matrix (Pla) Biocomposites with Plant Fibers for Manufacturing 3D Printing Filaments: A Review. J. Compos. Sci. 2024, 8, 67. [Google Scholar] [CrossRef]

- Zidi, S.; Miraoui, I. Mechanical and Morphological Analysis of Cellulose Extracted from Sisal Fibers and Their Effect on Bio-Based Composites Mechanical Properties. Funct. Compos. Struct. 2024, 6, 015008. [Google Scholar] [CrossRef]

- Patil, S.P.; Baikar, P.; Tayade, R.R.; Patil, S.P.; Baikar, P.; Tayade, R.R. Surface Modification of Nano Cellulose: The Path to Advanced Uses of Smart and Sustainable Bio-Material. GSC Adv. Res. Rev. 2023, 17, 127–137. [Google Scholar] [CrossRef]

- Hasanin, M.S. Cellulose-Based Biomaterials: Chemistry and Biomedical Applications. Starch-Stärke 2022, 74, 2200060. [Google Scholar] [CrossRef]

- Salgado, P.R.; Schmidt, V.C.; Molina Ortiz, S.E.; Mauri, A.N.; Laurindo, J.B. Biodegradable Foams Based on Cassava Starch, Sunflower Proteins and Cellulose Fibers Obtained by a Baking Process. J. Food Eng. 2008, 85, 435–443. [Google Scholar] [CrossRef]

- Engel, J.B.; Ambrosi, A.; Tessaro, I.C. Development of Biodegradable Starch-Based Foams Incorporated with Grape Stalks for Food Packaging. Carbohydr. Polym. 2019, 225, 115234. [Google Scholar] [CrossRef]

- Motloung, M.P.; Ojijo, V.; Bandyopadhyay, J.; Ray, S.S. Cellulose Nanostructure-Based Biodegradable Nanocomposite Foams: A Brief Overview on the Recent Advancements and Perspectives. Polymers 2019, 11, 1270. [Google Scholar] [CrossRef]

- Obradovic, J.; Voutilainen, M.; Virtanen, P.; Lassila, L.; Fardim, P. Cellulose Fibre-Reinforced Biofoam for Structural Applications. Materials 2017, 10, 619. [Google Scholar] [CrossRef] [PubMed]

- Cabezas, N.T.M.; Santos, D.K.C. Estudio Comparativo de Propiedades Funcionales y Fisicoquímicas de Aquafaba de Distintas Leguminosas. AlfaPublicaciones 2022, 4, 35–50. [Google Scholar] [CrossRef]

- Erem, E.; Icyer, N.C.; Tatlisu, N.B.; Kilicli, M.; Kaderoglu, G.H.; Toker, Ö.S. A New Trend among Plant-Based Food Ingredients in Food Processing Technology: Aquafaba. Crit. Rev. Food Sci. Nutr. 2023, 63, 4467–4484. [Google Scholar] [CrossRef] [PubMed]

- Thomas-Meda, A.; Vela-Gutiérrez, G.; Tavano, O.L.; Tacias-Pascacio, V.G. Effect of Processing Conditions on the Functional Properties of Aquafaba from Natural Chickpeas: Valorization of a Food Waste. Biotecnia 2023, 25, 23–29. [Google Scholar]

- Ruvalcaba, U. Mejoramiento de Las Características Bromatológicas (Proteína) del Aquafaba en SESAJAL; Universidad Jesuita de Guadalajara: Tlaquepaque, Mexico, 2022. [Google Scholar]

- Andrieux, S.; Medina, L.; Herbst, M.; Berglund, L.A.; Stubenrauch, C. Monodisperse Highly Ordered Chitosan/Cellulose Nanocomposite Foams. Compos. Part Appl. Sci. Manuf. 2019, 125, 105516. [Google Scholar] [CrossRef]

- Hassan, M.M.; Tucker, N.; Le Guen, M.J. Thermal, Mechanical and Viscoelastic Properties of Citric Acid-Crosslinked Starch/Cellulose Composite Foams. Carbohydr. Polym. 2020, 230, 115675. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Huang, J.; Lin, N.; Ahmad, I.; Mariano, M.; Dufresne, A.; Thomas, S.; Gałęski, A. Recent Developments in Nanocellulose-Based Biodegradable Polymers, Thermoplastic Polymers, and Porous Nanocomposites. Prog. Polym. Sci. 2018, 87, 197–227. [Google Scholar] [CrossRef]

- Spigno, G.; Pizzorno, T.; De Faveri, D.M. Cellulose and Hemicelluloses Recovery from Grape Stalks. Bioresour. Technol. 2008, 99, 4329–4337. [Google Scholar] [CrossRef]

- Cruz-Tirado, J.P.; Barros Ferreira, R.S.; Lizárraga, E.; Tapia-Blácido, D.R.; Silva, N.C.C.; Angelats-Silva, L.; Siche, R. Bioactive Andean Sweet Potato Starch-Based Foam Incorporated with Oregano or Thyme Essential Oil. Food Packag. Shelf Life 2020, 23, 100457. [Google Scholar] [CrossRef]

- Debiagi, F.; Kobayashi, R.K.T.; Nakazato, G.; Panagio, L.A.; Mali, S. Biodegradable Active Packaging Based on Cassava Bagasse, Polyvinyl Alcohol and Essential Oils. Ind. Crops Prod. 2014, 52, 664–670. [Google Scholar] [CrossRef]

- Ago, M.; Ferrer, A.; Rojas, O.J. Starch-Based Biofoams Reinforced with Lignocellulose Nanofibrils from Residual Palm Empty Fruit Bunches: Water Sorption and Mechanical Strength. ACS Sustain. Chem. Eng. 2016, 4, 5546–5552. [Google Scholar] [CrossRef]

- Blomfeldt, T.O.J.; Olsson, R.T.; Menon, M.; Plackett, D.; Johansson, E.; Hedenqvist, M.S. Novel Foams Based on Freeze-Dried Renewable Vital Wheat Gluten. Macromol. Mater. Eng. 2010, 295, 796–801. [Google Scholar] [CrossRef]

- Meurer, M.C.; De Souza, D.; Ferreira Marczak, L.D. Effects of Ultrasound on Technological Properties of Chickpea Cooking Water (Aquafaba). J. Food Eng. 2020, 265, 109688. [Google Scholar] [CrossRef]

- Maurya, A.; Prasad, J.; Das, S.; Dwivedy, A.K. Essential Oils and Their Application in Food Safety. Front. Sustain. Food Syst. 2021, 5. [Google Scholar] [CrossRef]

- Cabanillas, A.; Nuñez, J.; Cruz-Tirado, J.; Vejarano, R.; Tapia-Blácido, D.R.; Arteaga, H.; Siche, R. Pineapple Shell Fiber as Reinforcement in Cassava Starch Foam Trays. Polym. Polym. Compos. 2019, 27, 496–506. [Google Scholar] [CrossRef]

- Matsuda, D.K.M.; Verceheze, A.E.S.; Carvalho, G.M.; Yamashita, F.; Mali, S. Baked Foams of Cassava Starch and Organically Modified Nanoclays. Ind. Crops Prod. 2013, 44, 705–711. [Google Scholar] [CrossRef]

- Pelissari, F.M.; Grossmann, M.V.E.; Yamashita, F.; Pineda, E.A.G. Antimicrobial, Mechanical, and Barrier Properties of Cassava Starch−Chitosan Films Incorporated with Oregano Essential Oil. J. Agric. Food Chem. 2009, 57, 7499–7504. [Google Scholar] [CrossRef]

- The Jamovi Project. Jamovi (Version 2.4) [Computer Software]. 2023. Available online: https://www.jamovi.org (accessed on 20 April 2025).

- Iseppi, R.; Truzzi, E.; Sabia, C.; Messi, P. Efficacy and Synergistic Potential of Cinnamon (Cinnamomum zeylanicum) and Clove (Syzygium Aromaticum L. Merr. & Perry) Essential Oils to Control Food-Borne Pathogens in Fresh-Cut Fruits. Antibiotics 2024, 13, 319. [Google Scholar] [CrossRef]

- He, Y.; Meda, V.; Reaney, M.J.T.; Mustafa, R. Aquafaba, a New Plant-Based Rheological Additive for Food Applications. Trends Food Sci. Technol. 2021, 111, 27–42. [Google Scholar] [CrossRef]

- Crawford, K.; Tyl, C.; Kerr, W. Evaluation of Processing Conditions and Hydrocolloid Addition on Functional Properties of Aquafaba. Foods 2023, 12, 775. [Google Scholar] [CrossRef]

- Sanhawong, W.; Banhalee, P.; Boonsang, S.; Kaewpirom, S. Effect of Concentrated Natural Rubber Latex on the Properties and Degradation Behavior of Cotton-Fiber-Reinforced Cassava Starch Biofoam. Ind. Crops Prod. 2017, 108, 756–766. [Google Scholar] [CrossRef]

- Nabar, Y.; Raquez, J.M.; Dubois, P.; Narayan, R. Production of Starch Foams by Twin-Screw Extrusion: Effect of Maleated Poly(Butylene Adipate-Co-Terephthalate) as a Compatibilizer. Biomacromolecules 2005, 6, 807–817. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, S.M.H.; Razavi, S.; Mousavi, M. Antimicrobial, Physical and Mechanical Properties of Chitosan-Based Films Incorporated with Thyme, Clove and Cinnamon Essential Oils. J. Food Process. Preserv. 2009, 33, 727–743. [Google Scholar] [CrossRef]

- Chiellini, E.; Cinelli, P.; Ilieva, V.I.; Imam, S.H.; Lawton, J.W. Environmentally Compatible Foamed Articles Based on Potato Starch, Corn Fiber, and Poly(Vinyl Alcohol). J. Cell. Plast. 2009, 45, 17–32. [Google Scholar] [CrossRef]

- Benavides, S.; Villalobos-Carvajal, R.; Reyes, J.E. Physical, Mechanical and Antibacterial Properties of Alginate Film: Effect of the Crosslinking Degree and Oregano Essential Oil Concentration. J. Food Eng. 2012, 110, 232–239. [Google Scholar] [CrossRef]

- Caiza, J.C.; Vargas, D.; Olmedo, C.; Arboleda, M.; Boada, L.; Acurio, O.; Arroyo, C.; Debut, A.; Segovia-Salcedo, M. Morfometría y Morfología de Estomas y de Polen Como Indicadores Indirectos de Poliploidía En Especies Del Género Polylepis (Rosaceae) En Ecuador. Ecol. Austral 2018, 28, 175–187. [Google Scholar] [CrossRef]

- Tapia-Blácido, D.; Mauri, A.N.; Menegalli, F.C.; Sobral, P.J.A.; Añón, M.C. Contribution of the Starch, Protein, and Lipid Fractions to the Physical, Thermal, and Structural Properties of Amaranth (Amaranthus Caudatus) Flour Films. J. Food Sci. 2007, 72, E293–E300. [Google Scholar] [CrossRef]

- Versino, F.; López, O.V.; García, M.A. Sunflower Oil Industry By-Product as Natural Filler of Biocomposite Foams for Packaging Applications. J. Polym. Environ. 2021, 29, 1869–1879. [Google Scholar] [CrossRef]

- Torres, L.C. Efecto sinérgico del aceite esencial de Origanum vulgare a la Gentamicina en cultivos de Escherichia coli. C. Cienc. E Investig. Médica Estud. Latinoam. 2008, 13, 45–48. [Google Scholar]

- Gómez-Heincke, D.; Martínez, I.; Partal, P.; Guerrero, A.; Gallegos, C. Development of Antimicrobial Active Packaging Materials Based on Gluten Proteins. J. Sci. Food Agric. 2016, 96, 3432–3438. [Google Scholar] [CrossRef]

- Guaña Escobar, F.; Vaca Tenorio, M.; Aguilar, J. Biopelículas y envases activos, nuevas tecnologías en la industria alimentaria. FACSalud UNEMI 2022, 6, 18–32. [Google Scholar] [CrossRef]

- Gheorghita, R.; Filip, R.; Lobiuc, A. Novel Materials with Microencapsulated Essential Oils. Potential Applications for Skin Cellular Regeneration Dressings. Int. Multidiscip. Sci. GeoConference SGEM 2023, 23, 483–489. [Google Scholar]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of Bioplastics in Natural Environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef] [PubMed]

- Thakur, R.; Pristijono, P.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Starch-Based Films: Major Factors Affecting Their Properties. Int. J. Biol. Macromol. 2019, 132, 1079–1089. [Google Scholar] [CrossRef]

- Abdelatti, M.A.I.; Abd El-Aziz, N.K.; El-Naenaeey, E.-S.Y.M.; Ammar, A.M.; Alharbi, N.K.; Alharthi, A.; Zakai, S.A.; Abdelkhalek, A. Antibacterial and Anti-Efflux Activities of Cinnamon Essential Oil against Pan and Extensive Drug-Resistant Pseudomonas Aeruginosa Isolated from Human and Animal Sources. Antibiotics 2023, 12, 1514. [Google Scholar] [CrossRef]

- Bajić, M.; Oberlintner, A.; Kõrge, K.; Likozar, B.; Novak, U. Formulation of Active Food Packaging by Design: Linking Composition of the Film-Forming Solution to Properties of the Chitosan-Based Film by Response Surface Methodology (RSM) Modelling. Int. J. Biol. Macromol. 2020, 160, 971–978. [Google Scholar] [CrossRef]

- Atarés, L.; Chiralt, A. Essential Oils as Additives in Biodegradable Films and Coatings for Active Food Packaging. Trends Food Sci. Technol. 2016, 48, 51–62. [Google Scholar] [CrossRef]

- Stasiak, J.; Stasiak, D.M.; Libera, J. The Potential of Aquafaba as a Structure-Shaping Additive in Plant-Derived Food Technology. Appl. Sci. 2023, 13, 4122. [Google Scholar] [CrossRef]

- Intikhab, A. Aquafaba: Nutritional Significance for Vegans. A Way towards Environmental Sustainability. Life Sci. 2023, 4, 7. [Google Scholar] [CrossRef]

- Röhl, V.; van Noordenne-Bos, C.; Wieland, H.; Graupner, N.; Rottmann-Meyer, M.L.; Müssig, J. Effect of Different Natural Fibers on Mechanical and Disintegration Properties of Compostable Biobased Plastics. J. Nat. Fibers 2023, 20, 2248383. [Google Scholar] [CrossRef]

- Fayyazbakhsh, A.; Koutný, M.; Kalendová, A.; Šašinková, D.; Julinová, M.; Kadlečková, M. Selected Simple Natural Antimicrobial Terpenoids as Additives to Control Biodegradation of Polyhydroxy Butyrate. Int. J. Mol. Sci. 2022, 23, 14079. [Google Scholar] [CrossRef]

- Devi, N.; Sarmah, M.; Khatun, B.; Maji, T.K. Encapsulation of Active Ingredients in Polysaccharide–Protein Complex Coacervates. Adv. Colloid Interface Sci. 2017, 239, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Kumari, S.V.G.; Pakshirajan, K.; Pugazhenthi, G. Facile Fabrication and Characterization of Novel Antimicrobial and Antioxidant Poly (3-Hydroxybutyrate)/Essential Oil Composites for Potential Use in Active Food Packaging Applications. Int. J. Biol. Macromol. 2023, 252, 126566. [Google Scholar] [CrossRef] [PubMed]

- Kumari, S.V.G.; Pakshirajan, K.; Pugazhenthi, G. Development and Characterization of Active Poly (3-Hydroxybutyrate) Based Composites with Grapeseed Oil and MgO Nanoparticles for Shelf-Life Extension of White Button Mushrooms (Agaricus bisporus). Int. J. Biol. Macromol. 2024, 260, 129521. [Google Scholar] [CrossRef]

- Baffoe, E.; Dauer, E.; Ghahremaninezhad, A. Effect of Proteins on Biocementation in Construction Materials. iScience 2024, 27, 108743. [Google Scholar] [CrossRef]

- Rolim, H.M.L.; Ramalho, T.C. Chapter 7 - Biopolymer Essential Oil Nanocomposite for Antimicrobial Packaging. In Biopolymer-Based Nano Films; Rai, M., dos Santos, C.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 115–131. ISBN 978-0-12-823381-8. [Google Scholar]

- Castro, J.I.; Valencia-Llano, C.H.; Valencia Zapata, M.E.; Restrepo, Y.J.; Mina Hernandez, J.H.; Navia-Porras, D.P.; Valencia, Y.; Valencia, C.; Grande-Tovar, C.D. Chitosan/Polyvinyl Alcohol/Tea Tree Essential Oil Composite Films for Biomedical Applications. Polymers 2021, 13, 3753. [Google Scholar] [CrossRef] [PubMed]

- Hernández-López, M.; Correa-Pacheco, Z.N.; Bautista-Baños, S.; Zavaleta-Avejar, L.; Benítez-Jiménez, J.J.; Sabino-Gutiérrez, M.A.; Ortega-Gudiño, P. Bio-Based Composite Fibers from Pine Essential Oil and PLA/PBAT Polymer Blend. Morphological, Physicochemical, Thermal and Mechanical Characterization. Mater. Chem. Phys. 2019, 234, 345–353. [Google Scholar] [CrossRef]

- Callisaya, A.C.; Mendoza, G.J.C. Extracción de almidón de papa (Solanum tuberosum), yuca (Manihot esculenta), camote (Ipomoea batatas). Rev. Estud. AGRO-VET Univ. Mayor San Andrés 2022, 6, 22. [Google Scholar]

- Bayona Buitrago, C.A.; Cepeda, M.F.; León Castrillo, L.C. Aprovechamiento de los subproductos agroindustriales de la cadena productiva de la yuca (manihot esculenta): Una revisión. Rev. Limentech Cienc. Tecnol. Aliment. 2022, 20, 92–110. [Google Scholar] [CrossRef]

- de Oliveira, G.L.; Verdenelli, R.A.; Dominchin, M.F.; Zygadlo, J.A.; Meriles, J.M. Impacto de los aceites escenciales y monoterpenos sobre la nitrificación y las comunidades microbianas edáficas. Cienc. Suelo 2018, 36. [Google Scholar]

- Mustafa, R.; He, Y.; Shim, Y.Y.; Reaney, M.J.T. Aquafaba, Wastewater from Chickpea Canning, Functions as an Egg Replacer in Sponge Cake. Int. J. Food Sci. Technol. 2018, 53, 2247–2255. [Google Scholar] [CrossRef]

- Yazici, G.N.; Taspinar, T.; Ozer, M.S. Aquafaba: A Multifunctional Ingredient in Food Production. Biol. Life Sci. Forum 2022, 18, 24. [Google Scholar] [CrossRef]

- Fogašová, M.; Figalla, S.; Danišová, L.; Medlenová, E.; Hlaváčiková, S.; Vanovčanová, Z.; Omaníková, L.; Baco, A.; Horváth, V.; Mikolajová, M.; et al. PLA/PHB-Based Materials Fully Biodegradable under Both Industrial and Home-Composting Conditions. Polymers 2022, 14, 4113. [Google Scholar] [CrossRef] [PubMed]

- Cano, C.; Bonilla, P.; Roque, M.; Ruiz, J. Actividad Antimicótica in Vitro y Metabolitos Del Aceite Esencial de Las Hojas de Minthostachys Mollis (Muña). Rev. Peru. Med. Exp. Salud Publica 2008, 25, 298–301. [Google Scholar]

- Mares Jiménez, A.C.; Prado Rebolledo, O.F.; Hernandez Rivera, J.A.; Mendoza Muñoz, N.; García Casillas, A. Aceites esenciales y sus constituyentes para hacer frente a las bacterias patógenas. Abanico Vet. 2024, 15, 14. [Google Scholar]

- Sanla-Ead, N.; Jangchud, A.; Chonhenchob, V.; Suppakul, P. Antimicrobial Activity of Cinnamaldehyde and Eugenol and Their Activity after Incorporation into Cellulose-Based Packaging Films. Packag. Technol. Sci. 2012, 25, 7–17. [Google Scholar] [CrossRef]

- Martínez, A.; Manrique-Moreno, M.; Klaiss-Luna, M.C.; Stashenko, E.; Zafra, G.; Ortiz, C. Effect of Essential Oils on Growth Inhibition, Biofilm Formation and Membrane Integrity of Escherichia Coli and Staphylococcus Aureus. Antibiotics 2021, 10, 1474. [Google Scholar] [CrossRef]

- Gomes, D.S.; da Costa, A.; Pereira, A.M.; Casal, M.; Machado, R. Biocomposites of Silk-Elastin and Essential Oil from Mentha Piperita Display Antibacterial Activity. ACS Omega 2022, 7, 6568–6578. [Google Scholar] [CrossRef]

| Formulation | Water (mL) | Aq (mL) | CEO (% p/p) | Starch (g) | Guar Gum (g) | Glycerol (mL) | Mg Stearate (g) | Grape Stalk (g) |

|---|---|---|---|---|---|---|---|---|

| Aq-CEO-7.5% | 0 | 100 | 7.5 | 35 | 1 | 10 | 0.4 | 20 |

| Aq-CEO-0% | 0 | 100 | 0 | 35 | 1 | 10 | 0.4 | 20 |

| W-CEO-7.5% | 100 | 0 | 7.5 | 35 | 1 | 10 | 0.4 | 20 |

| W-CEO-0% | 100 | 0 | 0 | 35 | 1 | 10 | 0.4 | 20 |

| Grape Stalk | Aquafaba | Aq-CEO | W-CEO | |

|---|---|---|---|---|

| Protein (%) | 3.82 ± 0.04 | 20.99 ± 0.11 | 1.03 ± 0.01 a | 1.03 ± 0.02 a |

| Lipids (%) | 0.95 ± 0.01 | 8.57 ± 0.05 | 0.74 ± 0.06 a | 0.77 ± 0.01 a |

| Ash (%) | 3.26 ± 0.03 | 1.14 ± 0.03 | 0.69 ± 0.01 a | 0.65 ± 0.04 a |

| Fiber (%) | 54.54 ± 0.03 | 1.77 ± 0.06 | 4.24 ± 0.11 a | 3.58 ± 0.09 b |

| NFE (%) | 26.82 ± 0.02 | 64.61 ± 0.20 | 46.61 ± 0.05 a | 47.1 ± 0.09 b |

| Holocellulose (%) | 43 ± 0.12 | |||

| Alpha Cellulose (%) | 18 ± 0.03 | |||

| Lignin (%) | 19 ± 0.09 | |||

| Hemicellulose (%) | 25 ± 0.14 |

| Formulation | WAC-75%R.H (%) | WAC-98%R.H (%) | Maximum Resistance (N) |

|---|---|---|---|

| W-CEO-7.5% | 5.0 ± 0.625 a | 5.84 ± 0.358 a | 22.1 ± 1.925 a |

| W-CEO-0% | 11.0 ± 0.957 b | 12.5 ± 0.625 b | 10.4 ± 0.182 b |

| Aq-CEO-7.5% | 5.4 ± 1.30 a | 6.04 ± 1.30 a | 44.7 ± 2.493 c |

| Aq-CEO-0% | 10.8 ± 1.30 b | 11.7 ± 1.58 b | 33.7 ± 3.254 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moraga-Bustos, S.; Rivas, Y.; Villalobos, R.; Jarpa-Parra, M. Aquafaba and Cinnamon Essential Oil for the Production of Biodegradable and Compostable Wine Vineyard Waste-Based Material. Resources 2025, 14, 76. https://doi.org/10.3390/resources14050076

Moraga-Bustos S, Rivas Y, Villalobos R, Jarpa-Parra M. Aquafaba and Cinnamon Essential Oil for the Production of Biodegradable and Compostable Wine Vineyard Waste-Based Material. Resources. 2025; 14(5):76. https://doi.org/10.3390/resources14050076

Chicago/Turabian StyleMoraga-Bustos, Sergio, Yessica Rivas, Ricardo Villalobos, and Marcela Jarpa-Parra. 2025. "Aquafaba and Cinnamon Essential Oil for the Production of Biodegradable and Compostable Wine Vineyard Waste-Based Material" Resources 14, no. 5: 76. https://doi.org/10.3390/resources14050076

APA StyleMoraga-Bustos, S., Rivas, Y., Villalobos, R., & Jarpa-Parra, M. (2025). Aquafaba and Cinnamon Essential Oil for the Production of Biodegradable and Compostable Wine Vineyard Waste-Based Material. Resources, 14(5), 76. https://doi.org/10.3390/resources14050076