Abstract

The pursuit of energy security has become one of the most important challenges facing modern societies worldwide. The increase in energy consumption and the need to promote sustainability puts pressure on power generation systems. In this context, renewable energy sources have become a favorable option to improve both energy security and sustainability while promoting the use of domestic energy sources. The supply chain is an optimized methodology that includes all necessary activities to bring a product to the final consumer. Traditionally applied in the manufacturing industry, recent evidence shows its successful implementation in various renewable energy sectors. In this work, a novel methodology based on a supply chain was designed to evaluate the feasibility of mini wind power systems in urban areas in an integrated and measurable manner. The main contribution lies in the integration of several different approaches, currently recognized as the most relevant factors for determining the viability of wind energy projects. A five-link supply chain model was proposed, which includes an evaluation of wind potential, supplier network, project technical assessment, customer distribution, and equipment final disposal. Specific metric indicators for each link were developed to evaluate technical, legislative, and social considerations. The methodology was applied in a case study in the city of Mexicali, Mexico. The findings show that although wind as a resource remains the most important factor, local government policies that promote the use of renewable energy, the supplier’s availability, qualified human resources, and spare parts are also of equivalent significance for the successful implementation of mini wind power systems.

1. Introduction

1.1. Wind Power

The depletion of fossil fuels, coupled with environmental concerns and climate change mitigation strategies, has shifted global attention toward the feasibility and development of clean, reliable energy resources. The growing demand for energy, driven by technological advancements and the growing global population, along with the quest for sustainability, is placing significant pressure on power generation systems. In this context, domestic renewable energy sources have emerged as a favorable option to promote both energy security and sustainability. Among these, wind power stands out as one of the most sustainable energy sources [1].

Factors such as its widespread distribution and availability have driven wind energy to grow worldwide at an annual rate of nearly 20% over the past decade. During this period, countries like China, Germany, and the United States have doubled their installed capacity [2]. Among renewable sources, wind power boasts one of the highest energy densities, even surpassing photovoltaic systems [3]. Additionally, wind energy offers significant environmental benefits regarding land use compared to hydropower and exhibits excellent circularity at the end of its equipment’s lifecycle. Wind power is a mature technology that can be effectively utilized in both large and small-scale generation systems, such as wind farms or domestic installations. When combined with other energy sources, wind power enhances energy security and is a favorable option for countries committed to diversifying their energy generation with renewable sources.

Despite its advantages, wind power faces significant challenges. Wind energy generation schemes are generally complex, multi-component projects that encompass technical, economic, and political elements. While the location of a wind power facility is primarily determined by on-site wind properties, socio-political considerations also play a crucial role in the operation and success of wind power plants. Numerous methodologies have been developed to evaluate the feasibility of wind power projects, all of which include the forecasting of meteorological aspects, such as wind characteristics, speed, and seasonality [4,5,6,7,8].

Some models prioritize economic aspects, considering the initial investment, electricity prices, and the uncertainty in wind resource availability as key determinants of the economic success of power projects [9,10,11,12,13]. Other models emphasize the importance of incorporating social and political implications for the successful implementation of wind power generation projects [14,15,16,17,18]. In urban areas, there is a growing interest in evaluating the potential for wind power generation as a measure to promote energy security and sustainability. Favorable estimates that help reduce uncertainty have been obtained through models that incorporate Weibull distribution and on-site wind measurements and analysis [19,20,21].

In general, existing methodologies have focused on three main areas: (i) the evaluation of local wind potential, (ii) financial analysis to determine the economic viability of the project, and (iii) medium and long-term political certainty. Nevertheless, other factors, such as local policy frameworks, the availability of qualified manpower, and consistency with energy billing schemes, have demonstrated a strong direct relationship with the success of renewable energy generation investments.

1.2. Supply Chain as a Framework for Urban Wind Power Projects Analysis

The supply chain is a methodology used for the design, planning, and operation of companies, primarily focusing on production processes to achieve financial and operational profitability [22]. In recent decades, adaptations of the supply chain have been proposed in various areas and with different approaches, such as optimizing urban transport systems [23], enhancing logistics and traceability for manufacturing industries [24], and improving agricultural production processes [25], among others. Generally, after its implementation, the supply chain methodology has proven capable of improving sustainability, reducing waste, and increasing profitability [26].

In the field of renewable energy, previous research has highlighted the integration of the supply chain as a multi-criteria analysis to promote sustainable business practices in terms of economic, social, and environmental factors [27,28,29]. Poulsen and Lema (2017) address the role of the supply chain in the diffusion process of renewable energy, using the case of the offshore wind energy sector in Europe and China to assess the supply chain’s contribution to regional green transformation. Their study identified opportunities for improvement in equipment transportation, qualified manpower availability, and wind energy legislation. Similarly, companies involved in energy project development have leveraged the multi-component structure of the supply chain methodology not only for evaluating wind potential but also for addressing financial requirements, infrastructure development, regional regulations, policies, and environmental and socioeconomic aspects. However, the incorporation of the supply chain methodology has primarily focused on large-scale power plants. There is a research gap regarding mini-scale wind energy projects, which have considerable potential to contribute to distributed generation and penetrate the renewable energy market [14,30].

Despite the positive impact and applicability of the supply chain in the renewable energy sector, some authors have identified areas that require improvement. Previous research emphasizes the necessity of quantitative analysis in supply chain evaluations to enhance the transparency and reliability of performance indicators [31,32]. In particular, Ahi and Searcy (2015) highlighted the need to develop clear metrics that use standardized language when addressing the same core issues, thereby promoting greater comparability in the evaluation of different supply chains [15,33]. Similarly, when analyzing the role of the supply chain in developing countries, deficiencies have frequently been found in equipment marketing routes, making it a priority to evaluate the availability of equipment suppliers and qualified manpower [34].

In this work, a supply chain model was designed to evaluate distributed generation projects for mini wind energy in urban areas. The main contribution lies in the integration of several different approaches, currently recognized as the most relevant factors for determining the viability of wind energy projects. Unlike other approaches, this proposed methodology is based on quantitative analysis and clear objectives, highlighting both their potentialities and the barriers that could limit their implementation.

2. Methodology

2.1. Case Study

The case study was conducted in Mexicali, Mexico, located in the extreme northwest of the country on the border with the United States, at co-ordinates 32°39′48″ N latitude and 114°42′ to 115°56′ W longitude. Mexicali has a predominantly hot desert climate (BWh), with summer temperatures reaching up to 52 °C and winter temperatures ranging between 7 and 23 °C. The case study focuses on the domestic sector, which, according to the weather conditions, is classified under the 1F rate. This rate is divided into four categories, with a maximum limit of 30,000 kWh/year, after which the High Consumption Rate (HCR, or DAC in Spanish) scheme applies to all consumption above this threshold. A total of 364,046 1F users and 60 HCR clients were registered for the study. Table 1 describes the 1F rates in detail, with four categories that increase energy pricing according to consumption levels.

Table 1.

Evaluation criteria for link customer distribution.

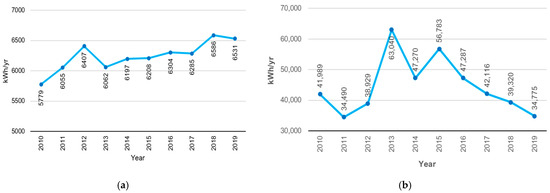

Under these criteria, the impact of various wind power generators was assessed by assigning a grade to each machine according to its contribution to the total energy consumption. The average annual consumption for 1F and HCR users is presented in Figure 1.

Figure 1.

Historical consumption: (a) 1F; (b) HCR.

To calculate the equivalent percentage of the rate, the consumption of each segment was added cumulatively. The basic category, which goes up to 2250 kWh/yr, represents the first 7.5% of the 1F rate. The low intermediate and high intermediate categories account for the next 3900 and 2400 kWh/yr segments, respectively. When added to basic consumption, these categories comprise 20.5% and 28.5% of the total, respectively. The surplus category applies to all consumptions ranging between 8550 kWh/yr (the sum of the previous levels) and 30,000 kWh/yr. Finally, the HCR rate is applied to all users who exceed the limit of 30,000 kWh/yr and imposes a fixed price for all their consumption, which can be up to eight times the price per kWh compared to the basic 1F rate.

According to Figure 1a, the average historical consumption for 1F users has ranged between 6000 and 6500 kWh/yr, while HCR consumers have an average consumption of 35,000 kWh/yr, showing a decline in the past few years. This trend can be attributed to the local desert climate, where air conditioning systems are the predominant domestic load. Under these conditions, the consumption trend depicted in Figure 1b is typically related to the continuous improvement in the energy efficiency of these systems [35,36,37].

A five-link model based on the supply chain framework was designed to facilitate a comprehensive evaluation of projects for developing mini wind power systems in urban areas. Six mini wind turbines from three different brands (AEOLOS, ENAIR, and COLIBRI) with power generation capacities ranging from 200 W to 10 kW were evaluated. As with most wind energy projects, the first step was to analyze the availability and characteristics of the on-site wind resource. In the same way, a close relationship has been observed between the availability of qualified manpower and the existence of a marketing network for equipment and spare parts, which is crucial for the successful development of renewable energy projects [38,39,40]. Therefore, the existence and quality of commercial suppliers, as well as specialized manpower, were analyzed. Subsequently, the generation impact on the billing for electrical consumption was determined for local domestic users [41,42]. Finally, the potential for a circular lifecycle or life extension of mini wind turbines was estimated [43,44].

2.2. Supply Chain Proposed Model

The proposed methodology incorporates five elements: (1) evaluation of wind potential, (2) supplier network, (3) project technical assessment, (4) customer distribution, and (5) final disposal of equipment. The model is summarized in Figure 2.

Figure 2.

Main links in the supply chain for the proposed model.

In accordance with the reviewed literature, the evaluation of each link incorporates parameters designed to address the key barriers identified for the development of the wind energy sector [45,46].

After each link was analyzed, the results were indicated using a “Traffic Light” color code. Red represents the lowest scores (zero and one point), yellow corresponds to two points, and green indicates the highest score (three). Consequently, the highest scores represent the most favorable conditions for the successful development of the project.

2.3. Supply Chain Links Evaluation Criteria

The evaluation of the first link in the supply chain, evaluation of wind potential, involves analyzing on-site wind conditions using three indicators: (i) the wind turbine start-up speed in meters per second (m/s), (ii) the capacity factor in percentage (%), and (iii) the criteria used to estimate the significance of energy generation contribution relative to user consumption. This calculation aligns with both domestic and international renewable energy regulations, including the energy contribution required to meet renewable generation objectives [47,48,49].

The second link in the supply chain is supplier network; this was structured under quality, delivery time, technology capacity, cost-price, customer support, and supply network. These criteria were originally proposed by Taherdoost and Brard (2019) to standardize the evaluation and selection of suppliers [50].

Project technical assessment was the third link in the supply chain. The instrument included 12 statements classified into four sections that describe the technical requirements necessary for the interconnection of mini wind power systems in accordance with established local legislation. The sections are (i) distributed generation, (ii) interconnection of distributed generation power plants, (iii) contract models, and (iv) compliance and surveillance.

The fourth link, customer distribution, evaluates the characteristics of the clients or market targeted by the project, such as the average consumption range (kWh/yr) and tariff specifications. This link provides an estimated impact of the project based on the client’s energy requirements and determines the minimum necessary contribution of renewable energy to access more economical electricity rates [51,52,53].

Finally, the equipment final disposal link was evaluated by analyzing the main component materials in mini wind power turbines and their applicable reverse logistics processes. This analysis identified materials with greater potential for life extension and processes with low resource consumption. The component materials were obtained directly from the technical datasheets provided by the manufacturers; the applicable processes were established according to ISO 14040 [54] and are in agreement with the International Electrotechnical Commission (IEC). Each link and its methodological approaches are summarized in Table 2 [55].

Table 2.

The proposed five links based on the supply chain framework (input/output of the methods used for its analysis).

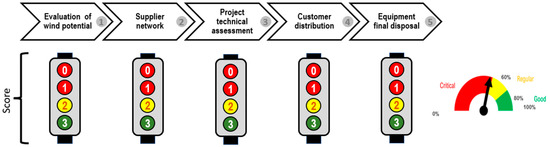

After assigning a value to each of the five links in the supply chain, the scores are summed and expressed as a percentage of the maximum possible, as illustrated in Figure 3. A critical evaluation (marked in red) is indicated when the score is between 0 and 60%. In this case, the supply chain model does not recommend proceeding with the development of the project. A regular evaluation (marked in yellow) is given if the overall score is between 60 and 80%, indicating acceptable conditions for the project’s development. However, it is recommended to address the points identified as risks increasing the project’s chances of success. Finally, a good evaluation (marked in green) is assigned when the score is between 80 and 100%, suggesting that the critical parameters of the project, both technical and legislative, are favorable for development, with a high likelihood of success (Figure 3).

Figure 3.

Model design. Proposed supply chain model, supported by a color code that includes red, yellow, and green, simulating a traffic light.

2.4. Evaluation of Wind Potential

Six small wind turbines from the brands AEOLOS, ENAIR, and COLIBRI, with power generation capacities ranging from 200 W to 10 kW, were evaluated based on the datasheets provided by the manufacturers. Ten-minute wind speed data were collected at a sampling rate of 10 Hz for a full year (2017) using a Campbell Scientific CSAT3B sonic anemometer positioned at a height of 20 m in an area free of buildings or obstacles. The scoring criteria for link 1 were determined by considering that typical start-up wind speeds range between 1 and 6 m/s for horizontal mini wind turbines with capacities from 40 W to 10 kW [56,57,58]. The indicators and the scores for link 1 are summarized in Table 3 [59,60,61,62].

Table 3.

Indicators for the evaluation of wind potential.

Consequently, in the start-up wind speed scoring criteria, a score of 0 was assigned to machines with a start-up speed of 4 m/s and higher, 1 for devices that start at 3 m/s, a score of 2 for those that start between 1 and 2 m/s, and a score of 3 for those under 1 m/s. For the capacity factor, four operational intervals were selected: 0–5% scored a 0, 6–10% scored a 1, 11–15% scored a 2, and a capacity factor of 16–20% scored a 3 [59,60,61]. Additionally, an indicator for generated energy was included to positively evaluate machines that contribute enough renewable energy to meet local government policy objectives. A wind turbine receives a maximum score of 3 if it can contribute at least 5% to consumption, as specified under RES/142/2017 from the Energy Regulatory Commission [62]. Table 3 summarizes the proposed scoring criteria for link 1.

2.5. Supplier Network Link

Two different instruments were developed to evaluate the supplier network link. The survey was structured around six criteria originally proposed by Taherdoost and Brard (2019) [50]. Four descriptions are added to each criterion to quantify them using a Likert scale. The values range from 1 to 5, where 1: totally disagree, 2: disagree, 3: neither agree nor disagree, 4: agree, 5: totally agree. The survey instrument is shown in Table 4.

Table 4.

Criteria for the supplier network link.

2.6. Project Technical Assessment Link

The project technical assessment was conducted using a checklist of 12 statements classified into four sections, as depicted in Table 5. This instrument describes the technical requirements necessary for the interconnection of mini wind power systems. The first section covers distributed generation, the second addresses the interconnection of distributed generation power plants, the third deals with contract models, and the final section analyzes compliance and surveillance. These statements were proposed in accordance with applicable local regulations, specifically articles 694 on mini wind power systems and 705 on interconnected power generation sources of NOM-001-SEDE-2012 [64].

Table 5.

Checklist for project technical assessment.

2.7. Customer Distribution

To evaluate the customer distribution link, the energy generated by the wind turbines was compared with the domestic sector average consumption to estimate the impact of the energy produced in terms of improvements in the tariff scheme. Local domestic electricity pricing is divided into two main categories: the 1F tariff and the HCR tariff. Users fall into one category or the other depending on their average consumption over the past 12 months. If the monthly average is lower than 2500 kWh, the user is classified under the 1F tariff. Otherwise, the user falls into the HCR scheme.

2.8. Equipment Final Disposal

The final disposal scoring criteria were proposed based on the reverse logistics processes for each component and material described in the wind turbine datasheet. Four scenarios were reviewed and categorized according to their environmental suitability: (i) reuse, (ii) remanufacturing, (iii) recycling, and (iv) disposal. If multiple processes are applicable to the same component or material, their scores are summed. Therefore, the more reverse logistics processes that apply to the components and their materials, the higher the final rating, which is then expressed as a percentage. Among the four applicable processes, reuse is weighted as the one with the lowest resource consumption and receives 4 points. The rating decreases for the other processes, down to 1 point assigned to the disposal process. Table 6 depicts the score of each component of the wind turbines.

Table 6.

Main components of mini wind turbines.

According to Table 6, the materials with the highest life extension include steel, neodymium magnets, zinc, inverter electronics, and wind turbine on/off controllers. Aluminum and copper are also in this category, excluding those materials located in the blades, terminals, wiring, and connections. In contrast, polymeric materials received a lower score compared to metallic-based materials due to their remanufacturing capabilities.

3. Results and Discussion

3.1. Evaluation of Wind Potential Link

The Weibull distribution has been used to determine wind speed distribution, and energy generation was calculated based on the individual parameters of each wind turbine. The results for link 1 are shown in Table 7; the scores were obtained by contrasting with Table 3.

Table 7.

Results of the first link in the supply chain: evaluation of wind potential.

The AEOLOS 200 received the highest score due to its low start-up speed and highest capacity factor, as per the criteria in Table 3. However, its energy generation was among the two lowest, with only 222 kWh/yr, just above the AEOLOS 400, which generated 207 kWh/yr. On the other hand, the largest generator, the COLIBRI 10000, was rated with 2 points due to its energy generation and capacity factor, but it had the drawback of a high start-up wind speed. Medium-sized generators like the ENAIR 5000 also received 2 points, penalized by their low-capacity factor, while the ENAIR 3000 and COLIBRI 5000 were the worst evaluated, with only 1 point each. Similar analyses in urban areas were conducted by Vallejo Díaz, Ricci, and Mitkov, using Computational Fluid Dynamic simulations to estimate generated energy. They emphasize the importance of in situ wind measurements to avoid potential overestimations [65,66,67].

3.2. Supplier Network and Project Technical Assessment Links

The combined results for both the supplier network link and the project technical assessment link are shown in Table 8.

Table 8.

Supplier network and project technical assessment results.

In the analysis of the supplier network link, suppliers X and Y obtained the best scores, considering their remarkable delivery time and process operation based on an established quality system. Supplier Z received a slightly lower grade because it failed in the technology and capacity criteria. The analysis showed that organization Z conducts limited research on advances in the field of wind turbine technology and lacks information on the status of its largest competitors. However, in the project technical assessment link, supplier Z was the top-ranked, owing to the high technical capacity of its human resources, which demonstrated the potential to provide valuable advice and support to clients at every stage of the process.

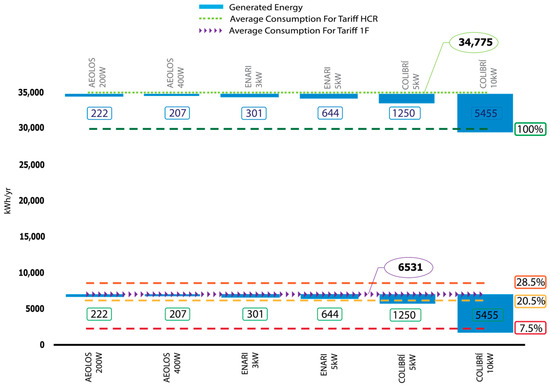

3.3. Customer Distribution Link

The average consumption for 1F and HCR users is illustrated in Figure 4. Additionally, the energy generated by each wind power turbine is shown to visualize each generator’s contribution to average user consumption and its potential impact on changing the user’s tariff scheme. For 1F users with an average energy consumption of 6595 kWh/yr, the Aeolos 200 and Aeolos 400 only made contributions of 222 and 207 kWh/yr, respectively. This falls within the first 7.5% of the 1F rate and is considered basic consumption. Medium-sized turbines, such as the ENAIR 3 kW and 5 kW, showed only small improvements, contributing 301 and 644 kWh/yr, respectively. In contrast, under the same conditions, the COLIBRI 5 kW performed better, generating 1250 kWh/yr and potentially producing around 80% of total consumption for 1F users.

Figure 4.

Contribution of generated energy for each tariff.

In the same figure, when analyzing the wind power contribution to HCR users, only the COLIBRI 10 kW was capable of producing enough energy to make a shift in the tariff scheme from HCR to 1F possible. In contrast, although the turbines of the ENAIR 3 kW and 5 kW allow energy savings, their generation was not enough to produce a change in the tariff scheme. The AEOLOS 200 W and 400 W turbines contributed only marginally in terms of energy savings.

A more detailed analysis of the AEOLOS 200 W and 400 W turbines reveals that even when operating 24/7 under optimal wind conditions, their power generation is limited to 1728 and 3456 kWh/yr, respectively. Both values fall below the 5000 kWh/yr required to shift the tariff scheme from HCR to the 1F pricing rate. When considering these results, wind turbines smaller than 5 kW should not be recommended under this tariff scheme. Table 9 shows the scores given to each device according to its energy contribution.

Table 9.

Customer distribution results.

3.4. Equipment Final Disposal Link

Three national companies specialized in the sale of mini wind turbines were sampled, identified as supplier X, supplier Y, and supplier Z. Figure 5 shows the results for the final disposal evaluation by the supplier, with scores concentrated by component and material type. It was observed that the steel of the braced tower (70%, 70%, and 100%), the steel of the inverter (60%, 60%, and 100%), the aluminum of the wiring (100%, 100%, and 29%), and the high-density polyurethane (100%, 14%, and 100%) of the mini wind turbine body are the best-evaluated materials in this category, with the highest potential for reuse and the lowest environmental impact.

Figure 5.

Final disposal evaluation by supplier.

Companies X and Y obtained 46% and 35%, respectively, both being rated as critical. In contrast, company Z obtained 79%, classifying it as regular. The results of extrapolating the percentages obtained for the decision criteria in the proposed model are shown in Table 10. This indicates that suppliers X and Y were the worst evaluated, each with a score of 1, while supplier Z was only slightly superior with a score of 2 points.

Table 10.

Equipment final disposal results.

3.5. Supply Chain Model Score

The evaluation results are shown in Table 11. The case study considered a total of 21 possible options, including the performance of 6 different models of mini wind turbines along with the on-site wind potential evaluation, 3 different distributors in the suppliers’ network, 3 companies for project technical assessment, and 3 more for equipment final disposal.

Table 11.

Best-scored alternatives for each link.

To determine project feasibility, selecting the best-rated options in each link was required. The final score was calculated, and it should be addressed to the decision-making criteria, as shown in Table 12. The project outcome can be categorized among three possible scenarios: (i) good: All items in the supply chain were evaluated high enough to consider that the project has high possibilities of success, and its implementation is recommended. (ii) Regular: In this case, the model identifies shortcomings that have the potential to be improved. The model recommends the execution of the project only after the identified obstacles are corrected. (iii) Critical: Finally, this rate is assigned when the model finds major drawbacks that not only block the execution of the project but create a situation where no potential solutions are identified either.

Table 12.

Decision criteria for supply chain evaluation.

The findings presented in Table 10 highlight the highest-rated options for each link of the proposed model to analyze a mini wind power project feasibility in Mexicali, Mexico. According to the proposed model, the final evaluation for the project is 87%, rated as good. This suggests its potential implementation, with a high probability of success.

The proposed methodology considers that links 2, 3, and 5 are independent; therefore, different companies can be selected for each link. However, a different situation is observed for links 1 and 4, where it is mandatory to select the same wind turbine for both links. Although the AEOLOS 200 obtained the best score in link 1, its poor performance in the customer distribution link resulted in a final project evaluation of 73%. Therefore, it is important to consider that, only in the case of wind turbine evaluation, additional inspection must be performed to determine the combination that yields the most favorable result.

4. Conclusions

In this case study, a model for evaluating the supply chain of mini wind energy in urban areas was designed and implemented. The proposed methodology enables the generation of quantitative results for each of the five links, allowing for a comprehensive assessment of project feasibility through standardized and comparable scoring. This approach facilitates decision-making in wind energy generation projects. Quantitative ratings were obtained for each of the model’s five links, resulting in an overall score representing the links’ interaction. The final score provides a basis for decision-making based on multifactorial criteria, increasing project success probability. Additionally, the supply chain model makes it possible to visualize the risks associated with each step of the process to assess potential project improvements.

For the wind potential evaluation, three important indicators were integrated: wind turbine start-up speed, capacity factor, and generated energy. These indicators are usually evaluated separately, but in this case, they were evaluated simultaneously, creating a cause-effect relationship between the results achieved and the performance drivers. When start-up wind speed and capacity factors are considered, small wind turbines rated below 1 kW typically score better compared to medium 2 kW and large 10 kW wind generators. However, the model also assigned significant weight to the energy generated and its impact relative to the average user’s consumption. For the final selection criteria of the wind power turbine, the model recommends considering all these factors based on the evaluated wind turbines’ performance.

Therefore, it is suggested that a study using statistical tools with different wind turbines and wind conditions be performed to determine capacity factors that maximize energy generation in mini wind power turbines. This is crucial, as there is limited information in the literature on the optimal capacity factor ranges for mini wind power turbines.

When evaluating suppliers, item quality was the highest rated for all organizations. This demonstrated the importance of having a quality management system in place. Additionally, equipment compliance with applicable regulations and the clear written presentation of the wind turbine technical specifications were found to be equally relevant. Another finding indicates that the best-evaluated companies included a design department within their organization, operating in conjunction with the production and distribution areas. In contrast, the worst-rated suppliers only offered commercialization services.

The amount of energy generated by the wind turbines could have three possible implications that vary in relevance based on local energy billing schemes and policies. One implication is directly related to economic savings. The second is associated with government requirements that mandate users to contribute a percentage of their energy consumption through renewable energy. Finally, the generated energy may offer the possibility of modifying the electric tariff scheme to a more favorable one.

Regarding the final disposal of equipment, it was observed that the braced tower and inverter steel, the wiring aluminum, and the turbine body high-density polyurethane were the best-evaluated materials due to their highest potential for reuse; hence, they had the lowest environmental impact. Conversely, the inverter high-density polyurethane, the fiberglass body, and the rudder high-density polyurethane obtained the lowest scores and were classified as the elements with the highest environmental impact.

Additionally, the proposed model structure can be applied to any geographic site by adjusting each of the links to the local conditions. This involves integrating the energy estimation based on the site wind speeds for the first link, applying evaluations to new wind turbine suppliers for the second link, and adapting the technical evaluation checklist for the study site in the third link, which varies according to the country and the applicable regulations regarding the classification of energy generation. For the fourth link, a characteristics analysis of the electricity tariff system applicable to the new study and the specific clients’ demand data must be performed to strengthen the general model. Finally, for the last link, as new wind turbines are integrated into the model, it will be necessary to analyze components and materials to propose the appropriate final disposal.

No public information was found regarding suppliers specializing in renewable energies despite the legislation in Baja, California, requiring it. It is suggested that a collaborative network of products and services be created to promote the penetration of renewable energies in Mexico and globally. It is highly recommended that an equipment catalog for services and suppliers (national and international) related to energy generation projects with renewable sources be created to strengthen the model design for future users. Additionally, the checklist used for technical evaluation must be adjusted to include the rest of the current tariff categories: domestic, commercial, industrial, and agricultural services. Clean Energy Certificates and tax benefits should be considered as a benefit to the customer distribution link. Regarding the final disposal link, an opportunity was identified to develop a business model for the remanufacturing and recycling of wind turbine components.

Previous models have focused on the technological, meteorological, and economic aspects of wind power development. However, the methodology proposed here seeks to address a broader range of parameters that are recognized as key barriers to wind power development, including the availability of skilled labor and spare parts. It also incorporates a life extension reverse logistics analysis through a detailed examination of the primary components and materials of mini wind power turbines. Moreover, the model can be improved if other factors are included, such as (i) a study of public acceptance of the incorporation of small wind power projects in urban areas, (ii) increasing the number of points for the study of wind due to the complex topography in the cities, and (iii) considering the impact of environmental pollution on the components of wind turbines, which could be a significant parameter.

Although this study was conducted in a specific region, its structure and key findings provide a valuable foundation for the scientific community, as well as technicians and practitioners in other areas seeking to apply a comprehensive analysis for assessing the feasibility of renewable energy projects in urban settings. For instance, the model can be adapted to additional renewable energy areas such as high-power wind, solar photovoltaics, and others. To achieve this adaptation, the specific needs of each renewable source must be studied and compared with the current model parameters, integrating new elements to address the differences. For example, solar photovoltaics require a method different from wind power for the first link to estimate energy generation. In this case, the adapted model would have a first link that is focused on evaluating solar power potential instead of wind power potential. The same five links of the model could work with adjustments for different renewable sources.

Author Contributions

Conceptualization, I.Z., E.V. and A.L.; Methodology, I.Z., E.V. and A.L.; formal analysis, I.Z., E.V. and A.L.; original draft preparation, I.Z., J.R.A. and R.G.; reviewing and editing I.Z., J.R.A. and R.G.; project administration, I.Z. and E.V.; funding acquisition, I.Z. and R.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Consejo Nacional de Humanidades, Ciencias y Tecnologías (CONAHCYT) through a Master’s degree, grant number 714982.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

Author Rodny García was employed by the company Chint Power of Mexico. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Almeida, R.M.; Shi, Q.; Gomes-Selman, J.M.; Wu, X.; Xue, Y.; Angarita, H.; Barros, N.; Forsberg, B.R.; García-Villacorta, R.; Hamilton, S.K.; et al. Reducing greenhouse gas emissions of Amazon hydropower with strategic dam planning. Nat. Commun. 2019, 10, 4281. [Google Scholar] [CrossRef]

- Estadísticas de Capacidad Renovable 2022. International Renewable Energy Agency. April 2022. Available online: https://www.irena.org/publications/2022/Apr/Renewable-Capacity-Statistics-2022-ES (accessed on 12 November 2023).

- Layton, B.E. A Comparison of Energy Densities of Prevalent Energy Sources in Units of Joules Per Cubic Meter. Int. J. Green Energy 2008, 5, 438–455. [Google Scholar] [CrossRef]

- Hernández-Escobedo, Q. Wind Energy Assessment for Small Urban Communities in the Baja California Peninsula, Mexico. Energies 2016, 9, 805. [Google Scholar] [CrossRef]

- Simões, T.; Estanqueiro, A. A new methodology for urban wind resource assessment. Renew. Energy 2016, 89, 598–605. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, Y.; Wu, M. Decision-making methodologies in offshore wind power investments: A review. J. Clean. Prod. 2021, 295, 126459. [Google Scholar] [CrossRef]

- Gualtieri, G. Analysing the uncertainties of reanalysis data used for wind resource assessment: A critical review. Renew. Sustain. Energy Rev. 2022, 167, 112741. [Google Scholar] [CrossRef]

- McKenna, R.; Pfenninger, S.; Heinrichs, H.; Schmidt, J.; Staffell, I.; Bauer, C.; Gruber, K.; Hahmann, A.N.; Jansen, M.; Klingler, M.; et al. High-resolution large-scale onshore wind energy assessments: A review of potential definitions, methodologies and future research needs. Renew. Energy 2022, 182, 659–684. [Google Scholar] [CrossRef]

- Castellanos, S.; Santibañez-Aguilar, J.E.; Shapiro, B.B.; Powell, D.M.; Peters, I.M.; Buonassisi, T.; Kammen, D.M.; Flores-Tlacuahuac, A. Sustainable silicon photovoltaics manufacturing in a global market: A techno-economic, tariff and transportation framework. Appl. Energy 2018, 212, 704–719. [Google Scholar] [CrossRef]

- Kinias, I.; Tsakalos, I.; Konstantopoulos, N. Investment evaluation in renewable projects under uncertainty, using real options analysis: The case of wind power industry. Invest. Manag. Financ. Innov. 2017, 14, 96–103. [Google Scholar] [CrossRef][Green Version]

- Song, M.; Kong, L.; Xie, J. Capacity investment decisions of energy storage power stations supporting wind power projects. Ind. Manag. Data Syst. 2023, 123, 2803–2835. [Google Scholar] [CrossRef]

- Krömer, S. Model risk regarding monthly wind energy production for the valuation of a wind farm investment. Int. J. Energy Sect. Manag. 2019, 13, 862–884. [Google Scholar] [CrossRef]

- Kristiansen, M.; Svendsen, H.G.; Korpås, M.; Fleten, S.-E. Multistage grid investments incorporating uncertainty in offshore wind development. Energy Procedia 2017, 137, 468–476. [Google Scholar] [CrossRef]

- Irfan, M.; Hao, Y.; Panjwani, M.K.; Khan, D.; Chandio, A.A.; Li, H. Competitive assessment of South Asia’s wind power industry: SWOT analysis and value chain combined model. Energy Strategy Rev. 2020, 32, 100540. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I. Issue on supply chain of renewable energy. Energy Convers. Manag. 2013, 76, 774–780. [Google Scholar] [CrossRef]

- Monjas-Barroso, M.; Balibrea-Iniesta, J. Valuation of projects for power generation with renewable energy: A comparative study based on real regulatory options. Energy Policy 2013, 55, 335–352. [Google Scholar] [CrossRef]

- Oguanobi, V.U.; Joel, O.T. Geoscientific research’s influence on renewable energy policies and ecological balancing. Open Access Res. J. Multidiscip. Stud. 2024, 7, 73–85. [Google Scholar] [CrossRef]

- May, N.; Neuhoff, K. Financing Power: Impacts of Energy Policies in Changing Regulatory Environments. Energy J. 2021, 42, 131–152. [Google Scholar] [CrossRef]

- Yang, A.-S.; Su, Y.-M.; Wen, C.-Y.; Juan, Y.-H.; Wang, W.-S.; Cheng, C.-H. Estimation of wind power generation in dense urban area. Appl. Energy 2016, 171, 213–230. [Google Scholar] [CrossRef]

- Juan, Y.-H.; Wen, C.-Y.; Chen, W.-Y.; Yang, A.-S. Numerical assessments of wind power potential and installation arrangements in realistic highly urbanized areas. Renew. Sustain. Energy Rev. 2021, 135, 110165. [Google Scholar] [CrossRef]

- Kim, C. A review of the deployment programs, impact, and barriers of renewable energy policies in Korea. Renew. Sustain. Energy Rev. 2021, 144, 110870. [Google Scholar] [CrossRef]

- Chopra, S. Administración de la Cadena de Suministro. Estrategia, Planeación y Operación. 2019. Available online: https://uabc.vitalsource.com/reader/books/9786073250672/pageid/16 (accessed on 9 August 2019).

- Viljoen, N.; Joubert, J. Supply chain micro-communities in urban areas. J. Transp. Geogr. 2019, 74, 211–222. [Google Scholar] [CrossRef]

- Jiang, R.; Kang, Y.; Liu, Y.; Liang, Z.; Duan, Y.; Sun, Y.; Liu, J. A trust transitivity model of small and medium-sized manufacturing enterprises under blockchain-based supply chain finance. Int. J. Prod. Econ. 2022, 247, 108469. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozkan-Ozen, Y.D.; Ozbiltekin, M. Minimizing losses in milk supply chain with sustainability: An example from an emerging economy. Resour. Conserv. Recycl. 2018, 139, 270–279. [Google Scholar] [CrossRef]

- Debnath, B.; Siraj, M.T.; Rashid, K.H.O.; Bari, A.M.; Karmaker, C.L.; Al Aziz, R. Analyzing the critical success factors to implement green supply chain management in the apparel manufacturing industry: Implications for sustainable development goals in the emerging economies. Sustain. Manuf. Serv. Econ. 2023, 2, 100013. [Google Scholar] [CrossRef]

- Fernando, Y.; Yahya, S. Challenges in Implementing Renewable Energy Supply Chain in Service Economy Era. Procedia Manuf. 2015, 4, 454–460. [Google Scholar] [CrossRef]

- Jelti, F.; Allouhi, A.; Büker, M.S.; Saadani, R.; Jamil, A. Renewable Power Generation: A Supply Chain Perspective. Sustainability 2021, 13, 1271. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. Industry 4.0 enabling sustainable supply chain development in the renewable energy sector: A multi-criteria intelligent approach. Technol. Forecast. Soc. Change 2022, 182, 121813. [Google Scholar] [CrossRef]

- Poulsen, T.; Lema, R. Is the supply chain ready for the green transformation? The case of offshore wind logistics. Renew. Sustain. Energy Rev. 2017, 73, 758–771. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. An AHP-based multi-criteria model for sustainable supply chain development in the renewable energy sector. Expert Syst. Appl. 2020, 150, 113321. [Google Scholar] [CrossRef]

- Sahebi, I.G.; Mosayebi, A.; Masoomi, B.; Marandi, F. Modeling the enablers for blockchain technology adoption in renewable energy supply chain. Technol. Soc. 2022, 68, 101871. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Liu, R.; Dan, B.; Zhou, M.; Zhang, Y. Coordinating contracts for a wind-power equipment supply chain with joint efforts on quality improvement and maintenance services. J. Clean. Prod. 2020, 243, 118616. [Google Scholar] [CrossRef]

- Jones, R.V.; Fuertes, A.; Lomas, K.J. The socio-economic, dwelling and appliance related factors affecting electricity consumption in domestic buildings. Renew. Sustain. Energy Rev. 2015, 43, 901–917. [Google Scholar] [CrossRef]

- Allouhi, A.; El Fouih, Y.; Kousksou, T.; Jamil, A.; Zeraouli, Y.; Mourad, Y. Energy consumption and efficiency in buildings: Current status and future trends. J. Clean. Prod. 2015, 109, 118–130. [Google Scholar] [CrossRef]

- Ruparathna, R.; Hewage, K.; Sadiq, R. Improving the energy efficiency of the existing building stock: A critical review of commercial and institutional buildings. Renew. Sustain. Energy Rev. 2016, 53, 1032–1045. [Google Scholar] [CrossRef]

- Ram, M.; Aghahosseini, A.; Breyer, C. Job creation during the global energy transition towards 100% renewable power system by 2050. Technol. Forecast. Soc. Change 2020, 151, 119682. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Afridhis, S.; Vijayaraghavan, R.R.; Subramaniam, U.; Nurunnabi, M. SWOT analysis: A framework for comprehensive evaluation of drivers and barriers for renewable energy development in significant countries. Energy Rep. 2020, 6, 1838–1864. [Google Scholar] [CrossRef]

- Vanegas Cantarero, M.M. Of renewable energy, energy democracy, and sustainable development: A roadmap to accelerate the energy transition in developing countries. Energy Res. Soc. Sci. 2020, 70, 101716. [Google Scholar] [CrossRef]

- Mirzania, P.; Ford, A.; Andrews, D.; Ofori, G.; Maidment, G. The impact of policy changes: The opportunities of Community Renewable Energy projects in the UK and the barriers they face. Energy Policy 2019, 129, 1282–1296. [Google Scholar] [CrossRef]

- Potrč, S.; Čuček, L.; Martin, M.; Kravanja, Z. Sustainable renewable energy supply networks optimization—The gradual transition to a renewable energy system within the European Union by 2050. Renew. Sustain. Energy Rev. 2021, 146, 111186. [Google Scholar] [CrossRef]

- Mello, G.; Ferreira Dias, M.; Robaina, M. Evaluation of the environmental impacts related to the wind farms end-of-life. Energy Rep. 2022, 8, 35–40. [Google Scholar] [CrossRef]

- Woo, S.M.; Whale, J. A mini-review of end-of-life management of wind turbines: Current practices and closing the circular economy gap. Waste Manag. Res. 2022, 40, 1730–1744. [Google Scholar] [CrossRef] [PubMed]

- International Renewable Energy Agency. Future of Wind; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2019. [Google Scholar]

- Murgas, B.; Henao, A.; Guzman, L. Evaluation of Investments in Wind Energy Projects, under Uncertainty. State of the Art Review. Appl. Sci. 2021, 11, 10213. [Google Scholar] [CrossRef]

- Xiaosan, Z.; Qingquan, J.; Shoukat Iqbal, K.; Manzoor, A.; Zia Ur, R. Achieving sustainability and energy efficiency goals: Assessing the impact of hydroelectric and renewable electricity generation on carbon dioxide emission in China. Energy Policy 2021, 155, 112332. [Google Scholar] [CrossRef]

- Dogaru, L. The Main Goals of the Fourth Industrial Revolution. Renewable Energy Perspectives. Procedia Manuf. 2020, 46, 397–401. [Google Scholar] [CrossRef]

- Baruch-Mordo, S.; Kiesecker, J.M.; Kennedy, C.M.; Oakleaf, J.R.; Opperman, J.J. From Paris to practice: Sustainable implementation of renewable energy goals. Environ. Res. Lett. 2019, 14, 024013. [Google Scholar] [CrossRef]

- Taherdoost, H.; Brard, A. Analyzing the Process of Supplier Selection Criteria and Methods. Procedia Manuf. 2019, 32, 1024–1034. [Google Scholar] [CrossRef]

- Bódis, K.; Kougias, I.; Jäger-Waldau, A.; Taylor, N.; Szabó, S. A high-resolution geospatial assessment of the rooftop solar photovoltaic potential in the European Union. Renew. Sustain. Energy Rev. 2019, 114, 109309. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, Y.; Lin, X.; Li, C.; Cai, Z.; Yang, P. Optimal Sizing of PV and BESS for a Smart Household Considering Different Price Mechanisms. IEEE Access 2018, 6, 41050–41059. [Google Scholar] [CrossRef]

- Burgess, R.; Greenstone, M.; Ryan, N.; Sudarshan, A. The Consequences of Treating Electricity as a Right. J. Econ. Perspect. 2020, 34, 145–169. [Google Scholar] [CrossRef]

- ISO 14040:2006(en); Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2024.

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef]

- Wright, A.K.; Wood, D.H. The starting and low wind speed behaviour of a small horizontal axis wind turbine. J. Wind Eng. Ind. Aerodyn. 2004, 92, 1265–1279. [Google Scholar] [CrossRef]

- Bourhis, M.; Pereira, M.; Ravelet, F. Experimental investigation of the effect of blade solidity on micro-scale and low tip-speed ratio wind turbines. Exp. Therm. Fluid Sci. 2023, 140, 110745. [Google Scholar] [CrossRef]

- Singh, R.K.; Ahmed, M.R. Blade design and performance testing of a small wind turbine rotor for low wind speed applications. Renew. Energy 2013, 50, 812–819. [Google Scholar] [CrossRef]

- Ahshan, R.; Al-Badi, A.; Hosseinzadeh, N.; Shafiq, M. Small Wind Turbine Systems for Application in Oman. In Proceedings of the 2018 5th International Conference on Electric Power and Energy Conversion Systems, EPECS 2018, Kitakyushu, Japan, 23–25 April 2018. [Google Scholar]

- Idriss, A.I.; Ahmed, R.A.; Omar, A.I.; Said, R.K.; Akinci, T.C. Wind energy potential and micro-turbine performance analysis in Djibouti-city, Djibouti. Eng. Sci. Technol. Int. J. 2020, 23, 65–70. [Google Scholar] [CrossRef]

- Mohsin, M.; Zhang, J.; Saidur, R.; Sun, H.; Sait, S.M. Economic assessment and ranking of wind power potential using fuzzy-TOPSIS approach. Environ. Sci. Pollut. Res. 2019, 26, 22494–22511. [Google Scholar] [CrossRef]

- Diario Oficial de la Federación, D. Disposiciones Administrativas de Carácter General, los Modelos de Contrato, la Metodología de Cálculo de Contraprestación y las Especificaciones Técnicas Generales, Aplicables a las Centrales Eléctricas de Generación Distribuida y Generación Limpia Distribuida. Diario Oficial de la Federación, Secretaría de Energía. 7 March 2017. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=5474790&fecha=07/03/2017 (accessed on 3 January 2020).

- International Electrotechnical Commission. Wind Energy Generation Systems. IEC 61400-1 (2019). Available online: https://webstore.iec.ch/ (accessed on 9 July 2021).

- Norma Oficial Mexicana NOM-001-SEDE-2012. NOM-001-SEDE-2012. Diario Oficial de la Federación, Secretaría de Energía. 2021. Available online: https://www.gob.mx/cms/uploads/attachment/file/512096/NOM-001-SEDE-2012.pdf (accessed on 3 January 2020).

- Vallejo Díaz, A.; Herrera Moya, I.; Castellanos, J.E.; Garabitos Lara, E. Optimal Positioning of Small Wind Turbines Into a Building Using On-Site Measurements and Computational Fluid Dynamic Simulation. J. Energy Resour. Technol. 2024, 146. [Google Scholar] [CrossRef]

- Ricci, A.; Burlando, M.; Repetto, M.P.; Blocken, B. Static downscaling of mesoscale wind conditions into an urban canopy layer by a CFD microscale model. Build. Environ. 2022, 225, 109626. [Google Scholar] [CrossRef]

- Mitkov, R.; Pantusheva, M.; Naserentin, V.; Hristov, P.O.; Wästberg, D.; Hunger, F.; Mark, A.; Petrova-Antonova, D.; Edelvik, F.; Logg, A. Using the Octree Immersed Boundary Method for urban wind CFD simulations. IFAC-PapersOnLine 2022, 55, 179–184. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).