Abstract

Mining activity has been and is one of the most important and indispensable industries for the development of society. Given its role in the provision of raw materials, advancing the development of environmentally friendly mining practices is essential for meeting the globally established goals of sustainable development. In this regard, actions and incentives are being promoted by the European Union, such as the Mine.io project presented in this research. In response to the needs identified within the mining sector, this research seeks to explore the functional and non-functional requirements across several mining contexts. The objective is to establish effective patterns that positively influence the sector activities. This effort is envisioned as a critical foundation for developing a digital architecture that addresses sector limitations and fosters the integration of Industry 4.0 principles into the mining domain. The results provide a solid basis for understanding the needs of the different mining sectors analyzed, while also demonstrating the potential advancements achievable through the project’s technological developments. They enable a comprehensive evaluation of the current technological state in relation to the broader context of global legacy practices, establishing informed guidelines for effective sector responses based on digitalization and the application of sustainable tools.

1. Introduction and Background

Mining is considered one of the oldest human activities that has boosted the technical, economic and cultural development of societies over time. Within the European context, stone quarrying dates to the Neolithic era, with relevant extraction sites in Sicily, Portugal, northern Norway and southern Russia [1]. In this sense, although the mining sector is essential for global development, it is commonly considered to be conflicting with sustainable growth due to the significant impact on the natural resources and environment [2,3], placing this industry under intensified pressure over the last decades. As a result of this social pressure, mining activity has begun to adopt different strategies aimed at improving the environmental and social efficiency of the involved processes [4,5]. In this way, different international institutions and organizations, such as the United Nations Development Programme (UNDP) and the International Council on Mining & Metals (ICMM), have provided standard frameworks to bring the mining sector closer to sustainable development [6,7]. These guidelines are a valuable tool for stakeholders to achieve sustainability at all stages of the sector.

In addition, given that the supply of primary raw materials plays a crucial role in the ways of sustainable development, the global consumption of primary metals is growing exponentially, making sustainable extraction a complex situation [8]. In fact, the transition to a low-carbon future involves potentially increasing the demand for certain minerals required for low-carbon technologies. In this context, and despite the negative impacts associated with the mining industry, EU Member States have assumed the importance of the sector in terms of satisfying the demand of raw materials for consumers, but also for a successful transition towards achieving the United Nations Sustainable Development Goals (SDGs) [9]. The European Green Deal (EGD) is thus presented as the first world agreement towards climate neutrality [10]. Above all the actions proposed by the EGD, it is about forging technological advancement and the efficient use of resources in the context of the European Union [11]. The achievement of these objectives is enacted at different levels through several political agendas. Regarding the mining industry, a series of statements are collected aimed at gradual digital transformation, as well as the automation of mining processes, without forgetting the inclusion of renewable energies within the processes involved in the sector [12].

However, despite the efforts carried out by the aforementioned institutions and initiatives (as well as many others), there is still a long way to go. In this respect, the development of European initiatives, such as the Mine.io project presented here, represents an important boost for the mining industry, also contributing to improving society’s conception of the sector. The Mine.io project entitled “A Holistic Digital Mine 4.0 Ecosystem” has been funded by the Horizon Europe Framework Programme (HORIZON) under the call “Digitized, Resource-Efficient and Resilient Industry 2022 (HORIZON-CL4-2022-RESILIENCE-01)”, with the final aim of developing a collaborative system architecture to promote the openness and sharing of data and improve cooperation among mining enterprises. Within the framework of this project, the concept of digitalization plays a special role within the effective development of mining activity in all aspects and processes involved [13,14,15].

1.1. Digitization of the Mining Industry

The Fourth Industrial Revolution resulted in the establishment of the foundations of the concept “Industry 4.0”, which was born to attest to the technological advances that have emerged in recent times, with the introduction of concepts such as the Internet of Things (IoT), augmented reality, autonomous robotic systems, the analysis of large datasets and big data, among many others [16,17].

In the context of general technological growth, the concept of Mining 4.0 (and its transition to Mining 5.0) has been coined to affirm that the mining industry can in turn integrate reliable technologies to improve the productivity of the processes involved in the sector. Although mining is considered by a large part of society as a traditional sector with a scarce possibility of change, technological progress is also part of the sector, contributing to the improvement of safety, increased productivity or more efficient use of resources [18,19,20,21]. In this way, Mining 5.0 means the automation of processes involved in the different stages of mining activities, such as exploration, extraction, processing or restoration [22,23], directly contributing to resource-sparing and sustainable raw material production.

In summary, the objectives of Mining 5.0 would include the selective production of raw materials, autonomous production, transportation and processing and the concept of a “low-impact mine” on both society and the ecosystem, with the expectations of high security and efficient resource consumption. In line with these purposes, the technological needs demanded by the sector arise, those being the digitization of these scenarios and related processes and activities, an essential issue that includes here aspects such as the application of artificial intelligence (AI) techniques and the use of ruggedized sensors or the exchange of automated information through Machine-to-Machine (M2M) communication systems [24,25].

Digitization refers thus to the use of digital computerized systems and digitized data with the aim of improving business productivity, reducing costs and transforming industrial practices [26], thanks to a better understating of all the involved assets. Focusing on the mining sector, it provides a variety of benefits related to the increased control over mining operations, increased worker safety or environmental and financial cost savings [27]. Mining 5.0 and the associated concept of digitization represent an immense potential to transform mining operations and ensure that the requirements of this type of scenario can be addressed satisfactorily. These terms are usually conceived as the result of the cyber-physical integration of the conventional mining machinery and smart manufacturing, which has a proven positive impact on the sector based on demonstrated facts such as the reduction in potential mineral losses, the reduction in the number of accidents and the increase in profitability and improvement of logistics [28]. Although digitization has not occurred in the mining sector as fast as in other industrial activities, it is expected that it will significantly transform the mining industry over the next ten to twenty years. More radical opinions even suggest that, by the year 2050, up to 90% of the minerals in the world will be mined within the Mining 5.0 platform, in which digital technologies and autonomous and automated equipment will be key to solve the social, economic and environmental problems that the mining industry is currently facing [29,30,31].

1.2. Mine.io Project

Despite the mentioned advances within the concept of Mining 5.0, frequent mining practices continue to face persistent challenges arising from the limited incorporation of sustainable and digitalized processes. Although technological progress has been widely documented in other industrial domains, mining practices remain largely dependent on resource-intensive methods associated with significant environmental and social externalities. Furthermore, the deployment of innovative technological solutions specifically adapted to the contextual requirements of mining operations has been scarce, thereby constraining opportunities for resource optimization, emission mitigation and efficiency enhancement. There are also relevant research gaps that remain evident in the existing literature. First, most studies focus on the theoretical potential of digital technologies such as the IoT, artificial intelligence and big data, while large-scale empirical evidence of their implementation in real mining operations is still limited [32]. Second, technological solutions are often presented as being generic, without sufficient adaptation to the geological, environmental and socio-economic contexts of specific mining sites, which limits their practical applicability. Third, barriers to adoption beyond technology, including a lack of skilled personnel, insufficient standardization, cybersecurity risks and organizational resistance to change, are insufficiently addressed in the current research [33]. Moreover, there is a lack of longitudinal studies that assess the long-term effects of digitalization on sustainability performance, particularly regarding reductions in environmental impact, improvements in safety and operational efficiency. Finally, while sustainability and digitalization are frequently studied as separate domains, few contributions explore their systematic integration into mining operations, leaving a gap in understanding how digital transformation can effectively support sustainable development goals in the sector [34]. Considering these facts, the European project Mine.io aims to enhance the systematization and digitization of the fundamental processes of the mining industry, which involve the optimization of assets and procedures concerning the mining exploration and production processes, also promoting sustainable mining and post-mining management. To this end, the Mine.io ecosystem includes validation in different demonstration sites, involving four operational mine facilities and two historic mine sites in five EU countries. Through the expected methodological development and its application in the aforementioned pilot cases, the project pursues the achievement of the following general objectives:

- The development of an open, digital and sophisticated digital infrastructure, conceived as the basis of the “hyper-connected business” in Mining 5.0 production.

- The creation of advanced, low-impact and smart integrated solutions to boost the sustainable discovery of strategic raw materials in the context of Europe.

- The advancement of innovative technologies regarding the concepts of advanced mobility, logistics and supply chain operations.

- The digitalization of assets, processes and their associated equipment.

- A movement towards the development of sustainable mining in line with European guidelines.

- The validation and evaluation of all Mine.io concepts and solutions in real-scale regional-scope pilots, and the demonstration of the feasibility of the innovative technological solutions supporting the Industry 4.0 transition in the mining sector.

- The planning and facilitation of the exploitation of the project results through their dissemination in different scientific initiatives and end-user communities.

Within the framework of one of the first phases of the Mine.io project, and based on the needs identified in the sector, this research aims to delve into the functional and non-functional requirements of different mining contexts in order to contribute to the establishment of effective patterns and guidelines with an expected positive impact on the sector in each of the associated activities. All of this is conceived as an essential starting point in the development of digital architecture that provides a solution to the limitations of the sector and contributes to the expansion of the concept known as Industry 4.0 within the mining context. In addition to this first introductory chapter, the research is structured as follows: Section 2 presents the description of the pilot cases and the methodology that has been followed for an effective establishment of requirements; subsequently, Section 3 includes the results associated with each of the study cases and a brief discussion of them; and, finally, Section 4 provides the main conclusions of the research.

2. Materials and Methods

2.1. Pilot Cases Description

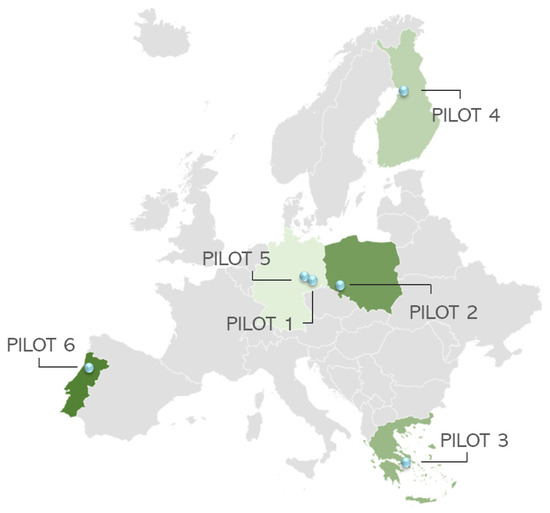

As mentioned in the introductory section, the Mine.io project, on which this research is based, comprises the technological validation and evaluation of six pilot cases distributed in five European countries (Figure 1).

Figure 1.

Location of the pilot cases included in Mine.io project.

Together with the first approximation of the pilot location presented in the previous Figure 1, the following Table 1 exhaustively describes the mining contexts that characterize each case study, as well as the technologies and processes intended to be developed and validated throughout the Mine.io project.

Table 1.

Description of the pilot cases and the technologies and processes that will be tested in each of them.

The selection of the previously described case studies is grounded in the pilot sites integrated within the Mine.io project. These pilots were specifically chosen as they provide the opportunity to explore and evaluate diverse mining contexts, each characterized by distinct operational conditions, technological frameworks and resource exploitation characteristics. This diversity ensures a comprehensive assessment of the project’s methodologies and facilitates the validation of its approaches under a wide range of real-world scenarios.

2.2. Goals and Standards for the Requirements Strategy Establishment

The Mine.io project tries to advance the future vision of digital mining, where different technological partners are involved in order to solve the challenges facing the sector. For this, as has been mentioned in this research, six European pilot sites will be the basis for representing and covering the principal mining scenarios that technology providers must cover.

In this sense, one of the first phases of the project requires the establishment of the specific requirements (both functional and non-functional) that each of the pilots involved in the project considers appropriate based on their activity and particular conditions. The definition of these requirements is essential, serving as the foundation of every successful project, in the context of establishing a mutual understanding among the mining scenarios and the technology partners, ensuring that they are aligned in pursuit of the same goal.

In the context of Mine.io, “functional requirements” are those referring to the essential tasks, behaviors and operations that a system, machinery, sensor or instrument must perform. These are the core functionalities that enable the system to meet its intended objectives. On the other hand, “non-functional requirements” pertain to the quality attributes that a system, organization or service must possess, such as scalability, reliability and performance. Within the same framework, this could encompass aspects like the durability of equipment and energy efficiency. Both functional and non-functional requirements are integral to the overall effectiveness and sustainability of mining operations, and they often complement each other to ensure a holistic approach for a successful project execution [35,36].

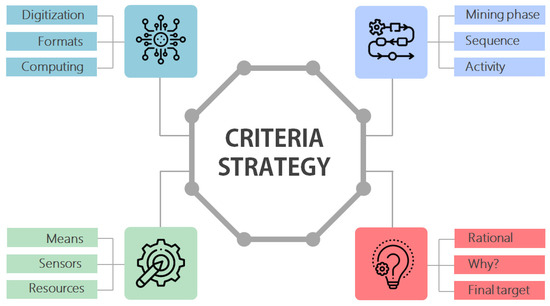

Once the concept of functional and non-functional requirements is deeply clarified, a first approach has been carried out with the objective of establishing standard criteria that facilitate the global definition of the aforementioned requirements. These criteria, graphically synthesized in the following Figure 2, cover the definition of each type of requirement (functional and non-functional), taking into account (i) the stage involved within a conventional mining cycle, the type of activity and the preliminary expected sequence; (ii) the need for the specific requirement and its final objective; (iii) the sensors, means and equipment necessary to satisfy the established requirement; and (iv) the factors related to the digitization and management of the data involved. All these criteria are of great importance to ensure that the requirements are established according to the same initial strategy, and taking into account all the processes and stages involved in each of the phases that constitute each pilot case [37,38,39].

Figure 2.

Criteria followed to establish the requirements of the pilot mining cases of Mine.io project.

3. Results and Discussion

In this section, the functional and non-functional requirements established by each pilot are presented following the criteria previously stated. From them, the way in which the project is expected to contribute to its fulfilment has been discussed according to the technological partners and means involved.

3.1. Pilot 1.1.—I4.0 Asset Digitalization

The development of the Digital Twin and all the associated digitization processes involved in this pilot case, and that are addressed by the Mine.io project, are linked to the requirements presented in Table 2.

Table 2.

Functional and non-functional requirements for the processes and stages of pilot case 1.1.

The requirements established in this first case study clearly demarcate the needs for digital developments, especially in relation to the drilling and ventilation processes of the mining scenario. As can be deduced from the previous Table 2, the incorporation into the pilot of a wide variety of sensors and digital and autonomous prediction tools is mandatory to optimize each of the involved processes.

Regarding the digitalizing of drilling operations, Mine.io digital infrastructure and edge systems will mean an essential starting point for providing real-time and secure data transmission, thus contributing to the preliminary defined requirements. Technologies included in the project are also expected to represent a significant advance in the overall drilling process, acting individually on each of the associated phases, maintenance, drilling time or investment, among other factors.

About the ventilation system, it is in fact one of the most relevant infrastructures to be installed in an underground mine. Although the concept of installing and operating a ventilation system seems to be simple, a complex network of underground openings and/or a complicated mining method demands the development and maintenance of a rather sophisticated ventilation system. The maintenance of these systems, which usually include major fans, either at the entrance of the mine or underground, smaller fan stations and a network of long ducts, is performed so far manually with inspections and measurements of the airflow, temperature and humidity. In this sense, the introduction of digital sensors capable of constant monitoring allows for a safer underground mining environment, but their application under these mining conditions is limited so far. The digitization of monitoring expected through Mine.io could allow for less time from the detection of a problem to its solution, also contributing to a smart predictive maintenance adapted to the process performance and the possible failures of the ventilation system.

In general terms, the satisfaction of the pilot’s requirements through the technologies provided in the project will mean an impact on the operational effectiveness, the maintenance costs and the safety and environmental dimensions. All this is expected thanks to the optimization of each of the involved different operations in terms of availability and time, the effective planning of labors and materials according to the maintenance needs, the reduction in work incidents and accidents and the reduction in contaminant release and the carbon footprint.

3.2. Pilot 1.2.—Digital Smelter

As already described in the previous section, this pilot case is focused on the optimization of smelting operations based on fully digitized solutions demanding minimal human intervention. In this context and based on the smelter technology contemplated by the pilot, the specific requirements for this scenario are shown in Table 3.

Table 3.

Functional and non-functional requirements for the processes and stages of pilot case 1.2.

The generic objective of the set of requirements established in this pilot is to achieve optimization in the recovery of metal and elimination of impurities during the smelting process. In general terms, the study case demands the development of a Digital Twin system based on the incorporation of advanced measurements and modelling equations derived from an extensive processing module. The Mine.io project will mean, in this sense, the possibility of including sensors of a diverse nature, such as acoustic measurements, radar and LIBS measurements (to assess slag properties), off-gas measurements (through FTIR methodology), temperature and the bath partial pressure of oxygen. The proposed technology represents a significant advancement over traditional metal smelting practices by integrating real-time monitoring, simulation platforms and advanced sensor technologies into a single, digitally driven framework. Unlike conventional operations, which often rely on periodic sampling and heuristic adjustments, the Digital Smelter continuously evaluates critical process parameters such as bath fluid dynamics, slag and metal phase properties, off-gas composition, oxygen potential and molten phase temperatures. This is achieved through the combination of the ACT Platform and HSC-Sim software with state-of-the-art sensors, including FMCW radar, LIBS, FTIR, partial oxygen pressure sensors and pyrometers.

Compared to traditional methods, which typically report broad operational ranges or rely on expert judgment, this approach provides quantitative, continuous and reproducible insights, allowing operators to maintain optimal process conditions and improve overall efficiency, yield and sustainability. This framework aligns with recent advances in intelligent metallurgical systems reported in the literature, where Digital Twins, AI and real-time sensor integration have demonstrated an enhanced control and performance in smelting operations [40,41].

With these contributions, it is expected to generate a great impact on the following items:

- Production performance—advanced process efficiency in the range of 3–10%, leading to the lowering of specific production costs.

- Energy consumption savings—the DT-based control leads to a higher critical raw material yield and decreases energy consumption per ton of production.

- Resource consumption savings—the optimum knowledge of in- and output streams entering the process allows an improved control of flux and reductants and minimizes the slag volume produced.

- Emissions—reduction of CO2 emissions due to efficient processing, also derived from a better definition of the flows to off-gas cleaning without upsetting the conditions.

3.3. Pilot 2—Digital Flotation System

Considering the objective of this pilot about the digitalization of the flotation technology for ore processing, the defined functional and non-functional requirements are presented in Table 4.

Table 4.

Functional and non-functional requirements for the processes and stages of pilot case 2.

As deduced from the above, the primary goal of this study case is the automation of the control techniques of the flotation processes through a PIT monitoring system. In this line, the functional and non-functional requirements linked to the pilot are focused on the optimization of all stages of the smelting processing through the incorporation of digitalization technologies based on a high-resolution vision system. This solution will be capable of performing the real-time scanning of the flotation froth and designating the copper content, also allowing a more precise selection of the flotation settings.

The computer system requires the application of specialized software based on ML and AI algorithms developed in the project, also making use of laboratory chemical analysis and XRF measurements, which will provide the “learning” feed for the software responsible for the corresponding data processing and analysis. The proposed approach introduces a digital, AI-driven framework for the real-time assessment and control of copper ore flotation. By leveraging image-based predictions of metal content in flotation froth, the system continuously monitors froth characteristics using cameras across visible and infrared spectral ranges, combined with specialized illumination. These images, together with flotation process data, are processed through a different intelligent and advanced processing software. The framework incorporates modules for image acquisition, data processing and analytical evaluation, storing the collected data in a dedicated database for further analysis. Despite significant technological developments undertaken by KGHM, such as the FloVis system that employs visual analyses of flotation froth images to monitor parameters such as bubble size, shape and mobility, this approach integrates real-time image acquisition with machine learning algorithms and an intuitive interface for decision support. This integration enables a more accurate and efficient assessment and control of the flotation process, providing immediate feedback for operational decision-making. Furthermore, it incorporates advanced sensors and analytical tools, such as X-ray fluorescence for metal content analysis and Fourier transform infrared spectroscopy for off-gas monitoring, which are not present in the current FloVis system [42,43]. Additionally, unlike conventional approaches, which rely on periodic sampling and offline chemical analysis, this system provides continuous, real-time and explainable predictions of metal content, supported by model explainability tools to ensure the quality and reliability of the AI outputs [44].

By meeting the requirements established in the pilot, it is expected that the Mine.io project can contribute to the improvement of the technological and economic performance of the flotation process in the following aspects:

- A reduction of copper ore content analysis time (expected 20%).

- A maximum measurement error compared to chemical analyses of 20%.

- At least a 3% increase in operational recovery in the rough flotation.

- A reduction in electricity consumption (around 40%) for chemical and X-ray analyses of metal content in the froth.

- A reduction in the consumption of flotation chemicals (around 1%).

- A 100% reduction in X-ray emission.

In addition to the above, the project’s contributions to the pilot could provide the opportunity of being scalable to various flotation operations (e.g., froth flotation, secondary flotation, cleaning) or different processing materials (e.g., lead, copper, zinc, etc.).

3.4. Pilot 3—Geochemical Mapping of Soils and Mining Wastes

Pilot site 3 includes the optimal characterization of a historic mining area (waste repository) to obtain exploitable ground composition and distribution information (exploration) and propose a valuable metal extraction method (extraction) and/or propose a management/remediation method for possible future application (waste management). The main functional and non-functional requirements for this pilot are presented in Table 5 for each mining/metallurgical phase.

Table 5.

Functional and non-functional requirements for the processes and stages of pilot case 3.

The present use case demands a series of functional and non-functional requirements mainly focused on the recovery of useful products containing pure metals and compounds demanded by the market, but also the remediation of polluted soils in the area. These requirements include the generation of digital models of the analyzed structure in order to achieve a precise characterization from a geometric and structural point of view, but also for the chemical and mineralogical analysis of the waste. For this, geophysical, geospatial and UAV technologies are required, integrated into modules associated with AI techniques and enriched with the contribution of more specific geochemical measurements and simulation tools.

The implementation of the described methodology within the development of the Mine.io project will allow for a significant progress in terms of the following:

- An increase in the rehabilitation performance by 10% in the second year and by 15% at the end of the project (end of 2026).

- A reduction in the energy consumption associated with waste management thanks to a precise waste mapping.

- Resource consumption savings—at least 5% more wastes are re-entered into the production in the second year (2025) and at least 7% at the end of the project (end of 2026).

- A reduction by 3% in the toxic waste of arsenic, copper, manganese and cadmium.

3.5. Pilot 4—Multi-Source Data Fusion and Interpretation for Surveillance of Tailings Embankments

Considering the principal objectives of this pilot in the context of developing a geophysical approach for monitoring the subsurface conditions of tailing embankments, the associated functional and non-functional requirements are presented in Table 6.

Table 6.

Functional and non-functional requirements for the processes and stages of pilot case 4.

In the case of this pilot, all the specific requirements are associated with the use of prospective technologies for the characterization of the structure, in terms of stability and composition. The role of the Mine.io project is, in this sense, mainly based on the contribution of infrastructure and specialized equipment for the complete in-depth evaluation of the particular mining context.

From the definition and satisfaction of the aforementioned requirements, a complex modelling of the environmental system will be developed, as well as an effective interpretation and fusion of multi-source data coming from all the prospective field campaigns, leading to the achievement of the following:

- An increase in the global production performance by the mapping of the subsurface structural conditions, also achieving an improvement in the structural performance of at least 10%.

- A minimization of the risk of personnel injuries by at least 10% in the second year and 30% at the end of the project.

- A minimization of the investment costs by at least 10% in the second year and 15% at the end of the project.

- A reduction in the CO2 emissions (at least 3%) by enabling the optimization of mechanical parameters.

3.6. Pilot 5—Advanced Mobility and Operational Excellence

As mentioned in Table 1, this pilot intends to develop an electrification solution with induction loops and autonomous driving functions that pretend to be tested in real-world use and that must comply with strict safety regulations. Based on this, the following functional and non-functional requirements presented in Table 7 have been defined.

Table 7.

Functional and non-functional requirements for the processes and stages of pilot case 5.

The final aim that can be deduced from the evaluation of this study case is to convert most of the extraction processes of mineral resources to CO2-neutral technologies by developing a transport system in which electrical power is transferred to the vehicles via induction coils integrated into the pit roadway. In this scenario, the functional and non-functional requirements are aimed at the installation and testing of demonstrators at the different levels of development involved, which finally allow the real implementation of the proposed solutions under the conditions of the mining industry. To do this, the use of registers, sensors and control systems of different natures is demanded under the ecosystem of the Mine.io project, which will in turn have an expected impact on the following:

- An increase in the production rate of the associated mining activity to levels of around 20%.

- An improvement of the energy efficiency of the transport systems by at least 70%.

- A reduction in the operational costs (20%) thanks to an optimized management of the processes where transportation is involved.

- A meaningful reduction in greenhouse gas emissions at expected levels of 30–50%.

In short, the achievement of the requirements of this pilot within the framework of Mine.io will be key for advancing a cross-border integrated industrial ecosystem capable of increasing the efficiency and scientific management of mineral resources in line with the concept of advanced mobility, logistics and supply chain operations.

3.7. Pilot 6—Underwater Exploration Technology for Water-Filled Mines

The scenario of this pilot site aims to use a novel prototype muon telescope for flooded environments as an underwater muon imaging system, together with the testing of an autonomous exploration underwater robot. Based on these conditions, Table 8 includes the functional and non-functional requirements associated with this study case.

Table 8.

Functional and non-functional requirements for the processes and stages of pilot case 6.

This last pilot aims to validate a series of exploration methodologies in underwater operating conditions. The requirements associated with this objective are aligned with the need of a scenario that allows for a validation of the equipment contemplated in the case study, fundamentally based on the use of a muography prototype and an autonomous exploratory device. The specific technologies and devices, as well as the scenarios contemplated within the framework of the project, represent an unparalleled opportunity to bring this type of mining application closer to achieving the needs and objectives that are currently being demanded. All of this will be reflected in the expected impact on the following aspects:

- A rise in the production of rock assessment of at least 5% in the second year and 15% at the end of the project.

- A contribution to personnel safety by minimizing the operational risks by at least 10% in the second year and 30% at the end of the project.

- A minimization of the operational costs, expecting a reduction of at least 10% in the second year and 15% at the end of the project.

- A reduction in greenhouse gas emissions by decreasing the need for pumping out water by at least 30%.

The aforementioned impacts that derive from the satisfaction of the functional and non-functional requirements associated with the pilot will ultimately represent an advancement in operation without the need for communication in complex scenarios, increasing the safety of the personnel involved and providing new exploratory and extractive opportunities for potential minerals that are sometimes discarded due to the conditions of the environment.

3.8. Evaluation of the European Initiatives Within the Global Policy Context

To advance the evaluation conducted in this research within a broader global policy context, it is also important to take into account the initiatives being implemented outside of the European Union. In this sense, one may refer to illustrative cases from China and Australia, where the trajectory of intelligent mining policies reveals a progression similar to (but in certain respects more advanced than) that of Europe. In China, for instance, the number of intelligent coal mining faces rose from 494 to 1019 between 2020 and 2023, and the number of fully “intelligent mines” increased from 242 to 572. Technologies such as 5G, cloud platforms, artificial intelligence and real-time monitoring systems have become central to Chinese mining operations, enabling greater operational safety and efficiency. Moreover, Chinese government policy has actively promoted digital coal mine development through multi-ministry coordination, though with an uneven implementation across provinces due to differences in local regulations and capabilities [46,47].

On the other hand, Australia provides a complementary vantage point from a mature mining jurisdiction. The country has adopted autonomous mining equipment early, and regulators have proactively developed codes of practice and safety guidelines for autonomous operations. Australia’s “Digital Mine” strategy highlights that digital innovation, data analytics and AI are integral across the full mining lifecycle (from exploration to rehabilitation), and emphasizes the need for regulatory sandboxes, workforce reskilling and institutional coordination to support technology deployment. The Minerals Council of Australia in Western Australia’s state government, for example, issued a “Code of Practice for Safe Mobile Autonomous Mining” even before large-scale autonomous truck deployment occurred, anticipating regulatory challenges ahead of practice [48,49].

Another remarkable example is India, which is actively advancing intelligent mining through a combination of artificial intelligence, machine learning and innovative technologies tailored to its unique challenges. The Rajasthan State Mineral Exploration Trust (RSMET), in collaboration with Indian Institutes of Technology (IITs), is implementing AI and ML for mineral exploration with the aim of identifying zones rich in critical minerals by analyzing satellite data, government records and ground-penetrating radar, enhancing accuracy and reducing exploration time and costs. Additionally, a proposed Smart Mining System integrates Internet of Things (IoT) devices for real-time monitoring, AI-driven decision-making and remote operation control. This system targets challenges such as operational inefficiencies, environmental degradation and security vulnerabilities in India’s mining sector. Furthermore, AI is utilized to process large datasets, identifying valuable minerals in waste materials, thereby reducing environmental impact and enhancing resource recovery. These initiatives reflect India’s commitment to integrating AI and modern technologies into its mining sector, aiming for increased efficiency, sustainability and safety [50].

When these international experiences are compared to the European context, several converging trends become evident: the shift from narrow concerns of mechanization and cost reduction to integrated objectives of safety, digital infrastructure, environmental sustainability and human-technology interaction. At the same time, divergences appear in regulatory culture, institutional readiness and the role of central vs. subnational authorities in policy execution.

4. Conclusions

This research has focused on the analysis of one of the first and most influential phases of development of the European Mine.io project: the establishment of the particular needs associated with different mining contexts. As has been explained, several standard criteria have been established for the correct establishment of the functional and non-functional requirements linked to each of the processes and stages that constitute each of the pilot cases included in the project. Once these requirements have been established, the way in which the technologies and partners involved in Mine.io can contribute to their fulfilment has been discussed, being clearly conceived as a starting point to achieve the initial objectives of the project. In general terms, it is considered that the project has the appropriate means to meet the established requirements, despite it being a challenge to bring together so many different partners and technologies in so many different mining activities.

Understanding the specific demands and requirements of different representative mining sectors is regarded as a critical step in driving innovation and progress within the industry. This knowledge provides a foundation for identifying opportunities to enhance operations and address challenges effectively. Equally important is the effort to define clear and actionable strategies for advancing the mining sector in a way that prioritizes both sustainability and digital transformation. By integrating modern technologies and adhering to environmentally conscious practices, the industry can work toward achieving long-term resilience and adaptability while meeting global demands. This comprehensive approach not only enhances efficiency and productivity but also contributes to the development of a more responsible and forward-thinking mining industry.

Author Contributions

Investigation, C.S.B. and M.F.; methodology, C.S.B. and I.M.N.; writing—original draft, C.S.B., V.P. and M.F.; reviewing and editing, C.S.B., V.P. and M.F.; formal analysis, V.P. and M.F.; data curation, I.M.N.; supervision, K.M. and D.G.-A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the European Union’s Horizon 2020 research and innovation programme under grant agreement, funded by MCIN/AEI/10.13039/501100011033 and by European Union “NextGenerationEU”/PRTR. C.S.B. gratefully acknowledges her Ramón y Cajal grants (RYC2021-034720-I), funded by MCIN/AEI/10.13039/501100011033 and co-financed by the European Union through the “NextGenerationEU”/PRTR initiative.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

Authors would also like to thank the Department of Cartographic and Land Engineering of the Higher Polytechnic School of Avila, University of Salamanca, for their collaboration during the experimental phase of this research.

Conflicts of Interest

Author Katerina Margariti was employed by the company ACCELIGENCE Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financialrelationships that could be construed as a potential conflict of interest.

References

- Lech, J. Flint mining among the early farming communities of Central Europe. P. 2, The basis of research into flint works hops. Przegląd Archeol. 1983, 30, 47–80. [Google Scholar]

- Parameswaran, K. Sustainability considerations in innovative process development. In Innovative Process Development in Metallurgical Industry: Concept to Commission; Springer: Berlin/Heidelberg, Germany, 2016; Volume 257–280. [Google Scholar]

- Agboola, O.; Babatunde, D.E.; Fayomi, O.S.I.; Sadiku, E.R.; Popoola, P.; Moropeng, L.; Yahaya, A.; Mamudu, O.A. A review on the impact of mining operation: Monitoring, assessment and management. Results Eng. 2020, 8, 100181. [Google Scholar] [CrossRef]

- Blengini, G.A.; Nuss, P.; Dewulf, J.; Nita, V.; Peirò, L.T.; Vidal-Legaz, B.; Latunussa, C.; Mancini, L.; Blagoeva, D.; Pennington, D.; et al. EU methodology for critical raw materials assessment: Policy needs and proposed solutions for incremental improvements. Resour. Policy 2017, 53, 12–19. [Google Scholar] [CrossRef]

- Endl, A.; Tost, M.; Hitch, M.; Moser, P.; Feiel, S. Europe’s mining innovation trends and their contribution to the sustainable development goals: Blind spots and strong points. Resour. Policy 2021, 74, 101440. [Google Scholar] [CrossRef]

- De Haan, J.; Dales, K.; McQuilken, J. Mapping artisanal and small-scale mining to the Sustainable Development Goals. In Minerals, Materials and Society Program in Partnership with Pact; University of Delaware: Newark, DE, USA, 2020. [Google Scholar]

- Andrews, N.; Essah, M. The sustainable development conundrum in gold mining: Exploring ‘Open, Prior and Independent Deliberate Discussion’ as a community-centered framework. Resour. Policy 2020, 68, 101798. [Google Scholar] [CrossRef]

- Abdullajanovich, U.T. The Role of Industrial Enterprises in the Development of the National Economy. In Conference Zone; ICMSEAS: Hamburg, Germany, 2022; pp. 271–276. [Google Scholar]

- Monteiro, N.B.R.; da Silva, E.A.; Neto, J.M.M. Sustainable development goals in mining. J. Clean. Prod. 2019, 228, 509–520. [Google Scholar] [CrossRef]

- Fetting, C. The European green deal. ESDN Rep. 2020, 2, 53. [Google Scholar]

- Almeida, D.V.; Kolinjivadi, V.; Ferrando, T.; Roy, B.; Herrera, H.; Gonçalves, M.V.; Van Hecken, G. The “Greening” of Empire: The European Green Deal as the EU first agenda. Political Geogr. 2023, 105, 102925. [Google Scholar] [CrossRef]

- Frenz, W.; Preuße, A.; Gurgel, M.J. Role of the UN Sustainable Development Goals and of the European Green Deal in View of the Mining and Energy Sector. In Yearbook of Sustainable Smart Mining and Energy 2021: Technical, Economic and Legal Framework; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–12. [Google Scholar]

- Mitra, R. Digitalization in Mining Geomechanics–Looking to the Future. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 25–28 June 2023; ARMA: Eaton, CO, USA, 2023; p. ARMA–2023. [Google Scholar]

- Nham, N.T.H.; Hoa, T.T.M. Influences of digitalization on sustaining marine minerals: A path toward sustainable blue economy. Ocean Coast. Manag. 2023, 239, 106589. [Google Scholar] [CrossRef]

- Durrant-Whyte, H.; Geraghty, R.; Pujol, F.; Sellschop, R. How Digital Innovation Can Improve Mining Productivity; McKinsey & Company Insights: Lisbon, Portugal, 2015; pp. 1–8. [Google Scholar]

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90–95. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Beloglazov, I.I.; Petrov, P.A.; Bazhin, V.Y. The concept of digital twins for tech operator training simulator design for mining and processing industry. Chem. Ind. 2020, 18, 19. [Google Scholar] [CrossRef]

- Zhironkin, S.; Ezdina, N. Review of transition from mining 4.0 to mining 5.0 innovative technologies. Appl. Sci. 2023, 13, 4917. [Google Scholar] [CrossRef]

- Qu, J.; Kizil, M.S.; Yahyaei, M.; Knights, P.F. Digital twins in the minerals industry–a comprehensive review. Min. Technol. 2023, 132, 267–289. [Google Scholar] [CrossRef]

- Don, M.G.; Wanasinghe, T.R.; Gosine, R.G.; Warrian, P.J. Digital Twins and Enabling Technology Applications in Mining: Research Trends, Opportunities, and Challenges. IEEE Access 2025, 13, 6945–6963. [Google Scholar] [CrossRef]

- Bartnitzki, T. Mining 4.0: Importance of Industry 4.0 for the raw materials sector. Artif. Intell 2017, 2, 25–31. [Google Scholar]

- Roldán, J.J.; Crespo, E.; Martín-Barrio, A.; Peña-Tapia, E.; Barrientos, A. A training system for Industry 4.0 operators in complex assemblies based on virtual reality and process mining. Robot. Comput.-Integr. Manuf. 2019, 59, 305–316. [Google Scholar] [CrossRef]

- Füllenbach, C. Digitisation in the Mining Industry: Networked Machines Making for Greater Efficiency. Min. Rep. 2018, 154, 351–355. [Google Scholar]

- Suciu, M.; Kowitz, S. Digitizing Raw Material Mining–End-to-End Integration into an IIoT Platform for the Analysis of Machine Data. Min. Rep. Glückauf 2019, 155, 382–388. [Google Scholar]

- Barnewold, L.; Lottermoser, B.G. Identification of digital technologies and digitalisation trends in the mining industry. Int. J. Min. Sci. Technol. 2020, 30, 747–757. [Google Scholar] [CrossRef]

- Storey, K. From FIFO to LILO: The place effects of digitalization in the mining sector. Extr. Ind. Soc. 2023, 13, 101206. [Google Scholar] [CrossRef]

- Nagovitsyn, O.; Churkin, O.; Gilyarova, A. Effects of application of industry-4.0 technologies and digitalization in mining. In Proceedings of the 21st International Multidisciplinary Scientific GeoConference SGEM, Albena, Bulgaria, 26 June–5 July 2021; pp. 347–354. [Google Scholar]

- Palka, D.; Rizaoğlu, T. The concept of hard coal mine in the perspective of Industry 4.0. Multidiscip. Asp. Prod. Eng. 2019, 2, 327–335. [Google Scholar] [CrossRef]

- Zhironkina, O.; Zhironkin, S. Technological and Intellectual Transition to mining 4.0: A review. Energies 2023, 16, 1427. [Google Scholar] [CrossRef]

- Ayuk, E.; Pedro, A.; Ekins, P.; Gatune, J.; Milligan, B.; Oberle, B.; Christmann, P.; Ali, S.; Kumar, S.V.; Bringezu, S.; et al. Mineral Resource Governance in the 21st Century: Gearing Extractive Industries Towards Sustainable Development; International Resource Panel, United Nations Envio: Nairobi, Kenya, 2020. [Google Scholar]

- Onifade, M.; Zvarivadza, T.; Adebisi, J.A.; Said, K.O.; Dayo-Olupona, O.; Lawal, A.I.; Khandelwal, M. Advancing toward sustainability: The emergence of green mining technologies and practices. Green Smart Min. Eng. 2024, 1, 157–174. [Google Scholar] [CrossRef]

- Olsson, T.; Franke, U. Risks and assets: A qualitative study of a software ecosystem in the mining industry. In Proceedings of the 2019 27th ACM Joint Meeting on European Software Engineering Conference and Symposium on the Foundations of Software Engineering, Tallinn, Estonia, 26–30 August 2019; pp. 895–904. [Google Scholar]

- Chatterjee, C.; Sindhwani, R.; Mangla, S.K.; Hasteer, N. Digitization of the mining industry: Pathways to sustainability through enabling technologies. Resour. Policy 2025, 100, 105450. [Google Scholar] [CrossRef]

- Gruenhagen, J.H.; Cox, S.; Parker, R. An actor-oriented perspective on innovation systems: Functional analysis of drivers and barriers to innovation and technology adoption in the mining sector. Technol. Soc. 2022, 68, 101920. [Google Scholar] [CrossRef]

- Jindal, R.; Malhotra, R.; Jain, A.; Bansal, A. Mining Non-Functional Requirements using Machine Learning Techniques. e-Inform. Softw. Eng. J. 2021, 15, 85–114. [Google Scholar] [CrossRef]

- Muller, S.; Beylot, A.; Sydd, O.; Doyle, K.; Bodin, J.; Villeneuve, J. Applying social life cycle assessment in the early stages of a project development—An example from the mining sector. Int. J. Life Cycle Assess. 2021, 26, 2436–2456. [Google Scholar] [CrossRef]

- Lazarenko, Y.; Garafonova, O.; Marhasova, V.; Tkalenko, N. Digital transformation in the mining sector: Exploring global technology trends and managerial issues. In E3S Web of Conferences; EDP Sciences: London, UK, 2021; Volume 315, p. 04006. [Google Scholar]

- Pouresmaieli, M.; Ataei, M.; Qarahasanlou, A.N.; Barabadi, A. Integration of renewable energy and sustainable development with strategic planning in the mining industry. Results Eng. 2023, 20, 101412. [Google Scholar] [CrossRef]

- Amankwaa-Kyeremeh, B.; McCamley, C.; Zanin, M.; Greet, C.; Ehrig, K.; Asamoah, R.K. Prediction and optimisation of copper recovery in the rougher flotation circuit. Minerals 2023, 14, 36. [Google Scholar] [CrossRef]

- Fu, T.; Liu, S.; Li, P. Digital twin-driven smelting process management method for converter steelmaking. J. Intell. Manuf. 2025, 36, 2749–2765. [Google Scholar] [CrossRef]

- Galas, J.; Litwin, D. Machine learning technique for recognition of flotation froth images in a nonstable flotation process. Minerals 2022, 12, 1052. [Google Scholar] [CrossRef]

- Ali, D.; Hayat, M.B.; Alagha, L.; Monyake, K.C.; Khalid, H. Artificial intelligence and machine learning models for predicting the metallurgical performance of complex sulfide ore flotation process. Miner. Process. Extr. Metall. 2025, 134, 13–32. [Google Scholar] [CrossRef]

- Galas, J.; Litwin, D.; Radziak, K.; Malkinski, W.; Karlinski, M.; Błocki, N.; Czyżewski, A.; Kozielski, M.; Foszcz, D.; Saramak, D.; et al. The ore content estimation in the mineral processing plant with the aid of the ML process: From classification to measurement. In Digital Optical Technologies; SPIE: Washington, DC, USA, 2025; Volume 13573, pp. 215–218. [Google Scholar]

- Martins, A.; Almeida, J.; Almeida, C.; Matias, B.; Kapusniak, S.; Silva, E. EVA a hybrid ROV/AUV for underwater mining operations support. In Proceedings of the 2018 OCEANS-MTS/IEEE Kobe Techno-Oceans (OTO), Kobe, Japan, 28–31 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar]

- Wo, X.; Li, G.; Sun, Y.; Li, J.; Yang, S.; Hao, H. The changing tendency and association analysis of intelligent coal mines in China: A policy text mining study. Sustainability 2022, 14, 11650. [Google Scholar] [CrossRef]

- Zhang, K.; Kang, L.; Chen, X.; He, M.; Zhu, C.; Li, D. A review of intelligent unmanned mining current situation and development trend. Energies 2022, 15, 513. [Google Scholar] [CrossRef]

- Hayes, A. On country: Australian aboriginal communities, mining, and artificial intelligence [Opinion]. IEEE Technol. Soc. Mag. 2017, 36, 37–40. [Google Scholar] [CrossRef]

- Leung, R.; Hill, A.J.; Melkumyan, A. Automation and Artificial Intelligence Technology in Surface Mining: A Brief Introduction to Open-Pit Operations in the Pilbara. IEEE Robot. Autom. Mag. 2023, 32, 164–183. [Google Scholar] [CrossRef]

- Elduri, H.P. Smart Mining Systems for Indian Terrain: A Proposed Solution for Productivity, Sustainability, and Security. Sustain. Secur. 2025, 1–9. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).