Biomass Valorisation Resources, Opportunities, and Barriers in Ireland: A Case Study of Counties Monaghan and Tipperary

Abstract

1. Introduction

2. Material and Methods

2.1. Biomass Resources Available from Waste Streams

2.2. Calculation of Available Biomass

- These materials are generally considered a nuisance and raise a challenge for disposal without polluting the environment.

- New biorefinery processes must be based on non-competing wastes and residues to reduce impacts on food availability and prices.

- Bio-based economy is fundamentally based on using biological processes to create energy rather than fossil fuels.

2.3. Stakeholder Perspective

3. Results

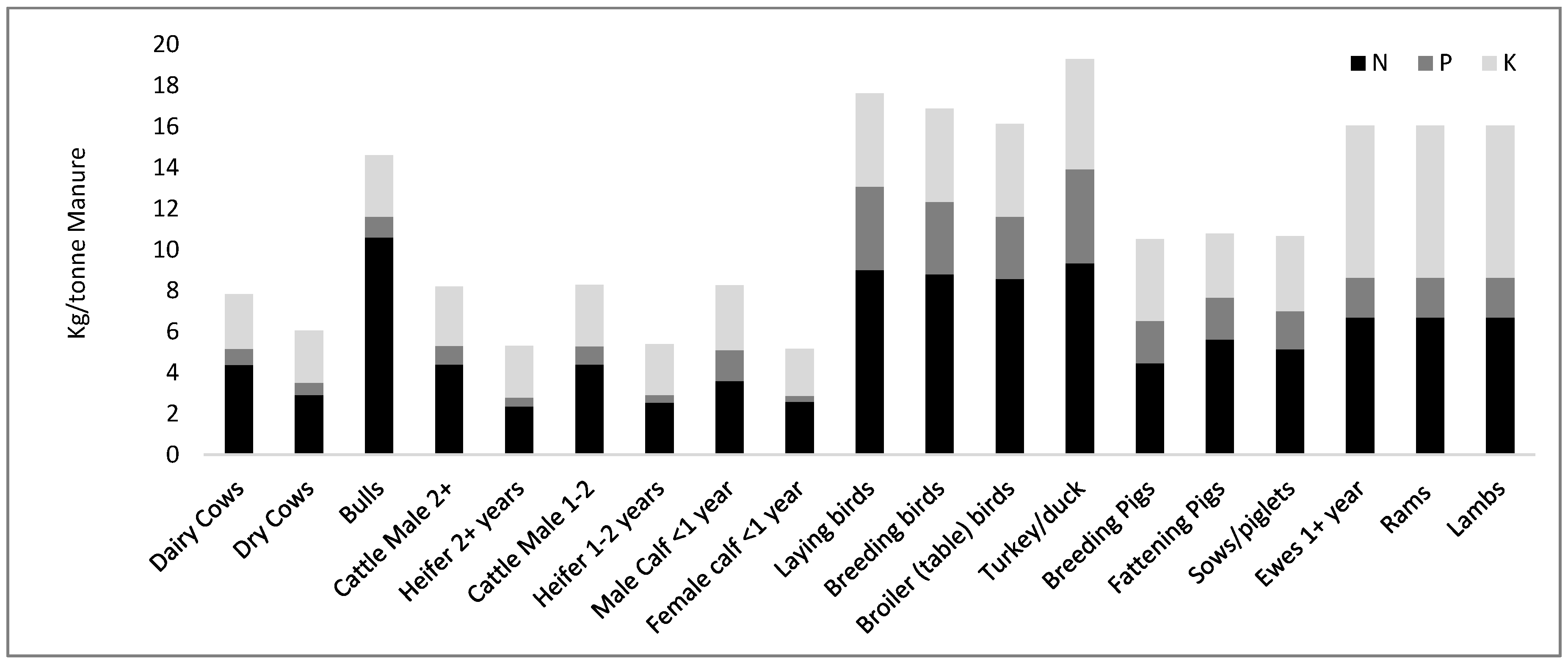

3.1. Livestock and Poultry

| Animal Category | Monaghan Heads | Tipperary Heads | Monaghan/Tipperary Share (%) † |

|---|---|---|---|

| Dairy cows | 38,100 | 182,500 | 17.3/82.7 |

| Dry cows | 31,100 | 53,600 | 36.7/63.3 |

| Bulls | 1700 | 3800 | 30.9/69.1 |

| Cattle male ≥ 2 yr | 11,200 | 47,600 | 19.0/81.0 |

| Heifer ≥ 2 yr | 14,300 | 29,500 | 32.6/67.4 |

| Cattle male 1–2 yr | 27,100 | 87,400 | 23.7/76.3 |

| Heifer 1–2 yr | 31,300 | 96,900 | 24.4/75.6 |

| Male calf < 1 yr | 30,300 | 102,100 | 22.9/77.1 |

| Female calf < 1 yr | 31,800 | 103,600 | 23.5/76.5 |

| Cattle total | 216,900 | 707,000 | 23.5/76.5 |

| Laying birds | 910,936 | 7809 | 99.2/0.8 |

| Breeding birds | 197,418 | 305 | 99.8/0.2 |

| Broiler (table) birds | 4,459,667 | 987 | 100.0/0.0 |

| Turkey/duck | 279,719 | 7035 | 97.5/2.5 |

| Poultry total | 5,847,740 | 16,136 | 99.7/0.3 |

| Breeding pigs | 1300 | 13,637 | 8.7/91.3 |

| Fattening pigs | 21,811 | 195,059 | 10.1/89.9 |

| Sows/piglets | 1 | 36 | 2.7/97.3 |

| Pig total | 23,112 | 208,732 | 10.0/90.0 |

| Breeding ewes ≥ 1 yr | 28,082 | 74,787 | 27.3/72.7 |

| Rams | 1156 | 2257 | 33.9/66.1 |

| Lambs | 18,471 | 38,402 | 32.5/67.5 |

| Sheep total | 47,709 | 115,446 | 29.2/70.8 |

| Grand total (all species) | 6,135,461 | 1,047,314 | 85.4/14.6 |

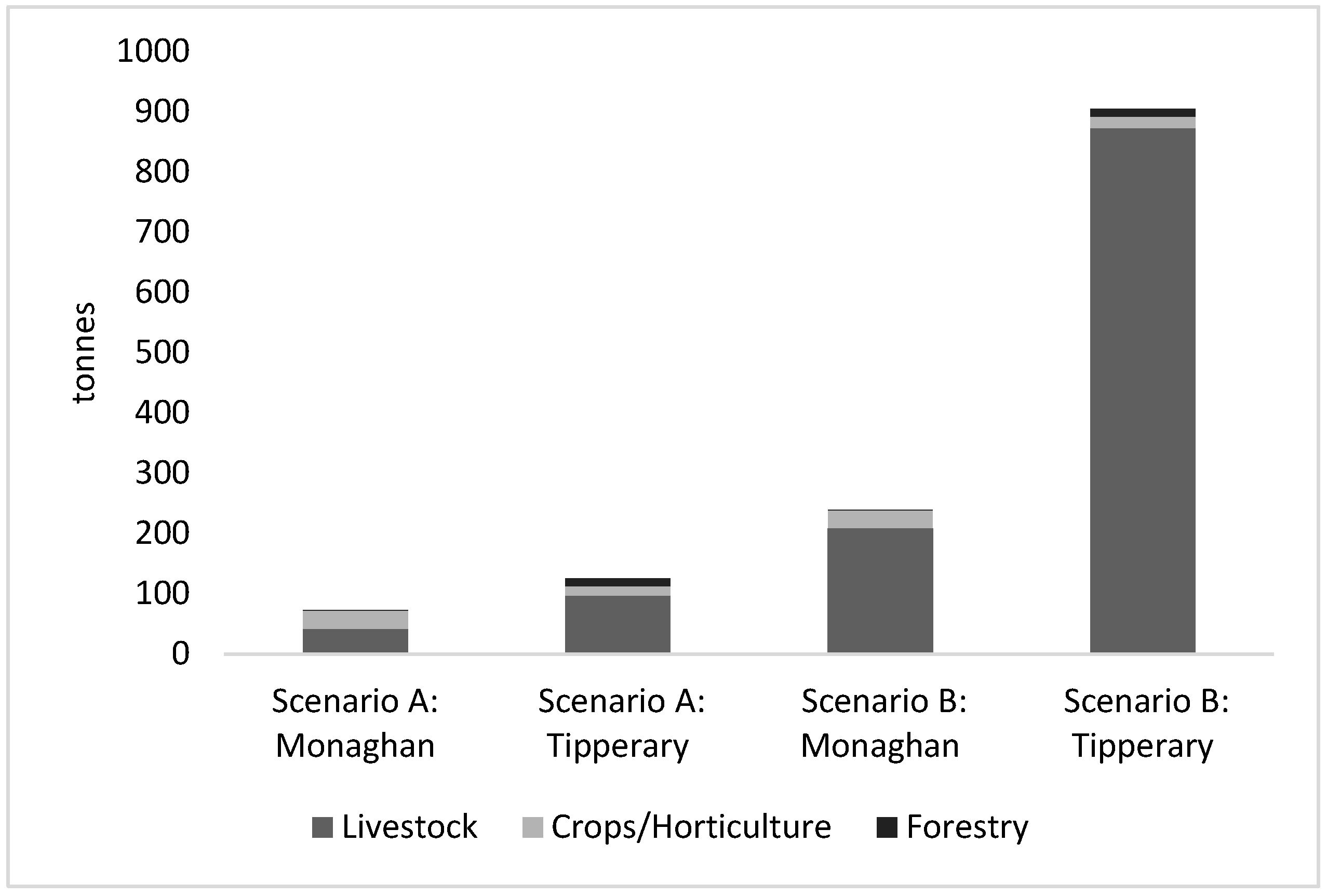

| Scenario A: Monaghan |

Scenario A:

Tipperary | Scenario B: Monaghan | Scenario B: Tipperary | |

|---|---|---|---|---|

| Kt/Year | Kt/Year | Kt/Year | Kt/Year | |

| Cattle manure | 22.6 | 79.2 | 180.7 | 634.0 |

| Poultry litter | 3.1 | 0.03 | 3.1 | 0.03 |

| Pig manure | 16.2 | 16.2 | 25.1 | 225.9 |

| Sheep manure | 0.4 | 1.0 | 3.3 | 8.1 |

| Total | 42.4 | 96.5 | 212.2 | 868.1 |

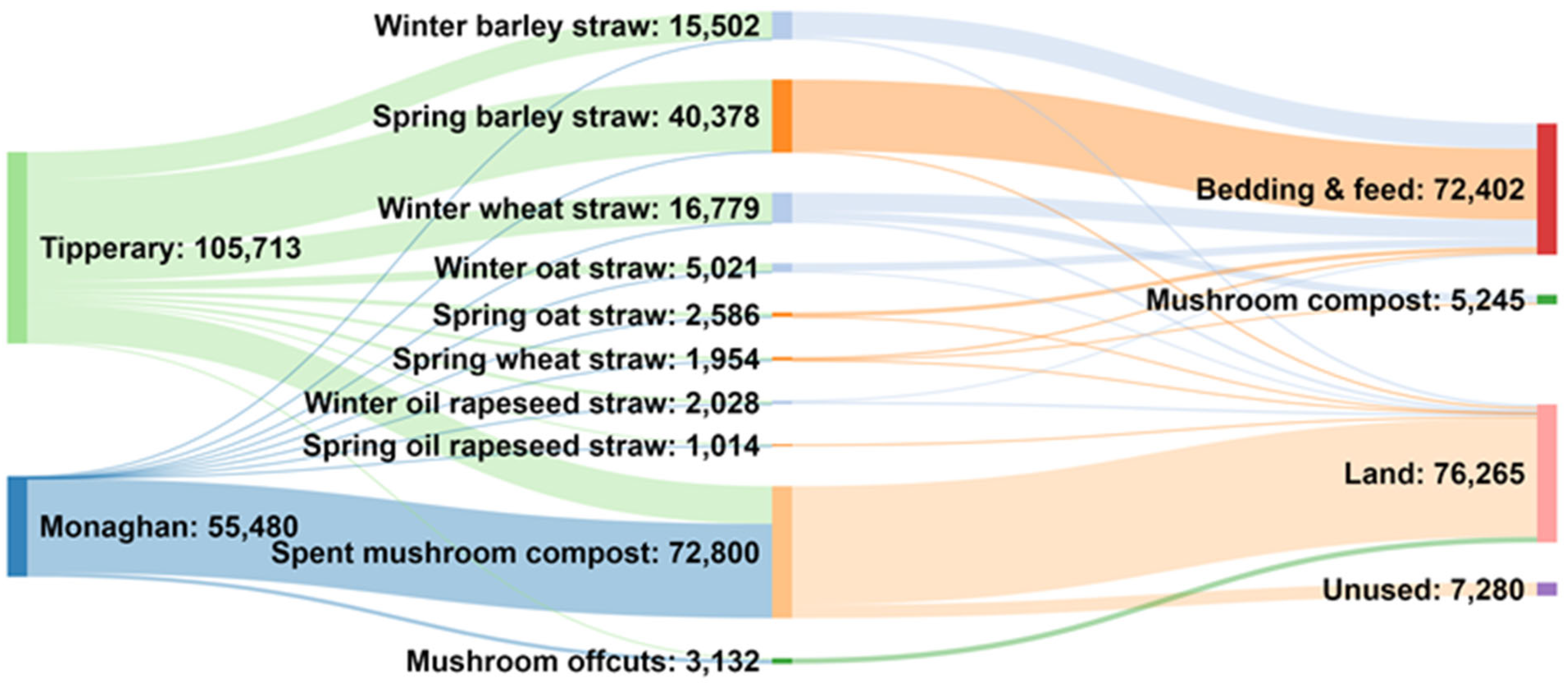

3.2. Crops and Horticulture

| Crop | Monaghan | Tipperary | Biomass Wastes | Monaghan | Tipperary |

|---|---|---|---|---|---|

| Hectares | Hectares | Tonnes | Tonnes | ||

| Winter wheat | 2 | 3993 | Winter wheat straw | 8 | 16,771 |

| Spring wheat | 3 | 648 | Spring wheat straw | 9 | 1944 |

| Winter barley | 40 | 3651 | Winter barley straw | 168 | 15,334 |

| Spring barley | 265 | 10,951 | Spring barley straw | 954 | 39,424 |

| Winter oats | 0 | 1068 | Winter oat straw | 0 | 5020 |

| Spring oats | 18 | 645 | Spring oat straw | 70 | 2516 |

| Oilseed rape | 4 | 367 | Winter oil rapeseed straw | 22 | 2006 |

| Spring oil rapeseed straw | 11 | 1003 | |||

| Mushrooms | 22,390 | 8176 | Spent Mushroom compost | 52,000 | 20,800 |

| Mushroom offcuts | 2237 | 895 |

| Scenario A: Monaghan | Scenario A: Tipperary | Scenario B: Monaghan | Scenario B: Tipperary | |

|---|---|---|---|---|

| Kt/Year | Kt/Year | Kt/Year | Kt/Year | |

| Unused SMC | 5.2 | 2.1 | 5.2 | 2.1 |

| SMC to land | 23.4 | 9.4 | 23.4 | 9.4 |

| Mushroom offcuts to land | 1.1 | 0.4 | 1.1 | 0.4 |

| Straw | 0.04 | 3.8 | 0.07 | 7.4 |

| Total | 29.8 | 15.7 | 29.8 | 19.3 |

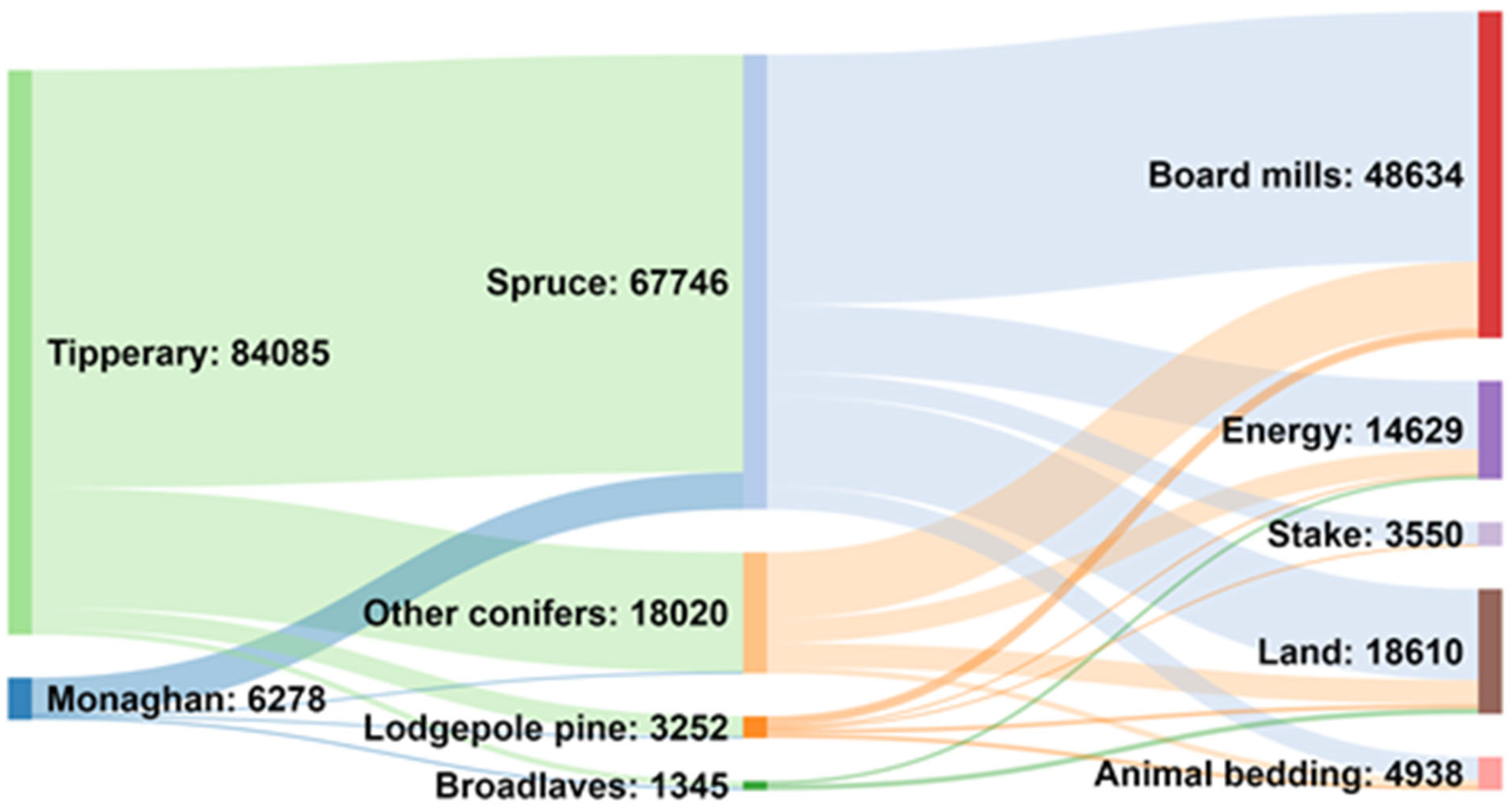

3.3. Forestry

| Monaghan | Tipperary | |

|---|---|---|

| Kt | Kt | |

| Forestry biomass to land | 0.5 | 6.0 |

| Forestry biomass to energy | 0.5 | 6.8 |

| Total | 1.0 | 12.8 |

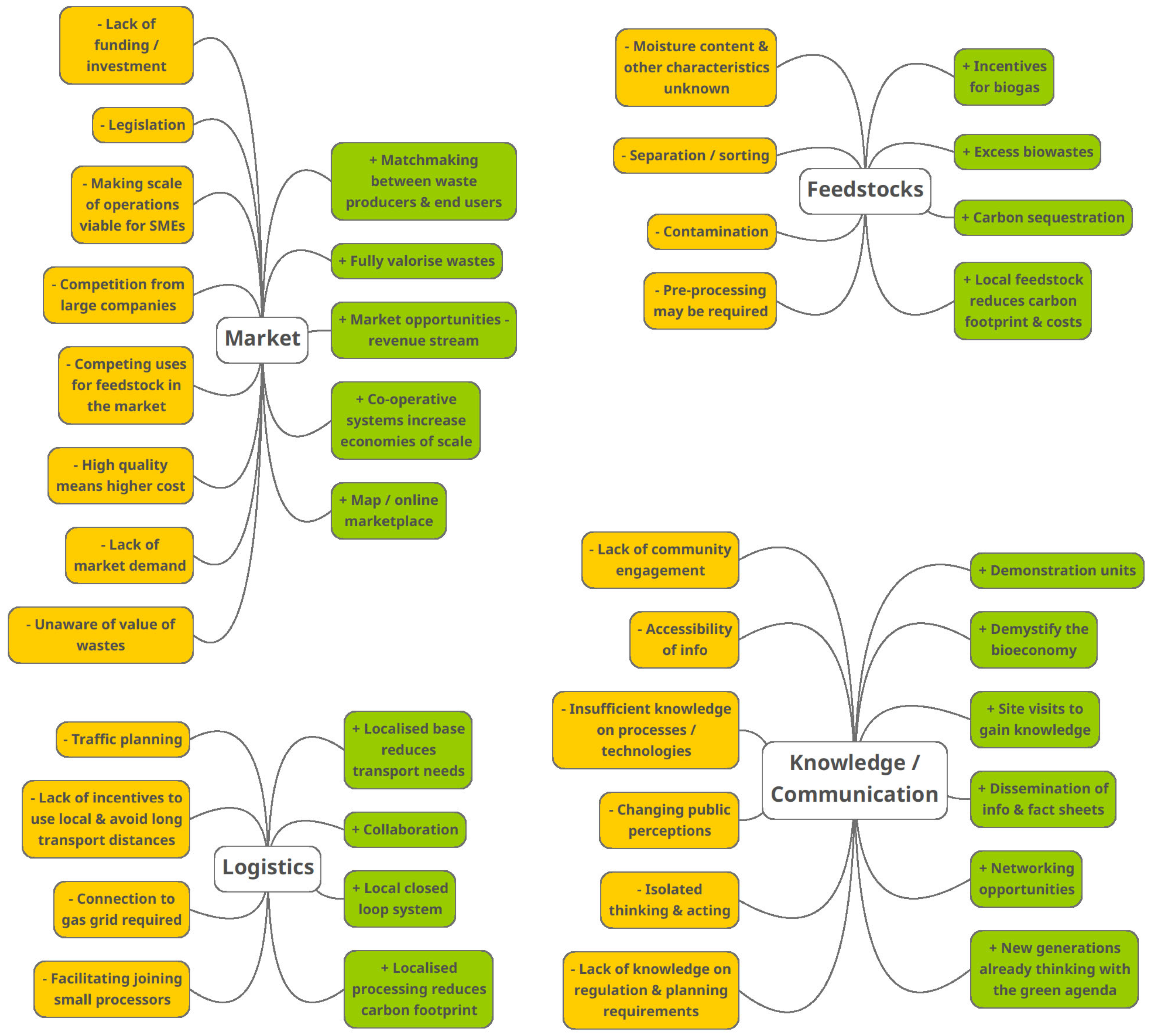

3.4. Stakeholder Analysis

3.4.1. Workshop 1: Mapping Barriers and Opportunities

3.4.2. Stakeholder Clusters and Salience Assessment

| Cluster | Typical Organisations | Power * | Interest * | Salient Issues |

|---|---|---|---|---|

| Primary producers | Dairy and poultry farmers, forestry owners, hemp growers | ●●○ | ●●● | Haulage cost, fertiliser offsets, CAP funding |

| Waste management and logistics firms | Hauliers, co-ops, circular-hub start-ups | ●●● | ●●○ | Transport incentives, grid connection, traffic planning |

| Technology and service providers | AD developers, pyrolysis vendors, engineering consultants | ●●○ | ●●● | Feedstock spec, finance, permits |

| Local authorities and regulators | County councils, EPA, planning boards | ●●● | ●●○ | Licensing, zoning, community acceptance |

| Financiers and policy makers | SEAI, LEADER, local enterprise offices | ●●● | ●●○ | Grants, tariffs, rural development |

| Civil society and knowledge brokers | Teagasc, academia, NGOs, farming unions | ●○○ | ●●● | Demonstration sites, outreach, “green agenda” |

3.4.3. Workshop 2: Stress-Testing Cascading Technology Chains

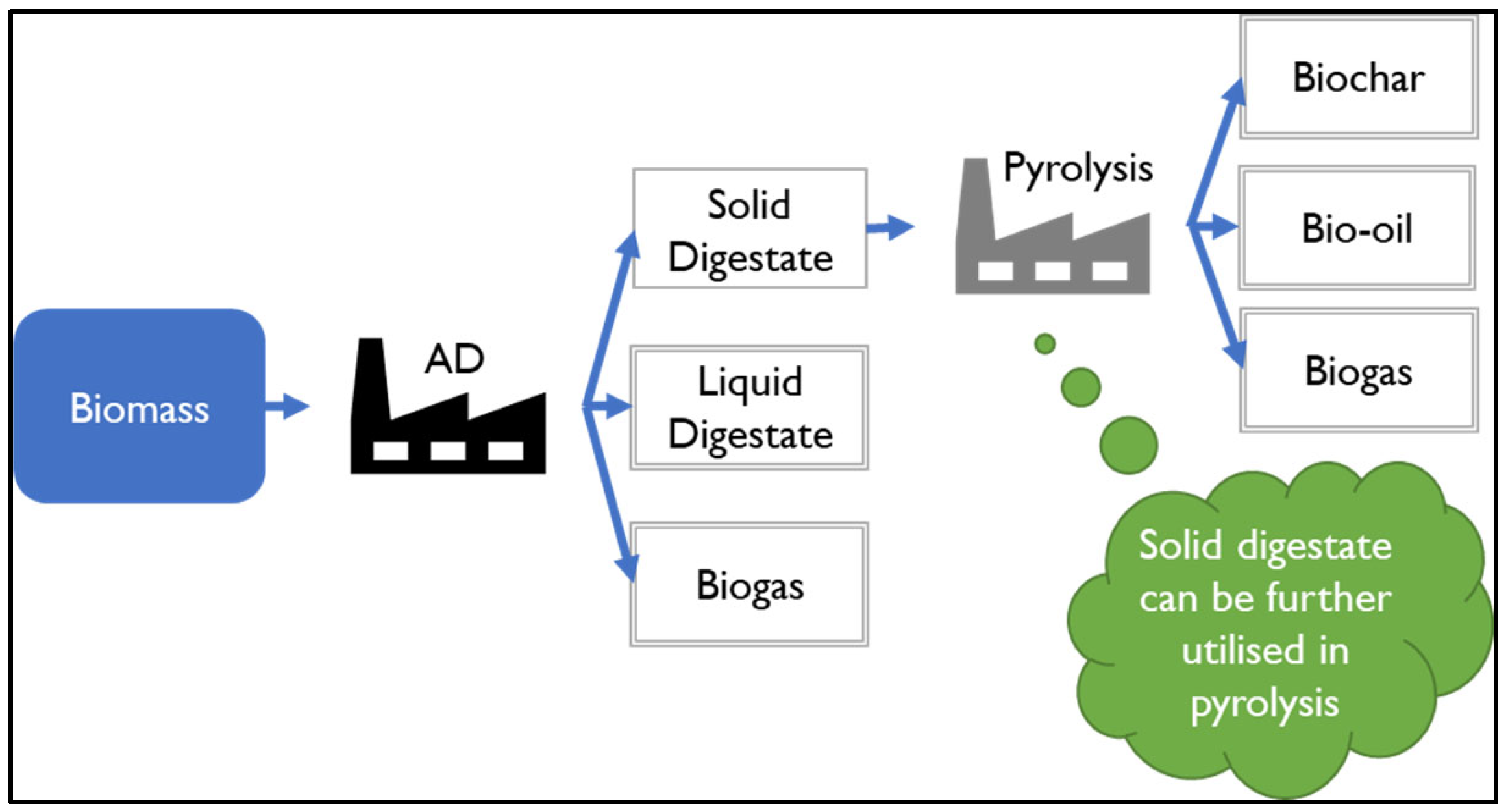

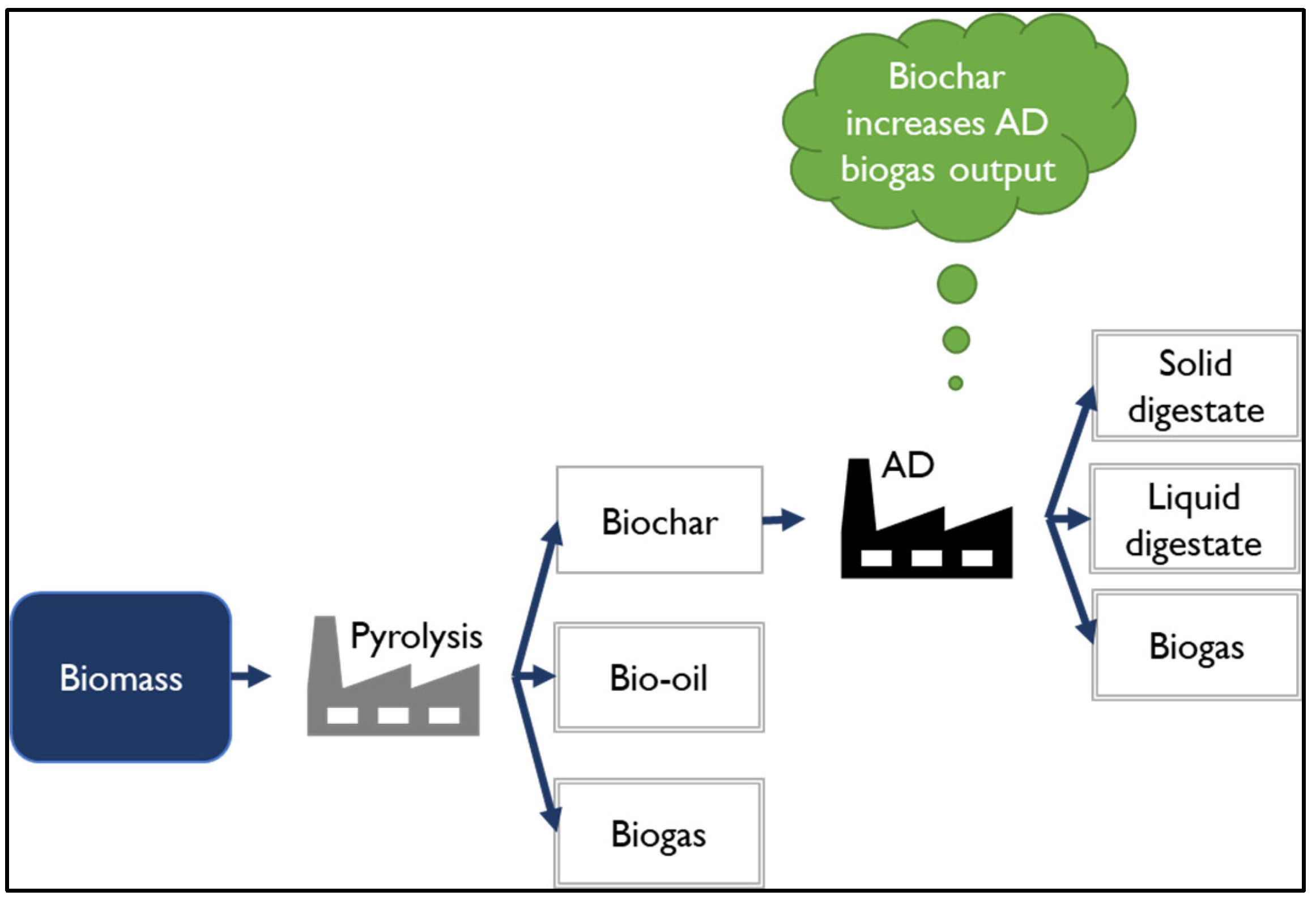

- Chain A: manures/poultry litter → anaerobic digestion → pyrolysis → [downstream steps] (Figure S18);

- Chain B: forestry and crop residues/spent mushroom compost (SMC) → [technology steps] (Figure S19).

- Biogas emerged as the most desirable output (4.6 ± 0.4), reflecting Ireland’s established renewable-gas market infrastructure [32].

- Biochar and digestate attracted medium to high interest (≥4.0), driven by fertiliser-offset potential and soil-health narratives [33].

- Operational inter-dependency was flagged as a vulnerability: if any unit in the cascade fails, feedstock back-logs accrue, incurring storage costs, which is a risk observed in other cascade pilots [34].

3.4.4. Synthesis and Implications for the Project

3.5. Cascading Technology Options

4. Discussion

| Scenario A: Business As Usual | Scenario B: Best-Case Co-Operative | |

|---|---|---|

| Cattle/sheep manure | 1% | 8% |

| Pig manure | 46% | 71% |

| Poultry litter | 50% | 50% |

| Unused SMC | 100% | 100% |

| SMC to land | 50% | 50% |

| Mushroom offcuts to land | 50% | 50% |

| Straw | 50% | 98% |

| Forest biomass to land | 35% | 35% |

| Forest biomass to energy | 50% | 50% |

4.1. Livestock and Poultry Biomass

4.2. Crop and Horticultural Biomass

4.3. Forestry Residues

4.4. Stakeholder Perspectives

4.5. Cascading Technology Options

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khanna, M.; Zilberman, D.; Hochman, G.; Basso, B. An Economic Perspective of the Circular Bioeconomy in the Food and Agricultural Sector. Commun. Earth Environ. 2024, 5, 507. [Google Scholar] [CrossRef]

- European Commission. Towards a Circular Economy: A Zero Waste Programme for Europe; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Kircher, M.; Maurer, K.-H.; Herzberg, D. KBBE: The Knowledge-Based Bioeconomy: Concept, Status and Future Prospects. EFB Bioeconomy J. 2022, 2, 100034. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Climate Science & Climate Change Environmental Monitoring & Assessment; Environmental Protection Agency: Washington, DC, USA, 2020.

- Teagasc. Teagasc Technology Foresight 2030 Irish Crop Production: Current Situation, Future Prospects to 2030 and Development Needs; Teagasc: Carlow, Ireland, 2021; Available online: https://teagasc.ie/wp-content/uploads/2025/05/Foresight-Crops-Background-Paper-final-1.pdf (accessed on 28 August 2025).

- Redmond; JohnJ Forests Statistics Ireland 2022. 2022. Available online: https://teagasc.ie/wp-content/uploads/2025/05/Forest-Statistics-Ireland-2022.pdf (accessed on 28 August 2025).

- da Costa, T.P.; Murphy, F.; Roldan, R.; Mediboyina, M.K.; Chen, W.; Sweeney, J.; Capareda, S.; Holden, N.M. Technical and Environmental Assessment of Forestry Residues Valorisation via Fast Pyrolysis in Ireland. Biomass Bioenergy 2023, 173, 106766. [Google Scholar] [CrossRef]

- Dudziec, P.; Stachowicz, P.; Stolarski, M.J. Diversity of Properties of Sawmill Residues Used as Feedstock for Energy Generation. Renew. Energy 2023, 202, 822–833. [Google Scholar] [CrossRef]

- Weituschat, C.S.; Pascucci, S.; Materia, V.C.; Caracciolo, F. Can Contract Farming Support Sustainable Intensification in Agri-Food Value Chains? Ecol. Econ. 2023, 211, 107876. [Google Scholar] [CrossRef]

- Lynch, J.; Donnellan, T.; Finn, J.A.; Dillon, E.; Ryan, M. Potential Development of Irish Agricultural Sustainability Indicators for Current and Future Policy Evaluation Needs. J. Environ. Manag. 2019, 230, 434–445. [Google Scholar] [CrossRef] [PubMed]

- COFORD. Forest-Based Biomass and Modern Bioenergy Moving to Net Zero—A COFORD Paper; COFORD: Dublin, Ireland, 2024. [Google Scholar]

- Berndes, G.; Hoogwijk, M.; Van Den Broek, R. The Contribution of Biomass in the Future Global Energy Supply: A Review of 17 Studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Central Statistics Office (CSO) CSO Data Hub. Available online: https://data.cso.ie/ (accessed on 28 August 2025).

- Netherlands Organisation for Applied Scientific Research (TNO). Phyllis2: Database for Biomass and Waste. Available online: https://phyllis.nl/ (accessed on 28 August 2025).

- ASAE/ASABE Standards. Manure Production and Characteristics; ASAE/ASABE Standards: St. Joseph, MI, USA, 2005. [Google Scholar]

- James, R.; Eastridge, M.L.; Brown, L.C.; Elder, K.H.; Foster, S.S.; Hoorman, J.J.; Joyce, M.J.; Keener, H.M.; Mancl, K.; Monnin, M.J.; et al. Bulletin 604. Ohio Livestock Manure Management Guide; OSU Extention: Columbus, OH, USA, 2006. [Google Scholar]

- Sustainable Energy Authority of Ireland. An Update of Potential Resource Quantities and Costs; Sustainable Energy Authority of Ireland: Dublin, Ireland, 2025. [Google Scholar]

- Beckers, S.J.; Dallo, I.A.; Del Campo, I.; Rosenauer, C.; Klein, K.; Wurm, F.R. From Compost to Colloids—Valorization of Spent Mushroom Substrate. ACS Sustain. Chem. Eng. 2019, 7, 6991–6998. [Google Scholar] [CrossRef]

- Mediboyina, M.K.; Murphy, F. Environmental Assessment of a Waste-to-Energy Cascading System Integrating Forestry Residue Pyrolysis and Poultry Litter Anaerobic Digestion. Energies 2024, 17, 1511. [Google Scholar] [CrossRef]

- Mulholland, E.; Rogan, F.; Gallachóir, B.P.Ó. Techno-Economic Data for a Multi-Model Approach to Decarbonisation of the Irish Private Car Sector. Data Br. 2017, 15, 922–932. [Google Scholar] [CrossRef]

- López-Linares, J.C.; Ballesteros, I.; Tourán, J.; Cara, C.; Castro, E.; Ballesteros, M.; Romero, I. Optimization of Uncatalyzed Steam Explosion Pretreatment of Rapeseed Straw for Biofuel Production. Bioresour. Technol. 2015, 190, 97–105. [Google Scholar] [CrossRef]

- Department of Agriculture food and the Marine Ireland’s National Forest Inventory 2017 Results. Dep. Agric. Food Mar. 2018, 3, 5.

- Murphy, F.; Devlin, G.; McDonnell, K. Forest Biomass Supply Chains in Ireland: A Life Cycle Assessment of GHG Emissions and Primary Energy Balances. Appl. Energy 2014, 116, 1–8. [Google Scholar] [CrossRef]

- Komkova, A.; Agergaard, S.K.; Holt Andersen, B.; Habert, G. Identifying Barriers and Enablers for Emerging Value Chains in Open-Loop Mineral Wool Waste Recycling within the Construction Sector. Dev. Built Environ. 2025, 22, 100662. [Google Scholar] [CrossRef]

- Tan, E.C.D.; Lamers, P. Circular Bioeconomy Concepts—A Perspective. Front. Sustain. 2021, 2, 701509. [Google Scholar] [CrossRef]

- Ntostoglou, E.; Ddiba, D.; Khatiwada, D.; Martin, V.; Engström, R.E.; Henrysson, M.; Lasaridi, K. Understanding the Interactions between Biowaste Valorisation and the Sustainable Development Goals: Insights from an Early Transition Stage. Int. J. Urban Sustain. Dev. 2024, 16, 53–72. [Google Scholar] [CrossRef]

- Bryson, J.M. What to Do When Stakeholders Matter: Stakeholder Identificatixon and Analysis Techniques. Public Manag. Rev. 2004, 6, 21–53. [Google Scholar] [CrossRef]

- Slabá, M. Stakeholder Power-Interest Matrix and Stakeholder-Responsibility Matrix in Corporate Social Responsibility. In Proceedings of the 8th International Days of Statistics and Economics, Prague, Czech Republic, 11–13 September 2014. [Google Scholar]

- Maqbool, R.; Rashid, Y.; Ashfaq, S. Renewable Energy Project Success: Internal versus External Stakeholders’ Satisfaction and Influences of Power-Interest Matrix. Sustain. Dev. 2022, 30, 1542–1561. [Google Scholar] [CrossRef]

- Campbell-Johnston, K.; Vermeulen, W.J.V.; Reike, D.; Brullot, S. The Circular Economy and Cascading: Towards a Framework. Resour. Conserv. Recycl. X 2020, 7, 100038. [Google Scholar] [CrossRef]

- Neill, A.M.; O’donoghue, C.; Stout, J.C. A Natural Capital Lens for a Sustainable Bioeconomy: Determining the Unrealised and Unrecognised Services from Nature. Sustainability 2020, 12, 8033. [Google Scholar] [CrossRef]

- IEA Bioenergy Workshop 1-South Africa. 2024. Available online: https://task36.ieabioenergy.com/wp-content/uploads/sites/34/2024/03/Task-36-Regional-Sustainability-Workshop-Series-Report.pdf (accessed on 10 August 2025).

- Maria Coelho Vianna, L.; de Oliveira, L.; Durante Mühl, D. Waste Valorization in Agribusiness Value Chains. Waste Manag. Bull. 2024, 1, 195–204. [Google Scholar] [CrossRef]

- Olsson, O. Cascading of Woody Biomass: The Tricky Path from Principle to Policy to Practice; SEI Discussion Breif; SEI: Stockholm, Sweden, 2017. [Google Scholar]

- Karkach, B.; Tahiri, M.; Haibi, A.; Bouya, M.; Kifani-Sahban, F. Review on Fast Pyrolysis of Biomass for Biofuel Production from Date Palm. Appl. Sci. 2023, 13, 10463. [Google Scholar] [CrossRef]

- Meyer, R. Bioeconomy Strategies: Contexts, Visions, Guiding Implementation Principles and Resulting Debates. Sustain. 2017, 9. [Google Scholar] [CrossRef]

- Gas Networks Ireland. Sustainability of Bio-Methane Production in Ireland Exploring How Ireland Can Deliver a Sustainable, Agriculture-Led Biomethane Industry; Gas Networks Ireland: Cork, Ireland, 2021. [Google Scholar]

- European Union. European Union (Good Agricultural Practice for Protection of Waters) Regulations 2022. Iris Oifigiúil; European Union: Brussels, Belgium, 2022. [Google Scholar]

- Department of Agriculture, Food and the Marine. Food Wise 2025: A Vision for Growth for the Irish Agricultural Economy for the Next 10 Years; Government of Ireland: 2015; 108p. Available online: https://faolex.fao.org/docs/pdf/ire179119.pdf (accessed on 20 August 2025).

- Department of Agriculture, Food and the Marine. European Union Targeted Agricultural Modernisation Scheme 3 Low Emission Slurry Spreading Scheme; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2025; p. 3.

- European Biogas Association. Integrated Nutrient Management Action Plan; European Biogas Association: Brussels, Belgium, 2023. [Google Scholar]

- CRE. The Potential Size of the Anaerobic Digestion Industry in Ireland by the Year 2030; CRE: Dublin, Ireland, 2016. [Google Scholar]

- European Parliament and Council of the European Union. Regulation (EC) No 1069/2009 of 21 October 2009 Laying Down Health Rules as Regards Animal By-Products and Derived Products Not Intended for Human Consumption and Repealing Regulation (EC) No 1774/2002 (Animal by-Products Regulation). Off. J. Eur. Union 2009, 300, 1–33. [Google Scholar]

- European Parliament and the Council of the European Union. Directive 2010/75/EU of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control). Off. J. Eur. Union 2010, L334, 17–119. [Google Scholar] [CrossRef]

- BIOrescue. Recommendations for a Circular Economy in EU Agriculture – BIOrescue. 2019. Available online: https://greenovate-europe.eu/wp-content/uploads/2020/06/Recommendations-for-a-circular-economy-in-EU-agriculture_BIOrescue.pdf (accessed on 20 August 2025).

- Magette, W.; Smyth, S.; Dodd, V. Logistical Considerations for Spent Mushroom Compost Utilisation. In Proceedings of the 8th International Conference on Management Strategies for Organic Waste in Agriculture (RAMIRAN), Rennes, France, 26–29 May 1998; pp. 23–30. [Google Scholar]

- Knaggs, G.; O’Driscoll, E. Woodflow and Forest-Based Biomass Energy Use on the Island of Ireland (2018); COFORD Connects Note No. 51; COFORD: Dublin, Ireland, 2019; Available online: https://www.coford.ie/media/coford/content/publications/2018/00900CCNPP51Woodflow%20-%20We.pdf (accessed on 15 August 2025).

- Government of Ireland. National Policy Statement on the Bioeconomy; Department of the Taoiseach: Dublin, Ireland, 2018. Available online: https://faolex.fao.org/docs/pdf/ire208378.pdf (accessed on 15 August 2025).

| Main Type | Sub-Type | Examples |

|---|---|---|

| Livestock/ Poultry | Manure | Pig manure, chicken manure, cow manure |

| Crops/Horticulture | Primary or harvesting residues, by-products of cultivation and harvesting activities | Wheat straw, barley straw, oat straw |

| Secondary processing residues of agricultural products, e.g., for food or feed production | Spent mushroom compost, mushroom offcuts | |

| Forestry | Primary forest products | Stemwood, thinnings |

| Primary forestry residues | Leftovers from harvesting: twigs, branches, stumps | |

| Secondary forestry residues | Residues resulting from processing: sawdust, bark, black liquor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talwar, N.; Kleemann, R.; Gusciute, E.; Murphy, F. Biomass Valorisation Resources, Opportunities, and Barriers in Ireland: A Case Study of Counties Monaghan and Tipperary. Resources 2025, 14, 155. https://doi.org/10.3390/resources14100155

Talwar N, Kleemann R, Gusciute E, Murphy F. Biomass Valorisation Resources, Opportunities, and Barriers in Ireland: A Case Study of Counties Monaghan and Tipperary. Resources. 2025; 14(10):155. https://doi.org/10.3390/resources14100155

Chicago/Turabian StyleTalwar, Nishtha, Rosanna Kleemann, Egle Gusciute, and Fionnuala Murphy. 2025. "Biomass Valorisation Resources, Opportunities, and Barriers in Ireland: A Case Study of Counties Monaghan and Tipperary" Resources 14, no. 10: 155. https://doi.org/10.3390/resources14100155

APA StyleTalwar, N., Kleemann, R., Gusciute, E., & Murphy, F. (2025). Biomass Valorisation Resources, Opportunities, and Barriers in Ireland: A Case Study of Counties Monaghan and Tipperary. Resources, 14(10), 155. https://doi.org/10.3390/resources14100155