Abstract

This paper investigates the total environmental impacts of a thermal caisson (TC) system by implementing a life cycle assessment methodology. The total environmental impacts consider the comprehensive effect on the environment across two life cycle stages: manufacturing and operation. A comparison between the TC results and two different HVAC systems, including air-conditioning/furnace and conventional ground-source heat pump (GSHP) systems, was made by adopting the ReCiPe 2016 methodology. This study reveals that the operation phase is the predominant contributor to environmental impacts across systems, mainly due to its extended duration. Specifically, the operational impacts of GSHPs are substantial, accounting for approximately 87% of total environmental impacts. A TC GSHP system demonstrates a notable environmental advantage, achieving a 79% reduction in total environmental impact when compared to traditional AC/furnace systems. This represents a 21% improvement over conventional GSHP systems. Despite this substantial reduction in total environmental impact, the TC GSHP system shows an almost 5% increase in the resource availability damage category relative to the conventional GSHP, which is attributed to its higher material consumption. These results highlight the TC GSHP system’s superior efficiency in reducing environmental impacts and its potential as a more sustainable alternative in residential heating and cooling applications.

1. Introduction

In 2019, residential, commercial, and public services buildings accounted for around 42% of global natural gas consumption and around 47% of global electricity consumption [1]. Buildings alone were responsible for 28% of global CO2 emissions in 2018 [2], and due to the increase in global energy demand, these numbers are expected to continue to grow. Under the Paris Agreement, the Government of Canada developed a Green Buildings plan to reduce the energy consumption and, ultimately, CO2 emissions of buildings, which are responsible for 13% of Canada’s GHG emissions [3]. Among all of the energy consumers in buildings, 78% of the emissions come from water and space heating equipment [3], making them the focus of energy reduction studies and energy efficiency improvements. Space heating and cooling in buildings are typically carried out by HVAC systems, including air source heat pumps (ASHPs), furnaces, air conditioners, chillers, and ground source heat pumps (GSHPs).

A GSHP system has three main components: a ground loop heat exchanger, a heat pump system, and a distribution subsystem. The ground loop, typically comprising boreholes, high-density polyethylene (HDPE) pipes, and grout, uses the ground as the heat sink and source. The closed-loop HDPE pipe, which acts as the heat exchanger, is filled with a mixture of water and antifreeze that will carry the extracted heat from the ground or reject the carried heat into the ground. Then, it flows into the heat pump system to exchange the heat with the refrigerant, transferring heat to or from the distribution subsystem [4,5].

Many studies have shown that the ground source heat pump is one of the best alternatives for conventional HVAC systems to help achieve energy and emission reductions as ground source heat pump systems use the free and abundant energy in the ground to heat and cool buildings [6,7,8,9,10]. Despite their higher coefficient of performance (COP) values, studies show that GSHP systems have some drawbacks, including higher upfront costs and COP degradation over time, particularly for buildings with highly imbalanced heating and cooling requirements. Various methods have been applied to solve these problems, including integrating GSHP systems with thermal storage abilities, solar heating and cooling technologies, and even conventional auxiliary HVAC systems [11,12,13,14,15,16]. Various investigations have been reported on potential ways of preventing COP degradation in GSHP systems. Using phase change material (PCM) as a grout in the ground loop has been one of the areas of great interest in recent years [17,18,19,20,21,22]. These studies show promising results that using PCM in GSHP systems can reduce the COP degradation of the system over time.

In continuation of previous works, Alavy et al. [22] investigated a new configuration for GSHPs to address the COP degradation and higher cost of implementation without using auxiliary systems. Their novel configuration incorporates the ground loop into the foundation caisson of the building to significantly reduce borehole drilling expenses and mitigate the installation costs. In addition, in this configuration, a phase change material (PCM) is used to mitigate, in part, COP degradation. Based on their results, the capital cost of the GSHP could be reduced by 49% when utilizing TCs, and the operating costs could drop by 30% due to the better average COP, specifically in colder months [22]. In addition, another study by Alavy et al. [9] has shown that a TC GSHP system can have a 22% better long-term energy performance compared to that of a conventional GSHP system.

Although GSHP systems have higher COPs than other HVAC systems, caution should be exercised when considering them as the greener option over other HVAC systems without considering the other factors that can hugely influence the environmental impacts. Measuring the environmental impact of a system during its life cycle requires performing a life cycle assessment (LCA), which is geographically dependent. An LCA often requires many assumptions due to the lack of data and information in different regions and industries. Many studies have investigated the LCA of GSHP systems and compared them to conventional HVAC systems for various regions, including hot, cold, and mild [23,24,25,26,27,28,29,30]. Smith et al. [29] investigated the LCA of a GSHP system in a typical home in New Jersey and concluded that the primary environmental impact is the required energy to operate the system over its assumed 25-year life cycle. Also, based on their results, the electricity generation mix can have a considerable impact on the environmental damage caused by the operation of the GSHP system, which can motivate the utilization of more renewable and greener sources of electricity. In addition, Smith et al. concluded that, in New Jersey, the GSHP is the ideal system for the heating needs of a residential building compared to oil or natural gas furnaces due to its higher efficiency and lower pollution.

Aresti et al. [30] performed LCAs of several ground heat exchangers and compared them to an air source heat pump (ASHP) as a base case. Consistent with the results of Smith et al. [29], Aresti et al. concluded that the operation stage of the life cycle has the highest environmental impact, accounting for at least 83% of the total impact. Also, their results show that all eight configurations they considered for ground heat exchangers outperformed the ASHP unit in terms of environmental impacts; vertical heat exchangers exhibited the best performance in reducing environmental impacts.

Greening and Azapagic [25] studied the environmental impacts of heat pumps in the UK and compared them to boilers. Their findings show that, due to the electricity generation mix in the UK, heat pumps are not the best option, since for the majority of the impact categories, boilers performed better. Between an ASHP and a water source heat pump, the latter leads to a smaller impact on the environment.

Hunter [23] showed that GSHP systems benefit from higher energy efficiency, reflecting on the life cycle’s operation stage with lower environmental impacts compared to natural gas and air conditioner systems. Based on their results, assuming installation in Toronto and using Ontario’s energy grid, the GSHP system is a better option by considering just the operation stage. However, due to higher material consumption in manufacturing and installing the GSHP system, this system will have a more significant impact in these two stages. Hunter concluded that more studies must be conducted on the manufacturing processes of GSHP systems to find ways to reduce their environmental impacts.

While multiple studies have been conducted on the life cycle assessment (LCA) of GSHP systems in different regions, to our knowledge, no study has been published on the LCA of TC GSHP systems. This study reports an LCA on a TC GSHP system and compares this system with a conventional GSHP system and AC/furnace system to investigate the long-term environmental impacts of these systems during the manufacturing, installation, and operation stages to identify the environmental impacts of implementing this system as a more efficient alternative.

2. Methodology

To assess the feasibility of the TC GSHP system and investigate its environmental impacts, a typical residential building is considered, and three different scenarios are developed. Each scenario considers one typical HVAC system, and its environmental impacts over 20 years are calculated. The three systems considered to provide the heating and cooling needs of the building are as follows: TC, traditional GSHP, and air conditioning/furnace. Details of the case study and the implemented LCA methodology are described, including the description of the system, goal and scope definition, system boundaries and functional unit, life cycle inventory, and the life cycle assessment.

2.1. Case Study Details

The case study considered for this study is a 150 m2 heating-dominated detached house in Ontario, Canada. The building’s real hourly heating and cooling loads and yearly demand are provided by Alavy et al. [9,22]. Based on the provided results, the peak heating and cooling loads are 7.5 kW and 4 kW, respectively. The annual heating and cooling energy consumption were calculated as 18,000 kWh and 4300 kWh, respectively [22].

For the AC/furnace configuration, a 2-ton air conditioner unit is responsible for the cooling demand, and a 20-kW gas furnace provides the heating demand. For the life cycle inventory analysis, the Carrier 24ACR3 was chosen as the air conditioner unit, and the 90TS-07EES furnace from Rheem was chosen for the furnace. Based on Alavy et al. [22], the efficiency of the furnace system is assumed to remain constant at 90% throughout its life cycle, and the energy efficiency ratio (EER) of the air conditioner is assumed to remain constant at 7.

Conventional GSHP and TC GSHP systems both use the ClimateMaster TS H/V/D 036 as the heat pump. In a conventional GSHP system, the ground loop comprises a single borehole with a 15 cm diameter and 183 m depth. A 0.03 m diameter HDPE U-loop ground heat exchanger is installed in the borehole, and the borehole is filled with 250 kg of bentonite grout. Also, a mixture of water and 25% propylene glycol flows in the HDPE pipes. Considering the 25% proportion of propylene glycol and the inner volume of the pipe, the amount of antifreeze that flows in the pipe is calculated as approximately 66 kg.

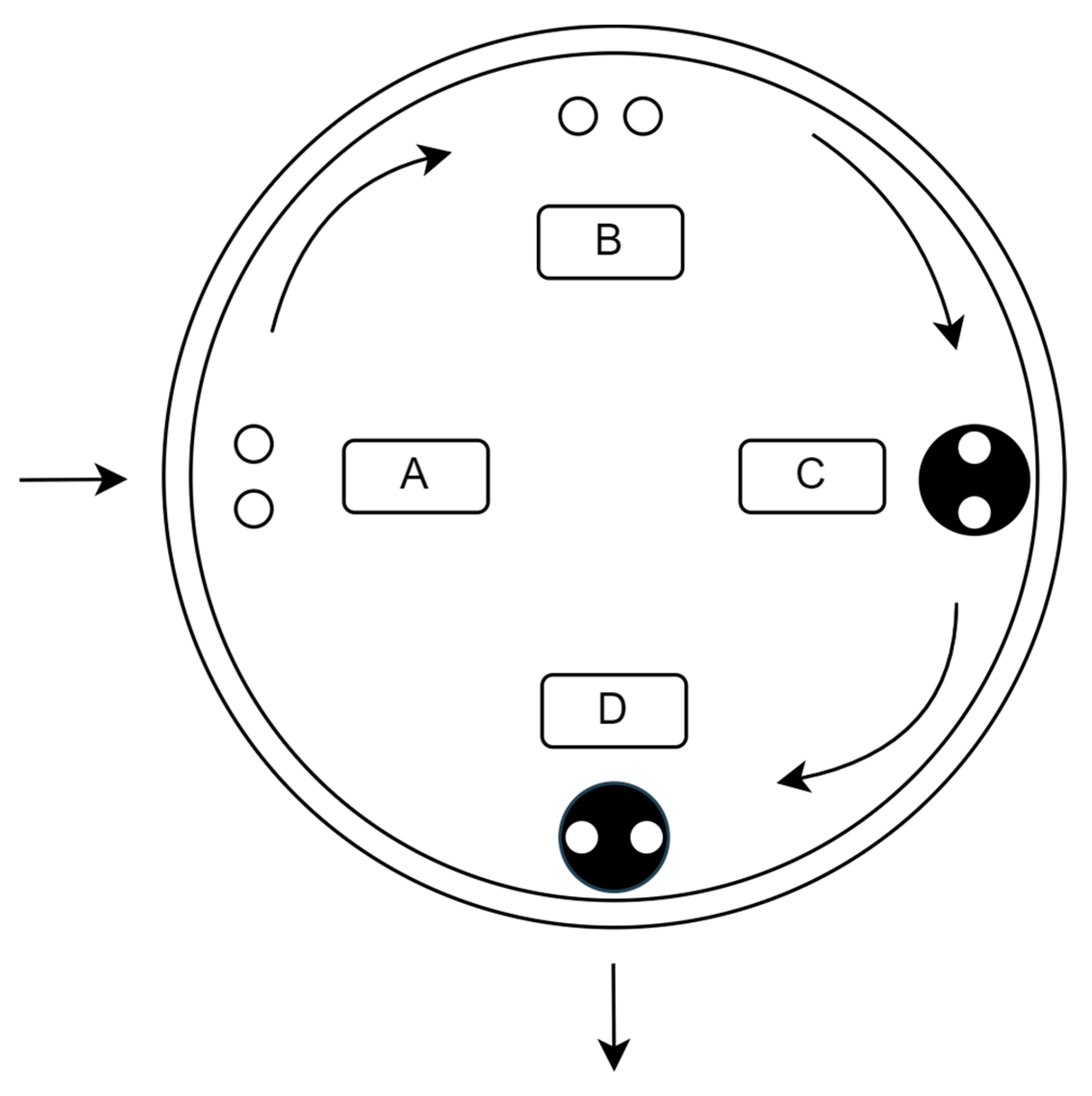

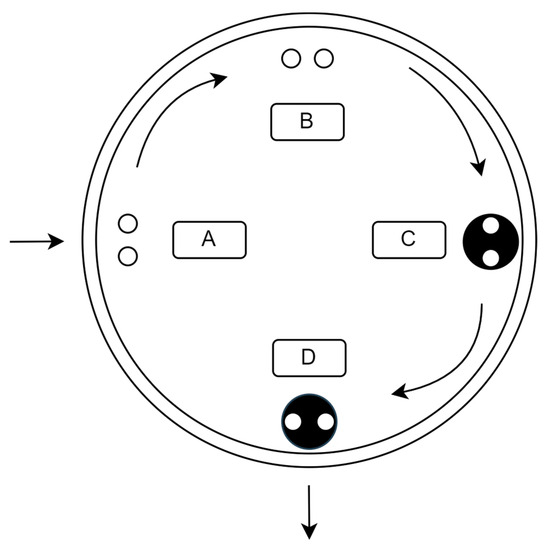

The TC ground loop configuration is shown in Figure 1. In this system, a single caisson with a 1.6 m diameter and 45 m depth accommodates four U-loop ground heat exchangers, each 43 m in length, which are named A, B, C, and D. U-loops C and D are enclosed in two nitrile rubber pipes, also known as nitrile butadiene rubber (NBR) pipes, each with a diameter of 0.15 m. HDPE U-loops with a 0.03 m diameter are installed in each NBR pipe. The two NBR pipes are filled with a phase change material (RT2HC) to improve the system’s efficiency and prevent degradation of the COP over the long term. The mixture of water and antifreeze enters the ground loop from U-loop A, passes through the other U-loops in a clockwise direction, and leaves the ground loop after exiting from U-loop D.

Figure 1.

Top view of ground loop configuration of thermal caisson ground source heat pump system, illustrating flow of water and antifreeze through U-loops, entering from A and continuing clockwise passing through B, C, and exit from D. U-loop pipes are indicated by small circles, while Nitrile rubber pipes containing PCM are shown in black circles.

2.2. Life Cycle Assessment

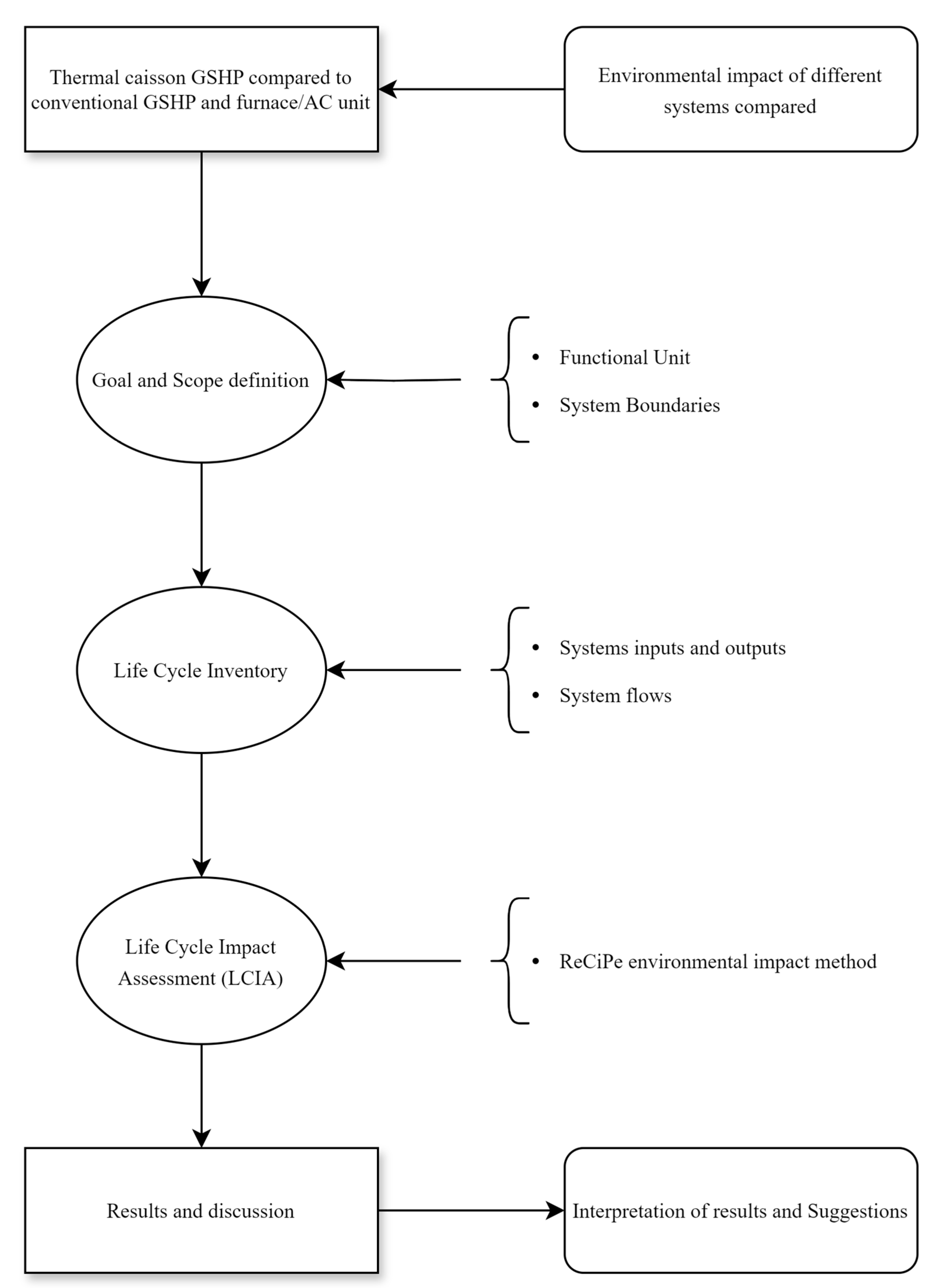

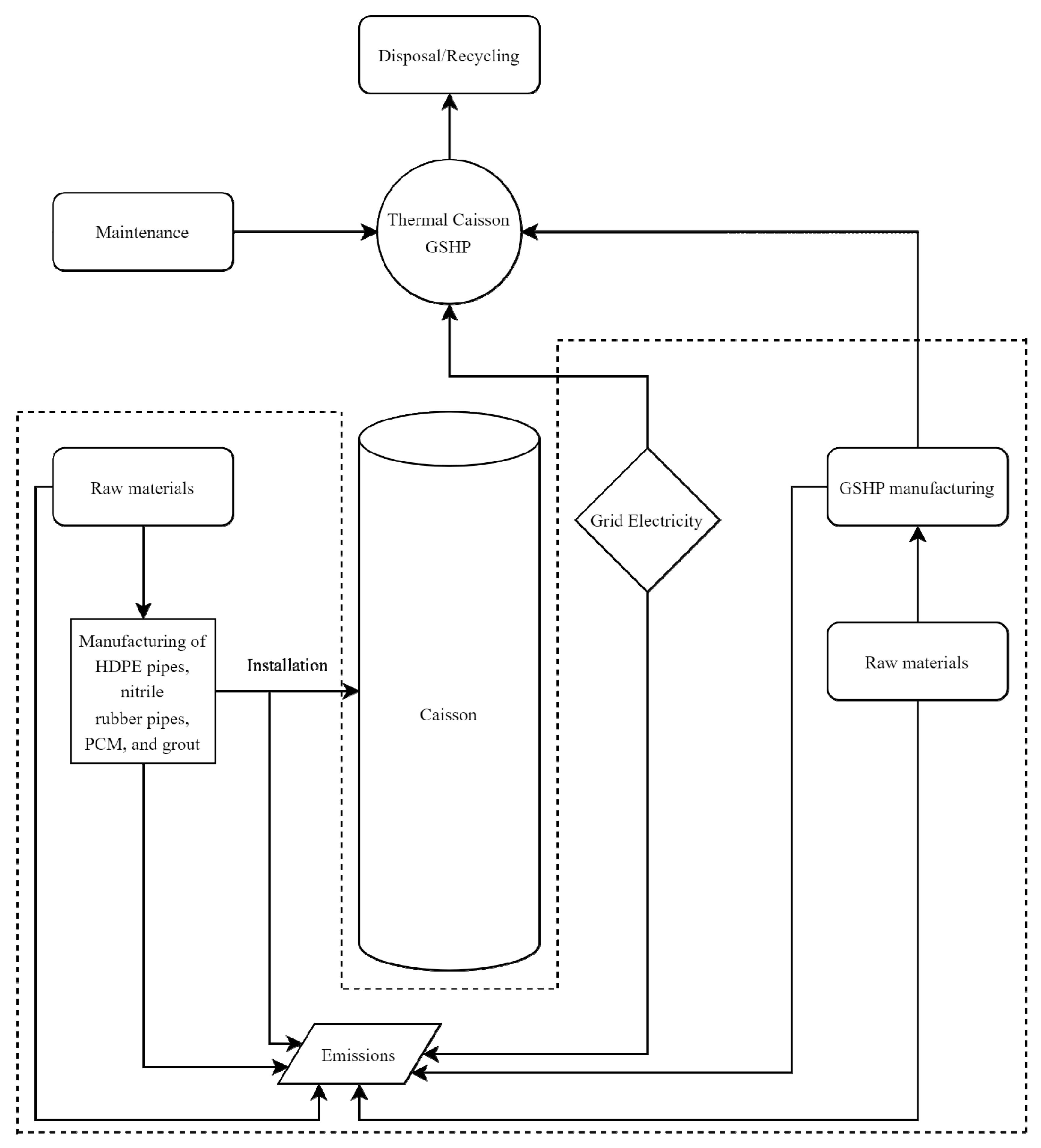

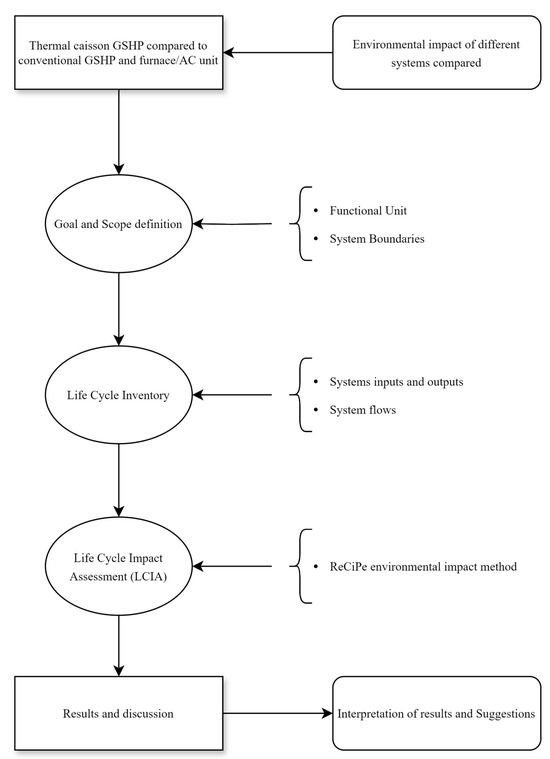

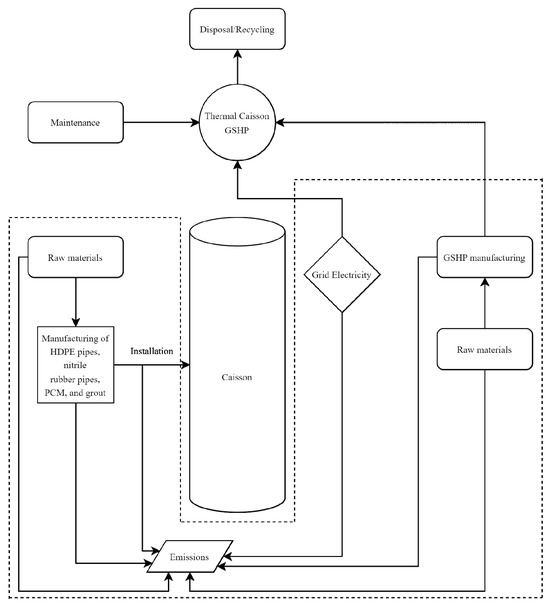

A useful method to investigate the environmental impacts of a product or process is a life cycle analysis (LCA). An LCA considers the environmental impacts in producing raw materials, transportation and distribution, operation, and the disposal or recycling of each product. The LCA methodology used in this study is based on ISO 14040 [31] and ISO 14044 [32]. According to the ISO 14040 and 14044 frameworks, every LCA has four phases: 1. goal and scope definition; 2. inventory analysis; 3. impact assessment; and 4. interpretation. Figure 2 shows the overall LCA flow diagram for the current study.

Figure 2.

Flow chart of life cycle assessment and stages involved to compare AC/furnace, conventional GSHP, and TC GSHP systems. Arrows depict the sequence of steps and the inputs and outputs.

In the following sections, all phases are addressed. First, the primary purpose of performing a life cycle assessment is to compare the impacts of three different HVAC systems, consisting of a TC, conventional GSHP, and AC/furnace systems. Based on the primary purpose, this study’s goal and scope are established by determining the functional unit and system boundaries. In the next step, all of the inputs and outputs of the systems are determined, and the system flows are determined to shape the life cycle inventory. This LCA step is particularly noteworthy due to the importance of the inputs and outputs.

The ReCiPe 2016 [33] methodology is employed as one of the impact assessment methodologies in the LCA to analyze the life cycle inventory, and the results obtained are discussed to clarify the environmental impacts of each system and their severities.

2.3. Goal and Scope

The goal of this study is to assess the environmental impacts of the three HVAC systems, namely TC, conventional GSHP, and AC/furnace, and to compare the results to better understand the environmental consequences of each one. This study includes raw material extraction, processing, production, and energy consumption through the life cycles of the systems. Various studies have shown that transportation and disposal impacts can be neglected as they have minimal impacts compared to other factors, such as manufacturing, installation, and operation [26,27,34,35]; therefore, the current study focuses on the production, installation, and operation phases of each system. In addition, it is worth noting that boreholes are expected to last much longer than heat pumps, typically 50 years or more, so we neglect the disposal of ground loops in the horizon of 20 years. Table 1 summarizes the inclusion and exclusion of phases for each system.

Table 1.

Defining system boundaries for life cycle assessment of each system, noting that transportation, maintenance, and disposal stages are excluded in this study.

2.4. System Boundaries and Functional Unit

Although the goal and scope have specified the general structure of the system boundaries, due to the different configurations and infrastructures needed to operate HVAC systems, the boundaries of each system must be precisely determined. Based on the defined boundaries, the inputs and outputs of the systems can be determined; therefore, the impact of boundary determination can be perceived in the life cycle inventory.

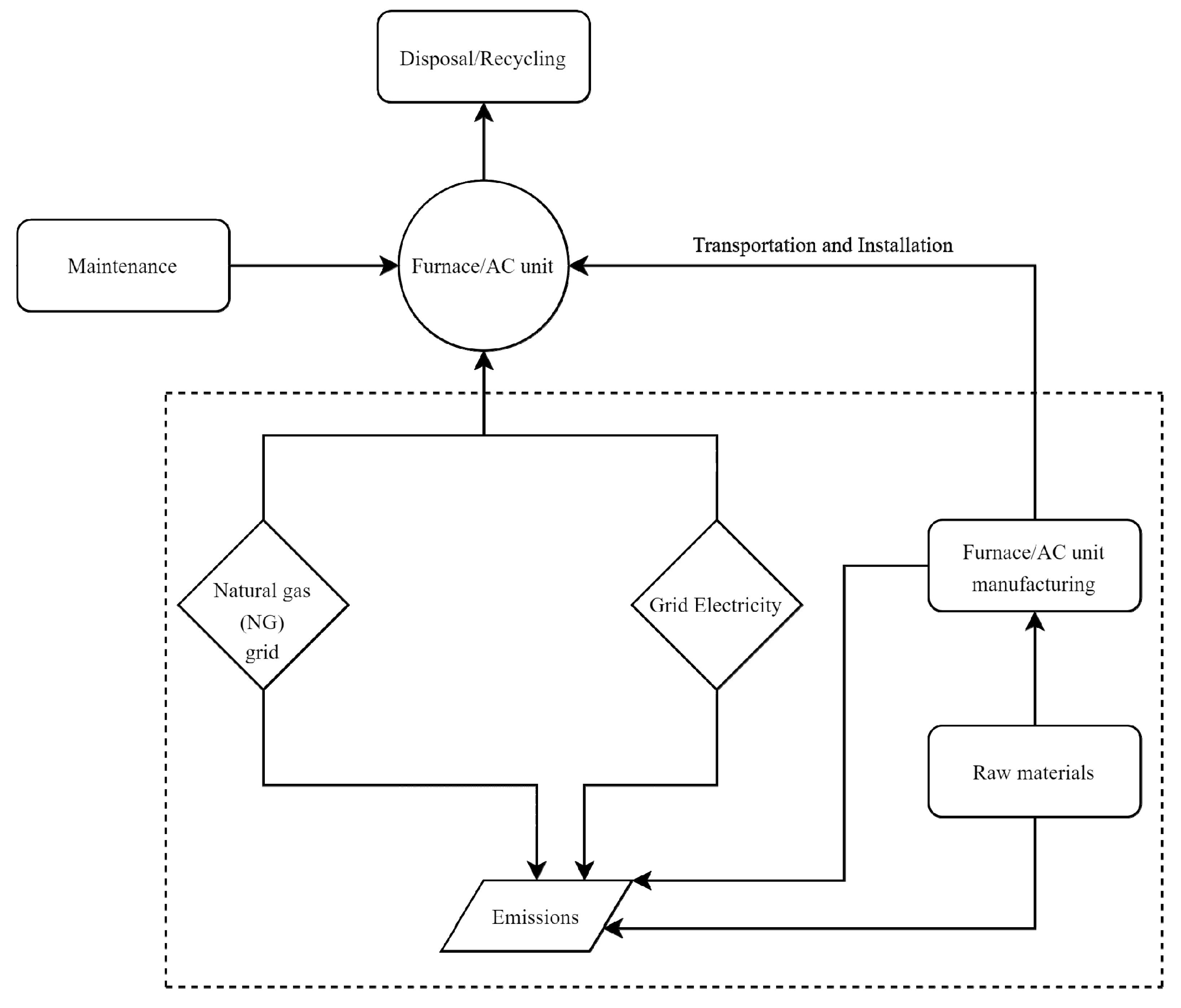

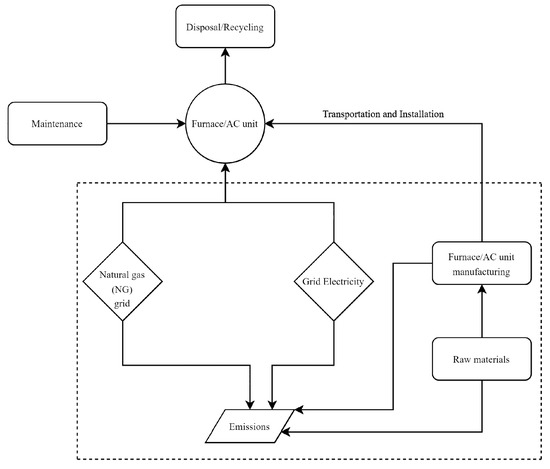

Figure 2 shows the defined system boundary for an AC/furnace system. In general, all processes related to the production and operation of the systems fall in the boundary; in particular, the extraction of raw materials, the material process and production of the air conditioner and furnace, and the extraction of natural gas and generation of electricity are all inside the boundary. As discussed, the system transportation, maintenance, and disposal are excluded due to their minor environmental impacts compared to the production and operation phases.

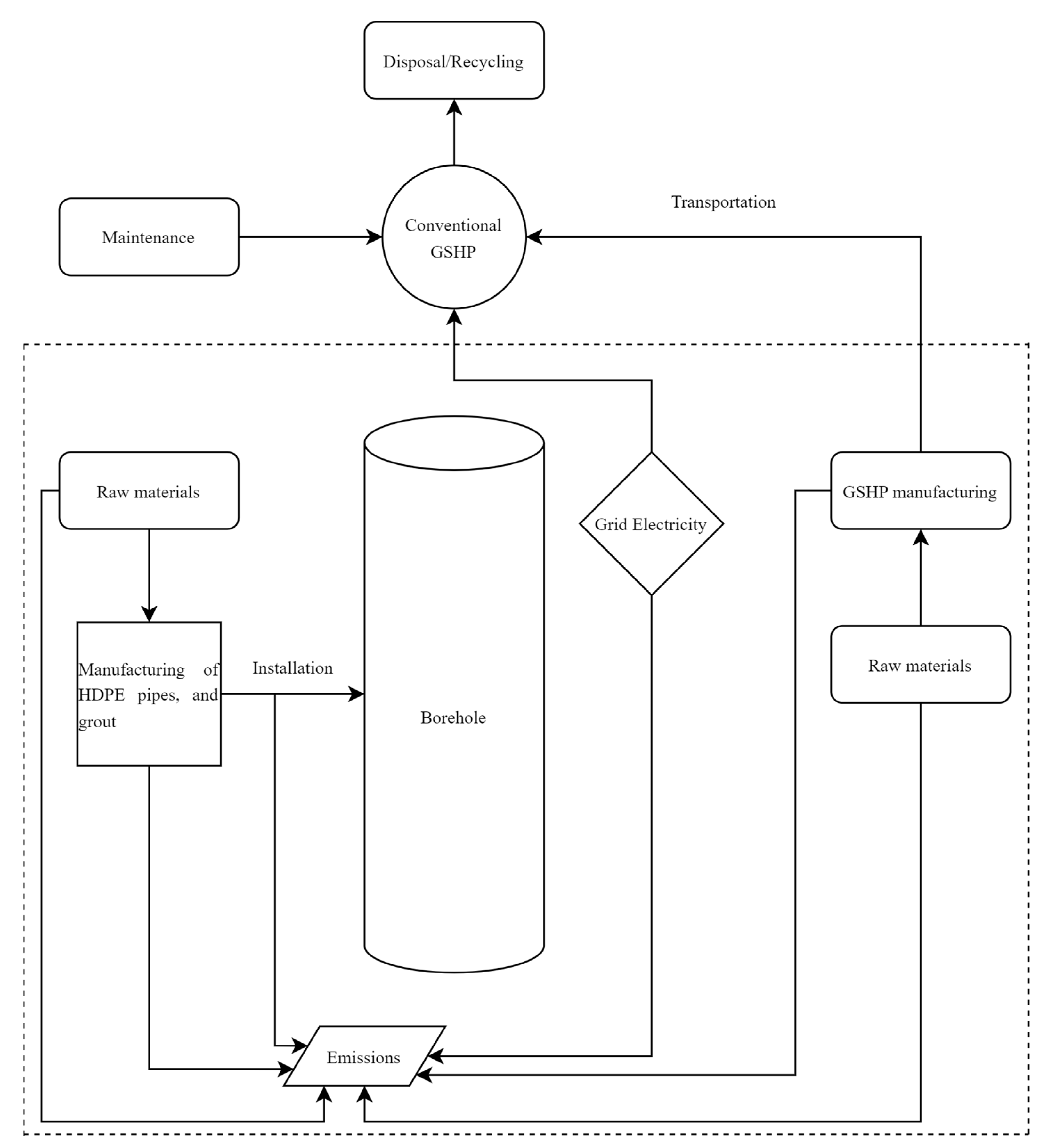

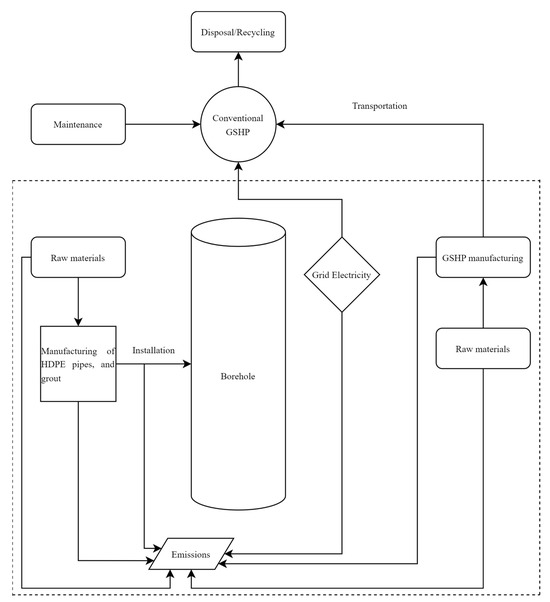

The boundary definition for a conventional GSHP system is similar to that of an AC/furnace system. However, the drilling and installation of the ground loop into the borehole are included in the boundary. Figure 3 shows that the raw materials associated with the ground loop, including the HDPE pipes and grout, are inside the boundary. Similar to an AC/furnace system, the energy consumption and raw materials used in heat pump production, system energy consumption, and associated emissions over its expected lifetime are considered. The disposal, maintenance, and transportation of the parts and materials are neglected for this system. Figure 4 shows the system boundary for conventional GSHP system.

Figure 3.

System boundary for AC/furnace system. Included parts are shown inside dotted line.

Figure 4.

System boundary for conventional GSHP system, highlighting included components within the dotted line, including borehole drilling impacts.

The boundary in a TC GSHP system is not the same as that in a conventional GSHP system, as shown in Figure 5. The reason behind this is that the concept of TC is to use the foundation caisson of a building as a borehole and install the U-pipes in it. Through this means, the effects of drilling a borehole are no longer associated with the TC since the caisson must be drilled for the foundation anyway, which is part of the construction effects. This can be translated into the exclusion of drilling effects. Although a conventional GSHP system and a TC GSHP system share similarities in the production of heat pumps, in the TC GSHP system, the production of phase change material (PCM) and NBR pipes must be considered inside the boundary. Similar to the other two systems, the maintenance, disposal, and transportation effects are neglected for this system.

Figure 5.

System boundary in TC GSHP system, indicating included components within dotted line. Borehole impacts are excluded, as they are integrated into caisson, with construction-related impacts considered for building construction.

The functional unit (FU) is a reference unit that provides the ability to compare similar systems regarding environmental impacts. The FU used in this study is the total annual energy demand for the heating and cooling of the case study, which is equal to 22.3 MWh/year. Similar functional units have been adopted in past studies [29,30,34,36,37].

2.5. Life Cycle Inventory

The current study uses Ecoinvent 3.7.1 [38] and data in the literature to obtain and adjust the related data. The heat pump, air conditioner, and furnace production data are obtained from the Ecoinvent 3 database and adjusted to represent the current study conditions. All emissions associated with generating and consuming electricity and natural gas are also obtained from Ecoinvent 3.7.1 by considering the Ontario network and energy mix. Shah et al. [28], Aresti et al. [34], Bonamente and Aquino [16], and Greening and Azapagic [25] provide detailed data on the materials used in GSHP and AC/furnace systems, and these are used to adjust the Ecoinvent data. However, the quantity of each material used in different studies and systems varies due to the difference in the size of the considered case studies. Similar to the procedure of Violante et al. [27], the data are adjusted in the current study by maintaining the proportions while considering the net weight of final products indicated by the manufacturers. Bonamente and Aquino [16] use paraffin to represent the PCM utilized in their study. Since the RT2HC (PCM) base material used in the TC configuration is paraffin in the life cycle inventory, the generic paraffin is chosen from the Ecoinvent 3.7.1 database. Table 2 summarizes the data for the life cycle inventory.

Table 2.

Life cycle inventory of AC/furnace, conventional GSHP, and thermal caisson GSHP systems.

2.6. Life Cycle Impact Assessment

After determining the life cycle inventory, each pollutant’s environmental impact associated with the system’s inputs can be assessed using the LCIA method. In this study, ReCiPe 2016 [33] is used to evaluate the impacts of each system on the environment. Based on the ReCiPe 2016 method, the environmental impacts can be measured in two ways. The first is the 18 midpoint categories, which directly measure the impacts arising from each process. To evaluate the midpoint impacts, different pollutants must be considered and summed up with all of the pollutants that potentially have the same effect on the environment. These midpoint impacts are then aggregated to endpoint categories, which can be expressed in points. The conversion of midpoint categories into point-based endpoint categories is carried out through the application of weighting variables. Also, to present the endpoint categories’ results in points, normalization factors are introduced using the ReCiPe 2016 method. Human health, ecosystem health, and resource scarcity are the three endpoint representatives that show the area of damage. Table 3 shows the abbreviation of each midpoint impact category and the measurement unit of each. Also, the three endpoint categories and their abbreviations are listed.

Table 3.

ReCiPe 2016’s midpoint and endpoint impact categories, with data from [29,33]. The unit of each impact category represents the assumed elements considered to measure each impact.

Among the three cultural perspectives presented by ReCiPe 106, which offer a range of choices related to aspects like time and expectations, the current study uses a 100-year hierarchy perspective to investigate the impacts. This extended time frame makes the results more reliable by providing the time needed for some pollutants to impact the environment fully in the considered 20-year lifetime of the systems.

3. Results and Discussion

The main focus of this study is to investigate the environmental impacts of the life cycle stages of three HVAC systems designed to satisfy 18,000 kWh annual heating and 4300 kWh cooling demands of the case study over their 20-year assumed lifetimes, including the production, installation, and operation of each. The three systems considered include an A/C and furnace unit, a conventional GSHP, and a TC. The life cycle inventory described previously is implemented in SimaPro 9.2.0.2 [39] to create the life cycle stages and processes involved in each.

In the operation stage of the systems, only the energy consumption of each is considered, and maintenance is neglected due to the minor effect it has compared to energy consumption. The coefficient of performance (COP), energy efficiency ratio (EER), and efficiency are three significant factors in determining the energy consumption of HVAC systems, which is an important element that can affect the environment. Several studies have shown that, due to the unbalanced heating and cooling load profiles in heating-dominated regions, the heating COP of a GSHP will decline due to the soil temperature variation each year [9,40,41,42]. To quantify the impact of time on the heating COP of the system, Alavy et al. [9] introduced two formulas for the COP of conventional and thermal caisson GSHP systems:

Here, t denotes the year of operation, and COP represents the median winter COP of the system. Considering the annual 18,000 kWh of heating energy demand for the case study building and the calculated COP of each system with the above formulas, each system’s total electricity energy consumption during the heating seasons over 20 years is obtained. In addition, the considered ground source heat pump in this study has an EER of 22 for the cooling cycle, which is assumed to be constant over the heat pump’s life cycle to reduce the calculation complexity. This is a valid simplification since the case study is in a heating-dominated region, and a decline in EER does not significantly impact energy consumption. The resulting electricity consumption of conventional and thermal caisson GSHP systems over their 20-year lifetimes are 125,130 kWh and 98,928 kWh, respectively. For the AC/furnace system, the electricity and natural gas consumption values over its 20-year lifetime are determined, assuming the EER of the AC and the efficiency of the natural gas furnace to be 7 and 90%, respectively. The electricity consumption in this scenario is 41,921 kWh, and the furnace consumes 39,032 m3 of natural gas over its lifetime.

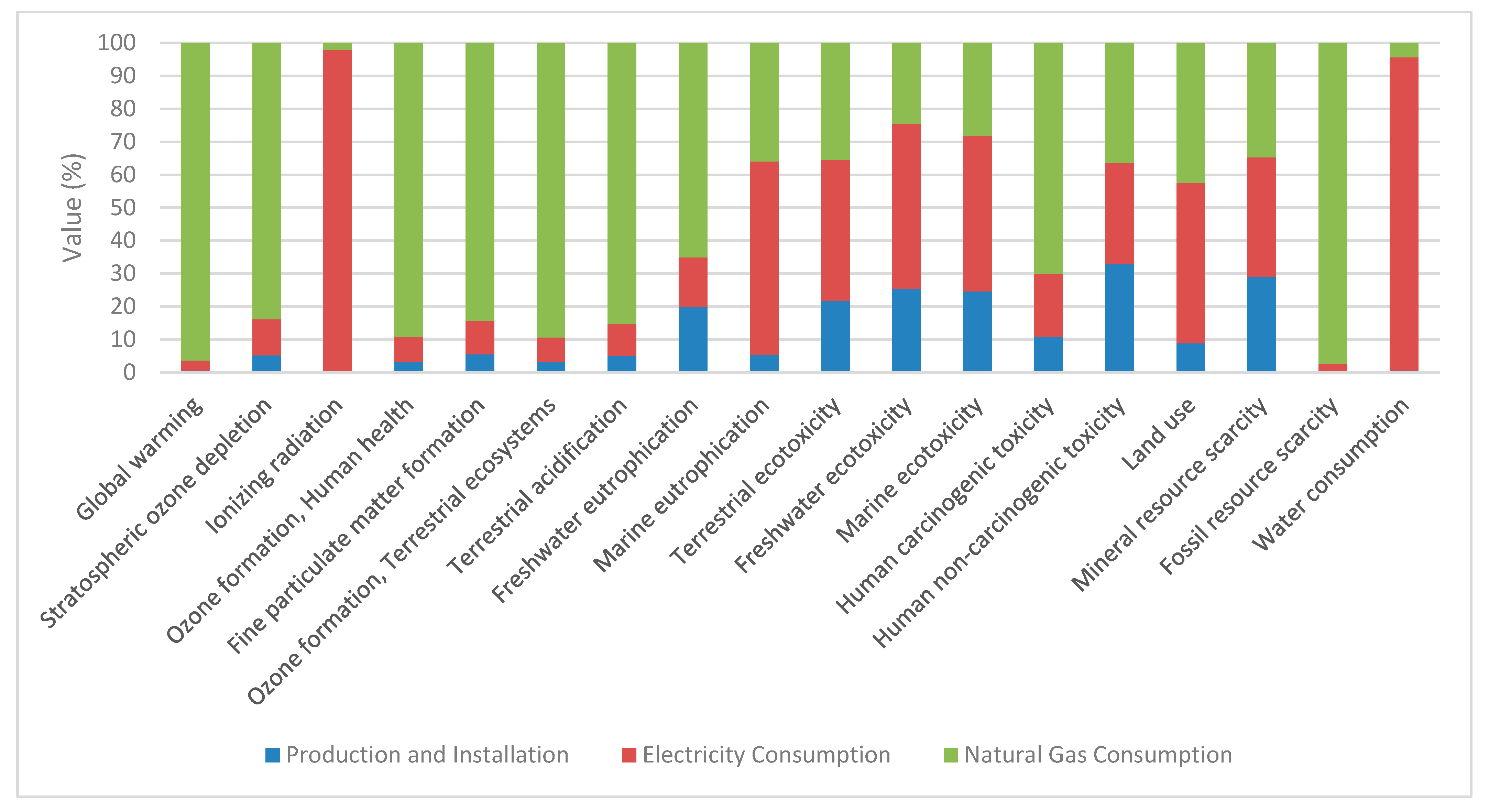

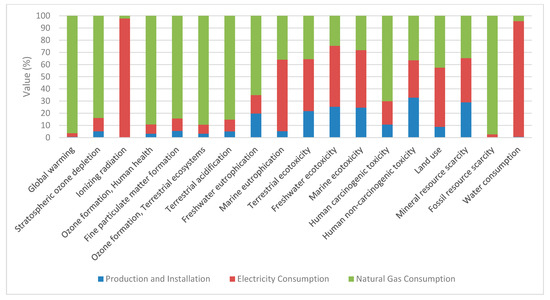

In the next step, the production and installation stages of the systems are investigated by developing a software model using SimaPro. The simulation is performed according to the main elements, parts, and processes involved in the production and usage of systems. Figure 6, Figure 7 and Figure 8 show the share of production, installation, and operation of AC/furnace, conventional GSHP, and TC GSHP systems in the 18 midpoint categories over their 20-year lifetimes, respectively. As expected, Figure 6 shows that, for the AC/furnace system, the operation stage of the life cycle has the greatest impact on every midpoint category due to the much longer duration compared to production and installation. The furnace’s natural gas consumption contributes the most to global warming, ozone depletion, air pollution, and fossil fuel depletion. Overall, 10 out of 18 midpoint categories are largely influenced by natural gas consumption, and the other eight are impacted by electricity consumption, including water consumption, marine eutrophication, terrestrial ecotoxicity, freshwater ecotoxicity, marine ecotoxicity, and land use. Note that the environmental impact of electricity is directly related to the electricity grid generation mix. In this study, Ontario’s electricity grid mix, as presented in the Ecoinvent database, was chosen.

Figure 6.

Results of ReCiPe 2016 LCA showing impacts of AC/furnace system on 18 midpoint categories for 20-year system lifetime.

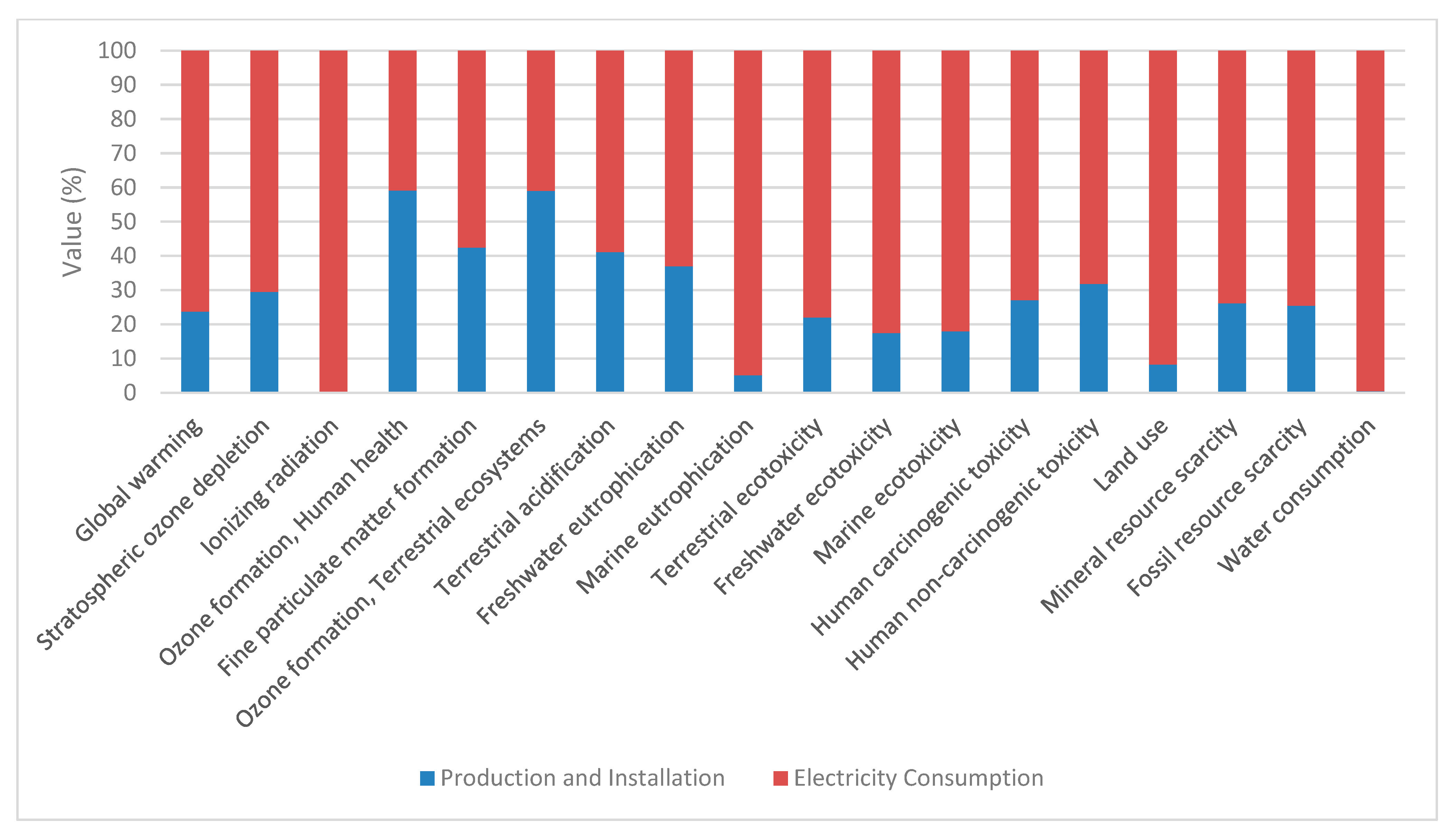

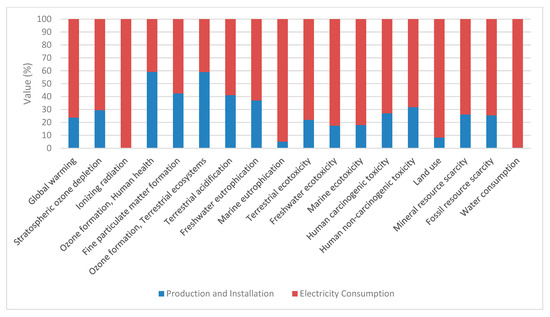

Figure 7.

Results of ReCiPe 2016 LCA showing impacts of conventional GSHP system on 18 midpoint categories for 20-year system lifetime.

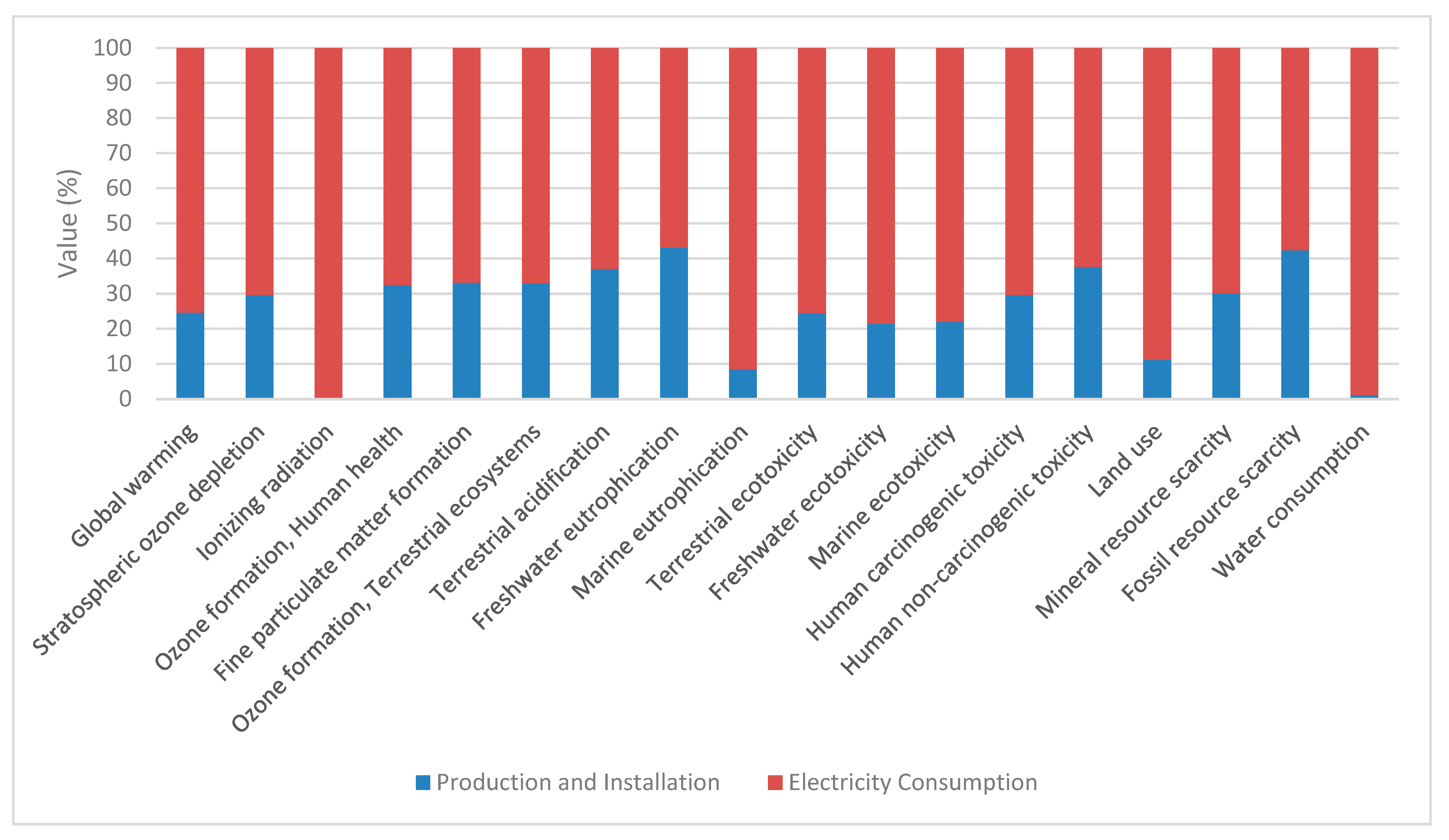

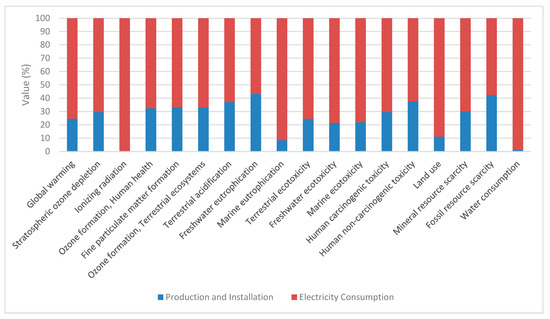

Figure 8.

Results of ReCiPe 2016 LCA showing impacts of TC GSHP system on 18 midpoint categories for 20-year system lifetime.

The differences between Figure 7 and Figure 8 are not substantial due to the same production stages of the heat pumps; the main differences lie in the ground loop production and installation, as well as the difference in the total electricity consumption of each system. Similar to the AC/furnace system, energy consumption is still the major influence on the environment. The production and installation of the borehole of the conventional GSHP are the main contributors to the ozone formation category, while the 17 other categories are predominantly influenced by electricity consumption.

Due to the incorporation of the ground loop of the TC GSHP system into the foundation caisson of the building, this system exhibits reduced impacts of production and installation on the ozone formation category, leaving energy consumption as the only major factor for all categories.

To help interpret the results, Table 4 shows the numerical results of the midpoint and endpoint categories, making it possible to compare the LCAs of the different systems. Global warming, expressed in equivalent kg of CO2, is a useful indicator of how a system can affect climate change by emitting greenhouse gases in the atmosphere, which can affect human and ecosystem health. The results in Table 4 show that the AC/furnace system, at 1.2 × 105 equivalent kg of CO2, is the greatest source of pollutant emissions compared to the conventional GSHP at 1.42 × 104 equivalent kg of CO2 and thermal caisson at 1.14 × 104 equivalent kg of CO2. The reason for the reduced global warming potential of GSHP systems is mainly rooted in their lower energy consumption due to their higher efficiencies.

Table 4.

Numerical results of midpoint and endpoint impact categories of life cycle assessment for three considered systems.

Stratospheric ozone depletion, described in equivalent kg of CFC11, represents the impacts of different gases that are responsible for degrading the stratospheric ozone, which can highly affect human health and alter the ecosystem. Refrigerants are one of the primary materials causing stratospheric ozone depletion, but they are not the only ones. In our field of focus, in addition to refrigerant manufacturing, the manufacturing process of high-density polyethylene (HDPE) pipes and energy generation are the other responsible factors. Figure 6, Figure 7 and Figure 8 demonstrate that the manufacturing and installation stages of GSHP systems have a higher share in stratospheric ozone depletion than AC/furnace systems. The utilization of HDPE pipes and a greater amount of refrigerant used in these systems are the reasons for these results. However, the higher energy consumption of an AC/furnace system, specifically the consumption of natural gas, plays the main role in stratospheric ozone depletion, making this system the worst in this midpoint category. The thermal caisson system at 1.39 × 10−2 equivalent kg of CFC11 performs almost 20% better than the conventional system mainly because of its lower electricity consumption.

Ionizing radiation is a human health midpoint indicator that measures the years of life lost and disabled because of increases in cancer and hereditary diseases due to radiation exposure. For all three systems, this midpoint category is heavily influenced by electricity consumption. The main reason behind this result is related to the electricity generation mixture in Ontario, Canada. In 2022, 53.7% of electricity in Ontario was generated by nuclear power plants [43], which are the main cause of ionizing radiation. Since GSHP systems rely entirely on electricity for heating and cooling cycles, their electricity consumption is much higher than that of AC units, resulting in a conventional GSHP having the highest ionizing radiation effect, followed by a thermal caisson GSHP.

Ozone formation at ground levels, in units of kg of equivalent NOx, can directly impact human health and ecosystems; hence, it is presented as two separate categories. Atmospheric conditions, precursor pollutants, sunshine, and complex chemical interactions all contribute to creating ozone at the ground level. Nitrogen oxides (NOx) and volatile organic compounds (VOCs) are the main precursor pollutants in creating ground-level ozone. Several human activities and natural sources both emit these contaminants. Ground-level ozone is created when these contaminants react in the presence of sunshine. Natural gas consumption in the furnace during the heating cycle has the highest impact among all the systems, with 84.3 kg of equivalent NOx. For GSHP systems, a conventional GSHP has a higher impact than a thermal caisson system, mainly due to borehole drilling and the installation of the ground loop.

Fine particulate matter formation (PMF) evaluates the emissions that lead to the formation of fine particulate matter in the atmosphere. These particles can adversely affect human health, causing respiratory and cardiovascular issues. The impact is measured regarding potential human health impacts from exposure to particulate matter. Combustion processes and vehicle usage, which can be translated to transport, are the two major factors in PMF. In all three systems, the operation stage is the main contributor to PMF, but due to the natural gas consumption of the furnace, the impact of this system on PMF is 1.9 and 2.8 times that of conventional and thermal caisson GSHP systems, respectively.

Terrestrial acidification describes the loss of plant species due to a decreased soil PH. Changes in the soil PH are caused by emissions of acidifying substances into the air, which are the main reasons for acid precipitation. Equivalent emission of SO2 to the air is the unit for measuring this impact category. As for the PMF, the main sources of SO2 emissions are transportation and fuel combustion, either for electricity generation or reasons other than transportation. This is why the amount of equivalent SO2 presented in Table 1 for the AC/furnace system is 87.1 kg. the furnace’s consumption of natural gas is responsible for 85.2% of this value, while the share of electricity consumption of the A/C is 9.7%, and the rest is attributable to the production stage. In conventional and thermal caisson GSHP systems, electricity consumption has shares of 78% and 75.5%, respectively, and the production stage is responsible for the rest. The higher share of production in GSHP systems directly connects to the utilization of more raw materials in heat pump and ground loop production.

Eutrophication occurs when excessive amounts of nutrients, particularly nitrogen and phosphorus, are added to freshwater and marine water bodies. Phytoplankton, algae, and aquatic plants overgrow due to this enrichment. A certain amount of nutrient enrichment is expected and essential for healthy ecosystems. However, human activities can dramatically speed up the process and have negative impacts. In the ReCiPe method, freshwater eutrophication and marine eutrophication are measured by equivalent kilograms of phosphorous and nitrogen, respectively, and the loss of aquatic species occurs due to their increased concentrations. According to Figure 6, Figure 7 and Figure 8, electricity and natural gas consumption are the main contributors to freshwater eutrophication, and electricity alone is the main factor in marine eutrophication. Although electricity consumption cannot be directly responsible for eutrophication, the processes and activities associated with electricity generation can exacerbate nutrient pollution. Hydroelectric reservoir construction, the thermal pollution of water bodies, and cooling water discharges are some potential causes of nutrient pollution. Unlike electricity, natural gas extraction and consumption can be indirectly responsible for eutrophication. Table 1 shows that, while the AC/furnace system has the highest impact on freshwater eutrophication, it has the lowest impact on marine eutrophication. A total of 65% of the impact on freshwater comes from natural gas consumption, which is possibly due to the higher chance of polluting freshwater in extracting natural gas. For both categories, the thermal caisson GSHP system is the least polluting system.

Terrestrial, freshwater, marine ecotoxicity, and human carcinogenic and non-carcinogenic toxicity are all expressed in 1.4-dichlorobenzene equivalents. The ecotoxicological effect factor is a metric used to gauge the impact that variations in the concentration of a chemical in the environment have on the potential reduction in a species’ population in a given area. This concept, referred to as the potentially disappeared fraction (PDF) of species, reflects the risk to biodiversity that arises from changes in the levels of pollutants or toxins to which organisms are exposed. Human-toxicological impact factors developed independently for carcinogenic and non-carcinogenic effects, indicating that changes in lifetime illness incidence are brought on by changes in the substance’s intake. Based on the results in Figure 6, Figure 7 and Figure 8, all toxicity categories are mainly impacted by electricity consumption. According to this finding, Table 4 shows that the conventional GSHP system has the greatest impact on all of the mentioned categories, followed by the thermal caisson system, while the AC/furnace has the lowest impact. These results clarify that the electricity generation mix in Ontario increases the toxicity of the environment, and increased dependency on the electricity grid can affect human health and the environment. These effects can vary dramatically by changing the electricity generation mix, which is expected to be one of the main reasons for the difference in the results of the life cycle assessment of the same systems in different regions.

The land use impact category represents the species loss caused by the transformation of natural land to used land, including the time it takes to restore the land to its natural state. Figure 6, Figure 7 and Figure 8 show that the production stage of the systems has the smallest impact on this category, while the operation stage has a significant impact. The required land for energy infrastructure is the main reason behind the results shown in Figure 6, Figure 7 and Figure 8. Since regional factors influence this impact category, it can be interpreted from the results that the land required for electricity generation infrastructure in Ontario overtakes the land required for the natural gas grid. As expected, the AC system, which requires the least electricity, has the smallest impact, and the conventional GSHP has the greatest impact.

Mineral resource scarcity measures the surplus ore potential. The extraction of a mineral resource results in the degradation of the concentration, which ultimately leads to more extraction. Based on this definition, systems that require more materials in the production stage are expected to have a higher impact on this category. By comparing Figure 7 and Figure 8, it is validated that the production stage of the TC GSHP system, which comprises more raw materials, has a higher impact on mineral resource scarcity compared to the conventional system. Since the AC/furnace system has different production processes, comparing it to GSHP systems is not possible, but generally, fewer raw materials are used to produce this system. Figure 6, Figure 7 and Figure 8 also show that the electricity energy consumption of the systems significantly affects this category, which could be justified by the materials used in developing the energy infrastructure. When combining the results, it can be seen that a conventional GSHP system has the highest impact on this category, and an AC/furnace system is the best option based on this impact category.

The possible depletion of fossil fuel resources as a result of human activity is measured by the fossil fuel depletion category. Fossil resources, such as coal, oil, and natural gas, are mined and used for energy production, transportation, and industrial activities. In all of the investigated systems, energy consumption is the main factor. Based on the results of Table 4, between the two GSHP alternatives, the thermal caisson system has a higher impact, which may not be intuitive due to its lower electricity consumption. However, it is pointed out that, in the production of the ground loop of this system, more raw materials, especially oil-based materials, are used. An AC/furnace system depletes more fossil fuels than GSHP alternatives due to the natural gas consumption in the furnace.

The water consumption impact category represents the predicted water consumption of the systems during their life cycles. Again, electricity consumption is the most influential factor across all of the systems in this category, resulting in the fact that a conventional GSHP system consumes almost 2.8 times more water than an AC system and 1.2 times more than a thermal caisson GSHP system. The consumed water is in the electricity generation processes involved in steam generation and cooling water. Like the other impact categories mainly influenced by the electricity generation mix, this category can vary substantially for different grids and regions.

The ReCiPe 2016 converges the damage pathways from midpoint categories into three endpoint categories to facilitate the comparison of the environmental effects of different systems. As per ReCiPe 2016 [33], the units for the endpoint categories are disability adjusted life years (DALYs), the potentially disappeared fraction of species per year (species·yr), and USD for human health, ecosystems, and resources, respectively.

Based on the endpoint results, a thermal caisson GSHP system imposes higher costs than a conventional GSHP system due to the utilization of more raw materials, while from the other two categories’ perspectives, the TC GSHP system is the least damaging option to the environment and human health. Overall, the AC/furnace system has the highest impact on human health and the environment; even the conventional GSHP system in the region of Ontario outperforms it.

Another way to present and contrast the overall results of the LCIA is to report each system’s score. In the single score model, each endpoint category has a different weight and, subsequently, a different impact on categories. The ReCipe method, by default, assumes a 40% weight for human health and ecosystem each and 20% for resources. Table 5 shows the single score results of the endpoint impact categories, which SimaPro calculates, and the percentage of change in each category between different systems. Knowing the weight of each category and assigning them to the obtained damage assessment results shows that by replacing an AC/furnace unit with a GSHP system, the impact on all the categories is reduced by between 72 and 90%, with resource depletion attaining the highest reduction at 90%. Although the reduction in endpoint categories by switching to GSHP systems is a beneficial result, the other goal of this study is to investigate the impacts of replacing a TC GSHP system with a conventional GSHP system. Based on the findings in Table 5, the TC GSHP system can reduce the overall endpoint impacts by 21.4% compared to the conventional GSHP system. The results show that the human health endpoint category experiences a 21.6% reduction in the current case study, and damage to the ecosystem is reduced by 22.6%. The single score results show that TC GSHP systems can be a better option than conventional ground source heat pumps due to their reduced impact on human health and ecosystems; however, resource availability is negatively impacted by 4.9% by choosing a TC GSHP system over a conventional system. This result is likely due to more materials being used to develop a TC GSHP system, which constitutes a potential field for further studies and development.

Table 5.

Single score results of endpoint impact categories, indicating reductions (%) from AC/furnace (A/F) to TC GSHP and from conventional GSHP (CGSHP) to TC GSHP systems.

4. Sensitivity Analysis

A sensitivity analysis was undertaken to evaluate the impact of Ontario’s electricity energy mix on the environmental implications associated with the three HVAC systems under consideration. Six distinct scenarios were examined by varying the proportion of electricity generation from nuclear power plants, natural gas power plants, and renewable sources, excluding hydroelectric plants. The proportion of electricity generation from these sources was adjusted by ±20% relative to the base condition, derived from Ontario’s electricity grid mix as delineated in the Ecoinvent database. It was assumed that adjustments to these allocations would be proportionally offset by alternative methods of electricity generation to maintain energy balances. Table 6 shows the results obtained from the sensitivity analysis on the single score results of the endpoint impact categories and the corresponding changes compared to the base case in percentage terms.

Table 6.

Single score results of endpoint impact categories from sensitivity analysis on Ontario’s energy mix, indicating changes (%) compared to base case.

The findings indicate that adjustments in energy mix proportions have the least environmental impact on the air conditioner and furnace system primarily due to its lower electricity consumption compared to ground source heat pump systems. However, the results highlight that a 20% reduction in the share of nuclear power plants’ generation leads to the most substantial increase in total environmental damage for a TC GSHP system, with a 5.4% rise compared to the base case. This is primarily attributed to the compensatory reliance on more pollutant-emitting power plants to offset the reduced share of nuclear power. Additionally, as anticipated, a 20% decrease in the share of natural gas power plants significantly reduces the environmental impacts of GSHP systems. Despite occasional increases in specific scenarios, the overall environmental impact of the air conditioner and furnace system remains notably predominant across all scenarios.

5. Results Validation and Comparison

Comparing the findings of different LCIA studies can be difficult due to the utilization of different LCIA methods and all of the assumptions and complexities incorporated in each model. Considering all of these limitations, the results of this study were compared with similar studies.

Smith et al. [29] used the ReCiPe model to perform an LCA for a 10.55 kW residential ground source heat pump system in New Jersey, USA over the assumed 25-year life cycle. In this study, the operation of the GSHP accounts for about 87% of the total impacts; the heating mode contributes the most. Overall, the trend of each midpoint impact category is, to a great extent, similar to the findings of this study, except for the ionizing radiational potential (IRP), which is five and seven times greater in the current study for the TC GSHP and conventional GSHP systems, respectively. The primary reason for this discrepancy is the share of nuclear electricity generation in the total electricity generation mix. The share of nuclear electricity generation in Ontario is 53.7%, while it is 34.5% for New Jersey. Ultimately, Smith et al. concluded that the impact of a GSHP system heavily depends on the electricity generation mix of the grid.

Sevindik et al. [44] used the ReCiPe method to conduct a life cycle assessment of a 10 kW GSHP system compared to natural gas boilers during heating season in the United Kingdom. Based on their findings, natural gas boilers have smaller footprints on the midpoint impact categories compared to GSHP systems. In this study, the operation phase, on average, has a 74.0% share of each impact category compared to 73.6% for a conventional GSHP system and 74.3% for a TC GSHP system in the current study. Changing the electricity generation mix and anticipating using more renewable energy sources based on the government’s targets and national policies show that the midpoint impacts of the GSHP systems can be improved and exacerbated simultaneously due to the impacts of developing the new electricity generation infrastructure, which again emphasizes the importance of the electricity generation mix. For the same reason, the results of the current study show that the average reductions in midpoint categories by using conventional and TC GSHP systems are around 52.3% and 65.8%, respectively.

Saner et al. [26] performed an LCA of a 10 kW ground source heat pump using the ReCiPe method. Considering the equivalent kilograms of CO2 as a proxy of environmental impacts, their results show that in different European countries, depending on the electricity generation mix of the grid and the heating and cooling demands of each country, the reduction in equivalent kilograms of CO2 due to changing gas furnace and AC systems with a GSHP system is in the range of 11 to 48 percent. Although our results show reductions of 88 and 90 percent for conventional and TC GSHP systems, the overall results show that GSHP systems are much better regarding CO2 emissions.

Aresti et al. [34] compared the life cycle assessment of an air source heat pump (ASHP) with three ground loop configurations of a ground source heat pump in three European countries using the ReCiPe method. Similar to other studies and our findings, the operation stage of the systems has the most impact on the midpoint categories due to a longer time of action. While the current study shows that using GSHP systems instead of AC/furnace systems can cause the endpoint impact categories to reduce between 72 and 90 percent, based on the results of the study by Aresti et al., using a GSHP system instead of an ASHP can cause the endpoint impact categories to reduce between 8 and 43 percent, which is mainly due to the different electricity generation mix.

Violante et al. [27] conducted a comparative LCA on GSHP vs. air source heat pump (ASHP) systems near Rome, Italy. The GSHP analyzed in their work is a conventional system with a 25-year operating life and four boreholes with different depths. Their results show that the production and installation stages in the GSHP system have a higher environmental impact than those of the ASHP system, which aligns with the current study’s findings. In addition, the operation phase in both systems is the most impactful, which is entirely affected by the electricity generation mix. Although their results show that the considered GSHP system in their case study has a higher overall environmental impact, they point out that the ground loop of the GSHP system can last for about 100 years, which means it can cover three to four heat pump operation lives. This neglected fact alters the first conclusions and makes the GSHP system the better option. This result indicates that, even in the current study, the overall impact of both GSHP systems can be much lower than the presented results. Following up on this merits future research.

Bonamente et al. [16] performed an LCA of a conventional GSHP compared to a GSHP equipped with thermal storage filled with PCM. The results presented for the 17 kW GSHP are consistent with the current study’s findings, which show that the endpoint categories exhibit better performance than the system equipped with PCM.

6. Conclusions

A comparative life cycle assessment is presented for three HVAC systems, including an air conditioner/furnace, a conventional ground source heat pump, and a thermal caisson GSHP system. The results show that, for a 150 m2 residential building located in Ontario, Canada, the majority of the environmental impacts originate from the operation phases of the systems, mainly due to their much greater durations. In the production stage, ground source heat pumps exhibit higher impacts on midpoint categories because more raw material is consumed in the production and installation of the ground loops. Between conventional and TC GSHP systems, the thermal caisson system has a higher impact, even though the borehole drilling process was omitted due to the incorporation of the ground loop into the caisson. The reason behind this result is the addition of phase change material and NBR pipes into the ground loop.

It was shown via the results of the endpoint impact categories that, by switching from an AC/furnace to a conventional GSHP system, the total damage can be reduced by 72.7%, while by switching to a TC GSHP system, the total reduction can reach 78.6%. In both cases, the reduction in the damage to resource availability is the greatest among the three endpoint categories. In addition, it is observed that by choosing a TC GSHP system over a conventional GSHP system, the total reduction in endpoint categories would be 21.4%, which suggests the superiority of this system over a conventional GSHP system. However, the amount of damage to the resource availability category caused by switching from a conventional system to a TC GSHP system increases by 4.9% due to the greater material consumption.

Author Contributions

Conceptualization, M.A.; methodology, M.A. and P.A.; software, M.A. and P.A.; validation, M.A.; formal analysis, M.A., Pouria Abbasi; investigation, M.A., P.A. and P.B.; writing—original draft preparation, P.A.; writing—review and editing, M.A., P.B. and M.A.R.; visualization, P.A.; supervision, M.A.R. and M.A.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ontario Center for Innovation.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors want to thank the Ontario Center for Innovation for their financial support.

Conflicts of Interest

Author Masih Alavy was employed by the company Capture Technologies. The remaining authors declare that this research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- International Energy Agency. Key World Energy Statistics 2021. Statistics Report. September 2021. Available online: https://www.iea.org/reports/key-world-energy-statistics-2021 (accessed on 10 May 2023).

- International Energy Agency and Global Alliance for Buildings and Construction. 2019 Global Status Report for Buildings and Construction; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Natural Resources Canada. Green Building Principles. Available online: https://natural-resources.canada.ca/energy-efficiency/green-buildings/green-building-principles/25301 (accessed on 3 April 2023).

- Sarbu, I.; Sebarchievici, C. General review of ground-source heat pump systems for heating and cooling of buildings. Energy Build. 2014, 70, 441–454. [Google Scholar] [CrossRef]

- Florides, G.; Kalogirou, S. Ground heat exchangers-A review of systems, models and applications. Renew. Energy 2007, 32, 2461–2478. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M.; Domanski, P.A. Selecting HVAC Systems to achieve comfortable and cost-effective residential net-zero energy buildings. Appl. Energy 2018, 212, 577–591. [Google Scholar] [CrossRef]

- Hakkaki-Fard, A.; Eslami-Nejad, P.; Aidoun, Z.; Ouzzane, M. A techno-economic comparison of a direct expansion ground-source and an air-source heat pump system in Canadian cold climates. Energy 2015, 87, 49–59. [Google Scholar] [CrossRef]

- Gao, B.; Zhu, X.; Yang, X.; Yuan, Y.; Yu, N.; Ni, J. Operation performance test and energy efficiency analysis of ground-source heat pump systems. J. Build. Eng. 2021, 41, 102446. [Google Scholar] [CrossRef]

- Alavy, M.; Shirazi, P.; Rosen, M.A. Long-term energy performance of thermal caisson geothermal systems. Energy Build. 2023, 292, 113152. [Google Scholar] [CrossRef]

- Maddah, S.; Goodarzi, M.; Safaei, M.R. Comparative study of the performance of air and geothermal sources of heat pumps cycle operating with various refrigerants and vapor injection. Alex. Eng. J. 2020, 59, 4037–4047. [Google Scholar] [CrossRef]

- Alavy, M.; Nguyen, H.V.; Leong, W.H.; Dworkin, S.B. A methodology and computerized approach for optimizing hybrid ground source heat pump system design. Renew. Energy 2013, 57, 404–412. [Google Scholar] [CrossRef]

- Choi, W.; Ooka, R.; Nam, Y. Impact of long-term operation of ground-source heat pump on subsurface thermal state in urban areas. Sustain. Cities Soc. 2018, 38, 429–439. [Google Scholar] [CrossRef]

- Zhu, N.; Hu, P.; Xu, L.; Jiang, Z.; Lei, F. Recent research and applications of ground source heat pump integrated with thermal energy storage systems: A review. Appl. Therm. Eng. 2014, 71, 142–151. [Google Scholar] [CrossRef]

- Ma, Z.; Xia, L.; Gong, X.; Kokogiannakis, G.; Wang, S.; Zhou, X. Recent advances and development in optimal design and control of ground source heat pump systems. Renew. Sustain. Energy Rev. 2020, 131, 110001. [Google Scholar] [CrossRef]

- Zhang, W.; Wei, J. Analysis on the Soil Heat Accumulation Problem of Ground Source Heat Pump System in High Temperature and High Humidity Areas. Energy Procedia 2012, 14, 198–204. [Google Scholar] [CrossRef]

- Bonamente, E.; Aquino, A. Life-Cycle Assessment of an Innovative Ground-Source Heat Pump System with Upstream Thermal Storage. Energies 2017, 10, 1854. [Google Scholar] [CrossRef]

- Shukla, S.; Bayomy, A.M.; Antoun, S.; Mwesigye, A.; Leong, W.H.; Dworkin, S.B. Performance characterization of novel caisson-based thermal storage for ground source heat pumps. Renew. Energy 2021, 174, 43–54. [Google Scholar] [CrossRef]

- Bayomy, A.M.; Nguyen, H.V.; Wang, J.; Dworkin, S.B. Performance analysis of a single underground thermal storage borehole using phase change material. Proc. IGSHPA Res. Track 2018, 1, 11. [Google Scholar] [CrossRef]

- Qi, D.; Pu, L.; Sun, F.; Li, Y. Numerical investigation on thermal performance of ground heat exchangers using phase change materials as grout for ground source heat pump system. Appl. Therm. Eng. 2016, 106, 1023–1032. [Google Scholar] [CrossRef]

- Yang, W.; Xu, R.; Yang, B.; Yang, J. Experimental and numerical investigations on the thermal performance of a borehole ground heat exchanger with PCM backfill. Energy 2019, 174, 216–235. [Google Scholar] [CrossRef]

- Chen, F.; Mao, J.; Chen, S.; Li, C.; Hou, P.; Liao, L. Efficiency analysis of utilizing phase change materials as grout for a vertical U-tube heat exchanger coupled ground source heat pump system. Appl. Therm. Eng. 2018, 130, 698–709. [Google Scholar] [CrossRef]

- Alavy, M.; Peiris, M.; Wang, J.; Rosen, M.A. Assessment of a novel phase change material-based thermal caisson for geothermal heating and cooling. Energy Convers. Manag. 2021, 234, 113928. [Google Scholar] [CrossRef]

- Hunter, A.K. Comparative Life Cycle Assessment: Ground Source Heat Pump System versus Gas Furnace and Air Conditioner System. Master’s Thesis, Toronto Metropolitan University, Toronto, ON, Canada, 2017. [Google Scholar] [CrossRef]

- Chiavetta, C.; Tinti, F.; Bonoli, A. Comparative life cycle assessment of renewable energy systems for heating and cooling. Procedia Eng. 2011, 21, 591–597. [Google Scholar] [CrossRef]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kübert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Violante, A.C.; Donato, F.; Guidi, G.; Proposito, M. Comparative life cycle assessment of the ground source heat pump vs. air source heat pump. Renew. Energy 2022, 188, 1029–1037. [Google Scholar] [CrossRef]

- Shah, V.P.; Debella, D.C.; Ries, R.J. Life cycle assessment of residential heating and cooling systems in four regions in the United States. Energy Build. 2008, 40, 503–513. [Google Scholar] [CrossRef]

- Smith, M.; Bevacqua, A.; Tembe, S.; Lal, P. Life cycle analysis (LCA) of residential ground source heat pump systems: A comparative analysis of energy efficiency in New Jersey. Sustain. Energy Technol. Assess. 2021, 47, 101364. [Google Scholar] [CrossRef]

- Aresti, L.; Christodoulides, P.; Florides, G.A. An investigation on the environmental impact of various Ground Heat Exchangers configurations. Renew. Energy 2021, 171, 592–605. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14047:2012; Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 to Impact Assessment Situations. International Organization for Standardization: Geneva, Switzerland, 2012.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2016, 22, 138–147. [Google Scholar] [CrossRef]

- Aresti, L.; Florides, G.A.; Skaliontas, A.; Christodoulides, P. Environmental Impact of Ground Source Heat Pump Systems: A Comparative Investigation From South to North Europe. Front. Built Environ. 2022, 8, 914227. [Google Scholar] [CrossRef]

- Koroneos, C.J.; Nanaki, E.A. Environmental impact assessment of a ground source heat pump system in Greece. Geothermics 2017, 65, 1–9. [Google Scholar] [CrossRef]

- Sutman, M.; Speranza, G.; Ferrari, A.; Larrey-Lassalle, P.; Laloui, L. Long-term performance and life cycle assessment of energy piles in three different climatic conditions. Renew. Energy 2020, 146, 1177–1191. [Google Scholar] [CrossRef]

- Ren, C.; Deng, Y.; Cao, S.-J. Evaluation of polyethylene and steel heat exchangers of ground source heat pump systems based on seasonal performance comparison and life cycle assessment. Energy Build. 2018, 162, 54–64. [Google Scholar] [CrossRef]

- Ecoinvent Association. Ecoinvent Database Version 3.7.1. Available online: https://ecoinvent.org/ (accessed on 20 July 2023).

- PRé Consultants, B.V. SimaPro 9.2.0.2. SimaPro. Available online: https://simapro.com/ (accessed on 20 July 2023).

- Kurevija, T.; Macenić, M.; Borović, S. Impact of grout thermal conductivity on the long-term efficiency of the ground-source heat pump system. Sustain. Cities Soc. 2017, 31, 1–11. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, Z.; Lin, X.; Wang, C.; Sun, Z.; Chen, Y. Designing and Optimizing Heat Storage of a Solar-Assisted Ground Source Heat Pump System in China. Int. J. Photoenergy 2020, 2020, e4102350. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Javed, S. Long-Term Performance Measurement and Analysis of a Small-Scale Ground Source Heat Pump System. Energies 2020, 13, 4527. [Google Scholar] [CrossRef]

- 2020 Year in Review. Available online: https://www.ieso.ca/en/Corporate-IESO/Media/Year-End-Data (accessed on 10 May 2023).

- Sevindik, S.; Spataru, C.; Aparisi, T.D.; Bleischwitz, R. A Comparative Environmental Assessment of Heat Pumps and Gas Boilers towards a Circular Economy in the UK. Energies 2021, 14, 3027. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).