Conceptual Management Framework for Oil and Gas Engineering Project Implementation

Abstract

1. Introduction

- The current geopolitical situation does not allow free exchange of goods between Russia and a number of countries, in particular with regard to technologies in the oil and gas industry.

- The key (supporting) state industries (one of which is the oil and gas sector for Russia) should not be fundamentally dependent on foreign technologies and equipment since inconsistencies with foreign partners or other circumstances leading to technological risks can seriously affect the national economy.

- The confirmation of the possibility of technology creation has not been received (the technological hypothesis has not been confirmed) [23]

- The project turned out to be technologically inefficient (the achieved technological effect was significantly inferior to the planned one) [26]. (The non-confirmation of a technological hypothesis reflects the impossibility of creating a specific technological solution under given conditions, while the insufficient technological efficiency of the solution reflects a situation in which a technological solution is created but its actual parameters (effect) are significantly inferior to those planned).

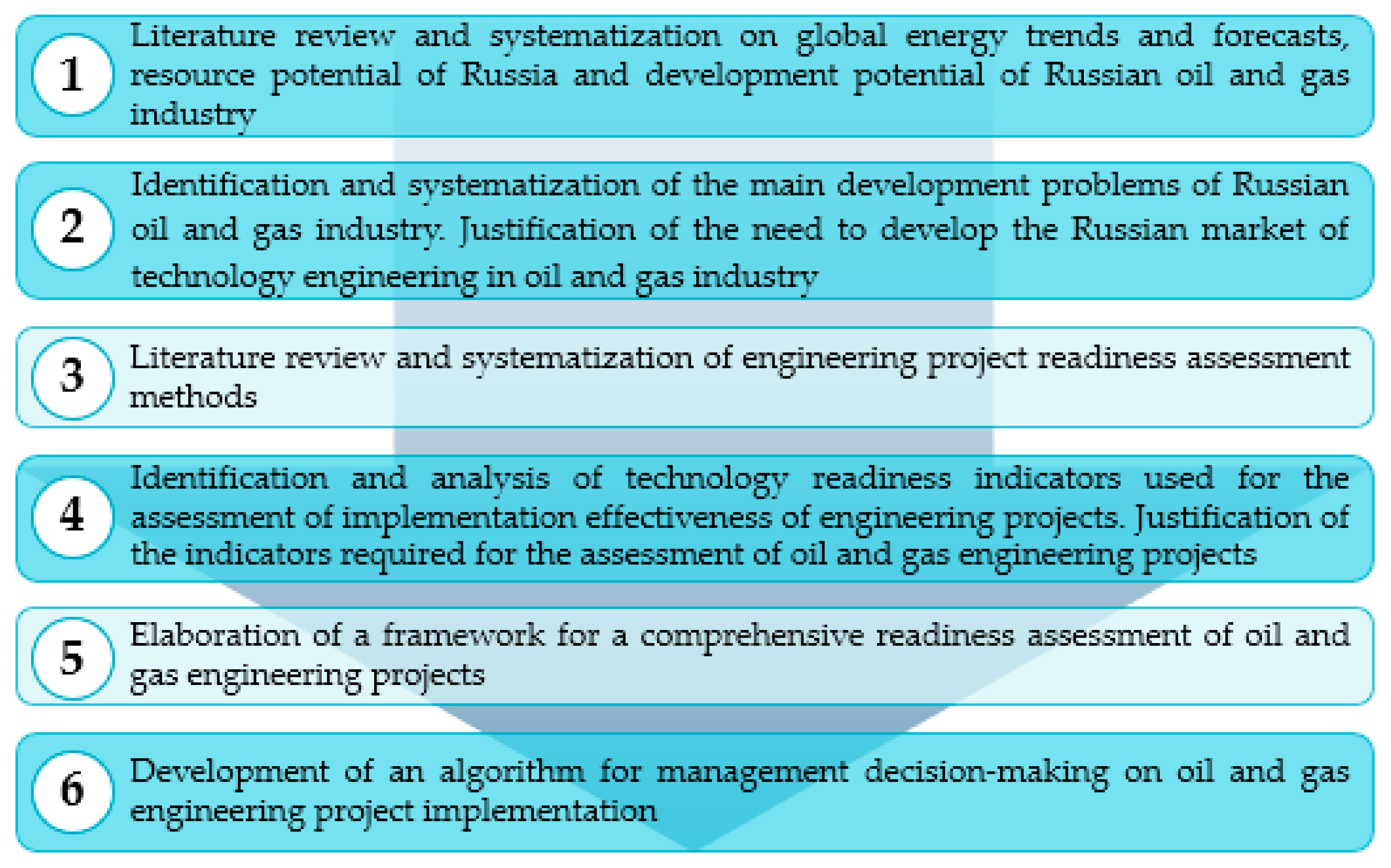

2. Materials and Methods

- Statistical data of analytical agencies, industry companies, core ministries, and departments—S&P Global, Reuters, Shell, IEA, ExxonMobil, BP, Deloitte, the World Bank, the Ministry of Finance of the Russian Federation, the Russian Federal State Statistics Service, the Russian Federal Customs Service, etc.

- Publications in scientific journals—Energies, Resources, Journal of Marine Science and Engineering, Sustainability, Applied Sciences, Oil & Gas Science and Technology, Journal of Mining Institute, International Journal of Engineering Research and Technology, Technological Forecasting and Social Change, Journal of Product Innovation Management, California Management Review, The North and the Market: Forming the Economic Order, Oil Industry, Oil and Gas Innovations, Oil and Gas Vertical, Mining Journal, The Economics of Science, etc.

3. Oil and Gas Resources: Trends, Forecasts, Problems, and Solutions

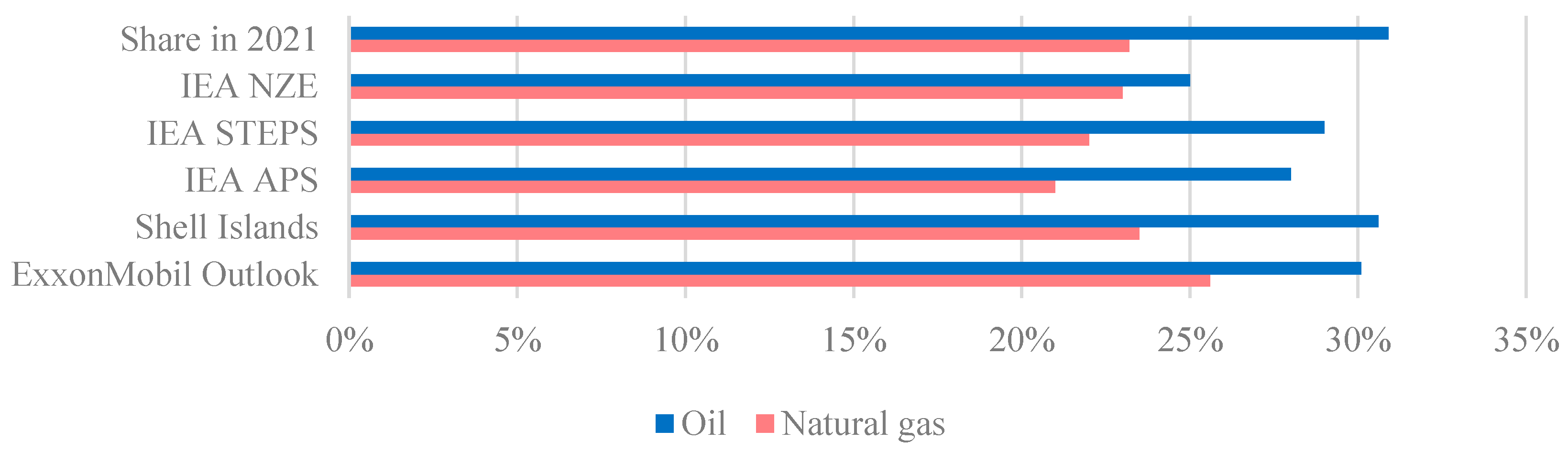

3.1. Global Energy Trends and Forecasts

- Analytical agencies apply different methodologies for making forecasts; therefore, their individual comparison is quite difficult and, in some cases, incorrect [31].

- The current forecasts do not yet fully reflect the change in volume of demand for energy resources and the change in structure of the global energy mix that occurred in 2022.

3.2. Problems and Prospects for the Development of Russian Oil and Gas Resources: An Engineering Approach

4. Technology Readiness Assessment Methods

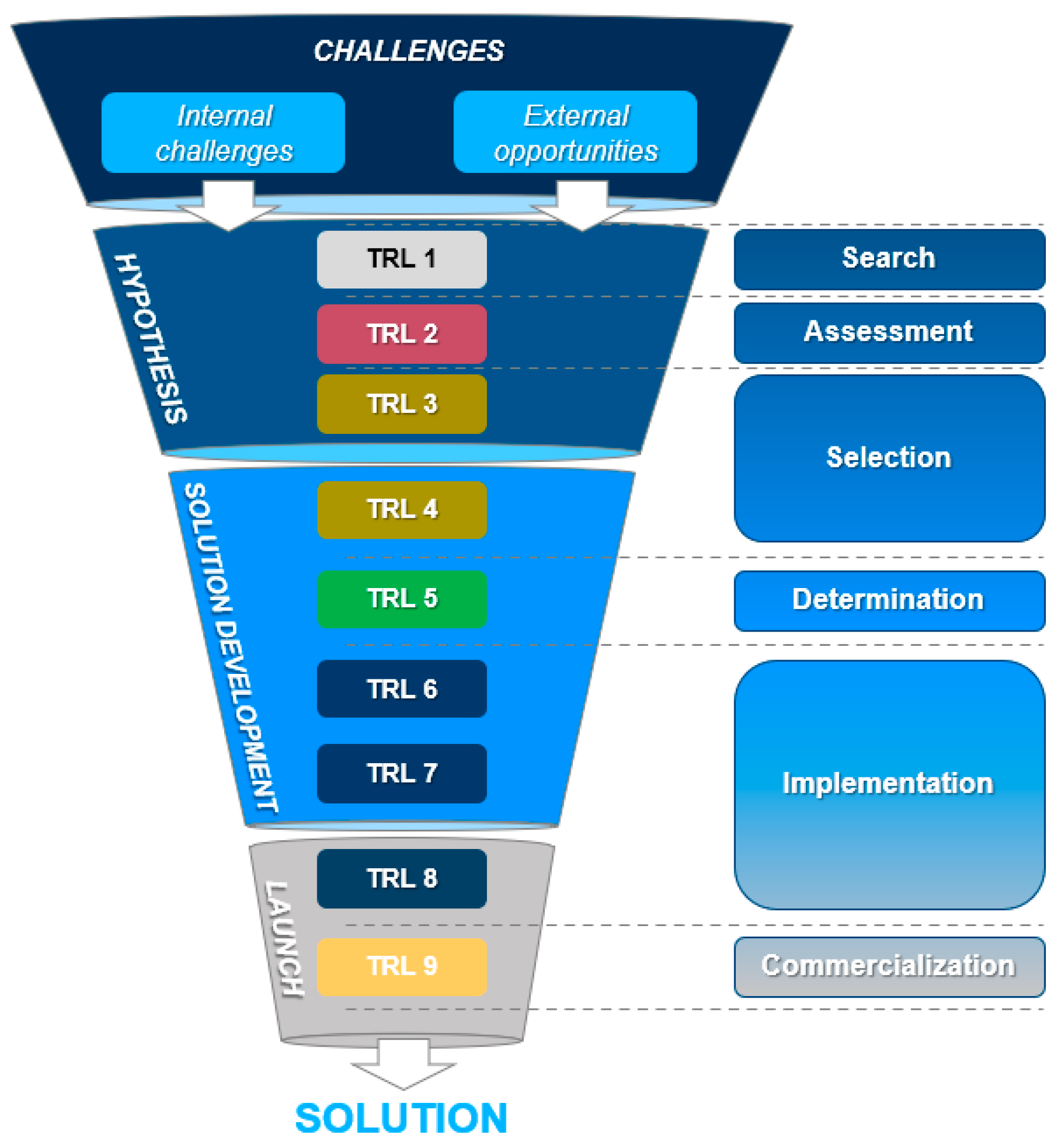

4.1. TRL and Stage-Gate®

- Subjectivity of the assessment—there is no formal method for implementing TRL; the TRL value is assigned to the technology by the developer, which may be biased; and the definitions of each TRL level tend to be broadly interpreted [82].

4.2. Other Methods for Technology Readiness Assessment

5. A Conceptual Management Framework for the Oil and Gas Engineering Project Implementation

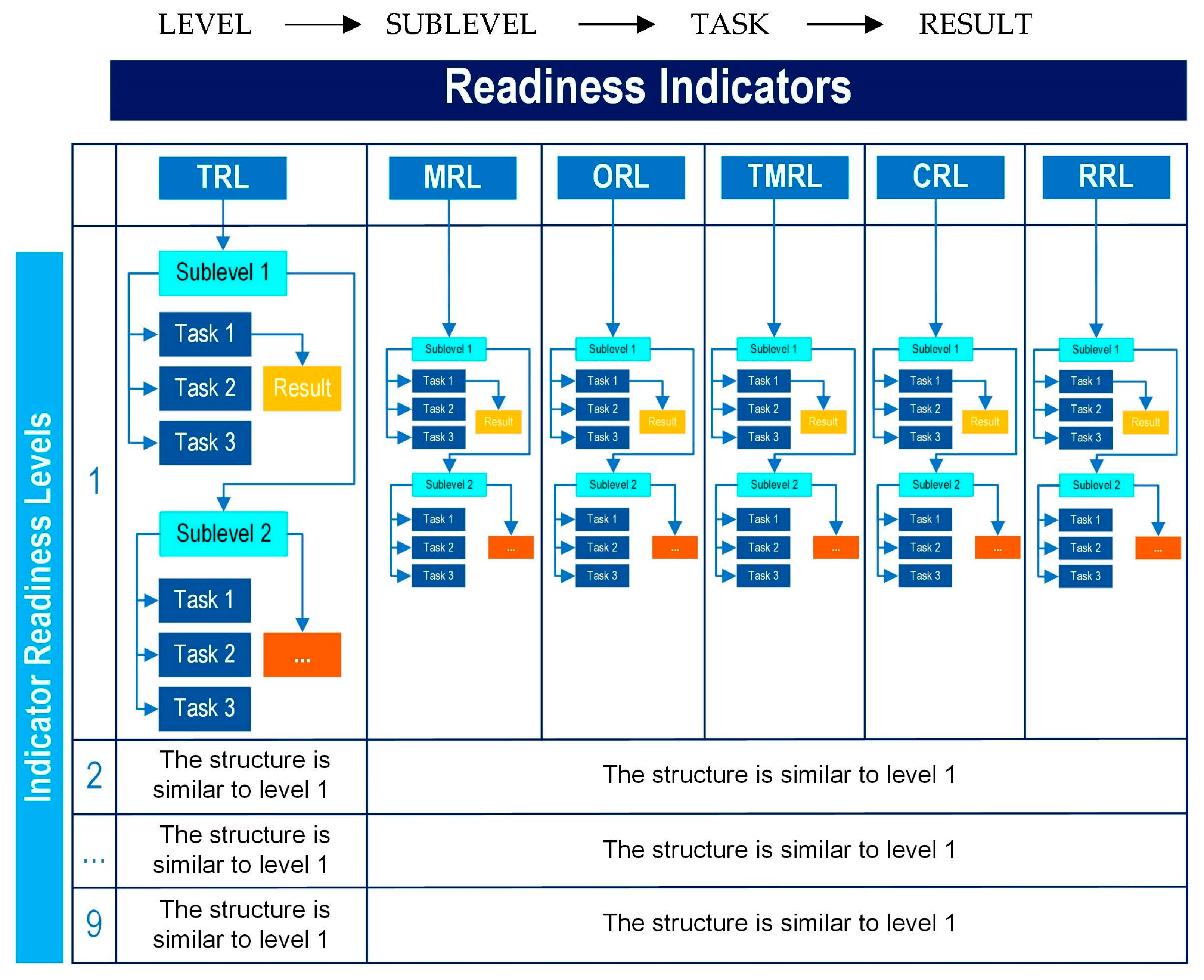

- Comprehensive readiness assessment of the technological solution

- A high degree of detail in the assessment

- Universal model structure

- Sufficient level of objectivity (due to the formal accounting of project results based on supporting documents)

- The ability to adapt the scale to the requirements of a particular industry or project without violating the general structure

- Availability of tools for monitoring the effectiveness and rating of projects when making management decisions

- An expertly-based set of readiness indicators for a comprehensive assessment of project readiness.

- A framework for a comprehensive readiness assessment of engineering projects, including a matrix model for achieved project results accounting (based on selected readiness indicators) and an analytical model for the integral readiness index estimation.

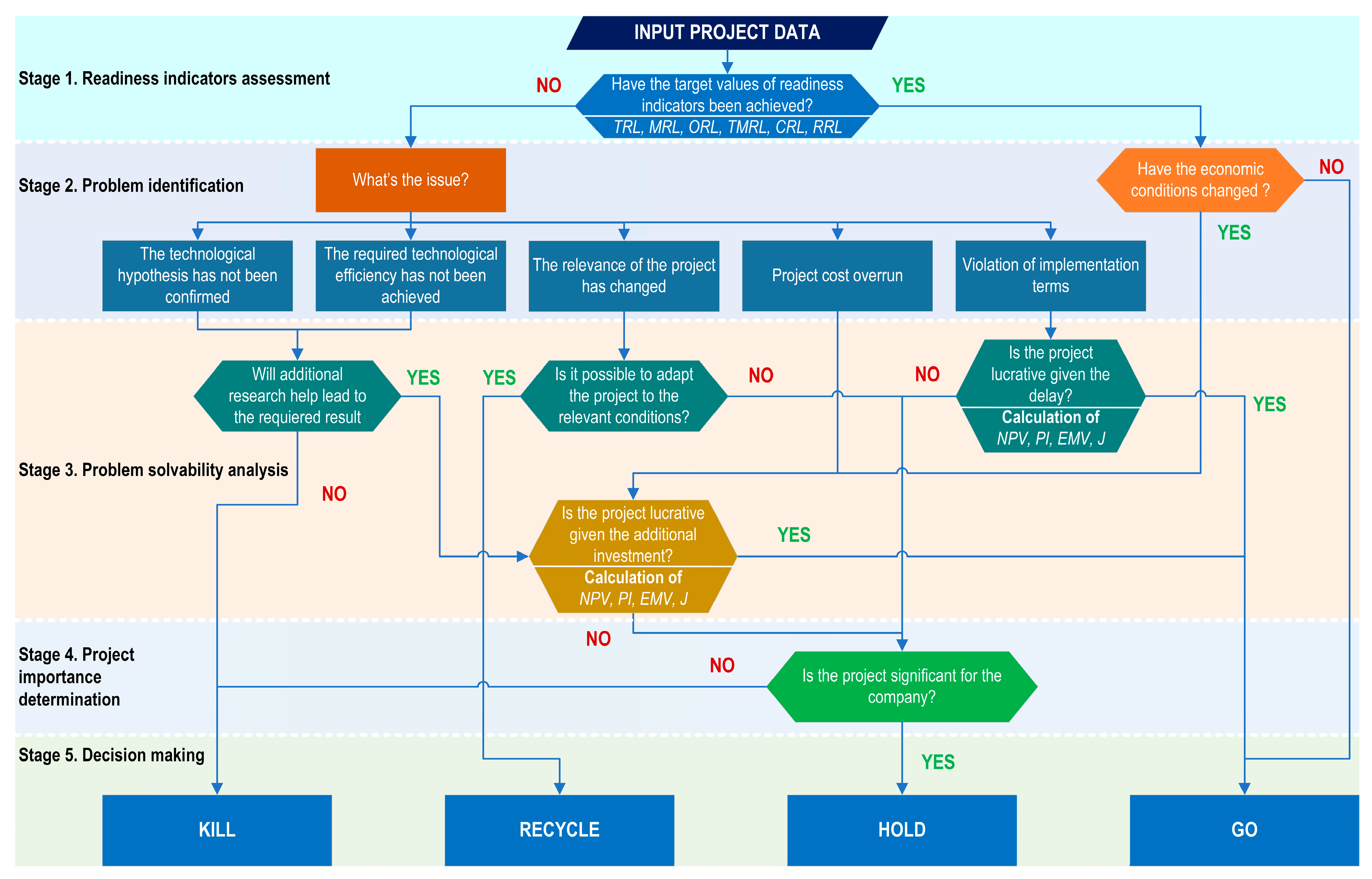

- An algorithm for management decision-making on engineering project implementation.

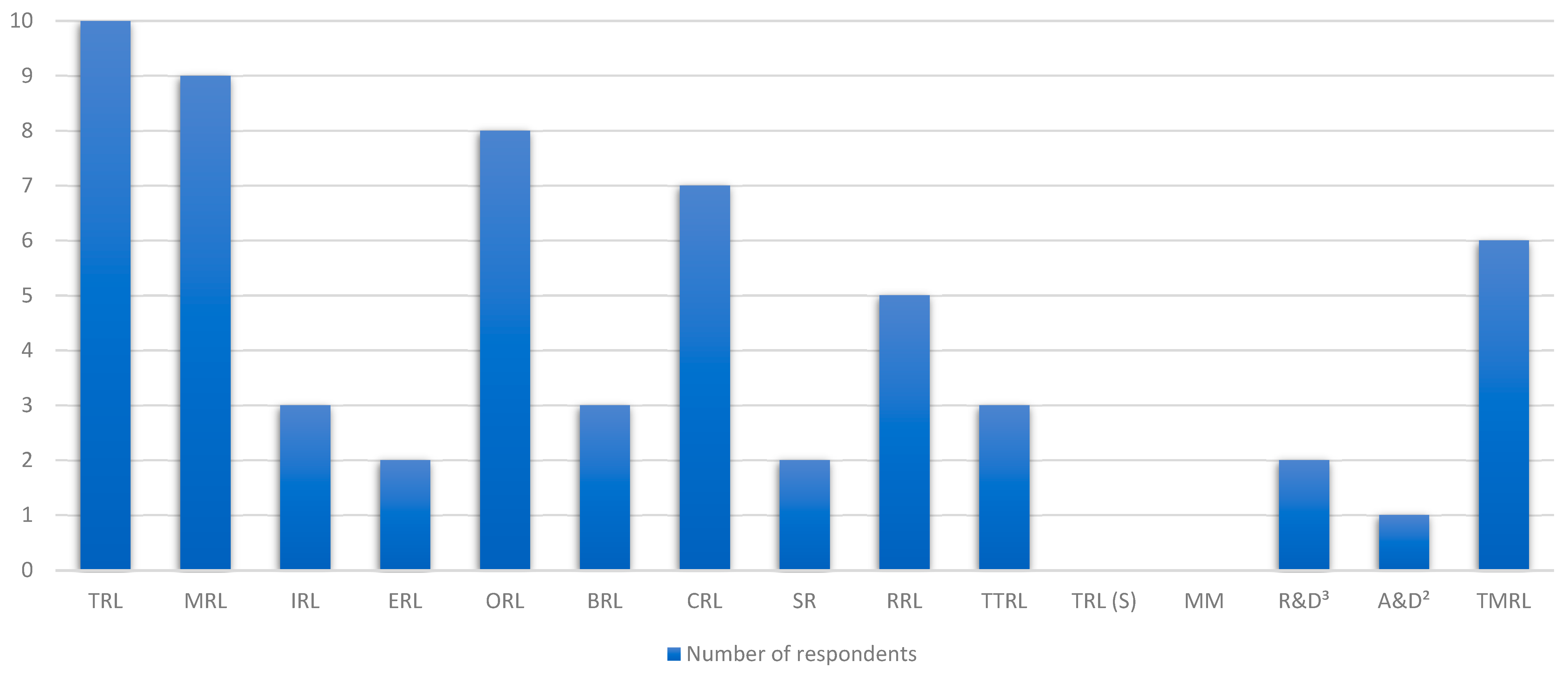

5.1. Readiness Indicators of Engineering Projects

- Technology Readiness Level (TRL)

- Manufacturing Readiness Level (MRL)

- Organization Readiness Level (ORL)

- Commercialization Readiness Level (CRL)

- Regulatory Readiness Level (RRL)

- Team Readiness Level (TMRL)

5.2. A Framework for a Comprehensive Readiness Assessment of Oil and Gas Engineering Projects

5.3. An Algorithm for Management Decision-Making on Engineering Project Implementation

6. Discussion

- Detailing the structure of assessment indicators and the project results accounting

- Substantiation of analytical dependencies in the integral readiness index calculation

- Application of the proposed framework for the project economic efficiency assessment and project portfolio ranking in terms of the company’s goals

7. Conclusions

- Effective management of the engineering project’s implementation should be based on a comprehensive and objective assessment of the technology’s readiness and emerging risks at all life cycle stages of the technology’s creation.

- Most modern TRA methods are based on the principles of two classical methods—TRL and Stage-Gate®—which can be successfully applied to assess technology readiness at a basic level; however, the complexity of modern technological processes and emerging innovative technologies confirms the limited possibility of their application and the necessity for adaptation.

- Modern methods for engineering project readiness assessment must meet certain requirements, in particular: 1. allow for a comprehensive and detailed assessment of the current maturity level of the technology; 2. have a universal structure; 3. exercise formalized control over the project results and have a sufficient level of objectivity; 4. have the ability to adapt the scale in accordance with the requirements of a specific industry or project (without violating the general structure); and 5. have tools for project effectiveness monitoring and rating when making management decisions.

- The most relevant indicators for the readiness assessment of oil and gas engineering projects are:

- Technology Readiness Level (TRL)

- Manufacturing Readiness Level (MRL)

- Organization Readiness Level (ORL)

- Team Readiness Level (TMRL)

- Commercialization Readiness Level (CRL)

- Regulatory Readiness Level (RRL)

According to the experts at Russian oil and gas companies, these indicators fully cover the process of engineering project implementation and allow for the most comprehensive assessment of the current readiness level of the technology. - For the effective implementation of an engineering project, management decisions on the project should be carried out on the basis of a 5-stage algorithm, including: 1. assessment of the completion of the current readiness level requirements; 2. problem identification; 3. problem solvability analysis; 4. project importance determination; and 5. informed decision-making.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- Please introduce yourself and tell us about your experience in the implementation of engineering projects, in particular, projects in the oil and gas industry.

- What are the main goals of the implementation of oil and gas engineering projects?

- What stages of the engineering projects implementation stand out in practice?

- What problems do companies face today when implementing engineering projects?

- What methods for the implementation of engineering projects are used today in oil and gas companies? Are you familiar with such methods as Technology Readiness Level (TRL) and Stage-Gate®? Are they used in your company?

- In your opinion, is it possible to solve a number of topical technological problems of oil and gas companies if, when implementing projects, it is used an approach for a comprehensive maturity assessment of the technology, which includes other readiness indicators in addition to TRL (for example, MRL (Manufacturing Readiness level, CRL (Commercialization Readiness level), others)? If so, what indicators do you think should be used?

| Thank you for participating! |

Appendix B

| Full name | |

| Age | |

| Job title | |

| Place of work |

| Indicator | Abbr. | Brief Description | Need for Accounting (+/−) |

|---|---|---|---|

| Technology Readiness Level | TRL | Readiness (maturity) of technology | |

| Manufacturing Readiness Level | MRL | Readiness of the technology production process | |

| Integration Readiness Level | IRL | Readiness of technology for integration within the system | |

| Engineering Readiness Level | ERL | Degree of engineering support for the technology development process | |

| Organization Readiness Level | ORL | Organizational readiness of the technology creation process | |

| Benefits and Risks | BRL | Availability of benefits and risks of technology creating | |

| Commercialization Readiness Level | CRL | Readiness of technology to enter the market in the form of a product | |

| Scaling Readiness | – | Readiness of the technology to obtain economies of scale in production | |

| Regulatory Readiness Level | RRL | Readiness of regulatory support for the technology development process | |

| Transfer Technology Readiness Level | TTRL | Readiness of technology for transfer from one system to a system with a different functioning mechanism (cross-field technologies) | |

| TRL for Software | TRL (S) | Readiness (maturity) of software technology | |

| Moorhouses Risk Versus TRL Metric | MRM | Regression of the risk of failure depending on the progression of technology readiness | |

| R&D Degree of Difficulty | RD3 | Difficulty in transitioning technology from the current readiness level to the next. RD3—5 stages of difficulty, AD2—9 stages | |

| Advanced Degree of Difficulty | AD2 | ||

| Other (specify) |

| Thank you for participating! |

Appendix C

| Readiness Level | Readiness Index | TRL | MRL | ORL | TMRL | CRL | RRL |

|---|---|---|---|---|---|---|---|

| 1 | (0;1] | Basic technology principles observed and reported | Basic requirements for technology components production defined | Business process scheme developed | Team basic skills in the target area confirmed | Potential business opportunities identified | Patent analysis on existing related technologies carried out |

| 2 | (1;2] | Technology concept and/or application formulated | Basic technology production concepts defined | Availability of materials and manufacturing processes assessed | Project documentation and feasibility studies experience of the team confirmed | Competitive environment assessed | Specific patentable inventions or other patentable RIAs identified |

| 3 | (2;3] | Confirmation of the possibility of technology development received | Production concept confirmation received | Technical characteristics of the technology discussed with the consumer | Team skills to research the technology creation possibility confirmed | Value proposition drafted | A detailed description of possible patentable inventions compiled |

| 4 | (3;4] | Technology component and/or breadboard validation in laboratory environment | Ability of prototype components manufacturing in a laboratory environment confirmed | Concept of technology application approved | Laboratory testing team skills confirmed | Suppliers, partners, pricing policy determined | Invention novelty and patentability confirmed |

| 5 | (4;5] | Technology component and/or breadboard validation in bench tests | Ability of prototype components manufacturing in a relevant environment confirmed | Requirements for technology service support clarified | Bench test team skills confirmed | Exact technology characteristics determined | First full patent application filed. Draft of IPRs protection strategy developed |

| 6 | (5;6] | Technology prototype demonstration in a relevant environment | Ability of prototype manufacturing in an operating environment confirmed | Project changes and adjustments stages completed | Skills of prototype creation and testing in relevant environment confirmed | Pricing model improved | A positive response to a patent application received |

| 7 | (6;7] | Technology prototype demonstration in a target/operating environment | Pilot production line capabilities confirmed | Partner staff trained | Skills of prototype testing in target/operating environment confirmed | Preliminary market launch of technology completed | Patent registered. Other formal IPRs registered |

| 8 | (7;8] | Successful functioning of a full-scale technological system | Initial small-scale production demonstrated | Agreements with interested parties concluded | Skills of full-scale technology creation and functionality testing confirmed | Customer comments worked out | First patent granted. IPRs protection strategy fully implemented. |

| 9 | (8;9] | Readiness of the technological system for full-scale implementation | Full-scale production demonstrated | Production and service support implemented | Skills of full-scale technology implementation confirmed | Full-scale market launch implemented | Patent granted in target countries. High level of IPRs support for business. |

References

- S&P Global. Global Energy Demand to Grow 47% by 2050, with Oil Still Top Source: US EIA. Available online: https://www.spglobal.com/commodityinsights/en/market-insights/latest-news/oil/100621-global-energy-demand-to-grow-47-by-2050-with-oil-still-top-source-us-eia (accessed on 1 March 2023).

- Reuters. Rising Global Energy Use Complicates Path to Net Zero. Available online: https://www.reuters.com/business/energy/rising-global-energy-use-complicates-path-net-zero-kemp-2021-07-27/ (accessed on 1 March 2023).

- Shell. The Energy Transformation Scenarios. Available online: https://www.shell.com/energy-and-innovation/the-energy-future/scenarios/the-energy-transformation-scenarios.html (accessed on 2 March 2023).

- Bp. Energy Outlook. 2023. Available online: https://www.bp.com/en/global/corporate/energy-economics/energy-outlook.html (accessed on 2 March 2023).

- Eskindarov, M.; Silvestrov, S. (Eds.) Innovative Development of Russia: Challenges and Solutions: A Monograph (Russian), 2nd ed.; Financial University under the Government of the Russian Federation: Moscow, Russian, 2014; 1376p, Available online: http://elib.fa.ru/fbook/gosteva.pdf/download/gosteva.pdf (accessed on 2 March 2023).

- The Russian Federal State Statistics Service. Available online: https://eng.rosstat.gov.ru/ (accessed on 1 March 2023).

- The Ministry of Finance of the Russian Federation. Available online: https://archive.minfin.gov.ru/en/ (accessed on 1 March 2023).

- The Federal Customs Service of Russian Federation. Available online: https://eng.customs.gov.ru/ (accessed on 1 March 2023).

- Russian State Commission Estimated Oil and Gas Reserves (Russian). Available online: https://www.vedomosti.ru/business/articles/2022/08/05/934801-naskolko-hvatit-nefti-gaza (accessed on 1 March 2023).

- Tikhonov, S. Hard-to-Recover Reserves and Taxes: Incentives and Barriers to the HTR Reserves Development (Russian). Neftegazov. Vertikal’ [Oil Gas Vert.] 2019, 6, 10–17. Available online: https://ngv.ru/upload/iblock/f2b/f2b91d12794a9ef8065e99fb700684a7.pdf (accessed on 1 March 2023).

- Klubkov, S.; Mosoyan, M. Not All Oil Is “Black Gold” (Russian). Neftegazov. Vertikal’ [Oil Gas Vert.] 2020, 20, 35–41. Available online: https://vygon.consulting/upload/iblock/49a/NGV_20_2020_Klubkov_Mosoyan.pdf (accessed on 1 March 2023).

- Tsvetkova, A.; Katysheva, E. Present Problems of Mineral and Raw Materials Resources Replenishment in Russia. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management (SGEM), Albena, Bulgaria, 30 June–6 July 2019; pp. 573–578. [Google Scholar] [CrossRef]

- Kapustin, N.O.; Grushevenko, D.A. A Long-Term Outlook on Russian Oil Industry Facing Internal and External Challenges. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2019, 74, 72. [Google Scholar] [CrossRef]

- Muslimov, R.K. Fundamental Problems of Oil Industry (Russian). Neft. Khozyaystvo-Oil Ind. 2017, 1, 6–11. Available online: https://onepetro.org/OIJ/article-abstract/2017/01/06/16596/Fundamental-problems-of-oil-industry-Russian (accessed on 1 March 2023).

- Mastepanov, A. The Future of the Oil Industry in the Face of Energy Transition. View Analysis and Ratings of Foreign Experts (Russian). Neft. Khozyaystvo-Oil Ind. 2020, 1, 10–14. [Google Scholar] [CrossRef]

- Ponomarenko, T.; Marin, E.; Galevskiy, S. Economic Evaluation of Oil and Gas Projects: Justification of Engineering Solutions in the Implementation of Field Development Projects. Energies 2022, 15, 3103. [Google Scholar] [CrossRef]

- Ismagilov, R. Present Day Trends in Oil and Gas Engineering (Russian). Neft. Gas. Novacii [Oil. Gas. Novations] 2017, 9, 26–30. Available online: https://www.elibrary.ru/item.asp?id=30586030 (accessed on 2 March 2023).

- Vasilenko, N. Development of Oil and Gas Service as Organizational Form of Entrepreneurship in Post-Industrial Economy. J. Min. Inst. 2017, 227, 602. [Google Scholar] [CrossRef]

- Russian State Standard GOST R 58916-2021. Engineering (Technology and Design). Terms and Definitions (Russian). Available online: https://docs.cntd.ru/document/1200181010 (accessed on 2 March 2023).

- Razmanova, S.; Andrukhova, O. Oilfield Service Companies as Part of Economy Digitalization: Assessment of the Prospects for Innovative Development. J. Min. Inst. 2020, 244, 482–492. [Google Scholar] [CrossRef]

- Nedosekin, A.; Rejshahrit, E.; Kozlovskij, A. Strategic Approach to Assessing Economic Sustainability Objects of Mineral Resources Sector of Russia. J. Min. Inst. 2019, 237, 354–360. [Google Scholar] [CrossRef]

- Marin, E.A.; Ponomarenko, T.V.; Vasilenko, N.V.; Galevskiy, S.G. Economic Evaluation of Projects for Development of Raw Hydrocarbons Fields in the Conditions of the Northern Production Areas Using Binary and Reverting Discounting (Russian). Sev. I Rynok Form. Ekon. Poryadka [N. Mark. Form. Econ. Order] 2022, 25, 144–157. [Google Scholar] [CrossRef]

- U.S. Department of Defense (DoD). Technology Readiness Assessment (TRA) Deskbook; U.S. Department of Defense (DoD): Arlington County, VA, USA, 2009. Available online: https://acqnotes.com/wp-content/uploads/2014/09/Technology-Readiness-Assessment-TRA-Deskbook.pdf (accessed on 2 March 2023).

- U.S. Government Accountability Office (GAO). Technology Readiness Assessment Guide: Best Practices for Evaluating the Readiness of Technology for Use in Acquisition Programs and Projects; U.S. Government Accountability Office (GAO): Washington, DC, USA, 2020. Available online: https://www.gao.gov/products/gao-20-48g (accessed on 2 March 2023).

- Mankins, J.C. Technology Readiness Assessments: A Retrospective. Acta Astronaut 2009, 65, 1216–1223. [Google Scholar] [CrossRef]

- Azizian, N.; Sarkani, S.; Mazzuchi, T. A Comprehensive Review and Analysis of Maturity Assessment Approaches for Improved Decision Support to Achieve Efficient Defense Acquisition. In Proceedings of the World Congress on Engineering and Computer Science (WCECS), San Francisco, CA, USA, 20–22 October 2009; Available online: https://www.iaeng.org/publication/WCECS2009/WCECS2009_pp1150-1157.pdf (accessed on 2 March 2023).

- Semenova, T. Value Improving Practices in Production of Hydrocarbon Resources in the Arctic Regions. J. Mar. Sci. Eng. 2022, 10, 187. [Google Scholar] [CrossRef]

- Cooper, R.G.; Edgett, S.J. Stage-Gate® and the Critical Success Factors for New Product Development. BPTrends 2006, 1–6. Available online: https://www.bptrends.com/publicationfiles/07-06-ART-Stage-GateForProductDev-Cooper-Edgett1.pdf (accessed on 2 March 2023).

- ExxonMobil. 2023 Advancing Climate Solutions Progress Report. Available online: https://corporate.exxonmobil.com/Climate-solutions/Advancing-climate-solutions-progress-report (accessed on 2 March 2023).

- IEA. World Energy Outlook. 2022. Available online: https://www.iea.org/reports/world-energy-outlook-2022 (accessed on 2 March 2023).

- Resources for the Future. Global Energy Outlook Comparison Methods: 2022 Update. Available online: https://www.rff.org/publications/reports/global-energy-outlook-comparison-methods-2022-update/ (accessed on 2 March 2023).

- Zhdaneev, O. Technological Sovereignty of the Russian Federation Fuel and Energy Complex. J. Min. Inst. 2022, 258, 1061–1070. [Google Scholar] [CrossRef]

- Nephew, R. Center on Global Energy Policy. Understanding and Assessing the New U.S. Sanctions Legislation Against Russia. Available online: https://www.energypolicy.columbia.edu/publications/understanding-and-assessing-new-us-sanctions-legislation-against-russia (accessed on 6 March 2023).

- Mitrova, T.; Grushevenko, E.; Malov, A. The Future of Oil Production in Russia: Life under Sanctions; Skolkovo Energy Centre (SEneC): Moscow, Russia, 2018; Available online: https://energy.skolkovo.ru/downloads/documents/SEneC/research04-en.pdf (accessed on 2 March 2023).

- Saitova, A.A.; Ilyinsky, A.A.; Fadeev, A.M. Scenarios for the Development of Oil and Gas Companies in Russia in the Context of International Economic Sanctions and the Decarbonization of the Energy Sector. Sev. I Rynok: Form. Ekon. Poryadka [N. Mark. Form. Econ. Order] 2022, 25, 134–143. [Google Scholar] [CrossRef]

- Mastepanov, A.M. Coronavirus and the Resulting Crisis: About the Prospects of the World Economy and Energy (Russian). Neft. Khozyaystvo-Oil Ind. 2020, 6, 6–12. [Google Scholar] [CrossRef]

- Mastepanov, A. The Influence of Oil Prices on the World Oil and Gas Industry Development Priorities (Russian). Neft. Khozyaystvo-Oil Ind. 2017, 2, 8–12. Available online: https://onepetro.org/OIJ/article-abstract/2017/02/08/16727/The-influence-of-oil-prices-on-the-world-oil-and (accessed on 2 March 2023).

- Kapustin, N.O.; Grushevenko, D.A. Global Prospects of Unconventional Oil in the Turbulent Market: A Long Term Outlook to 2040. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2018, 73, 67. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.; Rutenko, E.; Solovyova, V. Sustainable Development of Oil and Gas Resources: A System of Environmental, Socio-Economic, and Innovation Indicators. J. Mar. Sci. Eng. 2021, 9, 1307. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.; Rutenko, E. Strategic Planning of Oil and Gas Companies: The Decarbonization Transition. Energies 2022, 15, 6163. [Google Scholar] [CrossRef]

- Blinova, E.; Ponomarenko, T.; Tesovskaya, S. Key Corporate Sustainability Assessment Methods for Coal Companies. Sustainability 2023, 15, 5763. [Google Scholar] [CrossRef]

- Chvileva, T.A.; Golovina, E.I. Publication of Reporting of Metallurgical Companies in Context of the Concept of Corporate Sustainable Development. J. Ind. Pollut. Control 2017, 33, 926–930. [Google Scholar]

- Ulanov, V.L.; Ulanova, E.Y. Impact of External Factors on National Energy Security. J. Min. Inst. 2019, 238, 474–480. [Google Scholar] [CrossRef]

- Tcvetkov, P. Engagement of Resource-Based Economies in the Fight against Rising Carbon Emissions. Energy Rep. 2022, 8, 874–883. [Google Scholar] [CrossRef]

- The World Bank. The Return of Global Inflation. Available online: https://blogs.worldbank.org/voices/return-global-inflation (accessed on 6 March 2023).

- Shafranik, Y. Oil and Gas Industry in Russia: Problems and Development Goals (Russian). Gorn. Zhurnal 2015, 7, 55–59. [Google Scholar] [CrossRef]

- Katysheva, E.; Tsvetkova, A. Economic and Institutional Problems of the Russian Oil and Gas Complex Digital Transformation. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management (SGEM), Albena, Bulgaria, 30 June–6 July 2019; pp. 203–208. [Google Scholar] [CrossRef]

- Matrokhina, K.V.; Trofimets, V.Y.; Mazakov, E.B.; Makhovikov, A.B.; Khaikin, M.M. Development of Methodology for Scenario Analysis of Investment Projects of Enterprises of the Mineral Resource Complex. J. Min. Inst. 2023, 259, 112–124. [Google Scholar] [CrossRef]

- Muslimov, R.K. On a New Paradigm for the Development of the Oil and Gas Complex in Russia (Russian). Neft. Khozyaystvo -Oil Ind. 2021, 3, 8–13. [Google Scholar] [CrossRef]

- Zakaev, D.; Nikolaichuk, L.; Filatova, I. Problems of Oil Refining Industry Development in Russia. Int. J. Eng. Res. Technol. 2020, 13, 267–270. Available online: http://www.ripublication.com/irph/ijert20/ijertv13n2_10.pdf (accessed on 2 March 2023).

- Kontorovich, A.E.; Burshtein, L.M.; Livshits, V.R.; Ryzhkova, S.V. Main Directions of Development of the Oil Complex of Russia in the First Half of the Twenty-First Century. Her. Russ. Acad. Sci. 2019, 89, 558–566. [Google Scholar] [CrossRef]

- Gendler, S.G.; Fazylov, I.R.; Abashin, A.N. The Results of Experimental Studies of the Thermal Regime of Oil Mines in the Thermal Method of Oil Production. Min. Inf. Anal. Bull. 2022, 248–262. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Fetisov, V. Experience of Virtual Commissioning of a Process Control System for the Production of High-Paraffin Oil. Sci. Rep. 2022, 12, 18415. [Google Scholar] [CrossRef] [PubMed]

- Cherepovitsyn, A.; Lebedev, A. Drill Cuttings Disposal Efficiency in Offshore Oil Drilling. J. Mar. Sci. Eng. 2023, 11, 317. [Google Scholar] [CrossRef]

- Dmitrieva, D.; Cherepovitsyna, A.; Stroykov, G.; Solovyova, V. Strategic Sustainability of Offshore Arctic Oil and Gas Projects: Definition, Principles, and Conceptual Framework. J. Mar. Sci. Eng. 2021, 10, 23. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.; Tcvetkov, P.; Evseeva, O. Critical Analysis of Methodological Approaches to Assessing Sustainability of Arctic Oil and Gas Projects. J. Min. Inst. 2021, 249, 463–479. [Google Scholar] [CrossRef]

- Samylovskaya, E.; Makhovikov, A.; Lutonin, A.; Medvedev, D.; Kudryavtseva, R.-E. Digital Technologies in Arctic Oil and Gas Resources Extraction: Global Trends and Russian Experience. Resources 2022, 11, 29. [Google Scholar] [CrossRef]

- Chanysheva, A.; Ilinova, A. The Future of Russian Arctic Oil and Gas Projects: Problems of Assessing the Prospects. J. Mar. Sci. Eng. 2021, 9, 528. [Google Scholar] [CrossRef]

- Gizatullin, R.; Dvoynikov, M.; Romanova, N.; Nikitin, V. Drilling in Gas Hydrates: Managing Gas Appearance Risks. Energies 2023, 16, 2387. [Google Scholar] [CrossRef]

- Dvoynikov, M.; Buslaev, G.; Kunshin, A.; Sidorov, D.; Kraslawski, A.; Budovskaya, M. New Concepts of Hydrogen Production and Storage in Arctic Region. Resources 2021, 10, 3. [Google Scholar] [CrossRef]

- Kunshin, A.; Dvoynikov, M.; Timashev, E.; Starikov, V. Development of Monitoring and Forecasting Technology Energy Efficiency of Well Drilling Using Mechanical Specific Energy. Energies 2022, 15, 7408. [Google Scholar] [CrossRef]

- Grigorev, E.; Nosov, V. Improving Quality Control Methods to Test Strengthening Technologies: A Multilevel Model of Acoustic Pulse Flow. Appl. Sci. 2022, 12, 4549. [Google Scholar] [CrossRef]

- Oil and Gas Digest: Import Substitution in the Oil and Gas Industry (Russian). 2018. Available online: https://www.neftegaz-expo.ru/common/img/uploaded/exhibitions/neftegaz/doc_2018/Neftegaz_Digest_2018.04.pdf (accessed on 2 March 2023).

- Oil and Gas Digest: Import Substitution in the Oil and Gas Industry (Russian). 2020. Available online: https://www.neftegaz-expo.ru/common/img/uploaded/exhibitions/neftegaz2020/img/digest/Neftegaz_Digest_2020.14(21).pdf (accessed on 2 March 2023).

- Syas’ko, V.; Shikhov, A. Assessing the State of Structural Foundations in Permafrost Regions by Means of Acoustic Testing. Appl. Sci. 2022, 12, 2364. [Google Scholar] [CrossRef]

- Peretyatko, M.A.; Yakovlev, P.V.; Peretyatko, S.A.; Deev, A.S.; Dyachenok, G. The Study of Heart Transfer during Boiling Process of Organic Fluid. J. Phys. Conf. Ser. 2020, 1614, 012069. [Google Scholar] [CrossRef]

- Onopriuk, V. Expansion to the East (Russian). Ross. Gaz. (Ekon.) [Russ. Newsp. (Econ.)] 2017, 280, 11–13. Available online: https://cdnstatic.rg.ru/uploads/attachments/fascicle/3/53/64/35364-1512719780.pdf (accessed on 2 March 2023).

- Henderson, J.; Mitrova, T. Energy Relations between Russia and China: Playing Chess with the Dragon; The Oxford Institute for Energy Studies: Oxford, UK, 2016; Available online: https://a9w7k6q9.stackpathcdn.com/wpcms/wp-content/uploads/2016/08/Energy-Relations-between-Russia-and-China-Playing-Chess-with-the-Dragon-WPM-67.pdf (accessed on 5 March 2023).

- Marinina, O.; Tsvetkova, A.; Vasilev, Y.; Komendantova, N.; Parfenova, A. Evaluating the Downstream Development Strategy of Oil Companies: The Case of Rosneft. Resources 2022, 11, 4. [Google Scholar] [CrossRef]

- Katysheva, E. Analysis of the Interconnected Development Potential of the Oil, Gas and Transport Industries in the Russian Arctic. Energies 2023, 16, 3124. [Google Scholar] [CrossRef]

- Blinova, E.; Ponomarenko, T.; Knysh, V. Analyzing the Concept of Corporate Sustainability in the Context of Sustainable Business Development in the Mining Sector with Elements of Circular Economy. Sustainability 2022, 14, 8163. [Google Scholar] [CrossRef]

- North, D.W.; Stern, P.C.; Webler, T.; Field, P. Public and Stakeholder Participation for Managing and Reducing the Risks of Shale Gas Development. Environ. Sci. Technol. 2014, 48, 8388–8396. [Google Scholar] [CrossRef]

- Sergeev, I.; Shkatov, M.; Siraev, A. Oilfield Services Companies and Their Innovative Development (Russian). J. Min. Inst. 2011, 191, 293–301. Available online: https://pmi.spmi.ru/index.php/pmi/article/view/6408?setLocale=ru_RU (accessed on 5 March 2023).

- Deloitte. Reviews of the Russian Oilfield Services Market 2014–2020. Available online: https://www2.deloitte.com/kz/ru/pages/energy-and-resources/articles/2020/oil-gas-survey-russia-2020.html (accessed on 7 March 2023).

- Seregin, A.S.; Fazylov, I.R.; Prokhorova, E.A. Justification of safe operating conditions for mining transportation machines powered by internal combustion engines using air pollutant emission criterion. Min. Inf. Anal. Bull. 2022, 11, 37–51. [Google Scholar] [CrossRef]

- Gerasimova, I.G.; Oblova, I.S.; Golovina, E.I. The Demographic Factor Impact on the Economics of the Arctic Region. Resources 2021, 10, 117. [Google Scholar] [CrossRef]

- Fadeev, A.M.; Lipina, S.A.; Zaikov, K.S. Staffing for the Development of the Arctic Offshore Hydrocarbon Fields. Polar Geogr. 2022, 45, 101–118. [Google Scholar] [CrossRef]

- Katysheva, E.G. Application of BigData Technology to Improve the Efficiency of Arctic Shelf Fields Development. IOP Conf. Ser. Earth Environ. Sci. 2021, 937, 042080. [Google Scholar] [CrossRef]

- Yakovleva, T.A.; Romashev, A.O.; Mashevsky, G.N. Digital technologies for optimizing the dosing of flotation reagents during flotation of non-ferrous metal ores (Russian). Min. Inf. Anal. Bull. 2022, 175–188. [Google Scholar] [CrossRef]

- EARTO. The TRL Scale as a Research & Innovation Policy Tool, Recommendations. 2014. Available online: https://www.earto.eu/wp-content/uploads/The_TRL_Scale_as_a_R_I_Policy_Tool_-_EARTO_Recommendations_-_Final.pdf (accessed on 2 March 2023).

- Sauser, B.; Verma, D.; Ramirez-Marquez, J.; Gove, R. From TRL to SRL: The Concept of System Readiness Levels. In Proceedings of the Conference on Systems Engineering Research (CSER), Los Angeles, CA, USA, 7–8 April 2006; Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.562.3338&rep=rep1&type=pdf (accessed on 7 March 2023).

- Cornford, S.L.; Sarsfield, L. Quantitative Methods for Maturing and Infusing Advanced Spacecraft Technology. In Proceedings of the 2004 IEEE Aerospace Conference Proceedings (IEEE Cat. No.04TH8720), Big Sky, MT, USA, 6–13 March 2004; IEEE: Piscataway, NJ, USA, 2004; pp. 663–681. [Google Scholar] [CrossRef]

- Petrov, A.; Sartory, A.; Filimonov, A. Comprehensive Assessment of the Status of Scientific and Technical Projects Using Technology Project Readiness Level (Russian). Econ. Sci. 2016, 2, 244–260. [Google Scholar] [CrossRef]

- All about Stage-Gate Process for Product Development. Available online: https://slidemodel.com/stage-gate-process-for-product-development/ (accessed on 7 March 2023).

- Grönlund, J.; Sjödin, D.R.; Frishammar, J. Open Innovation and the Stage-Gate Process: A Revised Model for New Product Development. Calif. Manag. Rev. 2010, 52, 106–131. [Google Scholar] [CrossRef]

- Cooper, R.G. Perspective: The Stage-Gate ® Idea-to-Launch Process—Update, What’s New, and NexGen Systems. J. Prod. Innov. Manag. 2008, 25, 213–232. [Google Scholar] [CrossRef]

- U.S. Department of Defense (DOD). Manufacturing Readiness Level (MRL) Deskbook; U.S. Department of Defense (DoD): Arlington County, VA, USA, 2020. Available online: https://www.dodmrl.com/MRL%20Deskbook%20V2020.pdf (accessed on 5 March 2023).

- Wu, C.; Wang, B.; Zhang, C.; Wysk, R.A.; Chen, Y.-W. Bioprinting: An Assessment Based on Manufacturing Readiness Levels. Crit. Rev. Biotechnol. 2017, 37, 333–354. [Google Scholar] [CrossRef]

- Gove, R. Development of an Integration Ontology for Systems Operational Effectiveness. Master’s Thesis, Stevens Institute of Technology, Hoboken, NJ, USA, 2007. [Google Scholar]

- Hjorth, S.; Brem, A. How to Assess Market Readiness for an Innovative Solution: The Case of Heat Recovery Technologies for SMEs. Sustainability 2016, 8, 1152. [Google Scholar] [CrossRef]

- Greig, C.; Bonger, G.; Caroline, S.; Byrom, S.; The University of Queensland. Energy Security and Prosperity in Australia—A Roadmap for Carbon Capture & Storage. Available online: https://energy.uq.edu.au/files/2274/UQE003_CCS_report_HR.pdf (accessed on 7 March 2023).

- Sartas, M.; Schut, M.; Proietti, C.; Thiele, G.; Leeuwis, C. Scaling Readiness: Science and Practice of an Approach to Enhance Impact of Research for Development. Agric. Syst. 2020, 183, 102874. [Google Scholar] [CrossRef]

- Kobos, P.H.; Malczynski, L.A.; Walker, L.T.N.; Borns, D.J.; Klise, G.T. Timing Is Everything: A Technology Transition Framework for Regulatory and Market Readiness Levels. Technol. Forecast. Soc. Chang. 2018, 137, 211–225. [Google Scholar] [CrossRef]

- Vik, J.; Melås, A.M.; Stræte, E.P.; Søraa, R.A. Balanced Readiness Level Assessment (BRLa): A Tool for Exploring New and Emerging Technologies. Technol. Forecast. Soc. Chang. 2021, 169, 120854. [Google Scholar] [CrossRef]

- Holt, L.K. A Tool for Technology Transfer Evaluation: Technology Transfer Readiness Levels (TTRLs). In Proceedings of the 58th International Astronautical Congress; International Astronautical Federation, Hyderabad, India, 24–28 September 2007; pp. 8700–8704. [Google Scholar]

- Moorhouse, D.J. Detailed Definitions and Guidance for Application of Technology Readiness Levels. J. Aircr. 2002, 39, 190–192. [Google Scholar] [CrossRef]

- Mankins, J. Research & Development Degree of Difficulty (R&D3). A White Paper. 1998. Available online: https://www.economicswebinstitute.org/essays/nasadiff.pdf (accessed on 7 March 2023).

- Bilbro, J. Using the Advancement Degree of Difficulty (AD2) as an Input to Risk Management. In Proceedings of the Technology Maturity Conference, Virginia Beach, VA, USA, 8–12 September 2008; Available online: https://apps.dtic.mil/sti/pdfs/ADA507591.pdf (accessed on 7 March 2023).

- Sauser, B.J.; Ramirez-Marquez, J.; Magnaye, R.; Tan, W. System Maturity Indices for Decision Support in the Defense Acquisition Process. In Proceedings of the 5th Annual Acquisition Research Symposium of the Naval Postgraduate School, Monterey, CA, USA, 14 May 2008; Available online: https://core.ac.uk/download/pdf/36725967.pdf (accessed on 7 March 2023).

- Mankins, J.C. Approaches to Strategic Research and Technology (R&T) Analysis and Road Mapping. Acta Astronaut. 2002, 51, 3–21. [Google Scholar] [CrossRef]

- Mankins, J.C. Technology Readiness and Risk Assessments: A New Approach. Acta Astronaut. 2009, 65, 1208–1215. [Google Scholar] [CrossRef]

- Komarov, A.; Petrov, A.; Sartory, A. The Model of Integrated Assessment of Technological Readiness of Innovative Scientific and Technological Projects (Russian). Econ. Sci. 2018, 4, 47–57. [Google Scholar] [CrossRef]

- Aleksandrova, T.; Nikolaeva, N.; Kuznetsov, V. Thermodynamic and Experimental Substantiation of the Possibility of Formation and Extraction of Organometallic Compounds as Indicators of Deep Naphthogenesis. Energies 2023, 16, 3862. [Google Scholar] [CrossRef]

| Method | Abbr. | Description | Source |

|---|---|---|---|

| Manufacturing Readiness Level | MRL | Determines the current level of technology production readiness, identifies readiness deficiencies, and identifies associated risks in the transition from technology to production | [87,88] |

| Integration Readiness Level | IRL | Measures the readiness and compatibility of interfaces between different technologies, consistently compares the maturity of interfaces between multiple integration points, and reduces the uncertainty associated with the development and integration of technology into the system | [89] |

| Market/Commercialization Readiness Level | MRL/ CRL | Determines the readiness of the technology to enter the market as a commercial offer for a group of customers | [90,91] |

| Scaling Readiness | SR | Reflects the readiness of technology to achieve a specific effect at scale in a specific context | [92] |

| Regulatory Readiness Level | RRL | Reflects the reliability of regulatory support for the technology development process and the effectiveness of this support in the development of the necessary regulations | [93,94] |

| Technology Transfer Readiness Level | TTRL | Describes the process of technology transfer, which consists of identifying a new appropriate application of technology and its subsequent adaptation, and solves the problem of transferring technology from one industry to another | [95] |

| TRL for Software | TRL (S) | Characterizes the level of maturity of software technology by including other attributes specific to software development | [23] |

| Moorhouses Risk Versus TRL Metric | MRM | Reflects the regression of risk due to the progression of technological readiness | [96] |

| Research and Development Degree of Difficulty | RD3 | Reflects the degree of difficulty of the technology transition from one readiness level to another and includes five levels of difficulty | [97] |

| Advanced Degree of Difficulty | AD2 | Assesses the difficulty of moving a technology from its current readiness level to the desired one on a 9-level scale | [98] |

| Method | Abbr. | Description | Source |

|---|---|---|---|

| System Readiness Level | SRL | Determines the technology readiness level, as well as the degree of its readiness for integration into the system, based on a normalized matrix of pairwise comparisons of the TRL and IRL systems | [81,99] |

| Integrated Technology Analysis Methodology | ITAM | Reflects the cumulative maturity of the system based on the readiness of its constituent technologies and takes into account TRL, Delta TRL, R&D Degree of Difficulty (R&D3), and Technology Need Values (TNV) | [100] |

| Technology Readiness and Risk Assessment | TRRA | Assesses the impact of risks on technology creation and takes into account TRL, R&D3, and TNV | [101] |

| Technology Insertion Metric | TI | Reflects the degree to which a new subsystem is integrated into an existing host system and the interaction between the system and subsystem for the improvement of overall performance | [99] |

| Technology Project Readiness Level | TPRL | Reflects the level of comprehensive project readiness based on a balanced approach, taking into account six key criteria—TRL, MRL, IRL, ORL, BRL, and CRL | [83,102] |

| Indicator | Abbr. | Description | Applicability |

|---|---|---|---|

| Technology Readiness Level | TRL | The basic criterion for the readiness assessment of engineering projects, reflecting the current development stage of a particular technology | Recommended for use in the model based on the successful experience of its application by leading companies (Google, John Deere, etc.) and oil and gas companies (BP, Gazpromneft) |

| Manufacturing Readiness Level | MRL | Reflects the current level of production readiness for the release of a particular technology | Recommended for use in the model as it determines the features of the production process of the technology under development |

| Integration Readiness Level | IRL | Reflects the possibility of “inclusion” of a new technology into an existing system for its effective functioning | Oil and gas engineering projects are mostly aimed at creating complex technological solutions (fracturing technologies, hard-to-recover reserve production, etc.) that do not require integration with other production systems |

| Engineering Readiness Level | ERL | Reflects the current level of engineering support for the technology creation process | The indicator partially duplicates other considered indicators (TRL, MRL, and ORL), and therefore its use is not advisable |

| Organization Readiness Level | ORL | Reflects the current level of process organization for the creation of technology | Recommended for use in the model as it creates the basis for structuring and determining the relationships of all processes for the project’s implementation |

| Benefits and Risks | BRL | Reflects the competitive advantages and key risks associated with the creation of a particular technology | It is not advisable to single out all groups of benefits and risks into one category since it is more convenient to manage and account for each of them within the framework of a separate readiness indicator |

| Commercialization Readiness Level | CRL | Reflects the readiness of the developed technology to be brought to market | Recommended for use in the model as it allows for the identification of risks to technology commercialization, prepares a plan for their solution, and increases the efficiency of bringing the technology to market and its potential economic effect |

| Scaling Readiness | – | Reflects the readiness of the developed technology to achieve a specific effect at scale | Oil and gas engineering projects are primarily aimed at solving a specific technological problem, which does not always take on a mass character. It is inappropriate to include the indicator in the model since the low ability of technology to scale can lead to a slowdown in the process of its creation and a delay in the solution of an urgent industry problem. |

| Regulatory Readiness Level | RRL | Reflects the degree of reliability of regulatory support for the technology development process | Recommended for use in the model as it is a guarantor of copyright compliance and a potential tool for creating a company’s strategic competitive advantages |

| Transfer Technology Readiness Level | TTRL | Determines the possibility of technology transfer from one system to a system with a different functioning mechanism, which is most relevant for cross-field technologies | The creation of new technologies in the oil and gas complex is mainly based on the use of intra-industry technologies; however, at the present stage, there is also a widespread use of non-oil and gas technologies (Internet of things, artificial intelligence, etc.). Therefore, an optional use of the indicator is proposed depending on the specific situation. |

| TRL for Software | TRL (S) | Reflects the current stage of development of a certain software technology based on the attributes characteristic of software products | Modern modifications of the classic TRL have become more flexible and versatile, which allowed them to successfully assess the readiness of both hardware and software technologies, so the use of this indicator in the model is not relevant |

| Moorhouses Risk Versus TRL Metric | MRM | Characterizes the risk regression due to the progression of the technological readiness of the project; it is a derived indicator from TRL | The progress of the engineering project implementation is certainly accompanied by a decrease in the risk of its failure; therefore, the use of this indicator in the model is not necessary |

| R&D Degree of Difficulty | RD3 | Reflecting the difficulty of the project transition from one level of technological readiness to the next, they are additions to TRL (different in the number of levels—RD3 includes five levels of difficulty and AD2 includes nine levels) | They allow for the ranking of engineering projects according to the difficulty of their implementation and subsequently provide targeted support. However, they do not contribute critical information to the decision-making process for the creation of technology; therefore, the use of these indicators is not necessary |

| Advanced Degree of Difficulty | AD2 |

| Indicator | Functional Purpose |

|---|---|

| TRL |

|

| MRL |

|

| ORL |

|

| TMRL |

|

| CRL |

|

| RRL |

|

| Advantages | Disadvantages and Limitations |

|---|---|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsiglianu, P.; Romasheva, N.; Nenko, A. Conceptual Management Framework for Oil and Gas Engineering Project Implementation. Resources 2023, 12, 64. https://doi.org/10.3390/resources12060064

Tsiglianu P, Romasheva N, Nenko A. Conceptual Management Framework for Oil and Gas Engineering Project Implementation. Resources. 2023; 12(6):64. https://doi.org/10.3390/resources12060064

Chicago/Turabian StyleTsiglianu, Pavel, Natalia Romasheva, and Artem Nenko. 2023. "Conceptual Management Framework for Oil and Gas Engineering Project Implementation" Resources 12, no. 6: 64. https://doi.org/10.3390/resources12060064

APA StyleTsiglianu, P., Romasheva, N., & Nenko, A. (2023). Conceptual Management Framework for Oil and Gas Engineering Project Implementation. Resources, 12(6), 64. https://doi.org/10.3390/resources12060064