Abstract

The management of waste and its environmental impact remains an issue. Thus, various strategies are being explored to mitigate this problem. For this research case, the ash of plantain peel and coal was harnessed to enhance soil for usage in designing road pavements. The form of the soil, as regards its plasticity and grain assortment, positions it as a sandy lean clay material. Geotechnical parameters of the natural soil were established before being treated with coal ash (CA) and plantain peel ash (PPA), and subjected to tests for the Atterberg limits, California bearing ratio (CBR) and compaction, as well as investigations pertaining to its crystallinity and morphology. These assessments showed that strength parameters of soil increased on adding CA and PPA. However, the inclusion of these admixtures should be conducted until optimal strength is achieved as seen in 9% CA + 6% PPA. The use of soil stabilised with CA and PPA is suitable for general fillings and embankments. These findings revealed that integrating CA and PPA together would have the potential of stabilising soil as pavement layer material while also eliminating the pollution that emerges from the improper disposal of coal and plantain peels from the environment.

1. Introduction

The rate of waste generation around the world is rising. As a matter of fact, the world already generates about 2.01 billion tonnes of annual municipal solid wastes, with at least 33% not managed properly. The World Bank projected this amount to escalate to 3.40 billion tonnes by 2050, with each individual generating an average of 0.74 kg each day [1]. As a result of these alarming statistics, the United States Environmental Protection Agency (USEPA) conducted a study to determine the factors influencing the increase in the amount of wastes produced globally, and thus attributed it to economic activities, population growth, and consumption [2]. More so, rapid urbanisation, industrialisation, and infrastructural evolution are causing population and environmental concerns in many emerging nations. Since the 1980s, numerous sectors and industries have made advancements in waste management to help address this challenge [3]. In this aspect, the construction industry is notable for playing a vital role in the utilisation of these waste materials especially in the area of road pavement layer improvement [4], which entails altering the behaviour of the underlying soil so as to improve its geotechnical properties [5]. These waste materials are sought out for soil improvement due to the need to reduce the dependence on conventional stabilisers such as lime and cement. This is as a result of their costly nature and adverse effect on the environment, as cement production alone generates 7% of carbon dioxide on a global scale [6], hence the need to explore more sustainable alternative materials [7]. This advocates that the effects of environmental degradation and global warming due to the manufacture of cement for construction premises the desire for eco-friendly building materials [8]. Thus, it is no surprise that researchers have been studying industrial and agricultural wastes to improve earth minerals by devising methods in which they can be integrated as alternative materials in road construction and maintenance [9]. These waste materials are usually occurring in large quantities and have pozzolanic properties. Typical examples are coal ash (CA) and plantain peel ash (PPA), which are employed in this study.

CA is derived as a residue of burning lignite or pulverized coal in thermal power facilities [10]. CA is composed of coal fly ash (CFA) and coal bottom ash (CBA). CFA is accumulated and gathered from the top of furnaces, while CBA is obtained at the bottom of the combustor. About 25% of the total ash is CBA, whereas fly ash makes up for the remaining 75% [11]. Based on market trends and the current economy, global coal consumption is forecasted by the International Energy Agency (IEA) to rise at a rate of 0.7% in 2022 to 8 billion tonnes [12]. The ash from this coal is usually discarded as wastes, causing a huge environmental concern. CA comprises pollutants such as cadmium, arsenic, and mercury. These toxins can contaminate streams, groundwater, drinking water, and the atmosphere if they are not appropriately managed, hence causing serious health and environmental issues [13]. Utilising such a waste material for applications that minimise its interaction with the environment should be priority. One of such applications is their use for soil improvement within road pavement layers if they enhance the geotechnical properties of the subgrade soils. Various civil engineering researches have been conducted on the employment of coal waste ash. [14,15,16]. These studies prove that the use of CA has been advantageous over the years in improving road pavement layer materials and also in providing a feasible solution to the disposal of this waste material. CA generated vary with location. Consequently, the use of CA for road construction applications is better suited to some locations. However, in a situation where the amount of CA required to meet the need for road application is not available in and around the city where a road project is to be executed, other available wastes (especially agricultural wastes) having cementitious or pozzolanic properties can be combined with CA for soil stabilisation. One of such agricultural wastes is plantain peel. The peels obtained from plantain are a byproduct from its utilisation in processing industries, that is typically disposed of in landfill sites, waterways, and uncontrolled dumps [17]. This has triggered the need to address further and investigate ways in which these wastes can be effectively and efficiently removed from the environment on a large scale; hence, its potential as a possible low-cost stabiliser that can be utilised with other waste materials to enhance pavement layers especially in rural roads of rural communities in African countries such as Nigeria, where there is an excess of these wastes.

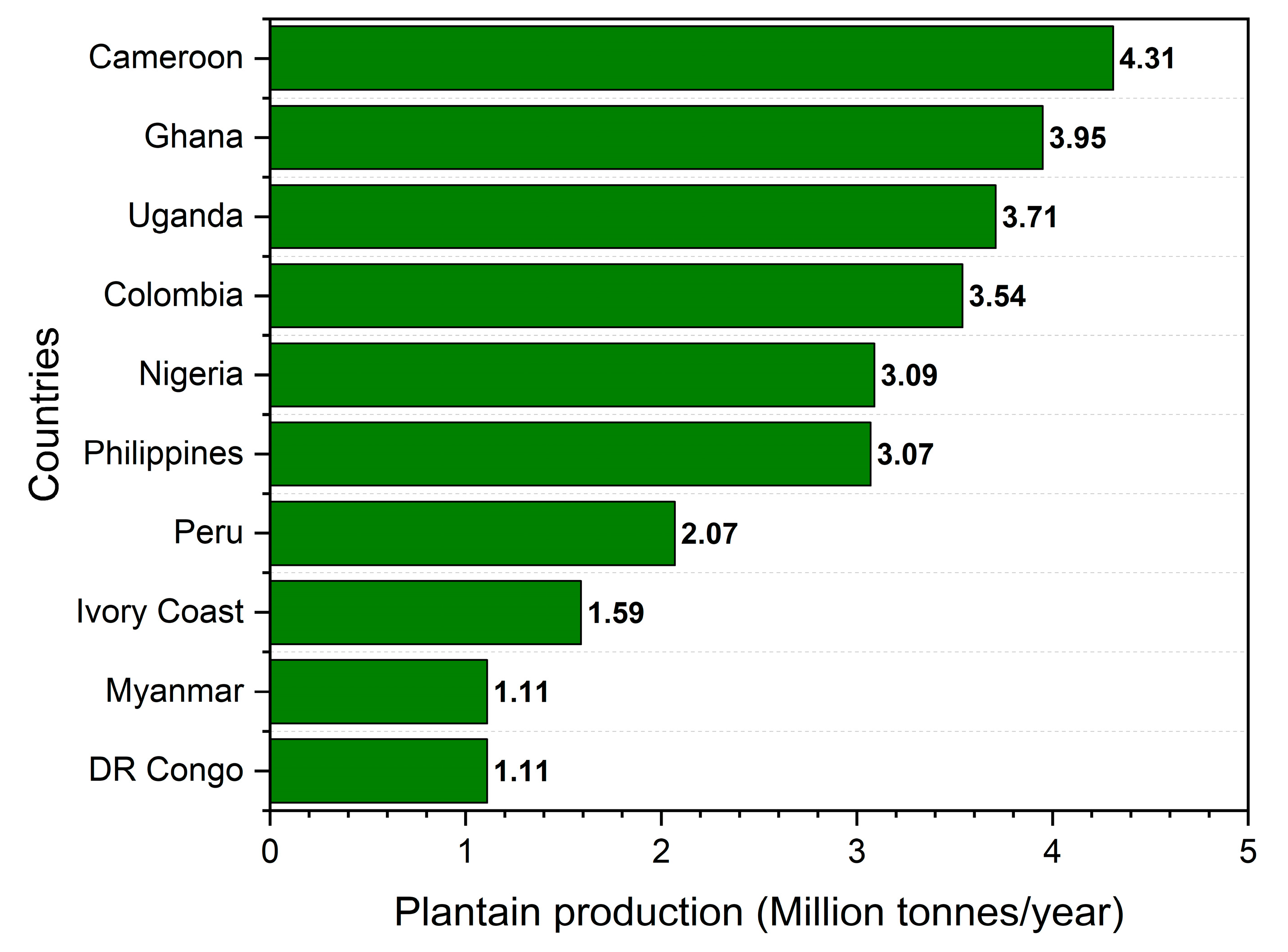

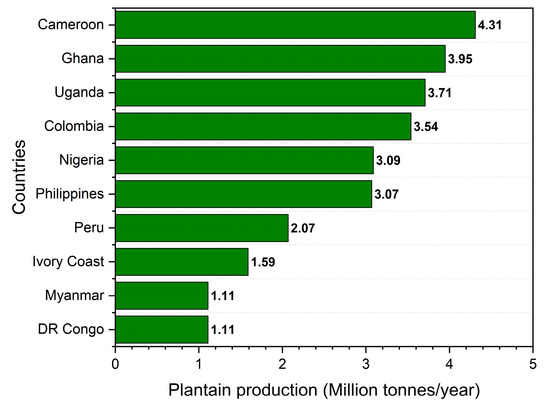

Nigeria is one of the nations with the highest plantain production on a global scale as presented in Figure 1 based on a report by World Atlas [18]. Plantains are produced in enormous quantities, but the nation does not export them because most of what is cultivated is locally consumed [19]. The consumption of plantain in these parts of the world has been on a steady increase. The strong demand for plantain also results in waste leftovers that are occasionally utilised as animal feed or are thrown away [19]. This disposal of plantain peel and its concomitant decomposition often yield noxious gases such as hydrogen sulfide (H2S) and ammonia (NH3), which pose environmental hazards [20]. Researchers have put forth an effort to determine how these plantain wastes, especially its ash, can be applied in the aspects of soil stabilisation. A study carried out by Ishola et al. [21] stated that PPA improves the compressive strength of soil. However, it was suggested that the soil stabilised with PPA can be admixed with other stabilising materials to yield better results. These justify the need for this study, which provides an experimental insight as to how industrial wastes (CA) and agricultural wastes (PPA) can be used together in improving road pavement materials while providing an economical and sustainable way of disposing these waste materials from the environment, mitigating the harm they pose. Both additives can complement each other for large-scale soil stabilisation. This combined usage can also be based on the availability of both additives in the region where they are to be used, as the generated wastes are distributed dispersedly among several regions. This means that some regions may have more abundance than others.

Figure 1.

The World’s leading plantain producers.

Apparently, the combined usage of both CA and PPA for enhancing soil in road pavement layer construction has not yet been described in a peer-reviewed article published in the open literature. Hence, the present examination aims to improve soil using blends of CA and PPA for road pavement construction. To achieve this, characterisation of the natural soil material was conducted. The particle size distribution was also performed so as to determine its classification. Additionally, by employing the pycnometer method, the specific gravity was evaluated. The standard proctor compaction was conducted so as to establish the optimum moisture content (OMC) and maximum dry unit weight of the natural soil. Additionally, Atterberg limits tests were performed to ascertain liquid limit (LL), plastic limit (PL), and plasticity index (PI), and the California bearing ratio (CBR) test was conducted to know the bearing capacity of compacted natural soil. Subsequently, the treated samples were obtained by combining CA and PPA as a portion of dry soil mass in the following proportions: 3% CA + 6% PPA; 6% CA + 6% PPA; 9% CA + 6% PPA, and 12% CA + 6% PPA. The percentage of CA was varied while that of the PPA was kept constant at 6%. Some agricultural wastes such as cassava peel ash [22], rice husk ash [23], banana leaf ash [24], oil palm frond ash [25], and corncob ash [26], which have been explored for use as soil stabilisers, have displayed soil-stabilising properties at an optimum value within 4% to 6%. Furthermore, on the premise of earlier research carried out by Ishola et al. [21] on the use of PPA as a soil stabiliser, a 6% PPA content was taken into account, as the natural soil stabilised had similar classifications as that investigated in this study. For each of the varied mixes, the Atterberg limits, compaction characteristics, and CBR were established. As a way of examining the impact of CA and PPA on soil morphology and mineralogy, scanning electron microscope (SEM) and X-ray diffraction (XRD) analysis were conducted on the untreated soil and also the treated samples. SEM produces an assortment of signals at the surface of the solid material using a targeted beam of electrons at high energy. This revealed details about the sample’s morphological and crystalline configuration. XRD on the other hand provided information about the crystalline and amorphous contents, and the overall mineralogy of the soil specimens. The tests utilised for the study objectives were adopted because most tropical African countries’ standards [27,28,29] employ these parameters as a guideline for choosing materials to be used in constructing pavement layers [30].

2. Materials and Methods

2.1. Materials

2.1.1. Soil

By using disturbed-sampling technique, the soil was dug up from a borrow pit 30 m below ground level at Owode, which is located between the coordinates 6°40′55″ N (latitude) and 3°11′15″ E (longitude) along Idiroko road in Ota, Ogun State, Nigeria. The soil was collected in plastic bags and conveyed to the geotechnical laboratory where it was air-dried at room temperature for subsequent testing.

2.1.2. Coal Ash (CA)

CA was obtained from a manufacturing company in Isolo, Mushin, Lagos State, Nigeria. After the coals were collected and stacked in large quantities, they were then burnt using the open field burning method. Fractions of the ash passing through sieve No. 200 (0.075 mm) were collected in a sack bag as seen in Figure 2 and used for the experiment. The chemical composition of typical CA is shown in Table 1.

Figure 2.

Coal ash.

Table 1.

Chemical composition of typical CA [31].

2.1.3. Plantain Peel Ash (PPA)

Plantain peels were also obtained from a manufacturing company in Isolo, Mushin, Lagos State, Nigeria. The peels were sun-dried for about two weeks till they were evenly dried and burnt to ash as seen in Figure 3. The PPA was sieved through the No. 200 sieve (0.075 mm) and the materials passed through were used. Table 2 displays the chemical constituents of typical PPA.

Figure 3.

Plantain peel ash.

Table 2.

Chemical composition of typical PPA [19].

Both materials were selected due to their considerable performance as “stand-alone” stabilisers in soil improvement. Their incorporation together was forecasted to serve as a means of improving the properties of soil while providing a strategy of reducing both wastes from the environment. The particle diameter (0.075 mm) of both materials used acted as a pozzolanic void filler [32] due to its small size, agglomerating the particles of the soil fabric, thereby yielding higher strength when compared to the natural soil as seen in previous studies of waste-soil stabilisation [21,33]. More so, it is known that the smaller the particle size of cementitious or pozzolanic materials, the better their reaction in stabilising soil. Hence, these fine-grained particles of CA and PPA utilised for this study provides a greater expanse to chemically react with the soil particles.

2.2. Experimental Methods

The soil sample was oven-dried for 24 h at a temperature of 110 °C after its collection to substantially reduce the soil water content. Subsequently, the geotechnical properties were examined in line with the ASTM International Standards as seen in Table 3. The executed experiments comprises sieve and hydrometer analysis, specific gravity, compaction, Atterberg limits, and CBR tests.

Table 3.

Experimental standards utilised for performed tests.

Thereafter, the treated samples were obtained by mixing CA and PPA as a portion of dry soil mass in these proportions: 3% CA + 6% PPA, 6% CA + 6% PPA, 9% CA + 6% PPA, and 12% CA + 6% PPA. Afterwards, Atterberg limits, compaction characteristics, and CBR tests were determined for the varied samples so as to evaluate their geotechnical characteristics. The strength performance of the soil–CA–PPA mixes was established by comparing the results in terms of percentage (%) increase in maximum dry unit weight and CBR, upon the inclusion of these additives to the natural soil. Furthermore, the impact of CA and PPA on the morphology and mineralogy of the untreated and treated soil were examined using SEM and XRD analysis. Table 4 outlines the experimental programme for this study.

Table 4.

Outline of experimental programme.

3. Results and Discussion

3.1. Geotechnical Properties of Natural Soil

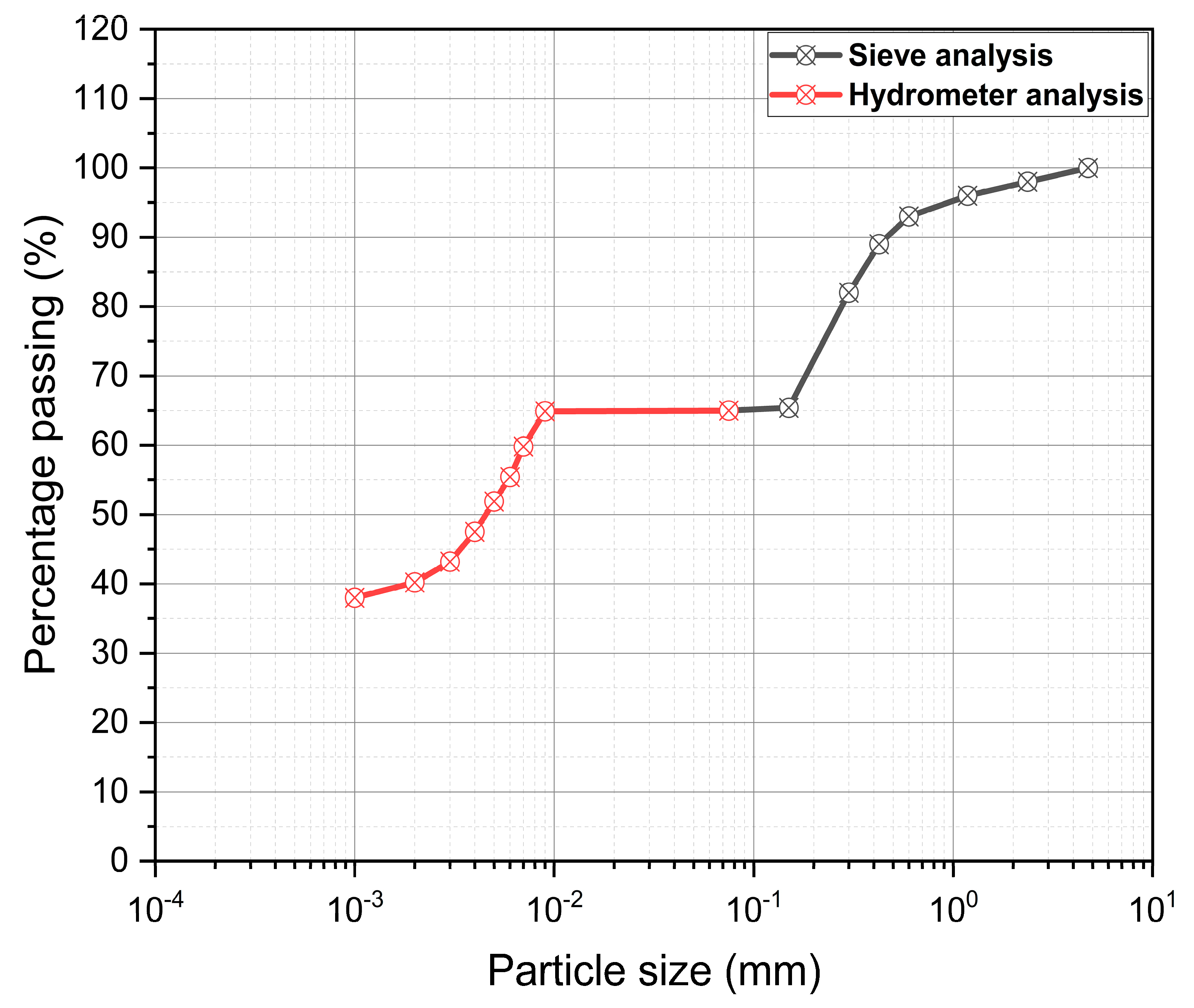

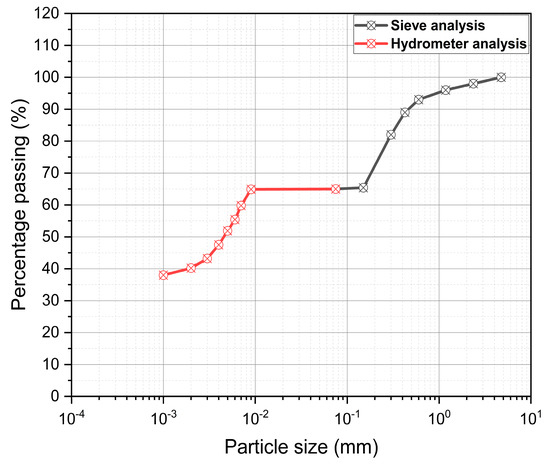

The geotechnical properties of the natural soil are displayed in Table 5. It has a PI and specific gravity of 25.4% and 2.45, respectively. The soil is grouped under A-7-6 based on the criteria by the American Association of State Highway and Transportation Officials (AASHTO). Additionally, the Unified Soil Classification System (USCS) categorises it as sandy lean clay (CL). Approximately 65% of the materials go through sieve No. 200 (0.075 mm). For the particle sizes of the natural soil, Figure 4 depicts the distribution curve. In line with the findings of the Atterberg limits experiments, the soil is highly plastic and cohesive. The optimum moisture content (OMC) and maximum dry unit weight of the soil were found to be 13.5% and 16.33 kN/m3, respectively. Additionally, a CBR of 8.5% was attained for the natural soil which is fair [40].

Table 5.

Geotechnical test values for the natural soil sample.

Figure 4.

Particle size distribution curve for the natural soil.

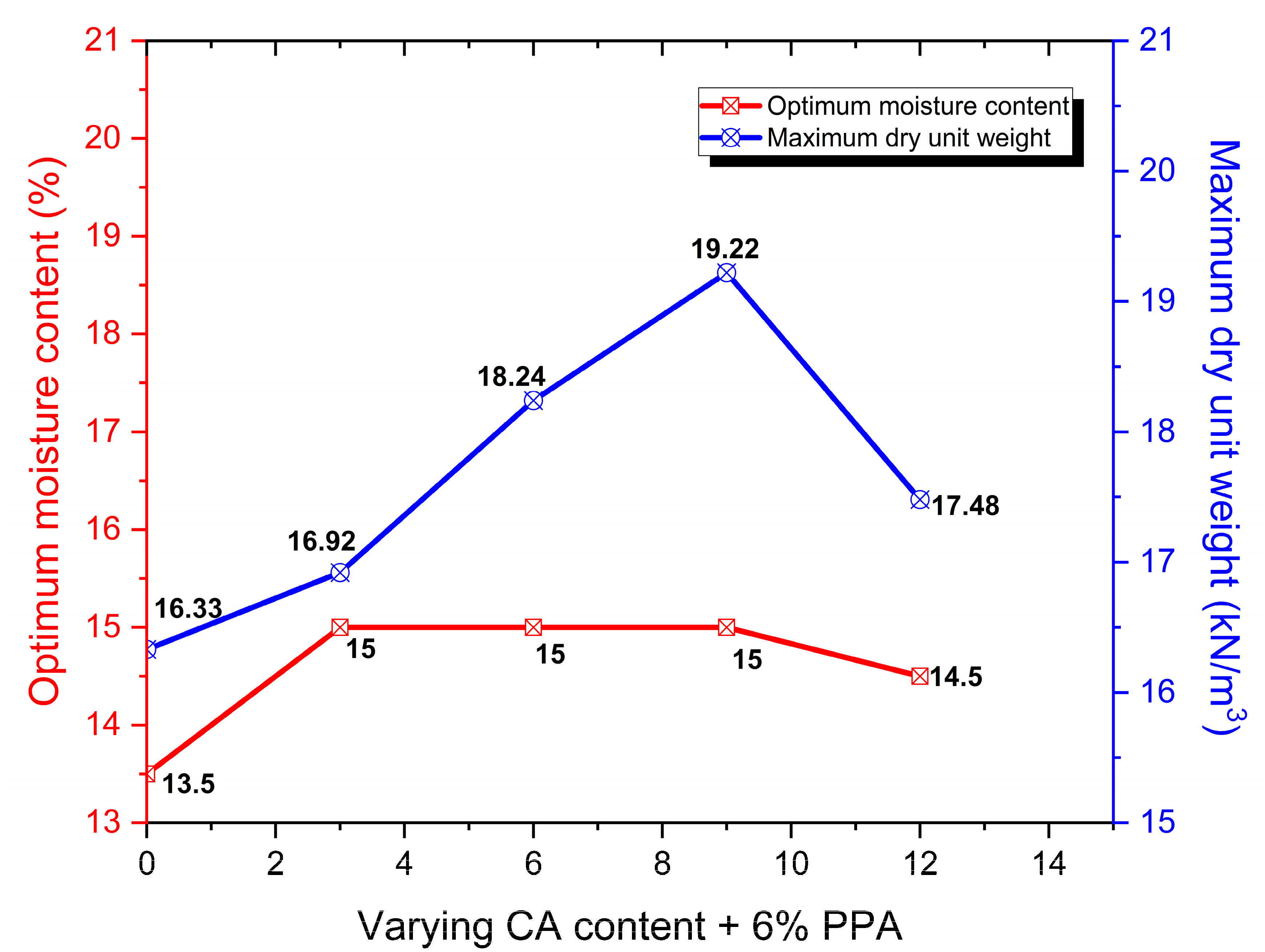

3.2. Compaction Characteristics

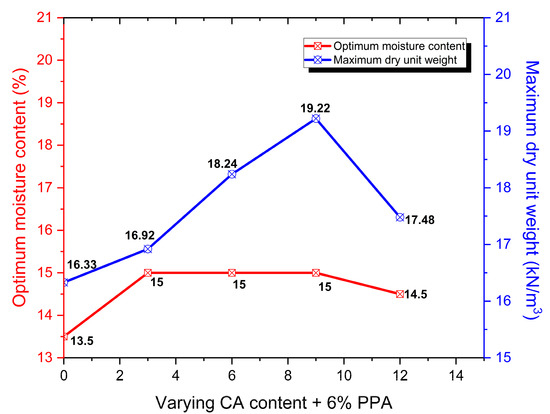

When CA was added to the soil with 6% PPA, an increase in OMC was observed at 3% CA content. This may be due to the addition of excess water needed for the hydration process [41]. The OMC was kept constant until it decreased at 12% CA and 6% PPA contents. This reduction might potentially have happened as a result of the admixtures non-plastic properties [21,42]. Moreover, the drop in OMC may be caused by a decline in the need for water from different cations and the hydration reactivity of the clay minerals [43]. However, researchers have proposed that when there is no flow of water into or out of the soil–CA–PPA fabric, the reaction (hydration) consumes all the available water, saturating the soil surface with low water content and lowering soil humidity levels. This answers why the OMC drops with increasing additive content [44,45,46].

When CA and PPA are at 3% and 6%, respectively, the maximum dry unit weight likewise increases. This increase might potentially be linked to agglomeration and flocculation, which would result in a volumetric drop in density [21]. An increase in maximum dry unit weight was also observed at 3% CA. A further increase was attained until 9% CA before decreasing at 12% CA. The volume and light weight of CA, as well as the lower specific gravity of the sample (2.45) in comparison to the specific gravity of PPA (usually 2.6), may be responsible for the decrease in the dry unit weight. This will cause a decrease in soil density [21]. The variations in compaction characteristics are seen in Figure 5.

Figure 5.

Variation of compaction characteristics with CA and PPA content.

The outcome of the compaction test indicates that introducing CA and PPA as soil additives would initially result in an increase in the OMC and maximum dry unit weight. However, a subsequent decrease of these parameters is expected upon the addition of these additives beyond the optimal limit.

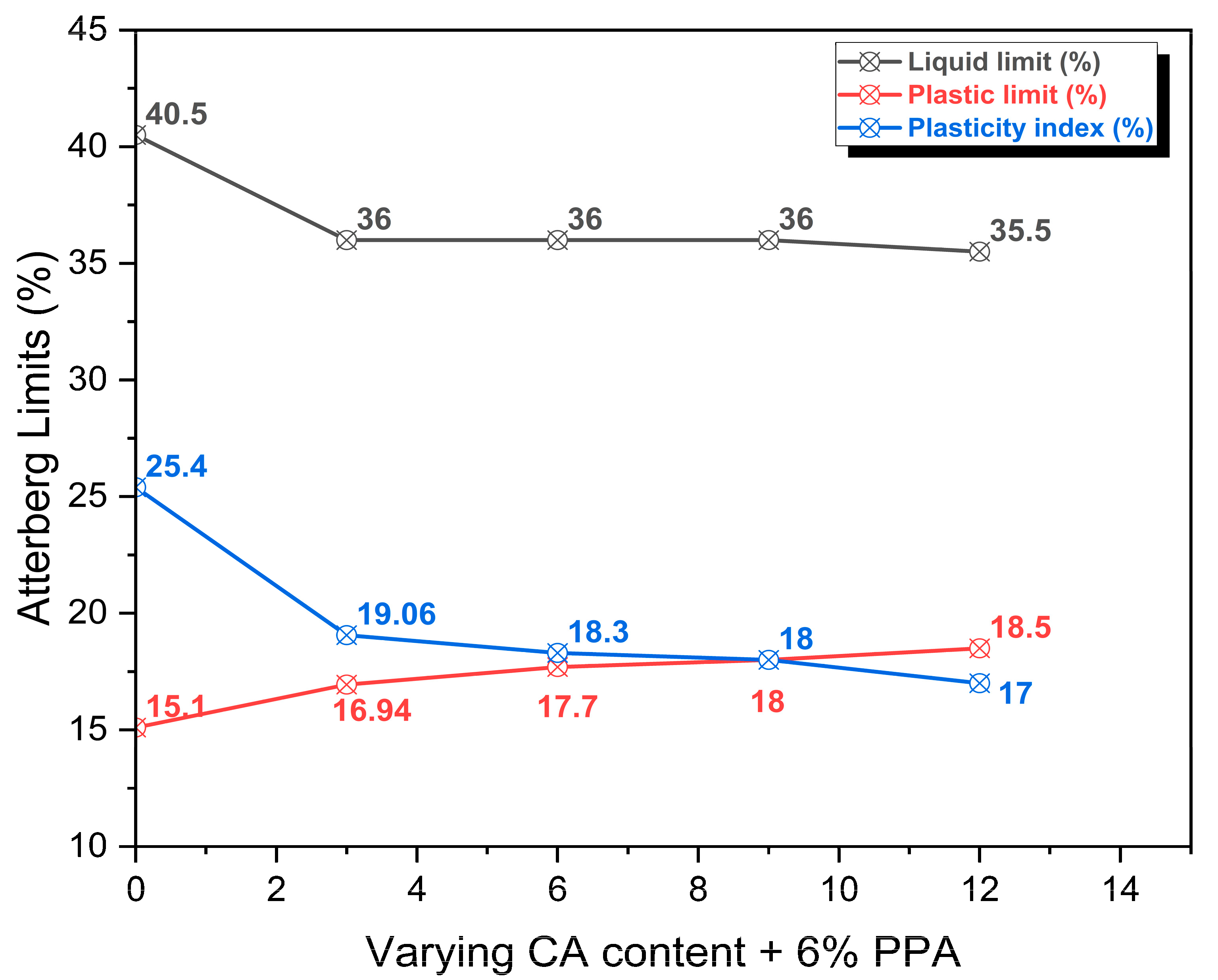

3.3. Atterberg Limits

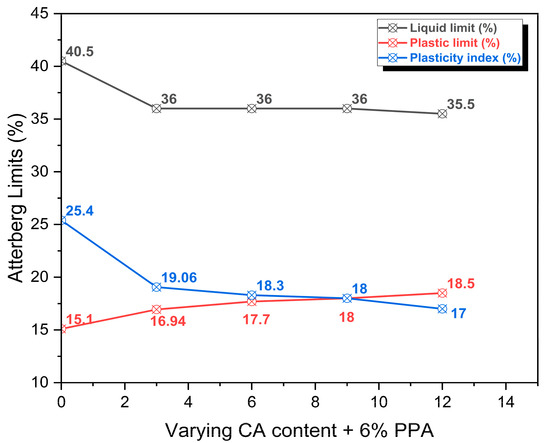

A reduction in LL was observed at CA and PPA of 3% and 6%, respectively. The value is kept the same until it reduces further at 12% CA and 6% PPA as seen in Figure 6. A higher CA content will only further reduce LL because LL is typically established when CA starts sliding along with soil particles that demand additional water in the mixture [16]. Moreover, the pozzolanic or cation exchange reactions between the divalent cations within the soil matrix and admixtures may be the cause of the general decrease. Additionally, the PL of the soil admixed with CA and PPA increased at all variations as illustrated in Figure 6. This is attributed to the increase in CA contents. The soil will become even more plastic when cementitious or pozzolanic materials are applied above a particular level because soil particles with adsorbed materials on their surfaces have a lower density [16]. Furthermore, a decrease in PI is observed at all variations of CA and PPA contents as depicted in Figure 6. The pozzolanic properties of PPA, which accelerated the soil-admixture reaction in the presence of water supplied to the soil, may be responsible for the decrease in PI [21].

Figure 6.

Variation of Atterberg limits with CA and PPA content.

From the test outcomes, it is evident that the incorporation of CA and PPA as stabilising agents would cause the LL and PI to reduce, but would bring about an increase in PL of the soil stabilised with these additives.

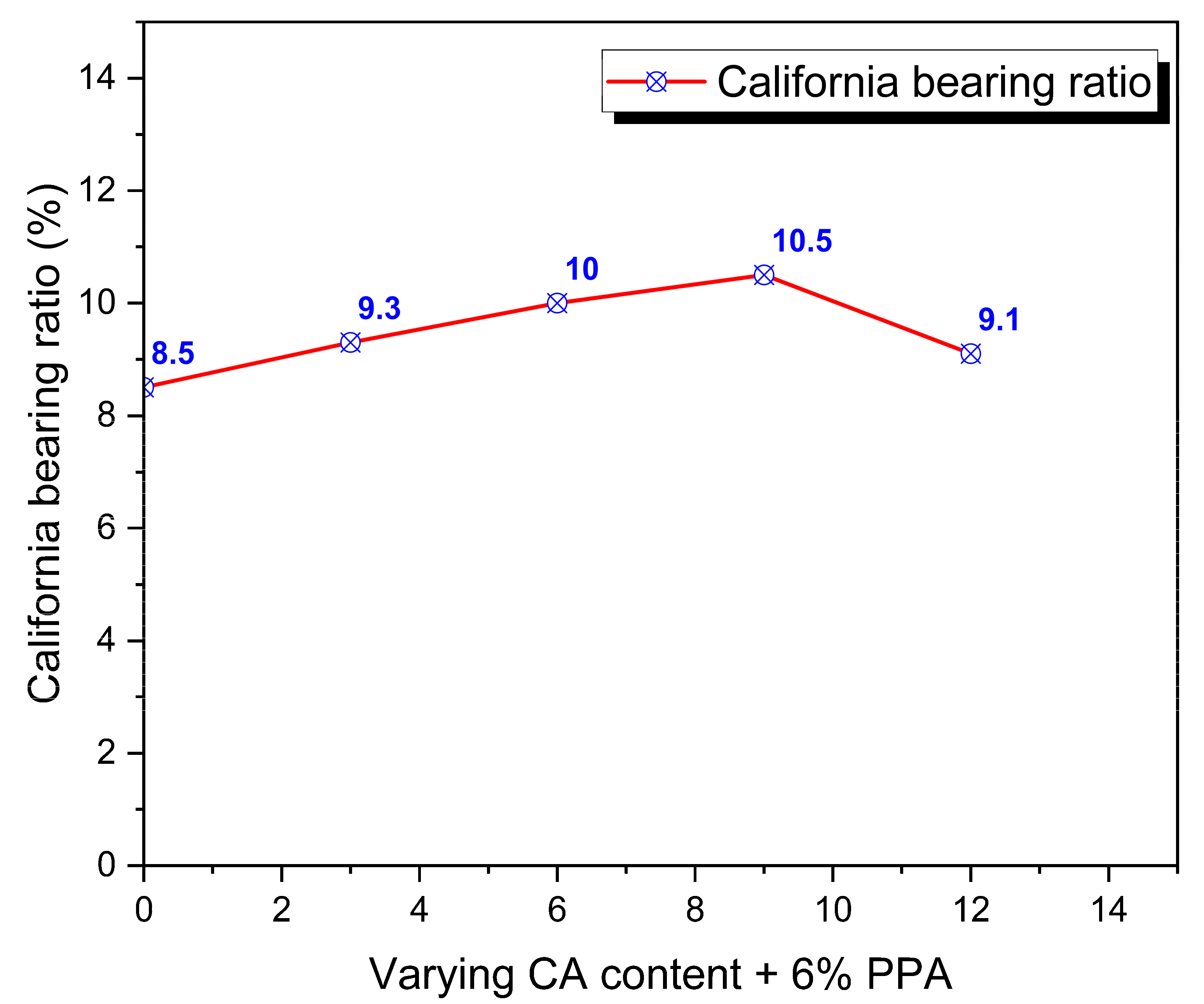

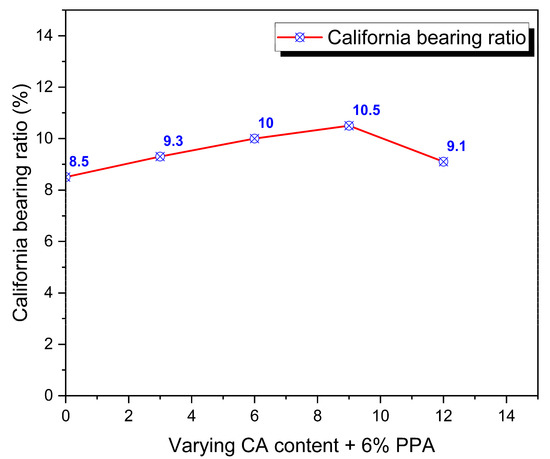

3.4. California Bearing Ratio (CBR)

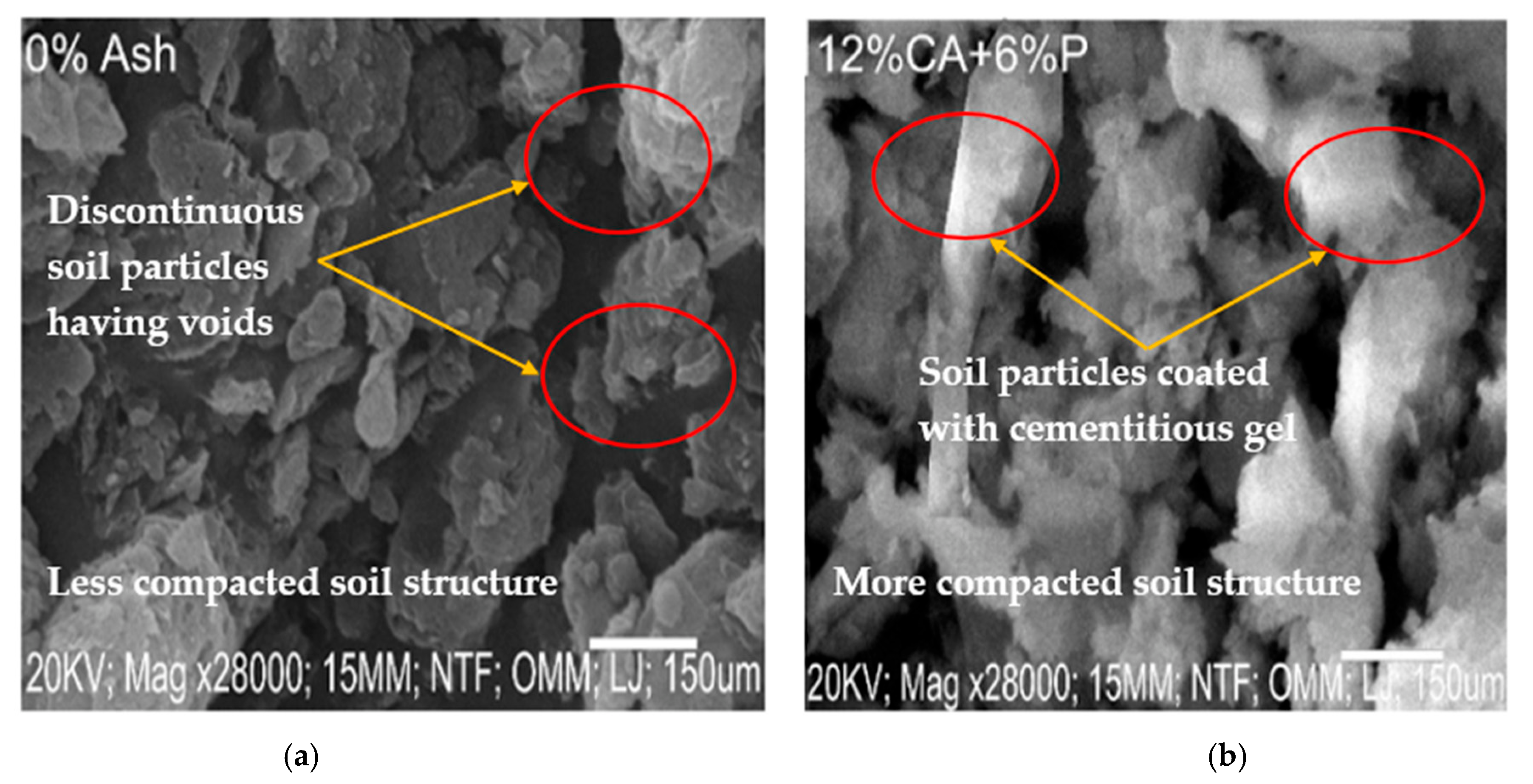

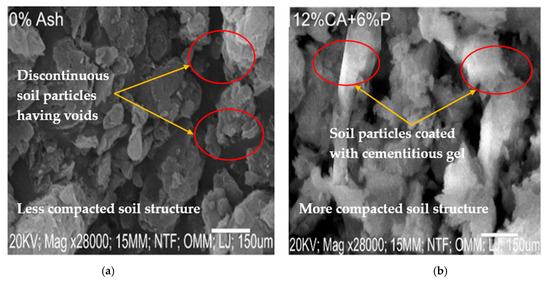

An increase in CBR was observed upon adding 3% CA to the soil with 6% PPA. This increase continued up to 9% CA content before a subsequent decrease at 12% CA. This variation is illustrated in Figure 7. Cadersa et al. [42] stated that an improvement in the CBR of stabilised soils with admixtures can be attributed to the particle size distribution becoming well-graded, causing the soil and ash particles to be packed closer together as seen in Figure 8b, thus improving the mechanical strength of the soil. Another reason for the minor CBR improvement could be ascribed to the calcium present in the admixtures which helps generate calcium silicate hydrate (CSH), the main constituent that increases strength [21]. However, when the CA concentrations increase, the arrangement of the particles becomes less tightly packed as the CA particle size begins to dominate the size distribution of the mix, which results in the CBR value dropping [42]. It is evident from the CBR results that the combination of CA and PPA in stabilising soil would enhance the bearing capacity of the treated soil. Although if these additives are utilised beyond its optimal points, the soil bearing capacity tends to decline.

Figure 7.

Variation of CBR with CA and PPA content. Pertaining to the test results, it has been noted that raising the amount of CA in soil over its ideal limit typically lowers the dry density of soil particles, making it easier for them to slide. After that, there is a subsequent strength decrement [16]. Kumar et al. [47] also observed via experiments and multiple regression modelling, that the CBR value of a soil stabilised with CA would decrease beyond its optimal limit of CA content.

Figure 8.

(a) SEM micrograph for the untreated sample. (b) SEM micrograph for the treated sample at 12% CA + 6% PPA.

3.5. SEM Analysis

This was performed on the natural soil and the sample having 12% of CA and 6% of PPA using a JEOL JSM-7600F scanning electron microscope at a voltage and magnification of 20 kV and ×28,000, respectively. From the micrograph of the untreated sample as seen in Figure 8a, pore spaces can be observed. However, from the treated sample in Figure 8b, it can be observed that there is pore size reduction. The untreated sample is distinguished further by discontinuous soil particles with voids and a less compacted structure, whereas the treated sample is distinguished by soil particles coated with cementitious gel and a more compacted structure. This is understood by the pozzolanic reaction that emerges in the soil fabric when cementitious components like calcium silicate hydrate (C-S-H) form [48]. This product acts as a binding agent within the soil matrix, filling up the pore spaces. This leads to the soil fabric becoming more solid [49]. The soil particles clump together as seen in Figure 8b due to flocculation and agglomeration; hence the decrease in LL, increase in PL, reduction in PI, and initial improvement in strength in terms of CBR [50].

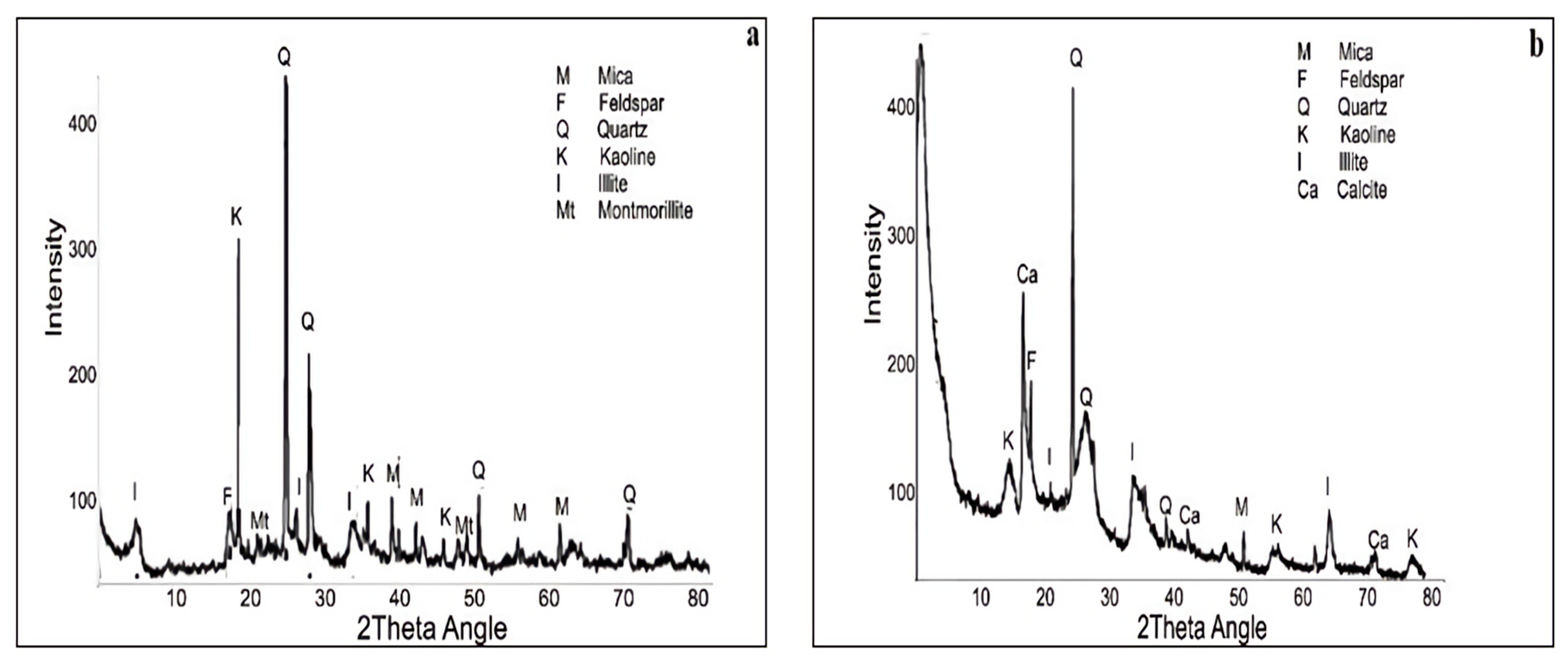

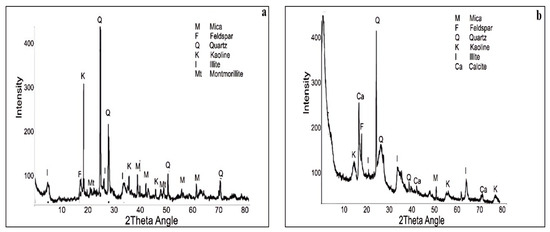

3.6. XRD Analysis

This was performed to detect the minerals present in the untreated and treated soil sample, and also to verify the emergence of new minerals, which is crucial for the stabilised soil strength properties [51]. This was performed for identification of compounds in the natural soil, and the sample stabilised with 12% CA + 6% PPA using a Rigaku D/MAX-IIIC X-ray diffractometer at a scanning rate of 2°/min in 2 to 50° at room temperature with a Cu-Kα radiation set at 40 kV and 20 mA. This aids better understanding of its crystalline nature [52]. Results from the XRD of the untreated soil revealed the presence of quartz (Q), kaolinite (K), mica (M), illite (I), feldspar (F), and montmorillonite (Mt), as seen in Figure 9a. The most prominent peaks were that of quartz (2θ = 25° at an intensity of approximately 450 cps), and kaolinite (2θ = 18° at an intensity of approximately 300 cps). It is observed that the peak of quartz is higher, hence showing quartz was the most prominent mineral in the untreated soil’s mineralogical composition. Quartz is the primary non-clayey constituent of expansive soils, loess, red clay, and soft clay [53]. The magnitude of quartz peak detected confirms its highly crystalline nature [54]. Illite, kaolinite, and montmorillonite all have lamellar structures and small grain sizes that affect Atterberg limits and soil anisotropy [53]. Additionally, the expansive character of the soil is attributed to the presence of montmorillonite [55], while the siliceous nature of the soil is ascribed to the presence of quartz and feldspar [56].

Figure 9.

(a) XRD spectrum for the untreated sample. (b) XRD spectrum for the treated sample at 12% CA + 6% PPA.

Upon stabilisation with CA and PPA, the intensity of quartz and kaolinite decreases in the treated sample as seen in Figure 9b, corresponding to 2θ = 25° at an intensity of approximately 420 cps and 2θ = 15° at an intensity of approximately 125 cps, respectively. This decrease indicates that the silica and alumina in the stabilised mix dissolves and becomes an amorphous gel product, thereby improving strength of the soil [57]. Gonzalez et al. [58] inferred that as a result of alkali activation with stabilised soil, which occurs during sample curing when the OH− ions catalyses the hydrolysis of the Si-O-Si and Si-O-Al bonds present in the clay aluminosilicates, stabilised soil produces weaker peaks, particularly of quartz and kaolinite, when compared to untreated samples. The drop in quartz peak shows that the CA and PPA significantly targeted the quartz in the soil, causing its crystalline structure to dissolve or degrade and produce silica gels [59]. This dissolution is essential for pozzolanic reactions to take place [60]. Akbari et al. [61] also explained that a decrease in kaolinite intensity of stabilised soils as compared to untreated soil samples can be achieved through the formation of complex structures, consumption of clay particles in pozzolanic reactions, and coverage of some clay particles by the generated cementitious compounds. The weathering of kaolinite due to pozzolanic actions alters the soil’s structure [62,63]. Generally, the CA and PPA consumed and reacted with the clay minerals in the soil to develop new cementing peaks like that of calcite, corresponding to 2θ = 18° at an intensity of approximately 250 cps for the treated soil.

When CA and PPA in the soil are hydrated, it dissociates into Ca2+ and OH− ions. The silica and alumina from clay minerals disintegrates when OH− ions are released, and when they combine with Ca2+ ions, they produce calcium-silicate-hydrates (C-S-H) and calcium-aluminate-hydrates (C-A-H). These two products take the form of calcite, which is an amorphous gel that holds the soil matrix together [60]. Calcite is also developed when there is a reaction between calcium hydroxide Ca(OH)2 and atmospheric carbon dioxide (CO2); a reaction referred to as “carbonation” [60,64]. This new mineral is expected to fill the pores of the soil and improve its characteristics [65]. Calcite generally contributes to an increase in strength [60,66]. The formation of calcite confirms the pozzolanic properties of CA and PPA, which helps to improve strength of the stabilised soil specimen [66,67], as seen in the improvement in CBR.

In addition to the formation of calcite and the reduction of the peaks of quartz and kaolinite, the peak of montmorillonite disappeared in the XRD spectrum of the treated soil. This may be attributed to the dissolution of minerals in the presence of admixtures [68]. This mineral dissolution gives rise to the formation of cementitious gels of calcite [54]. Additionally, the peak of kaolinite in the stabilised soil shows a greater degree of reduction compared to illite. This indicates that the kaolinite is quickly depleted during the pozzolanic reaction, while illite is less involved. Moreover, illite-based pozzolanic reactions occur considerably slower than kaolinite-based reactions [69]. As the cementitious by-products of the kaolinite-driven pozzolanic reaction build up on the surface, the illite clusters are progressively encased. Hence, the encapsulation of the illite prevents the CA and PPA from attacking it further. This hinders any further pozzolanic reaction from occurring that can adversely alter the peaks of illite [69]. This explains why the peak of illite only changes slightly in the stabilised soil, compared to kaolinite peaks.

Typically, XRD patterns and peaks of treated soils would change with respect to the reactions occurring between the stabilising agents and clay minerals within the soil fabric [55].

The outcomes of this study are comparable to those of Navigare et al. [16], where the modification of black cotton soil with CBA was studied. According to reports, adding CBA to the soil has a positive impact on soil-strength gain. However, the strength declined when CBA content was increased in the mix beyond its optimal point. This pattern was also observed on the effects of PPA on strength characteristics of tropical red soil [21].

Comparing the test results with the Nigerian General Specification [27] indicates that the soil treated with CA and PPA is suitable for general fillings and embankments.

This research is unique due to the fact that it incorporates two pozzolanic waste materials that are often used alone for soil improvement. Hence, this work contributes to providing a new dynamic of integrating both industrial and agricultural waste materials, so as to observe their performance. Although, CA and PPA are often used as “stand-alone” soil stabilisers to yield considerable strength gain in soil, results from this study suggest that they can also be used conjointly to yield a reasonable degree of improvement in soil for road pavement layer construction.

4. Conclusions

This research sought to provide an experimental insight to the improvement of soil using blends of CA and PPA as road pavement layer materials. The results can be summed up as follows:

- The initial inclusion of additives at 3% CA + 6% PPA, 6% CA + 6% PPA, and 9% CA + 6% PPA led to an increase in the maximum dry unit weight, decrease in PI, and increase in CBR of the soil. Afterwards, a decrease was shown at 12% CA + 6% PPA. This suggests that these admixtures should be applied to stabilise soils at optimum proportions so as to avoid considerable loss of strength.

- The optimum additive content is seen at 9% CA + 6% PPA where the maximum dry unit weight of the natural soil improved by 17.70%, and the CBR improved by 23.53% upon the inclusion of the stabilisers.

- The SEM analysis indicated pore reduction as the stabilisers were added to the soil. This was as a result of the pozzolanic reaction that takes place within the soil fabric after the formation of cementitious products.

- The XRD analysis indicated the formation of calcite to replace montmorillonite upon the addition of the stabilising agents. This formation is attributed to the impact of quartz during the pozzolanic reaction.

- The results show that the soil treated with CA and PPA is appropriate for general fills and embankment, especially for rural roads with low traffic volume, when taking the Nigerian General Specification into account.

These discoveries are especially notable since they have the possibility of enhancing soil using CA and PPA while also clearing up the environment from any possible pollution caused by the improper disposal of coal and plantain peels. However, insufficient literature on the stabilisation of soil using PPA and the absence of an electric furnace to combust these waste materials limited the scope of this investigation. This is safer than open burning as it protects against harmful fumes, provides better humidity balance and is energy efficient since it does not make use of fossil fuels. This should be taken into account for future studies. The results obtained are practicable for stabilising clay (lean clay), since it was the soil material used for the purpose of this research. Hence, the test outcomes are not generalised for all types of soils, as other soils may perform differently upon stabilisation with CA and PPA. Therefore, additional research can be conducted to explore and compare the geotechnical characteristics and behaviour of other soil types upon stabilisation with CA and PPA, as this study has provided an advantageous benchmark. This study also contributes to providing a reference point for soil stabilisation in the field, especially in regions having a high rate of wastes generated from coal consumption and plantain cultivation. Moreover, the results obtained in this study may be beneficial for further research on the application of CA and PPA in mine reclamation and concrete admixing, since these additives have already displayed a considerable potential in soil improvement. Additionally, the stabilisation potential of other industrial and agricultural wastes should also be investigated. For subsequent research, the stabilisation power and performance of these additives can also be investigated using compressive strength tests. Furthermore, as a way of supplementing the CBR test, a swelling test in the CBR mould can be investigated for further studies. This would facilitate comparing how much the treated and untreated soil could swell. Additionally, research to develop approaches to carry out full cost-benefit analysis on the application of these stabilisers on the field should be implemented.

Author Contributions

Conceptualization, I.A.; methodology and software, I.A. and M.O.; resources and data curation, M.O., P.E. and V.A.; writing—original draft preparation, M.O., P.E. and V.A.; writing—review and editing, I.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge and appreciate the Management of Covenant University and the Covenant University Centre for Research, Innovation and Discovery (CUCRID) for the publication support provided for this research project. The authors also thank the reviewers for their insightful remarks as well.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The World Bank. WHAT A WASTE 2.0: A Global Snapshot of Solid Waste Management to 2050. 2022. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 16 February 2023).

- United States Environmental Protection Agency. Wastes: Waste Generation. 2022. Available online: https://www.epa.gov/report-environment/wastes (accessed on 16 February 2023).

- Wiranata, D.Y.; Yang, S.-H.; Akgul, C.M.; Hsien, H.Y.; Nugraha, M.Z.P. Use of Coal Ash Cement Stabilized Material as Pavement Base Material: Laboratory Characterization and Field Evaluation. Constr. Build. Mater. 2022, 344, 128055. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Domo-Spiff, A.H.; Salami, A. Marine Plastic Pollution and Affordable Housing Challenge: Shredded Waste Plastic Stabilized Soil for Producing Compressed Earth Bricks. Case Stud. Constr. Mater. 2019, 11, e00241. [Google Scholar] [CrossRef]

- Modarres, A.; Nosoudy, Y.M. Clay Stabilization Using Coal Waste and Lime—Technical and Environmental Impacts. Appl. Clay Sci. 2015, 116–117, 281–288. [Google Scholar] [CrossRef]

- Chen, R.; Cai, G.; Congress, S.S.C.; Dong, X.; Duan, W. Dynamic properties and environmental impact of waste red mud-treated loess under adverse conditions. Bull. Eng. Geol. Environ. 2021, 80, 93–113. [Google Scholar] [CrossRef]

- Ofuyatan, O.M.; Adeniyi, A.G.; Ijie, D.; Ighalo, J.O.; Oluwafemi, J. Development of High-Performance Self Compacting Concrete Using Eggshell Powder and Blast Furnace Slag as Partial Cement Replacement. Constr. Build. Mater. 2020, 256, 119403. [Google Scholar] [CrossRef]

- Oyebisi, S.; Ede, A.; Olutoge, F.; Omole, D. Geopolymer Concrete Incorporating Agro-Industrial Wastes: Effects on Mechanical Properties, Microstructural Behaviour and Mineralogical Phases. Constr. Build. Mater. 2020, 256, 119390. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Bassey, D.E.; Olukanni, D.O.; Ngene, B.U.; Adegoke, D.; Odetoyan, A.O.; Kareem, M.A.; Enabulele, D.O.; Nworgu, A.T. Waste Materials in Highway Applications: An Overview on Generation and Utilization Implications on Sustainability. J. Clean. Prod. 2021, 283, 124581. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Jarusiripot, C. Removal of reactive dye by adsorption over chemical pretreatment coal based bottom ash. Procedia Chem. 2014, 9, 21–30. [Google Scholar] [CrossRef]

- International Energy Agency. Global Coal Demand Is Set to Return to Its All-Time High in 2022. 2022. Available online: https://www.iea.org/news/global-coal-demand-is-set-to-return-to-its-all-time-high-in-2022 (accessed on 16 February 2023).

- United States Environmental Protection Agency. Coal Ash Basics. 2022. Available online: https://www.epa.gov/coalash/coal-ash-basics (accessed on 16 February 2023).

- Rajakumar, C.; Meenambal, T. Effect of Coal Ash in the Stabilization of Expansive Soil for the Pavement. Int. J. Chemtech Res. 2015, 8, 170–177. [Google Scholar]

- Thi, N.; Truong, S.; Minh, N. Reusing Coal Ash of Thermal Power Plant in a Pavement Base Course. J. King Saud Univ. Eng. Sci. 2021, 33, 346–354. [Google Scholar]

- Navagire, O.P.; Sharma, S.K.; Rambabu, D. Stabilization of Black Cotton Soil with Coal Bottom Ash. Mater. Today Proc. 2022, 52, 979–985. [Google Scholar] [CrossRef]

- Osma, J.F.; Herrera, J.L.T.; Couto, S.R. Banana skin: A novel waste for lactase production by Tramets pubescens under solid-state conditions. Application to synthetic dye decolouration. Dyes Pigm. 2007, 5, 32–37. [Google Scholar] [CrossRef]

- Amaya, N. The World’s Leading Plantain Producers (WorldAtlas). 2018. Available online: https://www.worldatlas.com/articles/the-world-s-leading-plantain-producers.html (accessed on 16 February 2023).

- Usman, A.; Bala, N.; Bashiru, M. Effect of Plantain Peel Ash (PPA) on the Mechanical Properties of Concrete. Noble Int. J. Sci. Res. 2018, 2, 11–18. [Google Scholar]

- Ifetayo, O.; Pretorius, J.-H.C. Engineering Properties of Black Cotton Soil Stabilized with Plantain Peel Powder. Proc. Int. Conf. Ind. Eng. Oper. Manage. 2018, 9, 958–966. [Google Scholar]

- Ishola, K.; Olawuyi, O.A.; Bello, A.A.; Yohanna, P. Effect of Plantain Peel Ash on the Strength Properties of Tropical Red Soil. Niger. Res. J. Eng. Environ. Sci. 2019, 4, 447–459. [Google Scholar]

- Olutaiwo, A.O.; Adanikin, A. Evaluation of the Structural Performance of Lateritic Soil Stabilized with Cassava Peel Ash (CPA) and Cement. Int. J. Constr. Res. Civ. Eng. 2016, 2, 18–26. [Google Scholar]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil Stabilization with Non-Conventional Eco-Friendly Agricultural Waste Materials: An Experimental Study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Daramola, T.S.; Olaniregun, E.O.; Adunoye, G.O. Experimental Study on the Geotechnical Properties of Soils Treated with Banana Leaf Ash. N. Y. Sci. J. 2021, 14, 32–37. [Google Scholar]

- Abe, O.E. Comparison between Strength Properties of Lateritic Soils Stabilized with Banana Leaf Ash and Oil Palm Frond Ash. Int. Res. J. Innov. Eng. Technol. 2019, 3, 20–23. [Google Scholar]

- Sankar, V.S.; Raj, P.D.; Raman, S.J. Stabilization of Expansive Soil by using Agricultural Waste. Int. J. Eng. Adv. Technol. 2019, 8, 154–157. [Google Scholar]

- Federal Ministry of Works and Housing (FMWH). Nigerian General Specifications for Roads and Bridges; Federal Ministry of Works and Housing: Lagos, Nigeria, 1997.

- Committee of Land Transport Officials (COLTO). Structural Design of Flexible Pavements for Interurban and Rural Roads, TRH- 4; Committee of Land Transport Officials; Ministry of Transport; Committee of Land Transport Officials (COLTO): Pretoria, South Africa, 1996.

- Overseas Development Administration (ODA). Overseas Road Note 31: A Guide to the Structural Design of Bitumen-Surfaced Roads in Tropical and Sub-Tropical Countries; Overseas Centre, Transport Research Laboratory (TRL): Berkshire, UK, 1993. [Google Scholar]

- Akinwumi, I. Soil Modification by the Application of Steel Slag. Period. Polytech. Civ. Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- Musa, N.; Usaku, R.; Akinterinwa, A.; Maina, H.M. Studies on Elemental Composition and Physico-Chemical Properties of Coal Deposits in Lamza and Guyuk Local Government, Adamawa State, Nigeria. Bayero J. Pure Appl. Sci. 2019, 11, 267–273. [Google Scholar] [CrossRef]

- Vilakazi, A.Q.; Ndlovu, S.; Chipise, L.; Shemi, A. The Recycling of Coal Fly Ash: A Review on Sustainable Developments and Economic Considerations. Sustainability 2022, 14, 1958. [Google Scholar] [CrossRef]

- Villamizar, M.C.N.; Araque, V.S.; Reyes, C.A.R.; Silva, R.S. Effect of the Addition of Coal-Ash and Cassava Peels on the Engineering Properties of Compressed Earth Blocks. Constr. Build. Mater. 2012, 36, 276–286. [Google Scholar] [CrossRef]

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D7928; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D854; Standard Test Method for Specific Gravity Test. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D698; Standard Test Method for Compaction Test. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4318-00; Standard Test Methods for Liquid Limit, Plastic Limit and Plasticity Index of Soils. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2000; Volume 4, pp. 1–14.

- ASTM D1883-16; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2016.

- Bowles, J.E. Engineering Properties of Soils and Their Measurement, 4th ed.; Mc Graw-Hill Publishing Company: New York, NY, USA, 1992; ISBN 978-00-7911-266-8. [Google Scholar]

- Sumesh, M.; Singh, B.; Vigneshwaran, K.; Samsonchelladurai, C.; Vikranth, G. Effect of Coal Ash on Strength Characteristics of Clayey Silt Soil Treated with Cement. Mater. Today Proc. 2020, 2020, S2214785320378536. [Google Scholar] [CrossRef]

- Cadersa, A.S.; Seeborun, A.K.; Chan Chim Yuk, A. Use of Coal Bottom Ash as Mechanical Stabiliser in Subgrade Soil. J. Eng. 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Moses, G. Stabilization of black cotton soil with ordinary Portland Cement Using Bagasse ash as admixture. J. Res. Eng. 2008, 5, 107–115. [Google Scholar]

- Jadhao, P.D.; Nagarnaik, P.B. Influence of Polypropylene Fibers on Engineering Behavior of Soil−Fly Ash Mixtures for Road Construction. Electron. J. Geotech. Eng. 2008, 13, 1–11. [Google Scholar]

- Kumar, B.; Puri, N. Stabilization of weak pavement subgrades using cement kiln dust. Int. J. Civ. Eng. Technol. 2013, 1, 26–37. [Google Scholar]

- Osinubi, K.J.; Yohanna, P.; Eberemu, A.O. Cement Modification of Tropical Black Clay Using Iron Ore Tailing as Admixture. J. Transp. Geotech. 2015, 5, 35–49. [Google Scholar] [CrossRef]

- Vivek Kumar, C.; Swaminathen, A.N.; Vittalaiah, A.; Raja Kumar, C. Pavement Subgrade Stabilized with Waste Coal Ash and Geosynthetics: An Experimental Study and Multiple Regression Modelling. Mater. Today Proc. 2022, 52, 1543–1550. [Google Scholar] [CrossRef]

- Zimar, Z.; Robert, D.; Zhou, A.; Giustozzi, F.; Setunge, S.; Kodikara, J. Application of Coal Fly Ash in Pavement Subgrade Stabilisation: A Review. J. Environ. Manage. 2022, 312, 114926. [Google Scholar] [CrossRef]

- Saing, Z.; Samang, L.; Harianto, T.; Palanduk, J. Bearing Capacity Characteristic of Subgrade Layer Quicklime Treated Laterite Soil. MATEC Web Conf. 2018, 181, 11001. [Google Scholar] [CrossRef]

- Ural, N. The Significance of Scanning Electron Microscopy (SEM) Analysis on the Microstructure of Improved Clay: An Overview. Open Geosci. 2021, 13, 197–218. [Google Scholar] [CrossRef]

- Mohanty, S.; Roy, N.; Singh, S.P.; Sihag, P. Strength and Durability of Flyash, GGBS and Cement Clinker Stabilized Dispersive Soil. Cold Reg. Sci. Technol. 2021, 191, 103358. [Google Scholar] [CrossRef]

- Zhou, S.; Du, Y.; Feng, Y.; Sun, H.; Xia, W.; Yuan, H. Stabilization of Arsenic and Antimony Co-Contaminated Soil with an Iron-Based Stabilizer: Assessment of Strength, Leaching and Hydraulic Properties and Immobilization Mechanisms. Chemosphere 2022, 301, 134644. [Google Scholar] [CrossRef]

- Wang, F.; Li, K.; Liu, Y. Optimal Water-Cement Ratio of Cement-Stabilized Soil. Constr. Build. Mater. 2022, 320, 126211. [Google Scholar] [CrossRef]

- Corrêa-Silva, M.; Miranda, T.; Rouainia, M.; Araújo, N.; Glendinning, S.; Cristelo, N. Geomechanical Behaviour of a Soft Soil Stabilised with Alkali-Activated Blast-Furnace Slags. J. Clean. Prod. 2020, 267, 122017. [Google Scholar] [CrossRef]

- Atahu, M.K.; Saathoff, F.; Gebissa, A. Strength and Compressibility Behaviors of Expansive Soil Treated with Coffee Husk Ash. J. Rock Mech. Geotech. Eng. 2019, 11, 337–348. [Google Scholar] [CrossRef]

- Reiterman, P.; Mondschein, P.; Doušová, B.; Davidová, V.; Keppert, M. Utilization of Concrete Slurry Waste for Soil Stabilization. Case Stud. Constr. Mater. 2022, 16, e00900. [Google Scholar] [CrossRef]

- Li, F.; Zimmerman, A.R.; Zheng, Y.; Yang, Y.; Huang, J.; Zhang, Y.; Hu, X.; Yu, Z.; Huang, J.; Gao, B. P-Enriched Hydrochar for Soil Remediation: Synthesis, Characterization, and Lead Stabilization. Sci. Total Environ. 2021, 783, 146983. [Google Scholar] [CrossRef]

- Gonzalez, J.; Sargent, P.; Ennis, C. Sewage Treatment Sludge Biochar Activated Blast Furnace Slag as a Low Carbon Binder for Soft Soil Stabilisation. J. Clean. Prod. 2021, 311, 127553. [Google Scholar] [CrossRef]

- Dash, S.K.; Hussain, M. Lime Stabilization of Soils: Reappraisal. J. Mater. Civ. Eng. 2012, 24, 707–714. [Google Scholar] [CrossRef]

- Akula, P.; Little, D.N. Analytical Tests to Evaluate Pozzolanic Reaction in Lime Stabilized Soils. MethodsX 2020, 7, 100928. [Google Scholar] [CrossRef]

- Akbari, H.R.; Sharafi, H.; Goodarzi, A.R. Effect of Polypropylene Fiber and Nano-Zeolite on Stabilized Soft Soil under Wet-Dry Cycles. Geotext. Geomembr. 2021, 49, 1470–1482. [Google Scholar] [CrossRef]

- Ghobadi, M.H.; Abdilor, Y.; Babazadeh, R. Stabilization of Clay Soils Using Lime and Effect of PH Variations on Shear Strength Parameters. Bull. Eng. Geol. Environ. 2014, 73, 611–619. [Google Scholar] [CrossRef]

- Latifi, N.; Rashid, A.S.A.; Ecemis, N.; Tahir, M.M.; Marto, A. Time-Dependent Physicochemical Characteristics of Malaysian Residual Soil Stabilized with Magnesium Chloride Solution. Arab. J. Geosci. 2016, 9, 58. [Google Scholar] [CrossRef]

- Luo, Z.; Zhang, B.; Zou, J.; Luo, B. Sulfate Erosion Resistance of Slag-Fly Ash Based Geopolymer Stabilized Soft Soil under Semi-Immersion Condition. Case Stud. Constr. Mater. 2022, 17, e01506. [Google Scholar] [CrossRef]

- Zha, F.; Qiao, B.; Kang, B.; Xu, L.; Chu, C.; Yang, C. Engineering Properties of Expansive Soil Stabilized by Physically Amended Titanium Gypsum. Constr. Build. Mater. 2021, 303, 124456. [Google Scholar] [CrossRef]

- Ahmed, A. Compressive Strength and Microstructure of Soft Clay Soil Stabilized with Recycled Bassanite. Appl. Clay Sci. 2015, 104, 27–35. [Google Scholar] [CrossRef]

- Pokharel, B.; Siddiqua, S. Effect of Calcium Bentonite Clay and Fly Ash on the Stabilization of Organic Soil from Alberta, Canada. Eng. Geol. 2021, 293, 106291. [Google Scholar] [CrossRef]

- Wanare, R.; Jayanthi, P.; Iyer, K.K.R. Experimental Study on Sustainable Stabilization of Marine Soil with Ultrafine Slag and Activator for Controlling Its Cracking Characteristics. Constr. Build. Mater. 2022, 345, 128310. [Google Scholar] [CrossRef]

- Abdulhussein Saeed, K.; Kassim, K.A.; Nur, H. Physicochemical characterization of cement treated kaolin clay. GRAĐEVINAR 2014, 66, 513–521. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).