Sustainable Valorization of Organic Materials as Substrates for Soilless Crops in Protected Environments in the Venezuelan Andes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation and Composition of Substrates

2.2. Characterization of the Substrates

2.3. Experiment Design and Statistical Analysis

3. Results

3.1. Biological Property of Substrates

3.2. Chemical Properties of Substrates

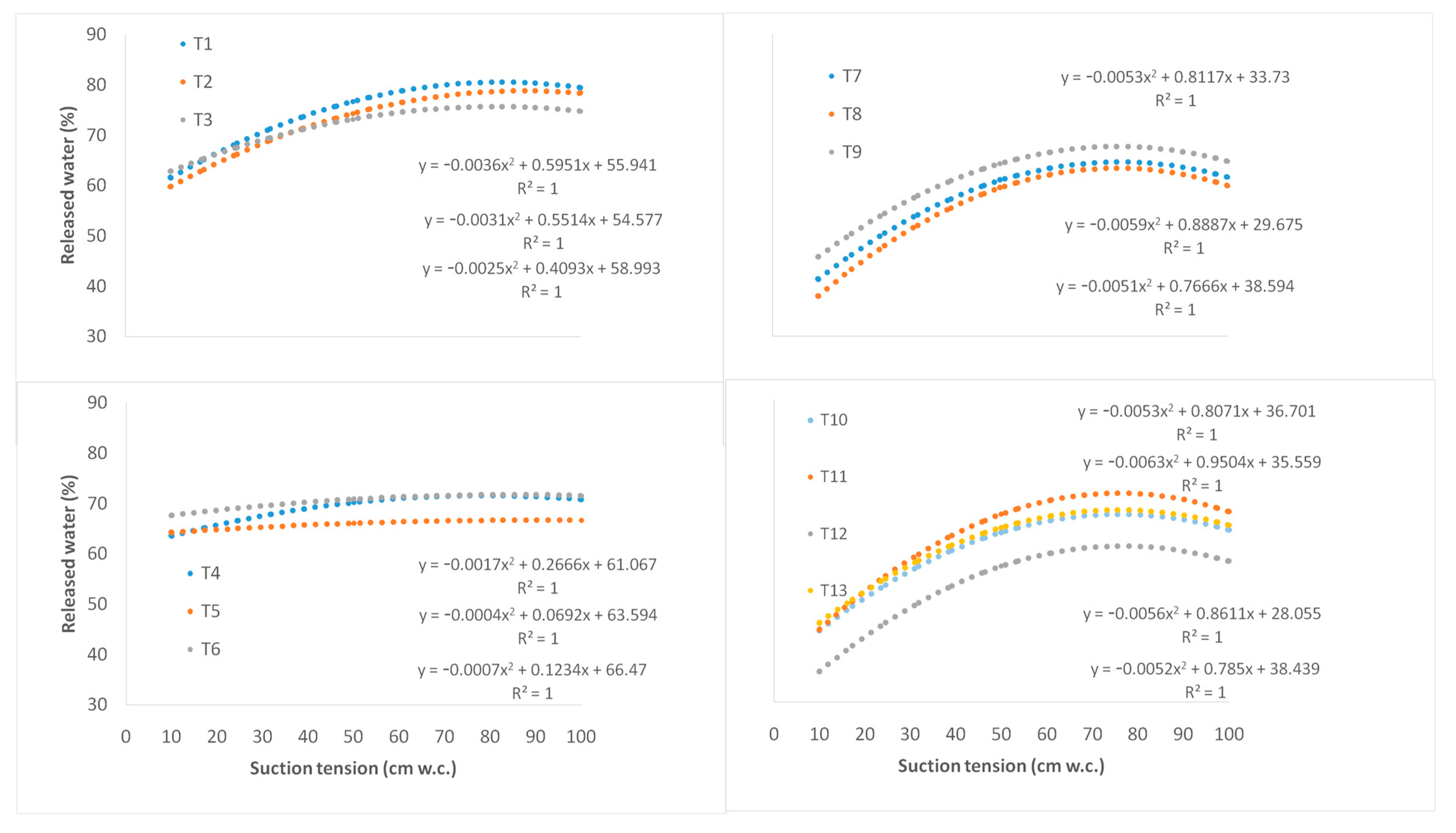

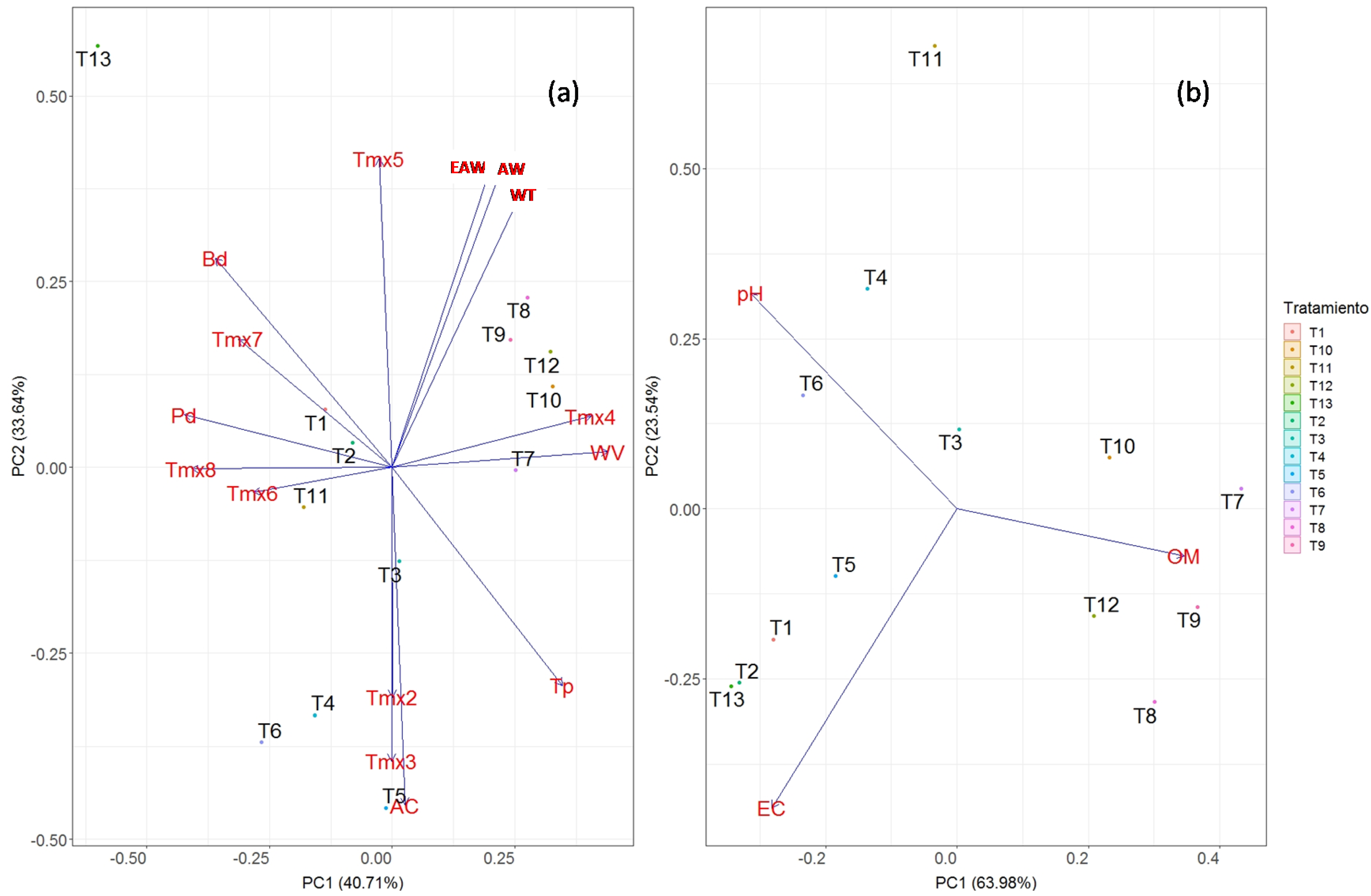

3.3. Physical Properties of Substrates

4. Discussion

4.1. Biological Property of Substrates

4.2. Chemical Properties of Substrates

4.3. Physical Properties of Substrates

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soria, C.B.; Oloverti, J.M. Cultivo sin suelo de hortalizas. Aspectos Prácticos y Experiencias. In Serie de Divulgación Técnica Ed Generalitat Valenciana; Consellería de Agricultura, Pesca y Alimentación: Valencia, Spain, 2002; 110p. [Google Scholar]

- Raviv, M.; Lieth, H.; Bar-Tal, A. (Eds.) Soilless Culture: Theory and Practice, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; 691p. [Google Scholar]

- Abad, M.; Noguera, M.P.; Carrión, C.B. Los sustratos de cultivo. In Tratado de Cultivo sin Suelo, 3rd ed.; Urrestarazú, M., Ed.; Ediciones Mundi-Prensa: Madrid, Spain, 2004; pp. 115–117. [Google Scholar]

- Burés, S. Manejo de Sustratos; Agrotécnicas, S.L.: Madrid, Spain, 1997; 340p. [Google Scholar]

- Nistor, A.; Karacsonyi, D.; Chiru, N.; Campeanu, G.; Atanasiu, N. Behavior of different potato varieties on seed production process, using of different culture substrates on greenhouse. Stud. Univ. “Vasile Goldis” Arad. Ser. Stiintele Vietii (Life Sci. Ser.) 2010, 20, 49. [Google Scholar]

- Martínez-Florián, P.; Roca, D. Sustratos para el cultivo sin suelo. Materiales, propiedades y manejo. In Sustratos, Manejo del Clima, Automatización y Control en Sistemas de Cultivo sin Suelo; Victor, J., Flórez, R., Eds.; Universidad Nacional de Colombia-Facultad de Agronomía: Bogotá, Colombia, 2011; pp. 37–78. [Google Scholar]

- Guerra, P.A.M.; Salas Sanjúan, M.D.C.; López, M.J. Evaluation of physicochemical properties and enzymatic activity of organic substrates during four crop cycles in soilless containers. Food Sci. Nutr. 2018, 6, 2066–2078. [Google Scholar] [CrossRef] [PubMed]

- Orozco, A.L.A.; Monzón, A.F.R.P.; Castillo, G.I.A. Sustratos Locales Para la Producción de Pilones de Tomate (Solanum lycopersicum L.), en dos Localidades del Departamento de San Marcos; CRIA: Guatemala City, Guatemala, 2019; 96p. [Google Scholar]

- Ramírez, W.V.; Pérez-Ascencio, M.A.; Lara-Ascencio, F. Evaluación de tres variedades de papa (Solanum tuberosum L.), tres densidades de siembra y dos sustratos para producción de semilla prebásica. Rev. Agrociencia 2019, 3, 33–49. [Google Scholar]

- Raviv, M.; Chen, Y.; Inbar, Y. Peat and peat substitutes as growth media for container-grown plants. In The Role of Organic Matter in Modern Agriculture. Developments in Plant and Soil Sciences; Springer: Dordrecht, The Netherlands, 1986; Volume 25, pp. 257–287. [Google Scholar] [CrossRef]

- Abad, G.; Abad, J. Historical evidence on the occurrence of late blight of potato, tomato and pearl melon in the Andes of South America. In Phytophthora Infestans 150; Boole Press Ltd.: Birdhill, Ireland, 1995; pp. 36–49. [Google Scholar]

- Cadahía, C. (Ed.) Fertirrigación. Cultivos Hortícolas, Frutales y Ornamentales, 3rd ed.; Ediciones Mundi-Prensa: Madrid, Spain, 2005; 681p. [Google Scholar]

- Flores-Mora, D.M.; Brenes-Madriz, J. Producción en invernadero de semilla de papa a partir de vitroplantas. Ser. Inf. Tecnol. Apropiada 1999, 26, 13. [Google Scholar]

- Fernández-Bravo, C.; Urdaneta, N.; Silva, W.; Poliszuk, H.; Marín, M. Germinación de semillas de tomate (Lycopersicon esculentum Mill.) cvRío Grande sembradas en bandejas plásticas, utilizando distintos sustratos. Rev. Fac. De Agron. LUZ 2006, 23, 188–196. [Google Scholar]

- Casbis, G.M.; Torres, O.G.V.; Rodríguez, M.A. Propiedades físicas y químicas de sustratos en función de su granulometría y componente orgánico-mineral. Acta Agrícola Y Pecu. 2022, 9, 1–9. [Google Scholar]

- Cifuentes-Faura, J. European Union policies and their role in combating climate change over the years. Air Qual. Atmos. Health 2022, 15, 1333–1340. [Google Scholar] [CrossRef]

- Instituto Nacional Tecnológico [INATEC]. Cultivos de Hortalizas, 2nd ed.; Instituto Nacional Tecnológico [INATEC]: Managua, Nicaragua, 2018; pp. 10–108. [Google Scholar]

- Rosa Arranz, J.M.; Santa Olalla, A.; Fernández Boy, E.; López Núñez, R.; Campos Díaz de Mayorga, P. Aplicación de residuos vegetales transformados para una agricultura sostenible: Efectos en la germinación, necesidades hídricas y productividad. In Proceedings of the IV Congreso Internacional en Tecnologías Limpias y V Encuentro de Investigación en Ingeniería Ambiental, Bogotá, Colombia, 8 November 2021. [Google Scholar]

- Luo, Y.; Liang, J.; Zeng, G.; Chen, M.; Mo, D.; Li, G.; Zhang, D. Seed germination test for toxicity evaluation of compost: Its roles, problems and prospects. Waste Manag. 2018, 71, 109–114. [Google Scholar] [CrossRef]

- Zucconi, F.; Pera, A.; Forte, M. Evaluating toxicity of immature compost. BioCycle 1981, 22, 54–57. [Google Scholar]

- Selim, S.M.; Zayed, M.S.; Atta, H.M. Evaluation of phytotoxicity of compost during composting process. Nat. Sci. 2012, 10, 69–77. [Google Scholar]

- UNE-EN 13041; Mejoradores de Suelo y Sustratos de Cultivo. Determinación de las Propiedades Físicas. Densidad Aparente Seca, Volumen de Aire, Volumen de Agua, Valor de Contracción y Porosidad Total. UNE: Madrid, Spain, 2012.

- BS EN 13041; Soil Improvers and Growing Media. Determination of Physical Properties. Dry Bulk Density, Air Volume, Water Volume, Shrinkage Value and Total Pore Space. British Standards Institution (BSI): London, UK, 2011.

- De Boodt, M.; Verdonck, O.; Cappaert, I. Method for measuring the waterrelease curve of organic substrates. Acta Hortic. 1974, 37, 2054–2063. [Google Scholar] [CrossRef]

- Ansorena, M.J. Sustratos, Propiedades y Caracterización; Editorial Mundi-Prensa: Madrid, Spain, 1994; 170p. [Google Scholar]

- NCh 2880; Norma Chilena de Compost. Norma Chilena Oficial. Compost-Clasificación y Requisitos. Instituto Nacional de Normalización. INN: Santiago, Chile, 2004; 27p. Available online: https://vdocuments.site/nch-2880.html (accessed on 1 January 2020).

- Sadzawka, A.; Carrasco, M.; Grez, R.; Mora, M.D.L.L. Métodos de Análisis de Compost; Serie No34; Centro Regional de Investigación La Platina: Santiago, Chile, 2005; 142p. [Google Scholar]

- UNE-EN 13040; Mejoradores de Suelo y Sustratos de Cultivo. Preparación de Muestras Para Ensayos Químicos y Físicos. Determinación del Contenido de Materia Seca, Contenido de la Humedad y de la Densidad Aparente Compactada en Laboratorio. UNE: Madrid, Spain, 2008.

- Haug, R.T. The Practical Handbook of Compost Engineering; Routledge: London, UK, 2018. [Google Scholar]

- Chung, W.J.; Chang, S.W.; Chaudhary, D.K.; Shin, J.; Kim, H.; Karmegam, N.; Ravindran, B. Effect of biochar amendment on compost quality, gaseous emissions and pathogen reduction during in-vessel composting of chicken manure. Chemosphere 2021, 283, 131129. [Google Scholar] [CrossRef] [PubMed]

- Jakubus, M.A. Comparative Study of Composts Prepared from Various Organic Wastes Based on Biological and Chemical Parameters. Agronomy 2020, 10, 869. [Google Scholar] [CrossRef]

- Acevedo-Alcalá, P.; Taboada-Gaytán, O.R.; Cruz-Hernández, J. Caracterización de fertilizantes orgánicos y estiércoles para uso como componentes de sustrato. Acta Agronómica 2020, 69, 234–240. [Google Scholar] [CrossRef]

- Barbaro, L.; Karlanian, M.; Rizzo, P.; Riera, N. Caracterización de diferentes compost para su uso como componente de sustratos. Chil. J. Agric. Anim. Sci. 2019, 35, 126–136. [Google Scholar] [CrossRef]

- López-Rodríguez, G.; Pérez-Esteban, J.; Ruiz-Fernández, J.; Masaguer, A. Caracterización física e hidrofísica de sustratos orgánicos sostenibles para sistemas de naturación en espacios urbanos. Rev. Ing. Agrícola 2017, 7, 33–40. [Google Scholar]

- Macías, R.R.; González, E.G.A.; Covarrubias, G.I.; Natera, F.Z.; López, P.M.G.; López, M.A.R.; Pérez, E.S. Caracterización física y química de sustratos agrícolas a partir de bagazo de agave tequilero. Interciencia 2010, 35, 515–520. [Google Scholar]

- Bracho, J.; Pierre, F.; Quiroz, A. Caracterización de componentes de sustratos locales para la producción de plántulas de hortalizas en el estado Lara, Venezuela. Bioagro 2009, 21, 117–124. [Google Scholar]

- Ansorena, J.; Batalla, E.; Merino, D. Evaluación de la calidad y usos del compost como componente de sustratos, enmiendas y abonos orgánicos. Esc. Agrar. Fraisoro 2014, 1–67. Available online: https://www.blueberrieschile.cl/subidas/2015/07/pdf_000304.pdf (accessed on 24 July 2023).

- Blok, C.; Baumgarten, A.; Baas, R.; Wever, G.; Lohr, D. Soilles Culture, 2nd ed.; Analytical Methods Used with Soilless Substrates; Elsevier: Amsterdam, The Netherlands, 2019; pp. 509–564. [Google Scholar] [CrossRef]

- Montoya-Jasso, V.M.; Ordaz-Chaparro, V.M.; Benedicto-Valdés, G.S.; Ruiz-Bello, A.; Arreola-Tostado, J.M. Caracterización química y física de sustratos enriquecidos con minerales y composta. Terra Latinoam. 2021, 39, 1-10.e601. [Google Scholar] [CrossRef]

- Bunt, B.R. Media and Mixes for Container-Grown Plants: A Manual on the Preparation and Use of Growing Media for Pot Plants; Springer Science y Business Media: Berlin, Germany, 2012. [Google Scholar]

- Gayosso-Rodríguez, S.; Borges-Gómez, L.; Villanueva-Couoh, E.; Estrada-Botello, M.A.; Garruña, R. Caracterización física y química de materiales orgánicos para sustratos agrícolas. Agrociencia 2018, 52, 639–652. [Google Scholar]

- Anicua, R.; Gutiérrez, M.; Sánchez, P.; Ortíz, C.; Volke, V.; Rubiños, J. Tamaño de partícula y relación micromorfológica en propiedades físicas de perlita y zeolita. Agric. Técnica México 2009, 32, 147–156. [Google Scholar]

- Gayosso-Rodríguez, S.; Villanueva-Couoh, E.; Estrada-Botello, M.A.; Garruña, R. Caracterización físico-química de mezclas de residuos orgánicos utilizados como sustratos agrícolas. Bioagro 2018, 30, 179–190. [Google Scholar]

- Pire, R.; Pereira, A. Propiedades físicas de componentes de sustratos de uso comúnen la horticultura del estado Lara. Bioagro 2003, 15, 55–64. [Google Scholar]

- Valenzuela, O.R.; Gallardo, C.S.; Carponi, M.S.; Aranguren, M.E.; Tabares, H.R.; Barrera, M.C. Manejo de las propiedades físicas en sustratos regionales para el cultivo de plantas en contenedores. Cienc. Doc. Y Tec. 2014, 4, 1–19. [Google Scholar]

- Boussaidi, N.; Jouadi, W.; Hamrouni, S. Effets de deux substrats (Marc de café et Grignons d’olives) sur la production de champignon de Paris (Agaricus bisporus L.) dans la ferme de l’Ecole Supérieure d’Agriculture du Kef (Tunisie). J. Adv. Res. Sci. Technol. 2022, 8, 35–49. [Google Scholar]

- Barbaro, L.A.; Karlanián, M.A. Efecto de las propiedades físicas del sustrato sobre el desarrollo de plantines florales en maceta. Cienc. Del Suelo 2020, 38, 1–11. [Google Scholar]

- Urrestarazu, M. Bases y sistemas de los cultivos sin suelo. In Tratado Internacional de Cultivo Sin Suelo; Prensa, M., Ed.; ESP: Almeria, Spain, 2004; 914p. [Google Scholar]

- Crespo González, M.R.; González Eguiarte, D.R.; Rodríguez Macías, R.; Ruiz Corral, J.A.; Durán Puga, N. Caracterización química y física del bagazo de agave tequilero compostado con biosólidos de vinaza como componente de sustratos para cultivos en contenedor. Rev. Int. Contam. Ambient. 2018, 34, 373–382. [Google Scholar] [CrossRef]

- Abad, M. Los sustratos hortícolas: Características y manejo. In Actas H Congreso Nacional de Fertirrigacion; Almería, Spain, 1991; pp. 1–5. [Google Scholar]

- Urrestarazu, M. Manual Práctico del Cultivo sin Suelo e Hidroponía; Ediciones Paraninfo, SA: Madrid, Spain, 2015; 269p. [Google Scholar]

- Abad, M.; Noguera, P. Sustratos para el cultivo sin suelo y fertirrigación. In Cultivos Hortícolas y Ornamentales; Cadahía, C. (coord). Fertirrigación; Mundi-Prensa: Madrid, Spain, 1998; pp. 287–342. [Google Scholar]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry—A review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Gruda, N.S. Soilless culture systems and growing media in horticulture: An overview. In Advances in Horticultural Soilless Culture; Burleigh Dodds Science Publishing: Cambridge, UK, 2021; pp. 1–20. [Google Scholar]

| Treatments | Composition |

|---|---|

| T1 | 50%/50% v/v compost–peat |

| T2 | 75%/25% v/v compost–peat |

| T3 | 25%/75% v/v compost–peat |

| T4 | 50%/50% v/v coconut fiber–compost |

| T5 | 75%/25% v/v coir fiber–compost |

| T6 | 25%/75% v/v coir fiber–compost |

| T7 | 50%/50% v/v coir fiber–peat |

| T8 | 75%/25% v/v coir fiber–peat |

| T9 | 25%/75% v/v coir fiber–peat |

| T10 | 100% peat |

| T11 | 100% compost |

| T12 | 100% coir fiber |

| T13 | INIA mix |

| Sample | Germination (%) | Radicle (Root) Length (%) | Germination Index (%) |

|---|---|---|---|

| Distilled water | 100.0 a * | 100.0 a | - |

| T10 | 96.7 a | 91.5 a | 88.4 a |

| T11 | 90.0 a | 37.8 b | 34.0 b |

| T12 | 93.3 a | 99.4 a | 92.8 a |

| Treatment | pH | EC (dS m−1) | OM (%) | Bd (g cm−3) | Pd (g cm−3) | Tp (%) | WV10 (%v/v) | AC10 (%v/v) | CV (%v/v) | EAW (%v/v) | BW (%v/v) | RW (%v/v) | AWC (%v/v) | WR (%v/v) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | 7.30 f * | 0.77 h | 35.13 b | 0.30 h | 2.12 j | 85.81 b | 38.47 a | 47.34 cde | 7.23 e | 15.17 bc | 2.77 d | 20.53 ab | 17.69 | 38.22 |

| T2 | 7.60 g | 0.85 i | 37.96 c | 0.29 h | 2.09 i | 85.97 b | 40.22 a | 45.74 cde | 3.87 c | 14.53 bc | 4.06 e | 21.63 ab | 18.31 | 39.94 |

| T3 | 7.10 e | 0.48 de | 56.51 f | 0.26 g | 1.89 e | 86.29 b | 37.17 a | 49.13 de | 5.27 d | 19.79 c | 1.27 c | 16.11 a | 20.85 | 36.96 |

| T4 | 8.30 h | 0.47 cd | 50.12 e | 0.19 e | 1.95 f | 90.19 b | 36.44 a | 53.75 e | 3.09 c | 6.59 a | 0.58 ab | 29.27 bcde | 7.17 | 36.44 |

| T5 | 8.20 h | 0.76 h | 66.44 g | 0.18 cd | 1.80 d | 90.25 b | 35.75 a | 54.50 e | 1.11 b | 1.84 a | 0.56 a | 33.35 cdefg | 2.4 | 35.75 |

| T6 | 8.20 h | 0.59 g | 41.64 d | 0.21 f | 2.04 h | 89.56 b | 32.37 a | 57.19 e | 3.24 c | 3.20 a | 0.74 abc | 28.43 bcd | 3.94 | 32.37 |

| T7 | 5.00 a | 0.27 a | 80.63 h | 0.18 de | 1.68 c | 89.05 b | 58.68 b | 30.36 b | 1.84 b | 19.68 c | 0.61 ab | 38.40 efg | 20.29 | 58.69 |

| T8 | 5.20 b | 0.53 ef | 83.86 i | 0.17 c | 1.65 b | 89.78 b | 62.03 b | 27.75 b | 5.83 d | 21.46 c | 0.42 a | 40.14 fg | 21.88 | 62.02 |

| T9 | 5.20 b | 0.42 c | 85.68 i | 0.17 c | 1.65 b | 89.66 b | 54.25 b | 35.42 bc | 1.60 b | 18.54 c | 0.45 a | 35.25 defg | 18.94 | 54.19 |

| T10 | 5.80 c | 0.35 b | 64.76 g | 0.12 a | 1.82 d | 93.62 b | 55.26 b | 38.36 bcd | 6.06 d | 22.83 c | 0.46 a | 31.98 cdef | 23.29 | 55.27 |

| T11 | 8.50 i | 0.22 a | 48.94 e | 0.26 g | 1.98 g | 86.75 b | 40.11 a | 46.64 cde | 3.60 c | 9.79 ab | 4.95 f | 25.37 bc | 15.01 | 40.38 |

| T12 | 6.60 d | 0.58 fg | 94.93 j | 0.14 b | 1.58 a | 91.20 b | 63.90 b | 27.30 b | 2.90 c | 20.96 c | 0.93 bc | 42.01 g | 21.89 | 63.9 |

| T13 | 6.80 d | 0.79 h | 16.86 a | 0.84 i | 2.37 k | 64.43 a | 54.23 b | 10.20 a | 0.00 a | 18.98 c | 0.46 a | 34.78 cdefg | 19.44 | 54.22 |

| Treatment | Diameter of Particles Present in the Substrates (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| >25 | 25–12.5 | 12.5–6.3 | 6.3–5.0 | 5.0–2.0 | 2.0–1.0 | 1.0–0.5 | 0.5–0.25 | 0.25–0.125 | IGr (%) | |

| T1 | 0.17 a * | 0.05 b | 9.71 de | 20.82 de | 56.73 a | 8.51 abc | 2.13 a | 1.43 ab | 0.09 ab | 95.99 |

| T2 | 0.22 a | 0.59 b | 16.99 cde | 26.00 bcd | 42.79 b | 7.53 abc | 1.74 a | 1.62 ab | 1.78 a | 94.12 |

| T3 | 0.13 a | 6.69 b | 44.74 a | 24.50 bc | 18.7 de | 2.35 c | 0.37 a | 1.88 ab | 0.42 ab | 97.11 |

| T4 | 0.05 a | 5.27 b | 49.79 a | 21.61 de | 10.72 e | 6.33 bc | 4.13 a | 2.00 ab | 0.09 ab | 93.77 |

| T5 | 0.13 a | 22.88 a | 29.32 bc | 23.23 de | 17.46 de | 6.01 bc | 0.41 a | 0.47 ab | 0.06 b | 99.03 |

| T6 | 0.01 a | 0.40 b | 49.43 a | 18.50 de | 14.59 e | 11.15 ab | 3.39 a | 1.94 ab | 0.11 ab | 94.08 |

| T7 | 0.13 a | 2.53 b | 41.42 ab | 32.29 abc | 13.07 e | 9.46 ab | 0.61 a | 0.45 ab | 0.03 b | 98.9 |

| T8 | 0.02 a | 0.26 b | 14.65 cde | 25.00 bcd | 54.57 a | 2.87 c | 2.34 a | 0.21 b | 0.04 b | 97.37 |

| T9 | 0.05 a | 0.17 b | 4.65 ef | 32.42 abc | 56.04 a | 3.63 c | 1.55 a | 0.84 ab | 0.63 ab | 96.96 |

| T10 | 0.03 a | 0.07 b | 22.27 cd | 36.68 a | 35.61 bc | 3.26 c | 1.45 a | 0.38 ab | 0.21 ab | 97.92 |

| T11 | 0.01 a | 0.35 b | 25.21 c | 25.48 bcd | 27.19 cd | 13.31 a | 6.23 a | 1.47 ab | 0.73 ab | 91.55 |

| T12 | 0.28 a | 1.70 b | 21.11 cd | 33.19 ab | 34.00 bc | 6.48 bc | 2.78 a | 0.34 ab | 0.10 ab | 96.76 |

| T13 | 0.01 a | 0.08 b | 3.05 f | 16.06 e | 60.58 a | 10.06 ab | 6.99 a | 2.56 a | 0.49 ab | 89.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arias, K.; Sulbarán, J.; Mendoza, W.; Escalona, A.; Salas-Sanjuán, M.d.C. Sustainable Valorization of Organic Materials as Substrates for Soilless Crops in Protected Environments in the Venezuelan Andes. Resources 2023, 12, 116. https://doi.org/10.3390/resources12100116

Arias K, Sulbarán J, Mendoza W, Escalona A, Salas-Sanjuán MdC. Sustainable Valorization of Organic Materials as Substrates for Soilless Crops in Protected Environments in the Venezuelan Andes. Resources. 2023; 12(10):116. https://doi.org/10.3390/resources12100116

Chicago/Turabian StyleArias, Karen, José Sulbarán, Welsk Mendoza, Argelia Escalona, and María del Carmen Salas-Sanjuán. 2023. "Sustainable Valorization of Organic Materials as Substrates for Soilless Crops in Protected Environments in the Venezuelan Andes" Resources 12, no. 10: 116. https://doi.org/10.3390/resources12100116

APA StyleArias, K., Sulbarán, J., Mendoza, W., Escalona, A., & Salas-Sanjuán, M. d. C. (2023). Sustainable Valorization of Organic Materials as Substrates for Soilless Crops in Protected Environments in the Venezuelan Andes. Resources, 12(10), 116. https://doi.org/10.3390/resources12100116