Responsible Resource Management in Remanufacturing—Framework for Qualitative Assessment in Small and Medium-Sized Enterprises

Abstract

1. Introduction

1.1. Motivation for this Study

- Economically efficient use of resources,

- reduction of waste and emissions generation,

- maximization of the recovery rate and use of secondary materials.

1.2. Aim of this Paper, its Originality, and Main Contributions

- A definition of the maturity levels for responsible resource management in a SME;

- a design of the responsible resource management practices (RRMP) that are relevant for each maturity level in a SME (measured with responsible resource management questionnaire RRMQ);

- a proposal of an integrated indicator OWEEM (Overall Water, Emissions, Energy, Materials), which allows for classifying a company in a synthetic way to relevant maturity level;

- a method for identification of the maturity’s gaps and prioritizing the improvement’s actions, which are necessary to progress towards a higher maturity level.

2. Materials and Methods

2.1. Research Design

- A descriptive tool for evaluation of company strengths and weaknesses,

- a prescriptive instrument for performance improvement,

- a comparative tool for evaluation of processes across companies and further comparison with standards and best practices.

- Development of MMs with regard to their prescriptive properties,

- extended empirical validation of MMs to prove their utilitarian function,

- detachment of the assessment methods from model’s description (separate descriptive and prescriptive layers).

- RQ1: How can the responsible resource management practices be evaluated in a SME based on the existing in-house expert’s knowledge?

- RQ2: How can the current management practices be improved in order to facilitate transformation towards responsible resource management in a SME?

- A descriptive layer, with: A definition of the maturity levels, and a description of the responsible resource management practices (RRMPs) in the assessment tool (RRMQ).

- A prescriptive layer, with: An indicator-based method for assessment and classification of the maturity level, and a benchmarking method for identifying the appropriate actions that should be taken to order to improve the current situation.

2.2. The Framework for Responsible Resource Management in Remanufacturing RRMRem—Structure, Methods, and Tools

- Level ML1 (very low)—the responsible resource management practices in the remanufacturing process are not applied or are applied incompletely by a company.

- Level ML2 (low)—the responsible resource management practices in the remanufacturing process are applied ad hoc (e.g., to solve a current problem or to comply with specific customer requirements/legal requirements) in a company, and processes are not formalized.

- Level ML3 (medium)—the responsible resource management practices are formalized, measured at facility, and ad hoc actions are taken.

- Level ML4 (high)—the responsible resource management practices are formalized, measured, and controlled at each stage of the process/each work station on a regular basis, and improvement actions are taken.

- Level ML5 (very high)—the responsible resource management practices are formalized, measured, and controlled at each stage of the process/each work station on a regular basis, and improvement actions are taken for continuous optimization.

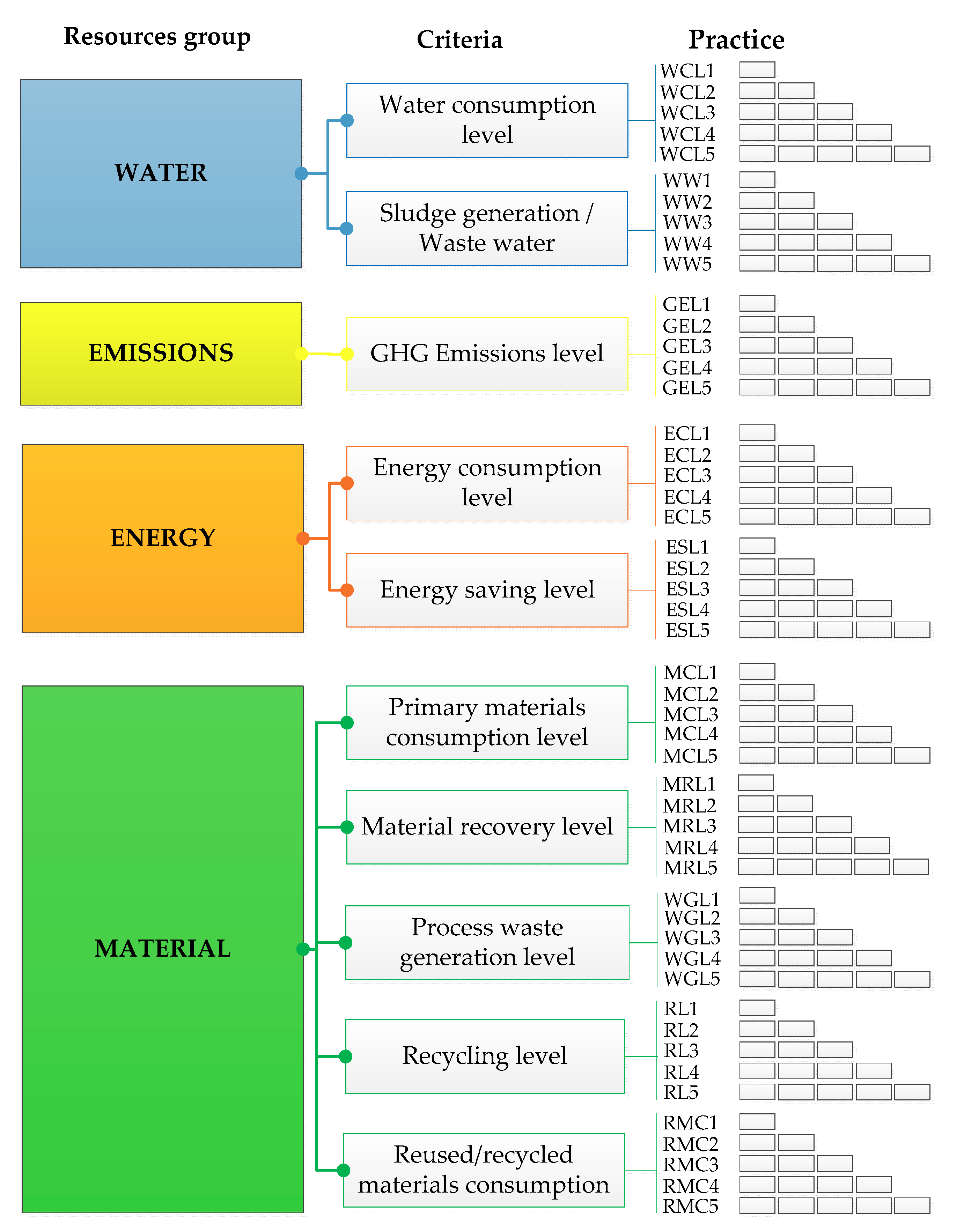

- I = Inputs (water, primary and secondary materials, energy consumption),

- outputs (emissions, sludge, waste), and

- value added in remanufacturing (energy saving, recycling, and increased material recovery).

- An indicator-based assessment method, and

- a benchmarking method in order to identify maturity gaps and prioritize necessary improvement’s actions.

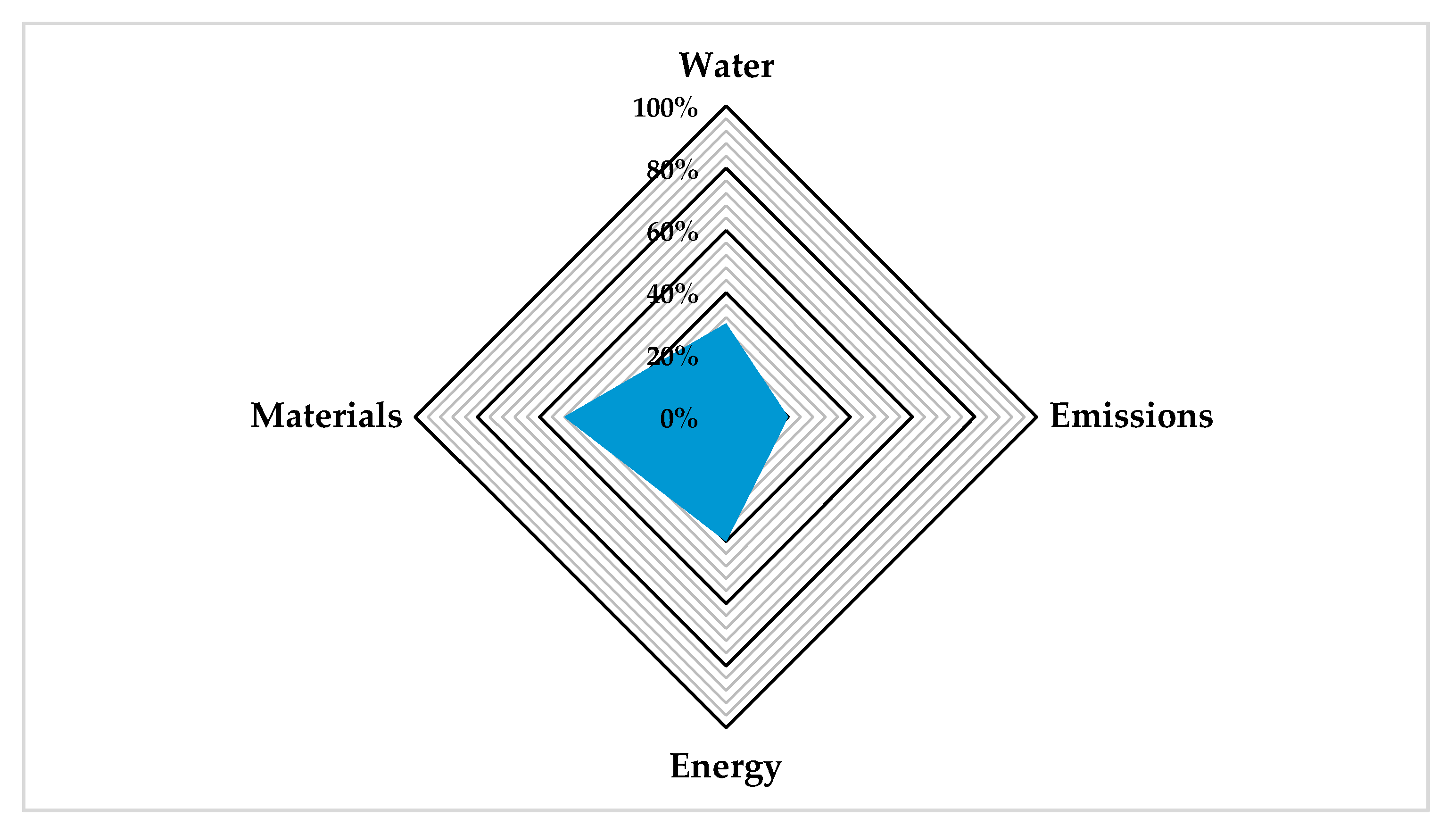

- RGW—is the aggregated score for category Water,

- RGEM—is the aggregated score for each category Emissions,

- RGE—is the aggregated score for each category Energy,

- RGM—is the aggregated score for category Material.

- RMMQRGCi is the score from responsible resource management questionnaire for the analyzed category,

- SRGj is the scoring for criterion “j” in the analyzed category and SRGj = {0, 1},

- WRGj is the weight Z.

- RMMQRG, is calculated as follows (Equation (3)):

- RIO Matrix (Resource’s Importance in Operations),

- the management practices (RRMPs) from the next maturity level ML(i+1),

- priority PrCi for the resource’s group.

3. Results

Testing Approach

- Company A is a small-sized company (below 50 employees), it remanufactures alternators, pumps, and starters. The company operates at one facility. It is an independent remanufacturer (IR).

- Company B is a medium-sized company, it remanufactures alternators and starters. The company operates at one facility, in a mixed model, as it remanufactures under own brand, and as a service provider for bigger automotive original parts suppliers.

- Company C is a small-sized company, it provides remanufacturing services of engines for transport companies.

- Company D is a small-sized company, it offers remanufacturing services of Diesel particulate filter (DPF) for individuals and companies.

- Grey—not relevant for operations,

- green—low importance,

- orange—medium importance,

- red—high importance.

4. Discussion and Managerial Implications

- RQ1: How can the responsible resource management practices be evaluated in a SME based on the existing in-house expert’s knowledge?

- RQ2: How can the current management practices be improved in order to facilitate transformation towards responsible resource management in a SME?

- Identifying in the synthetic way the current maturity level with usage of the RRMQ questionnaire, and then

- conducting in-depth analyses using RIO Matrix,

- prioritizing improvement’s actions which should be taken first in order to move towards more resource responsible remanufacturing practices.

5. Conclusions

- Maturity scoring;

- assessment of the maturity gap;

- prioritization of the required actions;

- design of the improvement’s actions at the operational level; and

- continuous improvement by benchmarking with a higher maturity level.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M. Product/Service-systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2018, 23, 22–35. [Google Scholar] [CrossRef]

- Tóth, G. Circular Economy and its Comparison with 14 Other Business Sustainability Movements. Resources 2019, 8, 159. [Google Scholar] [CrossRef]

- Fogarassy, C.; Finger, D. Theoretical and Practical Approaches of Circular Economy for Business Models and Technological Solutions. Resources 2020, 9, 76. [Google Scholar] [CrossRef]

- Schrettle, S.; Hinz, A.; Scherrer-Rathje, M.; Friedli, T. Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance. Int. J. Prod. Econ. 2014, 147, 73–84. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Bocken, N.M.; Hultink, E.J. Design thinking to enhance the sustainable business modelling process—A workshop based on a value mapping process. J. Clean. Prod. 2016, 135, 1218–1232. [Google Scholar] [CrossRef]

- Ellen Macarthur Foundation. Towards the Circular Economy: Accelerating the scale-up across global supply chains. In World Economic Forum Reports; 2014; Available online: https://www.ellenmacarthurfoundation.org/publications/towards-the-circular-economy-vol-3-accelerating-the-scale-up-across-global-supply-chains (accessed on 15 December 2020).

- Schaltegger, S.; Bennet, M.; Burritt, R.L.; Jasch, C. Environmental Management Accounting (EMA) as a Support for Cleaner Production. In Environmental Management Accounting for Cleaner Production; Springer: Dordrecht, The Netherlands, 2009; Volume 24, pp. 3–26. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Rashid, A.; Asif, F.M.; Krajnik, P.; Nicolescu, C.M. Resource conservative manufacturing: An essential change in business and technology paradigm for sustainable manufacturing. J. Clean. Prod. 2013, 57, 166–177. [Google Scholar] [CrossRef]

- Mancini, L.; Nuss, P. Responsible Materials Management for a Resource-Efficient and Low-Carbon Society. Resources 2020, 9, 68. [Google Scholar] [CrossRef]

- Statista 2020. Available online: https://www.statista.com/statistics/878412/number-of-smes-in-europe-by-size/ (accessed on 15 December 2020).

- Lundholm, T.; Lieder, M.; Rumpel, G. Resource Efficiency Assessment System. Leveraging Technology for a Sustainable World. In Proceedings of the 19th CIRP Conference on Life Cycle Engineering, University of California at Berkeley, Berkeley, CA, USA, 23–25 May 2012; pp. 423–428. [Google Scholar] [CrossRef]

- Golinska, P.; Kosacka, M.; Mierzwiak, R.; Werner-Lewandowska, K. Grey Decision Making as a Tool for the Classification of the Sustainability Level of Remanufacturing Companies. J. Clean. Prod. 2015, 105, 28–40. [Google Scholar] [CrossRef]

- Golinska-Dawson, P.; Kuebler, F. Sustainability Assessment in Remanufacturing Companies—Qualitative Approach. In Sustainability in Remanufacturing Operations; EcoProduction; Springer International Publishing: Cham, Switzerland, 2018; pp. 79–91. [Google Scholar] [CrossRef]

- Golinska-Dawson, P. Decision making framework enabling sustainable remanufacturing in small and medium sized enterprises in the automotive sector. In Proceedings of the 35th International Business Information Management Association Conference (IBIMA), Seville, Spain, 1–2 April 2020. [Google Scholar]

- Garengo, P.; Biazzo, S.; Bititci, U. Performance measurement systems in SMEs: A review for a research agenda. Int. J. Manag. Rev. 2005, 7, 25–47. [Google Scholar] [CrossRef]

- Golinska-Dawson, P. Sustainability in remanufacturing process—The challenges for its assessment. In Sustainability in Remanufacturing Operations; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–12. [Google Scholar] [CrossRef]

- Gutowski, T.; Sahni, S.; Graves, S.C. Remanufacturing and Energy Savings. Environ. Sci. Technol. 2011, 45, 4540–4547. [Google Scholar] [CrossRef]

- Yan, W.; Chai, J.; Qian, Z.; Tsai, S.-B.; Chen, H.; Xiong, Y. Operational Decisions on Remanufacturing Outsourcing Involved with Corporate Environmental and Social Responsibility—A Sustainable Perspective. Sustainability 2018, 10, 1132. [Google Scholar] [CrossRef]

- Matsumoto, M.; Chinen, K.; Endo, H. Paving the Way for Sustainable Remanufacturing in Southeast Asia: An Analysis of Auto Parts Markets. J. Clean. Prod. 2018, 205, 1029–1041. [Google Scholar] [CrossRef]

- Golinska, P.; Kuebler, F. The Method for Assessment of the Sustainability Maturity in Remanufacturing Companies. Procedia CIRP 2013, 15, 201–206. [Google Scholar] [CrossRef]

- Correia, E.; Carvalho, H.; Azevedo, S.G.; Govindan, K. Maturity Models in Supply Chain Sustainability: A Systematic Literature Review. Sustainability 2017, 9, 64. [Google Scholar] [CrossRef]

- Machado, C.G.; de Lima, E.P.; da Costa, S.E.G.; Angelis, J.J.; Mattioda, R.A. Framing maturity based on sustainable operations management principles. Int. J. Prod. Econ. 2017, 190, 3–21. [Google Scholar] [CrossRef]

- Bititci, U.S.; Garengo, P.; Ates, A.; Nudurupati, S.S. Value of Maturity Models in Performance Measurement. Int. J. Prod. Res. 2015, 53, 3062–3085. [Google Scholar] [CrossRef]

- Pullen, W. A Public Sector HPT Maturity Model. Perform. Improv. 2007, 46, 9–15. [Google Scholar] [CrossRef]

- Veleva, V.; Hart, M.; Greiner, T.; Crumbley, C. Indicators of Sustainable Production. J. Clean. Prod. 2001, 9, 447–452. [Google Scholar] [CrossRef]

- Lewis, M.; Brandon-Jones, A.; Slack, N.; Howard, M. Competing through Operations and Supply: The Role of Classic and Extended Resource-Based Advantage. Int. J. Oper. Prod. Manag. 2010, 30, 1032–1058. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; Rozenfeld, H.; McAloone, T.C. Ecodesign Maturity Model: A Management Framework to Support Ecodesign Implementation into Manufacturing Companies. J. Clean. Prod. 2013, 59, 160–173. [Google Scholar] [CrossRef]

- Butzer, S.; Schötz, S.; Steinhilper, R. Remanufacturing Process Capability Maturity Model. Manufacturing 2017, 8, 715–722. [Google Scholar] [CrossRef]

- Röglinger, M.; Pöppelbuß, J.; Becker, J. Maturity Models in Business Process Management. Bus. Process Manag. J. 2012, 18, 328–346. [Google Scholar] [CrossRef]

- Tarhan, A.; Turetken, O.; Reijers, H.A. Business Process Maturity Models: A Systematic Literature Review. Inf. Softw. Technol. 2016, 75, 122–134. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Singhal, K.; Van Wassenhove, L.N. Sustainable Operations Management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- Kurilova-Palisaitiene, J.; Sundin, E.; Poksinska, B. Remanufacturing Challenges and Possible Lean Improvements. J. Clean. Prod. 2018, 172, 3225–3236. [Google Scholar] [CrossRef]

- Matsumoto, M.; Yang, S.; Martinsen, K.; Kainuma, Y. Trends and research challenges in remanufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 129–142. [Google Scholar] [CrossRef]

- Schau, E.M.; Traverso, M.; Finkbeiner, M. Life Cycle Approach to Sustainability Assessment: A Case Study of Remanufactured Alternators. J. Remanuf. 2012, 2, 1–14. [Google Scholar] [CrossRef]

- Warsen, J.; Laumer, M.; Momberg, W. Comparative life cycle assessment of remanufacturing and new manufacturing of a manual transmission. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 67–72. [Google Scholar] [CrossRef]

| Resource Group | Criterion | Practice Code | Management Practice Description | Corresponding Maturity Level |

|---|---|---|---|---|

| Water W | Water consumption | WCL5 | Water consumption is measured and controlled at work stations, water is reused (or closed loop) where possible | Very high |

| WCL 4 | Water consumption is measured and controlled at work stations, water is not reused | High | ||

| WCL3 | Water usage is monitored ad hoc at output level/process level, water is not reused | Medium | ||

| WCL 2 | Water usage is monitored at hoc only at cost level (the invoices are reviewed), water is not reused | Low | ||

| WCL1 | Water usage is not monitored, water is not reused | Very low | ||

| Waste water | WW5 | Sludge generation is monitored at work stations, water is reused where possible | Very high | |

| WW4 | Sludge generation is monitored at work stations, water is not reused | High | ||

| WW3 | Sludge generation is monitored at process output, water is not reused | Medium | ||

| WW2 | Sludge generation is monitored at cost level (reviewing invoices), water is not reused | Low | ||

| WW1 | Sludge generation is not monitored, water is not reused | Very low | ||

| Materials M | Reused/recycled material consumption | RMC1 | Recycled materials usage is not monitored, no additional actions are taken | Very low |

| RMC2 | Recycled materials are used to meet legal requirements, no additional internal goals are defined | Low | ||

| RMC3 | Recycled materials are used where possible, internal goals for secondary materials/parts are defined | Medium | ||

| RMC4 | Recycled materials are used where possible, ad hoc actions are taken improve internal goal | High | ||

| RMC5 | Recycled materials are used where possible systematically actions are taken improve internal goal | Very high |

| OWEEM Score | Maturity Level | ||

|---|---|---|---|

| <3% | ML1 | ||

| <3%,13) | ML2 | ||

| IF | <13%,41) | THEN | ML3 |

| <41%,100) | ML4 | ||

| 100% | ML5 |

| Company | Testing Summary | Maturity Level |

|---|---|---|

| A | Application of the descriptive framework is feasible, the assessment with responsible resource management questionnaire (RRMQ) took approximately 8 min. | Company is at low maturity level (ML 2) |

| B | Application of the descriptive framework is feasible, the assessment with RRMQ took approximately 6 min. Expert has declared that the tool is easy to use, the criteria and description of the management practices are relevant. | Company is at medium maturity level (ML 3) |

| C | Application of the descriptive framework is feasible, the assessment with RRMQ took approximately 11 min. Expert has declared that the tool is easy to use, and the description of the management practices is suitable. | Company is at very low maturity level (ML 1) |

| D | Application of the descriptive framework is feasible, the assessment with RRMQ took approximately 5 min. Expert has declared that the tool is easy to use and the management practices are well defined. | Company is at very low maturity level (ML 1) |

| Category RGCi | RRMQRGCi Score (Equation (3)) | Maturity Gap MgapRGCi (Equation (4)) | Priority PrRGCi | OWEEM (Equation (1)) | Maturity Level |

|---|---|---|---|---|---|

| Water | 3 | 0.70 | 2 | 1.25% | ML1 |

| Emissions | 1 | 0.80 | 1 | ||

| Energy | 4 | 0.60 | 3 | ||

| Materials | 13 | 0.48 | 4 |

| Implementation of 1st Set. | |||||

|---|---|---|---|---|---|

| Category RGCi | RRMQRGCi Score (Equation (3)) | Maturity Gap MgapRGCi (Equation (4)) | Priority PrRGCi | OWEEM (Equation (1)) | Maturity Level |

| Water | 3 | 0.70 | 1 | 2.50% | ML1 |

| Emissions | 2 | 0.60 | 2 | ||

| Energy | 4 | 0.60 | 2 | ||

| Materials | 13 | 0.48 | 3 | ||

| implementation of 2nd set | |||||

| Category RGCi | RRMQRGCi Score | Maturity Gap MgapRGCi | Priority PrRGCi | OWEEM | Maturity Level |

| Water | 5 | 0.50 | 2 | 4.16% | ML2 |

| Emissions | 2 | 0.60 | 1 | ||

| Energy | 4 | 0.60 | 1 | ||

| Materials | 13 | 0.48 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golinska-Dawson, P.; Werner-Lewandowska, K.; Kosacka-Olejnik, M. Responsible Resource Management in Remanufacturing—Framework for Qualitative Assessment in Small and Medium-Sized Enterprises. Resources 2021, 10, 19. https://doi.org/10.3390/resources10020019

Golinska-Dawson P, Werner-Lewandowska K, Kosacka-Olejnik M. Responsible Resource Management in Remanufacturing—Framework for Qualitative Assessment in Small and Medium-Sized Enterprises. Resources. 2021; 10(2):19. https://doi.org/10.3390/resources10020019

Chicago/Turabian StyleGolinska-Dawson, Paulina, Karolina Werner-Lewandowska, and Monika Kosacka-Olejnik. 2021. "Responsible Resource Management in Remanufacturing—Framework for Qualitative Assessment in Small and Medium-Sized Enterprises" Resources 10, no. 2: 19. https://doi.org/10.3390/resources10020019

APA StyleGolinska-Dawson, P., Werner-Lewandowska, K., & Kosacka-Olejnik, M. (2021). Responsible Resource Management in Remanufacturing—Framework for Qualitative Assessment in Small and Medium-Sized Enterprises. Resources, 10(2), 19. https://doi.org/10.3390/resources10020019